Mapping Spatial Distribution of Pores in an Additively Manufactured Gold Alloy Using Neutron Microtomography

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Masmoudi, A.; Bolot, R.; Coddet, C. Investigation of the laser–powder–atmosphere interaction zone during the selective laser melting process. J. Mater. Process. Technol. 2015, 225, 122–132. [Google Scholar] [CrossRef]

- Pupo, Y.; Monroy, K.P.; Ciurana, J. Influence of process parameters on surface quality of CoCrMo produced by selective laser melting. Int. J. Adv. Manuf. Technol. 2015, 80, 985–995. [Google Scholar] [CrossRef]

- Cooper, F. DMLM Supports: Are They the Jewelry Industry’s New Sprue, Riser and Gate Feed. In The Santa Fe Symposium on Jewelry Technology; Santa Fe Symposium: Albuquerque, NM, USA, May 2014; pp. 1–22. [Google Scholar]

- Fischer-Buehner, J.; Poliero, P.; Bertoncello, R.; Basso, A.; Fischer-buehner, J.; Poliero, M. Rapid Jewelry Manufacturing By Laser Melting of Precious Metal Powders (PLM): Fiction Or Future. In The Santa Fe Symposium on Jewelry Manufacturing Technology; Santa Fe Symposium: Albuquerque, NM, USA, May 2011; pp. 177–202. [Google Scholar]

- Zito, D.; Carlotto, A.; Loggi, A.; Sbornicchia, P.; Maggian, D.; Progold, S.A.; Vi, T.; Fockele, M.; Unterberg, P. Optimization of the Main Selective Laser Melting Technology Parameters in the Production of Precious Metal Jewelry. In The Santa Fe Symposium on Jewelry Manufacturing Technology; Santa Fe Symposium: Albuquerque, NM, USA, May 2013; pp. 1–20. [Google Scholar]

- Zito, D.; Carlotto, A.; Loggi, A.; Sbornicchia, P.; Bruttomesso, D.; Progold, S.A. Definition and solidity idity of gold and platinum jewels produced using Selective Laser Melting SLMTM technology. In The Santa Fe Symposium on Jewelry Manufacturing Technology; Santa Fe Symposium: Albuquerque, NM, USA, May 2015; pp. 439–470. [Google Scholar]

- Klotz, U.E.; Tiberto, D.; Held, F. Optimization of 18-karat yellow gold alloys for the additive manufacturing of jewelry and watch parts. Gold Bull. 2017, 50, 111–121. [Google Scholar] [CrossRef]

- Archimedes; Archimedes ON FLOATING BODIES, BOOK I. The Works of Archimedes; Dover Publications: Mineola, NY, USA, 2010; pp. 253–262. [Google Scholar]

- Spierings, A.B.; Schneider, M.; Eggenberger, R. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- Obaton, A.-F.; Lê, M.-Q.; Prezza, V.; Marlot, D.; Delvart, P.; Huskic, A.; Senck, S.; Mahé, E.; Cayron, C. Investigation of new volumetric non-destructive techniques to characterise additive manufacturing parts. Weld. World 2018, 62, 1049–1057. [Google Scholar] [CrossRef]

- Hunter, L.W.; Brackett, D.; Brierley, N.; Yang, J.; Attallah, M.M. Assessment of trapped powder removal and inspection strategies for powder bed fusion techniques. Int. J. Adv. Manuf. Technol. 2020, 106, 4521–4532. [Google Scholar] [CrossRef]

- Du Plessis, A.; Sperling, P.; Beerlink, A.; Tshabalala, L.; Hoosain, S.; Mathe, N.; le Roux, S.G. Standard method for microCT-based additive manufacturing quality control 2: Density measurement. MethodsX 2018, 5, 1117–1123. [Google Scholar] [CrossRef]

- Limodin, N.; Salvo, L.; Suéry, M.; DiMichiel, M. In situ investigation by X-ray tomography of the overall and local microstructural changes occurring during partial remelting of an Al-15.8 wt.% Cu alloy. Acta Mater. 2007, 55, 3177–3191. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Corfield, M.R.; Tuck, C.; Clare, A.T.; Leach, R.K.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J.M. Quantification and characterisation of porosity in selectively laser melted Al-Si10-Mg using X-ray computed tomography. Mater. Charact. 2016, 111, 193–204. [Google Scholar] [CrossRef]

- Ziółkowski, G.; Chlebus, E.; Szymczyk, P.; Kurzac, J. Application of X-ray CT method for discontinuity and porosity detection in 316L stainless steel parts produced with SLM technology. Arch. Civ. Mech. Eng. 2014, 14, 608–614. [Google Scholar] [CrossRef]

- Aloisi, V.; Carmignato, S. Influence of surface roughness on X-ray computed tomography dimensional measurements of additive manufactured parts. Case Stud. Nondestruct. Test. Eval. 2016, 6, 104–110. [Google Scholar] [CrossRef]

- Hastie, J.C.; Kartal, M.E.; Carter, L.N.; Attallah, M.M.; Mulvihill, D.M. Classifying shape of internal pores within AlSi10Mg alloy manufactured by laser powder bed fusion using 3D X-ray micro computed tomography: Influence of processing parameters and heat treatment. Mater. Charact. 2020, 163, 110225. [Google Scholar] [CrossRef]

- Moorehead, C.A.; Sietins, J.M.; Swab, J.J. Meso-scale microstructural agglomerate quantification in boron carbide using X-ray microcomputed tomography. Mater. Charact. 2018, 141, 177–185. [Google Scholar] [CrossRef]

- Cai, X.; Malcolm, A.A.; Wong, B.S.; Fan, Z. Measurement and characterization of porosity in aluminium selective laser melting parts using X-ray CT. Virtual Phys. Prototyp. 2015, 10, 195–206. [Google Scholar] [CrossRef]

- Tremsin, A.S.; Rakovan, J.; Shinohara, T.; Kockelmann, W.; Losko, A.S.; Vogel, S.C. Non-Destructive Study of Bulk Crystallinity and Elemental Composition of Natural Gold Single Crystal Samples by Energy-Resolved Neutron Imaging. Sci. Rep. 2017, 7, 40759. [Google Scholar] [CrossRef]

- Brooks, A.J.; Ge, J.; Kirka, M.M.; Dehoff, R.R.; Bilheux, H.Z.; Kardjilov, N.; Manke, I.; Butler, L.G. Porosity detection in electron beam-melted Ti-6Al-4V using high-resolution neutron imaging and grating-based interferometry. Prog. Addit. Manuf. 2017, 2, 125–132. [Google Scholar] [CrossRef]

- Trtik, P.; Lehmann, E.H. Isotopically-enriched gadolinium-157 oxysulfide scintillator screens for the high-resolution neutron imaging. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2015, 788, 67–70. [Google Scholar] [CrossRef]

- Trtik, P.; Hovind, J.; Grünzweig, C.; Bollhalder, A.; Thominet, V.; David, C.; Kaestner, A.; Lehmann, E.H. Improving the Spatial Resolution of Neutron Imaging at Paul Scherrer Institut—The Neutron Microscope Project. In Proceedings of the Physics Procedia, Grindelwald, Switzerland, 5–10 October 2014; Volume 69. [Google Scholar]

- Trtik, P.; Lehmann, E.H. Progress in High-resolution Neutron Imaging at the Paul Scherrer Institut-The Neutron Microscope Project. J. Phys. Conf. Ser. 2016, 746, 012004. [Google Scholar] [CrossRef]

- Trtik, P. Neutron microtomography of voids in gold. MethodsX 2017, 4, 492–497. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi-Tabasi, H.; Jhabvala, J.; Boillat, E.; Ivas, T.; Drissi-Daoudi, R.; Logé, R.E. An effective rule for translating optimal selective laser melting processing parameters from one material to another. Addit. Manuf. 2020, 36, 101496. [Google Scholar] [CrossRef]

- Kumar, S. Additive Manufacturing Processes, 1st ed.; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-030-45089-2. [Google Scholar]

- AlMangour, B.; Grzesiak, D.; Yang, J.-M. Scanning strategies for texture and anisotropy tailoring during selective laser melting of TiC/316L stainless steel nanocomposites. J. Alloys Compd. 2017, 728, 424–435. [Google Scholar] [CrossRef]

- Trtik, P.; Meyer, M.; Wehmann, T.; Tengattini, A.; Atkins, D.; Lehmann, E.H.; Strobl, M. PSI ‘Neutron Microscope’ at ILL-D50 Beamline—First Results. Mater. Res. Proc. 2020, 15, 23–28. [Google Scholar] [CrossRef]

- Tengattini, A.; Lenoir, N.; Andò, E.; Giroud, B.; Atkins, D.; Beaucour, J.; Viggiani, G. NeXT-Grenoble, the Neutron and X-ray tomograph in Grenoble. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2020, 968, 163939. [Google Scholar] [CrossRef]

- Crha, J.; Vila-Comamala, J.; Lehmann, E.; David, C.; Trtik, P. Light Yield Enhancement of 157-Gadolinium Oxysulfide Scintillator Screens for the High-Resolution Neutron Imaging. MethodsX 2019, 6, 107–114. [Google Scholar] [CrossRef]

- Boillat, P.; Carminati, C.; Schmid, F.; Grünzweig, C.; Hovind, J.; Kaestner, A.; Mannes, D.; Morgano, M.; Siegwart, M.; Trtik, P.; et al. Chasing quantitative biases in neutron imaging with scintillator-camera detectors: A practical method with black body grids. Opt. Express 2018, 26, 15769–15784. [Google Scholar] [CrossRef]

- Carminati, C.; Boillat, P.; Schmid, F.; Vontobel, P.; Hovind, J.; Morgano, M.; Raventos, M.; Siegwart, M.; Mannes, D.; Gruenzweig, C.; et al. Implementation and assessment of the black body bias correction in quantitative neutron imaging. PLoS ONE 2019, 14, e0210300. [Google Scholar] [CrossRef] [PubMed]

- Guizar-Sicairos, M.; Diaz, A.; Holler, M.; Lucas, M.S.; Menzel, A.; Wepf, R.A.; Bunk, O. Phase tomography from x-ray coherent diffractive imaging projections. Opt. Express 2011, 19, 21345–21357. [Google Scholar] [CrossRef]

- Kaestner, A.P. MuhRec—A new tomography reconstructor. Nucl. Instruments Methods Phys. Res. Sect. A Accel. Spectrometers, Detect. Assoc. Equip. 2011, 651, 156–160. [Google Scholar] [CrossRef]

- Münch, B.; Trtik, P.; Marone, F.; Stampanoni, M. Stripe and ring artifact removal with combined wavelet—Fourier filtering. Opt. Express 2009, 17, 8567–8591. [Google Scholar] [CrossRef]

- Carminati, C.; Strobl, M.; Kaestner, A. KipTool, a general purpose processing tool for neutron imaging data. SoftwareX 2019, 10, 100279. [Google Scholar] [CrossRef]

- Kaestner, A.; Lehmann, E.; Stampanoni, M. Imaging and image processing in porous media research. Adv. Water Resour. 2008, 31, 1174–1187. [Google Scholar] [CrossRef]

- Brown, D.; Kienzle, P. Neutron Activation and Scattering Calculator. Available online: https://www.ncnr.nist.gov/resources/activation/ (accessed on 5 November 2020).

- Otsu, N. Threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, Y.; Wen, W.; Ge, J.; Liang, J. Effect of hatch spacing on melt pool and as-built quality during selective laser melting of stainless steel: Modeling and experimental approaches. Materials 2018, 12, 50. [Google Scholar] [CrossRef] [PubMed]

- Du Plessis, A. Effects of process parameters on porosity in laser powder bed fusion revealed by X-ray tomography. Addit. Manuf. 2019, 30, 100871. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Qi, H.; Azer, M.; Ritter, A. Studies of standard heat treatment effects on microstructure and mechanical properties of laser net shape manufactured INCONEL 718. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 2410–2422. [Google Scholar] [CrossRef]

- Mancisidor, A.M.; Garciandia, F.; Sebastian, M.S.; Álvarez, P.; Díaz, J.; Unanue, I. Reduction of the residual porosity in parts manufactured by selective laser melting using skywriting and high focus offset strategies. Phys. Procedia 2016, 83, 864–873. [Google Scholar] [CrossRef]

- Bian, L.; Shamsaei, N.; Usher, J. Laser-Based Additive Manufacturing of Metal Parts: Modeling, Optimization, and Control of Mechanical Properties, 1st ed.; CRC Press, Inc.: Boca Raton, FL, USA, 2017; ISBN 1498739989. ISBN 9781498739986. [Google Scholar]

- Renderos, M.; Torregaray, A.; Gutierrez-Orrantia, M.E.; Lamikiz, A.; Saintier, N.; Girot, F. Microstructure characterization of recycled IN718 powder and resulting laser clad material. Mater. Charact. 2017, 134, 103–113. [Google Scholar] [CrossRef]

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A.D. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef]

- Martin, A.A.; Calta, N.P.; Khairallah, S.A.; Wang, J.; Depond, P.J.; Fong, A.Y.; Thampy, V.; Guss, G.M.; Kiss, A.M.; Stone, K.H.; et al. Dynamics of pore formation during laser powder bed fusion additive manufacturing. Nat. Commun. 2019, 10, 1–10. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

- Griffiths, S.; Ghasemi Tabasi, H.; Ivas, T.; Maeder, X.; De Luca, A.; Zweiacker, K.; Wróbel, R.; Jhabvala, J.; Logé, R.E.; Leinenbach, C. Combining alloy and process modification for micro-crack mitigation in an additively manufactured Ni-base superalloy. Addit. Manuf. 2020, 36, 101443. [Google Scholar] [CrossRef]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 112, 160–161. [Google Scholar] [CrossRef]

- Lee, J.; Choe, J.; Park, J.; Yu, J.-H.; Kim, S.; Jung, I.D.; Sung, H. Microstructural effects on the tensile and fracture behavior of selective laser melted H13 tool steel under varying conditions. Mater. Charact. 2019, 155, 109817. [Google Scholar] [CrossRef]

- Jamshidinia, M.; Kovacevic, R. The influence of heat accumulation on the surface roughness in powder-bed additive manufacturing. Surf. Topogr. Metrol. Prop. 2015, 3, 014003. [Google Scholar] [CrossRef]

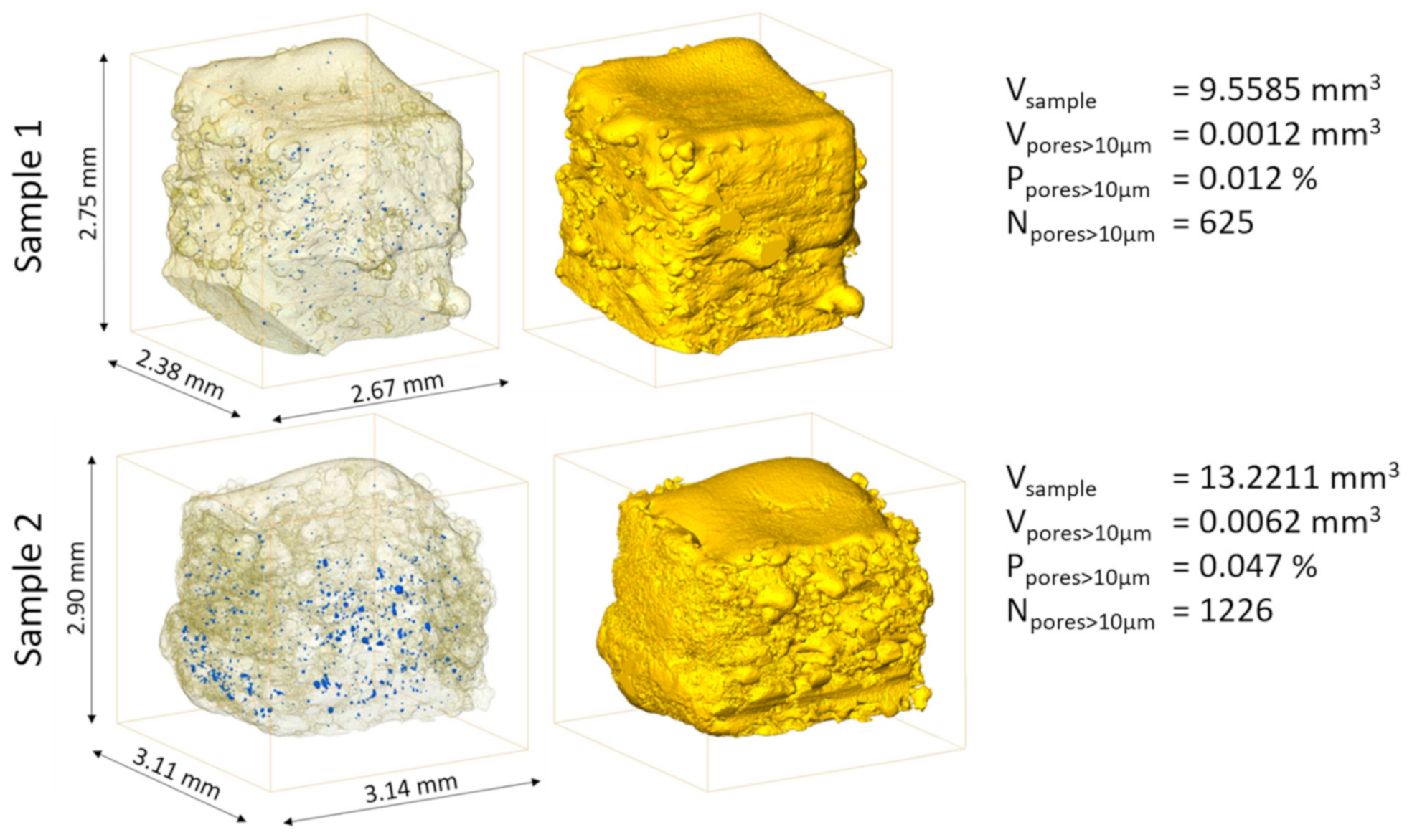

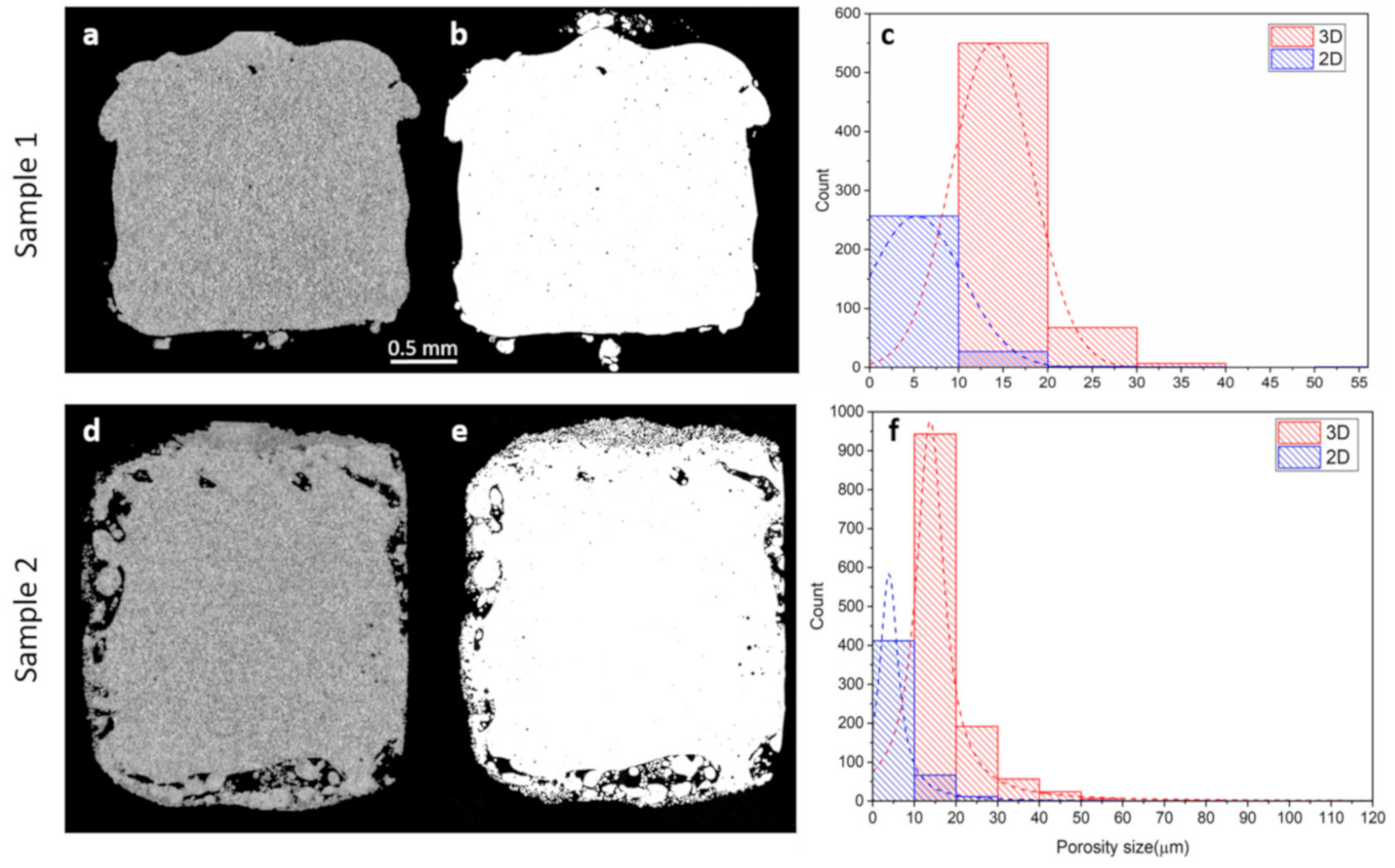

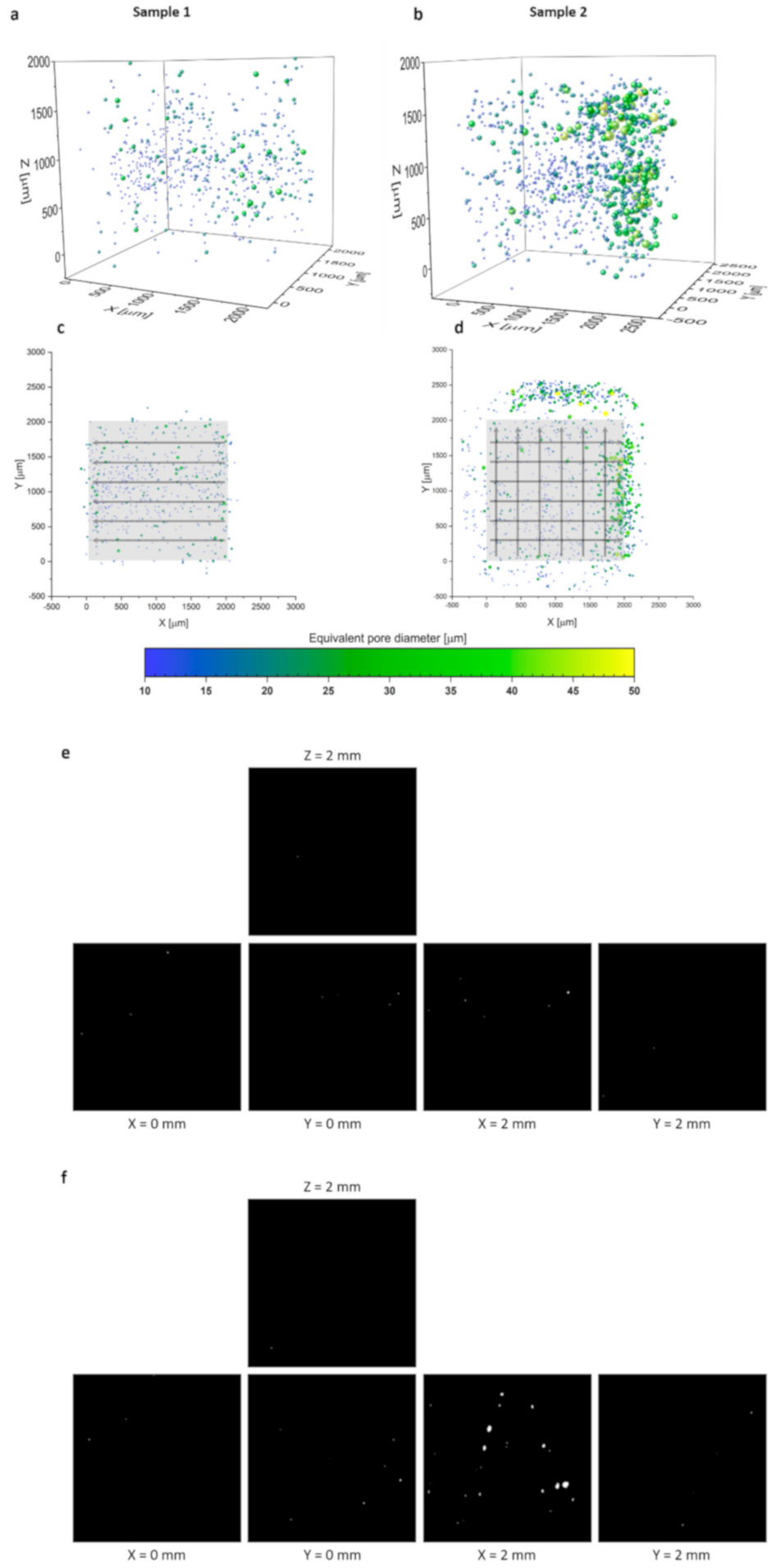

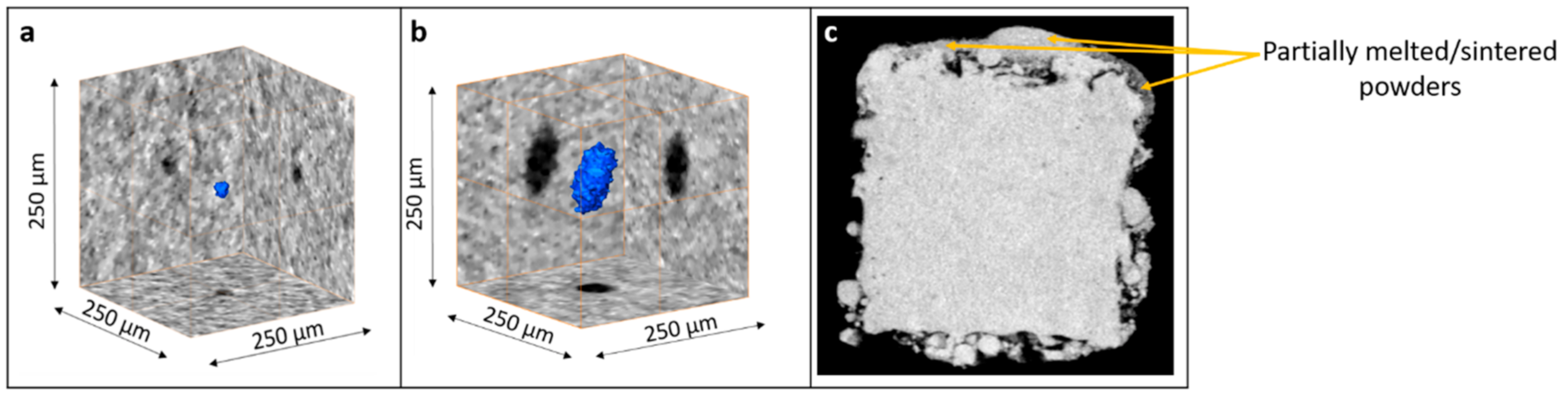

| Sample | Power (W) | Speed (mm/s) | Hatching Distance (µm) | Layer Thickness (µm) | Scanning Strategy |

|---|---|---|---|---|---|

| 1 | 210 | 220 | 100 | 40 | Parallel |

| 2 | 230 | 200 | 70 | 40 | Crosshatch |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghasemi-Tabasi, H.; Trtik, P.; Jhabvala, J.; Meyer, M.; Carminati, C.; Strobl, M.; Logé, R.E. Mapping Spatial Distribution of Pores in an Additively Manufactured Gold Alloy Using Neutron Microtomography. Appl. Sci. 2021, 11, 1512. https://doi.org/10.3390/app11041512

Ghasemi-Tabasi H, Trtik P, Jhabvala J, Meyer M, Carminati C, Strobl M, Logé RE. Mapping Spatial Distribution of Pores in an Additively Manufactured Gold Alloy Using Neutron Microtomography. Applied Sciences. 2021; 11(4):1512. https://doi.org/10.3390/app11041512

Chicago/Turabian StyleGhasemi-Tabasi, Hossein, Pavel Trtik, Jamasp Jhabvala, Michael Meyer, Chiara Carminati, Markus Strobl, and Roland E. Logé. 2021. "Mapping Spatial Distribution of Pores in an Additively Manufactured Gold Alloy Using Neutron Microtomography" Applied Sciences 11, no. 4: 1512. https://doi.org/10.3390/app11041512

APA StyleGhasemi-Tabasi, H., Trtik, P., Jhabvala, J., Meyer, M., Carminati, C., Strobl, M., & Logé, R. E. (2021). Mapping Spatial Distribution of Pores in an Additively Manufactured Gold Alloy Using Neutron Microtomography. Applied Sciences, 11(4), 1512. https://doi.org/10.3390/app11041512