Effect of Fly Ash on Compressive Strength, Drying Shrinkage, and Carbonation Depth of Mortar with Ferronickel-Slag Powder

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mixing Proportions and Specimen Preparation

3. Results and Discussion

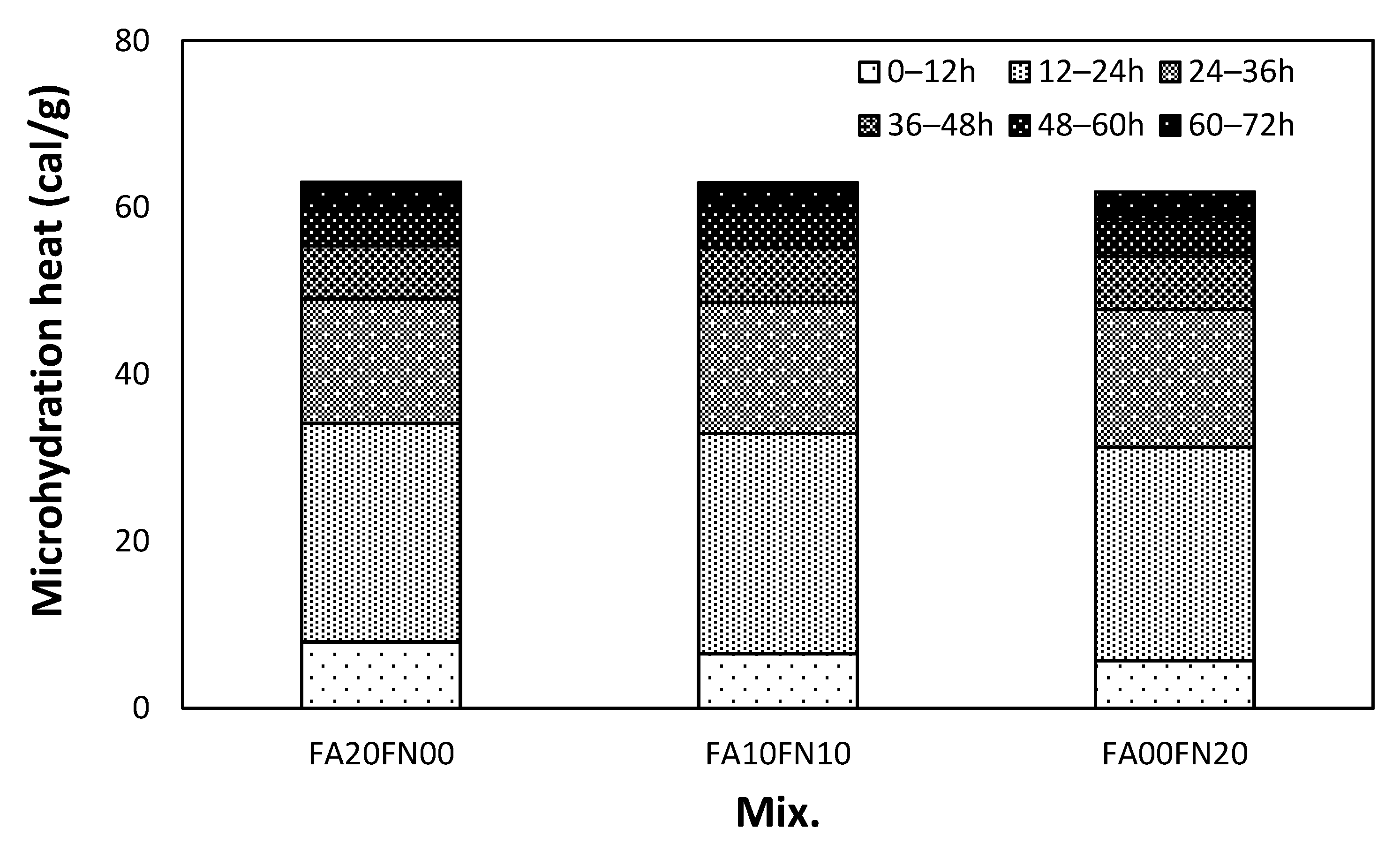

3.1. Microhydration Heat

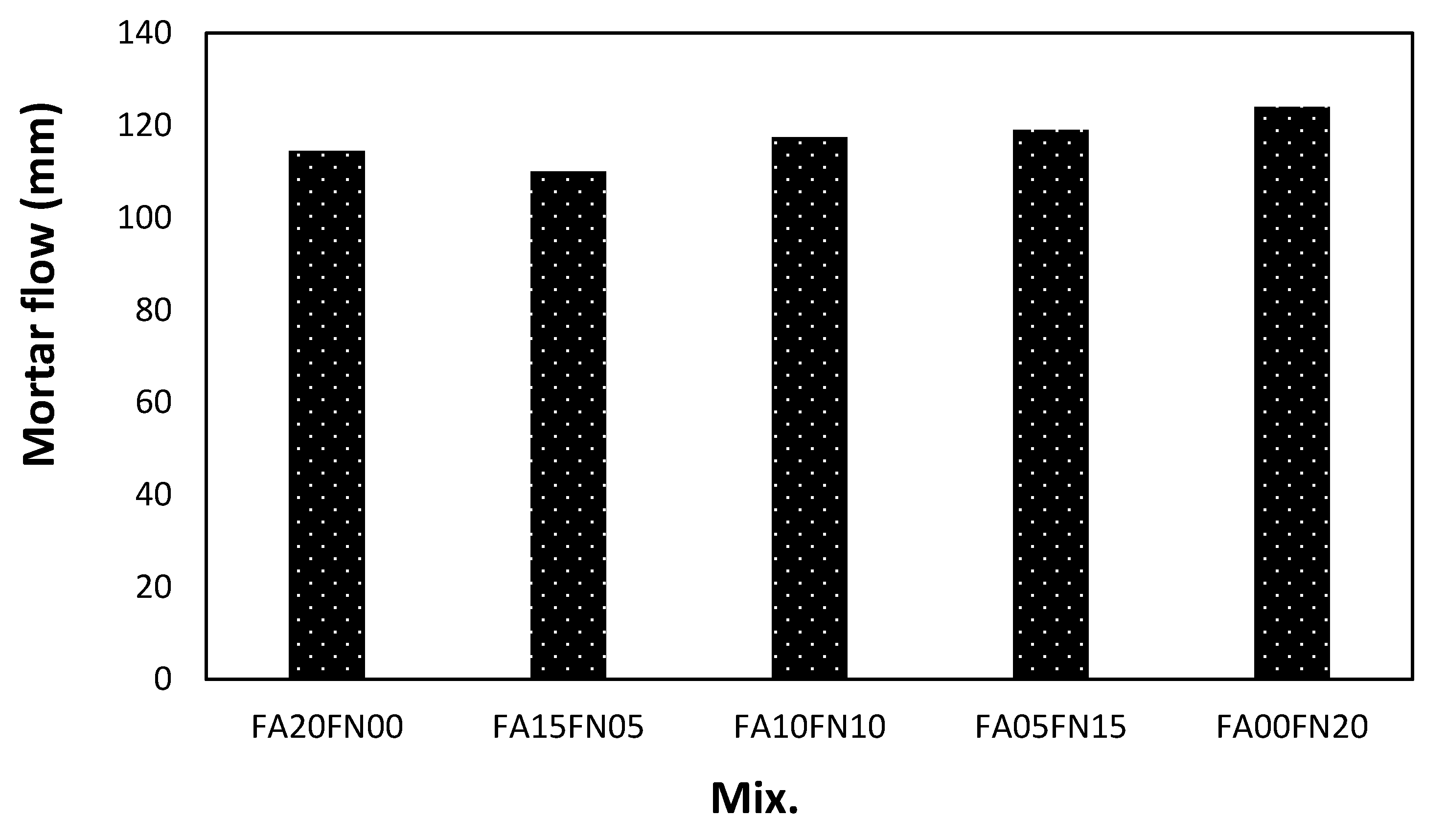

3.2. Mortar Flow

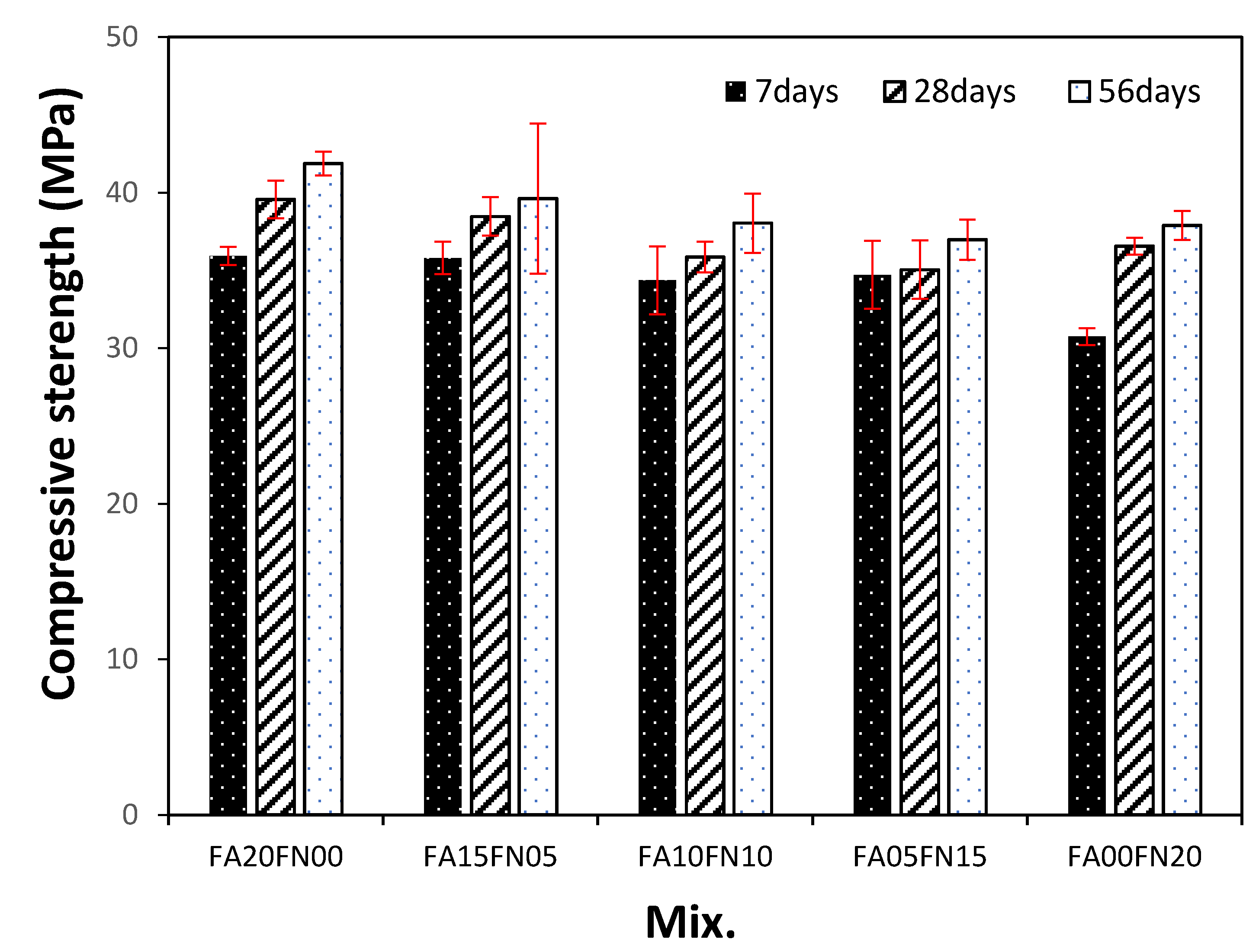

3.3. Compressive Strength

3.4. Drying Shrinkage

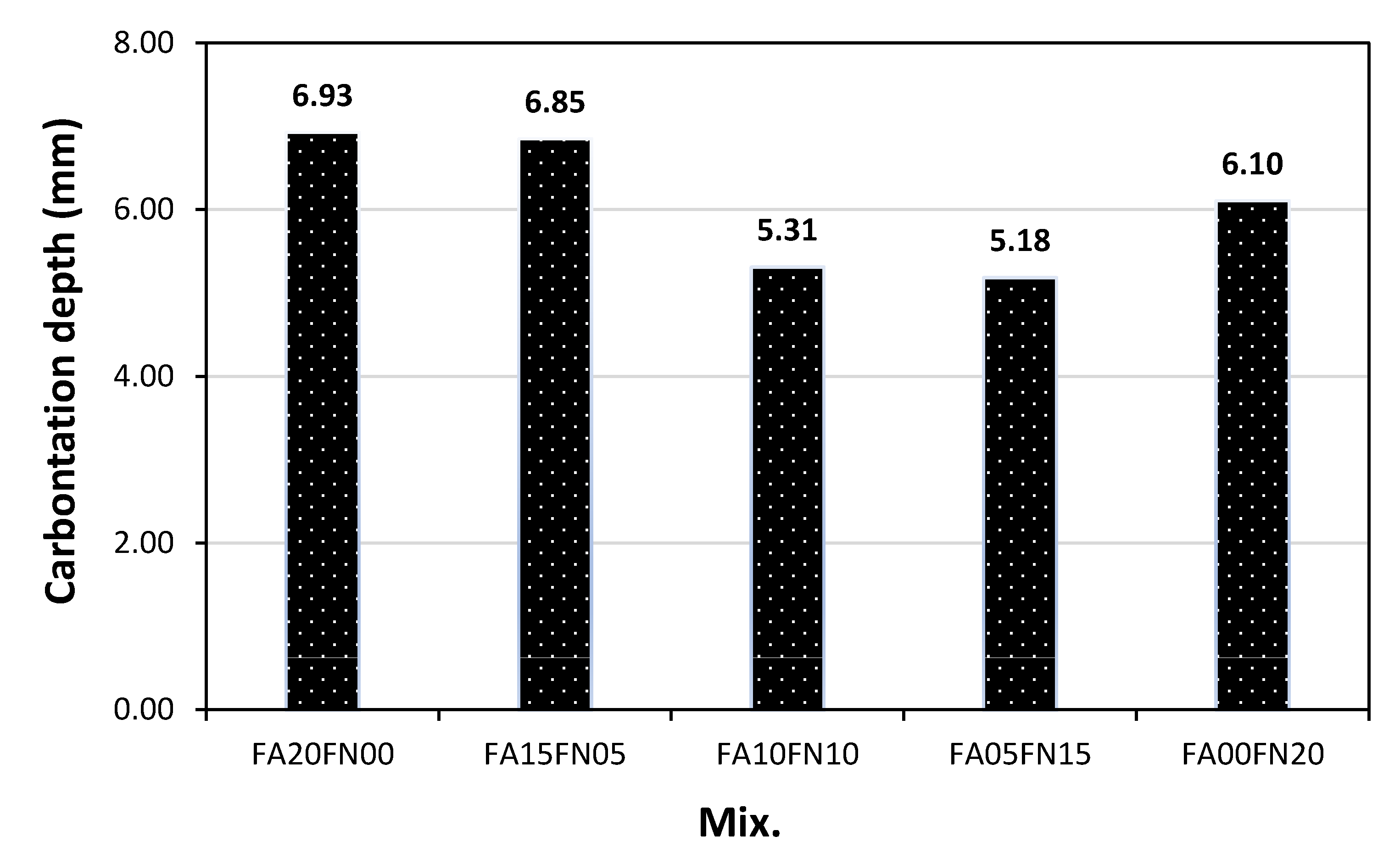

3.5. Carbonation Depth

4. Conclusions

- (1)

- The difference between the microhydration heat of the three mixes was not large. Note that the microhydration heat of the FA20FN00 mix was slightly higher than that of the FA00FN20 mix. It is supposed that the use of the ferronickel-slag powder can reduce the hydration heat of mortar and concrete. In addition, the flow of the samples containing at least 10% of ferronickel-slag powder ranged approximately from 117 to 124 mm. The mortar flow increased as the amount of ferronickel-slag powder increased.

- (2)

- The compressive strength of the FA15FN05 and FA20FN00 mixes using more than 15% of fly ash was relatively high, reaching approximately 35.8 MPa after 7 days. After 28 days, the compressive strength of the FA20FN00 mix was approximately 39.6 MPa, that is, higher than that of other samples, and the compressive strength of the FA05FN15 mix using 15% of ferronickel-slag powder was 35.0 MPa, that is, approximately 11.6% lower than the FA20FN00 mix including only fly ash.

- (3)

- The drying shrinkage of the FA20FN00 sample containing only fly ash was the highest, whereas the FA00FN20 sample without fly ash presented the lowest shrinkage compared to the other mixes. Therefore, if ferronickel-slag powder is used as a cement substitute, it is likely to be effective in controlling the drying shrinkage of cement mortar and concrete.

- (4)

- The carbonation depths of the FA20FN00 and FA15FN05 samples including more than 15% of fly ash ranged approximately from 6.85 to 6.92 mm, that is, larger than that of the other samples. The carbonation depth of the FA00FN20 sample without fly ash was lower than the carbonation depth of the sample containing more than 15% of fly ash, but it was higher than the carbonation depth of the FA10FN10 and FA05FN15 samples containing both fly ash and ferronickel-slag powder. In general, the carbonation resistance of the sample with FA and FN was better than that of the sample using FA or FN alone.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amendment Direction of 2030 Greenhouse Gas Reduction Roadmap Based on National Energy Transition Policy; Korea Environment Institute: Seoul, Korea, 2018.

- Escalante, J.; Gomez, L.; Johal, K.K.; Mendoza, G.; Mancha, H.; Méndez, J. Reactivity of blast-furnace slag in Portland cement blends hydrated under different conditions. Cem. Concr. Res. 2001, 31, 1403–1409. [Google Scholar] [CrossRef]

- Lemonis, N.; Tsakiridis, P.E.; Katsiotis, N.S.; Antiohos, S.; Papageorgiou, D.; Katsiotis, M.S.; Beazi-Katsioti, M. Hydration Study of Ternary Blended Cements Containing Ferronickel Slag and Natural Pozzolan. Constr. Build. Mater. 2015, 81, 130–139. [Google Scholar] [CrossRef]

- Yang, T.; Yao, X.; Zhang, Z. Geopolymer prepared with high-magnesium nickel slag: Characterization of properties and microstructure. Constr. Build. Mater. 2014, 59, 188–194. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P. Effect of Fly Ash on the Durability Properties of High Strength Concrete. Procedia. Eng. 2011, 14, 1149–1156. [Google Scholar] [CrossRef]

- Han, C.G.; Park, Y.K. Analysis of Fundamental Properties of Concrete for Rising up Fly Ash Contents. J. Rec. Const. Resour. 2011, 6, 89–96. [Google Scholar]

- Jo, S.A.; Yoo, J.H.; Park, S.S. Evaluation of Strength and Durability of Mortar using Ferronickel Slag Powder and Admixtures. J. Rec. Const. Resour. 2019, 7, 262–270. [Google Scholar]

- Guidelines for Concrete Construction of Ferronickel Slag Fine Aggregate; Korea Concrete Institute: Seoul, Korea, 2011.

- KS F 2527. Concrete Aggregate; Korea Standard Association: Seoul, Korea, 2018. [Google Scholar]

- KS F 4009. Ready-Mixed Concrete; Korea Standard Association: Seoul, Korea, 2016. [Google Scholar]

- Kim, Y.U.; Kim, D.B.; Choi, S.J. An Experimental Study on the Setting Time and Compressive strength of Mortar using Ferronickel Slag Powder. J. Korea Inst. Build. Constr. 2018, 18, 551–558. [Google Scholar]

- Kim, H.S.; Ann, K.Y. A Study on the Hydration Behavior and Porosimetry of Ferronickel Slag Powder in Cement Paste. J. Korea Concr. Inst. 2019, 31, 181–189. [Google Scholar] [CrossRef]

- Cho, W.J.; Kim, H.S.; Ann, K.Y. A Study on the Hydration Characteristics and Fundamental Properties of Ternary Blended Cement Using Ferronickel Slag. J. Rec. Const. Resources. 2020, 8, 39–48. [Google Scholar]

- Cho, B.S.; Kim, Y.U.; Kim, D.B.; Choi, S.J. Effect of Ferronickel Slag Powder on Microhydration Heat, Flow, Compressive Strength, and Drying Shrinkage of Mortar. Adv. Civ. Eng. 2018, 2018, 1–7. [Google Scholar] [CrossRef]

- KS L 5105. Testing Method for Compressive Strength of Hydraulic Cement Mortars; Korea Standards Association: Seoul, Korea, 2007. [Google Scholar]

- KS F 2424. Standard Test Method for Length Change of Mortar and Concrete; Korea Standards Association: Seoul, Korea, 2015. [Google Scholar]

- KS F 2584. Standard Test Method for Accelerated Carbonation of Concrete; Korea Standards Association: Seoul, Korea, 2015. [Google Scholar]

- Choi, Y.W.; Park, M.S.; Lee, K.M.; Bae, S.H.; Kim, J.S. Evaluation of Optimum Mixing Rate and Durability of Concrete Using Water Granulated Slag Fine Aggregate. J. Rec. Const. Resour. 2011, 6, 120–127. [Google Scholar]

- Choi, Y.W.; Park, M.S.; Bae, S.H.; Lee, H.H.; Jo, B.S. Properties of Water Granulated Ferro-Nickel Slag as Fine Aggregate for Concrete. Mag. KSCE 2010, 10, 1462–1465. [Google Scholar]

- Cho, B.S.; Lee, H.H.; Choi, Y.W.; Park, D.C.; Choi, Y.C. A Study on Performance of Concrete using FeNi Slag Aggregate. Mag. KCI 2014, 10, 583–584. [Google Scholar]

| Type | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Blaine (cm2/g) |

|---|---|---|---|---|---|---|---|

| Cement | 17.43 | 6.50 | 3.57 | 64.40 | 2.55 | 1.17 | 3430 |

| Ferronickel-slag powder (FN) | 48.91 | 2.08 | 11.6 | 0.82 | 32.41 | 0.09 | 3550 |

| Fly ash (FA) | 64.88 | 20.56 | 6.06 | 2.58 | 0.80 | 1.45 | 3710 |

| Mix. | FA | FN | W/Cm | W | C | FA | FN | Sand |

|---|---|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | |

| FA20FN00 | 20 | 0 | 50 | 170 | 272 | 68 | 0 | 902 |

| FA15FN05 | 15 | 5 | 51 | 17 | 906 | |||

| FA10FN10 | 10 | 10 | 34 | 34 | 909 | |||

| FA05FN15 | 5 | 15 | 17 | 51 | 912 | |||

| FA00FN20 | 0 | 20 | 0 | 68 | 915 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.-J.; Kim, J.-H.; Bae, S.-H.; Oh, T.-G. Effect of Fly Ash on Compressive Strength, Drying Shrinkage, and Carbonation Depth of Mortar with Ferronickel-Slag Powder. Appl. Sci. 2021, 11, 1037. https://doi.org/10.3390/app11031037

Choi S-J, Kim J-H, Bae S-H, Oh T-G. Effect of Fly Ash on Compressive Strength, Drying Shrinkage, and Carbonation Depth of Mortar with Ferronickel-Slag Powder. Applied Sciences. 2021; 11(3):1037. https://doi.org/10.3390/app11031037

Chicago/Turabian StyleChoi, Se-Jin, Ji-Hwan Kim, Sung-Ho Bae, and Tae-Gue Oh. 2021. "Effect of Fly Ash on Compressive Strength, Drying Shrinkage, and Carbonation Depth of Mortar with Ferronickel-Slag Powder" Applied Sciences 11, no. 3: 1037. https://doi.org/10.3390/app11031037

APA StyleChoi, S.-J., Kim, J.-H., Bae, S.-H., & Oh, T.-G. (2021). Effect of Fly Ash on Compressive Strength, Drying Shrinkage, and Carbonation Depth of Mortar with Ferronickel-Slag Powder. Applied Sciences, 11(3), 1037. https://doi.org/10.3390/app11031037