A Comprehensive Review of Microencapsulated Phase Change Materials Synthesis for Low-Temperature Energy Storage Applications

Abstract

:1. Introduction and Background

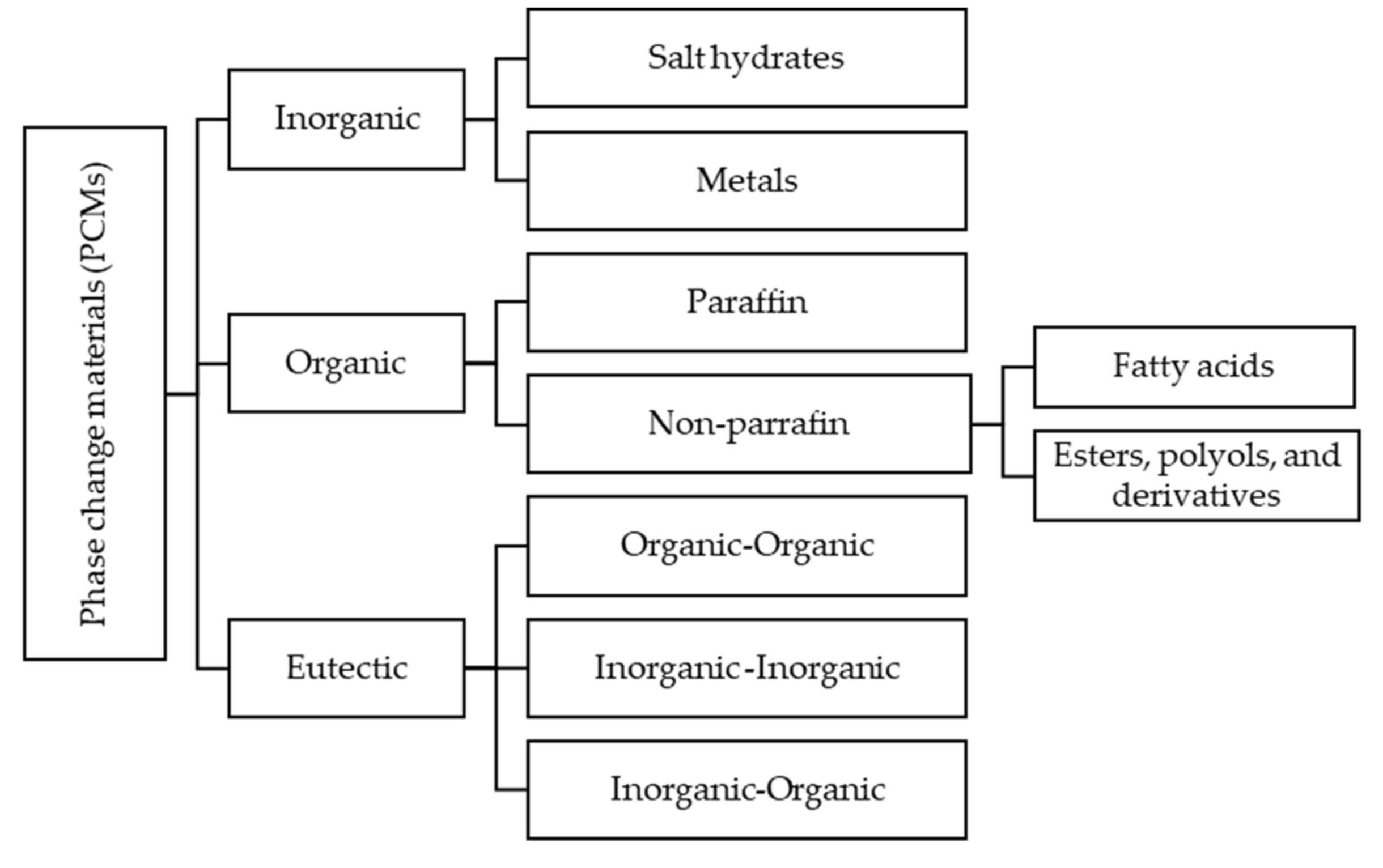

2. Classification of Phase Change Materials (PCMs)

2.1. Inorganic PCMs

2.1.1. Salt Hydrates

2.1.2. Metals

2.2. Organic PCMs

2.2.1. n-Alkanes

2.2.2. Fatty Acids, Esters, Polyols, and Derivatives

2.3. Eutectic PCMs

2.3.1. Theoretical Method

2.3.2. Experimental Method

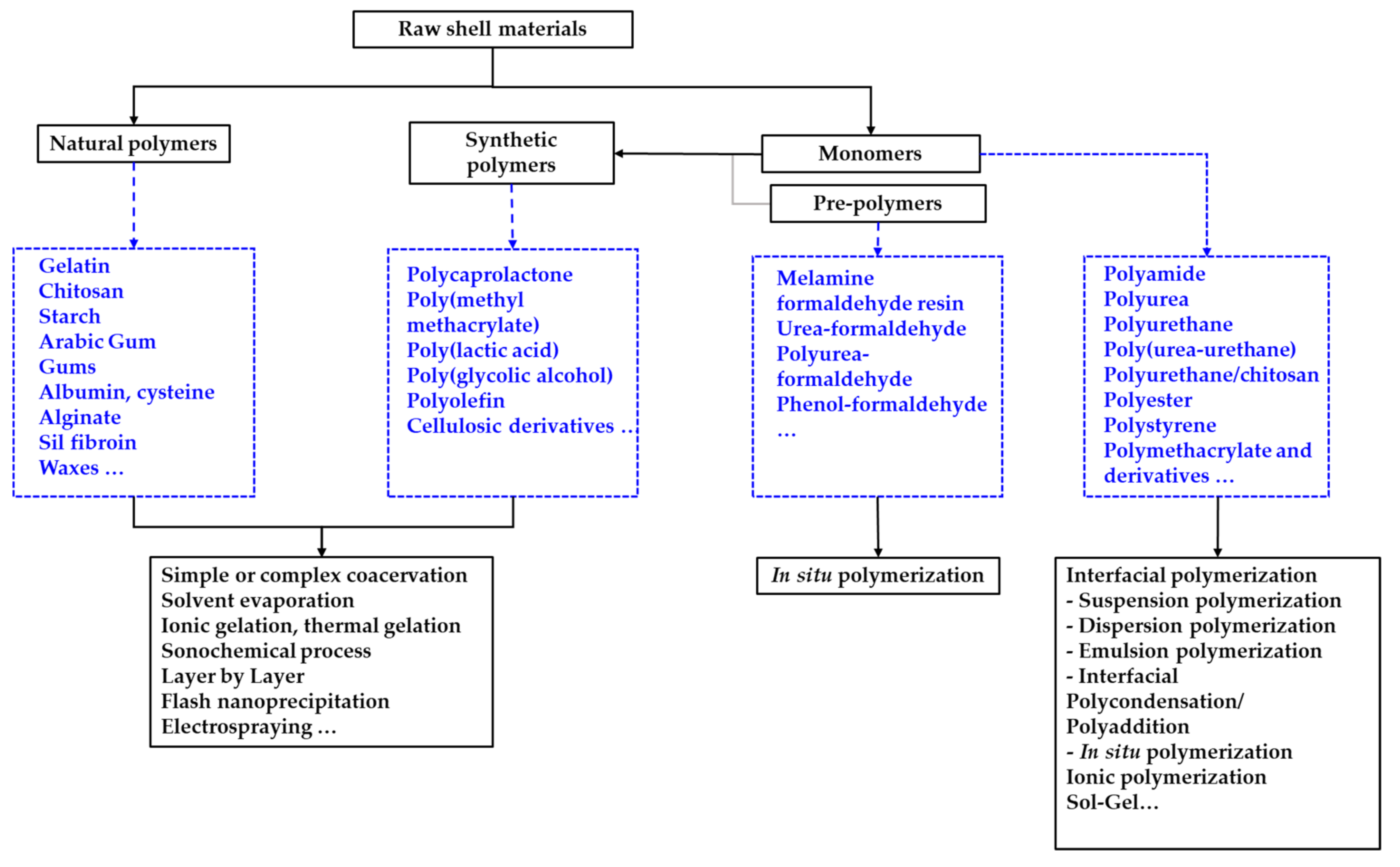

3. Shell Materials

4. Microencapsulation Techniques

4.1. Chemical Process

4.1.1. Microencapsulation by Heterophase Polymerization

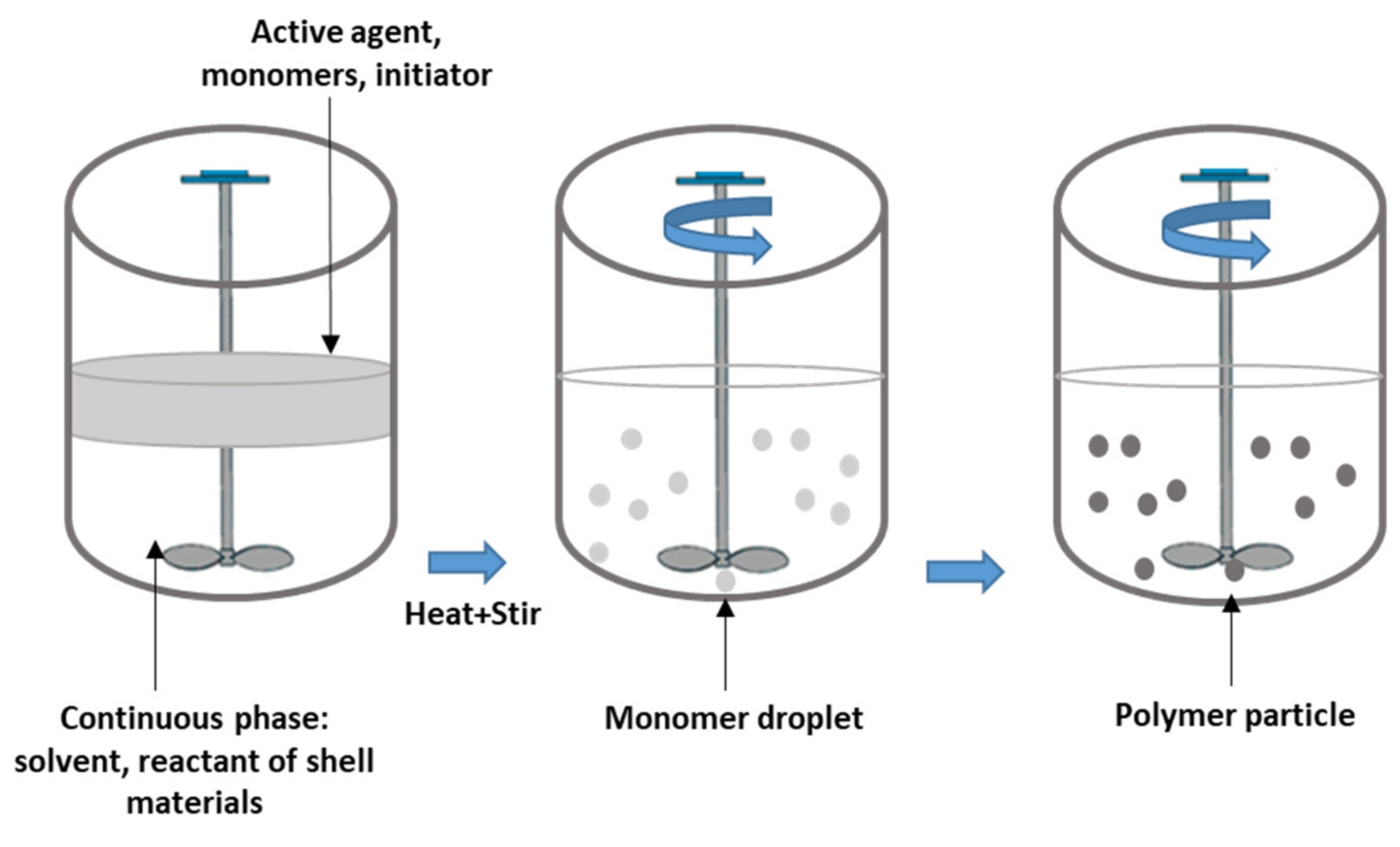

- Suspension polymerization

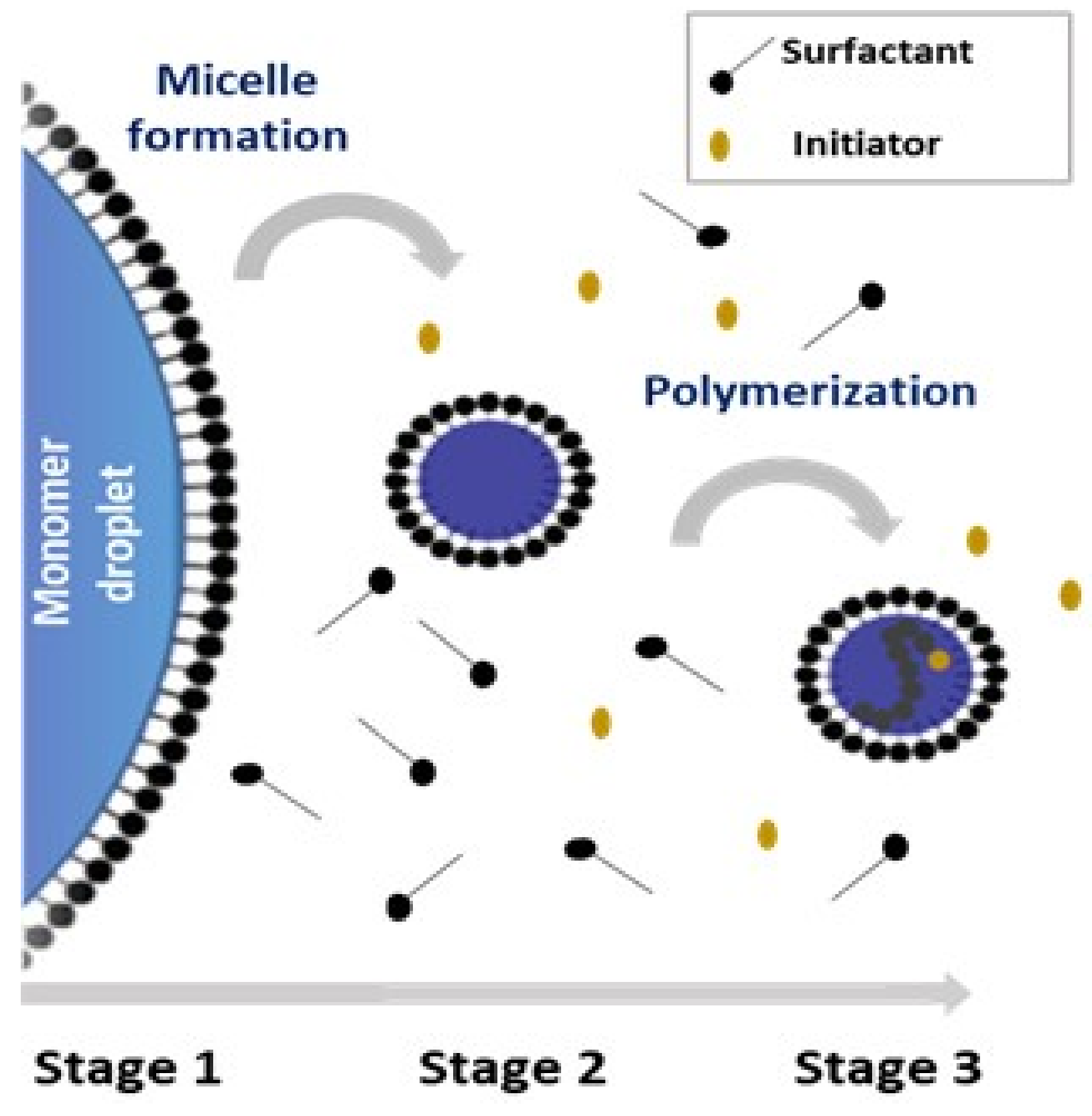

- Emulsion/miniemulsion polymerization

- Dispersion polymerization

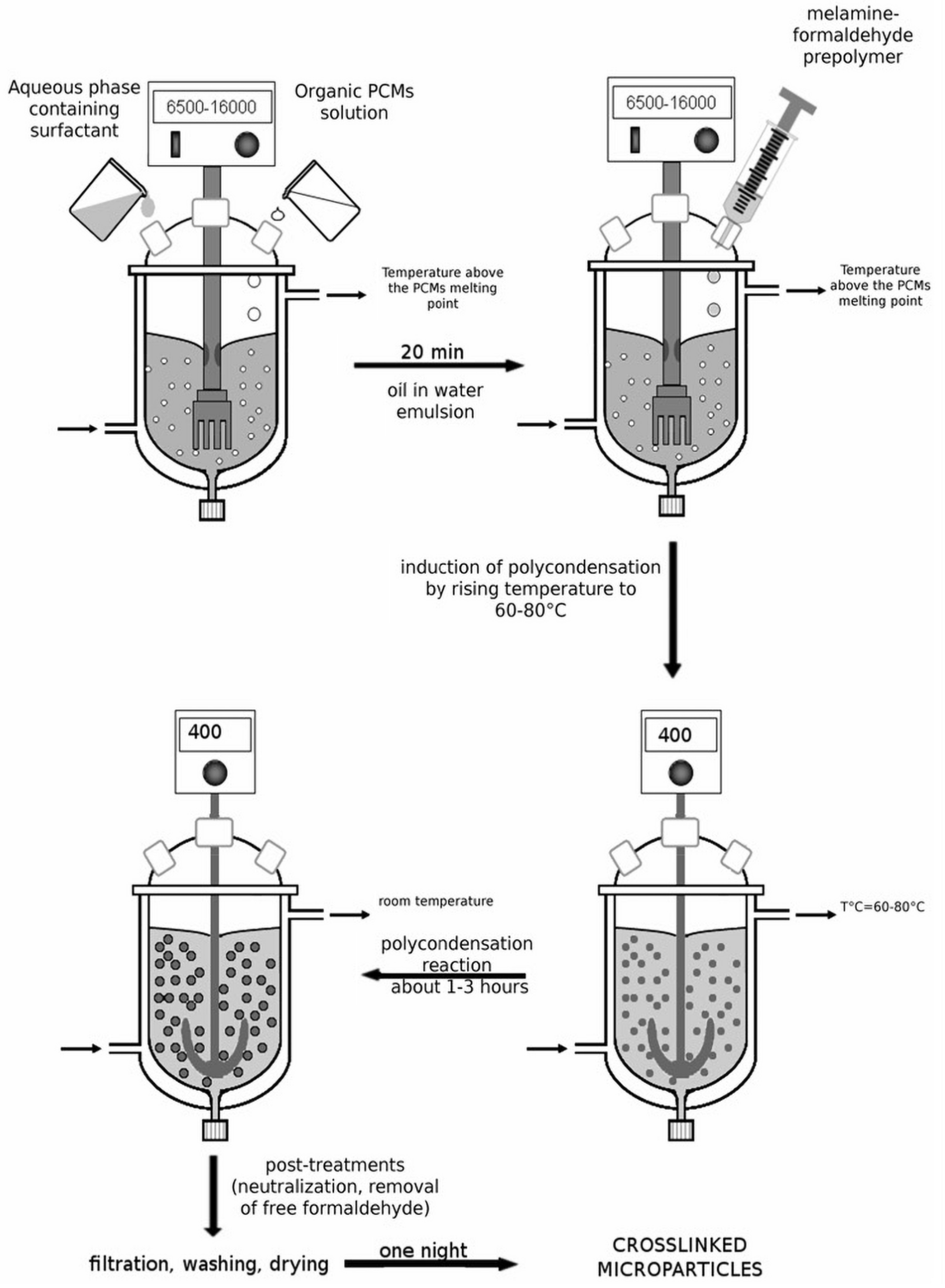

4.1.2. Microencapsulation by In Situ Polymerization

4.1.3. Microencapsulation by Interfacial Polycondensation

4.2. Physical Process

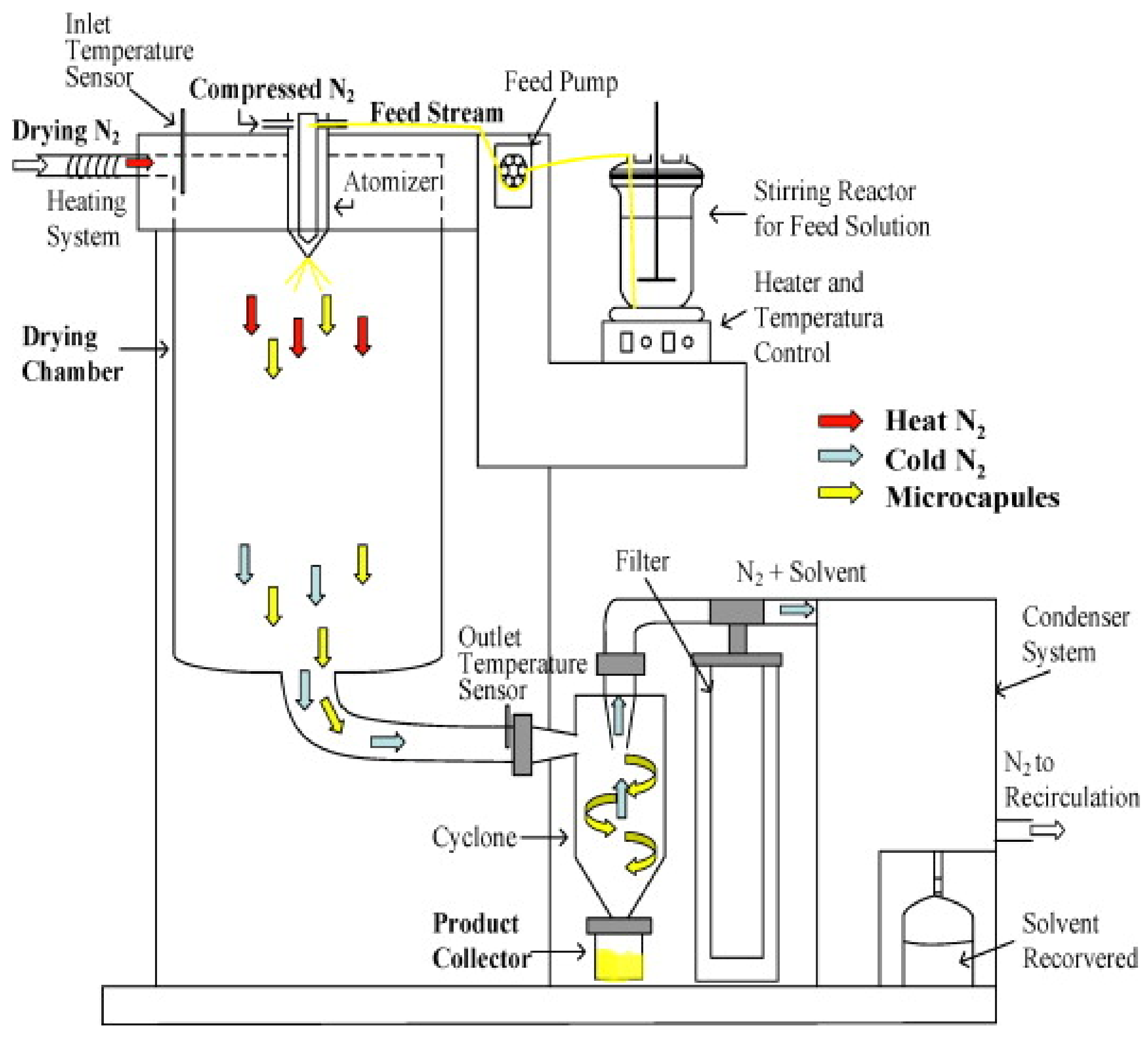

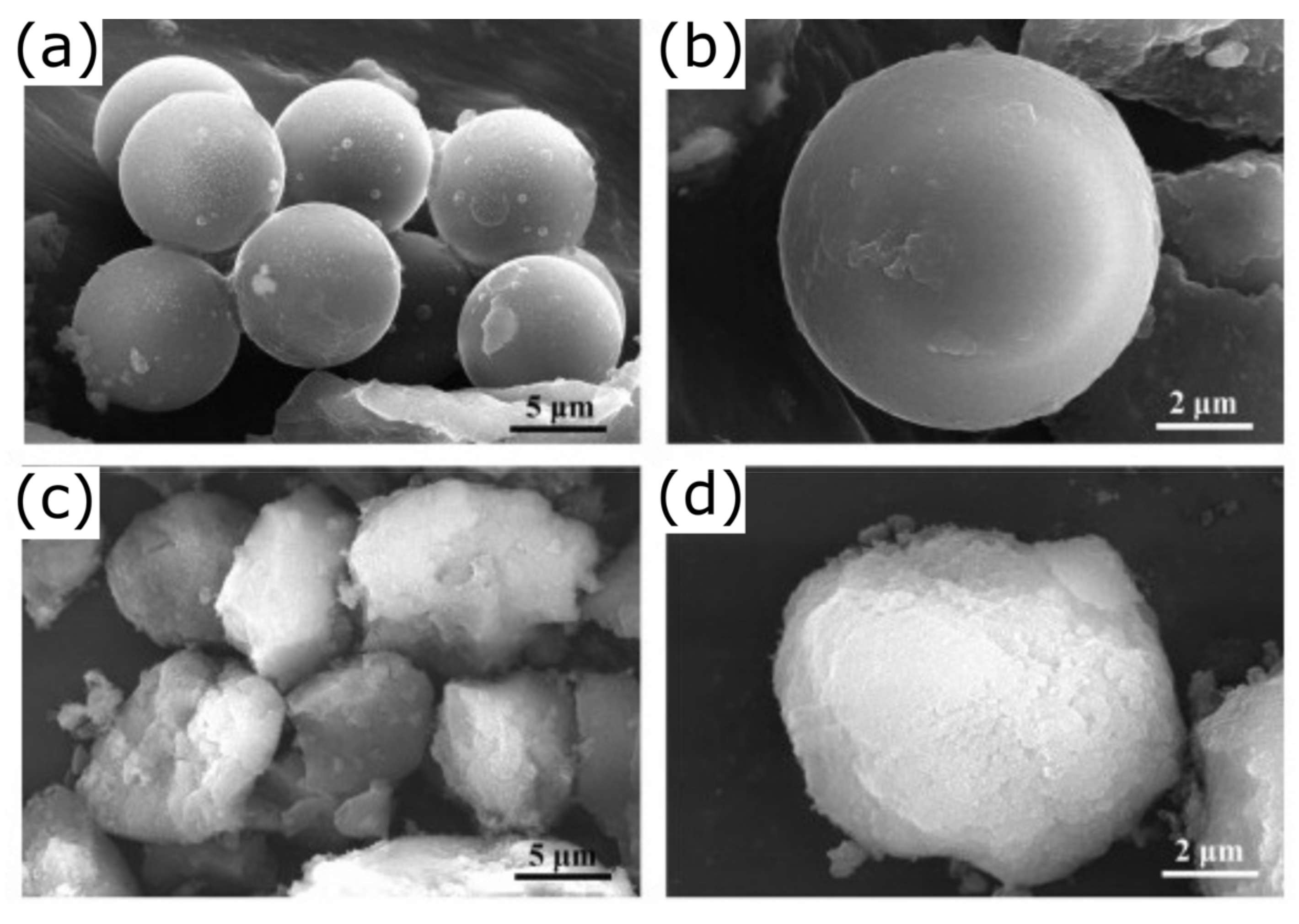

4.2.1. Spray Drying

4.2.2. Electrohydrodynamic Encapsulation

4.3. Physicochemical Process

4.3.1. Coacervation

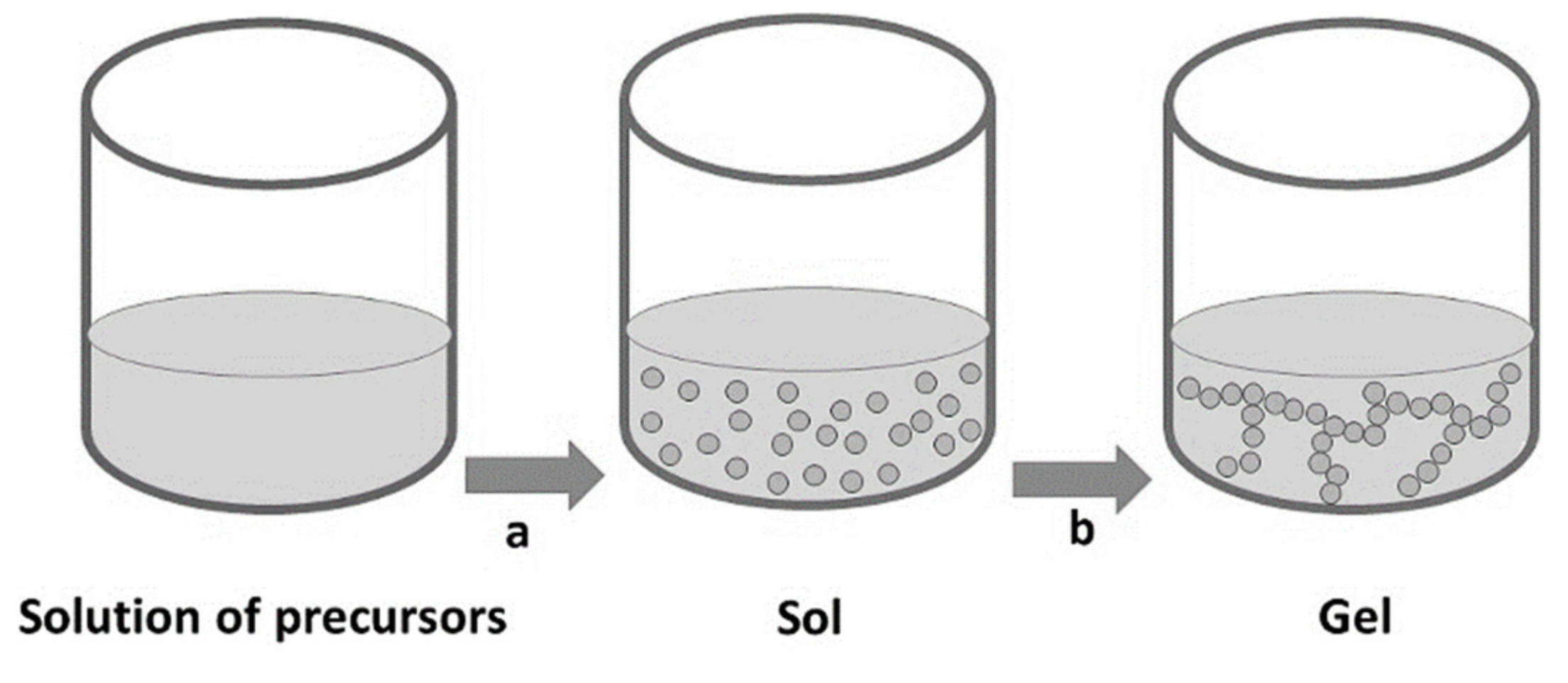

4.3.2. Sol-Gel

- Silica shell

- Titania shell

- Other inorganic shells

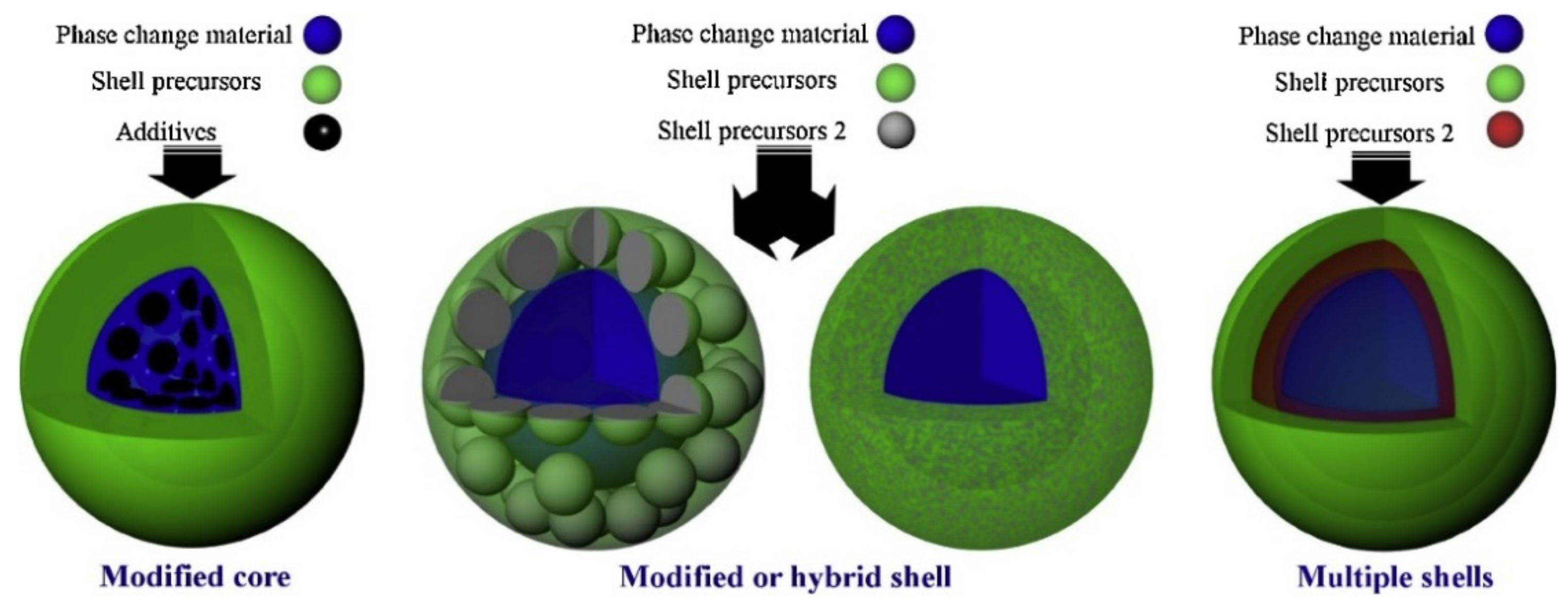

5. Multifunctional mPCMs

5.1. Multifunctional mPCMs

5.1.1. Photocatalytic and Antibacterial Activity

5.1.2. Photothermal Conversion Activity

5.1.3. Photoluminescence Activity

5.1.4. Miscellaneous Properties

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Kannan, N.; Vakeesan, D. Solar energy for future world: A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Waterson, M. The characteristics of electricity storage, renewables and markets. Energy Policy 2017, 104, 466–473. [Google Scholar] [CrossRef] [Green Version]

- Acar, C. A comprehensive evaluation of energy storage options for better sustainability. Int. J. Energy Res. 2018, 42, 3732–3746. [Google Scholar] [CrossRef]

- Chavan, S.; Rudrapati, R.; Manickam, S. A comprehensive review on current advances of thermal energy storage and its applications. Alex. Eng. J. 2021. [Google Scholar] [CrossRef]

- Lizana, J.; Chacartegui, R.; Padura, A.B.; Valverde, J.M. Advances in thermal energy storage materials and their applications towards zero energy buildings: A critical review. Appl. Energy 2017, 203, 219–239. [Google Scholar] [CrossRef]

- Prasad, J.S.; Muthukumar, P.; Desai, F.; Basu, D.N.; Rahman, M.M. A critical review of high-temperature reversible thermochemical energy storage systems. Appl. Energy 2019, 254, 113733. [Google Scholar] [CrossRef]

- Alva, G.; Liu, L.; Huang, X.; Fang, G. Thermal energy storage materials and systems for solar energy applications. Renew. Sustain. Energy Rev. 2017, 68, 693–706. [Google Scholar] [CrossRef]

- Alothman, A.; Sree Nandini, S.; Krishnaraj, L. A Phase Change Material for Building Applications—A Critical Review. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Jelle, B.; Kalnæs, S. Phase Change Materials for Application in Energy-Efficient Buildings. Cost-Eff. Energy Effic. Build. Retrofit. 2017, 57–118. [Google Scholar] [CrossRef]

- Vadhera, J.; Sura, A.; Nandan, G.; Dwivedi, G. Study of Phase Change materials and its domestic application. Mater. Today Proc. 2018, 5, 3411–3417. [Google Scholar] [CrossRef]

- Leong, K.Y.; Hasbi, S.; Gurunathan, B.A. State of art review on the solidification and melting characteristics of phase change material in triplex-tube thermal energy storage. J. Energy Storage 2021, 41, 102932. [Google Scholar] [CrossRef]

- Ferrer, G.; Solé, A.; Barreneche, C.; Martorell, I.; Cabeza, L.F. Review on the methodology used in thermal stability characterization of phase change materials. Renew. Sustain. Energy Rev. 2015, 50, 665–685. [Google Scholar] [CrossRef] [Green Version]

- Kunwer, R.; Bhurat, S.S. Thermal characterization of phase change materials (PCM) for heating applications. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Fernandez, A.I.; Solé, A.; Paloma, J.G.; Martínez, M.; Hadjieva, M.; Boudenne, A.; Constantinescu, M.; Anghel, E.M.; Malikova, M.; Krupa, I.; et al. Unconventional experimental technologies used for phase change materials (PCM) characterization: Part 2—Morphological and structural characterization, physico-chemical stability and mechanical properties. Renew. Sustain. Energy Rev. 2015, 43, 1415–1426. [Google Scholar] [CrossRef] [Green Version]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Famileh, I.Z.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Kant, K.; Biwole, P.; Shamseddine, I.; Tlaiji, G.; Pennec, F.; Fardoun, F. Recent advances in thermophysical properties enhancement of phase change materials for thermal energy storage. Sol. Energy Mater. Sol. Cells 2021, 231, 111309. [Google Scholar] [CrossRef]

- Wu, S.; Yan, T.; Kuai, Z.; Pan, W. Thermal conductivity enhancement on phase change materials for thermal energy storage: A review. Energy Storage Mater. 2020, 25, 251–295. [Google Scholar] [CrossRef]

- Qureshi, Z.A.; Ali, H.M.; Khushnood, S. Recent advances on thermal conductivity enhancement of phase change materials for energy storage system: A review. Int. J. Heat Mass Transf. 2018, 127, 838–856. [Google Scholar] [CrossRef]

- Umair, M.M.; Zhang, Y.; Iqbal, K.; Zhang, S.; Tang, B. Novel strategies and supporting materials applied to shape-stabilize organic phase change materials for thermal energy storage—A review. Appl. Energy 2019, 235, 846–873. [Google Scholar] [CrossRef]

- Shchukina, E.M.; Graham, M.; Zheng, Z.; Shchukin, D.G. Nanoencapsulation of phase change materials for advanced thermal energy storage systems. Chem. Soc. Rev. 2018, 47, 4156–4175. [Google Scholar] [CrossRef] [Green Version]

- Sharma, R.K.; Ganesan, P.; Tyagi, V.V.; Metselaar, H.S.C.; Sandaran, S.C. Developments in organic solid–liquid phase change materials and their applications in thermal energy storage. Energy Convers. Manag. 2015, 95, 193–228. [Google Scholar] [CrossRef] [Green Version]

- Jouhara, H.; Żabnieńska-Góra, A.; Khordehgah, N.; Ahmad, D.; Lipinski, T. Latent thermal energy storage technologies and applications: A review. Int. J. Thermofluids 2020, 5, 100039. [Google Scholar] [CrossRef]

- Sivanathan, A.; Dou, Q.; Wang, Y.; Li, Y.; Corker, J.; Zhou, Y.; Fan, M. Phase change materials for building construction: An overview of nano-/micro-encapsulation. Nanotechnol. Rev. 2020, 9, 896–921. [Google Scholar] [CrossRef]

- Khadiran, T.; Hussein, M.Z.; Zainal, Z.; Rusli, R. Encapsulation techniques for organic phase change materials as thermal energy storage medium: A review. Sol. Energy Mater. Sol. Cells 2015, 143, 78–98. [Google Scholar] [CrossRef]

- Zare, M.; Dziemidowicz, K.; Williams, G.; Ramakrishna, S. Encapsulation of Pharmaceutical and Nutraceutical Active Ingredients Using Electrospinning Processes. Nanomaterials 2021, 11, 1968. [Google Scholar] [CrossRef] [PubMed]

- Pillai, S.K.; Kleyi, P.; de Beer, M.; Mudaly, P. Layered double hydroxides: An advanced encapsulation and delivery system for cosmetic ingredients-an overview. Appl. Clay Sci. 2020, 199, 105868. [Google Scholar] [CrossRef]

- Coelho, S.C.; Estevinho, B.N.; Rocha, F. Encapsulation in food industry with emerging electrohydrodynamic techniques: Electrospinning and electrospraying—A review. Food Chem. 2021, 339, 127850. [Google Scholar] [CrossRef]

- Lane, G.A. Low temperature heat storage with phase change materials. Int. J. Ambient. Energy 1980, 1, 155–168. [Google Scholar] [CrossRef]

- Abhat, A. Low temperature latent heat thermal energy storage: Heat storage materials. Sol. Energy 1983, 30, 313–332. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. Enhanced thermophysical properties of organic PCM through shape stabilization for thermal energy storage in buildings: A state of the art review. Energy Build. 2021, 236, 110799. [Google Scholar] [CrossRef]

- Singh, P.; Sharma, R.; Ansu, A.; Goyal, R.; Sarı, A.; Tyagi, V. A comprehensive review on development of eutectic organic phase change materials and their composites for low and medium range thermal energy storage applications. Sol. Energy Mater. Sol. Cells 2021, 223, 110955. [Google Scholar] [CrossRef]

- Murali, G.; Sravya, G.; Jaya, J.; Vamsi, V.N. A review on hybrid thermal management of battery packs and it’s cooling performance by enhanced PCM. Renew. Sustain. Energy Rev. 2021, 150, 111513. [Google Scholar] [CrossRef]

- Wonorahardjo, S.; Sutjahja, I.M.; Tunçbilek, E.; Achsani, R.A.; Arıcı, M.; Rahmah, N. PCM-based passive air conditioner in urban houses for the tropical climates: An experimental analysis on the stratum air circulation. Build. Environ. 2021, 192, 107632. [Google Scholar] [CrossRef]

- Pathak, L.; Trivedi, G.; Parameshwaran, R.; Deshmukh, S.S. Microencapsulated phase change materials as slurries for thermal energy storage: A review. Mater. Today Proc. 2021, 44, 1960–1963. [Google Scholar] [CrossRef]

- Tyagi, V.; Chopra, K.; Sharma, R.; Pandey, A.; Tyagi, S.; Ahmad, M.S.; Sarı, A.; Kothari, R. A comprehensive review on phase change materials for heat storage applications: Development, characterization, thermal and chemical stability. Sol. Energy Mater. Sol. Cells 2022, 234, 111392. [Google Scholar] [CrossRef]

- Hassan, F.; Jamil, F.; Hussain, A.; Ali, H.M.; Janjua, M.M.; Khushnood, S.; Farhan, M.; Altaf, K.; Said, Z.; Li, C. Recent advancements in latent heat phase change materials and their applications for thermal energy storage and buildings: A state of the art review. Sustain. Energy Technol. Assess. 2021, 49, 101646. [Google Scholar] [CrossRef]

- Alehosseini, E.; Jafari, S.M. Micro/nano-encapsulated phase change materials (PCMs) as emerging materials for the food industry. Trends Food Sci. Technol. 2019, 91, 116–128. [Google Scholar] [CrossRef]

- Su, W.; Darkwa, J.; Kokogiannakis, G. Review of solid–liquid phase change materials and their encapsulation technologies. Renew. Sustain. Energy Rev. 2015, 48, 373–391. [Google Scholar] [CrossRef]

- Salaün, F. The Manufacture of Microencapsulated Thermal Energy Storage Compounds Suitable for Smart Textile. In Developments in Heat Transfer; Bernardes, M.A.D.S., Ed.; IntechOpen: London, UK, 2011; pp. 171–198. [Google Scholar] [CrossRef]

- Kee, S.Y.; Munusamy, Y.; Ong, K.S. Review of solar water heaters incorporating solid-liquid organic phase change materials as thermal storage. Appl. Therm. Eng. 2018, 131, 455–471. [Google Scholar] [CrossRef]

- Magendran, S.S.; Khan, F.S.A.; Mubarak, N.; Vaka, M.; Walvekar, R.; Khalid, M.; Abdullah, E.; Nizamuddin, S.; Karri, R.R. Synthesis of organic phase change materials (PCM) for energy storage applications: A review. Nano-Struct. Nano-Obj. 2019, 20, 100399. [Google Scholar] [CrossRef]

- Lin, Y.; Alva, G.; Fang, G. Review on thermal performances and applications of thermal energy storage systems with inorganic phase change materials. Energy 2018, 165, 685–708. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, X.; Xu, X.; Liu, L.; Zhao, Y.; Zhang, S. Application and research progress of phase change energy storage in new energy utilization. J. Mol. Liq. 2021, 343, 117554. [Google Scholar] [CrossRef]

- Mohamed, S.A.; Al-Sulaiman, F.A.; Ibrahim, N.I.; Zahir, H.; Al-Ahmed, A.; Saidur, R.; Yılbaş, B.; Sahin, A.Z. A review on current status and challenges of inorganic phase change materials for thermal energy storage systems. Renew. Sustain. Energy Rev. 2017, 70, 1072–1089. [Google Scholar] [CrossRef]

- Liu, M.; Saman, W.; Bruno, F. Review on storage materials and thermal performance enhancement techniques for high temperature phase change thermal storage systems. Renew. Sustain. Energy Rev. 2012, 16, 2118–2132. [Google Scholar] [CrossRef]

- Ge, H.; Li, H.; Mei, S.; Liu, J. Low melting point liquid metal as a new class of phase change material: An emerging frontier in energy area. Renew. Sustain. Energy Rev. 2013, 21, 331–346. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Hua, W. Review of preparation technologies of organic composite phase change materials in energy storage. J. Mol. Liq. 2021, 336, 115923. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, D.; Ling, X.; Li, Y.; Wang, Y.; Yu, Q.; She, X.; Li, Y.; Ding, Y. Yulong n-Alkanes Phase Change Materials and Their Microencapsulation for Thermal Energy Storage: A Critical Review. Energy Fuels 2018, 32, 7262–7293. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Pandey, A.K.; Hossain, M.; Tyagi, V.; Rahim, N.A.; Selvaraj, J.A.; Sari, A. Novel approaches and recent developments on potential applications of phase change materials in solar energy. Renew. Sustain. Energy Rev. 2018, 82, 281–323. [Google Scholar] [CrossRef]

- Daniel, J.; Rajasekharan, R. Organogelation of plant oils and hydrocarbons by long-chain saturated FA, fatty alcohols, wax esters, and dicarboxylic acids. J. Am. Oil Chem. Soc. 2003, 80, 417–421. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. A review on phase change materials for thermal energy storage in buildings: Heating and hybrid applications. J. Energy Storage 2021, 33, 101913. [Google Scholar] [CrossRef]

- Omara, A.A.; Abuelnour, A.A.A. Improving the performance of air conditioning systems by using phase change materials: A review. Int. J. Energy Res. 2019, 43, 5175–5198. [Google Scholar] [CrossRef]

- Salaün, F. Phase Change Materials for Textile Application, Textile Industry and Environment; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef] [Green Version]

- Feldman, D.; Shapiro, M.; Banu, D.; Fuks, C. Fatty acids and their mixtures as phase-change materials for thermal energy storage. Sol. Energy Mater. 1989, 18, 201–216. [Google Scholar] [CrossRef]

- Sharma, A.; Won, L.D.; Buddhi, D.; Park, J.U. Numerical heat transfer studies of the fatty acids for different heat exchanger materials on the performance of a latent heat storage system. Renew. Energy 2005, 30, 2179–2187. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, T.D.; Zheng, H.; Feng, H.X. Stearic acid/silica fume composite as form-stable phase change material for thermal energy storage. Energy Build. 2011, 43, 2365–2370. [Google Scholar] [CrossRef]

- Cai, Y.; Ke, H.; Lin, L.; Fei, X.; Wei, Q.; Song, L.; Hu, Y.; Fong, H. Preparation, morphology and thermal properties of electrospun fatty acid eutectics/polyethylene terephthalate form-stable phase change ultrafine composite fibers for thermal energy storage. Energy Convers. Manag. 2012, 64, 245–255. [Google Scholar] [CrossRef]

- Sari, A.; Alkan, C.; Kolemen, U.; Uzun, O. Eudragit S (methyl methacrylate methacrylic acid copolymer)/fatty acid blends as form-stable phase change material for latent heat thermal energy storage. J. Appl. Polym. Sci. 2006, 101, 1402–1406. [Google Scholar] [CrossRef]

- Sari, A.; Karlı, A.; Alkan, C.; Karaipekli, A. Polyethyl Methacrylate (PEMA)/Fatty Acids Blends as Novel Phase Change Materials for Thermal Energy Storage. Energy Sources, Part A Recover. Util. Environ. Eff. 2013, 35, 1813–1819. [Google Scholar] [CrossRef]

- Sari, A.; Kaygusuz, K. Thermal performance of myristic acid as a phase change material for energy storage application. Renew. Energy 2001, 24, 303–317. [Google Scholar] [CrossRef]

- Zuo, J.; Li, W.; Weng, L. Thermal properties of lauric acid/1-tetradecanol binary system for energy storage. Appl. Therm. Eng. 2011, 31, 1352–1355. [Google Scholar] [CrossRef]

- Mei, D.; Zhang, B.; Liu, R.; Zhang, Y.; Liu, J. Preparation of capric acid/halloysite nanotube composite as form-stable phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 2011, 95, 2772–2777. [Google Scholar] [CrossRef]

- Boulard, T.; Razafinjohany, E.; Baille, A.; Jaffrin, A.; Fabre, B. Performance of a greenhouse heating system with a phase change material. Agric. For. Meteorol. 1990, 52, 303–318. [Google Scholar] [CrossRef]

- Mondal, S. Phase change materials for smart textiles—An overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Wei, H.; Xie, X.; Li, X.; Lin, X. Preparation and characterization of capric-myristic-stearic acid eutectic mixture/modified expanded vermiculite composite as a form-stable phase change material. Appl. Energy 2016, 178, 616–623. [Google Scholar] [CrossRef]

- Yuan, Y.; Tao, W.; Cao, X.; Bai, L. Theoretic Prediction of Melting Temperature and Latent Heat for a Fatty Acid Eutectic Mixture. J. Chem. Eng. Data 2011, 56, 2889–2891. [Google Scholar] [CrossRef]

- Zhang, N.; Yuan, Y.; Yuan, Y.; Li, T.; Cao, X. Lauric–palmitic–stearic acid/expanded perlite composite as form-stable phase change material: Preparation and thermal properties. Energy Build. 2014, 82, 505–511. [Google Scholar] [CrossRef]

- Quanying, Y.; Wanyu, H.; Xiao, W. Thermal energy storage properties of a capric acid/stearic acid binary system and a 48# paraffin/liquid paraffin binary system. Int. J. Sustain. Energy 2015, 36, 695–706. [Google Scholar] [CrossRef]

- Lv, S.; Zhu, N.; Feng, G. Eutectic mixtures of capric acid and lauric acid applied in building wallboards for heat energy storage. Energy Build. 2006, 38, 708–711. [Google Scholar] [CrossRef]

- Yuan, Y.; Li, T.; Zhang, N.; Cao, X.; Yang, X. Investigation on thermal properties of capric–palmitic–stearic acid/activated carbon composite phase change materials for high-temperature cooling application. J. Therm. Anal. Calorim. 2016, 124, 881–888. [Google Scholar] [CrossRef]

- Nazir, H.; Batool, M.; Ali, M.; Kannan, A.M. Fatty acids based eutectic phase change system for thermal energy storage applications. Appl. Therm. Eng. 2018, 142, 466–475. [Google Scholar] [CrossRef]

- Karaipekli, A.; Sari, A.; Kaygusuz, K. Thermal Properties and Long-term Reliability of Capric Acid/Lauric Acid and Capric Acid/Myristic Acid Mixtures for Thermal Energy Storage. Energy Sources Part A Recover. Util. Environ. Eff. 2008, 30, 1248–1258. [Google Scholar] [CrossRef]

- Ke, H. Phase diagrams, eutectic mass ratios and thermal energy storage properties of multiple fatty acid eutectics as novel solid-liquid phase change materials for storage and retrieval of thermal energy. Appl. Therm. Eng. 2017, 113, 1319–1331. [Google Scholar] [CrossRef]

- Sari, A. Eutectic mixtures of some fatty acids for low temperature solar heating applications: Thermal properties and thermal reliability. Appl. Therm. Eng. 2005, 25, 2100–2107. [Google Scholar] [CrossRef]

- Karaipekli, A.; Sarı, A. Preparation, thermal properties and thermal reliability of eutectic mixtures of fatty acids/expanded vermiculite as novel form-stable composites for energy storage. J. Ind. Eng. Chem. 2010, 16, 767–773. [Google Scholar] [CrossRef]

- Zhao, P.; Yue, Q.; He, H.; Gao, B.; Wang, Y.; Li, Q. Study on phase diagram of fatty acids mixtures to determine eutectic temperatures and the corresponding mixing proportions. Appl. Energy 2014, 115, 483–490. [Google Scholar] [CrossRef]

- Peng, G.; Dou, G.; Hu, Y.; Sun, Y.; Chen, Z. Phase Change Material (PCM) Microcapsules for Thermal Energy Storage. Adv. Polym. Technol. 2020, 2020, 9490873. [Google Scholar] [CrossRef]

- Arshady, R.; George, M.H. Suspension, dispersion, and interfacial polycondensation: A methodological survey. Polym. Eng. Sci. 1993, 33, 865–876. [Google Scholar] [CrossRef]

- Huang, X.; Zhu, C.; Lin, Y.; Fang, G. Thermal properties and applications of microencapsulated PCM for thermal energy storage: A review. Appl. Therm. Eng. 2019, 147, 841–855. [Google Scholar] [CrossRef]

- Giro-Paloma, J.; Martínez, M.; Cabeza, L.F.; Fernandez, A.I. Types, methods, techniques, and applications for microencapsulated phase change materials (MPCM): A review. Renew. Sustain. Energy Rev. 2016, 53, 1059–1075. [Google Scholar] [CrossRef] [Green Version]

- Jonsson, M.; Nordin, O.; Malmström, E.; Hammer, C. Suspension polymerization of thermally expandable core/shell particles. Polymer 2006, 47, 3315–3324. [Google Scholar] [CrossRef]

- Sánchez, L.; Sánchez, P.; de Lucas, A.; Carmona, M.; Rodríguez, J.F. Microencapsulation of PCMs with a polystyrene shell. Colloid Polym. Sci. 2007, 285, 1377–1385. [Google Scholar] [CrossRef]

- Sánchez-Silva, L.; Rodríguez, J.F.; Romero, A.; Borreguero, A.M.; Carmona, M.; Sánchez, P. Microencapsulation of PCMs with a styrene-methyl methacrylate copolymer shell by suspension-like polymerisation. Chem. Eng. J. 2010, 157, 216–222. [Google Scholar] [CrossRef]

- Tanwar, S.; Kaur, R. Development and investigation of microencapsulated caprylic acid -based phase change materials for thermal energy storage applications. Int. J. Energy Res. 2021, 45, 17302–17314. [Google Scholar] [CrossRef]

- Arshady, R. Suspension, emulsion, and dispersion polymerization: A methodological survey. Colloid Polym. Sci. 1992, 270, 717–732. [Google Scholar] [CrossRef]

- Peng, H.; Wang, J.; Zhang, X.; Ma, J.; Shen, T.; Li, S.; Dong, B. A review on synthesis, characterization and application of nanoencapsulated phase change materials for thermal energy storage systems. Appl. Therm. Eng. 2021, 185, 116326. [Google Scholar] [CrossRef]

- Sarı, A.; Alkan, C.; Karaipekli, A.; Uzun, O. Microencapsulated n-octacosane as phase change material for thermal energy storage. Sol. Energy 2009, 83, 1757–1763. [Google Scholar] [CrossRef]

- Alkan, C.; Sarı, A.; Karaipekli, A.; Uzun, O. Preparation, characterization, and thermal properties of microencapsulated phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 2009, 93, 143–147. [Google Scholar] [CrossRef]

- Sari, A.; Alkan, C.; Biçer, A.; Altuntaş, A.; Bilgin, C. Micro/nanoencapsulated n-nonadecane with poly(methyl methacrylate) shell for thermal energy storage. Energy Convers. Manag. 2014, 86, 614–621. [Google Scholar] [CrossRef]

- Alay, S.; Göde, F.; Alkan, C. Preparation and characterization of poly(methylmethacrylate-coglycidyl methacrylate)/n-hexadecane nanocapsules as a fiber additive for thermal energy storage. Fibers Polym. 2010, 11, 1089–1093. [Google Scholar] [CrossRef]

- Chemtob, A.; Kunstler, B.; Croutxé-Barghorn, C.; Fouchard, S. Photoinduced miniemulsion polymerization. Colloid Polym. Sci. 2010, 288, 579–587. [Google Scholar] [CrossRef]

- Ma, S.; Song, G.; Li, W.; Fan, P.; Tang, G. UV irradiation-initiated MMA polymerization to prepare microcapsules containing phase change paraffin. Sol. Energy Mater. Sol. Cells 2010, 94, 1643–1647. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Xia, T.; Zhao, W.; Yang, W. Effects of fabricated technology on particle size distribution and thermal properties of stearic–eicosanoic acid/polymethylmethacrylate nanocapsules. Sol. Energy Mater. Sol. Cells 2014, 120, 481–490. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, M.; Zhang, Y.; Wang, Y. Microencapsulation of stearic acid with polymethylmethacrylate using iron (III) chloride as photo-initiator for thermal energy storage. Chin. J. Chem. Eng. 2017, 25, 1524–1532. [Google Scholar] [CrossRef]

- Sami, S.; Etesami, N. Thermal characterization of obtained microencapsulated paraffin under optimal conditions for thermal energy storage. J. Therm. Anal. Calorim. 2017, 130, 1961–1971. [Google Scholar] [CrossRef]

- Sami, S.; Sadrameli, S.; Etesami, N. Thermal properties optimization of microencapsulated a renewable and non-toxic phase change material with a polystyrene shell for thermal energy storage systems. Appl. Therm. Eng. 2018, 130, 1416–1424. [Google Scholar] [CrossRef]

- Fang, Y.; Liu, X.; Liang, X.; Liu, H.; Gao, X.; Zhang, Z. Ultrasonic synthesis and characterization of polystyrene/n-dotriacontane composite nanoencapsulated phase change material for thermal energy storage. Appl. Energy 2014, 132, 551–556. [Google Scholar] [CrossRef]

- Rezvanpour, M.; Hasanzadeh, M.; Azizi, D.; Rezvanpour, A.; Alizadeh, M. Synthesis and characterization of micro-nanoencapsulated n -eicosane with PMMA shell as novel phase change materials for thermal energy storage. Mater. Chem. Phys. 2018, 215, 299–304. [Google Scholar] [CrossRef]

- Zhou, J.; Cui, Y.; Yao, H.; Ma, J.; Ren, H. Nanocapsules containing binary phase change material obtained via miniemulsion polymerization with reactive emulsifier: Synthesis, characterization, and application in fabric finishing. Polym. Eng. Sci. 2019, 59, E42–E51. [Google Scholar] [CrossRef]

- Yu, F.; Chen, Z.-H.; Zeng, X.-R.; Gao, X.-N.; Zhang, Z.-G. Poly(methyl methacrylate) copolymer nanocapsules containing phase-change material (n-dodecanol) prepared via miniemulsion polymerization. J. Appl. Polym. Sci. 2015, 132, 132. [Google Scholar] [CrossRef]

- Khakzad, F.; Alinejad, Z.; Shirin-Abadi, A.R.; Ghasemi, M.; Mahdavian, A.R. Optimization of parameters in preparation of PCM microcapsules based on melamine formaldehyde through dispersion polymerization. Colloid Polym. Sci. 2014, 292, 355–368. [Google Scholar] [CrossRef]

- Pethurajan, V.; Sivan, S. Fabrication, characterisation and heat transfer study on microencapsulation of nano-enhanced phase change material. Chem. Eng. Process. Process. Intensif. 2018, 133, 12–23. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, T. Effects of parameters of the shell formation process on the performance of microencapsulated phase change materials based on melamine-formaldehyde. Text. Res. J. 2017, 87, 1848–1859. [Google Scholar] [CrossRef]

- Naikwadi, A.T.; Samui, A.B.; Mahanwar, P.A. Melamine-formaldehyde microencapsulated n-Tetracosane phase change material for solar thermal energy storage in coating. Sol. Energy Mater. Sol. Cells 2020, 215, 110676. [Google Scholar] [CrossRef]

- Yin, D.; Ma, L.; Geng, W.; Zhang, B.; Zhang, Q. Microencapsulation ofn-hexadecanol byin situpolymerization of melamine-formaldehyde resin in emulsion stabilized by styrene-maleic anhydride copolymer. Int. J. Energy Res. 2015, 39, 661–667. [Google Scholar] [CrossRef]

- Kumar, G.N.; Al-Aifan, B.; Parameshwaran, R.; Ram, V.V. Facile synthesis of microencapsulated 1-dodecanol/melamine-formaldehyde phase change material using in-situ polymerization for thermal energy storage. Colloids Surf. A Physicochem. Eng. Asp. 2021, 610, 125698. [Google Scholar] [CrossRef]

- Salaün, F.; Devaux, E.; Bourbigot, S.; Rumeau, P. Influence of process parameters on microcapsules loaded with n-hexadecane prepared by in situ polymerization. Chem. Eng. J. 2009, 155, 457–465. [Google Scholar] [CrossRef]

- Chai, Y.; Zhao, T.; Gao, X.; Zhang, J. Low cracking ratio of paraffin microcapsules shelled by hydroxyl terminated polydimethylsiloxane modified melamine-formaldehyde resin. Colloids Surf. A Physicochem. Eng. Asp. 2018, 538, 86–93. [Google Scholar] [CrossRef]

- Hu, X.; Huang, Z.; Yu, X.; Li, B. Preparation and Thermal Energy Storage of Carboxymethyl Cellulose-Modified Nanocapsules. BioEnergy Res. 2013, 6, 1135–1141. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, X. Fabrication and performances of microencapsulated phase change materials based on n-octadecane core and resorcinol-modified melamine–formaldehyde shell. Colloids Surf. A Physicochem. Eng. Asp. 2009, 332, 129–138. [Google Scholar] [CrossRef]

- Konuklu, Y.; Paksoy, H.O.; Unal, M.; Konuklu, S. Microencapsulation of a fatty acid with Poly(melamine–urea–formaldehyde). Energy Convers. Manag. 2014, 80, 382–390. [Google Scholar] [CrossRef]

- Wu, N.; Xu, L.; Zhang, C. The influence of emulsifiers on preparation and properties of microencapsules of melamine-urea-formaldehyde resins with n-dodecanol as phase-change material. Adv. Polym. Technol. 2018, 37, 3492–3498. [Google Scholar] [CrossRef]

- Zhang, H.; Li, W.; Huang, R.; Wang, N.; Wang, J.; Zhang, X. Microstructure regulation of microencapsulated bio-based n-dodecanol as phase change materials via in situ polymerization. New J. Chem. 2017, 41, 14696–14707. [Google Scholar] [CrossRef]

- Huang, R.; Li, W.; Wang, J.; Zhang, X. Effects of oil-soluble etherified melamine-formaldehyde prepolymers on in situ microencapsulation and macroencapsulation of n-dodecanol. New J. Chem. 2017, 41, 9424–9437. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, J.; Yu, F.; Zhang, Z.; Gao, X. Preparation and properties of graphene oxide-modified poly(melamine-formaldehyde) microcapsules containing phase change material n-dodecanol for thermal energy storage. J. Mater. Chem. A 2015, 3, 11624–11630. [Google Scholar] [CrossRef]

- Sarier, N.; Onder, E.; Ukuser, G. Silver incorporated microencapsulation of n-hexadecane and n-octadecane appropriate for dynamic thermal management in textiles. Thermochim. Acta 2015, 613, 17–27. [Google Scholar] [CrossRef]

- Daou, I.; El-Kaddadi, L.; Zegaoui, O.; Asbik, M.; Zari, N. Structural, morphological and thermal properties of novel hybrid-microencapsulated phase change materials based on Fe2O3, ZnO and TiO2 nanoparticles for latent heat thermal energy storage applications. J. Energy Storage 2018, 17, 84–92. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, P.; Xu, Z.; Chen, Z.; Gao, Y. Preparation of 1-dodecanol microcapsules with cellulose nanofibers-modified melamine-formaldehyde resin as a potential phase change material. Mater. Res. Express 2019, 6, 125376. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, Y.; Tao, X.; Yick, K.L. Fabrication and properties of microcapsules and nanocapsules containing n-octadecane. Mater. Chem. Phys. 2004, 88, 300–307. [Google Scholar] [CrossRef]

- Li, W.; Zhang, X.-X.; Wang, X.-C.; Niu, J.-J. Preparation and characterization of microencapsulated phase change material with low remnant formaldehyde content. Mater. Chem. Phys. 2007, 106, 437–442. [Google Scholar] [CrossRef]

- Siddhan, P.; Jassal, M.; Agrawal, A.K. Core content and stability ofn-octadecane-containing polyurea microencapsules produced by interfacial polymerization. J. Appl. Polym. Sci. 2007, 106, 786–792. [Google Scholar] [CrossRef]

- Kavouras, P.; Trompeta, A.; Larroze, S.; Maranhão, M.; Teixeira, T.; Beltri, M.; Koumoulos, E.; Charitidis, C. Correlation of mechanical properties with antifouling efficacy of coatings containing loaded microcapsules. Prog. Org. Coat. 2019, 136, 105249. [Google Scholar] [CrossRef]

- Han, P.; Lu, L.; Qiu, X.; Tang, Y.; Wang, J. Preparation and characterization of macrocapsules containing microencapsulated PCMs (phase change materials) for thermal energy storage. Energy 2015, 91, 531–539. [Google Scholar] [CrossRef]

- Lu, S.; Xing, J.-W.; Wu, Q. Preparation and Characterization of High Stability Polyurea MicroPCMs Using a Two-step Method of Adding DETA by Interfacial Polymerization. J. Fiber Bioeng. Inform. 2013, 6, 185–194. [Google Scholar] [CrossRef]

- Lu, S.; Shen, T.; Xing, J.; Song, Q.; Xin, C. Preparation, characterization, and thermal stability of double-composition shell microencapsulated phase change material by interfacial polymerization. Colloid Polym. Sci. 2017, 295, 2061–2067. [Google Scholar] [CrossRef]

- Zhang, F.; Jiang, X.; Zhu, X.; Chen, Z.; Kong, X.Z. Preparation of uniform and porous polyurea microspheres of large size through interfacial polymerization of toluene diisocyanate in water solution of ethylene diamine. Chem. Eng. J. 2016, 303, 48–55. [Google Scholar] [CrossRef]

- Tatiya, P.D.; Hedaoo, R.K.; Mahulikar, P.P.; Gite, V.V. Novel Polyurea Microcapsules Using Dendritic Functional Monomer: Synthesis, Characterization, and Its Use in Self-healing and Anticorrosive Polyurethane Coatings. Ind. Eng. Chem. Res. 2013, 52, 1562–1570. [Google Scholar] [CrossRef]

- Ma, Y.; Chu, X.; Tang, G.; Yao, Y. Adjusting phase change temperature of microcapsules by regulating their core compositions. Mater. Lett. 2012, 82, 39–41. [Google Scholar] [CrossRef]

- Lu, S.; Shen, T.; Xing, J.; Song, Q.; Shao, J.; Zhang, J.; Xin, C. Preparation and characterization of cross-linked polyurethane shell microencapsulated phase change materials by interfacial polymerization. Mater. Lett. 2018, 211, 36–39. [Google Scholar] [CrossRef]

- Yin, Q.; Zhu, Z.; Li, W.; Guo, M.; Wang, Y.; Wang, J.; Zhang, X. Fabrication and Performance of Composite Microencapsulated Phase Change Materials with Palmitic Acid Ethyl Ester as Core. Polymers 2018, 10, 726. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cai, C.; Ouyang, X.; Zhou, L.; Liu, G.; Wang, Y.; Zhu, G.; Yao, J.; Militky, J.; Venkataraman, M.; Zhang, G. Co-solvent free interfacial polycondensation and properties of polyurea PCM microcapsules with dodecanol dodecanoate as core material. Sol. Energy 2020, 199, 721–730. [Google Scholar] [CrossRef]

- Gao, Y.; Geng, X.; Wang, X.; Han, N.; Zhang, X.; Li, W. Synthesis and characterization of microencapsulated phase change materials with chitosan-based polyurethane shell. Carbohydr. Polym. 2021, 273, 118629. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Yang, Y.; Li, Y.; Zhao, L.; Wang, H.; Song, G.; Tang, G. Microencapsulated phase change materials with TiO 2 -doped PMMA shell for thermal energy storage and UV-shielding. Sol. Energy Mater. Sol. Cells 2017, 168, 62–68. [Google Scholar] [CrossRef]

- Tang, X.; Li, W.; Zhang, X.; Shi, H. Fabrication and characterization of microencapsulated phase change material with low supercooling for thermal energy storage. Energy 2014, 68, 160–166. [Google Scholar] [CrossRef]

- Du, X.; Fang, Y.; Cheng, X.; Du, Z.; Zhou, M.; Wang, H. Fabrication and Characterization of Flame-Retardant Nanoencapsulated n-Octadecane with Melamine–Formaldehyde Shell for Thermal Energy Storage. ACS Sustain. Chem. Eng. 2018, 6, 15541–15549. [Google Scholar] [CrossRef]

- Mahdavi, S.A.; Jafari, S.M.; Ghorbani, M.; Assadpoor, E. Spray-Drying Microencapsulation of Anthocyanins by Natural Biopolymers: A Review. Dry. Technol. 2014, 32, 509–518. [Google Scholar] [CrossRef]

- Mahdavi, S.A.; Jafari, S.M.; Assadpoor, E.; Dehnad, D. Microencapsulation optimization of natural anthocyanins with maltodextrin, gum Arabic and gelatin. Int. J. Biol. Macromol. 2016, 85, 379–385. [Google Scholar] [CrossRef] [PubMed]

- Borreguero, A.M.; Valverde, J.L.; Rodriguez, J.F.; Barber, A.; Cubillo, J.; Carmona, M. Synthesis and characterization of microcapsules containing Rubitherm®RT27 obtained by spray drying. Chem. Eng. J. 2011, 166, 384–390. [Google Scholar] [CrossRef]

- Zuo, J.; Zhan, J.; Luo, C.; Dong, B.; Xing, F.; Chen, D. Characteristics and release property of polylactic acid/sodium monofluorophosphate microcapsules prepared by spray drying. Adv. Powder Technol. 2017, 28, 2805–2811. [Google Scholar] [CrossRef]

- Wang, M.; Zhao, Q. Electrospinning and Electrospray for Biomedical Applications. In Encyclopedia of Biomedical Engineering; Narayan, R., Ed.; Elsevier: Oxford, UK, 2019; pp. 330–344. [Google Scholar]

- Rezaei, B.; Ghani, M.; Askari, M.; Shoushtari, A.M.; Malek, R.M.A. Fabrication of Thermal Intelligent Core/Shell Nanofibers by the Solution Coaxial Electrospinning Process. Adv. Polym. Technol. 2016, 35. [Google Scholar] [CrossRef]

- Moghaddam, M.K.; Mortazavi, S.M.; Khayamian, T. Preparation of calcium alginate microcapsules containing n-nonadecane by a melt coaxial electrospray method. J. Electrost. 2015, 73, 56–64. [Google Scholar] [CrossRef]

- Moghaddam, M.K.; Mortazavi, S.M.; Khaymian, T. Micro/nano-encapsulation of a phase change material by coaxial electrospray method. Iran. Polym. J. 2015, 24, 759–774. [Google Scholar] [CrossRef]

- Zhang, S.; Campagne, C.; Salaün, F. Preparation of n-Alkane/Polycaprolactone Phase-Change Microcapsules via Single Nozzle Electro-Spraying: Characterization on Their Formation, Structures and Properties. Appl. Sci. 2020, 10, 561. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Chen, Y.; Campagne, C.; Salaün, F. Influence of a Coaxial Electrospraying System on the n-Hexadecane/Polycaprolactone Phase Change Microcapsules Properties. Materials 2020, 13, 2205. [Google Scholar] [CrossRef] [PubMed]

- Onder, E.; Sarier, N.; Cimen, E. Encapsulation of phase change materials by complex coacervation to improve thermal performances of woven fabrics. Thermochim. Acta 2008, 467, 63–72. [Google Scholar] [CrossRef]

- Hawlader, M.; Uddin, M.; Khin, M.M. Microencapsulated PCM thermal-energy storage system. Appl. Energy 2003, 74, 195–202. [Google Scholar] [CrossRef]

- Demirbağ, S.; Aksoy, S.A. Encapsulation of phase change materials by complex coacervation to improve thermal performances and flame retardant properties of the cotton fabrics. Fibers Polym. 2016, 17, 408–417. [Google Scholar] [CrossRef]

- Tan, S.; Chan, A.P.C.; Li, P. Nanoencapsulation of Organic Phase Change Material in Water via Coacervation Using Amphoteric Copolymer. Ind. Eng. Chem. Res. 2019, 58, 21080–21088. [Google Scholar] [CrossRef]

- Butstraen, C.; Salaün, F. Preparation of microcapsules by complex coacervation of gum Arabic and chitosan. Carbohydr. Polym. 2014, 99, 608–616. [Google Scholar] [CrossRef] [PubMed]

- Buckley, A.M.; Greenblatt, M. The Sol-Gel Preparation of Silica Gels. J. Chem. Educ. 1994, 71, 599. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, X.; Wu, D. Silica encapsulation of n-octadecane via sol–gel process: A novel microencapsulated phase-change material with enhanced thermal conductivity and performance. J. Colloid Interface Sci. 2010, 343, 246–255. [Google Scholar] [CrossRef] [PubMed]

- Qian, T.; Li, J.; Ma, H.; Yang, J. The preparation of a green shape-stabilized composite phase change material of polyethylene glycol/SiO2 with enhanced thermal performance based on oil shale ash via temperature-assisted sol–gel method. Sol. Energy Mater. Sol. Cells 2015, 132, 29–39. [Google Scholar] [CrossRef]

- He, F.; Wang, X.; Wu, D. Phase-change characteristics and thermal performance of form-stable n -alkanes/silica composite phase change materials fabricated by sodium silicate precursor. Renew. Energy 2015, 74, 689–698. [Google Scholar] [CrossRef]

- He, F.; Wang, X.; Wu, D. New approach for sol–gel synthesis of microencapsulated n-octadecane phase change material with silica wall using sodium silicate precursor. Energy 2014, 67, 223–233. [Google Scholar] [CrossRef]

- Fang, G.; Chen, Z.; Li, H. Synthesis and properties of microencapsulated paraffin composites with SiO2 shell as thermal energy storage materials. Chem. Eng. J. 2010, 163, 154–159. [Google Scholar] [CrossRef]

- Chen, Z.; Cao, L.; Fang, G.; Shan, F. Synthesis and Characterization of Microencapsulated Paraffin Microcapsules as Shape-Stabilized Thermal Energy Storage Materials. Nanoscale Microscale Thermophys. Eng. 2013, 17, 112–123. [Google Scholar] [CrossRef]

- Chen, Z.; Cao, L.; Shan, F.; Fang, G. Preparation and characteristics of microencapsulated stearic acid as composite thermal energy storage material in buildings. Energy Build. 2013, 62, 469–474. [Google Scholar] [CrossRef]

- Yuan, H.; Bai, H.; Lu, X.; Zhang, X.; Zhang, J.; Zhang, Z.; Yang, L. Size controlled lauric acid/silicon dioxide nanocapsules for thermal energy storage. Sol. Energy Mater. Sol. Cells 2019, 191, 243–257. [Google Scholar] [CrossRef]

- Li, B.; Liu, T.; Hu, L.; Wang, Y.; Gao, L. Fabrication and Properties of Microencapsulated Paraffin@SiO2 Phase Change Composite for Thermal Energy Storage. ACS Sustain. Chem. Eng. 2013, 1, 374–380. [Google Scholar] [CrossRef]

- Yuan, H.; Bai, H.; Lu, X.; Zhao, X.; Zhang, X.; Zhang, J.; Zhang, Z.; Yang, L. Effect of alkaline pH on formation of lauric acid/SiO2 nanocapsules via sol-gel process for solar energy storage. Sol. Energy 2019, 185, 374–386. [Google Scholar] [CrossRef]

- Latibari, S.T.; Mehrali, M.; Mehrali, M.; Afifi, A.M.; Mahlia, T.M.I.; Akhiani, A.R.; Metselaar, H.S.C. Facile synthesis and thermal performances of stearic acid/titania core/shell nanocapsules by sol–gel method. Energy 2015, 85, 635–644. [Google Scholar] [CrossRef]

- Li, C.; He, G.; Yan, H.; Yu, H.; Song, Y. Synthesis of microencapsulated stearic acid with amorphous TiO2 as shape-stabilized PCMs for thermal energy storage. Energy Procedia 2018, 152, 390–394. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Y.; Wang, Z. Preparation and Characteristics of Microencapsulated Lauric Acid as Composite Thermal Energy Storage Materials. Mater. Sci. 2019, 26, 88–93. [Google Scholar] [CrossRef] [Green Version]

- Cao, L.; Tang, F.; Fang, G. Preparation and characteristics of microencapsulated palmitic acid with TiO2 shell as shape-stabilized thermal energy storage materials. Sol. Energy Mater. Sol. Cells 2014, 123, 183–188. [Google Scholar] [CrossRef]

- Cao, L.; Tang, F.; Fang, G. Synthesis and characterization of microencapsulated paraffin with titanium dioxide shell as shape-stabilized thermal energy storage materials in buildings. Energy Build. 2014, 72, 31–37. [Google Scholar] [CrossRef]

- Chai, L.; Wang, X.; Wu, D. Development of bifunctional microencapsulated phase change materials with crystalline titanium dioxide shell for latent-heat storage and photocatalytic effectiveness. Appl. Energy 2015, 138, 661–674. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, H.; Luo, J.; Liu, Y.; Song, G.; Tang, G. Fabrication and properties of microencapsulated n-octadecane with TiO 2 shell as thermal energy storage materials. Sol. Energy 2016, 127, 28–35. [Google Scholar] [CrossRef]

- Latibari, S.T.; Mehrali, M.; Mehrali, M.; Mahlia, T.M.I.; Metselaar, H.S.C. Fabrication and Performances of Microencapsulated Palmitic Acid with Enhanced Thermal Properties. Energy Fuels 2015, 29, 1010–1018. [Google Scholar] [CrossRef]

- Yu, S.; Wang, X.; Wu, D. Microencapsulation of n-octadecane phase change material with calcium carbonate shell for enhancement of thermal conductivity and serving durability: Synthesis, microstructure, and performance evaluation. Appl. Energy 2014, 114, 632–643. [Google Scholar] [CrossRef]

- Wang, T.; Wang, S.; Luo, R.; Zhu, C.; Akiyama, T.; Zhang, Z. Microencapsulation of phase change materials with binary cores and calcium carbonate shell for thermal energy storage. Appl. Energy 2016, 171, 113–119. [Google Scholar] [CrossRef]

- Pan, L.; Tao, Q.; Zhang, S.; Wang, S.; Zhang, J.; Wang, S.; Wang, Z.; Zhang, Z. Preparation, characterization and thermal properties of micro-encapsulated phase change materials. Sol. Energy Mater. Sol. Cells 2012, 98, 66–70. [Google Scholar] [CrossRef]

- Jamekhorshid, A.; Sadrameli, S.M.; Farid, M. A review of microencapsulation methods of phase change materials (PCMs) as a thermal energy storage (TES) medium. Renew. Sustain. Energy Rev. 2014, 31, 531–542. [Google Scholar] [CrossRef]

- Milián, Y.E.; Gutiérrez, A.; Grágeda, M.; Ushak, S. A review on encapsulation techniques for inorganic phase change materials and the influence on their thermophysical properties. Renew. Sustain. Energy Rev. 2017, 73, 983–999. [Google Scholar] [CrossRef]

- Kang, J.S.; Park, I.; Jung, J.H.; Kim, S.S. Free-surface electrospray technique using a multi-hole array. J. Aerosol Sci. 2013, 55, 25–30. [Google Scholar] [CrossRef]

- Cumplido, F.R.; Gelves, E.P.; Chejne-Jana, F. Recent developments in the synthesis of microencapsulated and nanoencapsulated phase change materials. J. Energy Storage 2019, 24, 100821. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Wu, D. Tailoring of bifunctional microencapsulated phase change materials with CdS/SiO2 double-layered shell for solar photocatalysis and solar thermal energy storage. Appl. Therm. Eng. 2018, 134, 603–614. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, X.; Wu, D. Design and synthesis of multifunctional microencapsulated phase change materials with silver/silica double-layered shell for thermal energy storage, electrical conduction and antimicrobial effectiveness. Energy 2016, 111, 498–512. [Google Scholar] [CrossRef]

- Fei, B.; Lu, H.; Qi, K.; Shi, H.; Liu, T.; Li, X.; Xin, J.H. Multi-functional microcapsules produced by aerosol reaction. J. Aerosol Sci. 2008, 39, 1089–1098. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Wu, D.; Ji, S. Fabrication and applications of dual-responsive microencapsulated phase change material with enhanced solar energy-storage and solar photocatalytic effectiveness. Sol. Energy Mater. Sol. Cells 2019, 193, 184–197. [Google Scholar] [CrossRef]

- Li, F.; Wang, X.; Wu, D. Fabrication of multifunctional microcapsules containing n -eicosane core and zinc oxide shell for low-temperature energy storage, photocatalysis, and antibiosis. Energy Convers. Manag. 2015, 106, 873–885. [Google Scholar] [CrossRef]

- Jiang, Z.; Yang, W.; He, F.; Xie, C.; Fan, J.; Wu, J.; Zhang, K. Microencapsulated Paraffin Phase-Change Material with Calcium Carbonate Shell for Thermal Energy Storage and Solar-Thermal Conversion. Langmuir 2018, 34, 14254–14264. [Google Scholar] [CrossRef]

- Ma, X.; Liu, H.; Chen, C.; Liu, Y.; Zhang, L.; Xu, B.; Xiao, F. Synthesis of novel microencapsulated phase change material with SnO2/CNTs shell for solar energy storage and photo-thermal conversion. Mater. Res. Express 2019, 7, 015513. [Google Scholar] [CrossRef]

- Yuan, K.; Wang, H.; Liu, J.; Fang, X.; Zhang, Z. Novel slurry containing graphene oxide-grafted microencapsulated phase change material with enhanced thermo-physical properties and photo-thermal performance. Sol. Energy Mater. Sol. Cells 2015, 143, 29–37. [Google Scholar] [CrossRef]

- Zhao, Q.; He, F.; Zhang, Q.; Fan, J.; He, R.; Zhang, K.; Yan, H.; Yang, W. Microencapsulated phase change materials based on graphene Pickering emulsion for light-to-thermal energy conversion and management. Sol. Energy Mater. Sol. Cells 2019, 203, 110204. [Google Scholar] [CrossRef]

- Xu, B.; Zhou, J.; Ni, Z.; Zhang, C.; Lu, C. Synthesis of novel microencapsulated phase change materials with copper and copper oxide for solar energy storage and photo-thermal conversion. Sol. Energy Mater. Sol. Cells 2018, 179, 87–94. [Google Scholar] [CrossRef]

- Xua, B.; Chena, C.; Zhoua, J.; Nib, Z.; Maa, X. Preparation of novel microencapsulated phase change material with Cu-Cu2O/CNTs as the shell and their dispersed slurry for direct absorption solar collectors. Sol. Energy Mater. Sol. Cells 2019, 200, 109980. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Wu, D. Design and fabrication of dual-functional microcapsules containing phase change material core and zirconium oxide shell with fluorescent characteristics. Sol. Energy Mater. Sol. Cells 2015, 133, 56–68. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Wu, D. Microencapsulation of n-dodecane into zirconia shell doped with rare earth: Design and synthesis of bifunctional microcapsules for photoluminescence enhancement and thermal energy storage. Energy 2016, 97, 113–126. [Google Scholar] [CrossRef]

- Wei, H.; He, F.; Li, Y.; Zhang, Q.; Zhou, Y.; Yan, H.; He, R.; Fan, J.; Yang, W. Bifunctional Paraffin@CaCO3:Ce3+ Phase Change Microcapsules for Thermal Energy Storage and Photoluminescence. ACS Sustain. Chem. Eng. 2019, 7, 18854–18862. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, H.; Wang, X.; Wu, D. Smart design and construction of nanoflake-like MnO2/SiO2 hierarchical microcapsules containing phase change material for in-situ thermal management of supercapacitors. Energy Convers. Manag. 2018, 164, 311–328. [Google Scholar] [CrossRef]

- Kalaiselvam, S. Bifunctional nanoencapsulated eutectic phase change material core with SiO2/SnO2 nanosphere shell for thermal and electrical energy storage. Mater. Des. 2018, 154, 291–301. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, X.; Wu, D. Fabrication of microencapsulated phase change materials with TiO2/Fe3O4 hybrid shell as thermoregulatory enzyme carriers: A novel design of applied energy microsystem for bioapplications. Appl. Energy 2017, 201, 20–33. [Google Scholar] [CrossRef]

- Jiang, F.; Wang, X.; Wu, D. Design and synthesis of magnetic microcapsules based on n-eicosane core and Fe3O4/SiO2 hybrid shell for dual-functional phase change materials. Appl. Energy 2014, 134, 456–468. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Wang, X.; Wu, D. Development of Thermoregulatory Enzyme Carriers Based on Microencapsulated n-Docosane Phase Change Material for Biocatalytic Enhancement of Amylases. ACS Sustain. Chem. Eng. 2017, 5, 8396–8406. [Google Scholar] [CrossRef]

- Li, J.; Zhu, X.; Wang, H.; Lin, P.; Jia, L.; Li, L.; Chen, Y. Synthesis and properties of multifunctional microencapsulated phase change material for intelligent textiles. J. Mater. Sci. 2021, 56, 2176–2191. [Google Scholar] [CrossRef]

- Wang, H.; Luo, J.; Yang, Y.; Zhao, L.; Song, G.; Tang, G. Fabrication and characterization of microcapsulated phase change materials with an additional function of thermochromic performance. Sol. Energy 2016, 139, 591–598. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, H.; Wu, Y.; Wang, X.; Wu, D. Design and fabrication of pH-responsive microencapsulated phase change materials for multipurpose applications. React. Funct. Polym. 2019, 140, 111–123. [Google Scholar] [CrossRef]

| Fatty Acids | Melting Temperature (°C) | Melting Latent Heat (J·g−1) | Density (kg·m−3) | Specific Heat (kJ·kg−1·°C−1) | Thermal Conductivity Liquid (W·m−1·°C−1) | Ref. | ||

|---|---|---|---|---|---|---|---|---|

| Solid | Liquid | Solid | Liquid | |||||

| Stearic acid (SA) CH3(CH2)16COOH | 69 | 202 | 965 | 848 | 1.6 | 2.2 | 0.172 | [56] |

| 60 | 178 | - | - | - | - | - | [57] | |

| 69 | 223 | - | - | - | - | - | [58] | |

| Palmitic acid (PA) CH3(CH2)14COOH | 64 | 185 | 989 | 850 | 1.9 | 2.8 | 0.162 | [56] |

| 60 | 233 | - | - | - | - | - | [59] | |

| Myristic acid (MA) CH3(CH2)12COOH | 58 | 187 | 990 | 861 | 1.7 | 2.4 | 0.150 | [56] |

| 54 | 187 | - | - | - | - | - | [58] | |

| 52 | 211 | - | - | - | - | - | [59] | |

| 52 | 178 | - | - | - | - | - | [60] | |

| 52 | 205 | - | - | - | - | - | [61] | |

| Lauric acid (LA) CH3(CH2)10COOH | 44 | 177 | 1007 | 862 | 1.7 | 2.3 | 0.147 | [56] |

| 42 | 190 | - | - | - | - | - | [59] | |

| 44 | 184 | - | - | - | - | - | [62] | |

| Capric acid (CA) CH3(CH2)8COOH | 32 | 153 | 1004 | 878 | 1.9 | 2.1 | 0.153 | [56] |

| 30 | 140 | - | - | - | - | - | [63] | |

| Eutectic Mixture | Mass Ratio wt% | Onset Melting Temperature (°C) | Melting Latent Heat (J·g−1) | Ref. |

|---|---|---|---|---|

| CA-LA | 64:36 | 19 | 163 | [73] |

| CA-MA | 78.39:21.61 | 25 | 123 | [74] |

| CA-PA CA-SA | 89:11 | 28 | 145 | [74] |

| 94.47:5.53 | 30 | 156 | [74] | |

| LA-PA | 77.51:22.49 | 38 | 151 | [74] |

| MA-SA | 76.29:23.71 | 48 | 148 | [74] |

| LA-MA | 63.63:36.37 | 34 | 130 | [74] |

| LA-SA | 86.51:13.49 | 41 | 164 | [74] |

| MA-PA | 64.96:35.04 | 45 | 152 | [74] |

| PA-SA | 62.99:37.01 | 54 | 179 | [74] |

| MA-SA | 64:36 | 44 | 182 | [75] |

| CA-PA | 76.5:23.5 | 23 | 156 | [76] |

| CA-MA-SA | 72.5:22.5:5.0 | 24 | 159 | [66] |

| CA-PA-SA | 79:13:8 | 20 | 129 | [71] |

| SA-PA-LA | 6.77:20.97:72.26 | 32 | 159 | [74] |

| LA-MA-SA | 57.5:34.3:8.2 | 29 | 140 | [77] |

| SA-PA-LA-MA | 11.86:18.54:45.6:24 | 27 | 128 | [72] |

| Tetradecane-octadecane | - | -4 | 228 | [38] |

| Tetradecane-docosane | - | 2–6 | 234 | [38] |

| Tetradecane-hexadecane | - | 2 | 156 | [38] |

| Method | Shell | Core | Tm mPCMs (°C) | LC (%) | ∆Hf (J·g−1) | Size (μm) | Ref. |

|---|---|---|---|---|---|---|---|

| Suspension polymerization | St/MMA | Paraffin | 42 | 43 | 88 | - | [84] |

| PMMA | Caprylic acid | 14 | 66 | 98.7 | 2–10 | [85] | |

| TiO2-PMMA | n-Octadecane | 25 | 73 | 84–142 | 10–20 | [134] | |

| OMA/MMA | n-Octadecane | 26 | 21 | 93 | 1.6–1.7 | [135] | |

| Emulsion polymerization | PMMA | Paraffin | 24–33 | 101 | 0.5–2 | [93] | |

| PMMA | SA-Eicosanoic | 57 | 69 | 126 | 0.046 | [94] | |

| PMMA | SA | 55 | 52 | 102 | 0.29 | [95] | |

| PMMA | Paraffin wax | 52–55 | 88 | 115 | 18 | [96] | |

| Polystyrene | LA | 44 | 167 | 1.32 | [97] | ||

| Dispersion polymerization | MF | Hexadecane | - | 79 | 162 | 3.9 | [102] |

| In situ polymerization | MF | n-Octadecane | - | 40 | 120 | 4 | [104] |

| MF | n-Tetracosane | 53 | 25 | 135 | 2–20 | [105] | |

| MF | n-Hexadecanol | 51 | 79 | 171 | 10–60 | [106] | |

| MF | 1-Dodecanol | 20 | 41 | 79 | 0.49 | [107] | |

| PUF | CA | 30 | - | 129 | 0.66 | [112] | |

| PMF | CA | 29 | - | 34 | 0.32 | [112] | |

| PMUF | CA | 29 | 54 | 61 | 0.29 | [112] | |

| MUF | n-Dodecanol | 21 | 91 | 131 | 38 | [113] | |

| MF/MMF | n-Dodecanol | 28 | 50–83 | 110–181 | 0.71–6.28 | [114] | |

| MMF/BMF | n-Dodecanol | 24 | 50 | 100 | 2–5 | [115] | |

| CNFs/MF | 1-Dodecanol | 26 | 50 | 100 | 1–3 | [119] | |

| PNDA/MF | n-Dodecanol | 32 | - | 110–141 | 0.08–0.14 | [136] | |

| Interfacial polycondensation | Polyurea | n-Octadecane | - | 70 | - | 7.3 | [122] |

| Polyurea/polyurethane | n-Octadecane | 29 | - | 143 | 3–5 | [126] | |

| Polyurea/polyurethane | Butyl stearate paraffin | 28–35 | 40–60 | 58–87 | 5–15 | [129] | |

| Polyurethane | Butyl stearate | 22 | - | 80 | 10–35 | [130] | |

| Polyurea | Ethyl palmitate | 19 | 62 | 123 | 10 | [131] | |

| Polyurethane | Ethyl palmitate | 17 | 55 | 110 | 10 | [131] | |

| SiO2/polyurea | Ethyl palmitate | 22 | 59 | 120 | 10 | [131] | |

| SiO2/polyurethane | Ethyl palmitate | 17 | 61 | 122 | 10 | [131] | |

| Polyurethane | Dodecanol dodecanoate | 32 | 54–74 | 103–140 | 10–40 | [132] | |

| c-PU | Butyl stearate | 24 | - | 106 | 4.46 | [133] |

| Process | Advantages | Drawbacks |

|---|---|---|

| Suspension polymerization | Uniform spherical particles; suitable heat control of the reaction; cost-effectiveness. | Process adapted only for water-insoluble monomers; coalescence of particles during polymerization. |

| Emulsion/miniemulsion polymerization | The possibility of employment of high molecular weight polymer; kinetics of polymerization. | Adjuvants and surfactants remain in the polymer; difficult control of polymerization step. |

| Dispersion polymerization | Encapsulation in a single-step process. | |

| In situ polymerization | Uniform coating. | The release of free formaldehyde. |

| Interfacial polymerization | High mechanical resistance. | Aggregation of particles. |

| Spray drying | Reproducible; cost-effectiveness; homogeneous particles; suitable controlling of particle size [139]. | High temperature; agglomeration of particles; remaining uncoated particles [174]; low thermal transfer efficiency; not adapted for inorganic PCMs [175]. |

| Electrospraying | One-step green process; high encapsulation efficiency; easy handling; non-toxic chemical additives nor surfactants. | Frequent clogging of the nozzle tip; the nozzle tips are more easily plugged by the used fluid or particulates; very low flow rate for smaller droplets [176]. |

| Coacervation | Efficient control of particles size and shell thickness [174]. | Employment of toxic chemical agents; residual solvents and coacervating agents on the capsules surfaces. |

| Sol-Gel | High thermal conductivity; suitable mechanical resistance; thermal stability; chemical inertness; non-toxicity. | Long reaction time; expensive row material [87]. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamad, G.B.; Younsi, Z.; Naji, H.; Salaün, F. A Comprehensive Review of Microencapsulated Phase Change Materials Synthesis for Low-Temperature Energy Storage Applications. Appl. Sci. 2021, 11, 11900. https://doi.org/10.3390/app112411900

Hamad GB, Younsi Z, Naji H, Salaün F. A Comprehensive Review of Microencapsulated Phase Change Materials Synthesis for Low-Temperature Energy Storage Applications. Applied Sciences. 2021; 11(24):11900. https://doi.org/10.3390/app112411900

Chicago/Turabian StyleHamad, Ghada Ben, Zohir Younsi, Hassane Naji, and Fabien Salaün. 2021. "A Comprehensive Review of Microencapsulated Phase Change Materials Synthesis for Low-Temperature Energy Storage Applications" Applied Sciences 11, no. 24: 11900. https://doi.org/10.3390/app112411900

APA StyleHamad, G. B., Younsi, Z., Naji, H., & Salaün, F. (2021). A Comprehensive Review of Microencapsulated Phase Change Materials Synthesis for Low-Temperature Energy Storage Applications. Applied Sciences, 11(24), 11900. https://doi.org/10.3390/app112411900