1. Introduction

In today’s new economy, Information Systems (ISs) or Technology (IT) are widely used, and they are mainly the reason why industries and businesses have evolved and changed rapidly [

1,

2,

3]. For example, big data is a very prominent IT technology for a variety of fields, such as computing, economics, business, agriculture, accounting, etc. [

4,

5,

6,

7,

8,

9,

10,

11]. The global competition that already exists among manufacturing firms will continue to be intensive into the future. This has led organizations to implement IT in order to gain advantages against their competitors. IS adoption may have induced dramatic changes in business internal processes by radically altering structures, strategies, and decision-making processes [

3,

12]. Globalization has led to an era where the competition has shifted from local to global, in other words from company against company to one supply chain against another supply chain [

13]. Businesses have recognized IT implementation as a critical factor that can contribute not only to an independent companies performance but also to the supply chain performance—in which the company might participate—as a whole [

13,

14]. In [

15], the authors focused on IS implementation in complex settings from a sociomaterial perspective and proposed that higher levels of motivation and intentionality are related to higher chances of successful implementation. Due to IS, enterprises were able to manage the abundance of information among their departments and also share them with their collaborators in the supply chain in a timely, accurate, and reliable way [

14]. Through IS, companies and supply chains try to achieve better in several areas such as competitive advantage, production planning, inventory management, distribution management, customer satisfaction and loyalty, financial gains and other—financial or nonfinancial—benefits that can be derived by the use of advanced systems [

12,

13,

14]. In addition, the use of social networking platforms and the formulation of communities [

16] further necessitate the extensive research on IT for businesses, as more and more companies make extensive use of data collected through social networks and communities to improve their customer satisfaction and increase their profit. Companies have realized that through IS they have the opportunity to implement important innovations in their processes, increased flexibility in information generation, and also improved decisions based on timely and reliable information [

17].

Even the early years of IS implementation, researchers considered it critically important to investigate the benefits and the impact ISs might have in the business performance. The first studies were not very promising regarding the positive and statistically significant relation between the Information and Communications Technology (ICT) adoption and business performance [

18], which made managers wonder whether they should invest in them. That impression has shifted since the mid-1990s, where research studies showed that there is significant positive relation between ICT investment and some aspects of business performance [

19].

Since then, there were several studies that tried to assess the effects of IS implementation not only in companies but also in supply chains performances. Several literature reviews have noted the need for empirical research and in particular for survey-based studies that could provide answers regarding the impact of IS adoption in several aspects of industry. In [

20], the authors call for more studies that would research the effects of ERP implementation on a company’s competitive advantage. In [

21], the authors call for further studies in order to investigate several types of IT applications and their respective impacts on businesses. As the awareness of the advantages of IT adoption is growing up, companies consider it important to come to a realization regarding the impact of IT on the firm’s performance [

14]. Studies regarding the long-term benefits of the ICT adoption could prove to be crucial to convince the Small–Medium Enterprises (SMEs) owners to apply an ICT system if it is proven that the benefits can overcome the additional costs of implementation, training, etc. [

3]. Several studies call for studies regarding the impact and benefits of ERP implementation [

13,

22,

23] as well as the effects of Supply Chain Management (SCM) on a company’s performance [

13,

23]. They also call for a focus on investigating the effects of performance in specific business areas such as financial, marketing, customer-based performance, etc. [

13]. Other studies call for further research regarding the impact of CRM in organizational performance and innovational capabilities of firms [

24,

25].

The motivation behind the research presented in this paper was the need to assess the impact and contribution of IS implementation in several aspects of business performance in manufacturing companies in North Greece. In other words, the paper is trying to determine whether Greek and multinational companies which operate in Greece benefited—financially and non-financially—from IS adoption. The financial crisis that hit the country the last decade has affected—more or less—Greek and multinational enterprises. Beyond that, Greece is close to other countries with weaker economies and lower taxes. That fact has driven several companies to transfer their facilities and their administration to countries such as Bulgaria in order to gain more benefits from their operations. Under those circumstances, it was interesting for the authors of this paper to know if the companies facilitated in this area gained any benefits from using IS.

Therefore, it is natural to pose the following broad hypothesis:

Hypothesis 1 (H1). The manufacturing companies in North Greece that have adopted—at least one—IS have declared that the implementation of IS has had a positive impact in their business.

The main objective of this research is to obtain answers—positive or negative—regarding the above general hypothesis and gain a better understanding of the relevant issues in North Greek industry, including Greek and multinational manufacturers that facilitate that area. That objective would be possible to be determined through an extensive questionnaire-based survey about IS in the manufacturing sector. A parallel objective is to contribute to the knowledge about the kind of influence IS adoption had in business performance in European industry.

This empirical research contributes to filling the research gaps which were described previously by making the following contributions:

It empirically investigates which kind of IS or ISs Greek companies have adopted to conduct their business.

It determines whether IS implementation is considered profitable.

It also determines how (positively or negatively) several management departments were affected as the companies apply more innovative technologies such as ISs.

It also tries to determine the contribution (positive or negative) of IS adoption in several factors that were considered important.

It investigates whether there are factors that affect the impact and contribution of IS implementation in several aspects of business process. The companies were divided into two groups regarding the profitability of IS adoption: those with high profitability and those with medium profitability. The two groups were compared regarding the impact and contribution of IS adoption.

The next section presents a literature review of the use of IS and the benefits that it might bring to businesses as well as presenting the research hypotheses.

Section 3 describes the research methodology and the data collection process.

Section 4 contains the research results, and the final section summarizes the main conclusions of this research along with our propositions for future research.

2. Literature Review and Research Hypotheses

Since the early days of IS implementation, several researchers have tried to determine the financial and nonfinancial benefits of modern-era technologies. Their goal was to find out if ICT positively affects the way manufacturers conduct their business and to what extent. They mostly agree that enterprises were more or less positively affected by the use of new technologies. Even an upgrade of a basic IT system to a more advanced one can lead to additional benefits. SMEs can gain much from ISs that would help their strategy and their management as they can provide better customer service, faster communication with customers, better distribution network to distribute their products, etc. The internet helped a lot to that extent, as it is easier for a company to reach the customers. A very important element of ICTs is that they increase systems integration, which greatly helps the managers run their departments based on a combination of information [

21]. In [

26], the authors suggest that in the supplier selection process the benefits derived from IS implementation are mostly nonfinancial and more related to management decision. In the study conducted in [

27], several variables were measured that can be considered as parts of different departments within an organization.

The managers of those departments—such as Production, Inventory, Customer, Supply, Distribution, Warehouse, etc.—constantly try to find ways to improve the way they manage the whole department. They also try to determine which parts of the department need more attention or which parts did better [

14]. In [

20], the authors researched the benefits of ERP regarding the firm’s performance. Among other areas of focus, they also studied the effects of ERP into the inventory levels, interaction with customers, and inventory and supplier management [

20]. In [

28], the authors’ research on performance measured those regarding customer service and satisfaction. Therefore, the following hypothesis is proposed:

Hypothesis 2 (H2). IS adoption has a positive impact on management (Supply management, Production management, Distribution management, Warehouse management, and Inventory management) and customer service.

Several studies have tried to determine which areas in a company were affected (positively or negatively) by the implementation of IS. In [

28], the authors try to determine whether IT influenced a positively competitive advantage which might positively influence the relationship with the suppliers and the customers. In the current market, a company deals simultaneously with various suppliers that can be culturally different and located at several geographic places of our planet. At the same time, customers constantly seek and demand a constantly increasingly high level of satisfaction. ISs, besides many other benefits, can also provide more negotiation power to the suppliers as they deal with their customers. The stakeholders that are related to a company can all be benefited in several areas of their business as the use of IS enables deeper, more stable, and more relevant relationships between them [

26]. ERP can benefit the performance of an organization in several areas such as reduced cost, improved productivity, customer services, and quality. ERP can also lead in better resource management, and it can help managers improve their decision making and planning, etc. [

12,

20,

29]. In [

30], the authors tried to determine whether companies benefited by IS adoption regarding cost saving and better coordination with the suppliers and the customers, as well as if it helped keep the inventory level lower and determine the cost more accurately. IS adoption can increase productivity and improve inventory control. It can also lead to faster delivery times and cost reduction—the latter benefiting several departments in a firm. With the use of IS, better resource management can improve decision making and planning which helps management, etc. [

12,

20,

29]. In [

30], the authors tried to determine whether the companies benefited from IS adoption regarding cost saving, keeping inventory level lower, being able to determine the cost more accurately, and better coordination with the suppliers and the customers. IS adoption can increase productivity, improve inventory control, and lead to faster delivery times and cost reduction—the latter benefits several departments in a firm—and products can reach higher levels [

12,

21]. It is considered that SCM activities are strongly associated with several aspects of business performance such as operating cost reduction, revenue growth, etc. [

31]. Taking all this into consideration, we pose the following hypotheses that are focused in areas that the authors subjectively considered more important, as they acknowledge that there are many others that could have been chosen to examine their effects that are derived from IS adoption.

The following hypotheses can be posed:

Hypothesis 3a (H3a). IS adoption positively affected the competitive advantage.

Hypothesis 3b (H3b). IS adoption positively affected the production process.

Hypothesis 3c (H3c). IS adoption led to less returned products.

Hypothesis 3d (H3d). IS adoption helped the company build a better relationship with the suppliers.

Hypothesis 3e (H3e). IS adoption led to cost reduction.

Hypothesis 3f (H3f). IS adoption led to faster customer service.

Hypothesis 3g (H3g). IS adoption helped the companies maintain their clientele.

More and more companies implement ISs because they hope and expect that they will benefit financially. They also hope to be able to maximize those benefits by using proper managerial techniques. It is not a surprise that quite frequently, several studies’ main subject is to assess the accountability of investments in ISs [

32]. In [

32], the authors tried to determine the relationship between the postimplementation practices of ERP and the financial performance. Similarly, a study conducted in [

33] by authors in several organizations focus more on determining the financial impacts—besides other impacts—and the profitability of ERP, SCM, and CRM at the postimplementation stage of the system. The results of that study were mixed. They confirmed that profitability and other financial metrics are positively influenced by ERP and SCM implementation but that does not apply to the CRM adopters. In [

25], the authors also studied whether the relationship between CRM adoption and organizations financial performance is positive, and they concluded that there is not a positive relationship, which is similar to the authors’ study in [

33]. In [

27], the authors included financial performance among the performance measures they researched in their study, among others. Thus, the following hypothesis is formed:

Hypothesis 4 (H4). IS adoption has a positive impact on a company’s profitability.

The former hypothesis has been actually verified in a previously published paper by the authors in [

34]. It was derived by the study that 92.7% of the companies stated that IS adoption was profitable at a high or at least a satisfactory level. Based on that, two prominent different groups of companies were identified regarding the level of profitability they obtained due to IS adoption: those which consider that IS adoption led their companies to a high level of profitability (IS1) and those where their company managed to accomplish medium level of profitability (IS2) due to IS adoption. Through the current research, there is an effort to assess whether there are statistically significant differences between these two groups regarding the impact and contribution of IS adoption in a company’s several aspects. Thus, two prominent hypotheses were formed:

Hypothesis 5a (H5a). “The higher the profitability, the more positive the impact of IS adoption which is followed by a statistically significant difference between the two groups (IS1 and IS2) in—Supply, Production, Distribution, Warehouse and Inventory—Management, respectively, as well as in Customer service.”

Hypothesis 5b (H5b). “The higher the profitability, the more positive the contribution of IS adoption which is followed by a statistically significant difference between the two groups (IS1 and IS2) in Competitive advantage, Production process, Returned products reduction, Relationship with the suppliers, Cost reduction, Fastest Customer service, and Maintain clientele, respectively.”

3. Research Methodology and Data Collection

The study was conducted on manufacturing companies—public and private—that are active in North Greece on the districts of Macedonia and Thrace. The population for the study was based on the companies which are active—producing—on those Greek areas. The list of the companies was obtained from ICAP’s Greek Financial Directory of the year 2017 [

35], volume 1: industry [

35]. ICAP’s directory includes detailed listings of manufacturing companies—Greek and multinationals—in Greece. The questionnaire was sent to several enterprises of that list, excluding those that according to ICAP’s directory [

35] were listed as “Very Small”. A total of 184 companies were instructed to answer the questionnaire that was sent to them. We received 96 replies by the end of January 2019.

According to the authors in [

36], the questionnaire was short in order to achieve the maximum response rate. The questionnaire consisted of 15 questions, 13 of which were closed-ended questions and the last two of them were open questions that the respondents could fill with additional comments. The objective of the penultimate question was to determine the respondents’ job title on the company, while the last question was asking about their thoughts regarding IS and Supply Chain (SC) in Greek industry. Of the 13 close-end questions, the first two were addressed to all respondents. The second question tried to determine whether the enterprises were using a form of Information System (IS) or not. Depending on the answer of that second question—yes or no—the respondents were instructed to either follow the natural course of the questionnaire or to proceed to the tenth question—its objective was to determine which reasons would prevent a company from investing in an IS.

The survey instrument was developed based on the extensive review of the current literature, which was delineated in

Section 2. In order to assess the questionnaire’s clarity, comprehensiveness, and overall suitability, the questionnaire was e-mailed in a pilot sample of five experts regarding IS in order to pretest it.The authors of this study took into consideration their suggestions for the few amendments that were applied on the questionnaire. After those changes it was ready to be sent to the manufacturing enterprises. The questionnaire, which was accompanied by a cover letter, was sent in November 2018 to 184 manufacturing enterprises to be filled out on the web. The cover letter provided a brief description of the research project, and in addition, it provided assurance that any information obtained from the companies that would participate in the study would be treated as confidential. The majority of the e-mail addresses were found in the ICAP directory, while the rest were found on the General Commercial Registry’s site [

37], as well as the Exporters’ Association of Northern Greece’s site [

38]. All the companies were contacted by phone to verify the e-mail addresses we had found but also to inform them about the research. Three weeks after the first invitation, the questionnaire was sent again—via e-mail—to the companies that had not responded and they were also informed again by phone, in order to improve the response rate. The same procedure was followed after the Christmas holidays once again.

Strict checks were performed in the returned questionnaire in order to ensure its completeness and consistency. According to the checks, the total amount of the questionnaires that were answered in a way found to be valid and usable for further analysis put the overall response rate at 52.17% percent.

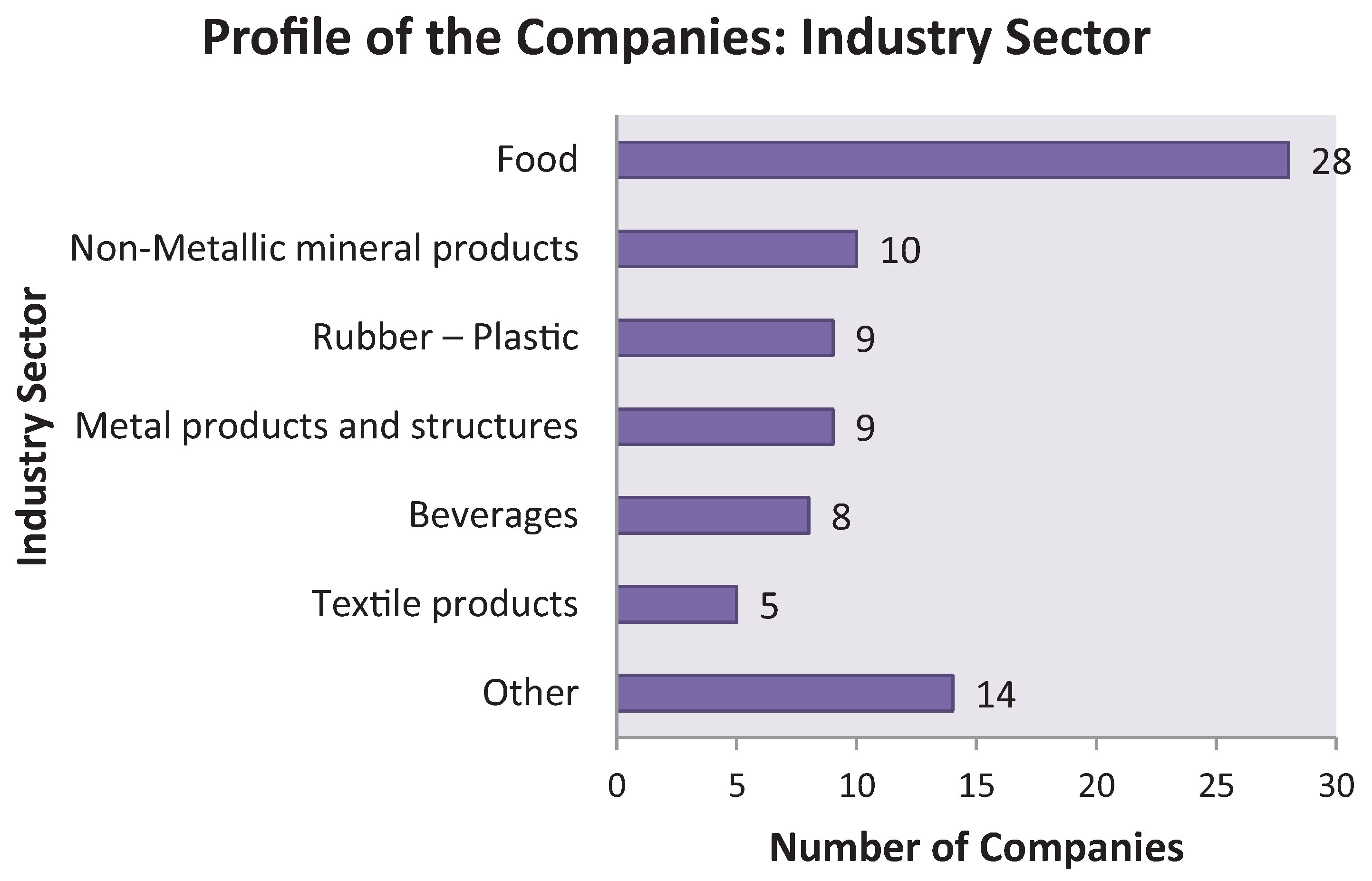

The sample was also checked for representativeness with respect to industry sector and also the district being facilitated. Regarding the industry sector, the

goodness-of-fit test shows that the sectorial representation of the sample does not differ significantly from that observed in the total population of manufacturing enterprises in North Greece; the

p-value of the test was 0.813. Accordingly, the

goodness-of-fit test regarding the district representation showed that the sample did not differ significantly from that observed in the total population of manufacturing enterprises in North Greece; the

p-value of the test was 0.717. The

p-value is considered as the minimal significance level for rejection or the null hypothesis [

39].

The questionnaire was also tested with the Cronbach Alpha method for its reliability. The Cronbach Alpha index value was found to be equal to 0.856, which is considered to be a very good value for validation [

40,

41,

42,

43,

44,

45,

46,

47].

5. Summary, Discussion, Conclusions, and Future Research

This empirical research addresses issues regarding which ISs that North Greek manufacturers have adopted to conduct their business, as well as the impact and contribution of IS adoption in several aspects of their business, including the cost effectiveness. During the research, 96 questionnaires were filled by North Greek manufacturing companies. Of those 96 responses, 83 of them use at least one IS, and those are the ones that this paper addresses more in depth. The statistical analysis of those 83 responses has led to some very interesting results.

The great majority of the companies (85.4%) use ERP to conduct their business. That is followed by WMS (39%), OMS (37.8%), CRM (35.4%), MES (25.6%), and MRP (20.7%) with a much lower percentage of companies that use them. The rest of the systems have a percentage of less than 14% each. Although SCM is relatively new and helps the companies to manage and organize the path a product or service needs to follow from the supplier to the customer integrating this whole chain, yet it is only used by 13.4% of the manufacturers. Even if the vast majority of them (90.4%) have invested in an IS in the last decade, which means that most of their systems are relatively new, the majority of the respondents state that they intent to invest in a new IS in the near future.

As a general conclusion of this paper, it can be said that IS adoption has a positive impact in business—financially and nonfinancially. A main aspect that keeps business running is the profit they gain from their activities. The vast majority of the respondents (92.7%) agree that ISs have a positive effect on their profits as they are at least satisfied of the amount they gained.

Managing a company is a challenging and difficult task. IS implementation helped the managers to improve the way they manage several business areas such as supply, production, distribution network, warehouse and inventory, as well as helping to improve their customer service. It is important that several departments of a company are able to work well individually but also as a part of the whole enterprise, communicating each other and forming a chain that would manage to deliver the product to the customers starting from their suppliers. Inventory management, Customer service and Warehouse management were more positively affected by IS adoption. On the other hand, Distribution network management was less positively affected by IS implementation. The lowest rank might be explained by the way the products are being distributed in Greece, as well as by her unique geography which contains many—big and small—islands. In mainland, the products are mostly distributed by road, as the rail network is not as modernized as of other countries (i.e., Italy). The islands make the distribution of a product a challenge because it must reach even the smallest one, which means companies must be able to take this into account when they send products there. The transportation in smaller islands is not so often, and it depends on the weather conditions, especially in the winter.

ISs also positively contributed to Faster Customer service, Production process, Cost reduction and Competitive advantage as they all have an average rating more than 4—“little positive”. The respondents also stated that they managed to maintain their clientele as it is close to 4, although it does not seem like IS helped a lot with Returned products reduction and the Relationship with the suppliers.

The companies with a high level of profitability (IS1) and those with a relatively satisfying level of profitability (IS2) were compared regarding the impact of IS in several aspects of their business. Both groups assessed the impact of IS as positive with IS1 group’s average ratings higher than those of IS2 group. In IS1 group, the positive impact of IS was greater in Customer service, followed by Inventory, Warehouse—the last two had same average—and Production management, while Distribution network management had the lowest average. On the other hand, in IS2 companies, the impact was more positive in Inventory management, followed by Supply and Warehouse management. Distribution network management had the lowest average slightly below 4—“little positive”. Although it seems like IS1 companies have better results than IS2, in some cases, there is no statistically significant difference which means that the results are similar and the two groups of companies are affected similarly by the use of IS. Therefore, there is a statistically significant difference in Distribution network management, Warehouse management, Production management and Customer service, which means that in those situations the better results are the ones that made the difference for the IS1 companies which led them to better performance. There is no statistically significant difference to the Supply and Inventory management.

Another comparison was held between the IS1 and IS2 companies regarding the contribution of IS implementation in certain aspects that were considered important by the authors. The IS1 companies give higher average ratings than the IS2 companies. As it was mentioned in the previous paragraph, there are cases with a statistically significant difference between the two groups and cases were there is not. A statistically significant difference occurs only in Competitive advantage and in Maintaining the Clientele between IS1 and IS2 companies. In both occasions, IS1 companies give a rating above 4 (4.32 and 4.20, respectively) while IS2 below 4 (3.92 and 3.67, respectively). It seems like IS1 companies paid more attention to improve their Competitive advantage as well as to try to maintain their customers than IS2 companies. Both companies have similar results by IS adoption in the rest (Production process, Returned products reduction, cost reduction, Relationship with the suppliers, and Faster Customer service). The two lowest average ratings for both groups are the Returned products reduction and the Relationship with the suppliers, which means that either the ISs did not help the companies to improve on those or that they paid much more attention to improve other aspects first so they did not have many resources available for those. The respondents for the IS1 companies ranked higher the Faster Customer service, Production process and Competitive advantage, while those for IS2 companies agreed on the first two, but they have as a third the Cost reduction, which was fourth for the IS1 companies. As a general conclusion, it can be said that the current research has shown that North Greek manufacturing companies use IS and they have realized that it has positive effect on their profitability. Manufacturers have also realized that IS implementation has a positive impact on the way they manage the several departments in their company. In addition, IS adoption has improved several—financial and nonfinancial—elements that help the company’s strategy and performance such as competitive advantage, cost reduction, customer service, etc. In

Figure 7, the authors present the total amount of the hypotheses presented into the current paper along with their validation status. At this point, the authors of this paper consider it important to acknowledge that this research was conducted under a geographical limitation since it was focused only on the manufacturing companies of North Greece and not those of the entire country. As mentioned in

Section 3, the representation of the sample does not differ from the population in regards to the manufacturing sector and the district in which the company operates. Nonetheless, it would be interesting to be able to have answers from companies from the whole country. It would also be interesting to research more about the financial and nonfinancial impact of IS adoption expanding the amount of variables, so to include several other areas that might have been affected and specify even more which parts of every department were mostly affected—positively or negatively. Another research could compare some ISs to find out which one affects more several variables.