Feasibility of Coupling Anaerobic Digestion and Hydrothermal Carbonization: Analyzing Thermal Demand

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

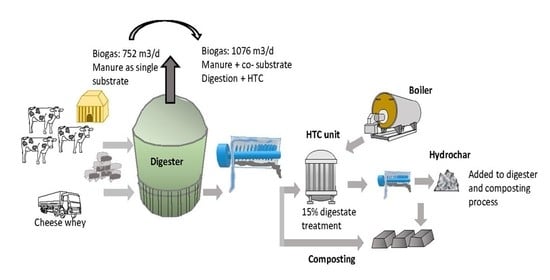

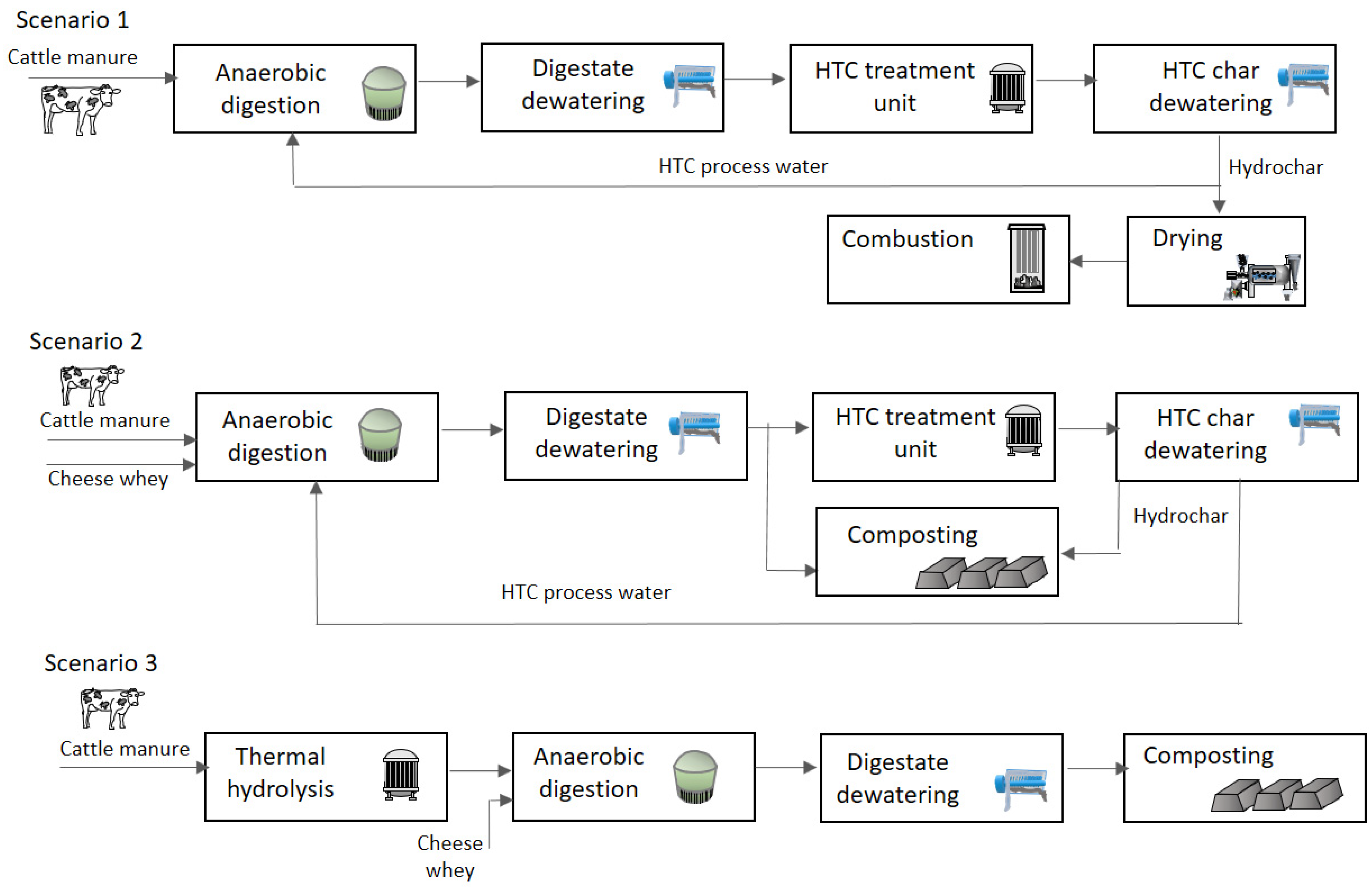

2.1. Description of Scenarios

2.2. Assumptions of Substrate Characteristics

2.3. Detailed Plant Description

3. Results

3.1. Scenario 1

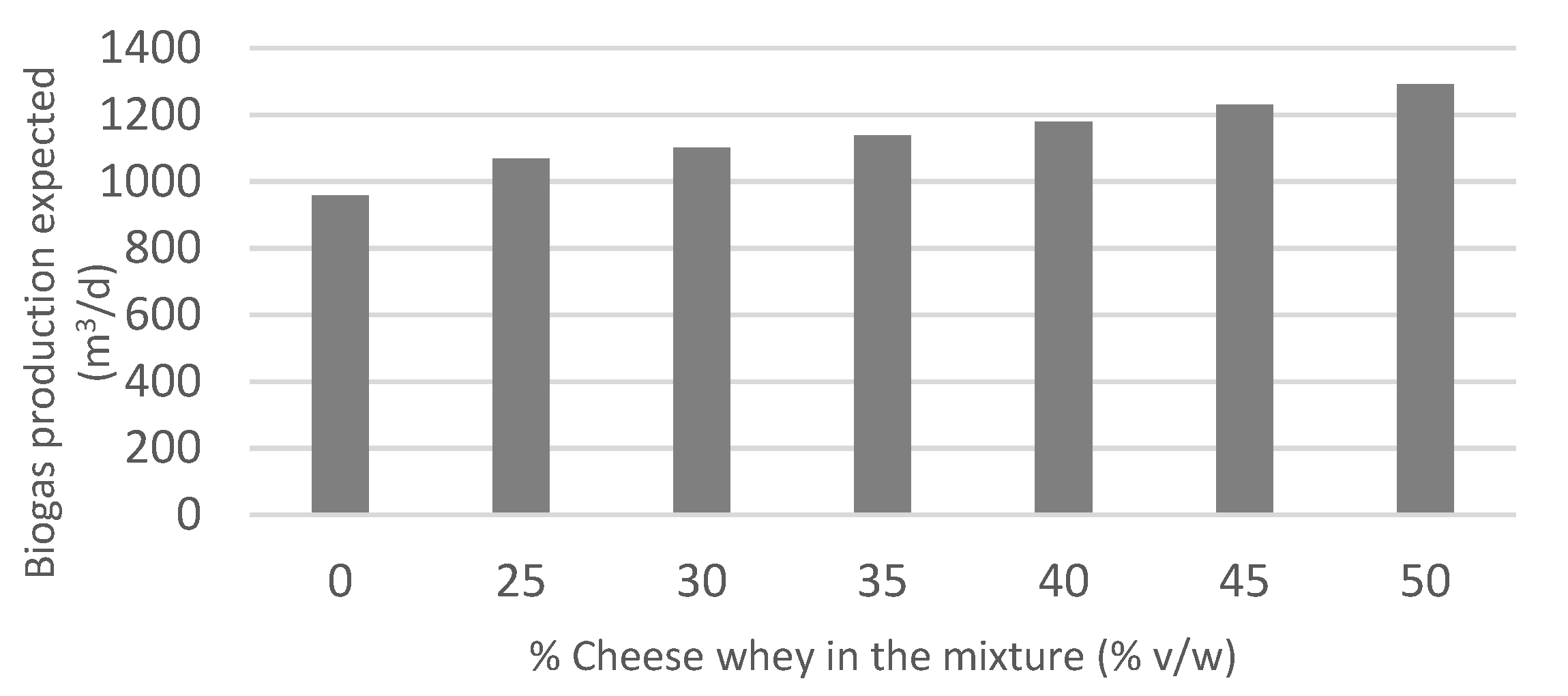

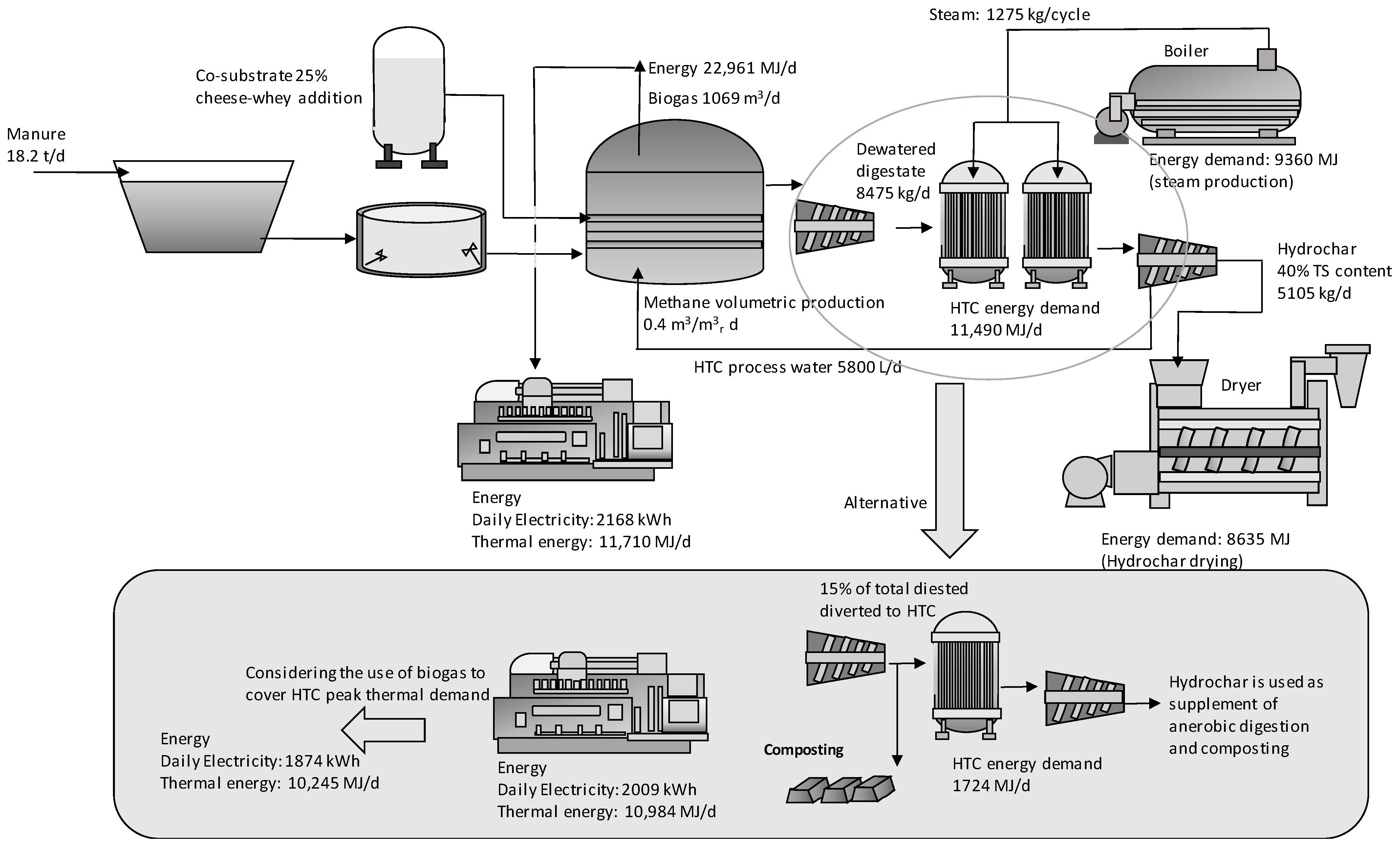

3.2. Scenario 2

3.3. Scenario 3

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Hoekman, S.K.; Broch, A.; Robbins, C. Hydrothermal carbonization (HTC) of lignocellulosic biomass. Energy Fuels 2011, 25, 1802–1810. [Google Scholar] [CrossRef]

- Kambo, H.S.; Minaret, J.; Dutta, A. Process water from the hydrothermal carbonization of biomass: A waste or a valuable product? Waste Biomass Valorization 2018, 9, 1181–1189. [Google Scholar] [CrossRef]

- Choi, J.M.; Han, S.K.; Lee, C.Y. Enhancement of methane production in anaerobic digestion of sewage sludge by thermal hydrolysis pretreatment. Bioresour. Technol. 2018, 259, 207–213. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Yi, H.; Li, H.; Guo, X.; Xiao, B. Effects of thermal and thermal-alkaline pretreatments on continuous anaerobic sludge digestion: Performance, energy balance and, enhancement mechanism. Renew. Energy 2020, 147, 2409–2416. [Google Scholar] [CrossRef]

- Hong, E.H.; Park, J.G.; Lee, B.; Shi, W.Q.; Jun, H.B. Improvement of Waste Dehydrated Sludge for Anaerobic Digestion through High-Temperature and High-Pressure Solubilization. Energies 2020, 13, 88. [Google Scholar] [CrossRef] [Green Version]

- Cuetos, M.J.; Gómez, X.; Otero, M.; Morán, A. Anaerobic digestion and co-digestion of slaughterhouse waste (SHW): Influence of heat and pressure pre-treatment in biogas yield. Waste Manag. 2010, 30, 1780–1789. [Google Scholar] [CrossRef]

- Phothilangka, P.; Schoen, M.A.; Huber, M.; Luchetta, P.; Winkler, T.; Wett, B. Prediction of thermal hydrolysis pretreatment on anaerobic digestion of waste activated sludge. Water Sci. Technol. 2008, 58, 1467–1473. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Jiang, M.; Yao, J.; Liu, H.; Dai, X. Anaerobic digestion of spectinomycin mycelial residues pretreated by thermal hydrolysis: Removal of spectinomycin and enhancement of biogas production. Environ. Sci. Pollut. Res. 2020, 27, 39297–39307. [Google Scholar] [CrossRef]

- Zhang, D.; Santha, H.; Pallansch, K.; Novak, J.T.; Wang, Z.W. Repurposing pre-pasteurization as an in situ thermal hydrolysis pretreatment process for enhancing anaerobic digestion of municipal sludge: A horizontal comparison between temperature-phased and standalone thermophilic or mesophilic anaerobic digestion. Environ. Sci. Water Res. Technol. 2020, 6, 3316–3325. [Google Scholar] [CrossRef]

- Martínez, E.J.; Gil, M.V.; Rosas, J.G.; Moreno, R.; Mateos, R.; Morán, A.; Gómez, X. Application of thermal analysis for evaluating the digestion of microwave pre-treated sewage sludge. J. Therm. Anal. Calorim. 2017, 127, 1209–1219. [Google Scholar] [CrossRef]

- Toutian, V.; Barjenbruch, M.; Unger, T.; Loderer, C.; Remy, C. Effect of temperature on biogas yield increase and formation of refractory COD during thermal hydrolysis of waste activated sludge. Water Res. 2020, 171, 115383. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; An, Z.; Strawn, M.; Broderick, T.; Khunjar, W.; Wang, Z.W. Understanding the formation of recalcitrant dissolved organic nitrogen as a result of thermal hydrolysis and anaerobic digestion of municipal sludge. Environ. Sci. Water Res. Technol. 2021, 7, 335–345. [Google Scholar] [CrossRef]

- How Does Thermal Hydrolysis Work?—Cambi—World Leader in Thermal Hydrolysis. Available online: https://www.cambi.com/what-we-do/thermal-hydrolysis/how-does-thermal-hydrolysis-work/ (accessed on 10 August 2021).

- Available online: https://www.veoliawatertech.com/en/expertise/municipal-market/biosolidsbioenergy/biothelys-batch-thermal-hydrolysis (accessed on 18 August 2021).

- Thermal Hydrolysis Process. Available online: https://haarslev.com/industries/environmental/municipal/thermal-hydrolysis-process/ (accessed on 18 August 2021).

- Available online: https://www.veoliawatertechnologies.com/en/products/exelys (accessed on 18 August 2021).

- DMT|TurboTec Thermal Hydrolosis|DMT Environmental Technology. Available online: https://www.dmt-et.com/products/turbotec/ (accessed on 2 September 2021).

- Bonmati, A.; Flotats, X.; Mateu, L.; Campos, E. Study of thermal hydrolysis as a pretreatment to mesophilic anaerobic digestion of pig slurry. Water Sci. Technol. 2001, 44, 109–116. [Google Scholar] [CrossRef]

- Zhou, Y.; Takaoka, M.; Wang, W.; Liu, X.; Oshita, K. Effect of thermal hydrolysis pre-treatment on anaerobic digestion of municipal biowaste: A pilot scale study in China. J. Biosci. Bioeng. 2013, 116, 101–105. [Google Scholar] [CrossRef]

- Ferrentino, R.; Merzari, F.; Fiori, L.; Andreottola, G. Biochemical methane potential tests to evaluate anaerobic digestion enhancement by thermal hydrolysis pretreatment. BioEnergy Res. 2019, 12, 722–732. [Google Scholar] [CrossRef]

- Nava-Valente, N.; Del Ángel-Coronel, O.A.; Atenodoro-Alonso, J.; López-Escobar, L.A. Effect of thermal and acid pre-treatment on increasing organic loading rate of anaerobic digestion of coffee pulp for biogas production. Biomass Conv. Bioref. 2021, 1–14. [Google Scholar] [CrossRef]

- Oosterhuis, M.; Ringoot, D.; Hendriks, A.; Roeleveld, P. Thermal hydrolysis of waste activated sludge at Hengelo wastewater treatment plant, The Netherlands. Water Sci. Technol. 2014, 70, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Kepp, U.; Machenbach, I.; Weisz, N.; Solheim, O.E. Enhanced stabilisation of sewage sludge through thermal hydrolysis-three years of experience with full scale plant. Water Sci. Technol. 2000, 42, 89–96. [Google Scholar] [CrossRef]

- Liu, J.; Smith, S.R. A multi-level biogas model to optimise the energy balance of full-scale sewage sludge conventional and THP anaerobic digestion. Renew. Energy 2020, 159, 756–766. [Google Scholar] [CrossRef]

- Feng, G.; Liu, L.; Tan, W. Effect of thermal hydrolysis on rheological behavior of municipal sludge. Ind. Eng. Chem. Res. 2014, 53, 11185–11192. [Google Scholar] [CrossRef]

- García-Cascallana, J.; Borge-Díez, D.; Gómez, X. Enhancing the efficiency of thermal hydrolysis process in wastewater treatment plants by the use of steam accumulation. Int. J. Environ. Sci. Technol. 2019, 16, 3403–3418. [Google Scholar] [CrossRef]

- García-Cascallana, J.; Gómez, X.; Martinez, E.J. Thermal Hydrolysis of Sewage Sludge: A Case Study of a WWTP in Burgos, Spain. Appl. Sci. 2021, 11, 964. [Google Scholar] [CrossRef]

- Taboada-Santos, A.; Lema, J.M.; Carballa, M. Energetic and economic assessment of sludge thermal hydrolysis in novel wastewater treatment plant configurations. Waste Manag. 2019, 92, 30–38. [Google Scholar] [CrossRef]

- Palma-Heredia, D.; Poch, M.; Cugueró-Escofet, M.À. Implementation of a decision support system for sewage sludge management. Sustainability 2020, 12, 9089. [Google Scholar] [CrossRef]

- Ferreira, L.C.; Nilse, P.J.; Fdz-Polanco, F.; Pérez-Elvira, S.I. Biomethane potential of wheal straw: Influence of particle size, water impregnation and thermal hydrolysis. Chem. Eng. J. 2014, 242, 254–259. [Google Scholar] [CrossRef]

- Liu, X.; Lee, C.; Kim, J.Y. Thermal hydrolysis pre-treatment combined with anaerobic digestion for energy recovery from organic wastes. J. Mater. Cycles Waste Manag. 2020, 22, 1370–1381. [Google Scholar] [CrossRef]

- Khan, M.U.; Ahring, B.K. Anaerobic digestion of digested manure fibers: Influence of thermal and alkaline thermal pretreatment on the biogas yield. BioEnergy Res. 2021, 14, 891–900. [Google Scholar] [CrossRef]

- Şenol, H.; Açıkel, Ü.; Demir, S.; Oda, V. Anaerobic digestion of cattle manure, corn silage and sugar beet pulp mixtures after thermal pretreatment and kinetic modeling study. Fuel 2020, 263, 116651. [Google Scholar] [CrossRef]

- Ahmed, B.; Aboudi, K.; Tyagi, V.K.; Álvarez-Gallego, C.J.; Fernández-Güelfo, L.A.; Romero-García, L.I.; Kazmi, A.A. Improvement of anaerobic digestion of lignocellulosic biomass by hydrothermal pretreatment. Appl. Sci. 2019, 9, 3853. [Google Scholar] [CrossRef] [Green Version]

- Ghimire, N.; Bakke, R.; Bergland, W.H. Mesophilic Anaerobic Digestion of Hydrothermally Pretreated Lignocellulosic Biomass (Norway Spruce (Picea abies)). Processes 2021, 9, 190. [Google Scholar] [CrossRef]

- Ro, K.S.; Flora, J.R.; Bae, S.; Libra, J.A.; Berge, N.D.; Álvarez-Murillo, A.; Li, L. Properties of animal-manure-based hydrochars and predictions using published models. ACS Sustain. Chem. Eng. 2017, 5, 7317–7324. [Google Scholar] [CrossRef]

- Xu, J.; Mustafa, A.M.; Lin, H.; Choe, U.Y.; Sheng, K. Effect of hydrochar on anaerobic digestion of dead pig carcass after hydrothermal pretreatment. Waste Manag. 2018, 78, 849–856. [Google Scholar] [CrossRef]

- Arenas, C.B.; Meredith, W.; Snape, C.E.; Gómez, X.; González, J.F.; Martinez, E.J. Effect of char addition on anaerobic digestion of animal by-products: Evaluating biogas production and process performance. Environ. Sci. Pollut. Res. 2020, 27, 24387–24399. [Google Scholar] [CrossRef] [PubMed]

- Ferrentino, R.; Merzari, F.; Fiori, L.; Andreottola, G. Coupling hydrothermal carbonization with anaerobic digestion for sewage sludge treatment: Influence of HTC liquor and hydrochar on biomethane production. Energies 2020, 13, 6262. [Google Scholar] [CrossRef]

- Chaher, N.E.H.; Chakchouk, M.; Engler, N.; Nassour, A.; Nelles, M.; Hamdi, M. Optimization of food waste and biochar in-vessel co-composting. Sustainability 2020, 12, 1356. [Google Scholar] [CrossRef] [Green Version]

- Hagemann, N.; Kammann, C.I.; Schmidt, H.P.; Kappler, A.; Behrens, S. Nitrate capture and slow release in biochar amended compost and soil. PLoS ONE 2017, 12, e0171214. [Google Scholar] [CrossRef]

- Scrinzi, D.; Andreottola, G.; Fiori, L. Composting Hydrochar-OFMSW Digestate Mixtures: Design of Bioreactors and Preliminary Experimental Results. Appl. Sci. 2021, 11, 1496. [Google Scholar] [CrossRef]

- Adjuik, T.; Rodjom, A.M.; Miller, K.E.; Reza, M.T.M.; Davis, S.C. Application of hydrochar, digestate, and synthetic fertilizer to a miscanthus X giganteus crop: Implications for biomass and greenhouse gas emissions. Appl. Sci. 2020, 10, 8953. [Google Scholar] [CrossRef]

- Paz-Ferreiro, J.; Álvarez-Calvo, M.L.; Figueiredo, C.C.D.; Mendez, A.M.; Gascó, G. Effect of Biochar and Hydrochar on Forms of Aluminium in an Acidic Soil. Appl. Sci. 2020, 10, 7843. [Google Scholar] [CrossRef]

- Pagés-Díaz, J.; Huiliñir, C. Valorization of the liquid fraction of co-hydrothermal carbonization of mixed biomass by anaerobic digestion: Effect of the substrate to inoculum ratio and hydrochar addition. Bioresour. Technol. 2020, 317, 123989. [Google Scholar] [CrossRef] [PubMed]

- Usman, M.; Shi, Z.; Ren, S.; Ngo, H.H.; Luo, G.; Zhang, S. Hydrochar promoted anaerobic digestion of hydrothermal liquefaction wastewater: Focusing on the organic degradation and microbial community. Chem. Eng. J. 2020, 399, 125766. [Google Scholar] [CrossRef]

- Gómez, X.; Diaz, M.C.; Cooper, M.; Blanco, D.; Morán, A.; Snape, C.E. Study of biological stabilization processes of cattle and poultry manure by thermogravimetric analysis and 13C NMR. Chemosphere 2007, 68, 1889–1897. [Google Scholar] [CrossRef] [PubMed]

- Otero, M.; Lobato, A.; Cuetos, M.J.; Sánchez, M.E.; Gómez, X. Digestion of cattle manure: Thermogravimetric kinetic analysis for the evaluation of organic matter conversion. Bioresour. Technol. 2011, 102, 3404–3410. [Google Scholar] [CrossRef] [PubMed]

- Fernández, C.; Cuetos, M.J.; Martínez, E.J.; Gómez, X. Thermophilic anaerobic digestion of cheese whey: Coupling H2 and CH4 production. Biomass Bioenergy 2015, 81, 55–62. [Google Scholar] [CrossRef]

- Bertin, L.; Grilli, S.; Spagni, A.; Fava, F. Innovative two-stage anaerobic process for effective codigestion of cheese whey and cattle manure. Bioresour. Technol. 2013, 128, 779–783. [Google Scholar] [CrossRef] [PubMed]

- Jansson, A.T.; Patinvoh, R.J.; Sárvári Horváth, I.; Taherzadeh, M.J. Dry anaerobic digestion of food and paper industry wastes at different solid contents. Fermentation 2019, 5, 40. [Google Scholar] [CrossRef] [Green Version]

- González, R.; Blanco, D.; García-Cascallana, J.; Carrillo-Peña, D.; Gómez, X. Anaerobic Co-Digestion of Sheep Manure and Waste from a Potato Processing Factory: Techno-Economic Analysis. Fermentation 2021, 7, 235. [Google Scholar] [CrossRef]

- González, R.; González, J.; Rosas, J.G.; Smith, R.; Gómez, X. Biochar and energy production: Valorizing swine manure through coupling co-digestion and pyrolysis. C 2020, 6, 43. [Google Scholar] [CrossRef]

- Available online: https://www.wolf-ps.de/fileadmin/WPS/Broschueren/WOLF_PS_CHP_solutions_with_added_value_EN.pdf (accessed on 18 September 2021).

- Nyakuma, B.B.; Johari, A.; Ahmad, A.; Abdullah, T.A.T. Comparative analysis of the calorific fuel properties of Empty Fruit Bunch Fiber and Briquette. Energy Procedia 2014, 52, 466–473. [Google Scholar] [CrossRef] [Green Version]

- Aragón-Briceño, C.I.; Ross, A.B.; Camargo-Valero, M.A. Mass and energy integration study of hydrothermal carbonization with anaerobic digestion of sewage sludge. Renew. Energy 2021, 167, 473–483. [Google Scholar] [CrossRef]

- Available online: https://www4.eere.energy.gov/manufacturing/tech_deployment/amo_steam_tool/equipBoiler (accessed on 18 September 2021).

- Available online: https://www4.eere.energy.gov/manufacturing/tech_deployment/amo_steam_tool/equipFlashtank (accessed on 18 September 2021).

- Lucian, M.; Volpe, M.; Merzari, F.; Wüst, D.; Kruse, A.; Andreottola, G.; Fiori, L. Hydrothermal carbonization coupled with anaerobic digestion for the valorization of the organic fraction of municipal solid waste. Bioresour. Technol. 2020, 314, 123734. [Google Scholar] [CrossRef] [PubMed]

- De la Rubia, M.A.; Villamil, J.A.; Rodriguez, J.J.; Mohedano, A.F. Effect of inoculum source and initial concentration on the anaerobic digestion of the liquid fraction from hydrothermal carbonisation of sewage sludge. Renew. Energy 2018, 127, 697–704. [Google Scholar] [CrossRef]

- Marin-Batista, J.D.; Villamil, J.A.; Qaramaleki, S.V.; Coronella, C.J.; Mohedano, A.F.; de la Rubia, M.A. Energy valorization of cow manure by hydrothermal carbonization and anaerobic digestion. Renew. Energy 2020, 160, 623–632. [Google Scholar] [CrossRef]

- Parmar, K.R.; Ross, A.B. Integration of hydrothermal carbonisation with anaerobic digestion; Opportunities for valorisation of digestate. Energies 2019, 12, 1586. [Google Scholar] [CrossRef] [Green Version]

- Wu, K.; Zhang, X.; Yuan, Q. Effects of process parameters on the distribution characteristics of inorganic nutrients from hydrothermal carbonization of cattle manure. J. Environ. Manag. 2018, 209, 328–335. [Google Scholar] [CrossRef]

- Reza, M.T.; Mumme, J.; Ebert, A. Characterization of hydrochar obtained from hydrothermal carbonization of wheat straw digestate. Biomass Convers. Biorefinery 2015, 5, 425–435. [Google Scholar] [CrossRef]

- Wu, K.; Gao, Y.; Zhu, G.; Zhu, J.; Yuan, Q.; Chen, Y.; Cai, M.; Feng, L. 342. Characterization of dairy manure hydrochar and aqueous phase products generated by hydrothermal carbonization at different temperatures. J. Anal. Appl. Pyrolysis 2017, 127, 335–342. [Google Scholar] [CrossRef]

- Gascó, G.; Paz-Ferreiro, J.; Álvarez, M.L.; Saa, A.; Méndez, A. Biochars and hydrochars prepared by pyrolysis and hydrothermal carbonisation of pig manure Biochars and hydrochars prepared by pyrolysis and hydrothermal carbonisation of pig manure. Waste Manag. 2018, 79, 395–403. [Google Scholar] [CrossRef]

- Sheng, C.; Azevedo, J.L.T. Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenergy 2005, 28, 499–507. [Google Scholar] [CrossRef]

- Kulikowska, D.; Bernat, K. Waste Willow-Bark from Salicylate Extraction Successfully Reused as an Amendment for Sewage Sludge Composting. Sustainability 2021, 13, 6771. [Google Scholar] [CrossRef]

- Chung, J.W.; Edewi, O.C.; Foppen, J.W.; Gerner, G.; Krebs, R.; Lens, P.N.L. Removal of Escherichia coli by intermittent operation of saturated sand columns supplemented with hydrochar derived from sewage sludge. Appl. Sci. 2017, 7, 839. [Google Scholar] [CrossRef] [Green Version]

- Purnomo, C.W.; Castello, D.; Fiori, L. Granular activated carbon from grape seeds hydrothermal char. Appl. Sci. 2018, 8, 331. [Google Scholar] [CrossRef] [Green Version]

- Diaz, E.; Manzano, F.J.; Villamil, J.; Rodriguez, J.J.; Mohedano, A.F. Low-cost activated grape seed-derived hydrochar through hydrothermal carbonization and chemical activation for sulfamethoxazole adsorption. Appl. Sci. 2019, 9, 5127. [Google Scholar] [CrossRef] [Green Version]

- Toufiq Reza, M.; Freitas, A.; Yang, X.; Hiibel, S.; Lin, H.; Coronella, C.J. Hydrothermal carbonization (HTC) of cow manure: Carbon and nitrogen distributions in HTC products. Environ. Prog. Sustain. Energy 2016, 35, 1002–1011. [Google Scholar] [CrossRef]

- Arauzo, P.J.; Atienza-Martínez, M.; Ábrego, J.; Olszewski, M.P.; Cao, Z.; Kruse, A. Combustion characteristics of hydrochar and pyrochar derived from digested sewage sludge. Energies 2020, 13, 4164. [Google Scholar] [CrossRef]

- Gómez, X.; Meredith, W.; Fernández, C.; Sánchez-García, M.; Díez-Antolínez, R.; Garzón-Santos, J.; Snape, C.E. Evaluating the effect of biochar addition on the anaerobic digestion of swine manure: Application of Py-GC/MS. Environ. Sci. Pollut. Res. 2018, 25, 25600–25611. [Google Scholar] [CrossRef]

- Sánchez, E.; Herrmann, C.; Maja, W.; Borja, R. Effect of organic loading rate on the anaerobic digestion of swine waste with biochar addition. Environ. Sci. Pollut. Res. 2021, 28, 38455–38456. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Guo, Y.; Wang, W.; Chen, L.; Sun, Y.; Xing, T.; Kong, X. Effect of Biochar Addition on the Microbial Community and Methane Production in the Rapid Degradation Process of Corn Straw. Energies 2021, 14, 2223. [Google Scholar] [CrossRef]

- González, J.; Sánchez, M.E.; Gómez, X. Enhancing anaerobic digestion: The effect of carbon conductive materials. C 2018, 4, 59. [Google Scholar] [CrossRef] [Green Version]

- Ren, S.; Usman, M.; Tsang, D.C.; O-Thong, S.; Angelidaki, I.; Zhu, X.; Zhang, S.; Luo, G. Hydrochar-facilitated anaerobic digestion: Evidence for direct interspecies electron transfer mediated through surface oxygen-containing functional groups. Environ. Sci. Technol. 2020, 54, 5755–5766. [Google Scholar] [CrossRef]

- Chiappero, M.; Cillerai, F.; Berruti, F.; Mašek, O.; Fiore, S. Addition of Different Biochars as Catalysts during the Mesophilic Anaerobic Digestion of Mixed Wastewater Sludge. Catalysts 2021, 11, 1094. [Google Scholar] [CrossRef]

- Martínez, E.J.; Rosas, J.G.; Sotres, A.; Moran, A.; Cara, J.; Sánchez, M.E.; Gómez, X. Codigestion of sludge and citrus peel wastes: Evaluating the effect of biochar addition on microbial communities. Biochem. Eng. J. 2018, 137, 314–325. [Google Scholar] [CrossRef]

- Sun, C.; Fang, L.; Zhiwei, S.; Jing, W.; Yongfeng, L.; Yu, P.; Tao, S.; Lixin, L. Feasibility of dry anaerobic digestion of beer lees for methane production and biochar enhanced performance at mesophilic and thermophilic temperature. Bioresour. Technol. 2019, 276, 65–73. [Google Scholar] [CrossRef]

- Quintana-Najera, J.; Blacker, A.J.; Fletcher, L.A.; Ross, A.B. The effect of augmentation of biochar and hydrochar in anaerobic digestion of a model substrate. Bioresour. Technol. 2021, 321, 124494. [Google Scholar] [CrossRef]

- Cai, J.; He, P.; Wang, Y.; Shao, L.; Lü, F. Effects and optimization of the use of biochar in anaerobic digestion of food wastes. Waste Manag. Res. 2016, 34, 409–416. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S.A. Life cycle assessment on the treatment of organic waste streams by anaerobic digestion, hydrothermal carbonization and incineration. Waste Manag. 2021, 130, 93–106. [Google Scholar] [CrossRef] [PubMed]

- Heidari, M.; Salaudeen, S.; Norouzi, O.; Acharya, B.; Dutta, A. Numerical comparison of a combined hydrothermal carbonization and anaerobic digestion system with direct combustion of biomass for power production. Processes 2020, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Dieguez-Alonso, A.; Funke, A.; Anca-Couce, A.; Rombolà, A.G.; Ojeda, G.; Bachmann, J.; Behrendt, F. Towards biochar and hydrochar engineering—Influence of process conditions on surface physical and chemical properties, thermal stability, nutrient availability, toxicity and wettability. Energies 2018, 11, 496. [Google Scholar] [CrossRef] [Green Version]

- Jugal Sukhesh, M.; Venkateswara Rao, P. Synergistic effect in anaerobic co-digestion of rice straw and dairy manure-a batch kinetic study. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 2145–2156. [Google Scholar] [CrossRef]

- Al Afif, R.; Amon, T. Mesophilic anaerobic co-digestion of cow manure with three-phase olive mill solid waste. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 1800–1808. [Google Scholar] [CrossRef]

- Baek, G.; Kim, D.; Kim, J.; Kim, H.; Lee, C. Treatment of cattle manure by anaerobic co-digestion with food waste and pig manure: Methane yield and synergistic effect. Int. J. Environ. Res. Public Health 2020, 17, 4737. [Google Scholar] [CrossRef]

- Aboudi, K.; Gómez-Quiroga, X.; Álvarez-Gallego, C.J.; Romero-García, L.I. Insights into anaerobic co-digestion of lignocellulosic biomass (sugar beet by-products) and animal manure in long-term semi-continuous assays. Appl. Sci. 2020, 10, 5126. [Google Scholar] [CrossRef]

- Gonzalez-Piedra, S.; Hernández-García, H.; Perez-Morales, J.M.; Acosta-Domínguez, L.; Bastidas-Oyanedel, J.R.; Hernandez-Martinez, E. A Study on the Feasibility of Anaerobic Co-Digestion of Raw Cheese Whey with Coffee Pulp Residues. Energies 2021, 14, 3611. [Google Scholar] [CrossRef]

- Hallaji, S.M.; Kuroshkarim, M.; Moussavi, S.P. Enhancing methane production using anaerobic co-digestion of waste activated sludge with combined fruit waste and cheese whey. BMC Biotechnol. 2019, 19, 19. [Google Scholar] [CrossRef] [PubMed]

- Monfet, E.; Aubry, G.; Ramirez, A.A. Nutrient removal and recovery from digestate: A review of the technology. Biofuels 2018, 9, 247–262. [Google Scholar] [CrossRef]

- Ujor, V.C.; Okonkwo, C.C.; Rush, B.B.; McCrea, G.E.; Ezeji, T.C. Harnessing the Residual Nutrients in Anaerobic Digestate for Ethanol Fermentation and Digestate Remediation Using Saccharomyces cerevisiae. Fermentation 2020, 6, 52. [Google Scholar] [CrossRef]

- Pastor-Bueis, R.; Mulas, R.; Gómez, X.; González-Andrés, F. Innovative liquid formulation of digestates for producing a biofertilizer based on Bacillus siamensis: Field testing on sweet pepper. J. Plant Nutr. Soil Sci. 2017, 180, 748–758. [Google Scholar] [CrossRef]

- Giuliano, A.; Catizzone, E.; Freda, C.; Cornacchia, G. Valorization of OFMSW digestate-derived syngas toward methanol, hydrogen, or electricity: Process simulation and carbon footprint calculation. Processes 2020, 8, 526. [Google Scholar] [CrossRef]

- Wang, D.; Xi, J.; Ai, P.; Yu, L.; Zhai, H.; Yan, S.; Zhang, Y. Enhancing ethanol production from thermophilic and mesophilic solid digestate using ozone combined with aqueous ammonia pretreatment. Bioresour. Technol. 2016, 207, 52–58. [Google Scholar] [CrossRef] [PubMed]

- Stoumpou, V.; Novakovic, J.; Kontogianni, N.; Barampouti, E.M.; Mai, S.; Moustakas, K.; Malamis, D.; Loizidou, M. Assessing straw digestate as feedstock for bioethanol production. Renew. Energy 2020, 153, 261–269. [Google Scholar] [CrossRef]

- Wang, W.; Lee, D.J. Valorization of anaerobic digestion digestate: A prospect review. Bioresour. Technol. 2020, 323, 124626. [Google Scholar] [CrossRef] [PubMed]

- Barba, F.J. An Integrated Approach for the Valorization of Cheese Whey. Foods 2021, 10, 564. [Google Scholar] [CrossRef] [PubMed]

- Mehari, B.B.; Chang, S.; Hong, Y.; Chen, H. Temperature-phased biological hydrolysis and thermal hydrolysis pretreatment for anaerobic digestion performance enhancement. Water 2018, 10, 1812. [Google Scholar] [CrossRef] [Green Version]

- Chang, S.; Filer, J. Thermal Hydrolysis to Enhance Anaerobic Digestion Performance of Wastewater Sludge. Curr. Pollut. Rep. 2020, 6, 452–467. [Google Scholar] [CrossRef]

- Antonopoulou, G.; Vayenas, D.; Lyberatos, G. Biogas production from physicochemically pretreated grass lawn waste: Comparison of different process schemes. Molecules 2020, 25, 296. [Google Scholar] [CrossRef] [Green Version]

- Raju, C.S.; Sutaryo, S.; Ward, A.J.; Møller, H.B. Effects of high-temperature isochoric pre-treatment on the methane yields of cattle, pig and chicken manure. Environ. Technol. 2013, 34, 239–244. [Google Scholar] [CrossRef] [Green Version]

- Cano, R.; Nielfa, A.; Fernández-Polanco, M. Thermal hydrolysis integration in the anaerobic digestion process of different solid wastes: Energy and economic feasibility study. Bioresour. Technol. 2014, 168, 14–22. [Google Scholar] [CrossRef]

- McVoitte, W.P.; Clark, O.G. The effects of temperature and duration of thermal pretreatment on the solid-state anaerobic digestion of dairy cow manure. Heliyon 2019, 5, e02140. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, L.C.; Souza, T.S.O.; Fernández-Polanco, F.; Pérez-Elvira, S.I. Thermal steam explosion pretreatment to enhance anaerobic biodegradability of the solid fraction of pig manure. Bioresour. Technol. 2014, 152, 393–398. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Li, H. Rheological behavior of sewage sludge with high solid content. Water Sci. Technol. 2015, 71, 1686–1693. [Google Scholar] [CrossRef] [PubMed]

- Abu-Orf, M.; Goss, T. Comparing Thermal hydrolysis processes (CAMBI™ and EXELYS™) for solids pretreatment prior to anaerobic digestion. Digestion 2012, 16, 8–12. [Google Scholar]

- Flesch, F.; Berger, P.; Robles-Vargas, D.; Santos-Medrano, G.E.; Rico-Martínez, R. Characterization and determination of the toxicological risk of biochar using invertebrate toxicity tests in the state of Aguascalientes, México. Appl. Sci. 2019, 9, 1706. [Google Scholar] [CrossRef] [Green Version]

| Plant Characteristics | Value |

|---|---|

| Manure treatment capacity | 6500 t/year |

| TS content of feed | 10% |

| Hydraulic retention time (HRT) | 40 d |

| Digester volume | 2190 m3 |

| TS content dewatered sludge | 30% |

| Co-substrate | Cheese whey |

| Co-substrate addition (% v/w) | 25–50% |

| TS content cheese whey | 33.1 g/L 1 |

| Plant Characteristics | Scenario 1 |

|---|---|

| Substrate | Manure |

| TS content of feed | 10% |

| TS of the feed after adding HTC process water | 8.5% |

| Organic loading rate (based on reactor working volume) | 1.8 kg/m3 d |

| Digester inlet (volumetric flow) | 38.2 m3/d |

| Digester thermal demand | 4120 MJ/d |

| Biogas production from manure | 752 m3 |

| Biogas production from manure and HTC process water | 852 m3 |

| Energy in biogas | 18,300 MJ/d |

| Mass flow of dewatered digestate (30% TS content) | 7970 kg/d |

| TS mass flow of digested material submitted to HTC | 2392 kg/d |

| HTC energy demand | 10,755 MJ/d |

| Thermal energy recovery (from flash steam) | 3245 MJ/d |

| Mass flow of hydrochar (at 40% TS content) | 4717 kg/d |

| Energy demand for hydrochar drying | 7521 MJ/d |

| Energy from hydrochar combustion (85% energy recovery) | 27,778 MJ/d |

| Plant Characteristics | Scenario 1 |

|---|---|

| Substrate | Manure + cheese whey (25%) |

| TS content of feed | 10% |

| TS of the feed after adding HTC process water | 8.9% |

| Organic loading rate (based on reactor working volume) | 2.2 kg/m3 d |

| Digester inlet (volumetric flow) | 40.4 m3/d |

| Digester thermal demand | 5141 MJ/d |

| Biogas production from manure + cheese whey | 976 m3 |

| Biogas production after adding HTC process water | 1076 m3 |

| Energy in biogas | 23,108 MJ/d |

| Mass flow of dewatered digestate (30% TS content) | 8476 kg/d |

| TS mass flow of digested material submitted to HTC | 2543 kg/d |

| HTC energy demand | 11,490 MJ/d |

| Thermal energy recovery (from flash steam) | 2432 MJ/d |

| Mass flow of hydrochar (at 40% TS content) | 5105 kg/d |

| Energy demand for hydrochar drying | 8635 MJ/d |

| Energy from hydrochar combustion (85% energy recovery) | 30,277 MJ/d |

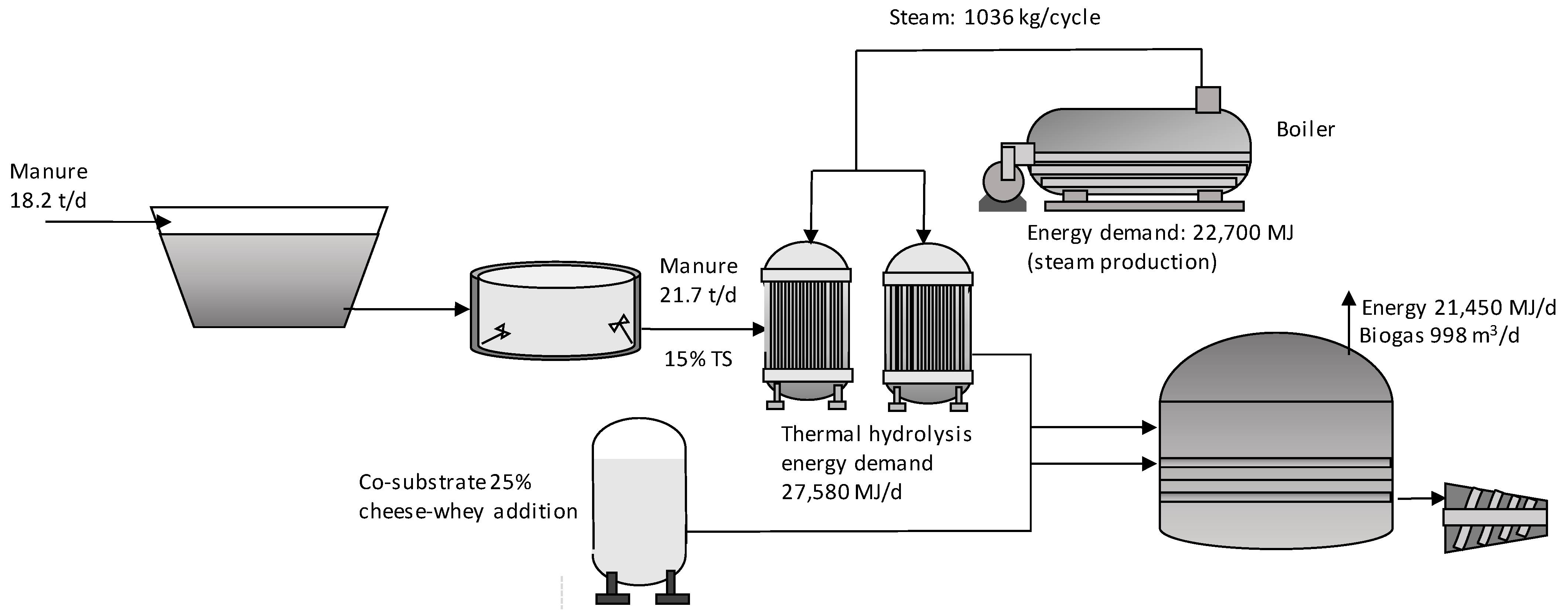

| Plant Characteristics | Scenario 1 |

|---|---|

| Substrate | Hydrolyzed manure + cheese whey (25% v/w) |

| TS content of feed to thermal hydrolysis process | 15% |

| TS of the feed after adding cheese whey to hydrolyzed manure | 10% |

| Organic loading rate (based on reactor working volume) | 2.5 kg/m3 d |

| Digester inlet (volumetric flow) | 34.6 m3/d |

| Digester thermal demand 1 | – |

| Biogas production from hydrolyzed manure | 902 m3 |

| Biogas production from hydrolyzed manure and cheese whey | 998 m3 |

| Energy in biogas | 21,450 MJ/d |

| Mass flow of dewatered digestate (30% TS content) | 7700 kg/d |

| TS mass flow of digested material | 2309 kg/d |

| Thermal hydrolysis energy demand | 27,580 MJ/d |

| Thermal energy recovery (from flash steam) | 6840 MJ/d |

| Energy demand for digestate drying | 14,726 MJ/d |

| Energy from digestate combustion (85% energy recovery) | 22,374 MJ/d |

| Scenario Main Characteristics | Strength | Weakness |

|---|---|---|

| Scenario 1: treatment of manure (AD 1 + HTC 2) | Great reduction of waste final disposal Char obtained as product and used as fuel to supply energy demand Treatment of HTC process water in the digestion unit | High energy demand for running the HTC unit (10,755 MJ/d) Combustion of hydrochar requires drying, increasing heat demand |

| Scenario 2: treatment of manure and co-substrate (cheese whey), (AD + HTC, compost production) | Production of active compost supplemented with hydrochar Enhanced biogas production Reduced thermal demand of the global process. HTC unit treats a fraction of digestate to cover the hydrochar amount needed in biological conversion | Producing active compost requires additional land A market should be available for commercializing compost Economic feasibility of the plant should be considered in future work due to the low market price of compost and high energy demand of HTC units |

| Scenario 3: Thermal hydrolysis of manure and co-substrate (cheese whey), (AD) | Enhanced biogas production Reduction of digestate disposal due to the higher conversion of manure VS | Excessive energy demand for running the thermal hydrolysis unit (27,580 MJ/d) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González, R.; Ellacuriaga, M.; Aguilar-Pesantes, A.; Carrillo-Peña, D.; García-Cascallana, J.; Smith, R.; Gómez, X. Feasibility of Coupling Anaerobic Digestion and Hydrothermal Carbonization: Analyzing Thermal Demand. Appl. Sci. 2021, 11, 11660. https://doi.org/10.3390/app112411660

González R, Ellacuriaga M, Aguilar-Pesantes A, Carrillo-Peña D, García-Cascallana J, Smith R, Gómez X. Feasibility of Coupling Anaerobic Digestion and Hydrothermal Carbonization: Analyzing Thermal Demand. Applied Sciences. 2021; 11(24):11660. https://doi.org/10.3390/app112411660

Chicago/Turabian StyleGonzález, Rubén, Marcos Ellacuriaga, Alby Aguilar-Pesantes, Daniela Carrillo-Peña, José García-Cascallana, Richard Smith, and Xiomar Gómez. 2021. "Feasibility of Coupling Anaerobic Digestion and Hydrothermal Carbonization: Analyzing Thermal Demand" Applied Sciences 11, no. 24: 11660. https://doi.org/10.3390/app112411660

APA StyleGonzález, R., Ellacuriaga, M., Aguilar-Pesantes, A., Carrillo-Peña, D., García-Cascallana, J., Smith, R., & Gómez, X. (2021). Feasibility of Coupling Anaerobic Digestion and Hydrothermal Carbonization: Analyzing Thermal Demand. Applied Sciences, 11(24), 11660. https://doi.org/10.3390/app112411660