1. Introduction

With the intensifying global water crisis and climate breakdown, water is a wealth we must conserve. The global water crisis is a serious threat and not only to those who suffer water-borne diseases or die due to dirty water drinking and use. While the global population increases, the amount of water available presents an opposing trend, being limited to 1250 cubic meters in 1995. Moreover, it is predicted that by 2025, the amount of water available will decrease further to 650 cubic meters worldwide [

1]. As a consequence, limited access to clean water has a severe impact on society development and economic growth. From an economical perspective, effective wastewater treatment has important effects on saving water and preventing unnecessary water losses [

2].

Water reuse in closed loops in different industrial processes is a very promising approach and one of the pillars of a sustainable circular economy. Moreover, more and more studies have recently underlined the increased common presence of antibiotic resistant bacteria in wastewater generated by household, municipal and industrial activities [

3,

4]. One must bear in mind that contaminated water is also a major threat to the environment. Wastewater is a complex aqueous solution, containing not only chemical inorganic and organic substances and physical contaminants, but also wide scope of the harmful microorganisms. Additionally, wastewater effluent contains pollutants of various types depending on its origin, thus sludge of different characteristics requires different specific treatment processes. Therefore, many physical, chemical, biological and hybrid processes have already been applied to wastewater treatment over the last few decades. Most treatment facilities employ several steps or combine steps in wastewater treatment [

5]. Every stage of the wastewater treatment process is important to achieve the desired treatment results. However, primary and tertiary treatment are critical to the overall process. In the primary treatment process, solid particles are reduced to fragments and grit is removed. However, this has little effect on the pathogens present in the wastewater [

6]. Nevertheless, without this step, subsequent treatment stages would be less effective. Tertiary treatment employs advanced treatment technology aimed at the removal of special pollutants such as harmful microbes to make the water ready for safe reuse [

7].

Nevertheless, each treatment method has its own limitations regarding feasibility, cost, efficiency, environmental impact, or pre-treatment requirements [

8]. Hence, advanced, simple, low-cost, and easy-to-use methods need to be developed to tackle the problem of wastewater remediation effectively.

Electron beam technology is a proven technology which has been applied commercially for sterilization, food hygenization or polymer cross-linking for decades [

9,

10,

11]. The high purification degree of sewage provided by EB treatment, and unachievable in some cases by conventional purification technologies, is the one of the most important advantages of radiation treatment of wastewater [

12,

13]. Moreover, detailed knowledge on the radiation mechanism of organic compounds conversion and decomposition, including available qualitative and quantitative data on primary events of energy absorption is another strong point of radiation-based wastewater treatment [

14]. Additionally, while using electricity to generate electrons, the EB accelerators used in the industry are tools with a conventional turn on and off system, therefore, they do not face the security, transportation, storage, and disposal issues that gamma-ray emitting sources, such as cobalt-60 cells confront. Application of EB wastewater treatment decreases the time of treatment and saves the costs of chemical solutions [

15]. It is important to underline that in the radiation-based wastewater remediation process, no secondary waste and no radioactive residues are generated.

Available literature on the economic feasibility of EB’s application in wastewater treatment plants indicates that operational and maintenance cost are nearly competitive, with conventional technologies widely applied nowadays [

16]. Annual savings calculated on the basis of a preliminary investigation carried out for the pilot wastewater plant equipped with an integrated EB unit were estimated in the range of USD 0.2–2.7 million depending upon specific application [

16]. The redundancy and reliability of the EB accelerator operation are the most important factors influencing economic feasibility. However, substantial improvements in reliability and operational stability of electron accelerators have been made recently, therefore the requirements concerning the continuous failure-free operation of wastewater plant employing EB units are more easily fulfilled. Nevertheless, the procurement, transportation and installation costs of electron accelerators vary from USD 0.6 to 2 million, depending on accelerator parameters [

17], therefore there is still a need to reduce the capital cost of electron accelerators irradiation facility.

It is also worth noting that electric power consumption by other eco-friendly disinfection methods such as UV or ozone is three orders of magnitude higher than in the case of EB treatment [

18].

Electron beam processing in wastewater treatment is an additive-free process that uses the short-lived reactive species formed during the radiolysis of water for the efficient decomposition of organic and microbiological pollutants therein [

19].

Absorbed energy ratio is proportional to mass fraction of given species and water is the main component of wastewater and ballast water as well. Hydrated electron e

aq−, H atom,

• OH and HO

2• radicals and hydrogen peroxide H

2O

2 and H

2 are the most important products of the primary interactions (radiolysis products):

with yields (G value, μmol/J) of 0.28(e

aq−), 0.062(H), 0.28(

•OH), 0.072(H

2O

2).

Hydrogen peroxide H

2O

2 and

•OH and HO

2• radicals are oxidizing species, while H atom and e

aq− are reducing species. The addition of ozone before or during irradiation converts the reducing species formed during water radiolysis into

•OH radicals [

20] and consequently enhances the

•OH radical yield from water radiolysis by a factor of 2.

Bacteria cells contain water (e.g., E. coli cell contains roughly 72% water by mass and 80% by volume) and the species listed in Eq.1 are capable of degrading and altering biopolymers such as DNA and protein. Breakage of DNA chains in radiation, direct and chemical pathways, and degradation of enzymes lead to the death of the irradiated cells. The bacteria cell wall, a rigid and non-living envelope around the cell, is an important structure. It is present just above the cell membrane and gives a specific shape to the cell. In addition, the reactive compounds formed in matrix matter attack bacteria walls. Damage to the cell wall disturbs the state of cell electrolytes, which can activate death pathways (apoptosis or programmed cell death).

It has been demonstrated that inactivation of fecal

Coliforms in municipal wastewater can be achieved with doses lower than 1 kGy. It is observed that nearly 100% of

E.Coli and total

Coliforms were inactivated with a dose of 0.8 kGy. Even with the lower dose of 0.2 kGy, the

E.Coli and total

Coliforms were successfully inactivated to the level of the guideline for effluent discharge. Besides the disinfection of total

Coliforms, an approximately 50% removal in biochemical oxygen demand (BOD) was pronounced at a dose of 0.2 kGy. More than 20% removal in suspended solids (SS) and turbidity was also observed at a dose of 1.0 kGy [

21].

Application of EB irradiation for wastewater treatment brings benefits for all types of streams treated. De-coloration, turbidity and COD (chemical oxygen demand) decrease in wastewater from the dye manufacturing industry [

21], degradation of pesticides and herbicides present in agriculture wastewaters [

22,

23], BOD5 (biochemical oxygen demand), COD and TOC (total organic carbon) and microbial contamination reduction to acceptable limits [

24] for municipal wastewaters, improvement of biodegradability and toxicity decrease in drugs present in the wastewater from pharmaceutical industry [

25,

26] and decomposition of polycyclic aromatic hydrocarbons (PAH) in wastewaters from the petrochemical industry [

27] have been reported in the literature.

The system for wastewater EB treatment must always contain a pre-treatment unit (screens, filters, etc.) and may also be equipped with the traditional biological treatment system [

28]. Present electron accelerators capabilities are well suited for continuous treatment of the wastewater with suitable thickness at a rate defined by electron beam power [

29].

In water or wastewater electron beam treatment facilities, as in each irradiation installation, the issue of radiation protection arises. The lower energy of electrons used in the process, the lower energy, and the yield of generated electromagnetic radiation. Reducing energy of electrons results in the decrease in energy of X-rays, which reduces the thickness of necessary shillings and investment costs. The accelerators working at or below an energy of 300 keV are constructed as self-shielded units and can easily be incorporated in existing processing lines [

30]. However, penetration of such beams is insufficient to treat water in order to decompose chemical compounds or inactivate biological hazards. Thus, a generated X-ray field needs to be considered in case of the application of electrons at energy levels of 800 keV.

2. Geometry of Technological Solution

Water treatment requires low-energy, high-power accelerators. The lower the electron beam energy, the lower the penetration of the wastewater stream that sets the technological requirements regarding the low liquid thickness [

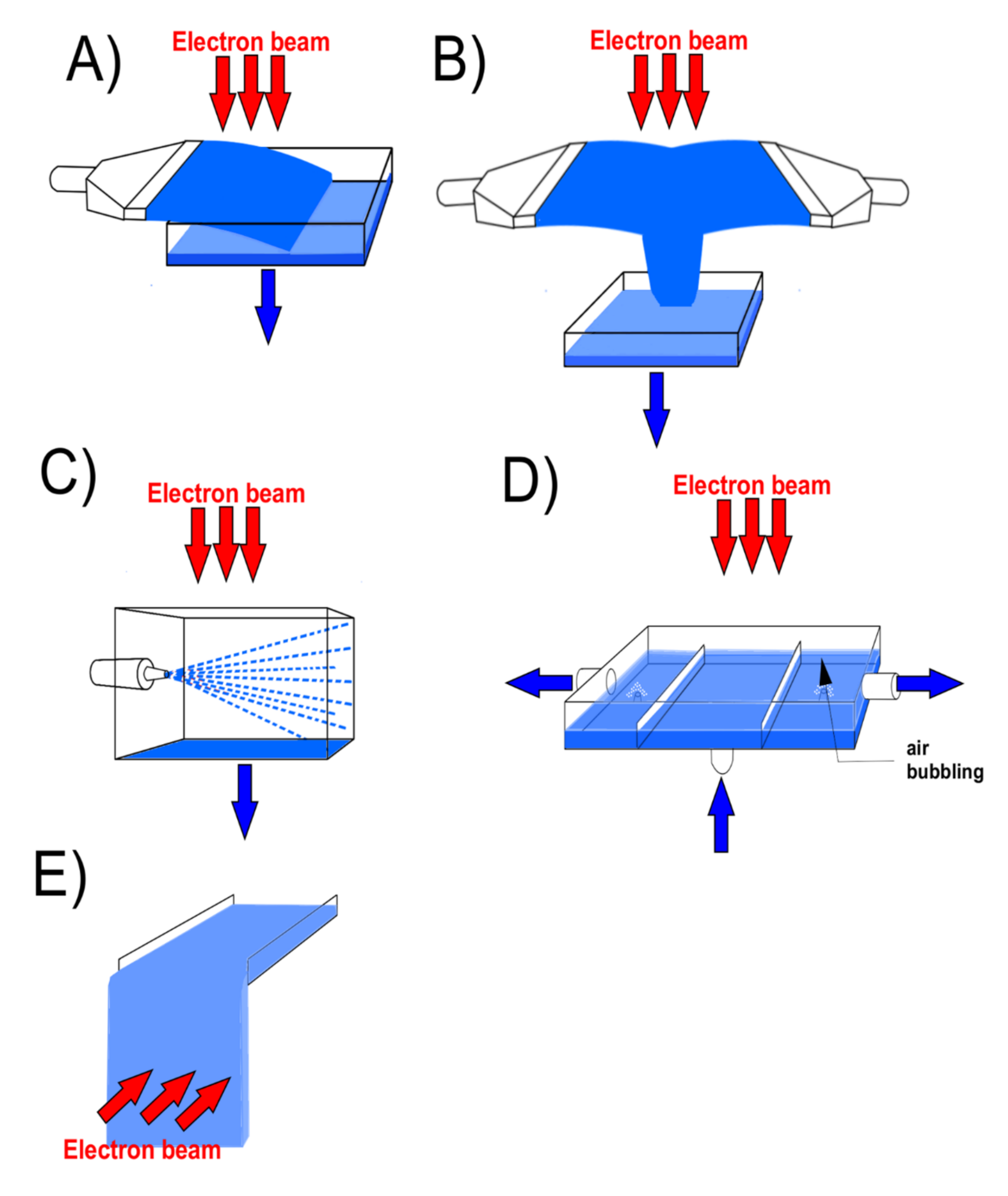

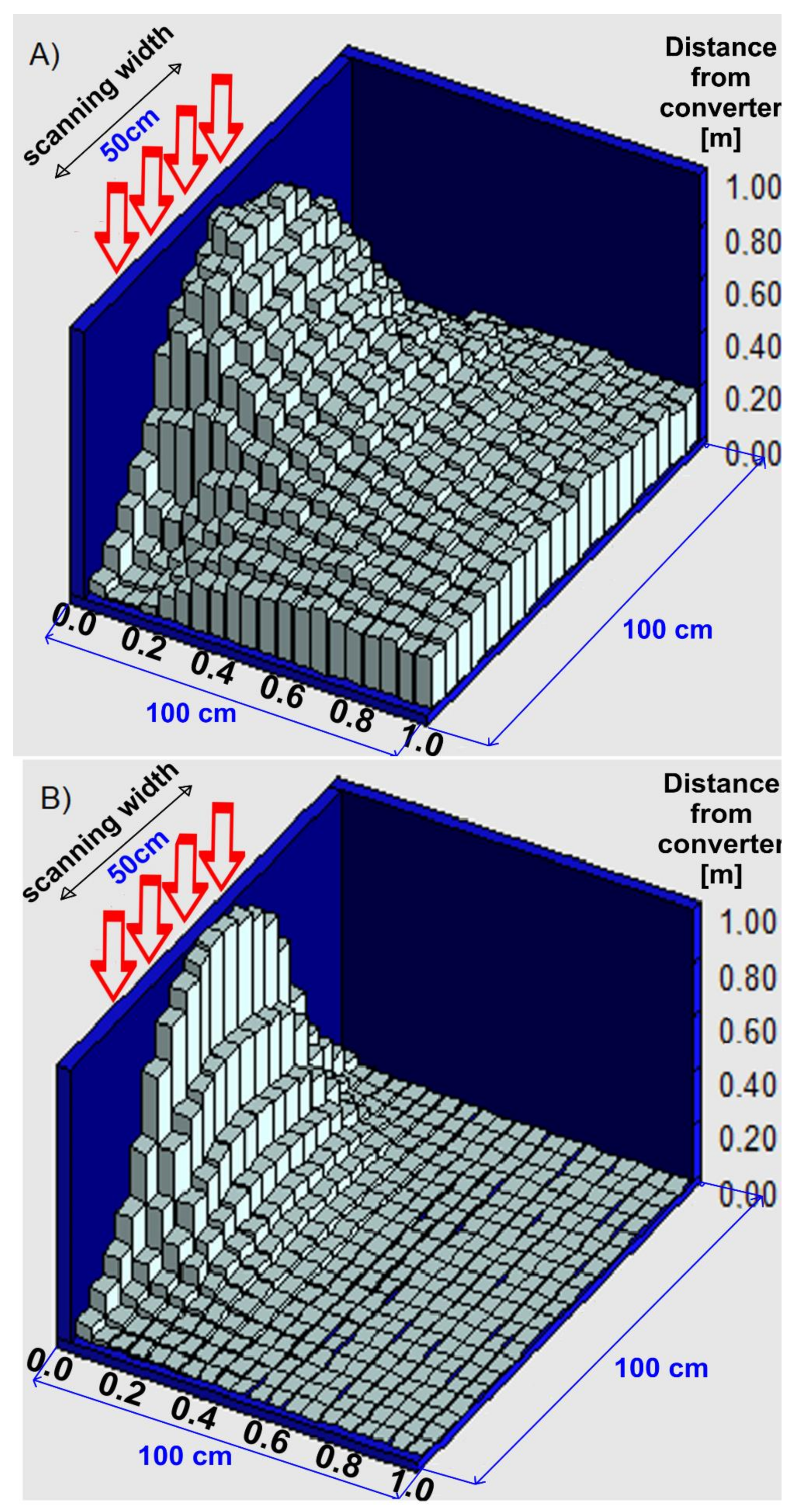

31]. Therefore, different geometry technological solutions and special injection nozzles are applied to ensure the appropriate thickness of the irradiated layer and the effective and homogeneous irradiation of the wastewater stream (

Figure 1).

The first kind of wastewater stream configuration (

Figure 1A) is the most common as the solution characterized with perfect displacement. A continuous wastewater jet with the width adjusted to the scanning width of the accelerator is formed by a nozzle injector. After irradiation by a transverse electron beam, wastewater is collected below in a tray. The thickness of the irradiated layer of wastewater is correlated with the penetration of accelerated electrons which depends on accelerator energy [

32]. Irradiation of either falling film or up-flow mode or injected wastewater stream ensures the most efficient EB utilization [

16].

Thus, in case of water and wastewater treatment plants equipped with EB accelerators selected parameters of the electron beam, energy of electrons and beam power, for the water or wastewater treatment influence design of pre-treatment steps, under beam system, shielding of irradiation chamber and also economical reliability of installation. In the presented study, it was estimated that the optimal parameters of the beam, reducing investment and operating costs, and at the same time providing sufficient penetration of electrons in treated medium at the required dose rate, will be reached using the transformer accelerator characterized with 50 kW beam power and electron energy level 800 keV. A very important step in the construction of the installation of the wastewater EB treatment plant is the design of an irradiation chamber to house the electron accelerator. The geometry and weight of the shielding play key roles in this design. The need of design guidance in shielding construction that allows to determine the minimum shielding requirements and reduce the cost of the whole installation has been signalized [

16]. The wastewater treatment EB plants previously tested and operated [

33,

34] have been constructed on land and shields were made of heavy concrete (magnetite admixture) or steel-reinforced concrete. No special attention was paid to the construction of the under beam system, which led to high intensity X-ray radiation. This phenomenon is called Bremsstrahlung, an electromagnetic radiation produced by the deceleration of a charged particle when deflected by another charged particle, typically an electron by an atomic nucleus, which yield is increasing with the energy of electrons and the atomic number of material hit by electrons. . The dose rate in the electron beam process chamber is extremely high compared to the natural background. Industrial accelerators are capable of delivering a dose rate of several kGy per second, while tolerable background radiation can be as low as 0.1 μGy/h. For this reason, an irradiation shield is required to attenuate radiation by a factor of 10–12 (bremsstrahlung) in order to protect personnel and the environment [

34]. Another factor is the cost of such a shielded room applied, which represents 1.5–2 million USD [

35]. It must be taken into account that not each EB installation can be shielded and using different concrete shielding materials can also be applied. In case of limited space, steel can be used, and with its density of about 7.8 g/cm

3 it can significantly reduce the thickness of constructed shielding. However, if these types of designs and constructions were applied, the weight of the shielding of the accelerator, which is made of steel, would be over 100 tons. From a technical point of view, this would make this application very costly and sometimes unfeasible. Therefore, an advanced EB wastewater treatment system with low background X –ray intensity generation has been developed on the basis of modelling and model testing. The presented solution can be applied in each environmental protection installation based on an electron accelerator application.

3. Conceptual Design of the System

Laboratory irradiation aims to treat wastewater or ships ballast water with an electron beam of energy 800 keV in order to inactivate biological contaminants. The industrial purification and disinfection system should also consist of a pre-treatment unit dedicated to the special composition of treated wastewater. Additional auxiliary equipment would contain tanks, pumps, piping, and control and a monitoring system. The pre-treatment unit has to be designed ensuring appropriate parameters of the stream treated in the irradiation unit and to form an irradiated layer with a thickness suitable for the penetration of the electrons from the accelerator with defined energy. The general concept of the installation combines the EB accelerator as the first stage process to decompose toxic compounds and make them prone to biodegradation and to eliminate microbial contamination with the following biological treatment. This approach allows for the application of lower irradiation doses and makes the electron accelerator application more cost-effective.

For an industrial irradiation unit, it is very important to consider the shielding requirements needed for the safe operation of the facility and also for the safety of the workers due to the health hazards involved with radiation. The shielding material must absorb the energy of scattered and induced radiation to prevent incidental leakage of radiation from the irradiation area.

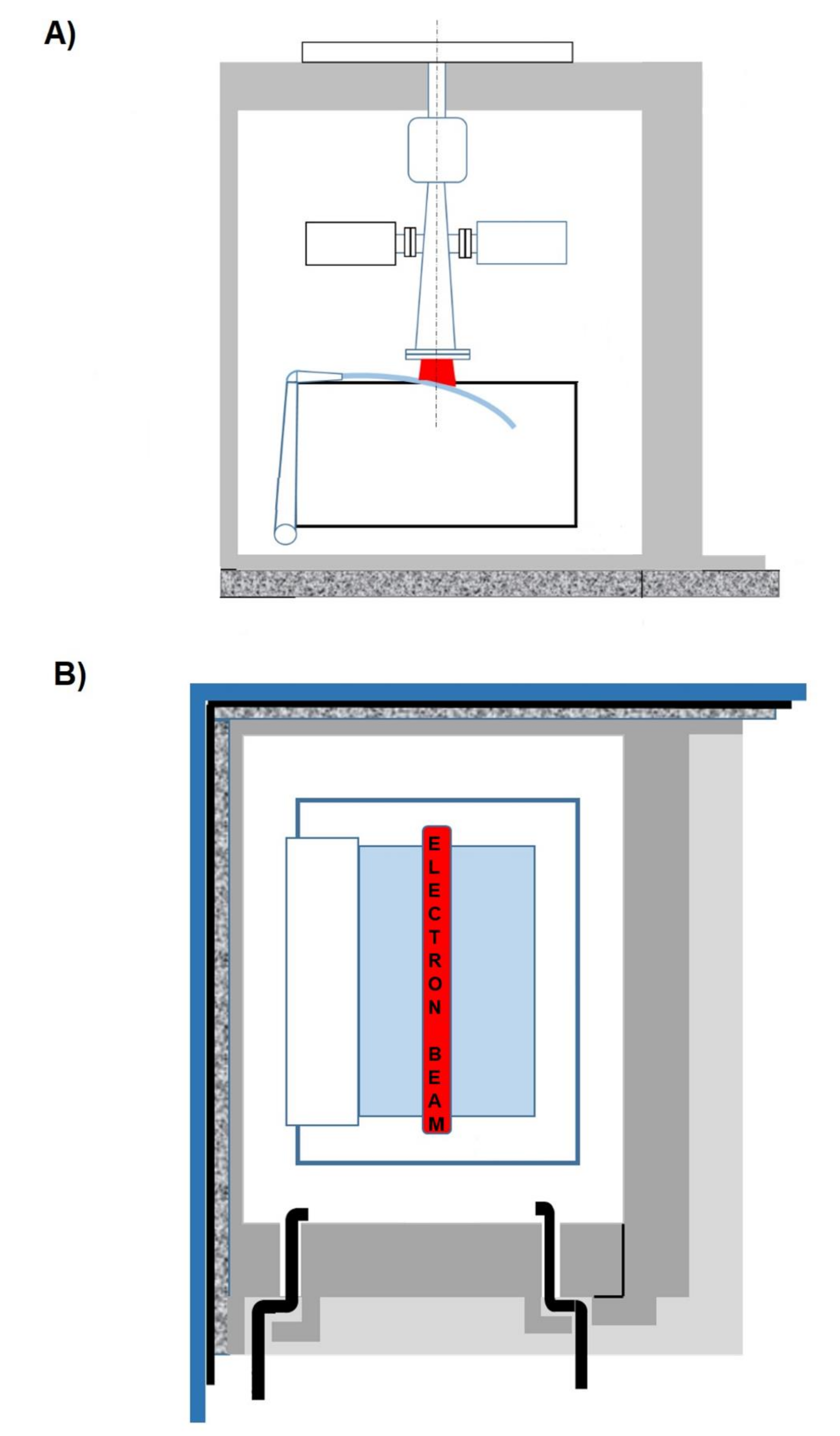

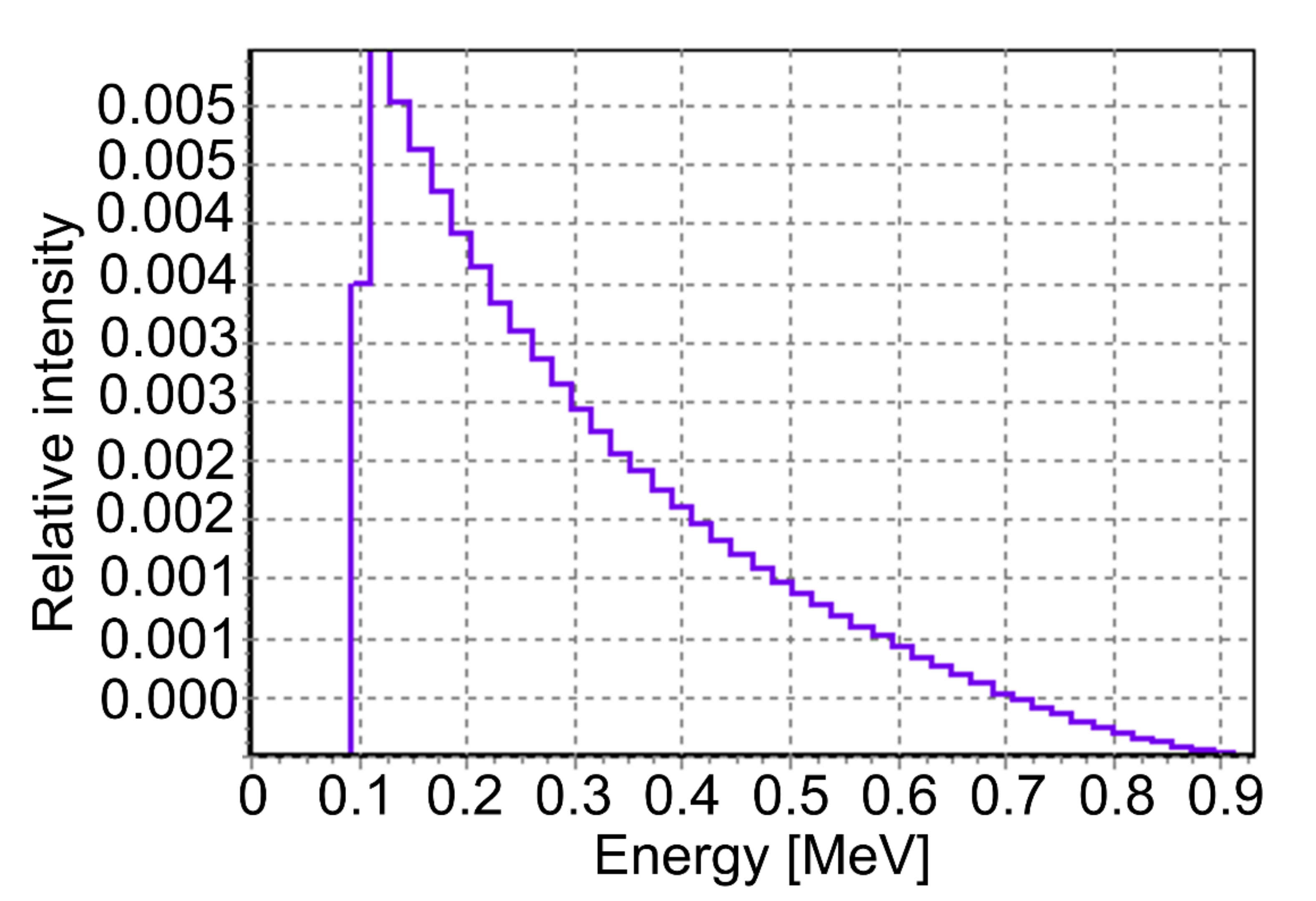

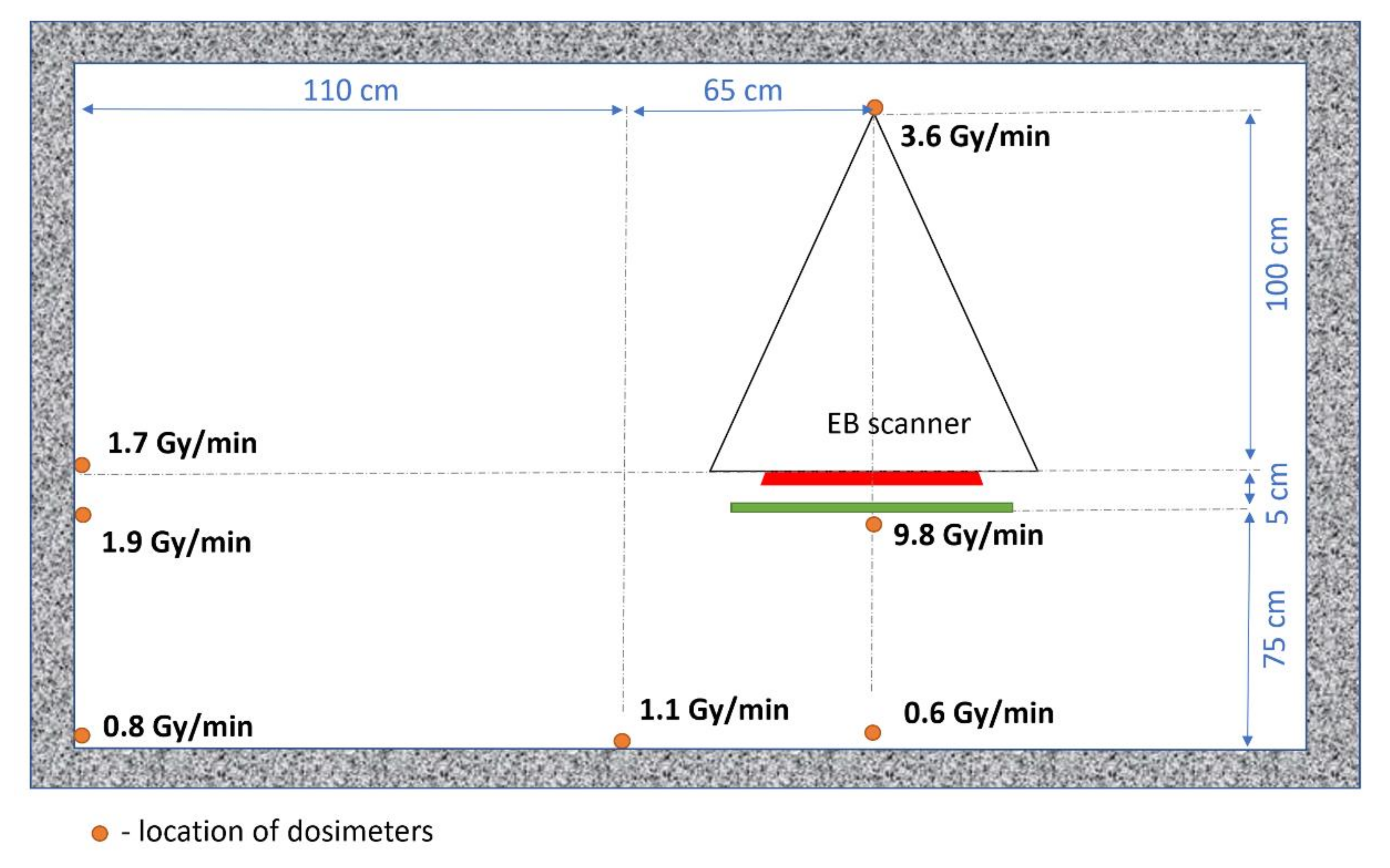

The radiation sources which must be considered are the primary radiation, which in the presented study is an electron beam of energy 800 keV, and secondary radiation, which is X-ray generated as an effect of electrons interaction with the atoms of irradiated medium. Due to the fact that the generation of X-rays depends on atomic number Z, the under beam system is constructed in a way where the electron beam contour lies on the surface of the water in a vessel or a floating dock (

Figure 2), in which two walls of shield are surrounded by water which attenuate radiation as well. The construction of walls of greater thickness is required on the sides of the rooms accessible for service

The design of the wastewater treatment installation, mathematical simulations and experimental measurements with the use of the model under beam system were performed in order to characterize the penetration ability of primary and secondary radiation and the exposure rate for the water and steel in the irradiation room.

4. Experiment

4.1. Model Calculations

Mathematical modelling was used to simulate a depth dose profile for electron beam irradiation and energy spectrum of bremsstrahlung radiation, to calculate the conversion yield of electrons of different material and the range of electromagnetic radiation in water and air [

13].

The Monte Carlo method for simulation of the transport of ionizing radiation through certain material was applied to realize the computer experiment and solve the practical problem of spatial dose distribution. Radiation-Technological Office (RT-Office) was applied as the common program shell, which provided a flexible interaction between specialized modules and the database for optimum planning of the process of irradiation and control of its realization. The module structure was developed in relation to the geometrical and physical properties calculation of EB and the X-ray irradiation process (ModeRL-LE and ModeXR-v-2.3 sub-programs), based on the Monte Carlo Method. RT-Office corresponds to the basic position of ASTM Standard E2232-21, the “Standard Guide for Selection and Use of Mathematical Methods for Calculating Absorbed Dose in Radiation Processing Applications” [

36].

Monte Carlo (MC) simulation uses a randomization of the EB scanning process which is used for an effective calculation scheme and the statistics. The MC simulation was chosen and through this method the required statistical error for simulation results were rendered. This method is intended for the effective solution of non-stationary tasks in which the desired quantity is the time integral of a process. The problem of a dose calculation in an irradiated object after its passage through an irradiation zone (travel or crossing through a zone) falls into such a class of tasks.

The uncertainty of the modelling results essentially depends on the values of the adjusting parameters of the models, which are used for the interaction processes of radiation with materials. Therefore, in the computation scheme the model parameters of the simulation are chosen according to the geometrical and physical characteristics of an irradiation process in order to minimize the run-time for obtaining the simulation results with the established accuracy. For the optimization of the model parameters the adaptive algorithm on the basis of semi-empirical formulas was used [

36].

The physical model of an irradiation process for EB and X-ray radiation processing includes the characteristics of an ionizing radiation source. The system parameters provide the necessary spatial characteristics and requirements for the simulation of the radiation process. A set of interaction processes for the ionizing radiation with the irradiator and product are used in the simulation and are necessary to provide results with the required accuracy. In the physical model, the relevant parameters of an electron accelerator, an EB scanner, an X-ray converter, a conveyor line, and an irradiated object as input data include:

Parameters of the electron beam: Average beam current, electron energy spectrum, angular distribution, beam diameter and spatial distribution of the beam intensity.

Parameters of the scanning system: Modes of operation, the type of scanned EB; width of scanning; distance between scanner and conveyer, form of scan magnet current; repetition frequency of scanner; parameters of the exit window for EB.

Parameters of the X-ray converter with cooling system: Geometrical characteristics of the X-ray converter with cooling system, thickness of plates (layers) and cooling agent, materials composition, distance between exit window and X-ray converter.

Parameters of the conveyor: Speed and geometrical characteristics of the conveyor.

Parameters of irradiated product: Geometrical characteristics of the irradiated product; elemental composition of the target material and density of the components; geometrical characteristics and size of the irradiation container; geometrical characteristics of the dosimetric film, elemental composition of the film material.

Regime irradiation: Product containers can be irradiated on, two or four sided; irradiation the product containers, such as stationary.

The following processes of interaction of electrons with matter and their modelling conceptions were included in the physical model:

Electron loss of energy by inelastic collisions with atomic electrons and bremsstrahlung;

Inelastic electron collision with atomic electrons leading to excitation and ionization of the atoms along the path of the particles (energy transfer mode);

Emission of the secondary electrons (model of the threshold energy);

Electrons participated in elastic collisions with atomic nuclear leading to changes in the electron direction (pulse transfer mode).

The following photon interactions are included in the physical model:

All physical processes necessary to obtain the results with predetermined accuracy are taken into account for the simulation. For example, for EB radiation processing in the energy range of the incident electrons from 100 keV to 10 MeV and irradiated materials with an atomic number Z ≤ 30, the model uncertainty is less than 5% for the calculated dose distribution. Uncertainty, a parameter associated with the results of measurements, characterizes the spread of values that could be attributed to the measured or derived quantity. In the physical model of the interaction of electrons with matter, the processes that determine (form) the trajectories of the motion of electrons and the loss of their energy are taken into account in detail. To significantly reduce the calculation time, the model does not take into account the processes of formation and transfer of energy by bremsstrahlung radiation. This leads to significant changes in the dose distribution in spatial regions, where the energy transferred from electrons to matter is small, and the contribution to the dose from the secondary bremsstrahlung is decisive.

The contribution of the secondary bremsstrahlung to the dose in the target was estimated at distances from the target boundary to depths at which the dose exceeded half the dose at the target boundary (i.e., the energy release region is important for practical applications). This conclusion was formulated because the energy of the secondary bremsstrahlung decreases with decreasing electron energy and the atomic number of the target material.

4.2. Experimental Set Up

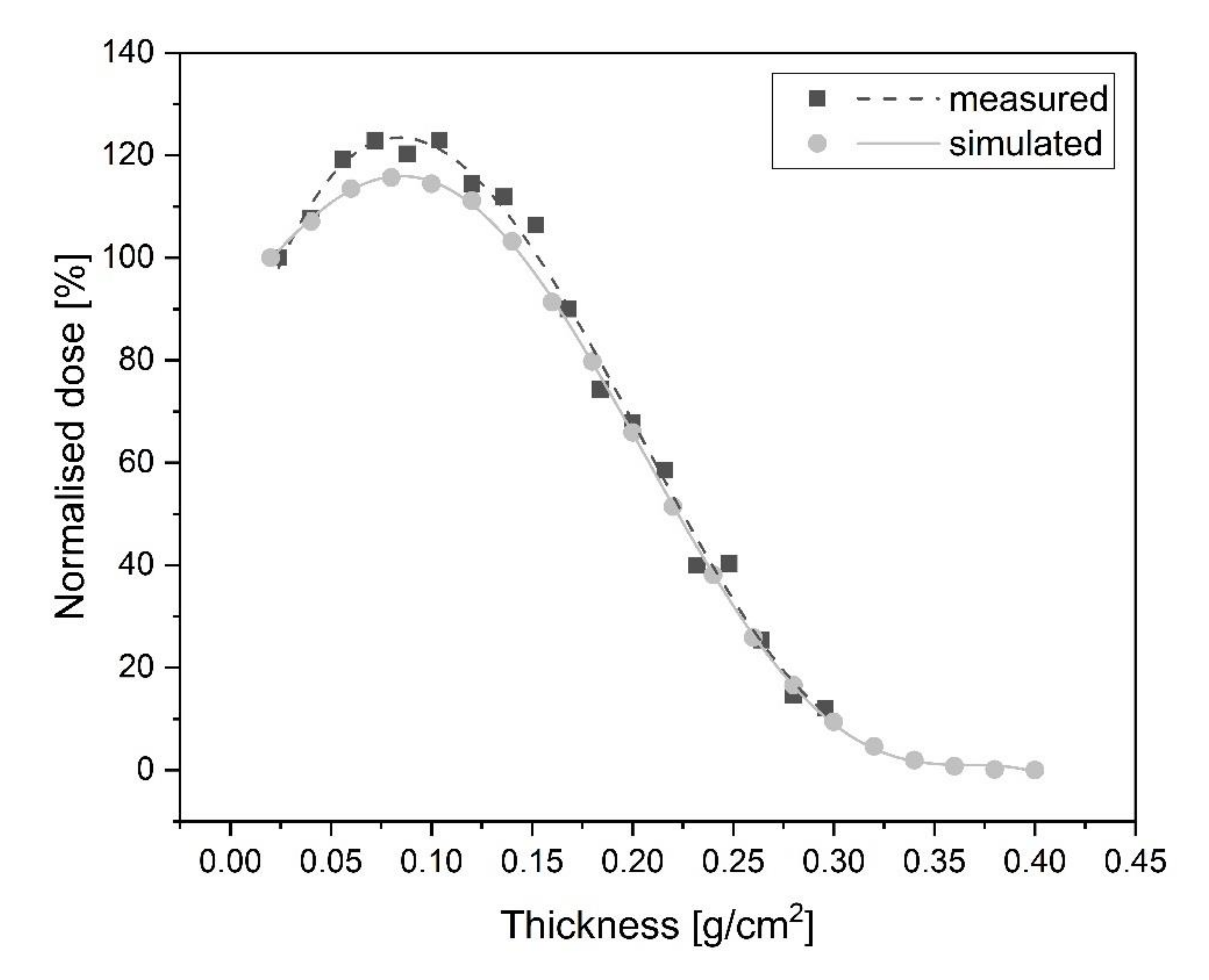

For the projected installation, the test measurements were performed on the pilot installation equipped with ILU 6 (INP, Russia) accelerator at INCT, Warsaw. The accelerator can emit beam of electrons of energy ranging from 0.2 to 2 MeV, average beam power up to 20 kW and can be used for polymers modification, liquids irradiation and gas treatment. The parameters of the beam in experiments were accelerating voltage—930 keV, beam current—1 mA, sweep width—50 cm. The parameters of experiments were selected taking into account the expected range of electrons in a commercial facility and absorption of electrons energy in an accelerator window, air in distance from accelerator widow to the irradiated surface as well or other used coverages. Penetration ability of electron beam was measured using stack of CTA dosimetric foil.

To model irradiation conditions in the target installation, the range of generated electromagnetic radiation was estimated for two target materials. One was water, a medium which will be treated in the projected installation and the second one was steel, a constructing material considered as a main source of generated bremsstrahlung radiation. In the experiments, a 0.5 mm thick steel plate with an average density 7.5 g/cm3 or 5 mm thick water layer were used. The properties of both materials provided complete absorption of the electron energy and the measured doses resulted from the bremsstrahlung effect. The measurements were performed using alanine dosimeters located under the target, in a distance of 20 cm and 1 m from accelerator window at floor, target and accelerator window levels

4.3. Dosimetry Methods

Absorbed dose rate measurements of X-rays generated were performed using alanine dosimeters. Alanine pellets (E2203, Aerial, France) had a diameter of 4 mm, a thickness of 2.35 mm and an average mass of 36.35 mg. The irradiated alanine dosimeters were placed in a quartz measuring tube and were measured using an MS-5000 EPR spectrometer (Magnettech, Germany) equipped with a rectangular TE 102 cavity and operating in the X-band at approximately 9.2–9.6 GHz. Dosimeters were read out, setting up the following parameters: microwave power 10 mW, modulation amplitude 0.7 mT, sweep time 120 s, magnetic field range 330–333 mT. Taking into account the dependence of the EPR signal amplitude on the orientation of each sample inside the resonant cavity, each sample was read out two times by rotating it 90°. The peak-to-peak amplitude of the central line of the spectrum was applied as a measure of the signal intensity, being proportional to the absorbed dose. EPR spectrum measurements were performed using ESR-studio software supplied by the manufacturer.

Cellulose triacetate (CTA) is 125 µm film dosimeters (FujiFilm) which can be used for dose measurement, especially where an electron beam was used. The dose range in which CTA can be used cover doses from 5 up to 300 kGy. A CTA dosimeter is an accurate and precise film of which the optical density increases by radiation exposure. Before the irradiation net absorbance of CTA was measured. In order to determine depth dose cure of the electron in experimental conditions, the stack of CTA dosimetry foil was irradiated with a surface dose of about 50 kGy. Thirty minutes after exposure to irradiation the same dosimeters were read-out at 280 nm using a UV-Vis spectrophotometer (Jasco V-650). The results of the depth dose curve were normalized to the surface dose and presented as a percent of the surface dose.

7. Conclusions

The well-known feature of every electron beam irradiation facility is that X-rays are emitted, influencing requirements of the protective shielding construction. We have shown that in EB wastewater processing, determination of the X-rays filed is very important for the proper construction of the installation shielding and safe operation. Experiments carried out in this work confirmed that the reduction in X-ray emission can be achieved by the appropriate configuration of the irradiation process. The results of the mathematical modelling obtained for the experimental condition were in agreement with the experimental data. The distance of the wastewater stream from the accelerator window should be as short as possible to provide effective irradiation and limit X-ray emission. The width of the wastewater layer should be adjusted to the scanning length of the EB accelerator to minimize the amount of electrons energy which is absorbed by the constructing material of the irradiation chamber. Additionally, the location of water reservoir under the irradiation area and in the zone of the highest X-ray field would absorb scattered radiation significantly. Such an approach allows for the reduction in the thickness of the accelerator shielding, thus the cost of the whole installation also decreases considerably.

Many laboratory experiments on the application of an EB accelerator to wastewater of different origins treatment in order to achieve toxic compound degradation, harmful microbe elimination, or wastewater parameters improvement to facilitate further steps of its purification have been already described in the literature. However, there are still only a few industrial plants using this wastewater treatment technology on a large scale. The main obstacle to make EB wastewater treatment a more common method is the slow diffusion of a new innovative technology to the market. Still conventional, well-proven, but not always green and cheaper technologies are applied more willingly.

Lack of public acceptance for technologies employing radiation and problems with approval from authorities are also barriers delaying the successful adoption of the technology to the market.

While more and more investigations regarding the application of EB accelerators demonstrating its ability to decontaminate various wastewater streams and with wider demonstrations of the technology through pilot studies, presenting more data on the economic feasibility, observed effectiveness, and cost-saving technological solution that can be adopted on large scale, uptake is slow, but continuous implementation of the technology on the market seems to be inevitable.

One of the factors which can facilitate the diffusion of EB technology to the market is the reduction in the shielding for the backscatter, which highly contribute to the total price of the installation and increases the cost. On the basis of the obtained results, we conclude that X-ray emission can be greatly reduced with application of an appropriate under beam system; thus, shielding applied in electron accelerator water treatment installation may be thicker and made of steel, greatly reducing the size and cost of installation.

This project has received funding from the European Union’s Horizon 2020 Research and Innovation programme under Grant Agreement No 101004730. The work published as part of an international project co-financed by the program of the Minister of Science and Higher Education entitled "PMW" in the years 2021–2025; contract no.5180/H2020/2021/2.

This project has received funding from the European Union’s Horizon 2020 Research and Innovation programme under Grant Agreement No 101004730. The work published as part of an international project co-financed by the program of the Minister of Science and Higher Education entitled "PMW" in the years 2021–2025; contract no.5180/H2020/2021/2.