Designing Light for Night Shift Workers: Application of Nonvisual Lighting Design Principles in an Industrial Production Line

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

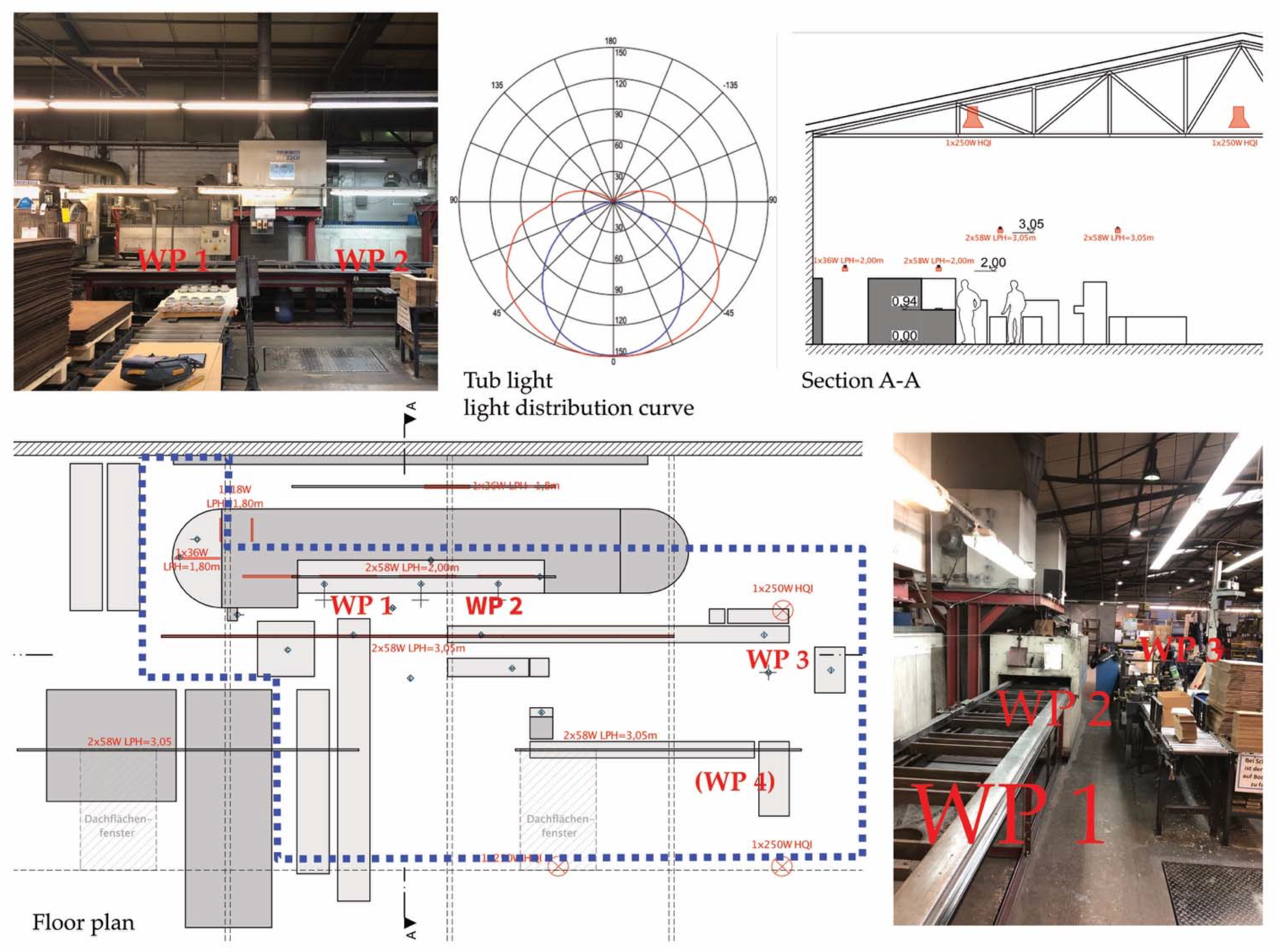

2.1. Project Description

2.2. Task Definition

2.3. Software and Measurement Equipment

2.4. Nonvisual Lighting Simulation

3. Results

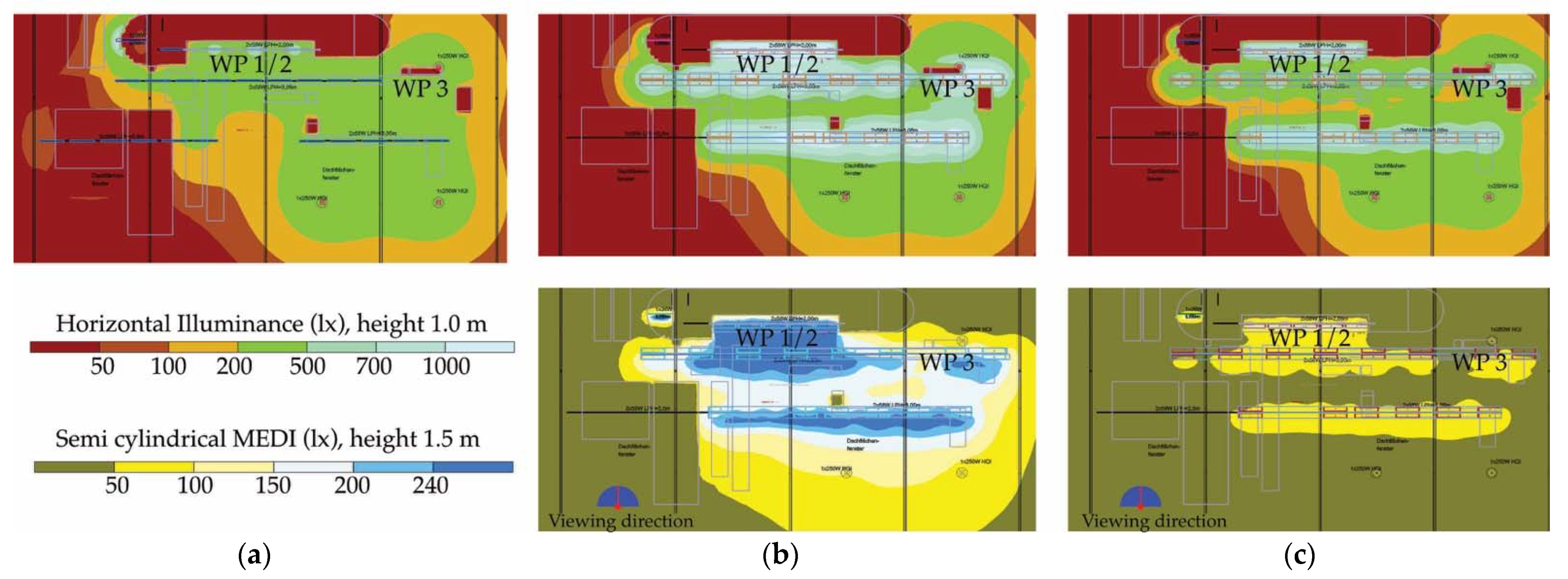

3.1. Stock Lighting Evaluation

3.1.1. Measurements

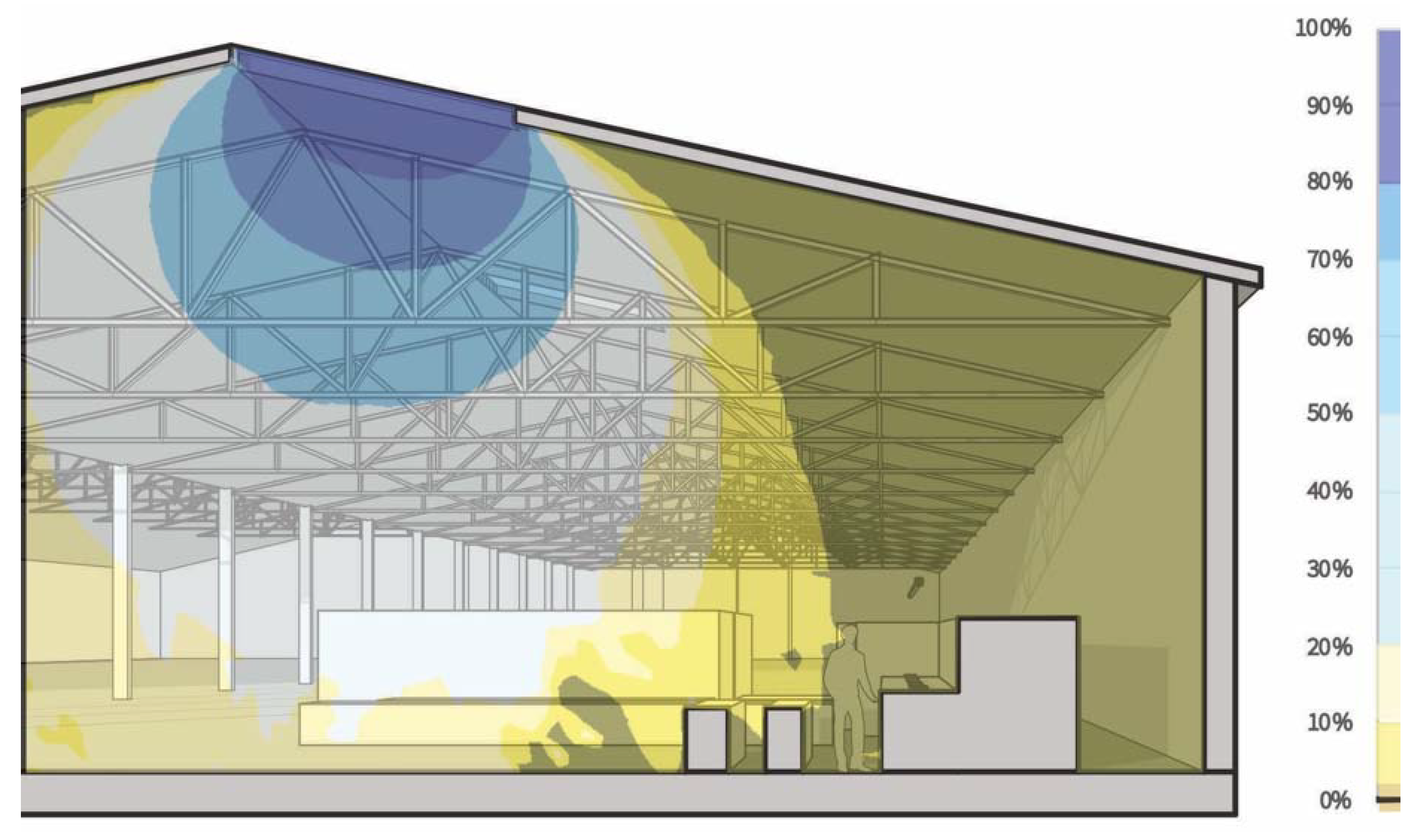

3.1.2. Daylight Simulation

3.1.3. Evaluation Result

3.2. Luminaire Drosa

3.3. Simulation

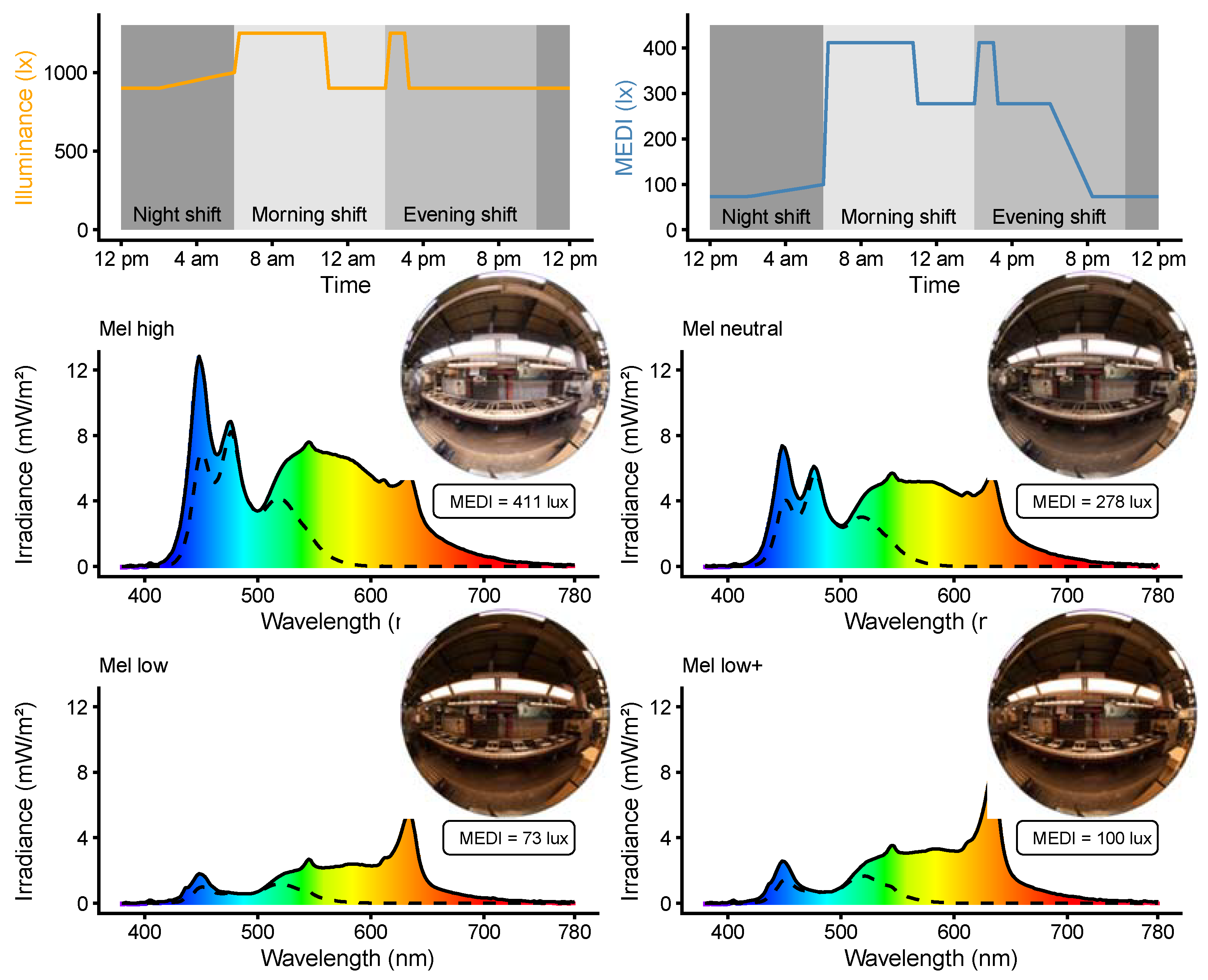

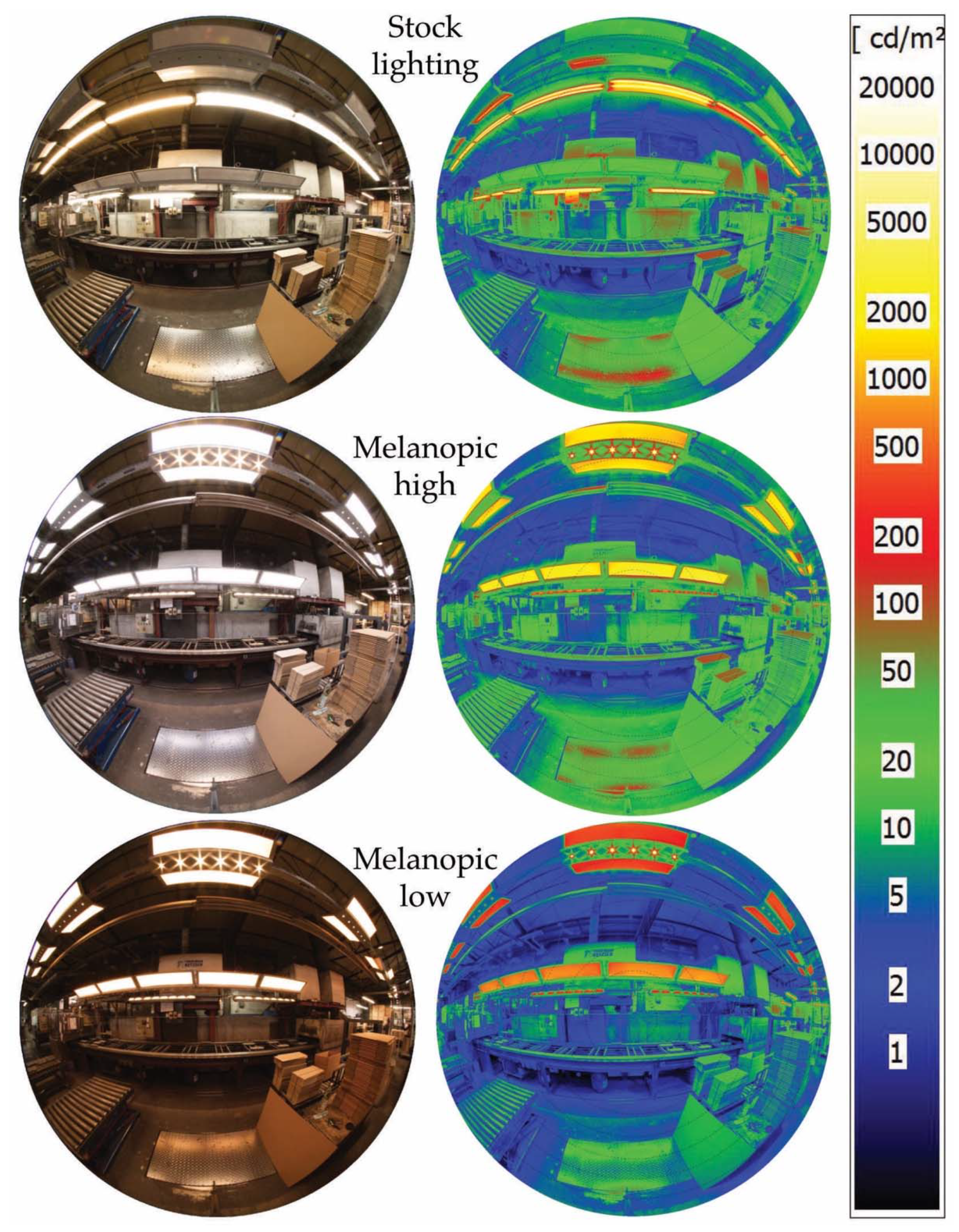

3.4. Spectral Illuminance Measurements, Automation Scenario, and Luminance Distribution

- From 6:15 a.m. to 10:45 a.m., the melanopic stimulus was set high for the morning shift for activation and synchronization (Mel high).

- From 11:00 a.m. to 2:00 p.m., the light was in a neutral setting for the morning shift (Mel neutral).

- From 2:15 p.m. to 3:15 p.m., the setting was identical to A., but for the evening shift for activation (Mel high).

- From 3:30 p.m. until one hour before sundown, the setting was identical to B., but for the evening shift (Mel neutral).

- From one hour after sunset, until 2:00 a.m., the melanopic stimulus was set minimal for the night shift (Mel low).

- At 6:00 a.m., the melanopic stimulus was still set low, but higher compared to E (Mel low+).

4. Discussion

4.1. Nonvisual Lighting Simulation

4.2. Lighting Design and Automation Rationale

- Provide an activating and synchronizing stimulus during the morning hours. According to the technical specification DIN SPEC 67600 [29], a melanopic stimulus of 240 lx MEDI is recommended for synchronization, and it activates the user by increasing alertness, wellbeing, and performance. The specification predates the MEDI notation; therefore, the recommendation was converted from 250 lx at 8000 K fluorescent light. Khalsa et al. [17] showed that the morning hours are best to phase shift the internal clock backward, with a phase response curve constructed from a laboratory experiment. This is supposed to counter opposing phase shifts through light and activity at night.

- Provide an activating and circadian amplitude strengthening stimulus at the beginning of the evening shift. The activating effect mirrors the one in the morning. At that time of day, workers would also still be able to receive at least similar levels of daylight, if they were outside. Kozaki et al. [18] showed that increased daytime illuminance reduces the suppression of melatonin through the light the following night. This stimulus might similarly benefit the workers in our project.

- At night (starting at one hour after sunset), the melanopic stimulus is to be minimal. This reduces both the suppression of melatonin and the forward phase shift induced by light at night [50,51]. On the negative side, the stronger activating effect of the stock lighting is also reduced. As a target stimulus, we set 100 lx as the upper threshold. While there is no recommendation for this particular value, we decided on it as a realistic lower threshold regarding the high visual illuminance requirement (Table 1) [26].

- Starting with the middle of the night shift, the visual stimulus is increased to promote alertness. Sleepiness inevitably rises during the night shift [49]. Some studies show, however, that alertness can be increased by a brighter light, independent of the melanopic stimulus and its detrimental effect on phase shift and melatonin suppression at night [50,52,53]. We do not expect this effect to fully compensate for the increasing sleepiness during the shift, but it might have an attenuating effect. If possible, the melanopic stimulus should not cross the threshold of 100 lx set for the night.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Nonvisual Lighting Simulation Process

References

- Patke, A.; Young, M.W.; Axelrod, S. Molecular mechanisms and physiological importance of circadian rhythms. Nat. Rev. Mol. Cell Biol. 2020, 21, 67–84. [Google Scholar] [CrossRef] [PubMed]

- Foster, R.G. Sleep, circadian rhythms and health. Interface Focus 2020, 10, 20190098. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Walker, W.H., II; Walton, J.C.; DeVries, A.C.; Nelson, R.J. Circadian rhythm disruption and mental health. Transl. Psychiatry 2020, 10, 28. [Google Scholar] [CrossRef] [Green Version]

- Schilperoort, M.; Rensen, P.C.; Kooijman, S. Time for Novel Strategies to Mitigate Cardiometabolic Risk in Shift Workers. Trends Endocrinol. Metab. 2020, 31, 952–964. [Google Scholar] [CrossRef] [PubMed]

- Stevens, R.G.; Hansen, J.; Costa, G.; Haus, E.; Kauppinen, T.; Aronson, K.J.; Castaño-Vinyals, G.; Davis, S.; Frings-Dresen, M.H.W.; Fritschi, L.; et al. Considerations of circadian impact for defining ‘shift work’ in cancer studies: IARC Working Group Report. Occup. Environ. Med. 2011, 68, 154–162. [Google Scholar] [CrossRef] [PubMed]

- Vetter, C. Circadian disruption: What do we actually mean? Eur. J. Neurosci. 2020, 51, 531–550. [Google Scholar] [CrossRef] [Green Version]

- Roenneberg, T.; Merrow, M. Entrainment of the Human Circadian Clock. Cold Spring Harb. Symp. Quant. Biol. 2007, 72, 293–299. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Foster, R. Fundamentals of circadian entrainment by light. Light. Res. Technol. 2021, 53, 377–393. [Google Scholar] [CrossRef]

- Hattar, S.; Liao, H.-W.; Takao, M.; Berson, D.M.; Yau, K.-W. Melanopsin-containing retinal ganglion cells: Architecture, projections, and intrinsic photosensitivity. Science 2002, 295, 1065–1070. [Google Scholar] [CrossRef] [Green Version]

- Berson, D.M.; Dunn, F.A.; Takao, M. Phototransduction by Retinal Ganglion Cells That Set the Circadian Clock. Science 2002, 295, 1070–1073. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lucas, R.J.; Peirson, S.N.; Berson, D.M.; Brown, T.; Cooper, H.M.; Czeisler, C.A.; Figueiro, M.G.; Gamlin, P.; Lockley, S.W.; O’Hagan, J.B.; et al. Measuring and using light in the melanopsin age. Trends Neurosci. 2014, 37, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Do, M.T.H.; Yau, K.-W. Intrinsically Photosensitive Retinal Ganglion Cells. Physiol. Rev. 2010, 90, 1547–1581. [Google Scholar] [CrossRef]

- Lasko, T.A.; Kripke, D.F.; Elliot, J.A. Melatonin Suppression by Illumination of Upper and Lower Visual Fields. J. Biol. Rhythm. 1999, 14, 122–125. [Google Scholar] [CrossRef] [PubMed]

- Thapan, K.; Arendt, J.; Skene, D.J. An action spectrum for melatonin suppression: Evidence for a novel non-rod, non-cone photoreceptor system in humans. J. Physiol. 2001, 535, 261–267. [Google Scholar] [CrossRef] [PubMed]

- Cajochen, C.; Münch, M.; Kobialka, S.; Kräuchi, K.; Steiner, R.; Oelhafen, P.; Orgül, S.; Wirz-Justice, A. High Sensitivity of Human Melatonin, Alertness, Thermoregulation, and Heart Rate to Short Wavelength Light. J. Clin. Endocrinol. Metab. 2005, 90, 1311–1316. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cajochen, C. Alerting effects of light. Sleep Med. Rev. 2007, 11, 453–464. [Google Scholar] [CrossRef] [PubMed]

- Khalsa, S.B.; Jewett, M.E.; Cajochen, C.; Czeisler, C.A. A Phase Response Curve to Single Bright Light Pulses in Human Subjects. J. Physiol. 2003, 549, 945–952. [Google Scholar] [CrossRef]

- Kozaki, T.; Kubokawa, A.; Taketomi, R.; Hatae, K. Effects of day-time exposure to different light intensities on light-induced melatonin suppression at night. J. Physiol. Anthropol. 2015, 34, 27. [Google Scholar] [CrossRef] [Green Version]

- Lowden, A.; Kecklund, G. Considerations on how to light the night-shift. Light. Res. Technol. 2021, 53, 437–452. [Google Scholar] [CrossRef]

- Brown, T.; Brainard, G.; Cajochen, C.; Czeisler, C.; Hanifin, J.; Lockley, S.; Lucas, R.; Munch, M.; O’Hagan, J.; Peirson, S.; et al. Recommendations for healthy daytime, evening, and night-time indoor light exposure. Preprints 2020. [Google Scholar] [CrossRef]

- Szkiela, M.; Kusideł, E.; Makowiec-Dąbrowska, T.; Kaleta, D. Night Shift Work—A Risk Factor for Breast Cancer. Int. J. Environ. Res. Public Health 2020, 17, 659. [Google Scholar] [CrossRef] [Green Version]

- CIE. CIE Position Statement—Proper Light at the Proper Time; CIE: Vienna, Austria, 2019; Available online: http://cie.co.at/publications/position-statement-non-visual-effects-light-recommending-proper-light-proper-time-2nd (accessed on 17 November 2021).

- DIN. DIN EN 12464-1:2011-08. Light and Lighting—Lighting of Work Places—Part 1: Indoor Work Places; Beuth Publishing Company: Berlin, Germany, 2011. [Google Scholar]

- CIE. CIE S 026/E:2018. CIE System for Metrology of Optical Radiation for ipRGC-Influenced Responses of Light; CIE: Vienna, Austria, 2018. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2017. [Google Scholar]

- Zauner, J.; Plischke, H.; Stijnen, H.; Schwarz, U.T.; Strasburger, H. Influence of common lighting conditions and time-of-day on the effort-related cardiac response. PLoS ONE 2020, 15, e0239553. [Google Scholar] [CrossRef]

- Plischke, H.; Linek, M.; Zauner, J. The opportunities of biodynamic lighting in homes for the elderly. Curr. Dir. Biomed. Eng. 2018, 4, 123–126. [Google Scholar] [CrossRef]

- DIN. DIN SPEC 5031-100:2020-05. DIN/TS 5031-100:2020-05—Draft Optical Radiation Physics and Illuminating Engineering—Part 100: Melanopic Effects of Ocular Light on Human Beings—Quantities, Symbols and Action Spectra; Beuth Publishing Company: Berlin, Germany, 2020. [Google Scholar]

- DIN. DIN SPEC 67600:2013-04. Biologically Effective Illumination—Design Guidelines; Beuth Publishing Company: Berlin, Germany, 2013. [Google Scholar]

- Available online: https://www.solemma.com/alfa (accessed on 17 November 2021).

- Available online: https://faculty.washington.edu/inanici/Lark/Lark_home_page.html (accessed on 17 November 2021).

- Available online: https://reluxnet.relux.com/ (accessed on 17 November 2021).

- Available online: https://www.dialux.com/ (accessed on 17 November 2021).

- Vangimalla, P.R.; Olbina, S.J.; Issa, R.R.; Hinze, J. Validation of Autodesk Ecotect™ accuracy for thermal and daylighting simulations. In Proceedings of the 2011 Winter Simulation Conference (WSC), Phoenix, AZ, USA, 11–14 December 2011. [Google Scholar]

- Knoop, M.; Stefani, O.; Bueno, B.; Matusiak, B.; Hobday, R.; Wirz-Justice, A.; Martiny, K.; Kantermann, T.; Aarts, M.P.; Zemmouri, N.; et al. Daylight: What makes the difference? Light. Res. Technol. 2019, 52, 423–442. [Google Scholar] [CrossRef] [Green Version]

- Mardaljevic, J. The implementation of natural lighting for human health from a planning perspective. Light. Res. Technol. 2021, 53, 489–513. [Google Scholar] [CrossRef]

- Dupláková, D.; Hatala, M.; Duplák, J.; Knapčíková, L.; Radchenko, S. Illumination simulation of working environment during the testing of cutting materials durability. Ain Shams Eng. J. 2019, 10, 161–169. [Google Scholar] [CrossRef]

- Dupláková, D.; Flimel, M.; Duplák, J.; Hatala, M.; Radchenko, S.; Botko, F. Ergonomic rationalization of lighting in the working environment. Part I: Proposal of rationalization algorithm for lighting redesign. Int. J. Ind. Ergon. 2019, 71, 92–102. [Google Scholar] [CrossRef]

- Acosta, I.; Leslie, R.; Figueiro, M. Analysis of circadian stimulus allowed by daylighting in hospital rooms. Light. Res. Technol. 2017, 49, 49–61. [Google Scholar] [CrossRef]

- Available online: https://www.radiance-online.org/community/workshops/2012-copenhagen/Day1/Jakubiec/jakubiec%2Creinhart_radiance-workshop-presentation_daysim.pdf (accessed on 17 November 2021).

- Bellia, L.; Pedace, A.; Fragliasso, F. Indoor lighting quality: Effects of different wall colours. Light. Res. Technol. 2017, 49, 33–48. [Google Scholar] [CrossRef]

- Konis, K. A novel circadian daylight metric for building design and evaluation. Build. Environ. 2017, 113, 22–38. [Google Scholar] [CrossRef]

- Cai, W.; Yue, J.; Dai, Q.; Hao, L.; Lin, Y.; Shi, W.; Huang, Y.; Wei, M. The impact of room surface reflectance on corneal illuminance and rule-of-thumb equations for circadian lighting design. Build. Environ. 2018, 141, 288–297. [Google Scholar] [CrossRef]

- Potočnik, J.; Košir, M. Influence of commercial glazing and wall colours on the resulting non-visual daylight conditions of an office. Build. Environ. 2020, 171, 106627. [Google Scholar] [CrossRef]

- Brown, T.M. Melanopic illuminance defines the magnitude of human circadian light responses under a wide range of conditions. J. Pineal Res. 2020, 69, e12655. [Google Scholar] [CrossRef] [Green Version]

- Glickman, G.; Hanifin, J.P.; Rollag, M.D.; Wang, J.; Cooper, H.; Brainard, G.C. Inferior Retinal Light Exposure Is More Effective than Superior Retinal Exposure in Suppressing Melatonin in Humans. J. Biol. Rhythm. 2003, 18, 71–79. [Google Scholar] [CrossRef]

- Spitschan, M. Photoreceptor inputs to pupil control. J. Vis. 2019, 19, 5. [Google Scholar] [CrossRef] [Green Version]

- Zeitzer, J.; Dijk, D.; Kronauer, R.E.; Brown, E.N.; Czeisler, C.A. Sensitivity of the human circadian pacemaker to nocturnal light: Melatonin phase resetting and suppression. J. Physiol. 2000, 526, 695–702. [Google Scholar] [CrossRef]

- Sletten, T.L.; Raman, B.; Magee, M.; Ferguson, S.A.; Kennaway, D.J.; Grunstein, R.R.; Lockley, S.W.; Rajaratnam, S.M. A Blue-Enriched, Increased Intensity Light Intervention to Improve Alertness and Performance in Rotating Night Shift Workers in an Operational Setting. Nat. Sci. Sleep 2021, 13, 647–657. [Google Scholar] [CrossRef]

- Regente, J.; de Zeeuw, J.; Bes, F.; Nowozin, C.; Appelhoff, S.; Wahnschaffe, A.; Münch, M.; Kunz, D. Can short-wavelength depleted bright light during single simulated night shifts prevent circadian phase shifts? Appl. Ergon. 2017, 61, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Smith, M.R.; Fogg, L.F.; Eastman, C.I. Practical Interventions to Promote Circadian Adaptation to Permanent Night Shift Work: Study 4. J. Biol. Rhythm. 2009, 24, 161–172. [Google Scholar] [CrossRef] [PubMed]

- Figueiro, M.G.; Sahin, L.; Wood, B.; Plitnick, B. Light at Night and Measures of Alertness and Performance: Implications for shift workers. Biol. Res. Nurs. 2016, 18, 90–100. [Google Scholar] [CrossRef]

- Sahin, L.; Figueiro, M.G. Alerting effects of short-wavelength (blue) and long-wavelength (red) lights in the afternoon. Physiol. Behav. 2013, 116–117, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Rukmini, A.V.; Milea, D.; Aung, T.; Gooley, J.J. Pupillary responses to short-wavelength light are preserved in aging. Sci. Rep. 2017, 7, 43832. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Najjar, R.; Chiquet, C.; Teikari, P.; Cornut, P.-L.; Claustrat, B.; Denis, P.; Cooper, H.M.; Gronfier, C. Aging of Non-Visual Spectral Sensitivity to Light in Humans: Compensatory Mechanisms? PLoS ONE 2014, 9, e85837. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Reading, V.M. Disability glare and age. Vis. Res. 1968, 8, 207–214. [Google Scholar] [CrossRef]

- DIN. Complementary Criteria for Lighting Design and Lighting Application with Regard to Non-Visual Effects of Light (DIN/TS 67600); DIN: Berlin, Germany, 2021; Available online: https://www.din.de/en/getting-involved/standards-committees/fnl/projects/wdc-proj:din21:342757492?destinationLanguage=&sourceLanguage= (accessed on 17 November 2021).

- CIE. ISO/CIE 11664-1:2019(E). Colorimetry—Part 1: CIE Standard Colorimetric Observers; CIE: Vienna, Austria, 2019. [Google Scholar]

- CIE. ISO 15469:2004 (E)/CIE S 011/E:2003. Spatial Distribution of Daylight—CIE Standard General Sky; CIE: Vienna, Austria, 2003. [Google Scholar]

| Description/Workplace 1 | Required Task Illuminance 2 (lx) | Stock Task Illuminance 3 (lx) | Stock Vertical Illuminance 3,4 (MEDI, lx) |

|---|---|---|---|

| Quality Control/1, 2 | 750 | 628–979 | 288–323 |

| Packaging/3 (4, seldom) | 300 | 311–366 | 75 |

| Movement area/- | 150 | 284–496 | not measured |

| Melanopic Setting | Quality Control | Packaging |

|---|---|---|

| Vertical MEDI (lx) 1 without/with FOV 4 | ||

| high | 412/398 | 324/151 |

| neutral | 278/268 | 158/110 |

| low | 73/70 | 97/79 |

| low+ | 100/96 | 122/81 |

| background | 9/NA | 75/NA |

| Horizontal illuminance (lx) 2 | ||

| high | 1250 | 1350 |

| neutral | 900 | 650 |

| low | 900 | 300 |

| low+ | 1000 | 600 |

| CCT at eye level (K) | ||

| high | 6547 | 4444 |

| neutral | 5218 | 4491 |

| low | 3097 | 4042 |

| low+ | 3085 | 4077 |

| CCT of area component (K) | Typical dimming level ofdirect/area component 3 | |

| high | 7000 | 80%/80% |

| neutral | 5500 | 75%/60% |

| low | 3000 | 70%/25% |

| low+ | 3000 | 80%/35% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zauner, J.; Plischke, H. Designing Light for Night Shift Workers: Application of Nonvisual Lighting Design Principles in an Industrial Production Line. Appl. Sci. 2021, 11, 10896. https://doi.org/10.3390/app112210896

Zauner J, Plischke H. Designing Light for Night Shift Workers: Application of Nonvisual Lighting Design Principles in an Industrial Production Line. Applied Sciences. 2021; 11(22):10896. https://doi.org/10.3390/app112210896

Chicago/Turabian StyleZauner, Johannes, and Herbert Plischke. 2021. "Designing Light for Night Shift Workers: Application of Nonvisual Lighting Design Principles in an Industrial Production Line" Applied Sciences 11, no. 22: 10896. https://doi.org/10.3390/app112210896

APA StyleZauner, J., & Plischke, H. (2021). Designing Light for Night Shift Workers: Application of Nonvisual Lighting Design Principles in an Industrial Production Line. Applied Sciences, 11(22), 10896. https://doi.org/10.3390/app112210896