Simulation and Experimental Study of Light and Thermal Environment of Photovoltaic Greenhouse in Tropical Area Based on Design Builder

Abstract

:1. Introduction

2. Materials and Methods

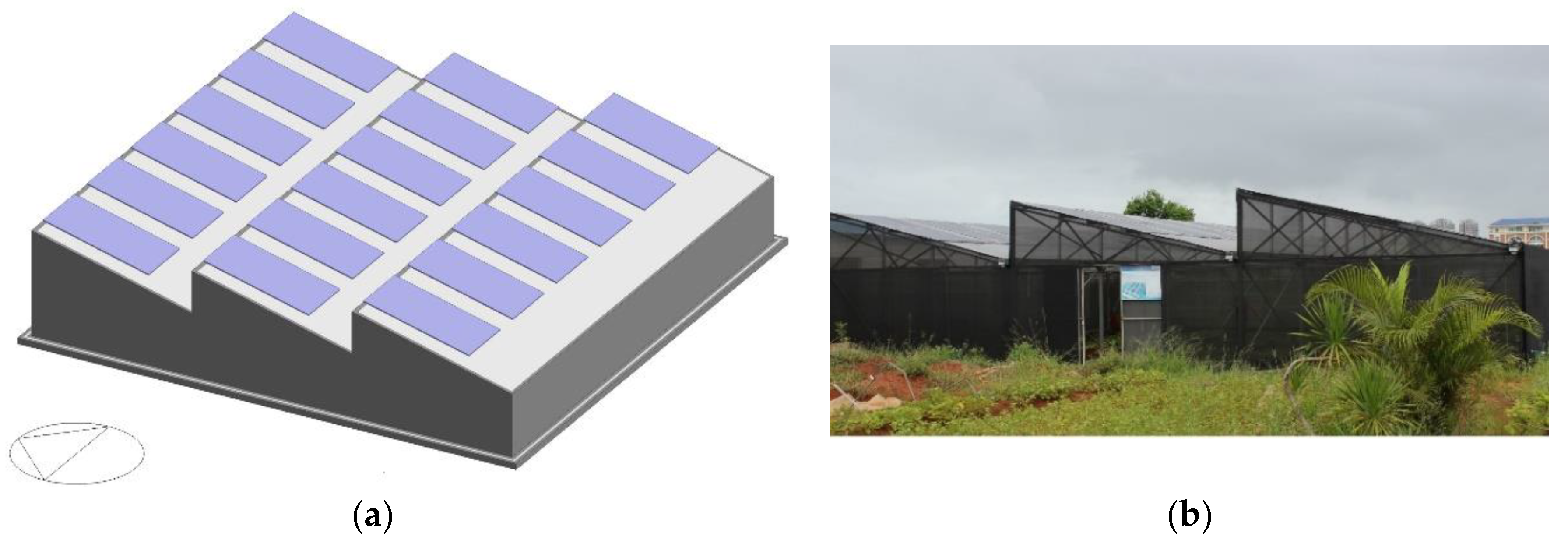

2.1. Experimental Photovoltaic Greenhouse

2.2. Test Instruments

2.3. Test Methods

2.3.1. Collection Time

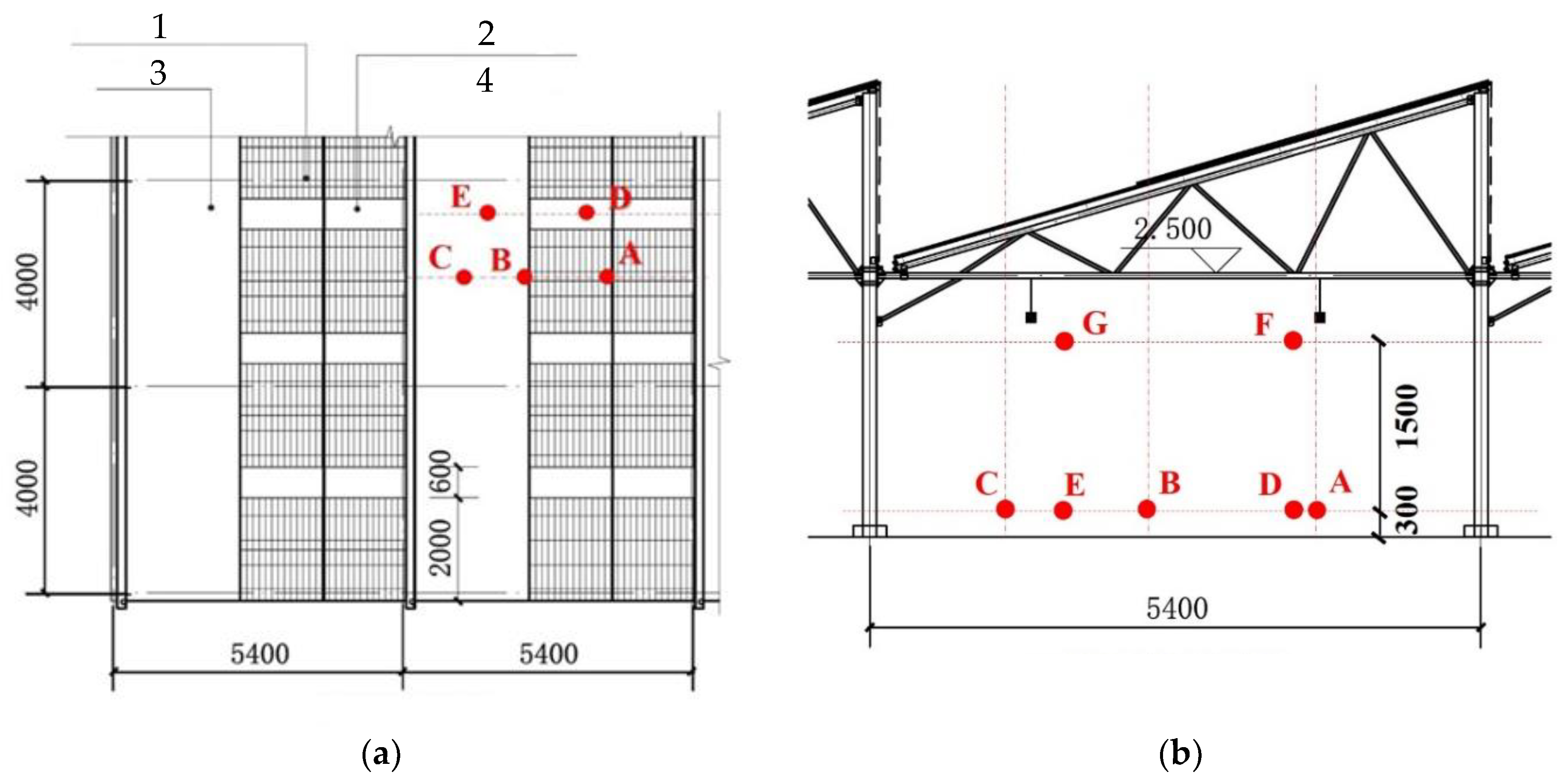

2.3.2. Illuminance Collection

2.3.3. Temperature and Humidity Data Collection

2.3.4. Contrast Greenhouse

2.3.5. Design Builder Simulation

3. Results and Analyses

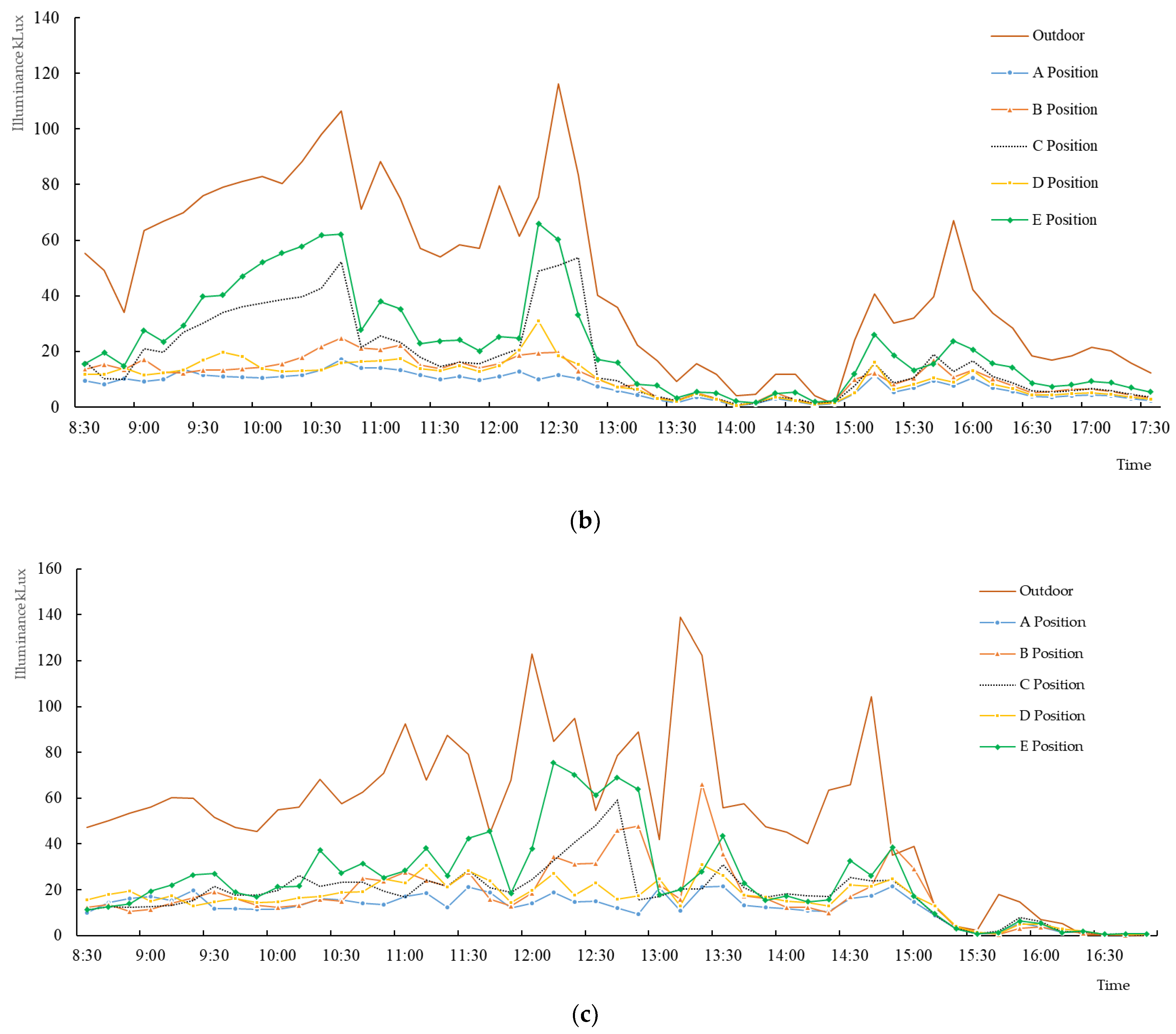

3.1. Illumination Analysis

3.1.1. Winter Illumination Analysis

3.1.2. Summer Illumination Analysis

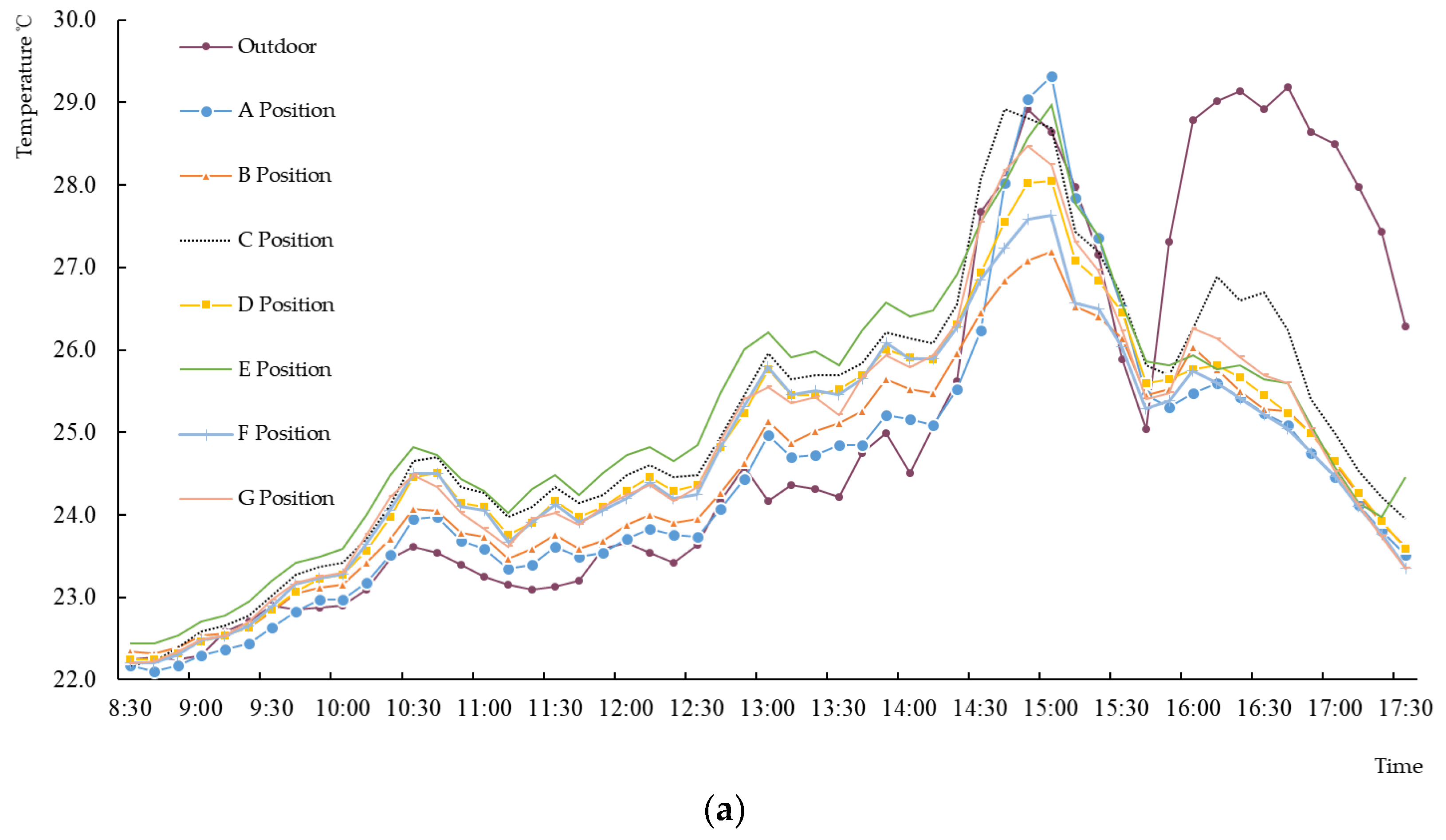

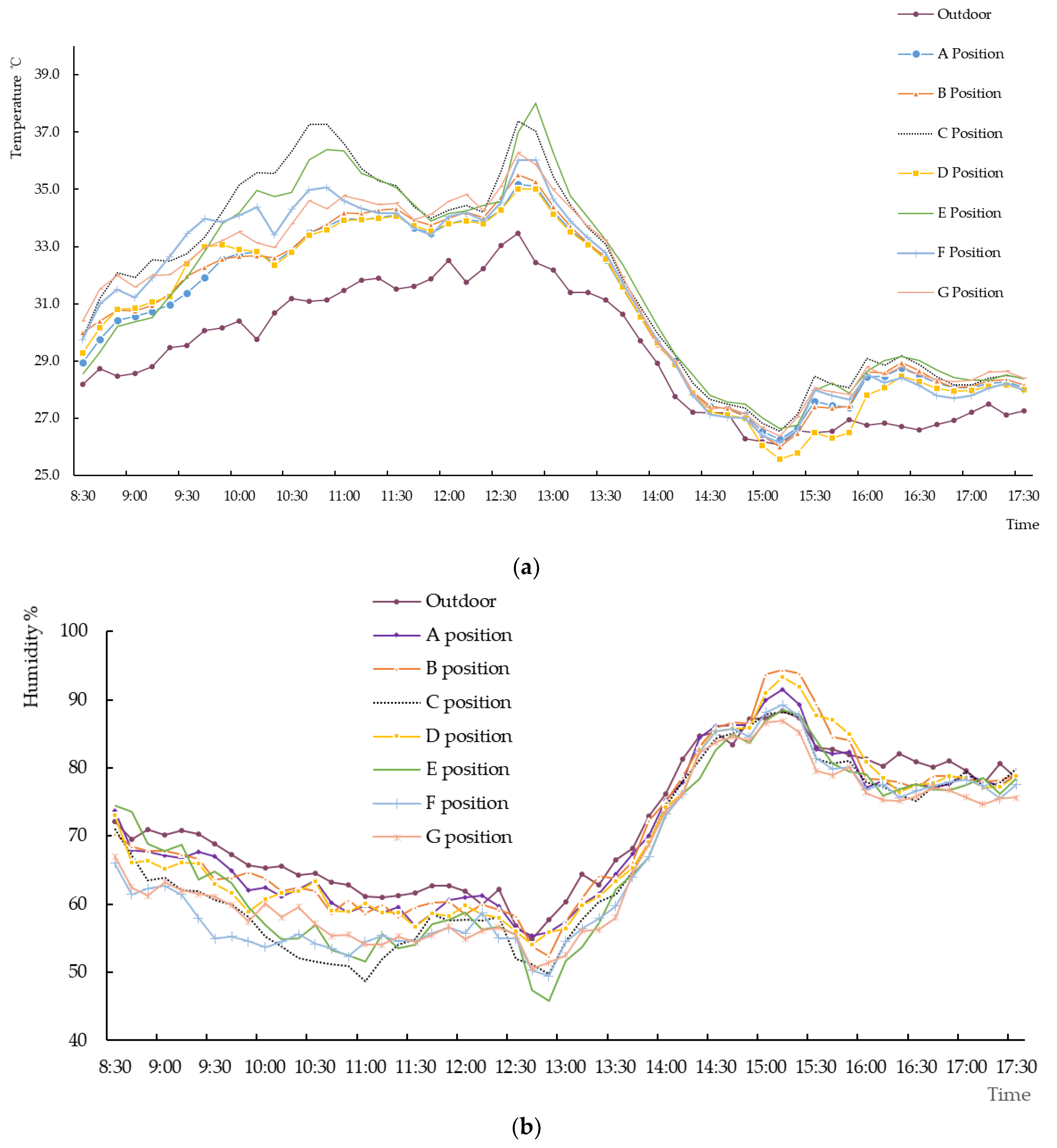

3.2. Temperature and Humidity Analysis

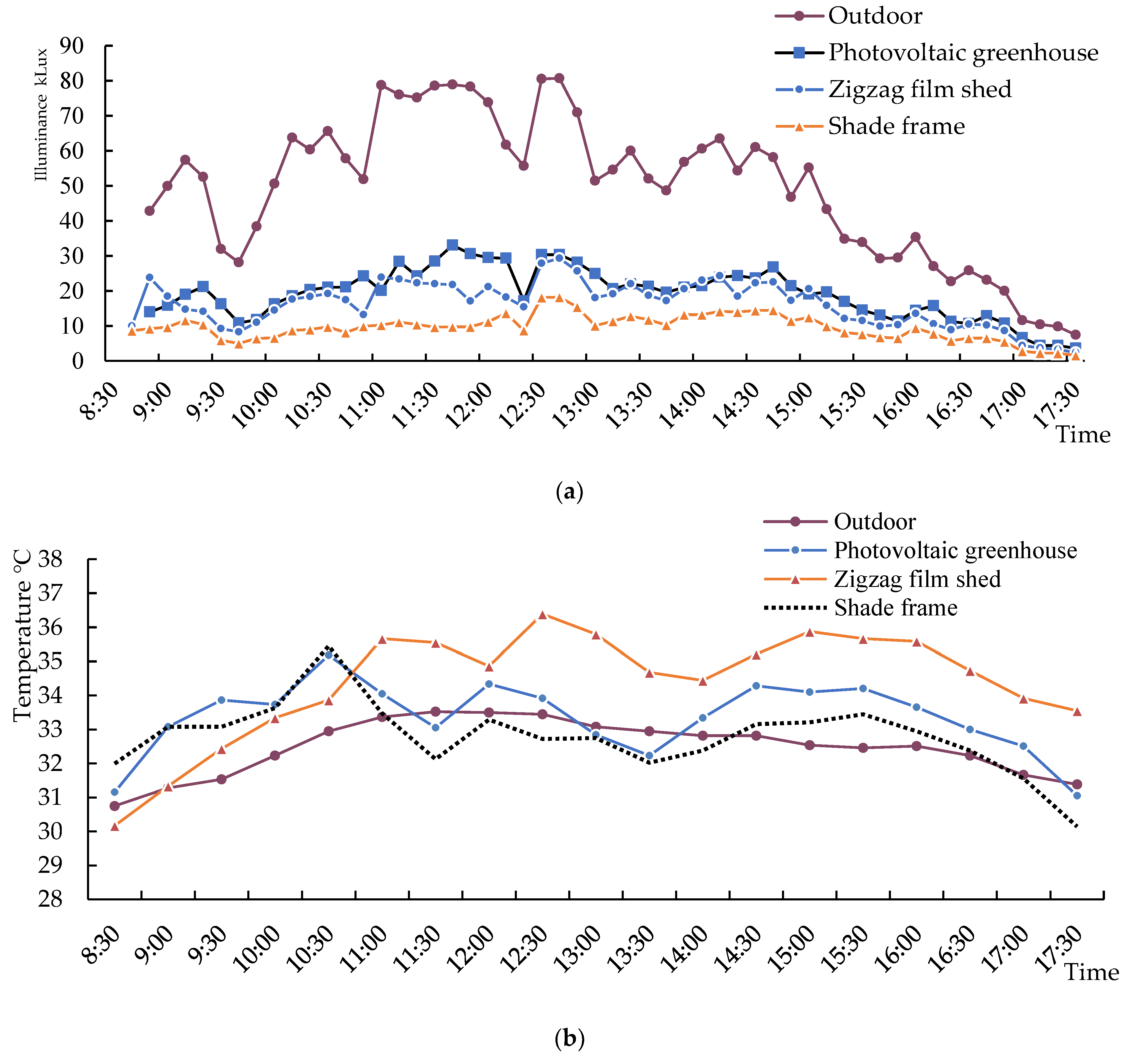

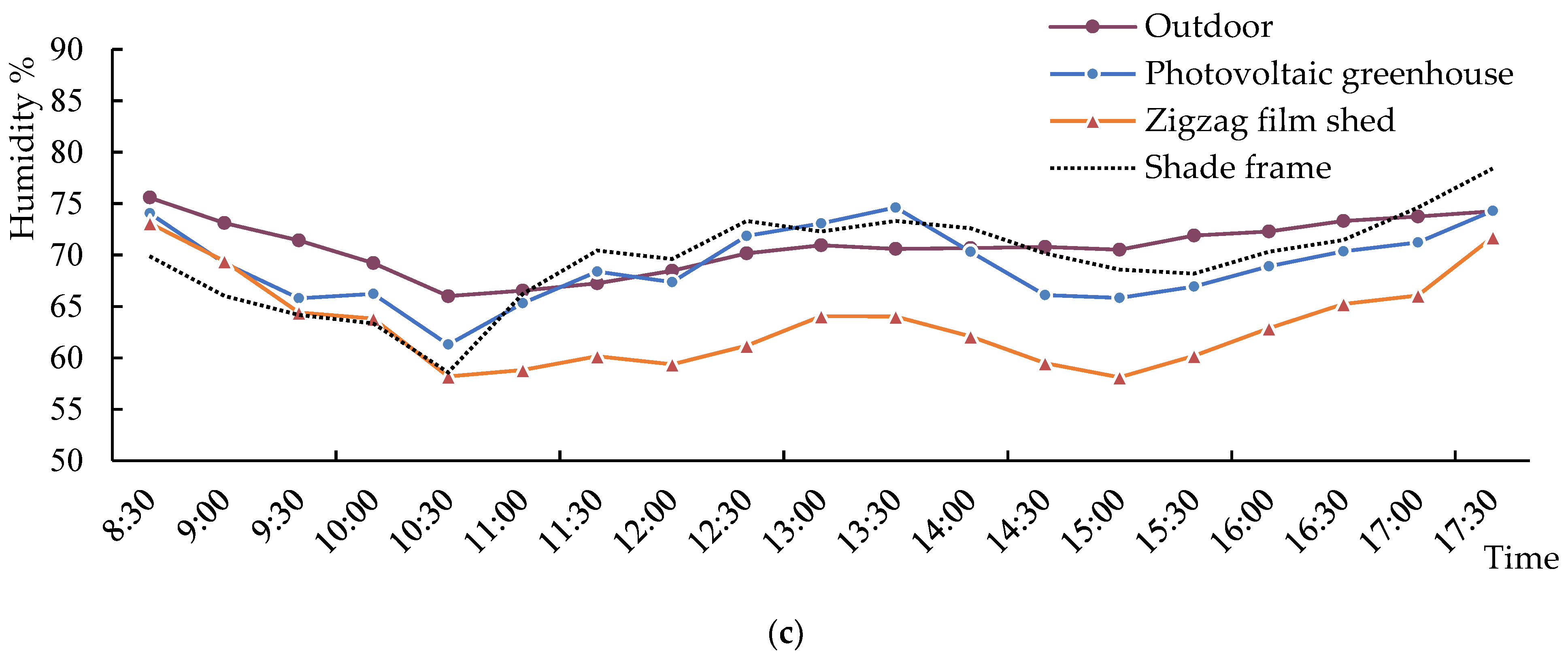

3.3. Analyses between the Photovoltaic Greenhouse and the Contrast Greenhouse

3.4. DesignBuilder Simulation Analysis

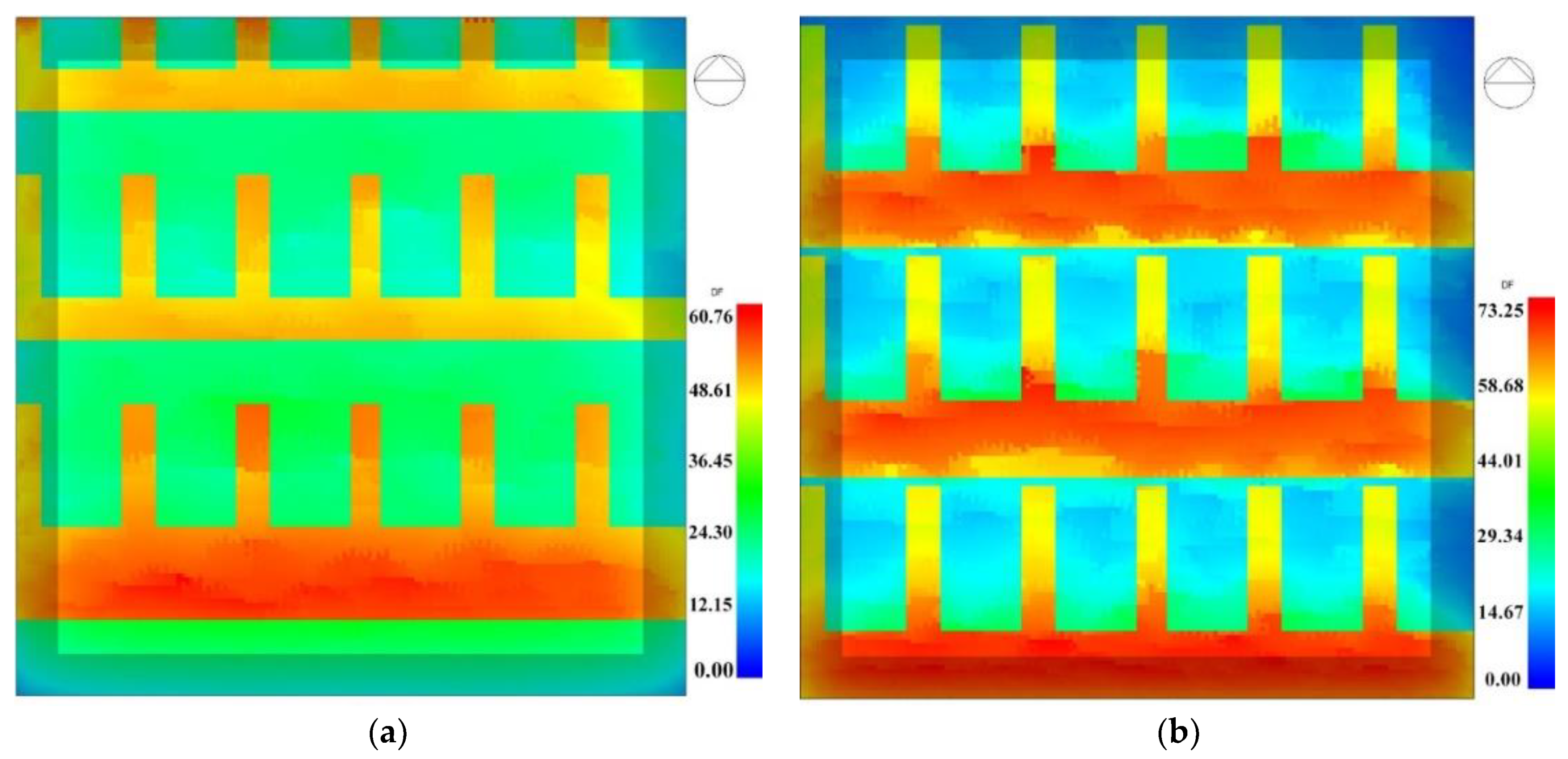

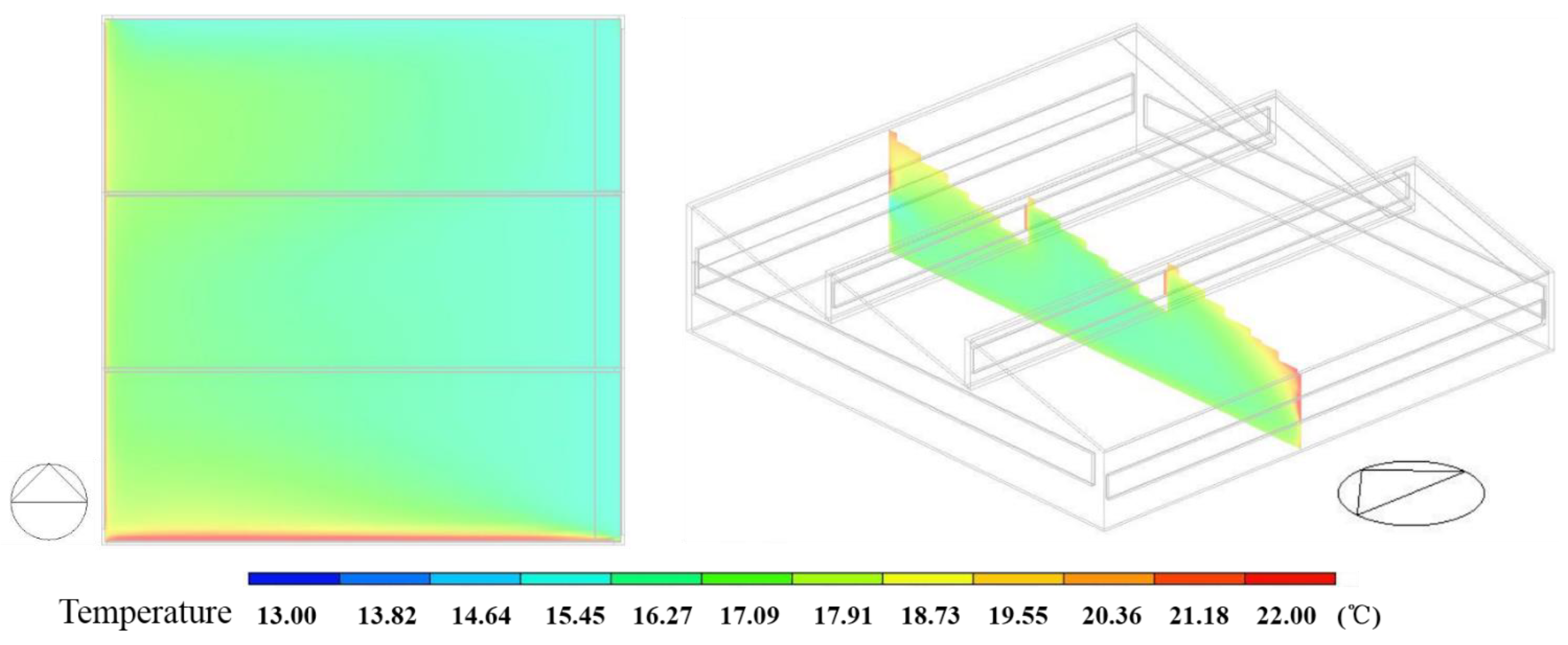

3.4.1. Light Environment Simulation

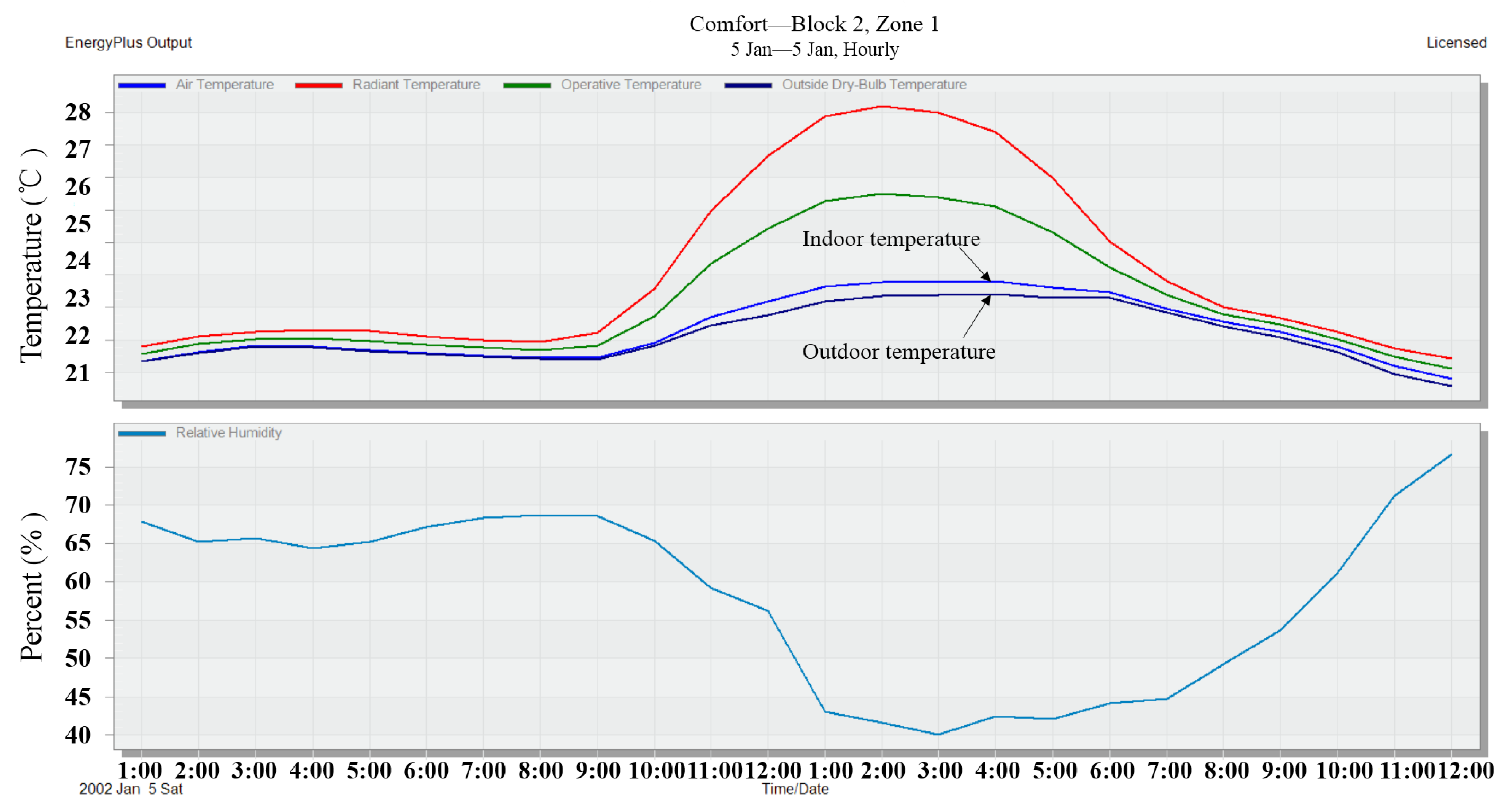

3.4.2. Thermal Environment Simulation

4. Discussion

4.1. Both Light and Temperature Factors Should Be Considered When Studying the Adaptivity of the Photovoltaic Greenhouse

4.2. Ventilation and Shading of Photovoltaic Greenhouses in Tropical Areas

5. Conclusions

5.1. The Indoor Illuminance, Temperature, and Humidity of a Photovoltaic Greenhouse Can Satisfy the Growth of Crops

5.2. Organic Combination of Greenhouse Production and Photovoltaic Power Generation

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, C. Doctor Zhou’s Investigation (29) Continuous innovation of Shouguang solar greenhouse in Shandong (2)—Development and application of solar photovoltaic greenhouse technology. Agric. Eng. Technol. Greenh. Hortic. 2013, 11, 40–41. [Google Scholar] [CrossRef]

- Zhou, C. Doctor Zhou’s Investigation (86) Photovoltaic solar greenhouse covered with photovoltaic modules and its performance. Agric. Eng. Technol. 2018, 38, 39–47. [Google Scholar]

- Zhou, C. Doctor Zhou’s Investigation (93) Diversified arrangement of photovoltaic modules in greenhouse—A case study of Nongguang Complementary Facilities Agricultural Industrial Park, Xintai city, Shandong Province. Agric. Eng. Technol. 2019, 39, 36–41. [Google Scholar]

- Qi, J.; Ca, L.; Li, J. Comparative study on the environment of different photovoltaic greenhouses and greenhouse in winter in Ningxia. Acta Agric. Zhejiangensis 2017, 29, 414–420. [Google Scholar] [CrossRef]

- Ezzaeri, K.; Fatnassi, H.; Wifaya, A.; Bazgaou, A.; Aharoune, A.; Poncet, C.; Bekkaoui, A.; Bouirden, L. Performance of photovoltaic canarian greenhouse: A comparison study between summer and winter seasons. Sol. Energy 2020, 198, 275–282. [Google Scholar] [CrossRef]

- Dong, W.; Zhou, Z.; Liu, W.; Tian, F.; Liu, S.; Zhao, J. Environment Condition Contrast between Indoor and Outdoor of Photovoltaic Greenhouse. Agric. Eng. 2015, 5, 44–48. [Google Scholar]

- Hassanien, R.; Ming, L.; Fang, Y. The integration of semi-transparent photovoltaics on greenhouse roof for energy and plant production. Renew. Energy 2018, 121, 377–388. [Google Scholar] [CrossRef]

- Fatnassi, H.; Poncet, C.; Bazzano, M.M.; Brun, R.; Bertin, N. A numerical simulation of the photovoltaic greenhouse microclimate. Sol. Energy 2015, 120, 575–584. [Google Scholar] [CrossRef]

- Fan, Y. Optimization of indoor thermal environment of traditional stone dwellings in South Shandong Based on Design Builder. In Proceedings of the 2020 International Conference on Green Building and Building Energy Conservation, Zurich, Switzerland, 27–28 July 2020; pp. 321–326. [Google Scholar]

- Song, T. Comparative study of building thermal simulation between DesignBuilder and Ecotect. Archit. Eng. Technol. Des. 2018, 2, 531–532. [Google Scholar] [CrossRef]

- Blanco, J.M.; Buruaga, A.; Rojí, E.; Cuadrado, J.; Pelaz, B. Energy assessment and optimization of perforated metal sheet double skin facades through Design Builder; A case study in Spain. Energy and Buildings. Energy Build. 2015, 111, 326–336. [Google Scholar] [CrossRef]

- Wang, C.; Wang, G. Study of Distribution Rule of Solar Energy Resources in Hainan. J. Hainan Norm. Univ. Nat. Sci. 2011, 24, 168–173. [Google Scholar]

- Liu, J. A Zigzag Multi-Span Photovoltaic Greenhouse for Agricultural Planting. China Patent ZL 201320738494.4, 14 January 2015. [Google Scholar]

- GB50797-2012. Code for Design of Photovoltaic Power Station; Ministry of Housing and Urban Rural Development of the People’s China: Beijing, China, 2012; pp. 101–102.

- Zhang, Y.; Zou, Z.; Bao, E.; Yang, Y.; Tang, Q. Experimental study and PAR Simulation of global transmittance of energy saving photovoltaic solar greenhouse. Agric. Eng. Technol. 2017, 37, 31–34. [Google Scholar] [CrossRef]

- Yan, D.; Xu, K.; Zhang, Q.; Li, X. Experimental study on wind load of insect repellent net with different mesh. Agric. Eng. Technol. 2020, 40, 57–63. [Google Scholar] [CrossRef]

- Zhao, X.; Zou, Z.; Xu, H.; Zhao, J.; Li, J. Effects of summer light environment on tomato growth in photovoltaic solar greenhouse. J. Northwest A F Univ. Nat. Sci. Ed. 2013, 41, 93–99. [Google Scholar] [CrossRef]

- Shu, S.; Yu, J.; Tao, M.; Yu, S.; Sun, J.; Guo, S. Effects of Photovoltaic Greenhouse on Growth. Photosynth. Qual. Pakchoi China Veg. 2017, 4, 44–47. [Google Scholar] [CrossRef]

- Zhang, Y. Effects of different color insect control nets on greenhouse coverage and growth of fast growing leaf vegetables. Shanghai Veg. 2000, 1, 32–34. [Google Scholar]

- Li, D.; Cai, X.; Fu, J. Comparison of several main wild vegetables and common leaf vegetables in Hainan Province. Heilongjiang Agric. Sci. 2014, 10, 168–169. [Google Scholar] [CrossRef]

| Outdoor | Site A | Site B | Site C | Site D | Site E | Compound Average | |

|---|---|---|---|---|---|---|---|

| Average light intensity (kLux) | 27.23 | 6.48 | 6.95 | 7.99 | 6.69 | 7.29 | 7.02 |

| Light transmittance | 23.79% | 25.53% | 29.35% | 24.56% | 26.77% | 25.77% |

| Date | Item | Outdoor | Site A | Site B | Site C | Site D | Site E | Compound Average |

|---|---|---|---|---|---|---|---|---|

| 28 July thundershower | Light intensity (kLux) | 34.04 | 8.30 | 12.33 | 15.13 | 10.32 | 19.39 | 12.53 |

| Light transmittance | 24.38% | 36.21% | 44.44% | 30.31% | 56.95% | 36.82% | ||

| 29 July thundershower to cloudy | Light intensity (kLux) | 51.43 | 8.47 | 12.28 | 19.10 | 11.41 | 26.16 | 14.18 |

| Light transmittance | 16.47% | 23.87% | 37.13% | 22.19% | 50.86% | 27.57% | ||

| 31 July cloudy and sunny | Light intensity (kLux) | 60.31 | 13.50 | 20.33 | 21.77 | 17.60 | 28.00 | 19.71 |

| Light transmittance | 22.38% | 33.71% | 36.09% | 29.19% | 46.43% | 32.67% | ||

| Average of the three days | Light intensity (kLux) | 48.60 | 10.09 | 14.98 | 18.66 | 13.11 | 24.52 | 15.47 |

| Light transmittance | 21.08% | 31.27% | 39.22% | 27.23% | 51.41% | 32.35% |

| 5 January 2016 | Outdoor | Site A | Site B | Site C | Site D | Site E | Site F | Site G | Indoor Average |

|---|---|---|---|---|---|---|---|---|---|

| Highest temperature (°C) | 29.2 | 29.3 | 27.2 | 28.9 | 28.0 | 29.0 | 27.6 | 28.5 | 28.4 |

| Lowest temperature (°C) | 22.3 | 22.1 | 22.3 | 22.2 | 22.3 | 22.4 | 22.2 | 22.2 | 22.2 |

| Highest relative humidity (%) | 95 | 96 | 96 | 97 | 97 | 94 | 96 | 95 | 95.8 |

| Lowest relative humidity (%) | 66 | 65 | 71 | 69 | 70 | 67 | 72 | 68 | 68.8 |

| 29 July | Outdoor | Site A | Site B | Site C | Site D | Site E | Site F | Site G | Indoor Average |

|---|---|---|---|---|---|---|---|---|---|

| Highest temperature (°C) | 33.5 | 35.2 | 35.5 | 37.4 | 35.0 | 38.0 | 36.0 | 36.3 | 36.2 |

| Lowest temperature (°C) | 26.1 | 26.3 | 26.0 | 26.5 | 25.6 | 26.6 | 26.2 | 26.4 | 26.2 |

| Highest relative humidity (%) | 88 | 91 | 94 | 88 | 93 | 88 | 89 | 87 | 90.3 |

| Lowest relative humidity (%) | 55 | 55 | 52 | 49 | 54 | 46 | 49 | 51 | 50.9 |

| 9 May 2015 | Outdoor | Photovoltaic Greenhouse | Zigzag-Film Greenhouse | Sunshelter |

|---|---|---|---|---|

| Average daylight illumination (kLux) | 49.56 | 21.51 | 18.17 | 10.66 |

| Light transmittance rate | 43.41% | 36.67% | 21.52% | |

| Highest temperature (°C) | 33.5 | 35.2 | 36.4 | 35.4 |

| Average temperature (°C) | 32.5 | 33.3 | 34.4 | 32.8 |

| Lowest temperature (°C) | 30.7 | 31.1 | 30.2 | 30.1 |

| Highest relative humidity | 76% | 75% | 73% | 78% |

| Average relative humidity | 71% | 69% | 63% | 70% |

| Lowest relative humidity | 66% | 61% | 58% | 59% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Chen, Y.; Wang, B.; Wu, X.; Na, Y. Simulation and Experimental Study of Light and Thermal Environment of Photovoltaic Greenhouse in Tropical Area Based on Design Builder. Appl. Sci. 2021, 11, 10785. https://doi.org/10.3390/app112210785

Liu J, Chen Y, Wang B, Wu X, Na Y. Simulation and Experimental Study of Light and Thermal Environment of Photovoltaic Greenhouse in Tropical Area Based on Design Builder. Applied Sciences. 2021; 11(22):10785. https://doi.org/10.3390/app112210785

Chicago/Turabian StyleLiu, Jian, Yini Chen, Baolong Wang, Xuyong Wu, and Yi Na. 2021. "Simulation and Experimental Study of Light and Thermal Environment of Photovoltaic Greenhouse in Tropical Area Based on Design Builder" Applied Sciences 11, no. 22: 10785. https://doi.org/10.3390/app112210785

APA StyleLiu, J., Chen, Y., Wang, B., Wu, X., & Na, Y. (2021). Simulation and Experimental Study of Light and Thermal Environment of Photovoltaic Greenhouse in Tropical Area Based on Design Builder. Applied Sciences, 11(22), 10785. https://doi.org/10.3390/app112210785