Abstract

In this study, an engineering characteristic test was conducted on cement milk using expansive additives during the construction of bored piles. Expansive additive mixtures with various mixing ratios were prepared according to the construction standards of the Korea Expressway Corporation. Segregation resistance, compressive strength, frictional resistance stress, scanning electron microscope images, porosity, and economic feasibility were analyzed. It was found that segregation effects due to expansive additive incorporation were insignificant, and it was confirmed that all specimens exceeded 0.5 N/mm2, the compressive strength standard of the Korea Expressway Corporation pile bearing capacity. Given a water–binder ratio of 83% mixed with 10% expansive additives, frictional resistance increased up to ~35%, skin friction force was significantly improved, and a cost-saving effect of up to ~33.24% was achieved.

1. Introduction

As recent buildings have become larger and taller, pile foundations have seen wider use [1,2]. The driven pile method, a technology introduced earlier in history, inserts piles by applying percussion or vibration [3]. Although it is advantageous in terms of support and material economy, the method also causes social problems due to severe noise and vibration [3,4,5]. With the enforcement of Korea’s Noise and Vibration Control Act in the 1990’s, the low-noise and low-vibration bored pile method has attracted attention [6,7,8]. The bored pile method drills the ground in advance, as deep as the length of a precast pile, before pile insertion [9]. The method started in Japan during the early 1980’s, and it has been modified for use in Korea’s construction conditions [10]. The most common variations used in Korea are the soil–cement injected precast pile method, special auger and injected precast pile method, separated doughnut auger method, percussion rotary drill method, and Correx method [11]. According to the Korea Expressway Corporation, the 3-year span of 2008–2010 saw 92.5% of steel pipe piles for highway bridges constructed using the bored pile method [12]. In particular, the separated doughnut auger method (55.6%) and the special auger and injected precast pile method (36.8%) are mainly used [12] among the variations. General construction using the bored pile method involves drilling the ground 100 mm larger than the diameter of the precast pile. Injecting a thin cement paste called “cement milk” before and after inserting the pile improves the stability and bearing capacity of the excavation wall [9]. The bearing capacity of the bored pile includes the end bearing capacity supported by the pile end’s bottom and skin friction force (a frictional force acting along the pile surface). According to previous studies conducting static load tests, the share of a pile’s skin friction force in relation to its total bearing capacity accounts for 66–97% of the capacity, making skin friction force one of the important considerations in structural foundation design [13].

Generally, ordinary Portland cement has been used without admixture as a filling material for each bored pile. Occasionally, blast furnace slag cement is used as a filling material to improve long-term strength, chemical resistance, and seawater resistance along with cost reduction. However, the use of blast furnace slag reduces effectiveness due to a decrease in early age strength and an increase in shrinkage [14]. In addition, to effectively use construction waste, recycled solidified soil from sludge is used as a filling material and thickener is used to prevent soil loss around buried piles by increasing the viscosity, thereby reducing the consumption of cement [15]. However, applying these techniques is not useful and is mostly considered from an environmental point of view. Therefore, this study focused on cost reduction and ensured the rigidity of the bored pile by using the expansive additive as an admixture to increase the skin friction force. Meanwhile, expansive additives mainly produce calcium hydroxide or ettringite during the early stages of hydration reactions [16,17]. This production expands the matrix and reduces matrix cracking due to compressive force [16,18]. If expansive additives are added to cement milk used in bored pile construction, knowing the addictive characteristics can ensure that the compressive force applied to the principal plane of the piles is expansive while also ensuring that pores are sealed during hardening [9]. It is thought that this can improve pile bearing capacity.

Thus, in this study, the applicability of using expansive additives to increase bored pile bearing capacity was examined. Segregation resistance, compressive strength, frictional resistance stress, scanning electron microscope (SEM) images, porosity, and economic feasibility were analyzed by adding expansive additives to cement milk.

2. Materials and Methods

2.1. Experiment Outline

Table 1 shows the experimental plan. The water–binder (W/B) ratio was set to two levels, 70% and 83%, which are commonly used by the Korea Expressway Corporation and the Korea Land and Housing Corporation based on the basic Design Guide for the foundation (2015). An expansive additive, calcium sulfoaluminate, was mixed into the cement in 0%, 5%, 10%, and 15% proportions based on the cement weight after being mixed with water for 1 min. Test specimens were prepared according to each mixing ratio to evaluate the segregation resistance, compressive strength, frictional resistance stress, SEM images, porosity, and economic feasibility of the filling material for each bored pile. All experiments were conducted under an environment of 60 ± 5% relative humidity and temperature of 20 ± 2 °C.

Table 1.

Experimental plan.

Table 2 shows the chemical properties of the cement and expansive additives used in the experiment.

Table 2.

Materials used.

2.2. Experiment Method

2.2.1. Segregation Resistance

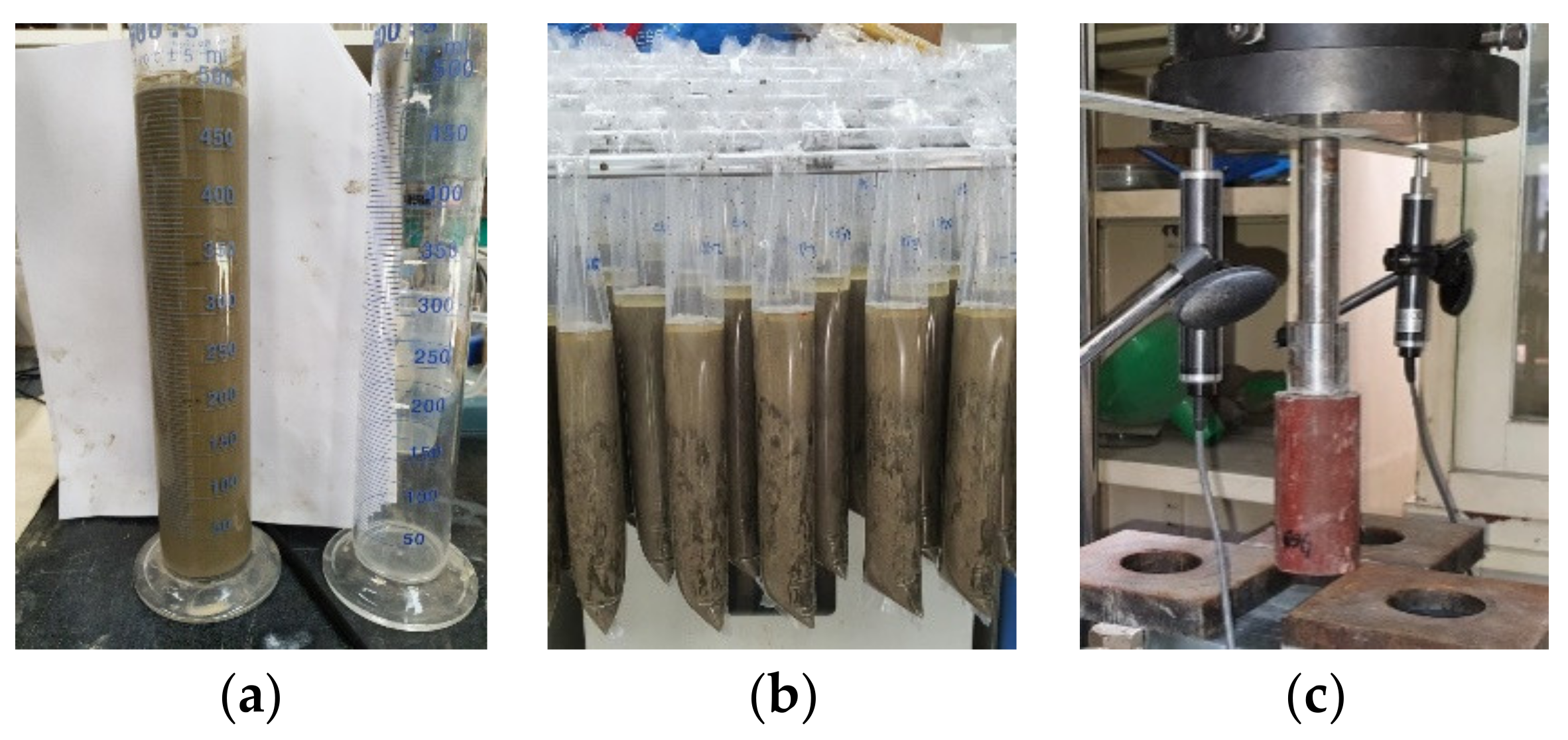

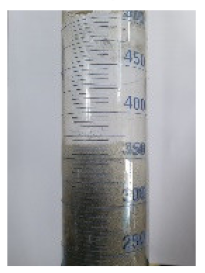

To measure the segregation resistance in W/B 83% (a commonly used construction ratio), specimens containing 0% and 15% expansive additives were prepared. As shown in Figure 1a, after pouring cement milk into a 500 mL transparent beaker with a 50 mm diameter, the settlement was measured immediately after pouring and after 3 h, 24 h, and 28 days.

Figure 1.

(a) Segregation Resistance; (b) Compressive Strength; (c) Frictional Resistance.

2.2.2. Compressive Strength

To measure compressive strength, specimens were manufactured by referring to the “Strength Test Method of Side Fixing Materials and Tip Fixing Materials for Bored Piles” of the previous study [11]. As shown in Figure 1b, the bottom of a polyethylene bag with an inner diameter of 5 cm was sealed and the filling height was marked at a height of 30 cm, and the polyethylene bag was fixed to the rod. After fixing the funnel at the entrance of the polyethylene bag, cement paste was injected each at a height of 30 cm in consideration of the height of the finally hardened specimen being ~25–30 cm. After curing at room temperature (60 ± 5% RH, 20 ± 2 °C) for 3 days, the lower 10 cm of each cured specimen deformed by the weight of the cement paste was removed, and another 10 cm was cut from the cut surface, followed by water curing at 20 °C. The compressive strength of each specimen was subsequently measured at ages of 3, 7, and 28 days using a hydraulic universal testing machine.

2.2.3. Frictional Resistance

To measure frictional resistance, a special steel pipe mold that simulates the conditions of the field was manufactured. The special steel pipe mold, composed of an outer diameter of 49 mm, inner diameter of 43 mm, thickness of 3 mm, and height of 100 mm, was washed with a neutral detergent to remove friction-related factors on the inner wall of the mold. Thereafter, cellophane paper was attached to the lower part of the pipe, and cement paste was injected up to a height of 100 mm. Three specimens were prepared for each mixing condition and cured at room temperature (60 ± 5% RH, 20 ± 2 °C) for 3 and 7 days, and then, the cellophane paper on the bottom was removed. Furthermore, as shown in Figure 1c, the specimen was placed on a fixing support so that it could be freely drawn to the floor when a compressive force was applied to the internal cement paste using a hydraulic universal testing machine, and the lower part of the steel pipe was removed. At this time, to measure the stress between the inside of the steel pipe mold and the cement paste, a steel pipe with a diameter of 35 mm was placed vertically on the cement paste, and the frictional resistance was measured by applying a compressive force. In addition, two linear variable differential transformers were installed on the round top plate of a hydraulic universal testing machine to measure the displacement pattern against the compressive force.

2.2.4. Scanning Electron Microscope Image and Porosity

To observe SEM images and porosity after friction resistance testing, specimens were collected and put in an acetone solution to stop hydration. An SEM (SNE 3200M) was used to observe each specimen after platinum coatings were performed. Microstructures were observed at a magnification of 3000 times with an acceleration voltage of 15 kV. In addition, specimens were dried fully in a drying furnace at 60 °C before mercury was pressurized to each specimen at 0–60,000 psi. A porosity analyzer (AutoPore V 9620) was then used to measure the porosity and pore size of each specimen from the penetration amount.

3. Results and Discussion

3.1. Segregation Resistance

Table 3 shows the settlement results. The specimen with 83% W/B and 0% expansive additives had 135 mL bleeding at 3 h, and the settlement amount was maintained until 28 days of age. By contrast, the specimen with 83% W/B and 15% expansive additives had 80 mL bleeding at 3 h and 150 mL at 24 h, the latter of which was maintained after that. This indicates 15 mL more settlement than the specimen with no expansive additives. However, this 3% difference seems insignificant based on the total amount of cement milk. The change in surplus water was also insignificant, indicating that material separation effects due to expansion material were small.

Table 3.

Segregation resistance.

3.2. Compressive Strength

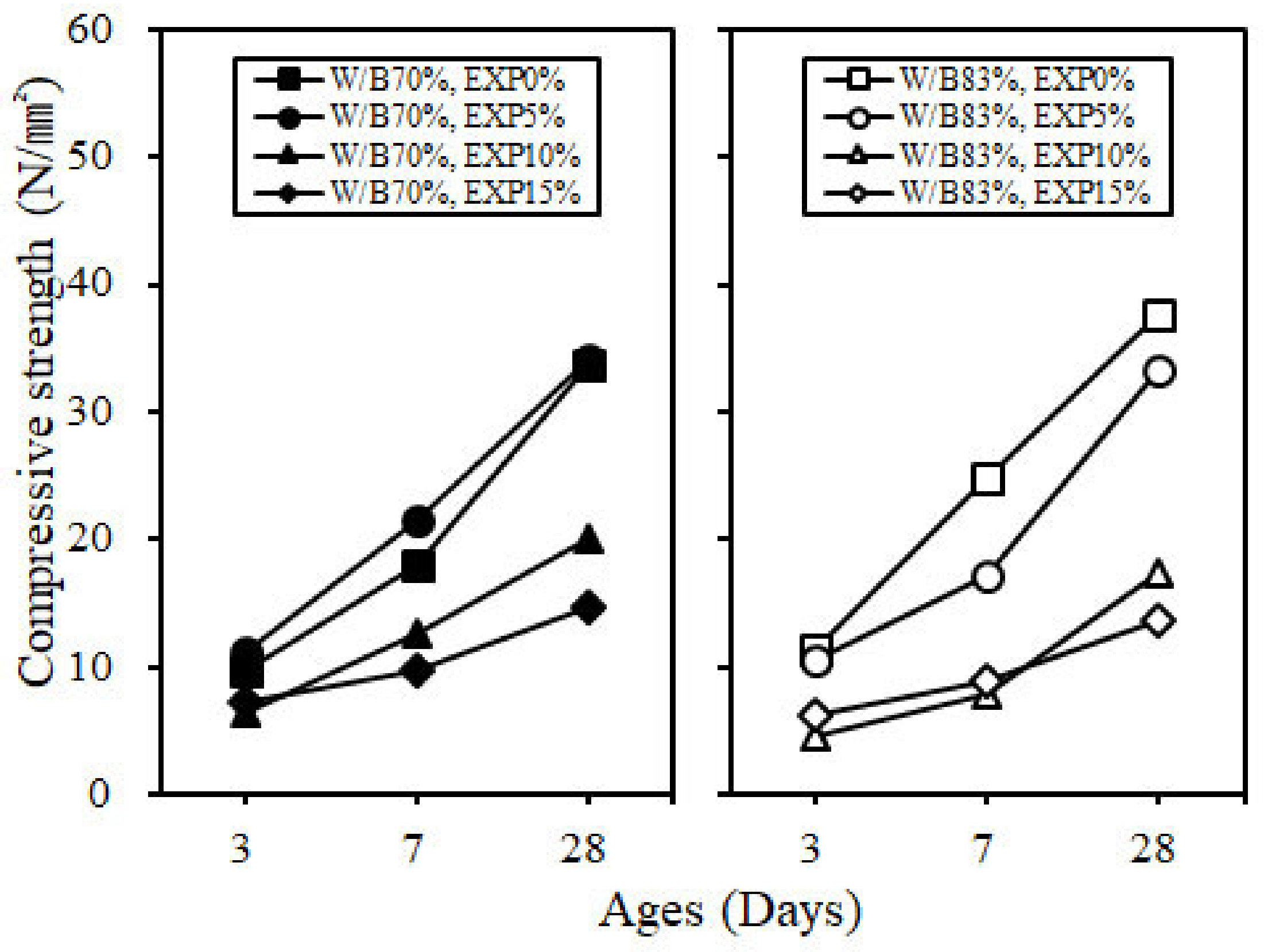

Figure 2 shows the compressive strength results. Regardless of W/B, the compressive strength increased as the age increased. However, the compressive strength decreased as the amount of expansive additive increased for all specimens, except for those with a W/B of 70% and an expansive additive mixing rate of 5%. This may be due to tissue relaxing inside the matrix due to the expansive additives and lowering strength [19]. However, this does not present a usability problem as all test specimens exceed 0.5 N/mm2 sufficiently, which is the standard strength of filling material under the Korea Expressway Corporation special specifications. Given that experimental conditions were not constrained by the polyethylene bags used, an increase in compressive strength could be expected by creating a constrained condition similar to actual construction conditions.

Figure 2.

Compressive strength.

3.3. Frictional Resistance

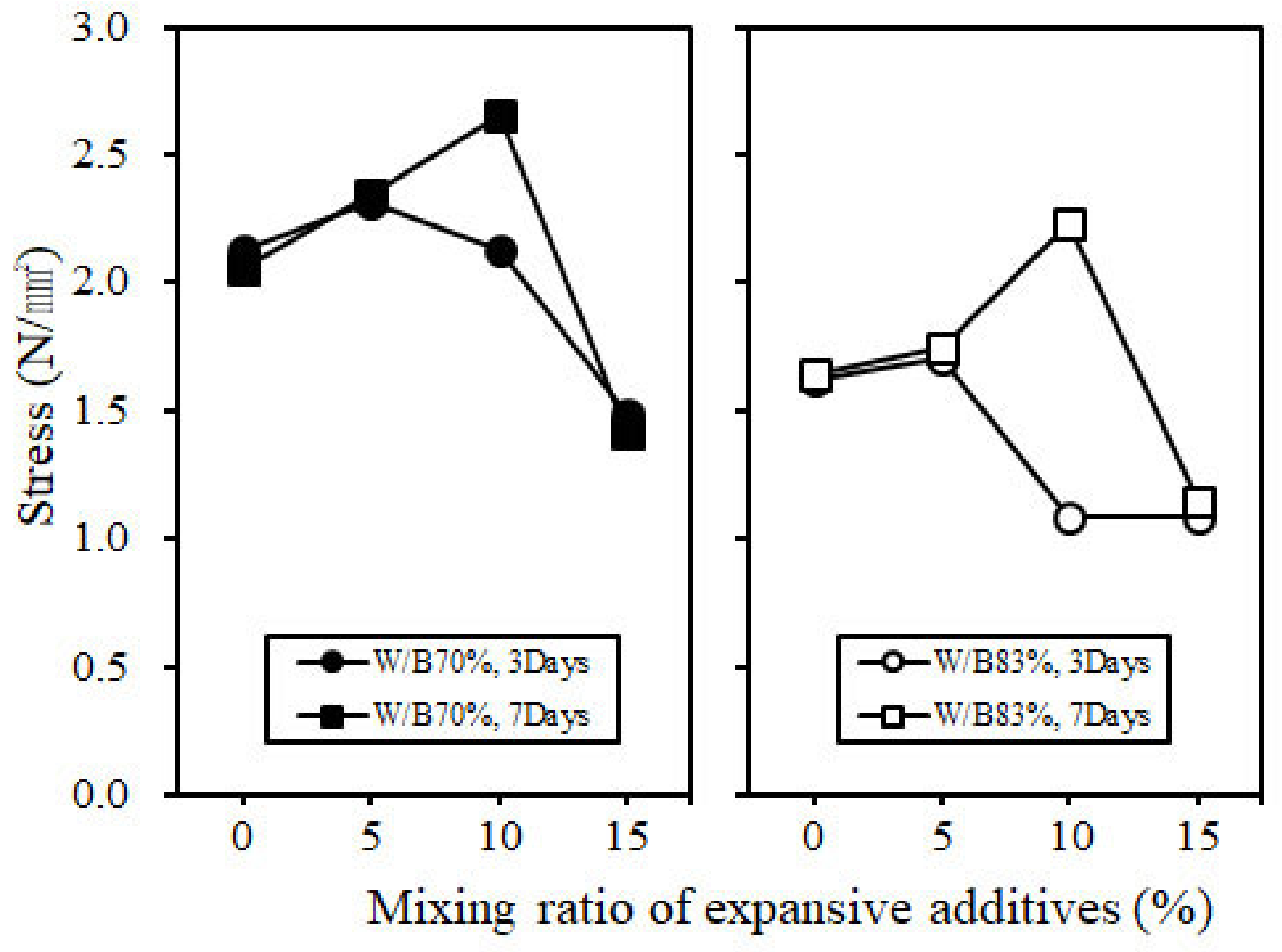

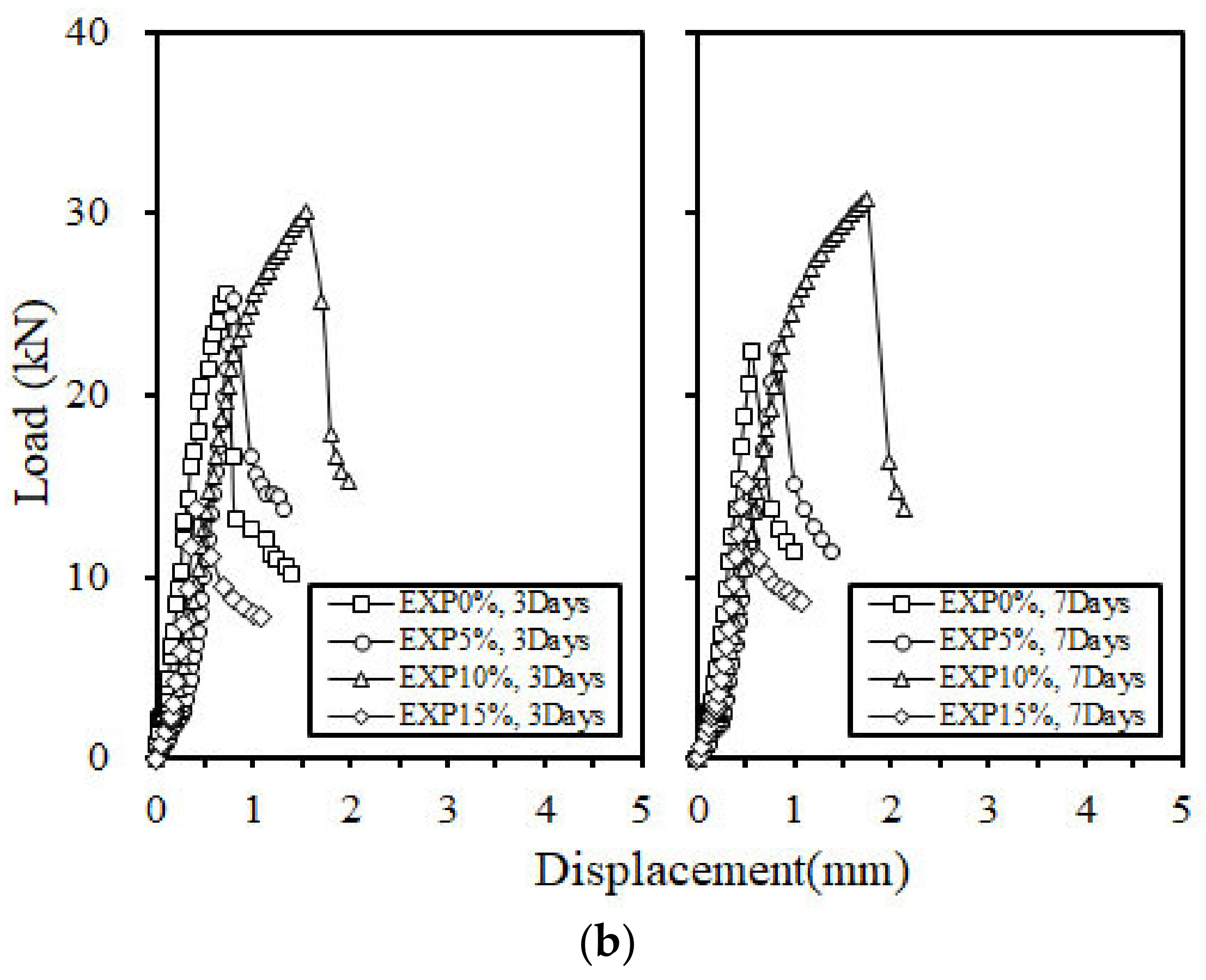

Figure 3 shows the frictional resistance results. Regardless of W/B, the frictional resistance increased as the mixing ratio of the expansive additive increased in the range of 0–10% at the age of 7 days. However, frictional resistance was significantly reduced in specimens containing 15% expansive additive. Although these specimens are in a restrained state, the strength was deemed lowered because of overexpansion and delayed expansion caused by mixing an excessive amount of expansive additive [20,21]. For specimens containing 10% expansive additive, the frictional resistance increased significantly with age, and a W/B of 83% showed a 35.92% greater tendency than specimens containing no expansive additive. The expansion element of the expansive additive may have been a factor in the strength decrease at 3 days, but the strength was recovered by compensating for the contraction with expansion after 7 days [22].

Figure 3.

Frictional resistance stress.

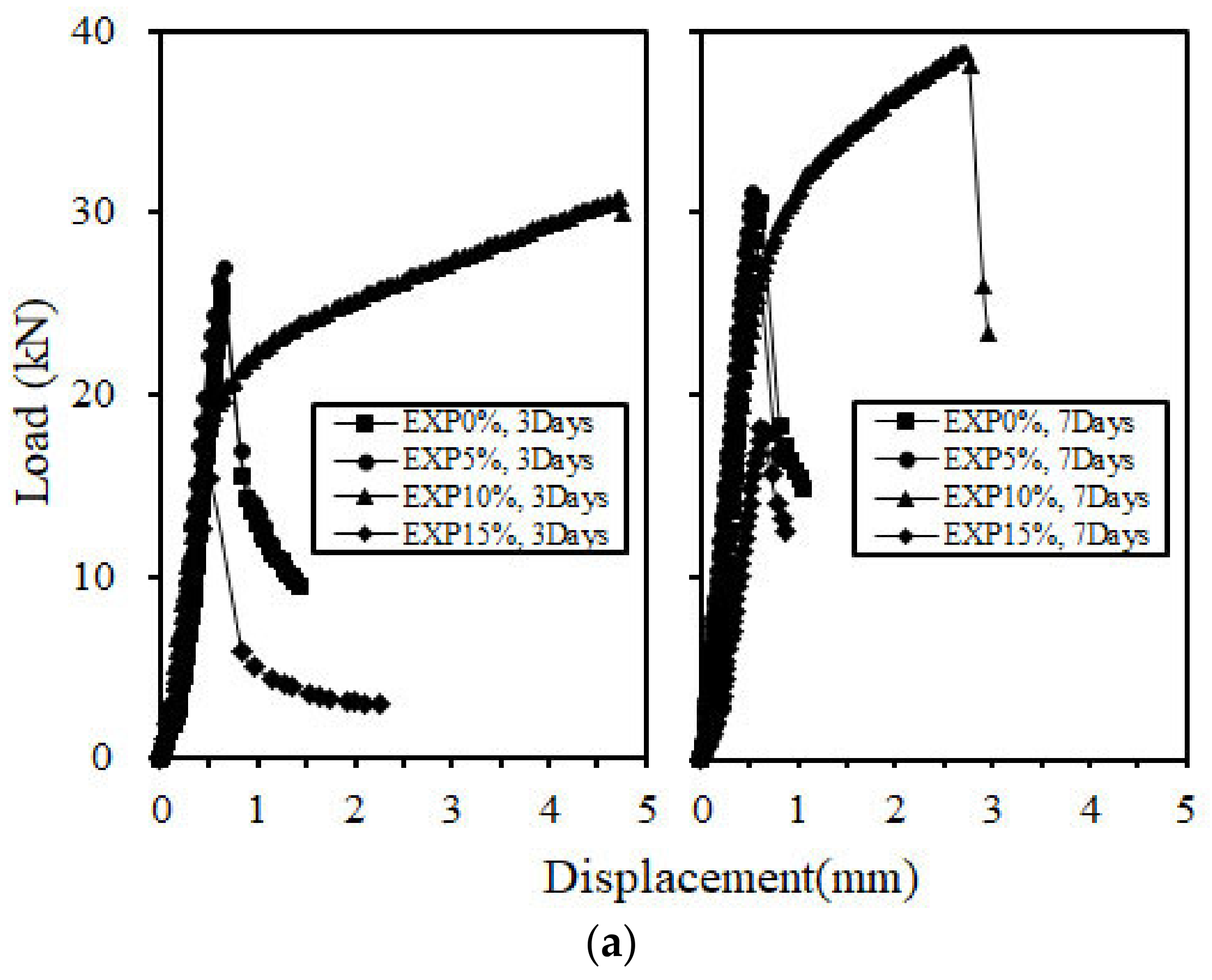

Figure 4 shows the load–displacement curves. As the mixing ratio of the expansive additive increases, the frictional resistance increases, which causes the initial support force and displacement to increase linearly and proportionally. However, in the range containing 0%, 5% expansive additive, and containing excessively 15% expansive additive, it showed a tendency to fracture immediately after showing the maximum main surface bearing force at a displacement of 0.5–1.0 mm. However, in the range containing 10% expansive additive, it was confirmed that the introduction of an appropriate compressive stress using the expansive additive under the restraint conditions showed ductile behavior after a displacement of 0.5–1.0 mm; it was also plastically deformed at its maximum bearing capacity. Displacement only increased after reaching maximum frictional resistance, with no specific change in the bearing capacity for all specimens. Therefore, the expansive additive mixing rate of the filling material should be within 10%, and special management is required when more than 10% additive is used.

Figure 4.

Load–displacement curves: (a) W/B of 70% and (b) W/B of 83%.

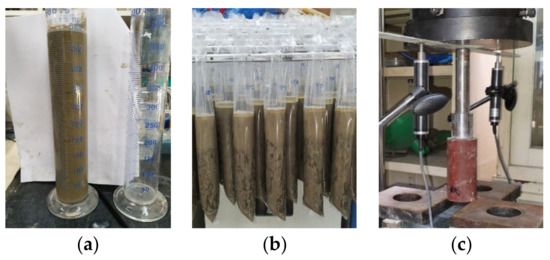

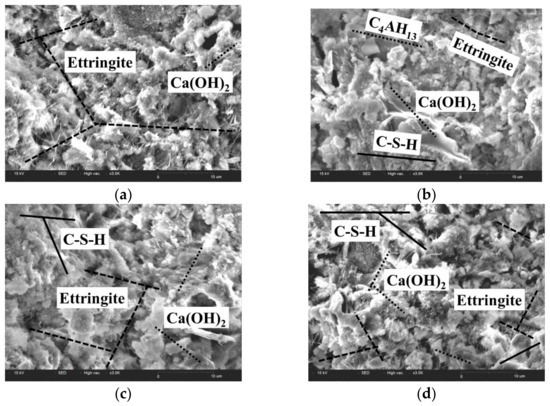

3.4. Scanning Electron Microscope Image and Porosity

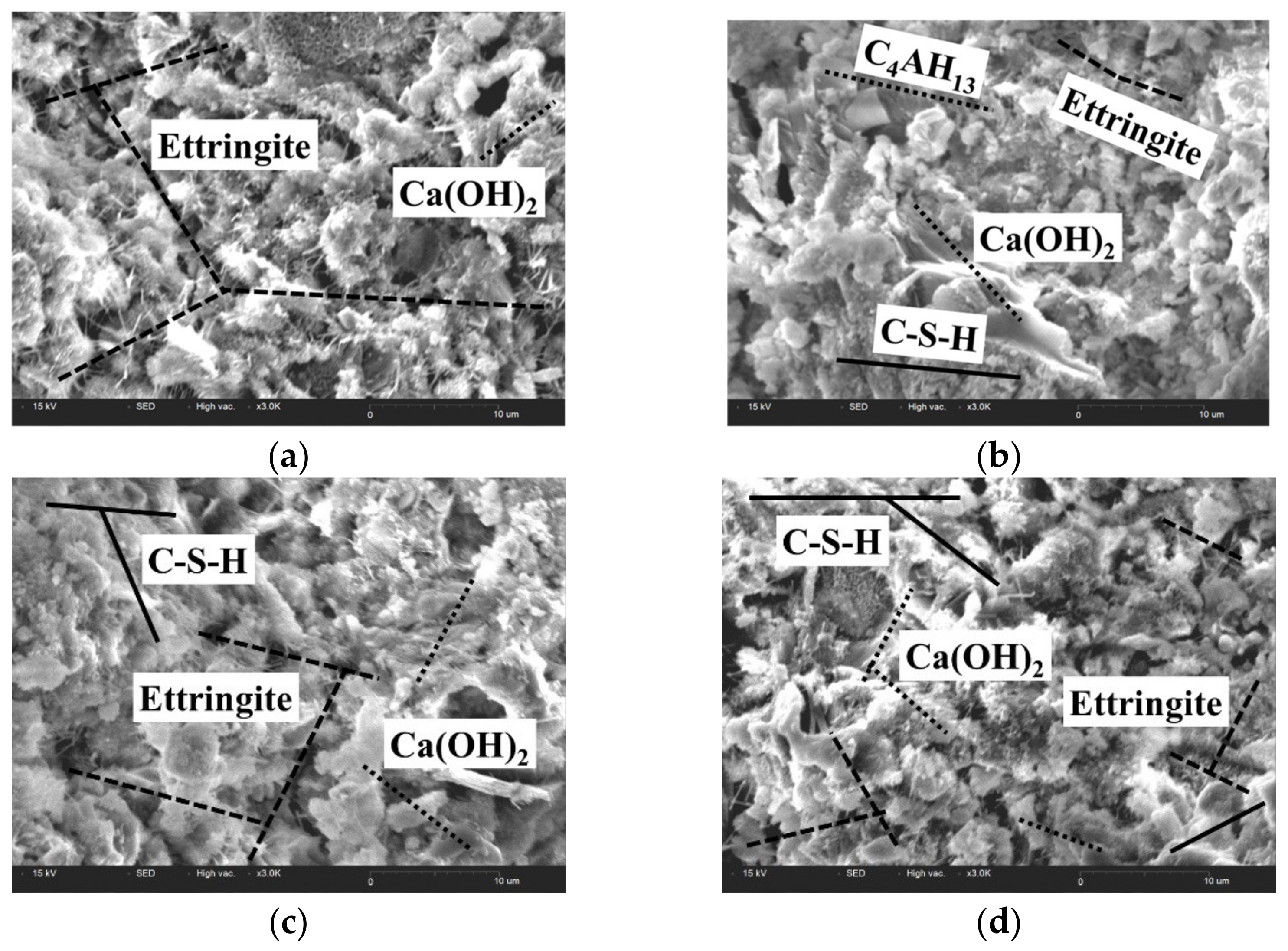

Figure 5 shows the SEM image observation results. After 3 days, all specimens exhibited ettringite, calcium hydroxide, and calcium silicate hydrate (C–S–H) gels. After 7 days, the residual amount of SO3 significantly decreased after the reaction of C3A and SO3 at the beginning of hydration, producing monosulfate or C4AH13. In particular, the specimen containing 10% expansive additive showed a large amount of C–S–H and ettringite developing into a thick needle-like structure that formed a dense network structure that tightly filled the matrix pores.

Figure 5.

SEM W/B of 70% ×3000: (a) EXP 0%, 3 days; (b) EXP 0%, 7 days; (c) EXP 10%, 3 days; (d) EXP 10%, 7 days.

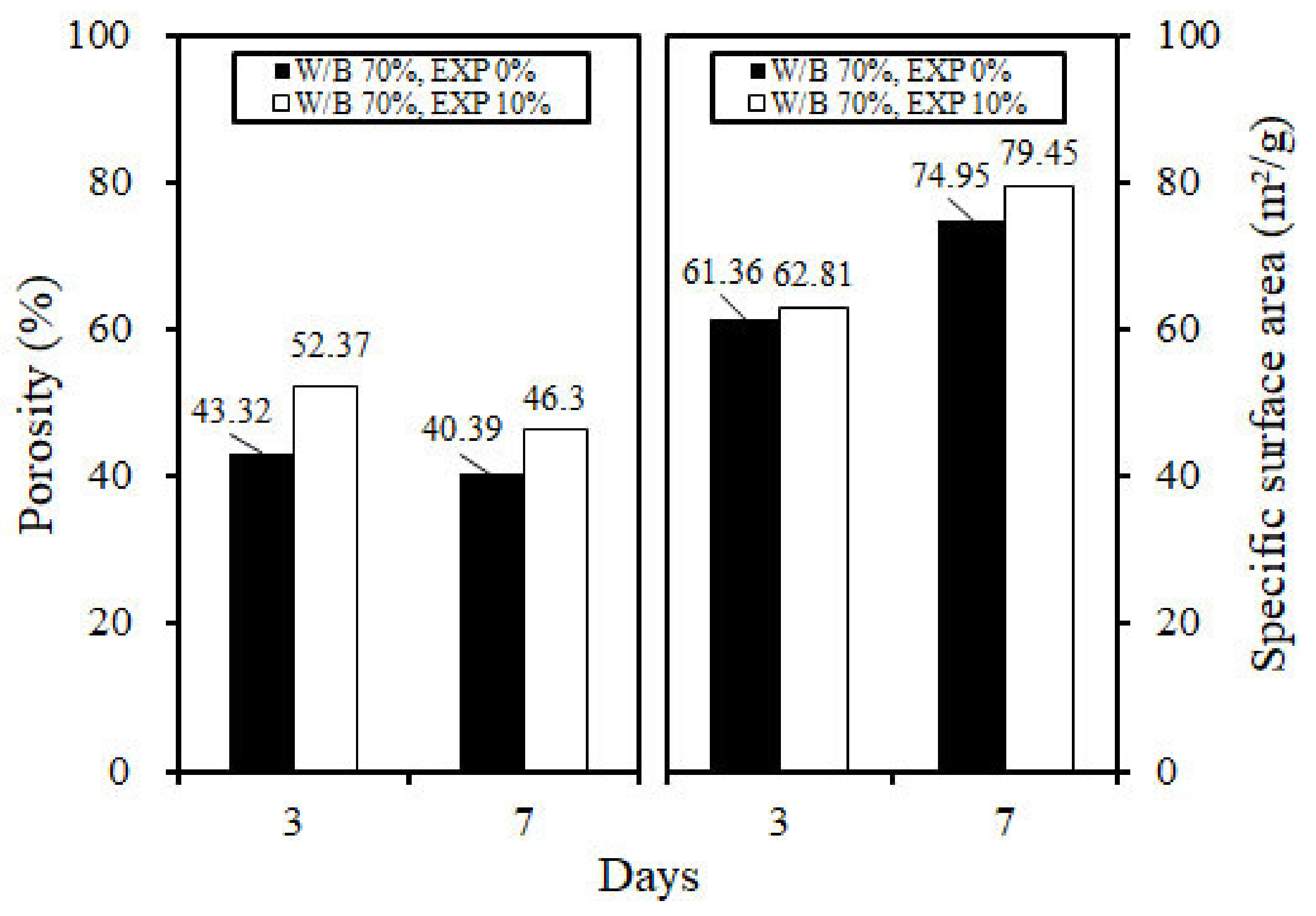

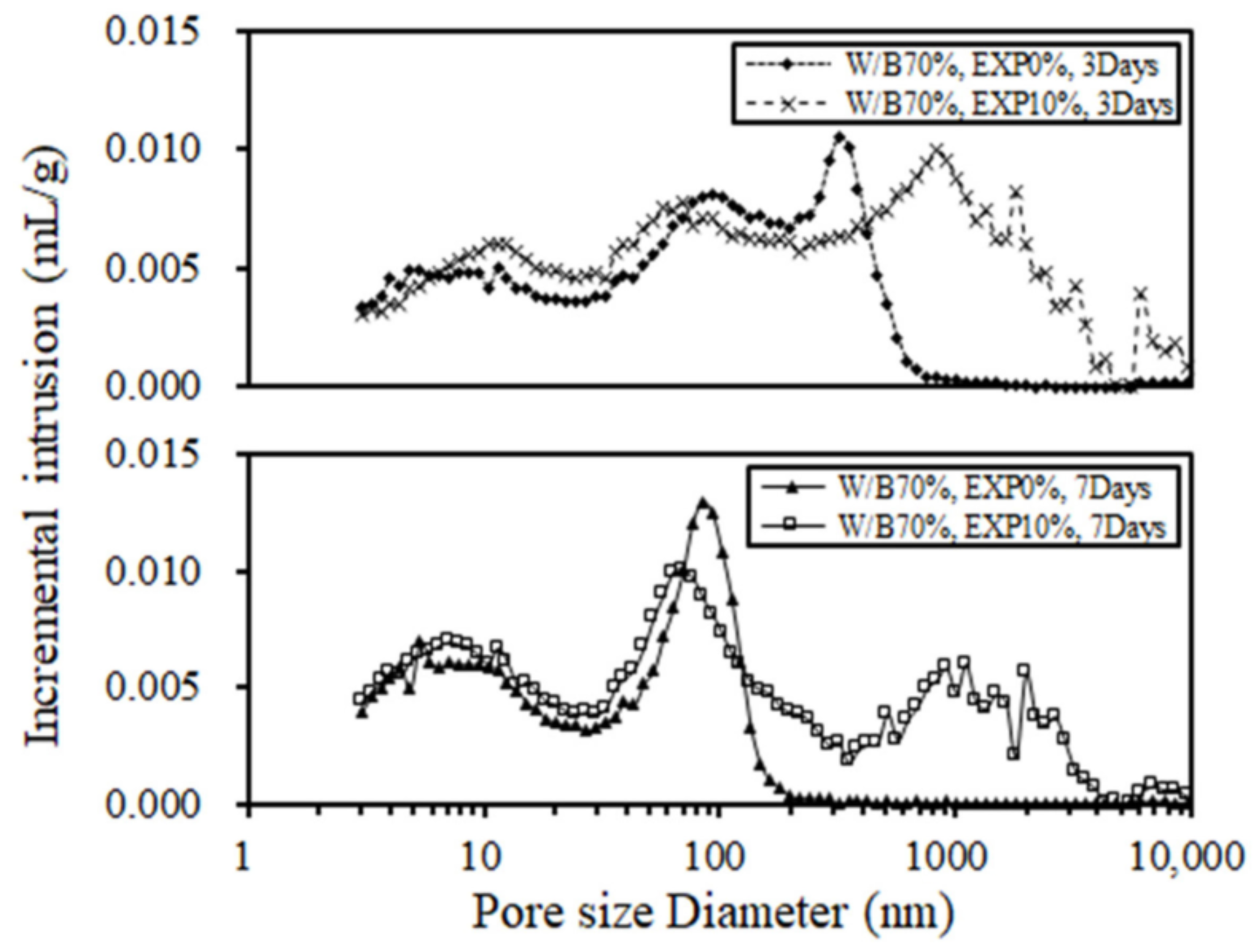

Figure 6 and Figure 7 show the porosity, specific surface area, and pore size distribution results. For 3 and 7 days of age, the porosity showed a tendency to increase as the amount of expansive additive increased. This difference in microcrystal composition is believed to be correlated with an increasing mixing ratio of expansive additives [17]. It is considered that the porosity increased due to the formation of the initial expandable hydration product by the addition of the expansive additives and the generation of large pores increased, and thus, the specific surface area also slightly increased. Generally, when an expansive additive was mixed, the strength tended to decrease due to the increase in porosity by the generation of expandable hydration products at the early age, but the strength recovered with age [16]. In addition, the compression stress was effectively introduced due to the expansion of the early age under the restraint conditions, thereby improving the performance of the hardening cement. As a result, it is believed that the frictional resistance increased in the range of 10%, in which the expansive additive was properly mixed in the cement milk.

Figure 6.

Porosity and total pore area.

Figure 7.

Comparison of incremental intrusion vs. pore size in specimens according to the W/B ratio and expansive addition content.

3.5. Economic Feasibility

To examine economic feasibility, it was assumed that 100 round steel pipe piles (10 m long, design load of 123 ton/each) were constructed using the bored pile method with DH508 drilling equipment, a T4 mounting auger (18.5 m long) and casing (6.5 m long) in strata composed of a buried layer (1.5 m thick), sedentary deposit (6.5 m thick), and weathered layer (5 m thick). In KS F 4306 standard, the material and labor costs, cost required for the construction of 10 m long piles and buried piles among 5–15 m round steel pipe piles produced for piles, and the input construction cost were calculated. Construction costs included processes such as drilling, hydraulic driving, floating soil treatment, head clearance, and remnant crushing. The required material cost was set as low as possible by comparing price data, price information, and transaction prices from the Ministry of Strategy and Finance of Korea. Equipment and operating costs were set on the basis of the standard estimating from Korea Institute of Civil Engineering and Building Technology.

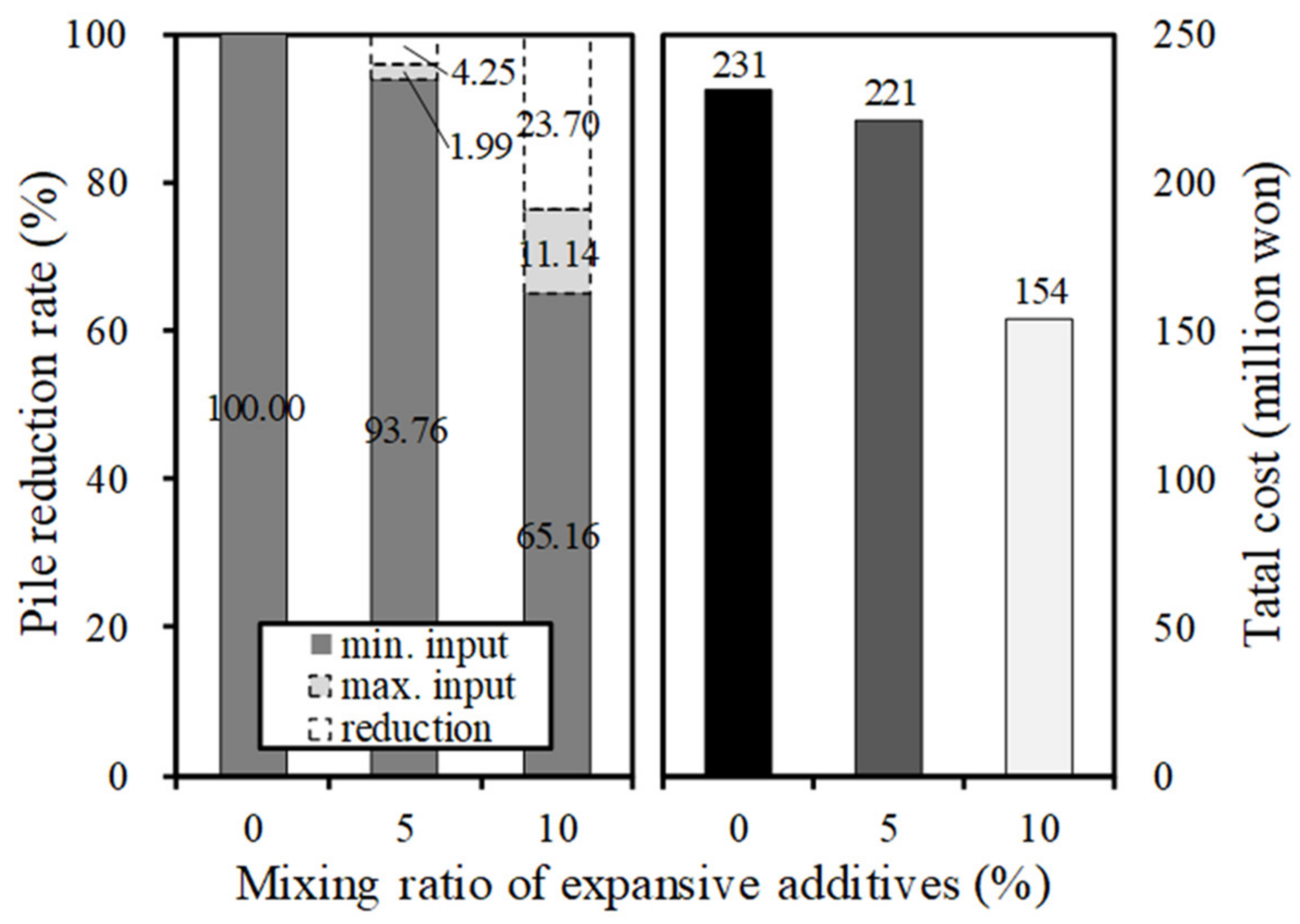

Figure 8 shows the pile reduction/mixing ratios and total construction costs for 100 10 m steel pipe piles. Considering the 66–97% share of the skin friction force to the total bearing capacity of the pile (as noted in previous studies), expansive additives can be expected to reduce the number of piles required for foundation design due to increased frictional resistance [13]. In particular, the W/B of 83% showed a large increase in frictional resistance, and when 5% expansive additive was mixed in, the number of required piles was reduced by 4.25% to 6.24%; when 10% expansive additive was mixed in, the required number was reduced further to ~23.70–34.84%. When costed out, the 10% expansive additive mix provided a greater cost reduction effect than the 5% mix (i.e., the former mix could reduce total construction costs by up to 33.24%), demonstrating the greatest economic feasibility.

Figure 8.

Pile reduction percentage and construction cost projections based on the mixing ratio of expansive additives.

4. Conclusions

In this study, a method was reviewed to increase the bearing capacity of cement milk using expansive additives during the construction of bored piles. The following conclusions were obtained:

- Measuring segregation resistance showed an insignificant difference in settlement amounts due to expansive additive mixing when a 15% concentration was used. The change in the surplus water was also insignificant, showing no specific material separation tendency.

- Compressive strength increased with age but decreased after expansive additive mixing in all specimens, except those with W/B of 70% and 5% expansive additive. However, usability was not an issue as all test specimens exceeded the standard strength of 0.5 N/mm2 for filling material. It is also expected that the strength will increase under constraint conditions created in actual construction conditions.

- Frictional resistance increased as up to a 10% expansive additive was mixed in but decreased at 15%. Specimens containing 10% expansive additive showed stable ductile behavior during settling and a tendency to plastically deform.

- SEM image and porosity analysis revealed that as the age increased, monosulfate and C–S–H gels were densely composed, porosity decreased, and the specific surface area of pores increased, resulting in large numbers of small-scale pores. This trend increased with the mixing of an expansive additive, showing a denser microstructure.

- Regarding economic feasibility, the number of required piles was reduced as the expansive additive was mixed into W/B of 83% specimens at ratios up to 10% when the greatest frictional resistance increase was achieved. Specifically, a 10% expansive additive ratio reduced the number of required piles by up to 34.84%, providing the greatest economic feasibility by reducing the total construction cost by as much as 33.24%.

Author Contributions

Conceptualization, H.C. (Hyeonggil Choi) and K.L.; methodology, H.C. (Hyeonggil Choi) and K.L.; investigation, H.C. (Hyeonggil Choi), T.L., H.C. (Heesup Choi) and K.L.; writing—original draft preparation, H.C. (Hyeonggil Choi) and K.L.; writing—review and editing, H.C. (Hyeonggil Choi), T.L., H.C. (Heesup Choi), K.L. and D.-E.L.; funding acquisition, H.C. (Hyeonggil Choi) and D.-E.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was also supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (nos. 2018R1A5A1025137 and 2021R1C1C1011347).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lizi, Z.; Chen, Q.; Wang, L.; Zeng, Z.; Gu, D. Numerical simulation and analysis of the pile underpinning technology used in shield tunnel crossings on bridge pile foundations. Undergr. Space 2021, 6, 396–408. [Google Scholar] [CrossRef]

- Zahraa, A.K.; Mohamed, G.A.; Adel, D. Analysis of the arching phenomenon of bored piles in sand. Alex. Eng. J. 2016, 55, 2639–2645. [Google Scholar] [CrossRef]

- Fall, M.; Gao, Z.; Ndiaye, B.C. Driven pile effects on nearby cylindrical and semi-tapered pile in sandy clay. Appl. Sci. 2021, 11, 2919. [Google Scholar] [CrossRef]

- Park, J.B. Strength and friction behavior of cement paste poured in the bored pile. J. Korean Geoenviron. Soc. 2004, 5, 31–39. [Google Scholar]

- Prayogo, D.; Susanto, Y.T.T. Optimizing the prediction accuracy of friction capacity of driven piles in cohesive soil using a novel self-tuning least squares support vector machine. Adv. Civ. Eng. 2018, 2018, 6490169. [Google Scholar] [CrossRef] [Green Version]

- Singh, G.; Walia, B. Performance evaluation of nature-inspired algorithms for the design of bored pile foundation by artificial neural networks. Neural Comput. Appl. 2017, 28, 289–298. [Google Scholar] [CrossRef]

- Luan, S.; Wang, F.; Wang, T.; Lu, Z.; Shui, W. Characteristics of gravelly granite residual soil in bored pile design: An in situ test in Shenzhen. Adv. Mater. Sci. Eng. 2018, 2018, 7598154. [Google Scholar] [CrossRef] [Green Version]

- Jung, K.J.; Kim, D.H.; Lee, C.J.; Jeong, S.S. Analysis of skin friction behavior in prebored and precast piles based on field loading test. J. Korean Geotech. Soc. 2017, 33, 31–38. [Google Scholar] [CrossRef]

- Al-Recaby, M. Assessing the increase in bearing capacity of bored piles in sandy soil using expansive additives. Kufa. J. Eng. 2019, 10, 12–28. [Google Scholar] [CrossRef]

- Jung, K.J. A strategy for developing load resistance factor design method of prebored and precast piles. Korean Soc. Civil Eng. Conv. 2016, 2016, 53–54. [Google Scholar]

- Do, J.N.; Nam, M.S.; Shim, J.W.; Park, Y.H.; Lee, S.J. Engineering characteristics of cement milk for bored piles. J. Korean Geotech. Soc. 2015, 31, 29–43. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.H.; Jung, G.J.; Jeong, S.S.; Jeon, Y.J.; Kim, J.S.; Lee, C.J. A study on the behaviour of prebored and precast steel pipe piles from full-scale field tests and class-A and C1 type numerical analyses. J. Korean Geo. Env. Soc. 2017, 18, 37–47. [Google Scholar] [CrossRef]

- Choi, Y.K.; Lee, W.J.; Lee, C.U.; Kwon, O.K. Study (I) on development of charts and formulae predicting allowable axial bearing capacity for prebored PHC pile socketed into weathered rock through sandy soil layer (an analysis of sharing ratio of skin friction to total bearing capacity (SRF) by analyzing pile load test data). J. Korean Geotech. Soc. 2019, 35, 17–30. [Google Scholar] [CrossRef]

- Kim, K.W.; Chae, J.G.; Han, B.K. Applicability of solidified soil as a filling materials of bored pile. J. Korean Geosynth. Soc. 2012, 11, 37–42. [Google Scholar] [CrossRef]

- Ko, H.B.; Lee, H.S. Experimental study of file filling meterial with A thickener. Proc. Korean Inst. Build. Constr. Conf. 2020, 20, 21–22. [Google Scholar]

- Choi, H.G.; Lim, M.K.; Kitagaki, R.; Noguchi, T.; Kim, G.Y. Restrained shrinkage behavior of expansive mortar at early ages. Constr. Build. Mater. 2015, 84, 468–476. [Google Scholar] [CrossRef]

- Treesuwan, S.; Maleesee, K. Effects of shrinkage reducing agent and expansive additive on mortar properties. Adv. Mater. Sci. Eng. 2017, 2017, 8917957. [Google Scholar] [CrossRef] [Green Version]

- Qian, X.; Jiang, L.; Song, Z.; Chu, H.; Yan, X.; Zhang, Y. Impact of elevated curing temperature on mechanical properties and microstructure of MgO-based expansive additive cement mortars. Struct. Concr. 2020, 21, 1082–1092. [Google Scholar] [CrossRef]

- Park, M.S.; Kim, H.S.; Park, C.Y.; Kang, B.H. The strength property with restrained effects of the expansive mortar. J. Korea Inst. Build. Constr. 2006, 53–56. [Google Scholar]

- Lee, S.W.; Kim, N.H. Usage of CSA expansive additives for the concrete. Mag. Korea Concr. Inst. 1996, 8, 59–66. [Google Scholar]

- Gao, X.; Liu, C.; Shui, Z.; Yu, R. Effects of expansive additives on the shrinkage behavior of coal gangue based alkali activated materials. Crystals 2021, 11, 816. [Google Scholar] [CrossRef]

- Han, C.G.; Bahn, H.Y.; Jun, B.C.; Shin, E.G. A study on the properties of concrete with the addition ratio of expansive additives. JAIK 1998, 14, 349–354. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).