1. Introduction

The increasing number of people with motor deficiencies has been a crucial factor in developing rehabilitation devices. Motor injuries frequently occur in the upper and lower extremities due to degenerative diseases, neuronal disorders, sports injuries, traffic, and work accidents. Presently, rehabilitation devices for upper and lower limbs have been developed [

1,

2]. Stationary rehabilitation devices are used more frequently in the rehabilitation of the patient. However, these devices are generally expensive because the control of several degrees of freedom is required to generate a rehabilitation routine. Rehabilitation systems based on closed-chain mechanisms are a low-cost alternative for health care [

3]. These systems can provide a pre-established rehabilitation routine that controls a degree of freedom. Therefore, these devices can be considered for rehabilitation at home.

In the design of closed-chain mechanisms, a synthesis process of the mechanism is carried out [

4]. In this process, the length of links is determined to achieve the desired movements for rehabilitation. The graphic, analytic, and optimal methods [

5] are the used techniques for the synthesis of closed-chain mechanisms. Graphic synthesis of mechanisms is performed by a visual representation of the mechanism, where Euclidean geometry concepts are used to obtain the design solutions. This method is characterized by providing quick solutions with a low precision rate.

The analytical synthesis is based on getting algebraic expressions that describe the movement of the mechanism. This method offers solutions with a high precision rate. However, the number of precision points is limited by the number of independent variables of the closed-chain mechanism because it results in an overdetermined system of equations [

6] requiring a numeric solution to solve them. The optimal synthesis of mechanisms is performed through the optimization problem solution. This synthesis method supports multiple-precision points, but the precision rate can decrease caused by the numerical optimization technique used. Currently, the last method is frequently used for the synthesis of mechanisms.

In the optimal synthesis of closed-chain mechanisms for rehabilitation, indirect and direct search methods (numerical optimization techniques) [

7] have been used to find suitable solutions. In the indirect search methods, derivatives of the objective function and constraints are required. For instance, Ávila-Hernández and Cuenca-Jiménez [

8] designed a thumb prosthesis using a nine-bar spatial mechanism. For the solution of the synthesis problem, the function “findminimum” of Mathematica

® was used. Zhiming Ji and Yazan Manna [

9] designed a lower limb rehabilitation system using a four-bar linkage. In the syntheses process, the method “lsqnonlin” of MATLAB

® was implemented.

Wang et al. [

10] designed a rehabilitation system using a four-bar linkage mechanism in the synthesis process. In that work, the search method “fmincon” of MATLAB

® was implemented. Tsuge et al. [

11] designed a rehabilitation system using a ten-bar linkage mechanism. The synthesis problem was solved by Bertini™ software.

Tsuge et al. [

12] designed a rehabilitation system using a Stephenson III linkage mechanism. The synthesis problem was solved using algorithms, such as Fletcher–Reeves, Newton, conjugate gradient, interior point, and Quasi-Newton.

On the other hand, direct search methods do not require such derivatives, and the objective function is considered in its original form to find a solution. The use of metaheuristic algorithms as the direct search method is gaining more attention in the solution of mechanism synthesis problems [

13] because they do not depend on the problem features (nonlinear, discontinuous, etc.), they can endow different operators to find the most promising solution, and they are easy to implement. A summary of various studies found in the literature that use metaheuristic algorithms in the synthesis problem of mechanisms is presented in

Table 1.

The particular interest in this study is in the works related to the mechanism design for rehabilitation presented at the end of such table. For instance, Bataller et al. [

14] proposed a mechanism for finger rehabilitation, where the direct search algorithm Málaga University Mechanism Synthesis Algorithm (MUMSA) was used, and a penalty function was implemented as a constraint-handling technique in the synthesis process.

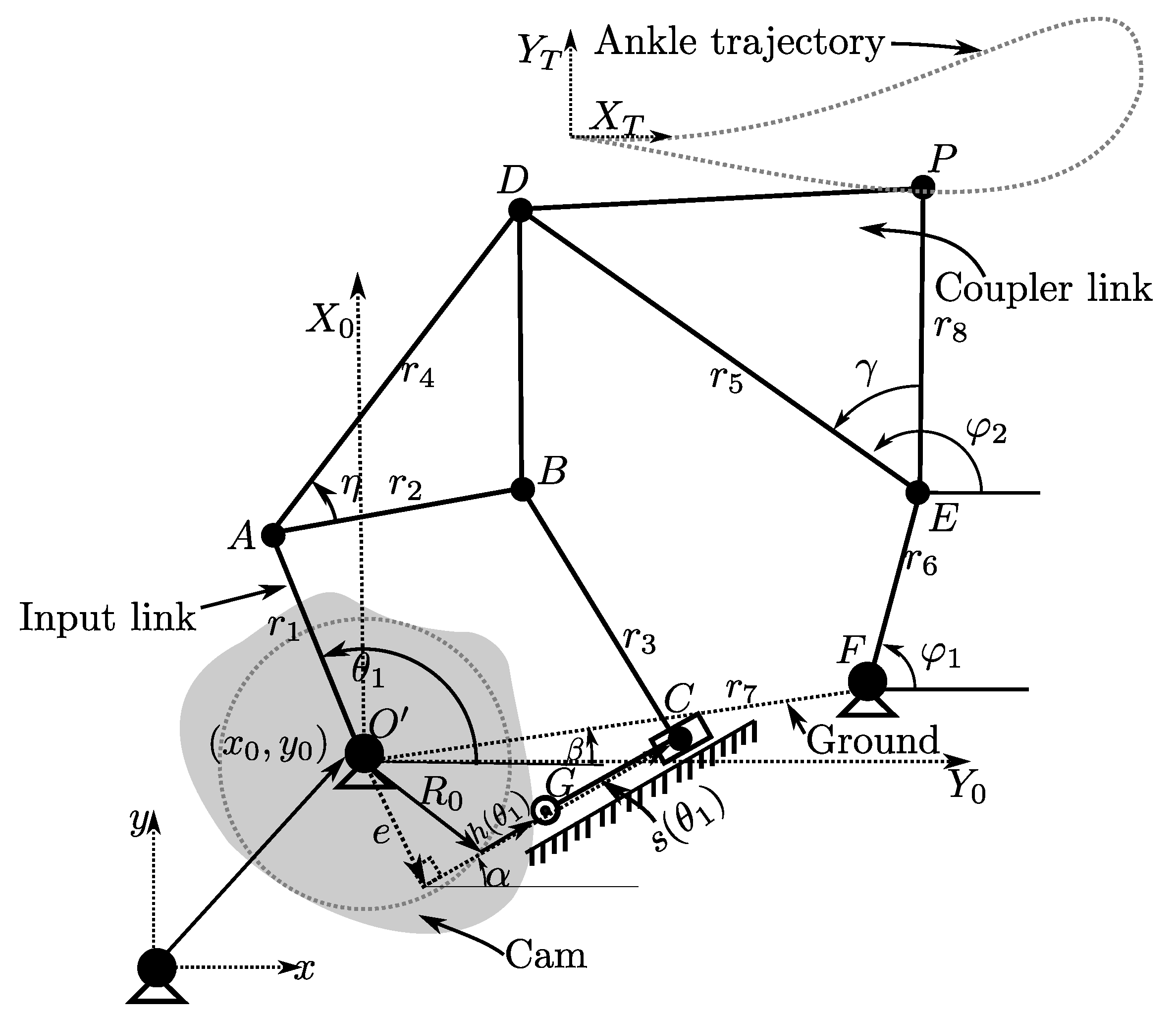

Shao et al. [

15] designed a rehabilitation system using a cam-linkage mechanism for the lower limb rehabilitation to perform the gait. The synthesis problem was solved by a genetic algorithm, where a penalty function was considered as the constraint-handling technique.

Calva-Yáñez et al. [

16] designed a gait rehabilitation system for children using a four-bar linkage mechanism. The indirect search algorithm Sequential Quadratic Programming (SQP) and the direct one given by Differential Evolution (DE) algorithm were used in the synthesis process. In this work, feasibility rules were considered as a constraint-handling technique.

Singh et al. [

17] designed knee–ankle–foot, hip–knee–ankle-foot, and knee orthoses using a four-bar linkage mechanism. Metaheuristic algorithms, such as Particle Swarm Optimization (PSO) and the Teaching-Learning-Based Optimization (TLBO) algorithm, were considered.

In this work, mechanical constraints in the synthesis process are not considered. Leal-Naranjo et al. [

18] presented the design of a wrist prosthesis using a spherical parallel manipulator. In the synthesis process, Nondominated Sorting Genetic Algorithm (NSGA-II), Multiobjective Particle Swarm Optimization (MOPSO), and Multiobjective Evolutionary Algorithm based on Decomposition (MOEA/D) algorithms were considered, and the feasibility rules were implemented as constraint-handling technique.

Muñoz-Reina et al. [

3] designed a lower limb rehabilitation machine. The differential evolution algorithm was considered in the synthesis process, and the feasibility rules were used as the constraint-handling technique.

We observed in the literature that metaheuristic algorithms in their original versions were proposed to solve unconstrained optimization problems. Thus, it is important to find the most promising techniques for including real-word constraints [

37,

38,

39]. Currently, for the solution of constrained optimization problems, CHTs have been proposed. According to [

40], these can be classified into two generations, where the penalty functions, decoders, special operators, and separation of the objective function and constraints are included in the first generation. On the other hand, the feasibility rules, stochastic ranking, and

-constraint involve the second generation. The first generation is characterized by a high calibration complexity and a high probability of convergence to local minimums. The second generation is characterized by overcoming the mentioned limitations in the first generation.

From the literature review regarding the design of closed-chain mechanisms for rehabilitation and the general framework of kinematic synthesis of mechanisms, both included in

Table 1, the metaheuristic algorithms incorporate only one constraint-handling technique to solve the constraint optimization problem.

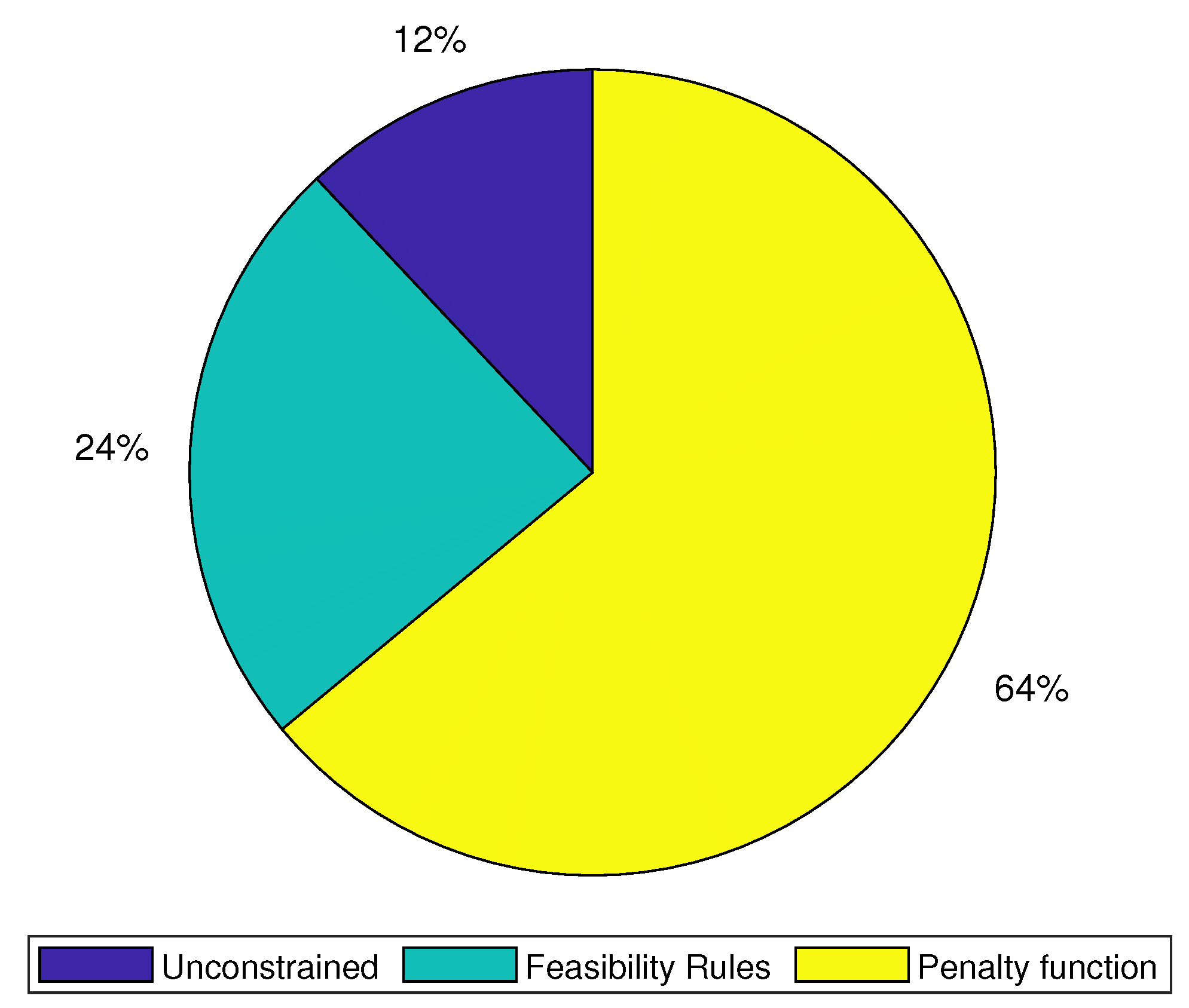

Figure 1 shows the use of CHTs reported in the literature for the synthesis of mechanisms using metaheuristic algorithms. As observed in that figure, 64% of the reviewed literature uses the penalty functions, followed by the feasibility rules with a 24% of use.

According to [

37,

39,

41], the constraint-handling technique is an essential factor to solve constrained optimization problems because these techniques influence the exploration and exploitation capabilities of algorithms for the search of the most promising solution. However, other CHTs in the second generation, such as stochastic ranking and

-constraint have not been evaluated in solving these types of problems.

Depending on the problem nature in the kinematic synthesis for rehabilitation (multimodality, types of functions, design variable space, and the feasible space ratio), the most frequently used algorithms and the constraint-handling techniques can be suitable during the search process of the metaheuristic algorithms. Nevertheless, the high interactions in the problem nature and the metaheuristic algorithms make it difficult to suggest a constraint-handling technique that is more likely to perform well against different algorithms.

Motivated by these facts, and to the best of the author’s knowledge, there is a gap in the comparative study of the performance of different constraint-handling techniques in the dimensional synthesis of mechanisms. This research can aid researchers or practitioners interested in applying metaheuristic algorithms in the kinematic synthesis of this kind of problem with insights about the quality and consistency of the obtained results in the studied CHTs and can identify the most promising CHT alternatives for the synthesis problems.

Thus, researchers and practitioners can have some basic knowledge in the analyzed CHTs about the likelihood of increasing the optimization efficiency and the consistency of the obtained results when those CHTs are included in different metaheuristic algorithms. Hence, this work can suggest the use of a particular CHT in the optimizers to achieve optimum kinematic synthesis.

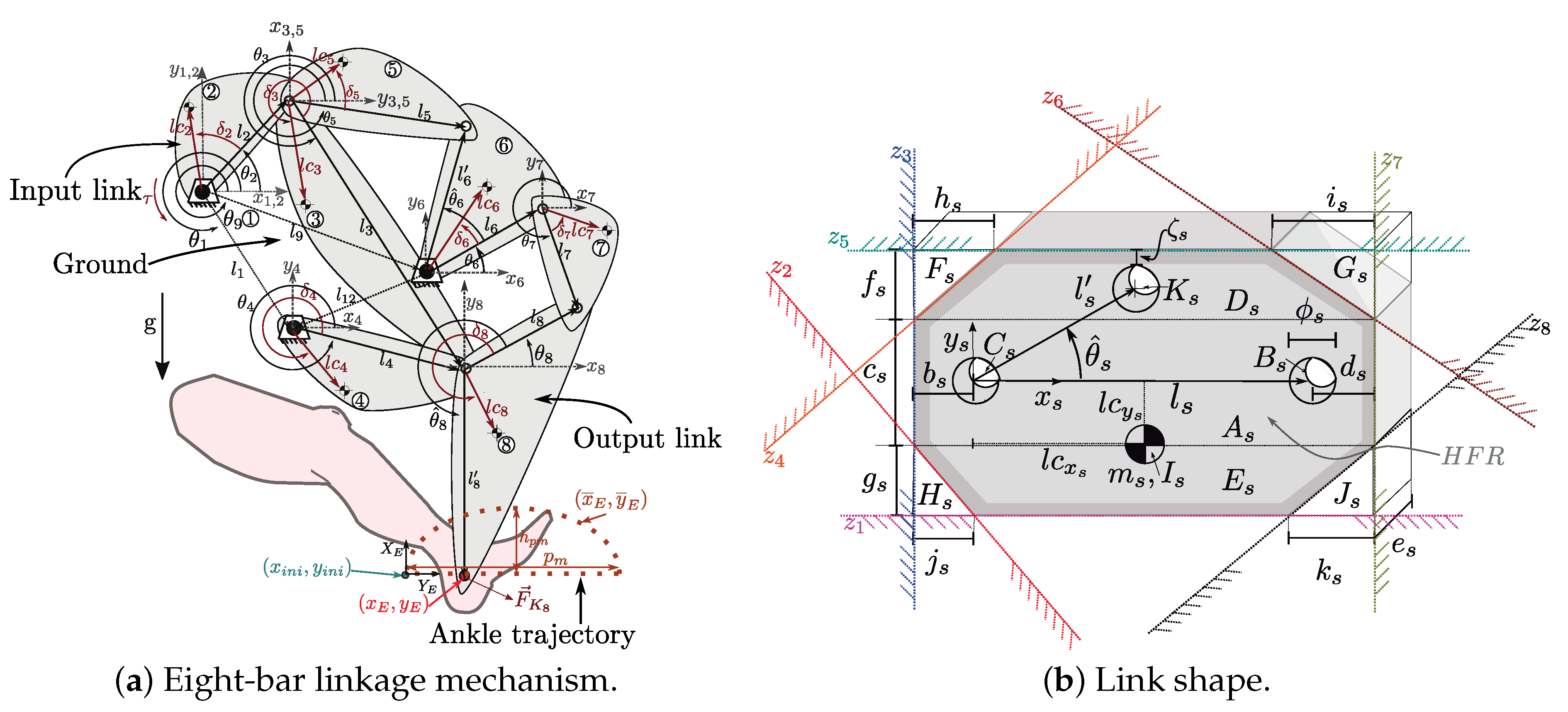

Therefore, in this work, the performance of the penalty function, feasibility rules, stochastic-ranking, and -constraint is studied to solve three real-world engineering problems reported in the literature related to the synthesis of mechanisms for rehabilitation by using metaheuristic algorithms. In this study, ten metaheuristic algorithms commonly used in the synthesis of mechanisms for rehabilitation are implemented in such CHTs. These are eight variants of a differential evolution algorithm, a Genetic Algorithm (GA), and a Particle Swarm Optimization (PSO) algorithm.

The parameters of the algorithms are tuned using the irace package to make a fair comparison and provide useful insights about the studied CHTs. On the other hand, the four-bar linkage mechanism, the cam-linkage mechanism, and the eight-bar linkage mechanism are considered in the mechanism synthesis for rehabilitation.

This paper is organized as follows: In

Section 2, the general problem of mechanism synthesis for rehabilitation is presented.

Section 3 describes the metaheuristic algorithms and the constraint-handling techniques used in this study.

Section 4 states three state-of-art synthesis problems for rehabilitation to be solved. In

Section 5, the study of the constraint-handling techniques is presented and discussed. In addition, the best and worst solution are analyzed and compared. Finally,

Section 6 presents our conclusions.

5. Comparative Experimental Study

We analyzed four Constraint-Handling Techniques (CHTs) in lower limb rehabilitation mechanism synthesis. These CHTs are the Feasibility Rules (FR), the Stochastic-Ranking (SR), the -Constraint ( C) method, and the Penalty Function (PF). The constraint-handling techniques are included in ten Metaheuristic Algorithms (MAs) frequently used in the synthesis of mechanisms. These algorithms are: Particle Swarm Optimization (PSO), Genetic Algorithm (GA), and eight variants of Differential Evolution (DER1B, DER1E, DEB1B, DEB1E, DECR, DECB, DECR1B, and DECR1E).

Each metaheuristic algorithm solves three study cases of mechanism synthesis problems related to lower limb rehabilitation using four-bar linkage, cam-linkage, and eight-bar linkage mechanisms. A summary of the main attributes of the study cases is included in

Table 5 because there is no single attribute to measure the problem’s complexity. In such a table, the terms

and

mean the number of linear and nonlinear inequality constraints, respectively.

The ratio

provides the relative size of the feasible region in the search space (a measure of how difficult is to generate feasible solutions) by using

random design variables (suggested in [

58]), and the number of feasible solutions

. A high value in

indicates that the MA would find the feasible region in an early number of generations. Based on those attributes, the less complex optimization problem is given by study case 1, followed by study case 2, and study case 3, in that order.

The following comparative analysis is divided into three subsections. First, the conditions for making the parameter tuning of the CHTs in the algorithms are described in

Section 5.1. In

Section 5.2, the descriptive and inferential statistics of the overall performance for each algorithm with different CHTs are compared and discussed. Six performance metrics used in constrained optimization problems are included in

Section 5.3 for evaluating the behavior of the CHTs in the metaheuristic algorithms. In

Section 5.4, the best and worse solutions per each study case are visualized and evaluated to investigate the performance of the obtained mechanisms in the rehabilitation routine.

5.1. Parameter Tuning Conditions of the CHTs in the Algorithms

The parameter tuning for each metaheuristic algorithm with the different CHTs was performed for each study case. The irace package [

59] was used for parameter tuning and to make the comparative study more fair and meaningful [

60]. The parameters obtained by the irace package are presented in

Table A4,

Table A5 and

Table A6 of

Appendix A.

For solving each study case, the same number of objective function evaluations is also considered to make fair comparisons. The penalty factor

in the CHT by PF in (

18) is taken into account as a constant value in all cases. Thus, these parameters are set in

Table 6.

5.2. Statistical Analysis of the Overall Performance

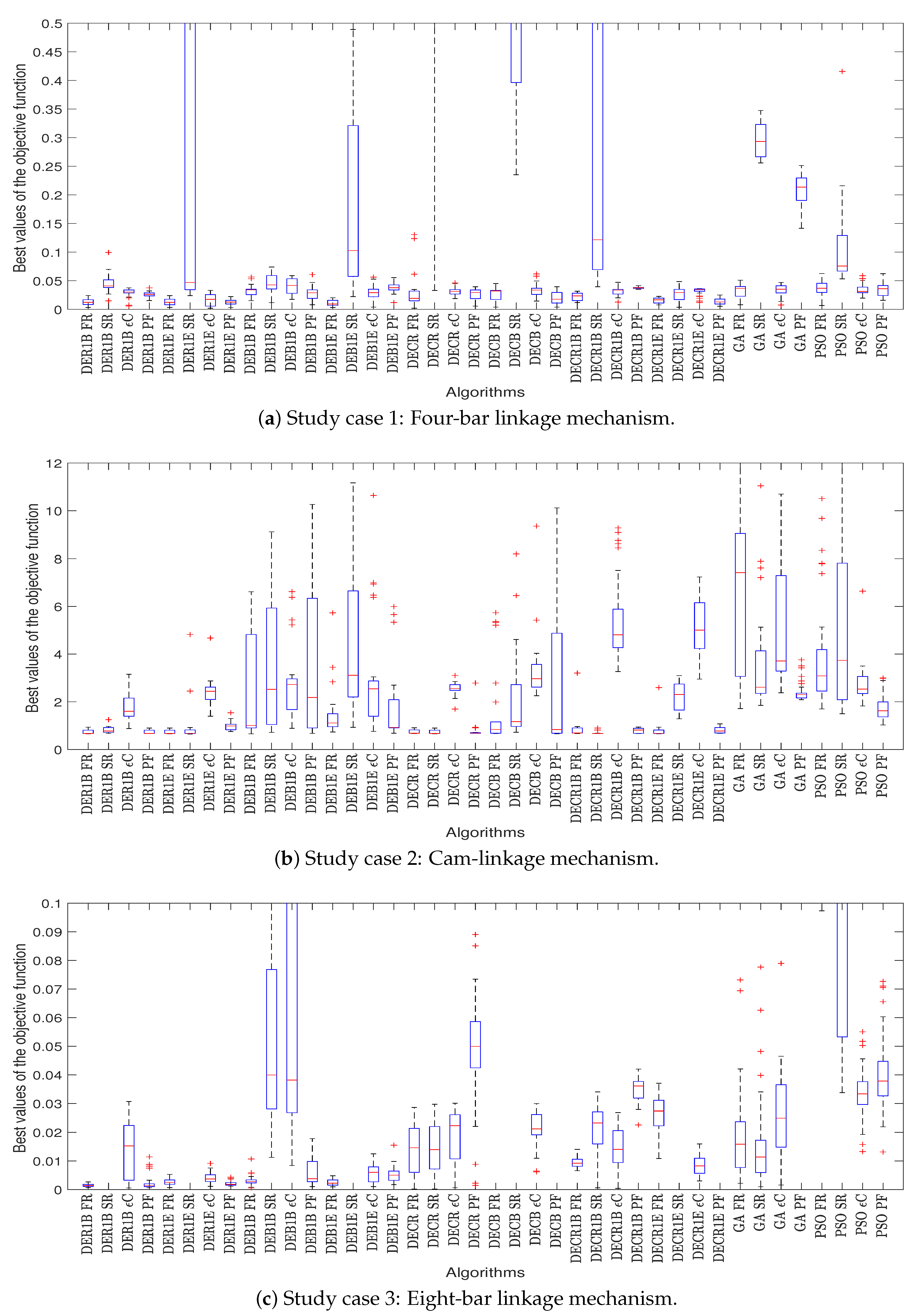

In this work at each study case, thirty executions of the four CHTs are carried out per each of the ten metaheuristics. Each study case groups a total of forty samples (four CHTs per ten metaheuristics). Each sample contains the best thirty objective functions of an algorithm. Descriptive statistics analyzes those samples. The descriptive statistical results are shown in

Table A7,

Table A8 and

Table A9 of

Appendix C, and these consider the following measures: the mean, the standard deviation (std), the median, and the maximum (max) and minimum (min) values of the samples. The graphical visualization of the distribution of the samples is shown in the box plot of

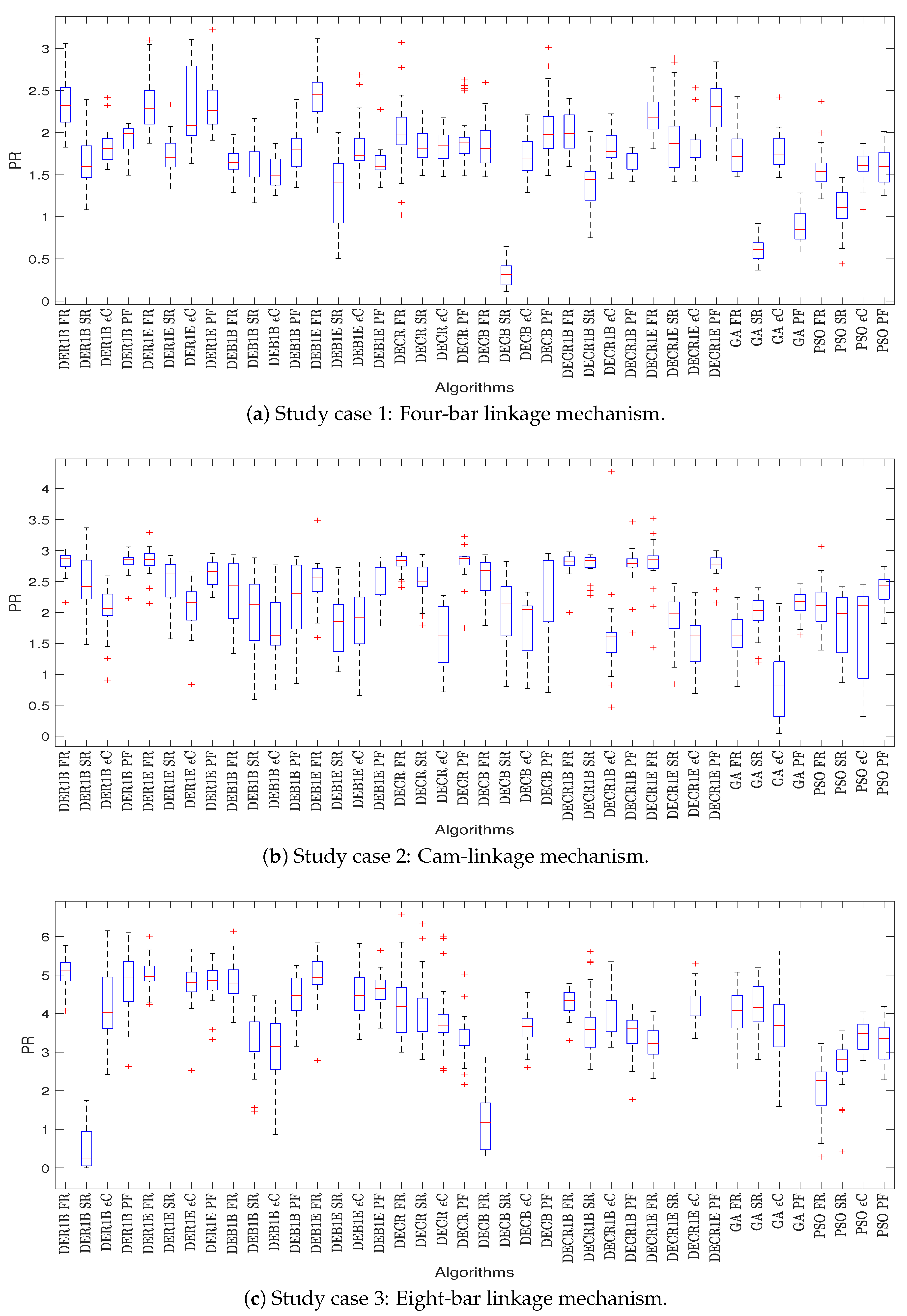

Figure 5.

Based on the results presented in such tables, it is possible to define the CHT that delivers the best performance in search of the most promising solution for each study case. Thus, the best behavior of a metaheuristic algorithm is related to the ability to search for the best solutions and provide more reliable results in different runs. The mean, the standard deviation (std), the median, and the maximum (max) and minimum (min) values of the samples are chosen as the statistical measure to indicate the algorithm capacity to find suitable solutions through runs in the particular samples. The best CHT between two CHTs, called A and B, included in the algorithms, is obtained by the following comparison procedure:

The CHT A can be compared to the CHT B if their CHTs are different, and the algorithms that implement such CHTs are the same. On the contrary, they cannot be compared.

The statistical measure from the thirty executions of the CHT A is better than the CHT B for the same algorithm if the former presents less value than the latter. When this happens, the CHT A obtains the point (a win) in favor. Thus, the maximum number of points for comparing each CHT is 150 (three CHT comparisons per five measures per ten algorithms).

The CHT with the highest number of points is the best constraint-handling technique.

In the comparison method, the lower values of the statistical measures (the mean, the standard deviation (std), the median, and the maximum (max) and minimum (min) values of the samples) are preferable in each algorithm. All measures are considered in the comparison procedure. The results obtained by the comparison process are presented in

Table 7. The best performances of metaheuristic algorithms include the FR for the solution of the three study cases. For study case 1, it wins 115, for study case 2, it wins 104, and for study case 3, it wins 105. The next CHT alternative is the PF because it obtains the second-best performance in two study cases (study cases 1 and 2).

The inferential statistical analysis was performed to make general conclusions about the performance of the CHTs incorporated in the metaheuristic algorithms for the solution of the lower limb rehabilitation mechanism synthesis. Nonparametric statistical tests [

61] were used because the independence, normality, and homoscedasticity assumptions in the samples were not fulfilled due to the stochastic nature of the algorithms.

The inferential statistical analysis consists of performing a multi-comparative post-hoc analysis with Holm post-hoc error correction method [

61] in all CHTs incorporated in the algorithms. The first step is to guarantee that at least one comparison of the constraint-handling technique in the metaheuristic algorithms is different. The

-confidence Friedman test is applied for that purpose, and the results are presented in

Table A10 of

Appendix D. The obtained

p-value near to zero proves the existence of such differences with confidence close to

.

Once the first step was done, the Friedman test for multiple comparisons with the Holm post-hoc error correction method was performed to make the general conclusions of comparisons and confirm the results’ confidence. The forty samples (four CHTs included in ten algorithms), conformed to each one by the best thirty objective functions of the executions, can be compared if both CHTs are incorporated in the same metaheuristic algorithm.

In

Table A11 of

Appendix D, the results obtained by the multi-comparative analysis are shown. The two-sided alternative hypothesis was selected, which means that, in the case that the

p-value of the test is less than the

statistical significance, the comparison between the CHT

A and the one in

B for the same algorithm presents significant differences (the alternative hypothesis is accepted). On the contrary, if the results are not convincing, and significant differences are not observed in the comparative result then the null hypothesis is accepted. Once the alternative hypothesis is accepted, the Friedman

z-value sign defines the winner between both CHTs in the algorithms. The negative sign of

z indicates that the CHT in the algorithm

A was better than the one in

B, and vice versa.

Three comparisons related to the four CHTs are made per each metaheuristic algorithm. A total of thirty comparisons are carried out per each CHT at each study case (considering the ten algorithms), and the highest number of wins defines the most suitable constraint-handling technique in the synthesis of lower limb rehabilitation mechanisms for each study case. A total of ninety comparisons was carried out, considering the three CHT comparisons with the ten metaheuristic algorithm for the three study cases.

The number of wins per CHT in algorithms from the comparisons is presented in

Table 8. The results indicate that the feasible rules improve the algorithm performance in the comparisons at

for study case 1,

for study case 2, and

for study case 3. The overall improvement for the ninety comparisons (in all study cases) with the FR is around

. It is also observed in

Table A11 of

Appendix D that only eight comparisons with other CHTs (DECB EC, DECR1B SR, DECR1E EC, GA SR, GA PF, PSO SR, PSO

C, and PSO PF) outperformed the values obtained in FR (around

of the total comparisons).

Nevertheless, the obtained solutions in such comparisons did not surpass the best solutions provided by the FR as is observed visually in

Figure 5 and numerically in

Table A7,

Table A8 and

Table A9 of

Appendix C. Then, the improvement in the eight algorithms using the CHTs in such comparisons did not influence a better overall behavior. In addition, in the remaining ninety comparisons (around

) with respect to the FR, there were no conclusive results about improving an algorithm. The latter means that there are no other CHTs in the algorithms that present a better behavior than the FR.

On the other hand, the penalty function outperformed at

in study case 1,

in study case 2, and

in study case 3 of the comparisons with respect to the other CHTs. The

-constraint method improved at

,

, and

in the corresponding study cases. The stochastic ranking outperformed at

,

, and

of the comparisons. Nevertheless, in the last three CHTs, several comparisons exist where the CHTs in the algorithm to which it is compared outperformed such results as shown in

Table A11 of

Appendix D.

Thus, it is confirmed, with confidence, that the feasibility rules improved the search capabilities of the algorithm with respect to the other CHTs. This implies that the optimal synthesis of the lower limb rehabilitation mechanism can be benefited by using the FR to solve such a constrained optimization problem because this can improve the quality and the consistency of results in most of the algorithms reviewed in this work.

5.3. Statistical Analysis of the CHT Behavior through Metrics

This work is also interested in knowing the search capabilities of metaheuristic algorithms with the constraint-handling techniques related to different performance metrics. Then, six performance metrics [

62] found in the specialized literature were used. Each of these metrics is described below:

The feasibility probability (FP) is obtained by dividing the number of feasible executions by the total number of executions. FP is in the range of , where 0 represents that there are not feasible solutions, and 1 represents that all found solutions are feasible.

The convergence probability (P) is obtained by dividing the number of successful executions by the total number of executions. The successful solutions are defined as the solutions

x close to the best solution

in the objective function space. Therefore, a satisfactory solution can be determined by

, where the best executions per each study case is shown in

Table A7,

Table A8 and

Table A9 of

Appendix C. The value of

is related to the bias region in the synthesis problem where the mechanism executes a suitable rehabilitation routine.

For the four-bar mechanism, and are considered; for the cam-linkage mechanism, and are chosen; and for the eight-bar linkage mechanism, and are selected. The P metric value is in the interval , where a higher value (the best P metric) implies that all executions converge to the region. The metric is related to the reliability of an algorithm to find successful solutions.

AFES is the average number of function evaluations required for each successful execution. Successful execution is considered when it finds the first solution in the bias region . If successful executions are not found, Non-Successful Executions (NSE) are accounted for. The best result in the AFES metric is first related to the minimum value in NSE and then to the lower values of the AFES. This metric indicates a convergence speed measure to the bias region .

Successful performance (SP) divides the AFES by P. The best result in the SP metric is first related to the minimum value in NSE and then to the lower values of the SP.

EVALS counts the number of evaluations an algorithm needs to find the first feasible solution in every execution. Lower evaluations mean a low computational cost to reach a feasible solution; therefore, this is preferred. This metric is presented with the use of statistics.

The Progress Ratio (PR) measures the improvement capability of an algorithm inside the feasible region in every execution. This metric is calculated by (

86) where

is the value of the objective function of the first feasible solution, and

is the value of the objective function of the best feasible solution in the algorithm execution. It is assumed in (

86) that

is fulfilled. A higher value in this metric is preferred and also presented by using statistics.

As commented previously, thirty executions of each constraint-handling technique included in the metaheuristic algorithms were carried out for each study case. The values of the metrics

,

P,

, and

for the thirty executions for each algorithm at each study case are presented in

Table A12,

Table A13,

Table A14 and

Table A15 of

Appendix E. The summaries (averages values) of those metrics are displayed in

Table 9. We observed that, for the metric FP, the

C provided the best results in the three study cases, followed by the FR and PF, in that order. For the metric P, the FR obtained the best results in cases 1 and 3. In the second study case, the result in FR was close to the best one provided by the PF. In the AFES metric, the FR,

C, and PF won in only one study case. For the SP value, the FR provided the best result in two study cases.

In the case of the metrics

and

, inferential statistics using the non-parametric Friedman test for multiple comparisons are included to confirm the performance. The distribution of the samples related to such metric values per each algorithm at each study case is shown in the box plots of

Figure 6 and

Figure 7, respectively, and the numerical results of the

and

metrics are presented in

Table A16,

Table A17,

Table A18,

Table A21,

Table A22 and

Table A23 of

Appendix E, respectively. The multi comparative Friedman test is presented in

Appendix E.6 and

Appendix E.8. Summaries of the winning numbers of these comparisons are displayed in

Table 10 and

Table 11.

The metric for study case 1 indicates that feasible solutions were found in the initialization of the 200 individuals (particles) of the population (swarm). As a result, all executions required at least 200 evaluations to find a feasible solution (the feasible region). For this reason, the samples were not significant to determine a winner in the CHT in such a metric. In study case 2, the confirmed the superior performance in the metric. In study case 3, the -constraint method improved the convergence to the feasible region in fewer generations. Finally, in the metric, it was confirmed in two study cases that the -constraint method can improve the solutions through the feasible region when the generations occur, followed by the SR that won in only one study case.

According to the results obtained by the previous analysis in the performance metrics, the following findings of the CHTs in the optimal synthesis of the lower limb rehabilitation mechanism synthesis were observed:

The FR had one of the best performance and the best one of the search for feasible solutions and satisfactory regions for the three study cases, respectively, because this constraint-handling technique has a high probability value in the FP and P metrics. The relationship between the AFES and P gave by SP is the best among the CHTs. Therefore, among the studied CHTs, the Feasibility Rules technique is the most reliable one for the synthesis of mechanisms for rehabilitation.

The PF can be considered the second option for solving mechanism synthesis for rehabilitation problems because it showed a suitable performance to find satisfactory solutions (P and SP metrics) compared to Stochastic-Ranking and -constraint. This establishes acceptable reliability to find feasible solutions (FP metric).

C method presented the best performance in the search for feasible regions as shown in FP. Inside the feasible region, this CHT produces improved solutions based on the PR metric. Nevertheless, the probability of this CHT to search for satisfactory solutions was low (P and SP metrics). This behavior is attributed to the gradient-based mutation where fast convergence to feasible local regions is promoted.

SR is the less reliable CHT because some algorithm executions can not find feasible solutions (FP metric). This presents a low performance in the search for suitable solutions (P metric).

According to the results in this section, the Feasibility Rules presented the best performance for handling constraints in the mechanism synthesis for rehabilitation problems. The Penalty Functions gave the second best performance. Those CHTs improved the quality and the consistency in most of the algorithms reviewed in this work.

5.4. Evaluation of the Obtained Mechanisms

In this section, the best solutions obtained by the feasibility rules (according to the overall performance presented in

Table 8), and the worst constraint-handling technique are presented.

In study case 1, the best constraint-handling technique was the feasibility rules, and the worst was stochastic-ranking. The Computer-Aided Design (CAD) and the generated trajectory of the best mechanisms obtained by both constraint-handling techniques are presented in

Figure 8, where the objective function values of the mechanisms obtained by the feasibility rules (with the algorithm DECR) is

, and by stochastic-ranking (with the algorithm DECR1E) is

. Those values are given in

Table A7 of

Appendix C.

According to the design parameters obtained in both CHTs (see

Table A26 of

Appendix F), the feasibility rules present a Pearson correlation coefficient of

with respect to the stochastic-ranking. This indicates a high degree of similarity (see

Figure 8). On the other hand, the performance of the design goals is presented in

Figure 8c,d.

Figure 8c shows the trajectory of the mechanisms, the current, and the desired precision points. The average error between the desired precision points and the current ones is

[m] by Feasibility Rules (FR) and

[m] by Stochastic-Ranking (SR).

Figure 8d shows the angles obtained by the crank and the desired angles, where the average angular error is

[rad] by feasibility rules, and

[rad] by stochastic-ranking. We observed that the design goals in both mechanisms related to

and

, present a trade-off, i.e., in one goal, it is better but in the other not. Then, solutions obtained by the feasible rules and the stochastic-ranking are suitable for the rehabilitation mechanism. Nevertheless, the feasible rules provide more reliable results through different algorithm executions and with a better overall performance (related to the objective function

J).

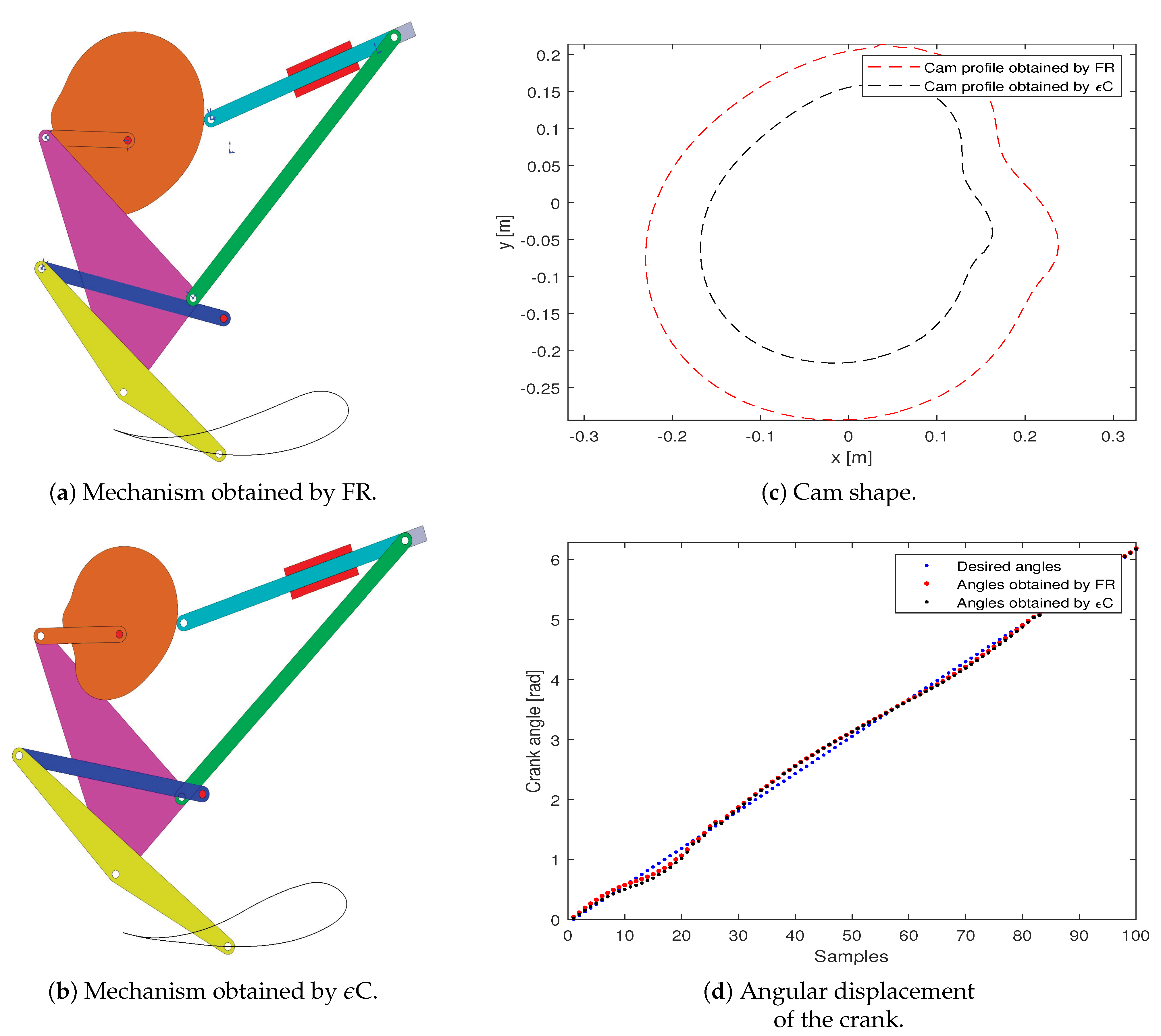

In study case 2, the feasibility rule was the best constraint-handling technique, and the worst was the epsilon-constraint. The CAD and the generated trajectory of the best mechanisms obtained by both constraint-handling techniques are presented in

Figure 9. The objective function values given by the mechanisms obtained by the feasibility rules (DEB1B) is

and by epsilon-constraint (DEB1E) is

. Those values are given in

Table A8 of

Appendix C.

According to the design parameters obtained in both CHTs (see

Table A27 of

Appendix F), the feasibility rules present a Pearson correlation coefficient of

with respect to the epsilon-constraint. This correlation is larger than the obtained mechanisms in the previous study case 1, which implies a fairly strong relationship. In order to highlight the difference, the performance of the design goals is presented in

Figure 9c,d for the cam shapes and the angles obtained by the crank, respectively.

The normalized average error between the desired crank angles and the current ones is by feasibility rules and by epsilon-constraint. The normalized base radius of the cam is by FR, and by epsilon-constraint. It is observed again that the design goals present a trade-off, such that both mechanisms are suitable for the rehabilitation routine, and it depends on the application that one selects. However, the feasible rules can search for solutions with a similar performance through different executions and with better quality in the overall performance in the weighted objective function J.

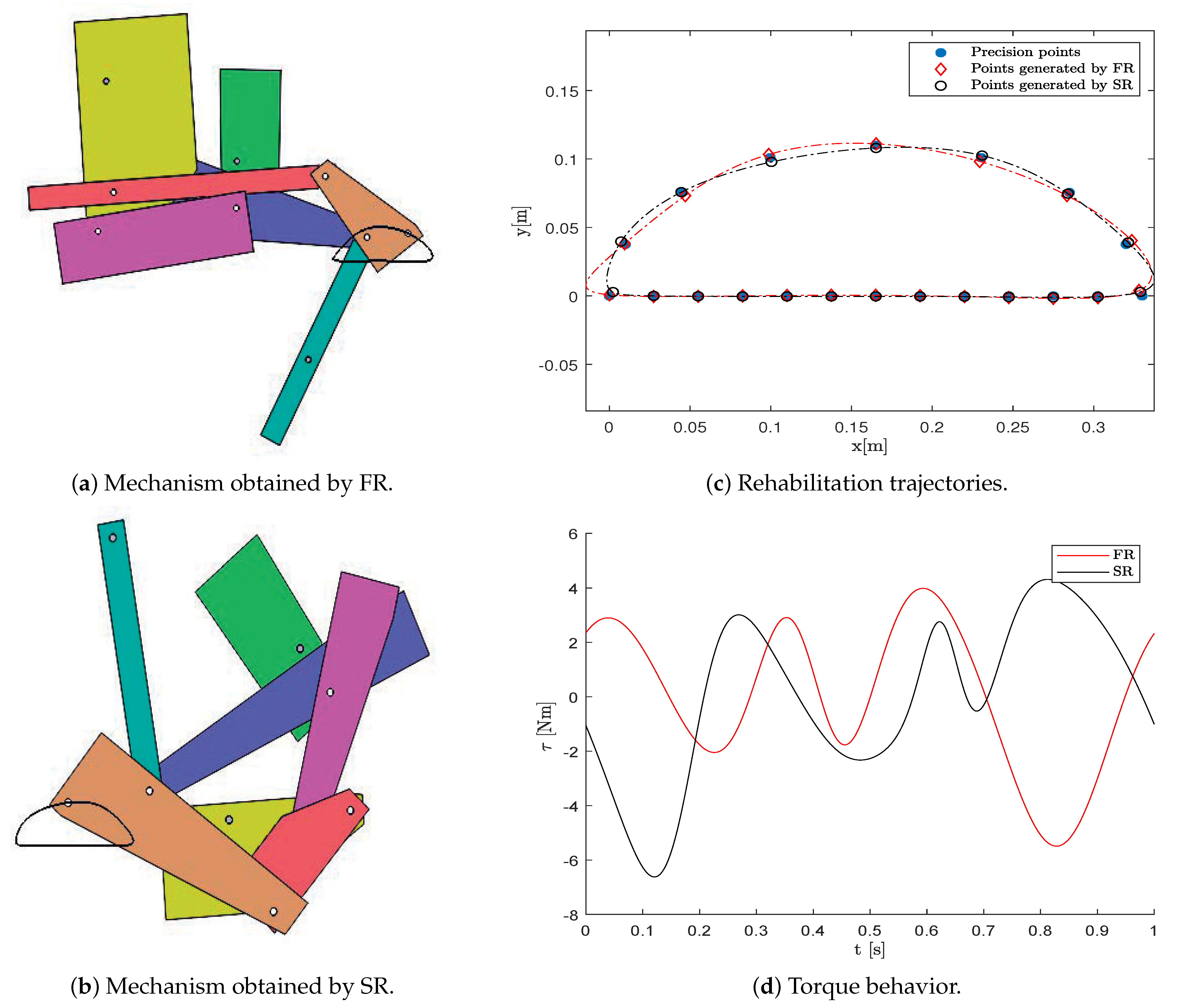

Finally, for study case 3, the best constraint-handling technique was the feasibility rules, and the worst one was stochastic-ranking. The CAD and the generated trajectory are presented in

Figure 10, where the objective function values of the mechanisms obtained by the feasibility rules (DECR) is

, and by stochastic-ranking (DECR) is

. Those values are given in

Table A9 of

Appendix C.

According to the design parameters obtained in both CHTs (see

Table A28 of

Appendix F), the feasibility rules present a Pearson correlation coefficient of

with respect to the stochastic-ranking. As the problem complexity in study case 3 is higher than in the other cases, the obtained solution presents differences, as is observed in

Figure 10a,b. The behavior of the design goals related to the generated trajectory in the mechanisms and the torque applied in the crank link are displayed in

Figure 10c,d, respectively.

In this case, the average error between the desired precision points and the current ones is [m] by feasibility rules and [m] by stochastic-ranking. The average torque is [Nm] by feasibility rules, and [Nm] by stochastic-ranking. Neither mechanism can be considered the best because they present a trade-off in the design goals. Thus, design solutions obtained by the feasible rules and the stochastic-ranking are suitable for the rehabilitation mechanism. Nevertheless, the feasible rule provides more reliable results through different executions and the second-best overall performance (related to the objective function J).