Workspace Analysis of a Mobile Manipulator with Obstacle Avoidance in 3D Printing Tasks

Abstract

:1. Introduction

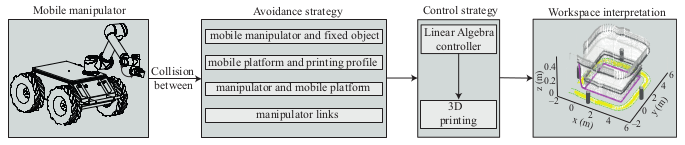

2. Materials and Methods

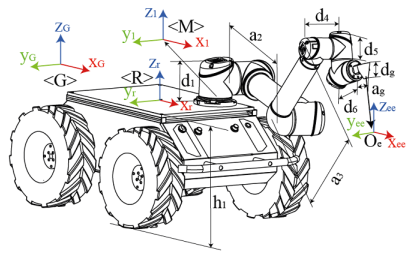

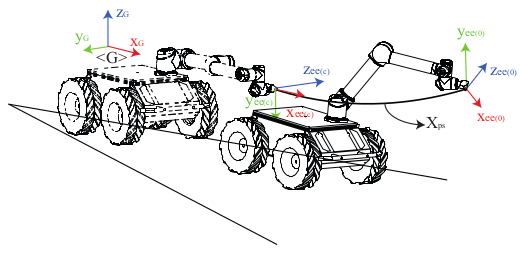

2.1. Robotic Platform

2.2. Mobile Manipulator

2.3. Modelling the Environment

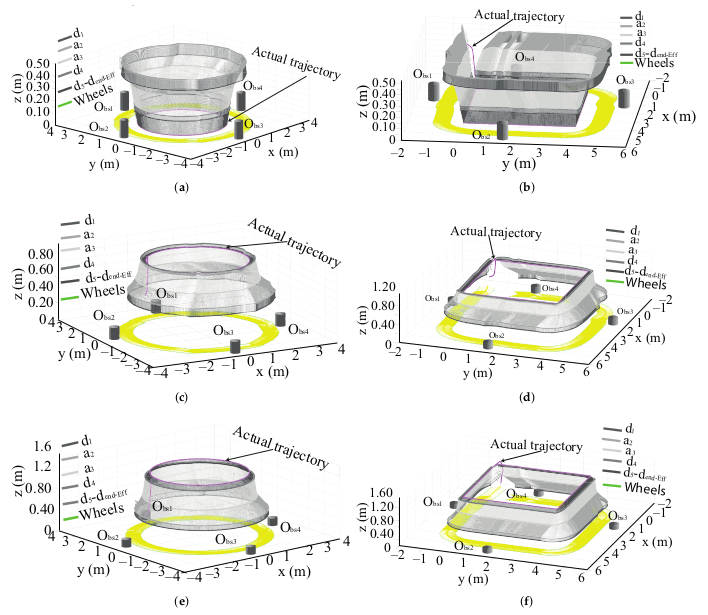

2.3.1. Workspace of Mobile Manipulator

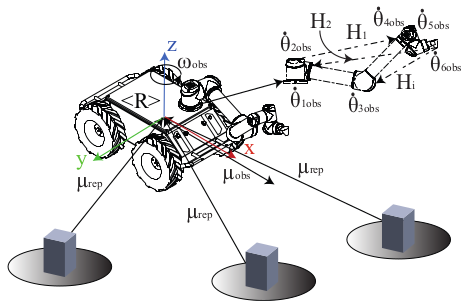

2.3.2. Obstacle Avoidance

2.4. Motion Control

2.4.1. Point Stabilization

2.4.2. Trajectory Tracking

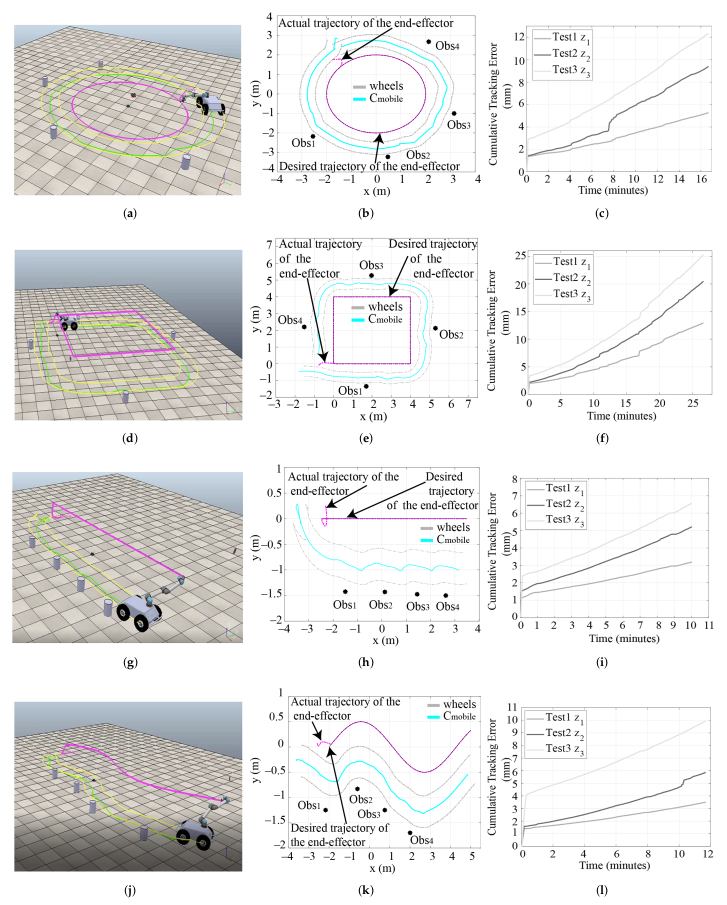

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Parhi, R. A review of three-dimensional printing for pharmaceutical applications: Quality control, risk assessment and future perspectives. J. Drug Deliv. Sci. Technol. 2021, 64, 102571. [Google Scholar] [CrossRef]

- Daminabo, S.; Goel, S.; Grammatikos, S.; Nezhad, H.; Thakur, V.K. Fused deposition modeling-based additive manufacturing (3D printing): Techniques for polymer material systems. Mater. Today Chem. 2020, 16, 100248. [Google Scholar] [CrossRef]

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Aggarwal, L. Reconfigurable Validation Model for Identifying Kinematic Singularities and Reach Conditions for Articulated Robots and Machine Tools. Master’s Thesis, University of Windsor, Windsor, ON, Canada, 2014. [Google Scholar]

- Alebooyeh, M.; Urbanic, R.J. Neural Network Model for Identifying Workspace, Forward and Inverse Kinematics of the 7-DOF YuMi 14000 ABB Collaborative Robot. IFAC-PapersOnLine 2019, 52, 176–181. [Google Scholar] [CrossRef]

- Panda, S.; Mishra, D.; Biswal, B.; Choudhury, B. An appropriate formulation for workspace cross section area of 3R robot manipulator. In Proceedings of the 2009 International Conference on Industrial and Information Systems (ICIIS), Peradeniya, Sri Lanka, 28–31 December 2009; pp. 511–515. [Google Scholar]

- Aboulissane, B.; El Haiek, D.; El Bakkali, L.; El Bahaoui, J. On The Workspace Optimization of Parallel Robots Based on CAD Approach. Procedia Manuf. 2019, 32, 1085–1092. [Google Scholar] [CrossRef]

- Hu, B.; Cui, H.; Shi, D.; Zhang, D.; Wang, A.; Wang, Y.; Zhang, Q. Reachable workspace determination for a spatial hyper-redundant manipulator formed by several parallel manipulators. J. Mech. Sci. Technol. 2019, 33, 869–877. [Google Scholar] [CrossRef]

- Mahmoodi, M.; Tabrizi, M.G.; Alipour, K. A new approach for Kinematics-based design of 3-RRR delta robots with a specified workspace. In Proceedings of the 2015 AI & Robotics (IRANOPEN), Qazvin, Iran, 12 April 2015; pp. 1–6. [Google Scholar]

- Anvari, Z.; Ataei, P.; Masouleh, M.T. Collision-free workspace and kinetostatic performances of a 4-DOF delta parallel robot. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 99. [Google Scholar] [CrossRef]

- Bader, A.M.; Maciejewski, A.A. Maximizing the failure-tolerant workspace area for planar redundant robots. Mech. Mach. Theory 2020, 143, 103635. [Google Scholar] [CrossRef]

- Li, Z.Y.; Zhao, D.J.; Zhao, J.S. Structure synthesis and workspace analysis of a telescopic spraying robot. Mech. Mach. Theory 2019, 133, 295–310. [Google Scholar] [CrossRef]

- Moulianitis, V.; Xidias, E.; Azariadis, P. Optimal Task Placement in a Metamorphic Manipulator Workspace in the Presence of Obstacles. In Proceedings of the International Conference on Robotics in Alpe-Adria Danube Region, Patras, Greece, 6–8 June 2018; pp. 359–367. [Google Scholar]

- Yovchev, K. Iterative learning control for precise trajectory tracking within a constrained workspace. In Proceedings of the International Conference on Robotics in Alpe-Adria Danube Region, Patras, Greece, 6–8 June 2018; pp. 483–492. [Google Scholar]

- Ferraguti, F.; Landi, C.T.; Costi, S.; Bonfè, M.; Farsoni, S.; Secchi, C.; Fantuzzi, C. Safety barrier functions and multi-camera tracking for human–robot shared environment. Robot. Auton. Syst. 2020, 124, 103388. [Google Scholar] [CrossRef]

- Mohan, C.; Verma, H. Direction and distance sensors and sensing system for elderly people. Mater. Today Proc. 2020, 34, 667–674. [Google Scholar] [CrossRef]

- Luu, T.H.; Tran, T.H. 3D vision for mobile robot manipulator on detecting and tracking target. In Proceedings of the 2015 15th International Conference on Control, Automation and Systems (ICCAS), Busan, Korea, 13–16 October 2015; pp. 1560–1565. [Google Scholar]

- Safeea, M.; Neto, P.; Bearee, R. On-line collision avoidance for collaborative robot manipulators by adjusting off-line generated paths: An industrial use case. Robot. Auton. Syst. 2019, 119, 278–288. [Google Scholar] [CrossRef] [Green Version]

- Goyal, K.; Sethi, D. An analytical method to find workspace of a robotic manipulator. J. Mech. Eng. 2010, 41, 25–30. [Google Scholar] [CrossRef] [Green Version]

- Djuric, A.; Urbanic, J.; Filipovic, M.; Kevac, L. Effective work region visualization for serial 6 DOF robots. In Enabling Manufacturing Competitiveness and Economic Sustainability; Springer: Munich, Germany, 2013; pp. 207–212. [Google Scholar]

- Urbanic, R.; Gudla, A. Functional Work Space Estimation of a Robot using Forward Kinematics, DH Parameters, and Shape Analyses. In Proceedings of the ASME 2012 11th Biennial Conference on Engineering Systems Design and Analysis, Nantes, France, 2–4 July 2012; pp. 381–391. [Google Scholar]

- Liu, Z.; Zhang, R.; Wang, W.; Ma, X.; You, R.; Li, Z. Robot Workspace Reconstructing Solving Method Based on Image Engine. In Proceedings of the 2017 International Conference on Industrial Informatics-Computing Technology, Intelligent Technology, Industrial Information Integration (ICIICII), Wuhan, China, 2–3 December 2017; pp. 181–185. [Google Scholar]

- Zaplana, I.; Basanez, L. A novel closed-form solution for the inverse kinematics of redundant manipulators through workspace analysis. Mech. Mach. Theory 2018, 121, 829–843. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhang, J.; Yang, C.; Niu, B. The workspace mapping with deficient-DOF space for the PUMA 560 robot and its exoskeleton arm by using orthogonal experiment design method. Robot. Comput.-Integr. Manuf. 2007, 23, 478–487. [Google Scholar] [CrossRef]

- Jha, R.; Chablat, D.; Baron, L.; Rouillier, F.; Moroz, G. Workspace, joint space and singularities of a family of delta-like robot. Mech. Mach. Theory 2018, 127, 73–95. [Google Scholar] [CrossRef] [Green Version]

- Fiore, E.; Giberti, H.; Sbaglia, L. Dimensional synthesis of a 5-DOF parallel kinematic manipulator for a 3d printer. In Proceedings of the 2015 16th International Conference on Research and Education in Mechatronics (REM), Bochum, Germany, 18–20 November 2015; pp. 41–48. [Google Scholar]

- Peidró, A.; Reinoso, Ó.; Gil, A.; Marín, J.M.; Payá, L. An improved Monte Carlo method based on Gaussian growth to calculate the workspace of robots. Eng. Appl. Artif. Intell. 2017, 64, 197–207. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, K.; Gao, J. Dynamically Based Motor Parameters for Delta Robots Using the Specified Workspace. In Proceedings of the 2019 IEEE 6th International Conference on Industrial Engineering and Applications (ICIEA), Tokyo, Japan, 12–15 April 2019; pp. 814–818. [Google Scholar]

- Zhang, S.; Teizer, J.; Pradhananga, N.; Eastman, C.M. Workforce location tracking to model, visualize and analyze workspace requirements in building information models for construction safety planning. Autom. Constr. 2015, 60, 74–86. [Google Scholar] [CrossRef]

- Hosny, A.; Nik-Bakht, M.; Moselhi, O. Workspace planning in construction: Non-deterministic factors. Autom. Constr. 2020, 116, 103222. [Google Scholar] [CrossRef]

- Kassem, M.; Dawood, N.; Chavada, R. Construction workspace management within an Industry Foundation Class-Compliant 4D tool. Autom. Constr. 2015, 52, 42–58. [Google Scholar] [CrossRef]

- Scaglia, G.; Montoya, L.Q.; Mut, V.; di Sciascio, F. Numerical methods based controller design for mobile robots. Robotica 2009, 27, 269–279. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Zhu, M.; Wang, X.; He, S.; He, J.; Xu, Z. An improved artificial potential field method of trajectory planning and obstacle avoidance for redundant manipulators. Int. J. Adv. Robot. Syst. 2018, 15, 1729881418799562. [Google Scholar] [CrossRef] [Green Version]

- Husky Unmanned Ground Vehicle. Husky UGV—Outdoor Field Research Robot by Clearpath. Available online: https://clearpathrobotics.com/husky-unmanned-ground-vehicle-robot/ (accessed on 12 July 2021).

- Universal Robots. Collaborative Robotic Automation|Cobots from Universal Robots. Available online: https://www.universal-robots.com/ (accessed on 12 July 2021).

- Rivera, R.G.; García Alvarado, R.; Martínez-Rocamora, A.; Auat Cheein, F. A Comprehensive Performance Evaluation of Different Mobile Manipulators Used as Displaceable 3D Printers of Building Elements for the Construction Industry. Sustainability 2020, 12, 4378. [Google Scholar] [CrossRef]

- Yao, J.; Sun, X.; Zhang, S.; Yang, M.; Zhang, X. Monte Carlo method for searching functional workspace of an underwater manipulator. In Proceedings of the 2018 Chinese Control And Decision Conference (CCDC), Shenyang, China, 9–11 June 2018; pp. 6431–6435. [Google Scholar]

- Cao, B.; Sun, K.; Gu, Y.; Jin, M.; Liu, H. Workspace Analysis Based on Manipulator Pose Dexterity Map. In Proceedings of the 2018 3rd International Conference on Robotics and Automation Engineering (ICRAE), Guangzhou, China, 17–19 November 2018; pp. 166–170. [Google Scholar]

- Liu, Q.; Chen, C.Y.; Wang, C.; Wang, W. Common workspace analysis for a dual-arm robot based on reachability. In Proceedings of the 2017 IEEE International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE Conference on Robotics, Automation and Mechatronics (RAM), Ningbo, China, 19–21 November 2017; pp. 797–802. [Google Scholar]

- Coppelia Robotics. Robot Simulator CoppeliaSim: Create, Compose, Simulate, any Robot—Coppelia Robotics. Available online: https://www.coppeliarobotics.com/ (accessed on 12 July 2021).

| Industrial Prototypes | Optimal Workspace Analysis | References | |

|---|---|---|---|

| RV-M1 Mitsubishi | The model of the optimal workspace of an industrial manipulator is based on the Denavit–Hartenberg parameters. | [20] | |

| FANUC cr | The workspace is estimated with a window algorithm with singularity visualization for manipulator configuration. | [21] | |

| ABB IRB-140 | The study of the workspace uses the kinematic model and shape analyses. | [22] | |

| Robotic arm | ABB IRB-1660ID | A visual method is compared with the Monte Carlo method to obtain the optimal workspace of the manipulator robot. The results show that the visual model presents better modeling and digitalization features. | [23] |

| Kuka LWR 4+ Staubli TX90 | The study analyses the workspace of two redundant robots by discretising some joints and then reconstructs the 3D by revoluting the plane area computed. The advantage of this method is that it calculates the value of the workspace volume, allowing better tracking of the differences between the workspaces. | [24] | |

| PUMA 560 | The technique of mapping the workspace with deficient-DOF solves the problems of maneuverability and stability of the robotic arm. | [25] | |

| Delta 3DOF | The algorithm of Cylindrical Algebraic Decomposition is studied to obtain the optimal workspace of the industrial manipulator. The SIROPA library represents the complexity and singularity of the workspace. | [26] | |

| Delta 5DOF | Genetic algorithms are analyzed to find the optimal workspace. | [27] | |

| Parallel Robot | Delta 10 DOF | The Monte Carlo method is used along with a Gaussian distribution to evaluate the limits of the optimal workspace. | [28] |

| FANUC-Delta | The SolidWorks software determines the limits of the robot arm joints. The dynamic simulation function accurately describes the motion of the robot platform in an optimal workspace. | [29] |

| Robotic Platform | Weight | Payload | Reach | Speed | I/O Power Suply |

|---|---|---|---|---|---|

| UR5 (Manipulator) | 18.4 kg | 5 kg | 850 mm | rad/s | 24 V 2 A |

| Husky (Mobile platform) | 50 kg | 75 kg | - | 1.0 m/s | 24 V 5 A |

| Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Length (m) | 0.0892 | 0.425 | 0.392 | 0.1093 | 0.09475 | 0.0823 | 0.005 | 0.01 | 0.41 |

| Robotic Arm | Mobile Platform | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (rad) | 0 | (m/s) | (rad/s) | |||||||

| (rad) | (m/s) | (rad/s) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guamán Rivera, R.; García Alvarado, R.; Martínez-Rocamora, A.; Auat Cheein, F. Workspace Analysis of a Mobile Manipulator with Obstacle Avoidance in 3D Printing Tasks. Appl. Sci. 2021, 11, 7923. https://doi.org/10.3390/app11177923

Guamán Rivera R, García Alvarado R, Martínez-Rocamora A, Auat Cheein F. Workspace Analysis of a Mobile Manipulator with Obstacle Avoidance in 3D Printing Tasks. Applied Sciences. 2021; 11(17):7923. https://doi.org/10.3390/app11177923

Chicago/Turabian StyleGuamán Rivera, Robert, Rodrigo García Alvarado, Alejandro Martínez-Rocamora, and Fernando Auat Cheein. 2021. "Workspace Analysis of a Mobile Manipulator with Obstacle Avoidance in 3D Printing Tasks" Applied Sciences 11, no. 17: 7923. https://doi.org/10.3390/app11177923

APA StyleGuamán Rivera, R., García Alvarado, R., Martínez-Rocamora, A., & Auat Cheein, F. (2021). Workspace Analysis of a Mobile Manipulator with Obstacle Avoidance in 3D Printing Tasks. Applied Sciences, 11(17), 7923. https://doi.org/10.3390/app11177923