Numerical Study on the Effect of Enhanced Buffer Materials in a High-Level Radioactive Waste Repository

Abstract

:1. Introduction

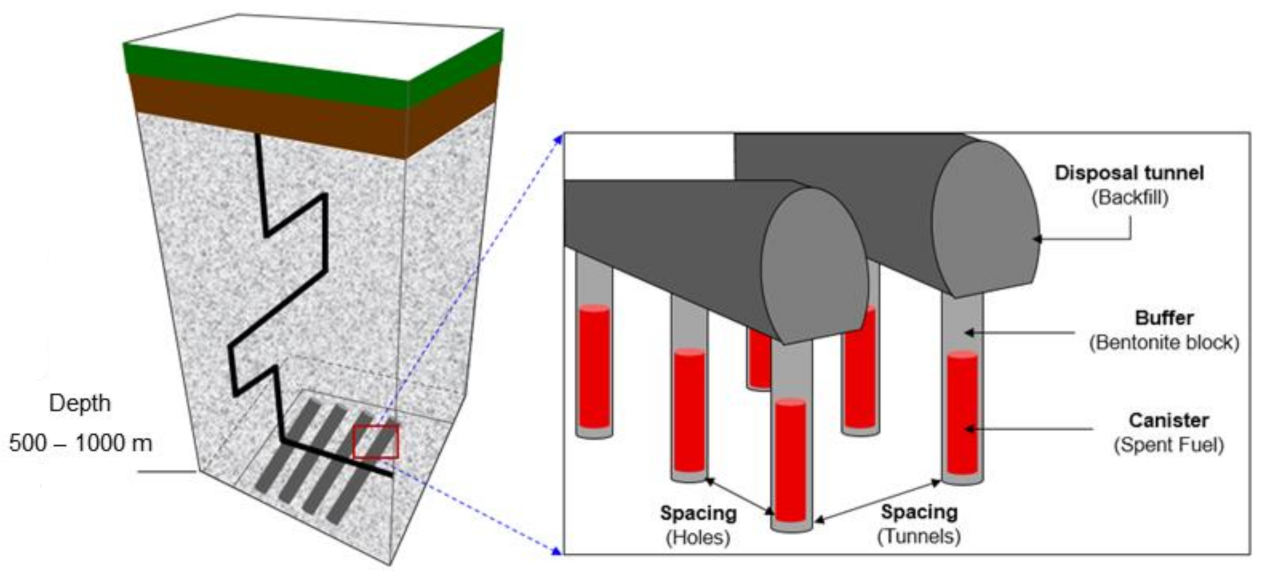

2. Preparation for the Numerical Analysis

2.1. Input Parameters for DEM

2.2. Construction of the Numerical Model

3. Results: Numerical Analysis

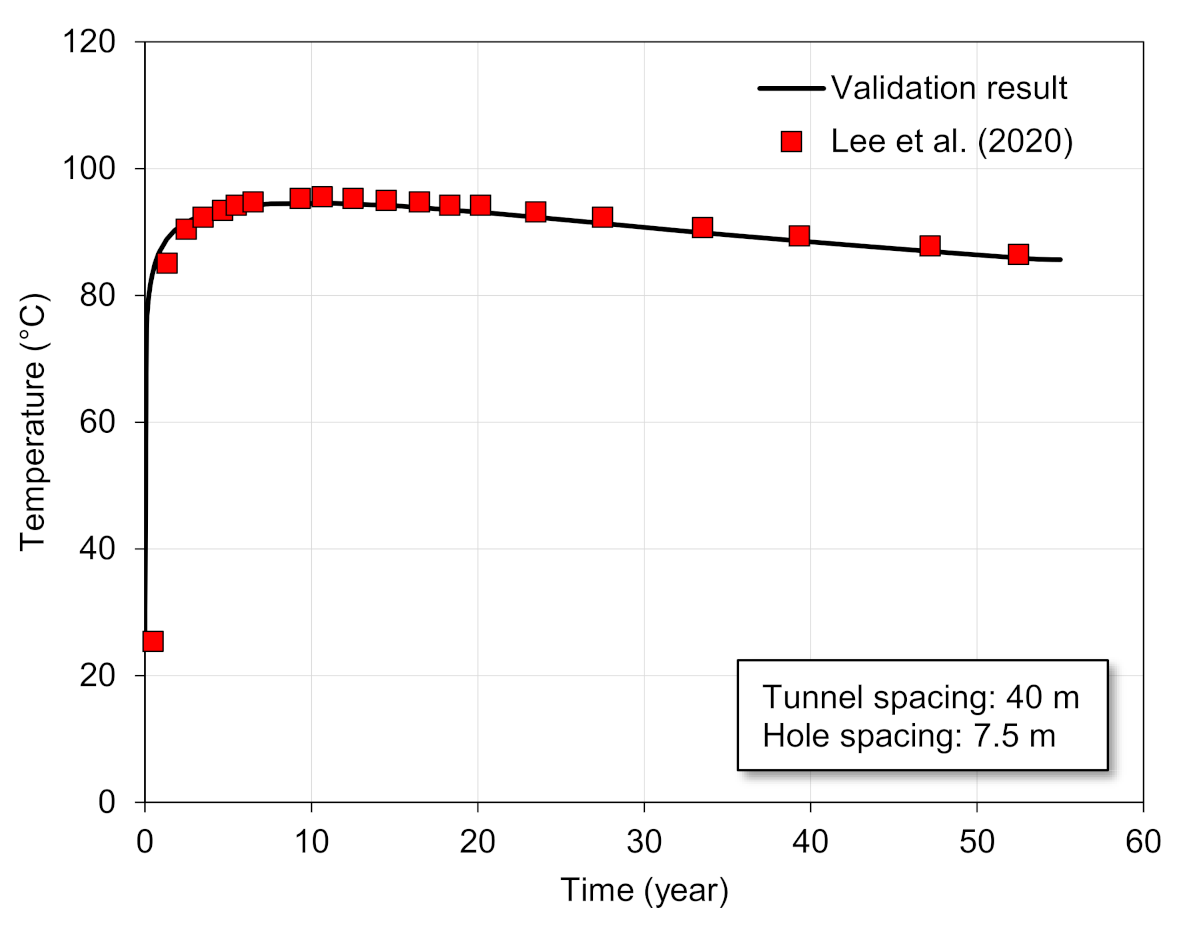

3.1. Validation

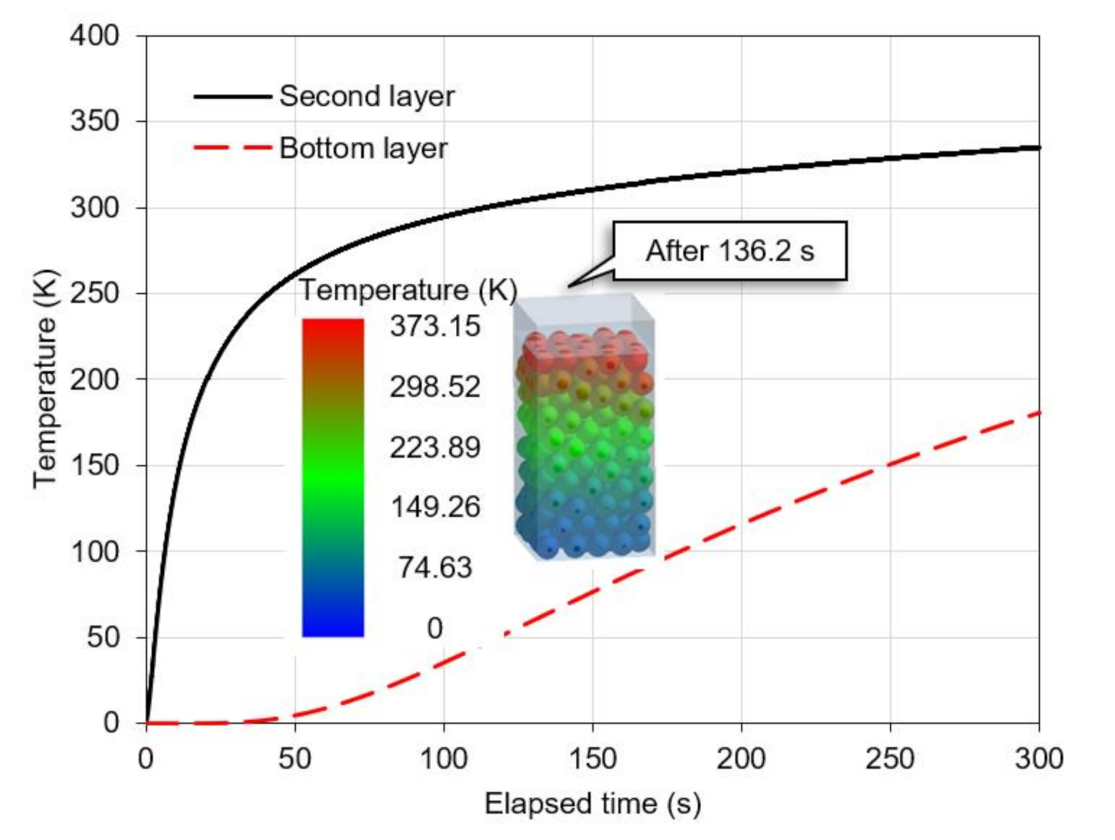

3.1.1. Input Parameters for DEM

3.1.2. Thermal Analysis Using FEM

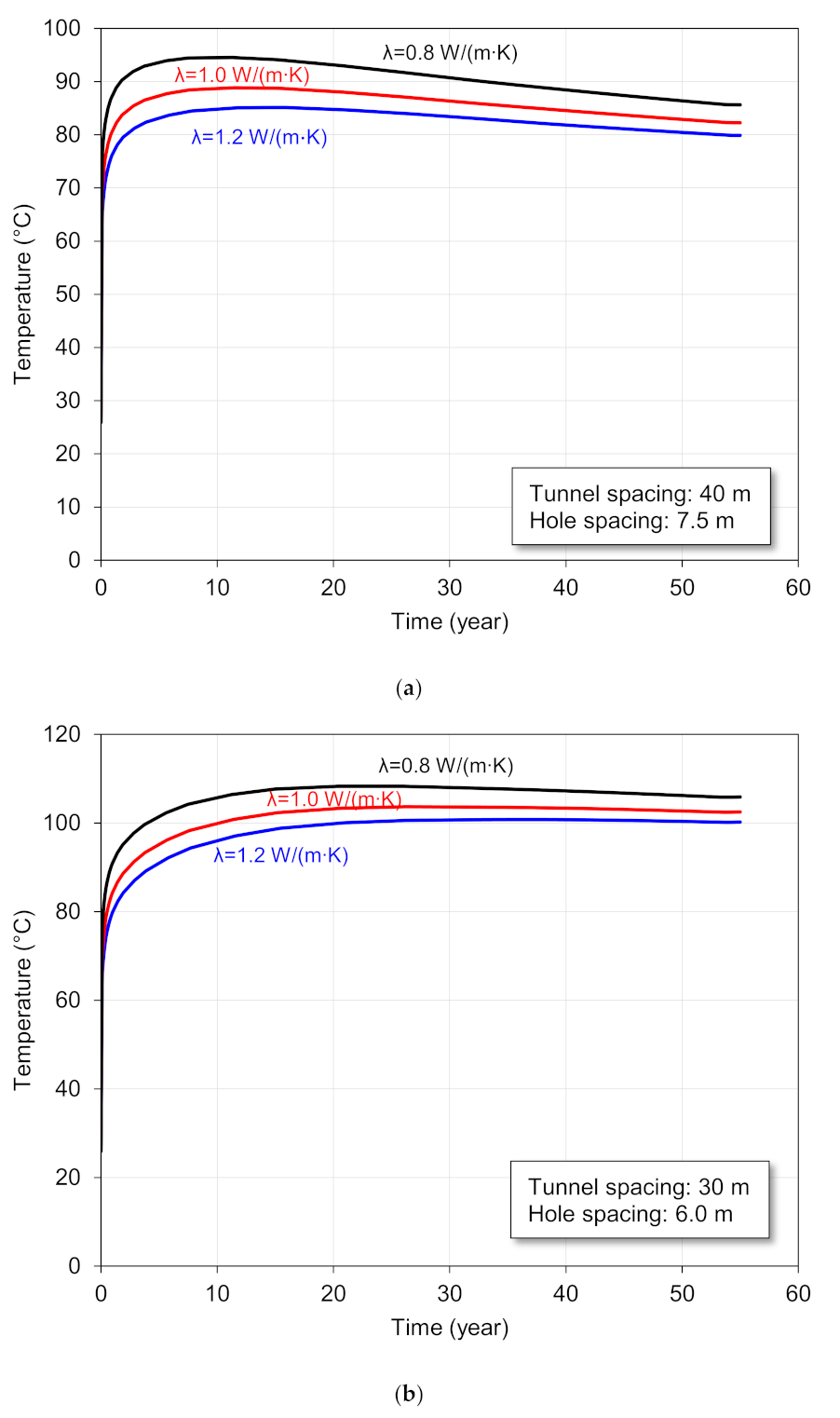

3.2. Parametric Study

4. Discussion

5. Conclusions

- A high-performance buffer material with improved thermal conductivity was used in the study. We analyzed the reduction in the distance between the disposal tunnels and disposal holes from the R-SNF of KRS+ conditions in 3D using the FEM model.

- When a buffer material with a thermal conductivity of approximately 1.2 W/(m∙K) added with graphite was used, the R-SNF condition of 40 m distance between the disposal tunnels and 7.5 m distance between the disposal holes could be reduced to 30 m and 6 m between the disposal tunnels and between the disposal holes, respectively.

- Additionally, the thermal conductivity test results conducted by Lee et al. (2013) [17] for bentonite mixed with graphite matched well with the results obtained from the DEM numerical analysis verification.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Juvankoski, M.; Ikonen, K. Buffer Production Line 2012-Design, Production and Initial State of the Buffer; POSIVA Oy: Olkiluoto, Finland, 2012; pp. 73–74. [Google Scholar]

- Svensk Karnbranslehantering AB (SKB). Buffer and Backfill Process Report for the Safety Assessment SR-Can. In SKB Technical Report; SKB: Solna, Sweden, 2006; pp. 27–33. [Google Scholar]

- Simmons, G.R.; Baumgartner, P. The Disposal of Canada’s Nuclear Fuel Waste: Engineering for a Disposal Facility; Atomic Energy of Canada Ltd.: Chalk River, ON, Canada, 1994. [Google Scholar]

- Kim, M.J.; Lee, S.R.; Yoon, S.; Jeon, J.S.; Kim, M.S. Optimal Initial Condition of a Bentonite Buffer with Regard to Thermal Behavior in a High-Level Radioactive Waste Repository. Comput. Geotech. 2018, 104, 109–117. [Google Scholar] [CrossRef]

- Wang, Y.; Hadgu, T. Enhancement of Thermal Conductivity of Bentonite Buffer Materials with Copper Wires/Meshes for High-Level Radioactive Waste Disposal. Nucl. Technol. 2020, 206, 1584–1592. [Google Scholar] [CrossRef]

- Jobmann, M.; Buntebarth, G. Influence of Graphite and Quartz Addition on the Thermo-Physical Properties of Bentonite for Sealing Heating-Generating Radioactive Waste. Appl. Clay Sci. 2009, 44, 206–210. [Google Scholar] [CrossRef]

- Colin, L.; David, H.; Roger, T. Review of the Current Status of Work on Enhanced Bentonite Buffer Material; AMEC: London, UK, 2014. [Google Scholar]

- Knutsson, S. On the Thermal Conductivity and Thermal Diffusivity of Highly Compacted Bentonite. In SKB Technical Report; SKB: Solna, Sweden, 1983; pp. 72–83. [Google Scholar]

- Xu, Y.; Zeng, Z.; Lv, H. Temperature Dependence of Apparent Thermal Conductivity of Compacted Bentonites as Buffer Material for High-Level Radioactive Waste Repository. Appl. Clay Sci. 2019, 174, 10–14. [Google Scholar] [CrossRef]

- Japan Nuclear Cycle Development Institute. H12 Project to Establish the Scientific and Technical Basis for HLW Disposal in Japan, Supporting Report 2: Repository Design and Engineering Technology; Japan Nuclear Cycle Development Institute: Ibaraki, Japan, 2000. [Google Scholar]

- Sun, D.A.; Cui, H.; Sun, W. Swelling of Compacted Sand-Bentonite Mixtures. Appl. Clay Sci. 2009, 43, 485–492. [Google Scholar] [CrossRef]

- Sun, W.; Fang, L. Swelling Characteristics of Gaomiaozi Bentonite and Its Prediction. J. Rock Mech. Geotech. Eng. 2014, 6, 113–118. [Google Scholar] [CrossRef] [Green Version]

- Cui, S.L.; Zhang, H.Y.; Zhang, M. Swelling Characteristics of Compacted GMZ Bentonite-Sand Mixtures as a Buffer/Backfill Material in China. Eng. Geol. 2012, 141, 65–73. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, H.; Cui, S.; Jia, L.; Zhou, L.; Chen, H. Engineering Properties of GMZ Bentonite-Sand as Buffer/Backfilling Material for High-Level Waste Disposal. Eur. J. Environ. Civ. Eng. 2012, 16, 1216–1237. [Google Scholar] [CrossRef]

- Xu, L.; Ye, W.M.; Chen, B.; Chen, Y.G.; Cui, Y.J. Experimental Investigations on Thermo-Hydro-Mechanical Properties of Compacted GMZ01 Bentonite-Sand Mixture Using as Buffer Materials. Eng. Geol. 2016, 213, 46–54. [Google Scholar] [CrossRef]

- Zhuang, Y.C.; Xie, K.H.; Sun, Y.H. Experimental Study on Thermal Conductivity of Mixed Materials of Sand and Bentonite. Rock Soil Mech. 2005, 26, 261–264. [Google Scholar]

- Lee, M.; Choi, H.J.; Lee, J.W.; Lee, J.P. Improvement of the Thermal Conductivity of a Compact Bentonite Buffer; Korea Atomic Energy Research Institute: Daejeon, Korea, 2013. [Google Scholar]

- Molina, J.M.; Prieto, R.; Narciso, J.; Louis, E. The Effect of Porosity on the Thermal Conductivity of Al-12 wt.% Si/SiC Composites. Scr. Mater. 2009, 60, 582–585. [Google Scholar] [CrossRef]

- Prieto, R.; Molina, J.M.; Narciso, J.; Louis, E. Thermal Conductivity of Graphite Flakes-SiC Particles/Metal Composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1970–1977. [Google Scholar] [CrossRef]

- Molina, J.M.; Rodríguez-Guerrero, A.; Louis, E.; Rodríguez-Reinoso, F.; Narciso, J. Porosity Effect on Thermal Properties of Al-12 Wt% Si/Graphite Composites. Materials 2017, 10, 177. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yoon, S.; Jeon, J.S.; Kim, G.Y.; Seong, J.H.; Baik, M.H. Specific Heat Capacity Model for Compacted Bentonite Buffer Materials. Ann. Nucl. Energy 2019, 125, 18–25. [Google Scholar] [CrossRef]

- Picard, S.; Burns, D.T.; Roger, P. Determination of the Specific Heat Capacity of a Graphite Sample Using Absolute and Differential Methods. Metrologia 2007, 44, 294. [Google Scholar] [CrossRef]

- Comsol Inc. Comsol Multiphysics User’s Manual; Comsol Inc.: Burlington, MA, USA, 2019. [Google Scholar]

- Incropera, F.P.; Dewitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer, 6th ed.; John Willey Sons Inc.: New Jersey, NJ, USA, 2007. [Google Scholar]

- Lee, J.; Kim, I.; Choi, H.; Cho, D. An Improved Concept of Deep Geological Disposal System Considering Arising Characteristics of Spent Fuels from Domestic Nuclear Power Plants. J. Nucl. Fuel Cycle Waste Technol. 2019, 17, 405–418. [Google Scholar] [CrossRef]

- Choi, H.J.; Lee, J.Y.; Choi, J. Development of Geological Disposal Systems for Spent Fuels and High-Level Radioactive Wastes in Korea. Nucl. Eng. Technol. 2013, 45, 29–40. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Kim, I.; Ju, H.; Choi, H.; Cho, D. Proposal of an Improved Concept Design for the Deep Geological Disposal System of Spent Nuclear Fuel in Korea. J. Nucl. Fuel Cycle Waste Technol. 2020, 18, 1–19. [Google Scholar] [CrossRef]

- Anthony, J. Probability and Statistics for Engineers and Scientists, 4th ed.; Thomson Brooks/Cole: Pacific Grove, CA, USA, 2012. [Google Scholar]

- Lee, J.O.; Choi, H.; Lee, J.Y. Thermal Conductivity of Compacted Bentonite as a Buffer Material for a High-Level Radioactive Waste Repository. Ann. Nucl. Energy 2016, 94, 848–855. [Google Scholar] [CrossRef]

- Yoon, S.; Kim, M.J.; Park, S.; Kim, G.Y. Thermal Conductivity Prediction Model for Compacted Bentonites Considering Temperature Variations. Nucl. Eng. Technol. 2021, 53, 3359–3366. [Google Scholar] [CrossRef]

| Density (kg/m3) | Thermal Conductivity (W/(m∙K)) | Specific Heat Capacity (J/kgK) | |

|---|---|---|---|

| Copper Shell | 8900 | 386 | 383 |

| Cast Insert | 7200 | 52 | 504 |

| Backfill | 1970 | 0.8 | 1380 |

| Rock | 2270 | 2 | 1190 |

| Bentonite Buffer | Parametric study | ||

| Items | y0 | x0 | A1 | t1 |

| Value | 297.9526 | 0.7805 | 3218.3828 | 2.9441 |

| Itemps | A2 | t2 | A3 | t3 |

| Value | 10394.9385 | 1.0966 | 2036.4309 | 42.7499 |

| Case | Tunnel Spacing (m) | Hole Spacing (m) | Thermal Conductivity of Buffer (W/(m∙K)) |

|---|---|---|---|

| 1 | 40 | 7.5 | 0.8 |

| 2 | 1.0 | ||

| 3 | 1.2 | ||

| 4 | 30 | 6.0 | 0.8 |

| 5 | 1.0 | ||

| 6 | 1.2 | ||

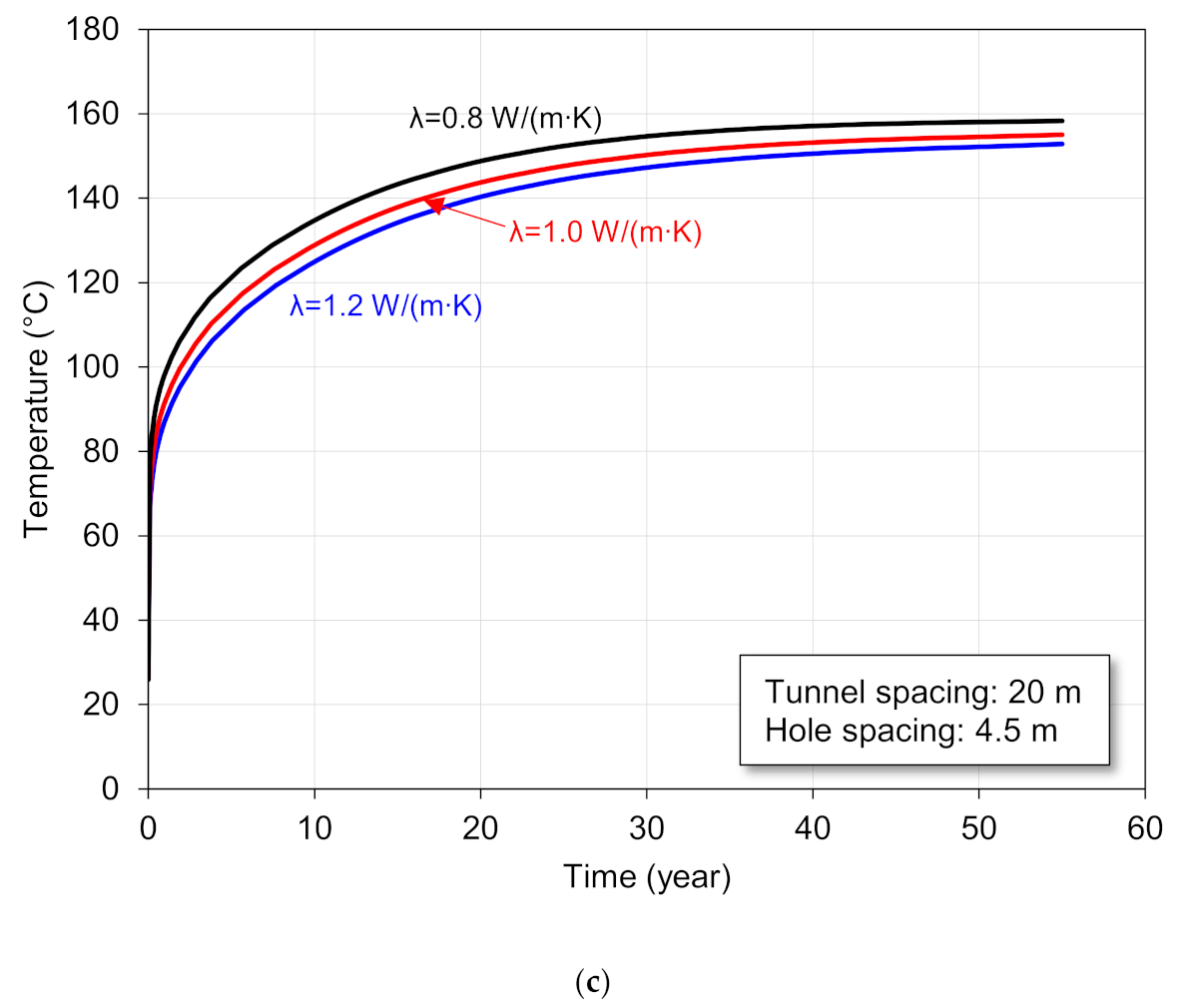

| 7 | 20 | 4.5 | 0.8 |

| 8 | 1.0 | ||

| 9 | 1.2 |

| Cases | Thermal Conductivities (λ, W/(m∙K)) | |||

|---|---|---|---|---|

| 0.8 | 1.0 | 1.2 | ||

| Tunnel spacing: 40 m Hole spacing: 7.5 m | Max.temperature (T, °C) | 94.53 | 88.85 | 85.15 |

| Time to reach max.T (years) | 11.3 | 11.5 | 15.7 | |

| Tunnel spacing: 30 m Hole spacing: 6.0 m | Max.temperature (T, °C) | 108.28 | 103.66 | 100.76 |

| Time to reach max.T (years) | 20.4 | 26.1 | 34.9 | |

| Tunnel spacing: 20 m Hole spacing: 4.5 m | Max.temperature (T, °C) | Divergence within 55 years | ||

| Time to reach max.T (years) | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.-J.; Lee, G.-J.; Yoon, S. Numerical Study on the Effect of Enhanced Buffer Materials in a High-Level Radioactive Waste Repository. Appl. Sci. 2021, 11, 8733. https://doi.org/10.3390/app11188733

Kim M-J, Lee G-J, Yoon S. Numerical Study on the Effect of Enhanced Buffer Materials in a High-Level Radioactive Waste Repository. Applied Sciences. 2021; 11(18):8733. https://doi.org/10.3390/app11188733

Chicago/Turabian StyleKim, Min-Jun, Gi-Jun Lee, and Seok Yoon. 2021. "Numerical Study on the Effect of Enhanced Buffer Materials in a High-Level Radioactive Waste Repository" Applied Sciences 11, no. 18: 8733. https://doi.org/10.3390/app11188733

APA StyleKim, M.-J., Lee, G.-J., & Yoon, S. (2021). Numerical Study on the Effect of Enhanced Buffer Materials in a High-Level Radioactive Waste Repository. Applied Sciences, 11(18), 8733. https://doi.org/10.3390/app11188733