Reliability-Based Design of Driven Piles Considering Setup Effects

Abstract

:1. Introduction

2. Basic Estimation Methods of Pile Setup

3. Estimation of the Resistance Factor of Driven Piles

3.1. General LRFD Principle of Driven Piles

3.2. Considering Setup Effects in the LRFD Principle of Driven Piles

4. Parametric Analysis

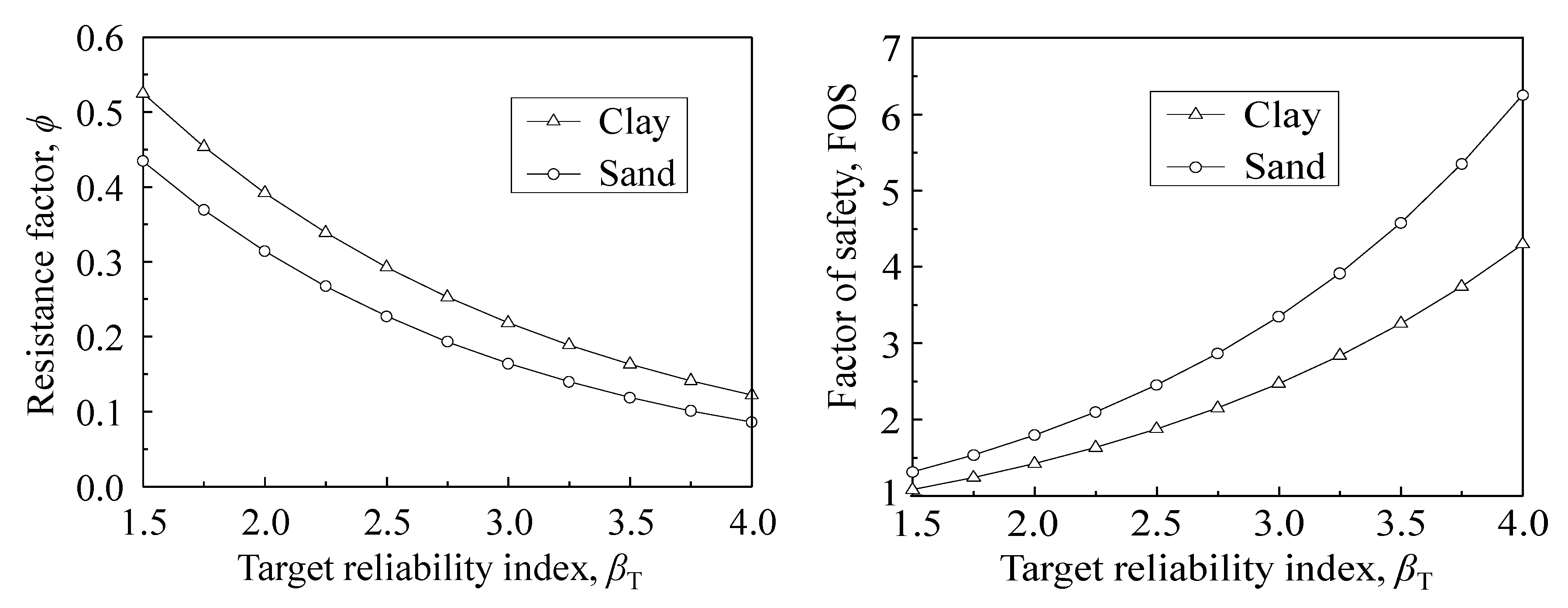

4.1. Effect of ρ on the Resistance Factor and the Factor of Safety

4.2. Effect of βT on the Resistance Factor and the Factor of Safety

4.3. Effect of Msetup on the Resistance Factor and the Factor of Safety

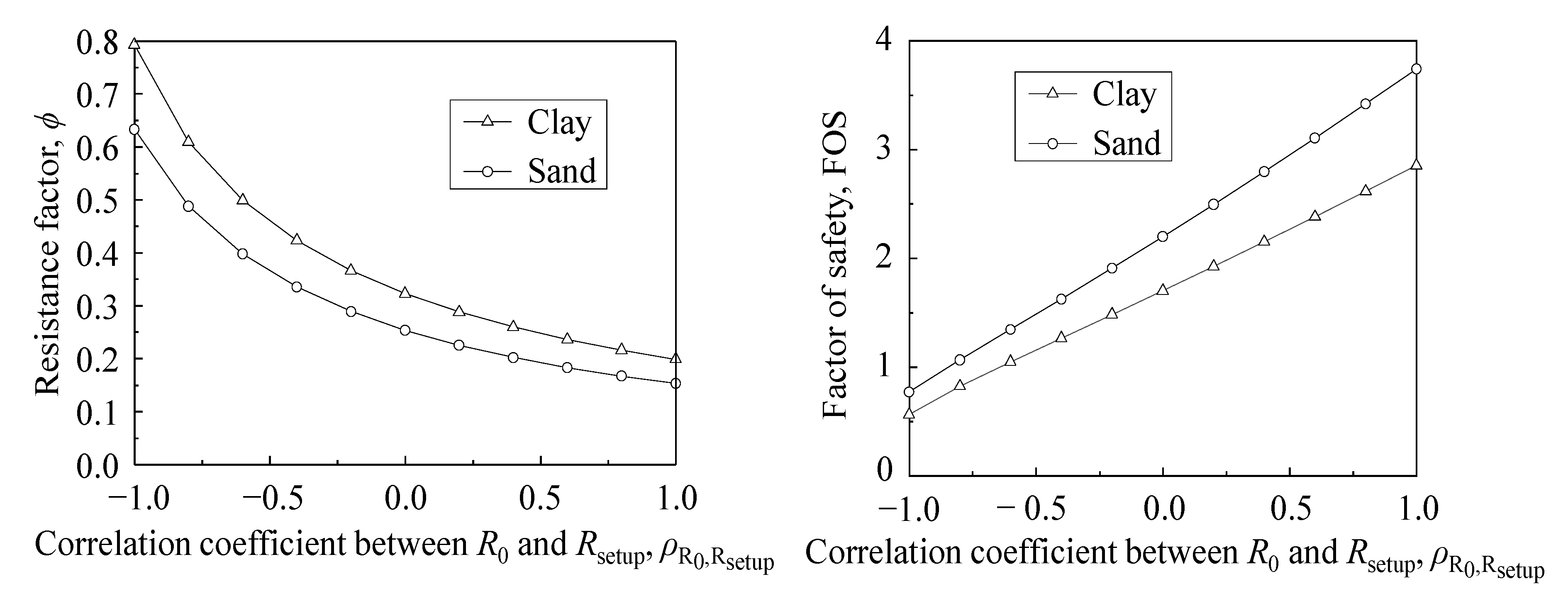

4.4. Effect of on Resistance Factor and Factor of Safety

5. Conclusions

- (1)

- ρ = QD/QL has basically no effect on the resistance factor of driven piles in clay and sand, so ρ can be regarded as a constant. Meanwhile, the resistance factor of driven piles in clay is greater than the resistance factor of driven piles in sand under the same ratio of dead load to live load level. It shows that the uncertainty of driven piles considering setup effects in sand is greater than the uncertainty of driven piles considering setup effects in clay.

- (2)

- Through the analysis of parametric βT, it is found that the smaller the resistance of the driven piles is, the higher the factor of safety for the driven piles, and the more reliable the driven piles are.

- (3)

- Through the analysis of parametric Msetup, it is found that the soil type has a great influence on the reliability-based design of driven piles. Meanwhile, whichever value of Msetup is selected, the resistance factor of driven piles considering setup effects in sand and clay are basically 0.25 and 0.32, respectively, and the factor of safety for driven piles considering setup effects in clay and sand are basically 1.7 and 2.2, respectively.

- (4)

- The analysis of the influence of ρR0,Rsetup on the resistance factor and factor of safety for driven piles indicates that the negative correlation between R0 and Rsetup has a significant influence on the resistance factor of driven piles, while the positive correlation between R0 and Rsetup has a slight influence on the resistance factor of driven piles. However, the factor of safety is just the opposite. Therefore, the correlation between R0 and Rsetup should be paid attention to in engineering applications.

Author Contributions

Funding

Conflicts of Interest

References

- Konrad, J.M.; Roy, M. Bearing capacity of friction piles in marine clay. Geotechnique 1987, 37, 163–175. [Google Scholar] [CrossRef]

- Carter, J.P.; Randolph, M.F.; Wroth, C.P. Stress and pore pressure changes in clay during and after the expansion of a cylindrical cavity. Numer. Anal. Methods Geomech. 1980, 17, 305–322. [Google Scholar] [CrossRef]

- Chow, F.C.; Jardine, R.J.; Brucy, F.; Nauroy, J.F. Effects of time on capacity of pipe piles in dense marine sand. J. Geotech. Geoenvironmental Eng. 1999, 125, 254–264. [Google Scholar]

- Fellenius, B.H.; Riker, R.E.; O’Brien, A.J.; Tracy, G.R. Dynamic and static testing in soil exhibiting set-up. J. Geotech. Eng. 1989, 115, 984–1001. [Google Scholar] [CrossRef]

- Bullock, P.J.; Schmertmann, J.H.; McVay, M.C.; Townsend, F.C. Side shear set-up. I: Test piles driven in florida. J. Geotech. Geoenvironmental Eng. 2005, 131, 292–300. [Google Scholar] [CrossRef]

- Haque, M.N.; Abu-Farsakh, M.Y.; Zhang, Z.J. Evaluation of pile capacity from CPT and pile setup phenomenon. Int. J. Geotech. Eng. 2020, 14, 196–205. [Google Scholar] [CrossRef]

- Ng, K.; Ksaibati, R. Effect of soil layering on shorter-term pile setup. J. Geotech. Geoenvironmental Eng. 2018, 144, 04018020. [Google Scholar] [CrossRef]

- Haque, M.N.; Abu-Farsakh, M.Y. Development of analytical models to estimate the increase in pile capacity with time (pile setup) from soil properties. Acta Geotech. 2019, 14, 881–905. [Google Scholar] [CrossRef]

- Afsharhasani, R.; Karakouzian, M.; Farhangi, V. Effect of competent caliche layers on measuring the capacity of axially loaded drilled shafts using the osterberg test. Appl. Sci. 2020, 10, 6169. [Google Scholar] [CrossRef]

- Doan, L.V.; Lehane, B.M. CPT-based design method for axial capacities of drilled shafts and auger cast-in-place piles. J. Geotech. Geoenvironmental Eng. 2021, 147, 04021077. [Google Scholar] [CrossRef]

- Farhangi, V.; Karakouzian, M.; Geertsema, M. Effect of micropiles on clean sand liquefaction risk based on CPT and SPT. Appl. Sci. 2020, 10, 3111. [Google Scholar] [CrossRef]

- Qubain, B.S.; Seksinsky, E.J.; Li, J.C.; Nuzha, K.; Eshete, D.W. Drilled shaft load testing during Design. In Proceedings of the International Foundations Congress and Equipment Expo, Dallas, TX, USA, 10–14 May 2021; Volume 323, pp. 257–266. [Google Scholar]

- Baca, M.; Rybak, J. Pile base and shaft capacity under various types of loading. Appl. Sci. 2021, 11, 3396. [Google Scholar] [CrossRef]

- Roling, M.J.; Sritharan, S.; Suleiman, T.M. Introduction to PILOT database and establishment of LRFD resistance factors for the construction control of driven steel H-piles. J. Bridge Eng. 2011, 16, 728–738. [Google Scholar] [CrossRef]

- Abu-Hejleh, N.; DiMaggio, W.M.; Kramer, S. Implementation of AASHTO LRFD design specifications for driven piles. Fed. Highw. Adm. 2013. Rep. No FHWA RC-13-001. [Google Scholar]

- Haque, M.N.; Abu-Farsakh, M. Estimation of pile setup and incorporation of resistance factor in load resistance factor design framework. J. Geotech. Geoenvironmental Eng. 2018, 144, 04018077. [Google Scholar] [CrossRef]

- Foye, K.C.; Salgado, R.; Scott, B. Resistance factors for use in shallow foundation LRFD. J. Geotech. Geoenvironmental Eng. 2006, 132, 1208–1218. [Google Scholar] [CrossRef]

- Komurka, V.E.; Winter, C.J.; Maxwell, S.G. Applying separate safety factors to end-of-drive and set-up components of driven pile capacity. In Proceeding of the 13th Great Lakes Geotechnical and Geoenvironmental Conference, Milwaukee, WI, USA, 13 May 2005; pp. 65–80. [Google Scholar]

- Yang, L.; Liang, R. Incorporating set-up into reliability-based design of driven piles in clay. Can. Geotech. J. 2006, 43, 946–955. [Google Scholar] [CrossRef]

- Kim, D.; Lee, J. Resistance factor contour plot analyses of load and resistance factor design of axially-loaded driven piles in clays. Comput. Geotech. 2012, 44, 9–19. [Google Scholar] [CrossRef]

- Ng, K.; Sritharan, S. Integration of construction control and pile setup into load and resistance factor design of piles. Soils Found. 2014, 54, 197–208. [Google Scholar] [CrossRef] [Green Version]

- Bian, X.Y.; Zheng, J.J.; Xu, Z.J.; Zhang, R.J. A method to calculate resistance factors for LRFD of driven piles. In Proceedings of the 6th Asian-Pacific Symposium on Structural Reliability and its Applications (APSSRA2016), Shanghai, China, 28–30 May 2016; pp. 157–163. [Google Scholar]

- Bian, X.Y.; Xu, Z.J.; Zhang, R.J. Resistance factor calculations for LRFD of driven piles based on setup effects. Results Phys. 2018, 11, 489–494. [Google Scholar] [CrossRef]

- Skov, R.; Denver, H. Time dependence of bearing capacity of piles. In Proceedings of the 3rd International Conference on the Application of Stress-Wave Theory to Piles, Ottawa, ON, Canada, 25–27 May 1988; pp. 879–888. [Google Scholar]

- Long, J.H.; Kerrigan, J.A.; Wysochey, M.H. Measured time effects for axial capacity of driven piling. Transp. Res. Rec. 1999, 1663, 8–15. [Google Scholar] [CrossRef]

- Svinkin, M.R.; Morgano, C.M.; Morvant, M. Pile capacity as a function of time in clayey and sandy soils. In Proceedings of the 5th International Conference and Exhibition on Piling and Deep Foundations, Bruges, Belgium, 13–15 June 1994; pp. 1.11.1–1.11.8. [Google Scholar]

- Bogard, J.D.; Matlock, H. Application of model pile tests to axial pile design. Am. Soc. Civ. Eng. 1990, 3, 217–278. [Google Scholar]

- AASHTO. LRFD Bridge Design Specifications, 4th ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2007. [Google Scholar]

- Yang, L.; Liang, R. Incorporating setup into load and resistance factor design of driven piles in sand. Can. Geotech. J. 2009, 46, 296–305. [Google Scholar] [CrossRef]

- Paikowsky, S.G.; Birgisson, B.; McVay, M.; Nguyen, T.; Kuo, C.; Beacher, G.; Ayyub, B.; Stenersen, K.; O’Malley, K.; Chernauskas, L. Load and resistance factor design (LRFD) for deep foundations. In Proceeding of the 6th International Conference on the Application of Stress-Wave Theory to Piles, Sao Paulo, Brazil, 28–29 September 2004; pp. 281–304. [Google Scholar]

- Hansell, W.C.; Viest, I.M. Load factor design for steel highway bridges. AISC Eng. J. Am. Inst. Steel Constr. 1971, 8, 113–123. [Google Scholar]

- Perez, A.; Birgisson, B.; Zhang, L.; McVay, M.C.; Putcha, S. Load and resistance factor design (LRFD) for driven piles using dynamic methods-a florida perspective. Geotech. Test. J. 2000, 23, 55–66. [Google Scholar]

- Zhang, L.M.; Li, D.Q.; Tang, W.H. Reliability of bored pile foundations considering bias in failure criteria. Can. Geotech. J. 2005, 42, 1086–1093. [Google Scholar] [CrossRef] [Green Version]

- Barker, R.; Duncan, J.; Rojiani, K. Manuals for the Design of Bridge Foundations; National Cooperative Highway Research Program (NCHRP) Report 343; Transportation Research Board: Washington, DC, USA, 1991. [Google Scholar]

- Zhang, L.M.; Tang, W.H. Bias in axial capacity of single bored piles arising from failure criteria. In Proceedings of the International Conference on Structural Safety and Reliability, Newport Beach, CA, USA, 17–22 June 2001; pp. 1–8. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bian, X.; Chen, J.; Chen, X.; Xu, Z. Reliability-Based Design of Driven Piles Considering Setup Effects. Appl. Sci. 2021, 11, 8609. https://doi.org/10.3390/app11188609

Bian X, Chen J, Chen X, Xu Z. Reliability-Based Design of Driven Piles Considering Setup Effects. Applied Sciences. 2021; 11(18):8609. https://doi.org/10.3390/app11188609

Chicago/Turabian StyleBian, Xiaoya, Jiawei Chen, Xuyong Chen, and Zhijun Xu. 2021. "Reliability-Based Design of Driven Piles Considering Setup Effects" Applied Sciences 11, no. 18: 8609. https://doi.org/10.3390/app11188609

APA StyleBian, X., Chen, J., Chen, X., & Xu, Z. (2021). Reliability-Based Design of Driven Piles Considering Setup Effects. Applied Sciences, 11(18), 8609. https://doi.org/10.3390/app11188609