Theoretical Study on the Relationship of Building Thermal Insulation with Indoor Thermal Comfort Based on APMV Index and Energy Consumption of Rural Residential Buildings

Abstract

:Featured Application

Abstract

1. Introduction

2. Simulation and Research Methods

2.1. Simulation Tool

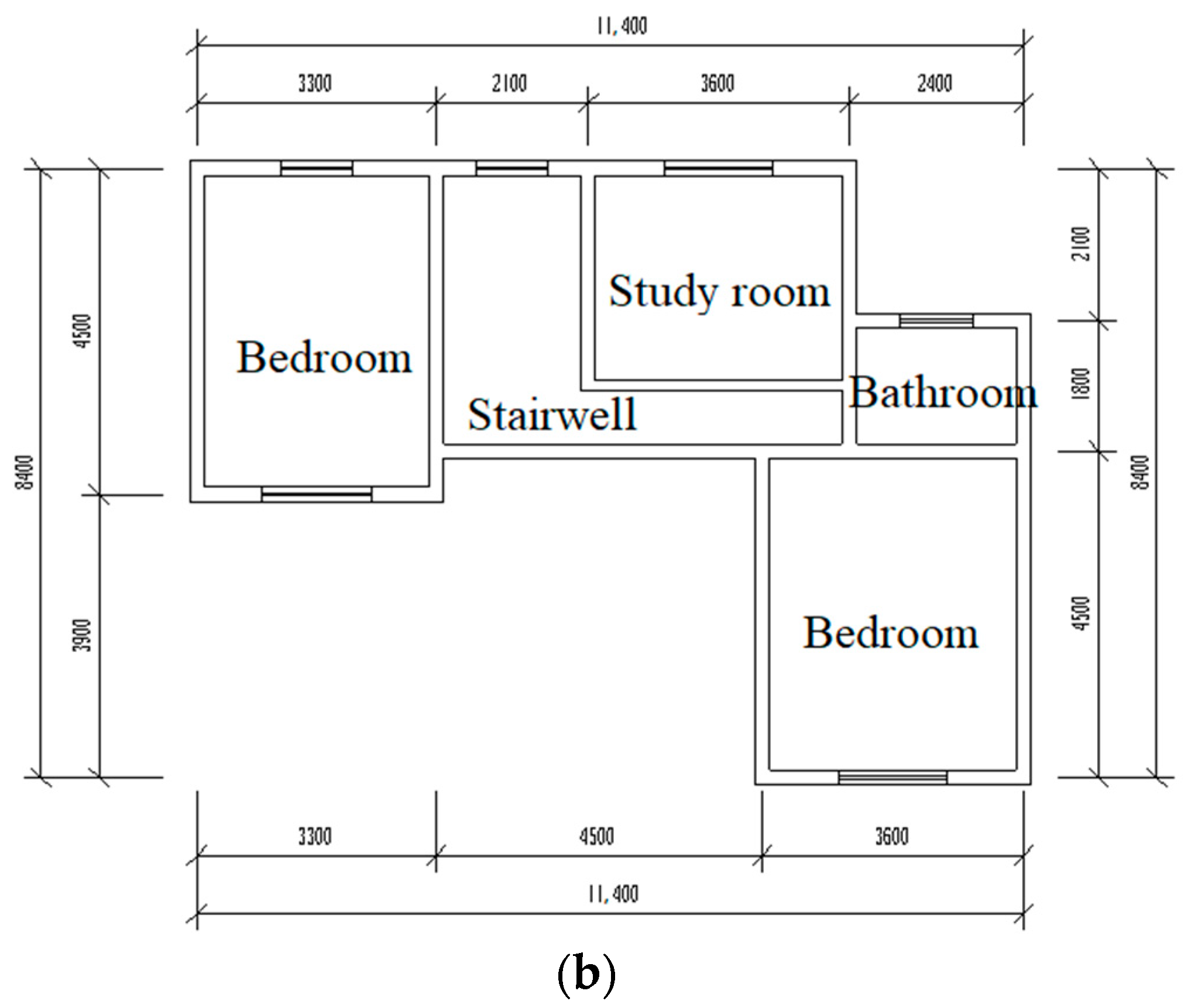

2.2. Building Description

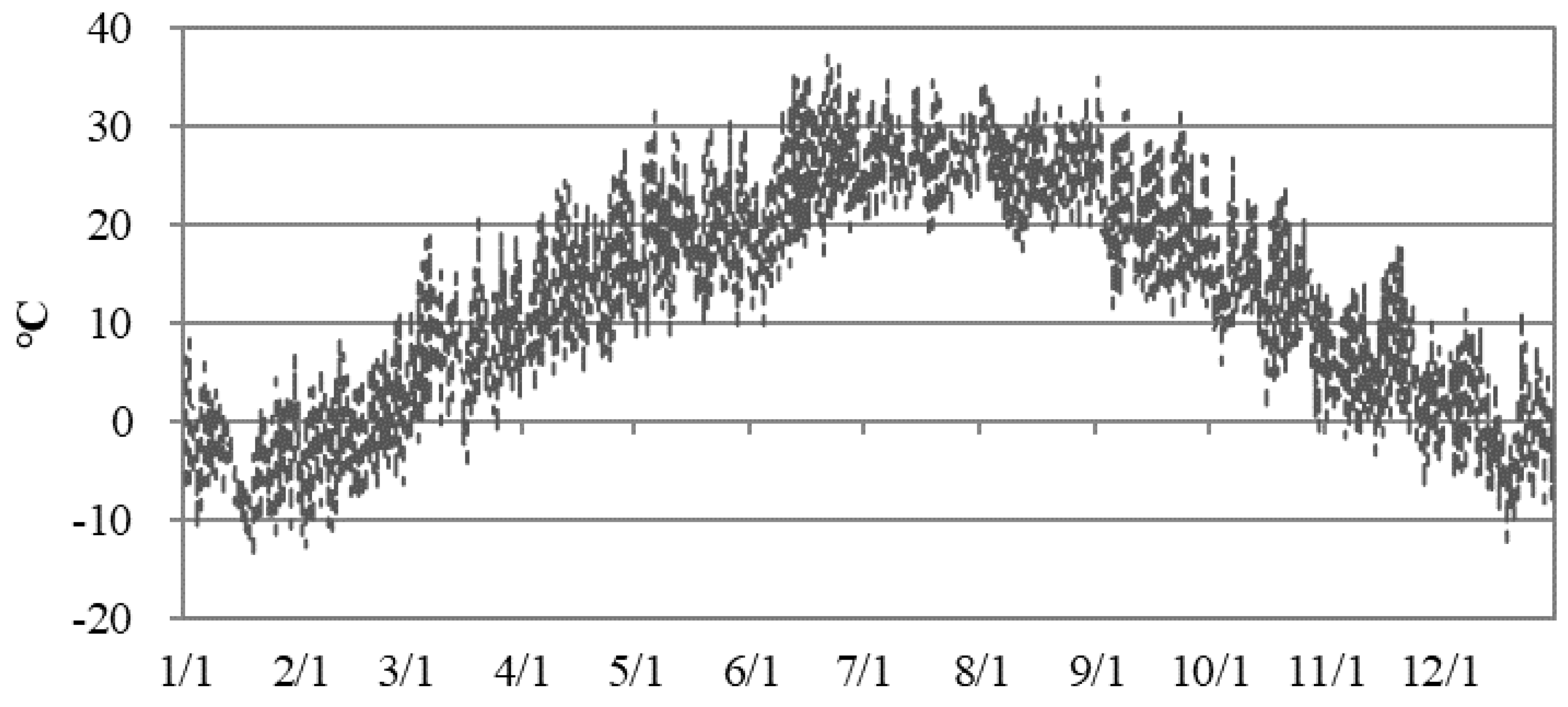

2.3. Calculation Parameters of Building Model

2.4. Thermal Comfort Model

2.5. Research Methods

- Calculate the APMV of each room and compare the effect of the envelope on the thermal comfort of the room at the same indoor air temperature;

- Calculate the energy saving rate of buildings before and after retrofitting at the same thermal comfort value, and explore the impact of envelope energy retrofitting on building energy needs for space heating during the heating season;

- Adjust the thickness of the insulation layer of the envelope to obtain the linear relationship between the indoor thermal comfort values and the heat transfer coefficient by adjusting the thickness of insulation layer with different heat transfer coefficients.

3. Results and Discussion

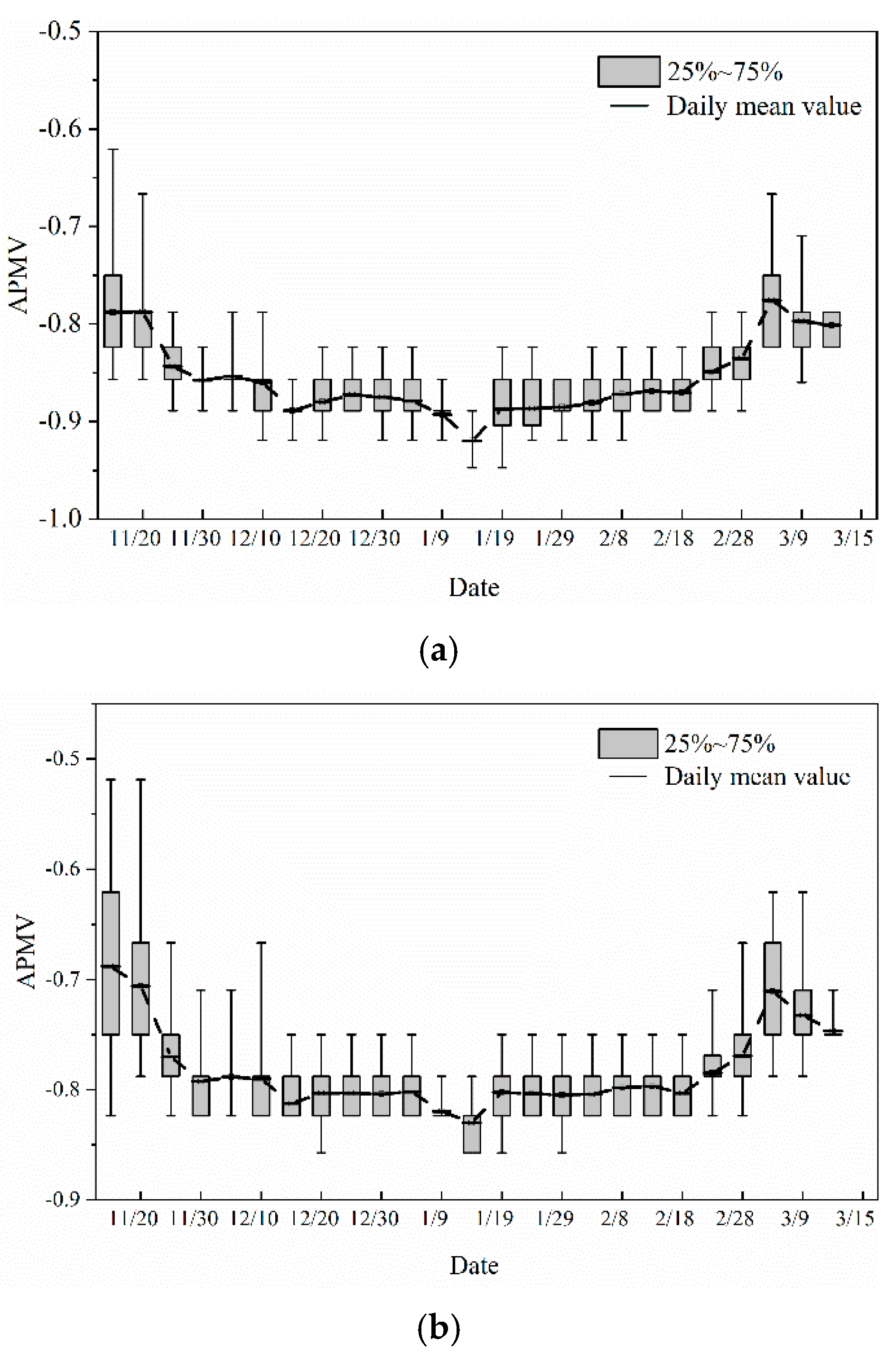

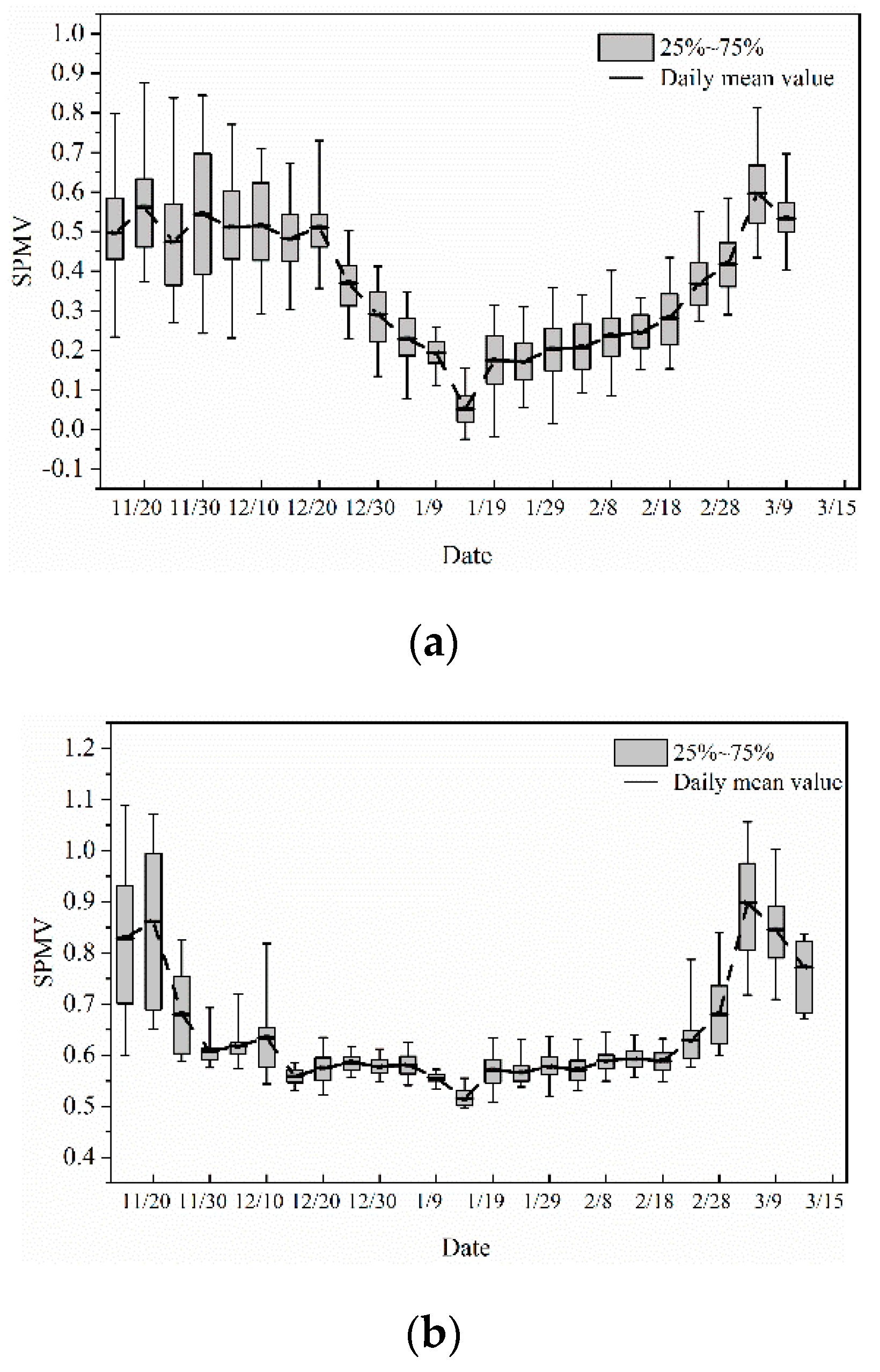

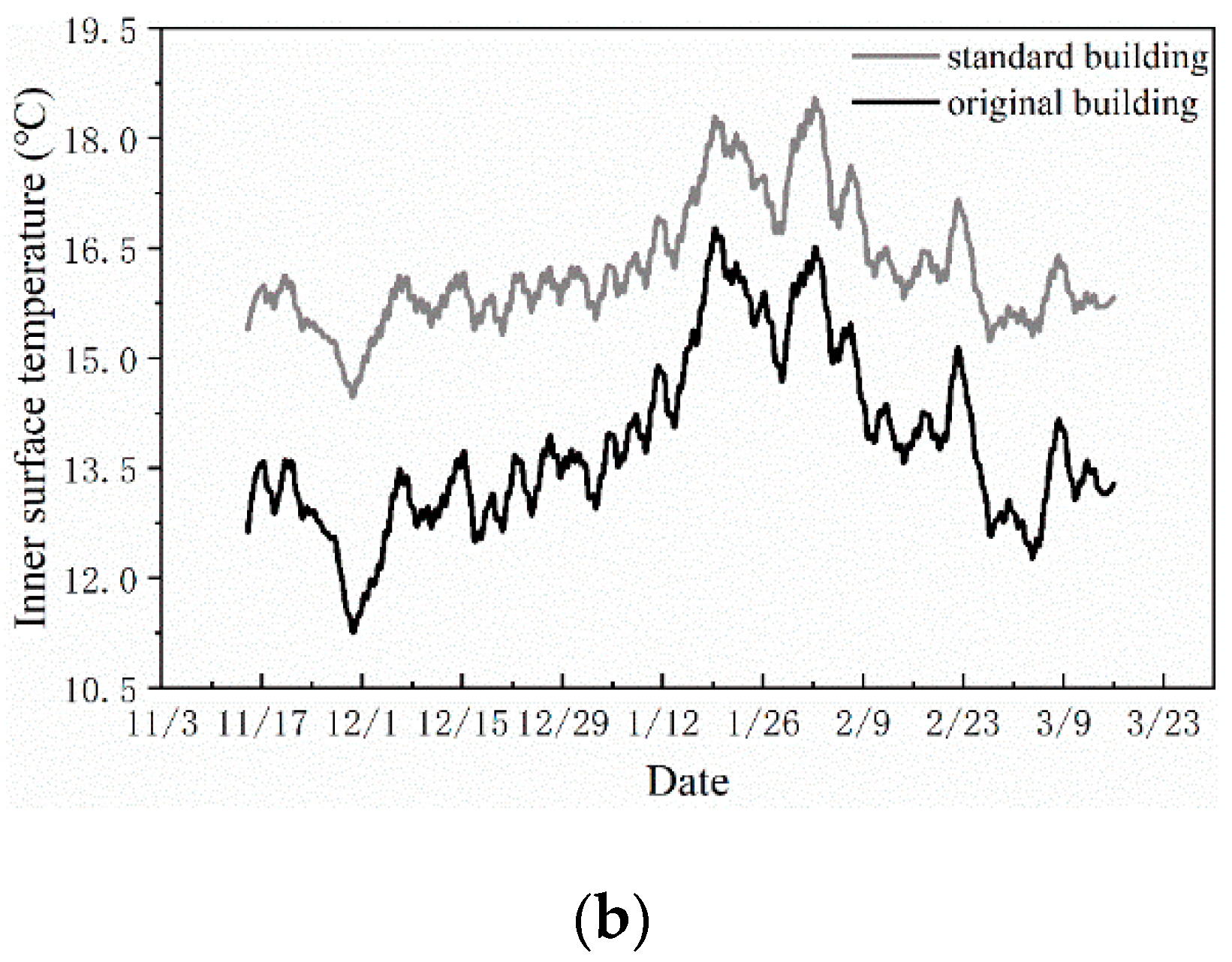

3.1. The Effect of Exterior Wall Envelope Insulation on Thermal Comfort

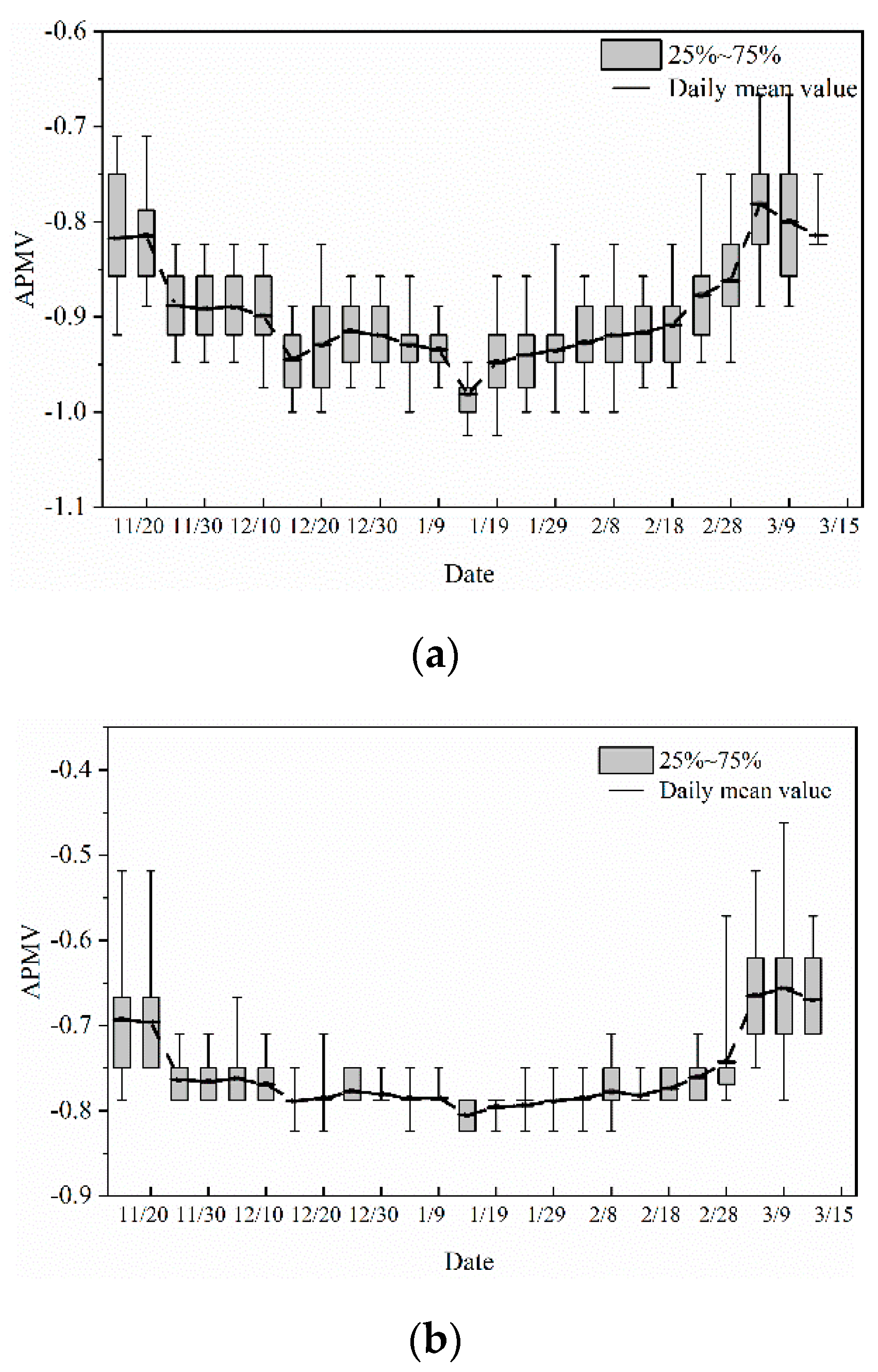

3.2. The Energy Saving Rate Based on Thermal Comfort

3.3. The Relationship between the Indoor Thermal Comfort Values and the Heat Transfer Coefficient

4. Conclusions

- (1)

- Setting the building model parameters to control the original building and the specification building are at the same indoor air temperature. The APMV of the original building is always lower than the standard building, indicating that the indoor temperature is not representative of the thermal comfort of the room.

- (2)

- Adding a building envelope can reduce the cumulative heat load while enhancing indoor thermal comfort. Compared with the original building with the same thermal comfort value, the energy saving rate after adding envelope insulation is 67%.

- (3)

- By adjusting the thickness of the insulation layer, the paper obtains the relationship between the heat transfer coefficient and the indoor APMV value. Additionally, according to this equation, the heat transfer coefficient of the envelope should not be higher than 0.5 W/(m2·K) when the room is in comfort.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameters | Outdoor Air Temperature (°C) | Heat Transfer Coefficient | Indoor Air Temperature (°C) | Relative Humidity (%) | Ventilation Rate |

|---|---|---|---|---|---|

| Inputs | Dynamically meteorological of DeST | Pre-retrofit: 1.79 Post-retrofit: 0.65 | Winter: 16 °C Summer: 25 °C | Winter: 30% Summer: 60% | 1 time per 2 h |

| Room | The Maximum Power of The Lights (W) | The Maximum Power of The Equipments (W) | Personnel Heat Load (W) | Personnel Wet Load (kg/Hr) | Maximum Number of Occupants in The Room |

|---|---|---|---|---|---|

| Bedroom | 6 | 0 | 53 | 0.061 | 3 |

| The study | 6 | 9.3 | 53 | 0.061 | 3 |

| Living room | 6 | 9.3 | 53 | 0.061 | 3 |

| Bathroom | 6 | 0 | 60 | 0.102 | 1 |

| Stairwell | 7 | 6 | 53 | 0.061 | 3 |

| Rate/Time | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lights | 0% | 50% | 100% | |||||||||||||||||||||

| Equipment | 0% | 50% | 100% | |||||||||||||||||||||

| Personnel (Weekdays) | 100% | 0% | 50% | 100% | ||||||||||||||||||||

| Personnel (Weekends) | 0% | 33.3% | 100% | 33.3% | ||||||||||||||||||||

| Rate/Time | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lights | 0% | 100% | 50% | |||||||||||||||||||||

| Equipment | 0% | 68.8% | 0% | 100% | 0% | |||||||||||||||||||

| Personnel (Weekdays) | 0% | 33.3% | 0% | 33.3% | 100% | 0% | ||||||||||||||||||

| Personnel (Weekends) | 0% | 33.3% | 100% | |||||||||||||||||||||

| Air Temperature (°C) | Relative Humidity (%) | Inner Surface Temperature (°C) | Air Velocity (m/s) | Metabolic Rate (met) | Clothing Level (clo) | |

|---|---|---|---|---|---|---|

| PMV | Derived from DeST report | Derived from DeST report | Derived from DeST report | 0.15 | 1.2 | 1.0 |

| SPMV | Derived from DeST report | Derived from DeST report | Derived from DeST report | 0.15 | 0.7 | 4.5 |

References

- Houkai, W.; Zhixiong, D. China Rural Development Report, 3rd ed.; China Social Sciences Press: Beijing, China, 2020; pp. 480–503. [Google Scholar]

- Building Energy Conservation Research Center, Tsinghua University. China Building Energy Consumption Annual Report 2020; Building Energy Efficiency; China Architecture & Building Press: Beijing, China, 2021. [Google Scholar]

- Song, B.; Deng, Q. Technology for present situation and prospect of energy rural construction. District Heat 2018, 5, 111–116. [Google Scholar]

- Zhang, T.T.; Tan, Y.F.; Niu, C.K. Current Situation of Energy and Indoor Environment in Rural Buildings of Northeast China. Appl. Mech. Mater. 2014, 3013, 1756–1759. [Google Scholar] [CrossRef]

- Homod, R.Z.; Almusaed, A.; Almssad, A.; Jaafar, M.K.; Sahari, K.S.M. Effect of different building envelope materials on thermal comfort and air-conditioning energy savings: A case study in Basra city, Iraq. J. Energy Storage 2021, 34, 101975. [Google Scholar] [CrossRef]

- Hamdy, M.; Siren, K. Applying a multi-objective optimization approach for Design of low-emission cost-effective dwellings. Build. Environ. 2020, 46, 109–123. [Google Scholar] [CrossRef]

- Paola, C.; Simone, F.; Giulio, F.; Federica, Z. Preliminary Energy Evaluations for the Retrofit of Rural Protected Buildings in a Peripheral Context of Milan. J. Sustain. Dev. Energy Water Environ. Syst. 2020, 8, 715–734. [Google Scholar]

- Sengul, G. Calculation of optimum insulation thickness of external walls in residential buildings by using exergetic life cycle cost assessment method: Case study for Turkey. Environ. Prog. Sustain. Energy 2019, 38, e13232. [Google Scholar]

- Siudek, A.; Klepacka, A.M.; Florkowski, W.J.; Gradziuk, P. Renewable Energy Utilization in Rural Residential Housing: Economic and Environmental Facets. Energies 2020, 13, 6637. [Google Scholar] [CrossRef]

- Shao, T.; Jin, H. Analysis of the Indoor Thermal Environment and Passive Energy-Saving Optimization Design of Rural Dwellings in Zhalantun, Inner Mongolia, China. Sustainability 2020, 12, 1103. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Wang, Z.; Yang, C.; Xu, L.; Chen, W. Influence of Trombe wall on indoor thermal environment of a two-story building in rural Northern China during summer. Sci. Technol. Built Environ. 2019, 25, 438–449. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, Y.; Nie, J. A New Mixture Refrigerant for Space Heating Air Source Heat Pump: Theoretical Modelling and Performance Analysis. Appl. Sci. 2018, 8, 622. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.; Xiang, Y.; Zhang, H.; Lin, Q.; Wang, W.; Wang, H. Active–passive combined energy-efficient retrofit of rural residence with non-benchmarked construction: A case study in Shandong province, China. Energy Rep. 2021, 7, 1360–1373. [Google Scholar] [CrossRef]

- Cao, W.; Yang, L.; Zhang, Q.; Chen, L.; Wu, W. Evaluation of Rural Dwellings’ Energy-Saving Retrofit with Adaptive Thermal Comfort Theory. Sustainability 2021, 13, 5350. [Google Scholar] [CrossRef]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. Thermal Environmental Conditions for Human Occupancy; ASHRAE 55; American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2013. [Google Scholar]

- Ioannou, A.; Itard, L.; Agarwal, T. In situ real time measurements of thermal comfort and comparison with the adaptive comfort theory in Dutch residential dwellings. Energy Build 2018, 170, 229–241. [Google Scholar] [CrossRef]

- Ma, H. Zhangjiakou a residential building envelope structure optimization design. Appl. Mech. Mater. 2014, 3308, 247–251. [Google Scholar] [CrossRef]

- Zhu, D.D.; Hong, T.Z.; Yan, D.; Wang, C. A detailed loads comparison of three building energy modeling programs: EnergyPlus, DeST and DOE-2.1E. Build. Simul. 2013, 6, 323–335. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of PRC. Design Standard for Energy Efficiency of Rural Residential Buildings; Ministry of Housing and Urban-Rural Development of PRC: Beijing, China, 2014. [Google Scholar]

- Shao, T.; Jin, H. A field investigation on the winter thermal comfort of residents in rural houses at different latitudes of northeast severe cold regions, China. J. Build. Eng. 2020, 32, 101476. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of PRC. Design Standard for Lighting Design of Buildings; Ministry of Housing and Urban-Rural Development of PRC: Beijing, China, 2014. [Google Scholar]

- Van, H.J. Forty years of Fanger’s model of thermal comfort: Comfort for all? Indoor Air 2008, 18, 182–201. [Google Scholar] [CrossRef]

- Chinese Standard GB/T 50785-2012. Evaluation Standard for Indoor Thermal Environment in Civil Buildings; China Academy of Building Research: Beijing, China, 2012. [Google Scholar]

- Lin, Z.P.; Deng, S.M. A study on the thermal comfort in sleeping environments in the subtropics—Measuring the total insulation values for the bedding systems commonly used in the subtropics. Build. Environ. 2006, 43, 70–81. [Google Scholar] [CrossRef]

- CBE Thermal Comfort Tool. Available online: https://comfort.cbe.berkeley.edu/ (accessed on 24 August 2021).

- Zhang, N.; Cao, B.; Zhu, Y.X. Effects of bedding insulation and indoor temperature on bed microclimate and thermal comfort. Energy Build. 2020, 223, 520. [Google Scholar] [CrossRef]

| Enclosure Structure | Thickness and Material of Each Layer from Outside to Inside | Heat Transfer Coefficient K (W/(m2·K)) |

|---|---|---|

| Exterior wall | Pre-retrofit: 20 mm Cement mortar + 240 mm red brick + 20 mm Mixed mortar | 1.79 |

| Post-retrofit: 20 mm Cement mortar + 240 mm red brick + 46 mm Polystyrene foam (EPS) + 20 mm Mixed mortar | 0.65 | |

| Roof | 20 mm Reinforced concrete + 43 mm Polystyrene foam (EPS) + 20 mm Cement mortar | 0.50 |

| Exterior window (south) | Hollow glass casement window (6 + 6A + 6) | 2.80 |

| Exterior window (others) | Hollow glass casement window (6 + 12A + 6) | 2.50 |

| Exterior doors | wooden exterior door | 2.50 |

| Thickness of the Thermal Insulation Material (mm) | Heat Transfer Coefficient K (W/(m2·K)) | Mean APMV Values |

|---|---|---|

| 10 | 1.30 | −0.86 |

| 20 | 1.02 | −0.85 |

| 30 | 0.84 | −0.84 |

| 40 | 0.71 | −0.80 |

| 50 | 0.62 | −0.76 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nie, J.; Pang, Y.; Wang, C.; Zhang, H.; Yin, K. Theoretical Study on the Relationship of Building Thermal Insulation with Indoor Thermal Comfort Based on APMV Index and Energy Consumption of Rural Residential Buildings. Appl. Sci. 2021, 11, 8565. https://doi.org/10.3390/app11188565

Nie J, Pang Y, Wang C, Zhang H, Yin K. Theoretical Study on the Relationship of Building Thermal Insulation with Indoor Thermal Comfort Based on APMV Index and Energy Consumption of Rural Residential Buildings. Applied Sciences. 2021; 11(18):8565. https://doi.org/10.3390/app11188565

Chicago/Turabian StyleNie, Jinzhe, Yuxin Pang, Congcong Wang, Han Zhang, and Kuichao Yin. 2021. "Theoretical Study on the Relationship of Building Thermal Insulation with Indoor Thermal Comfort Based on APMV Index and Energy Consumption of Rural Residential Buildings" Applied Sciences 11, no. 18: 8565. https://doi.org/10.3390/app11188565

APA StyleNie, J., Pang, Y., Wang, C., Zhang, H., & Yin, K. (2021). Theoretical Study on the Relationship of Building Thermal Insulation with Indoor Thermal Comfort Based on APMV Index and Energy Consumption of Rural Residential Buildings. Applied Sciences, 11(18), 8565. https://doi.org/10.3390/app11188565