Valorization of Insulation Cellulose Waste as Solid Biomass Fuel

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

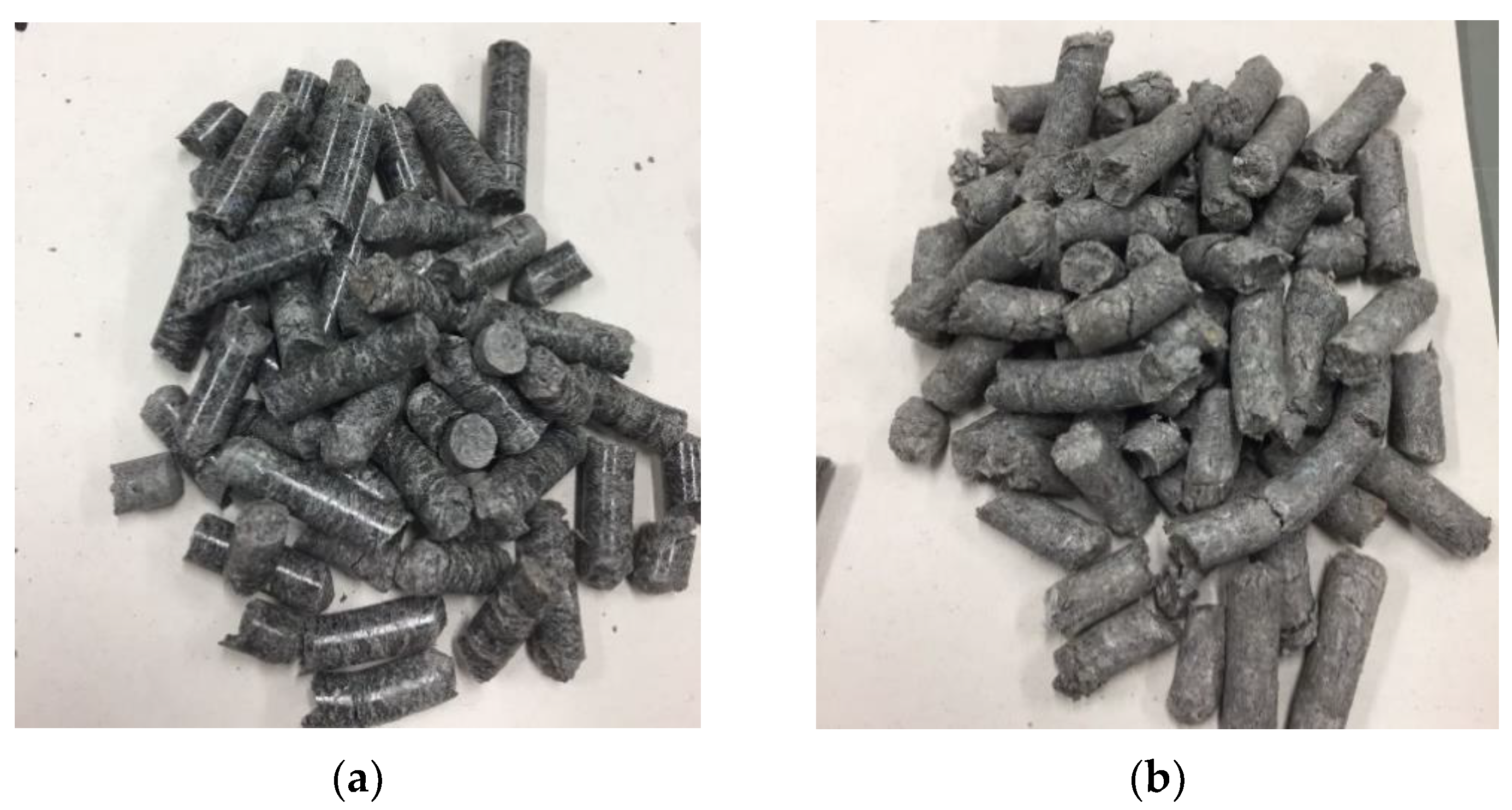

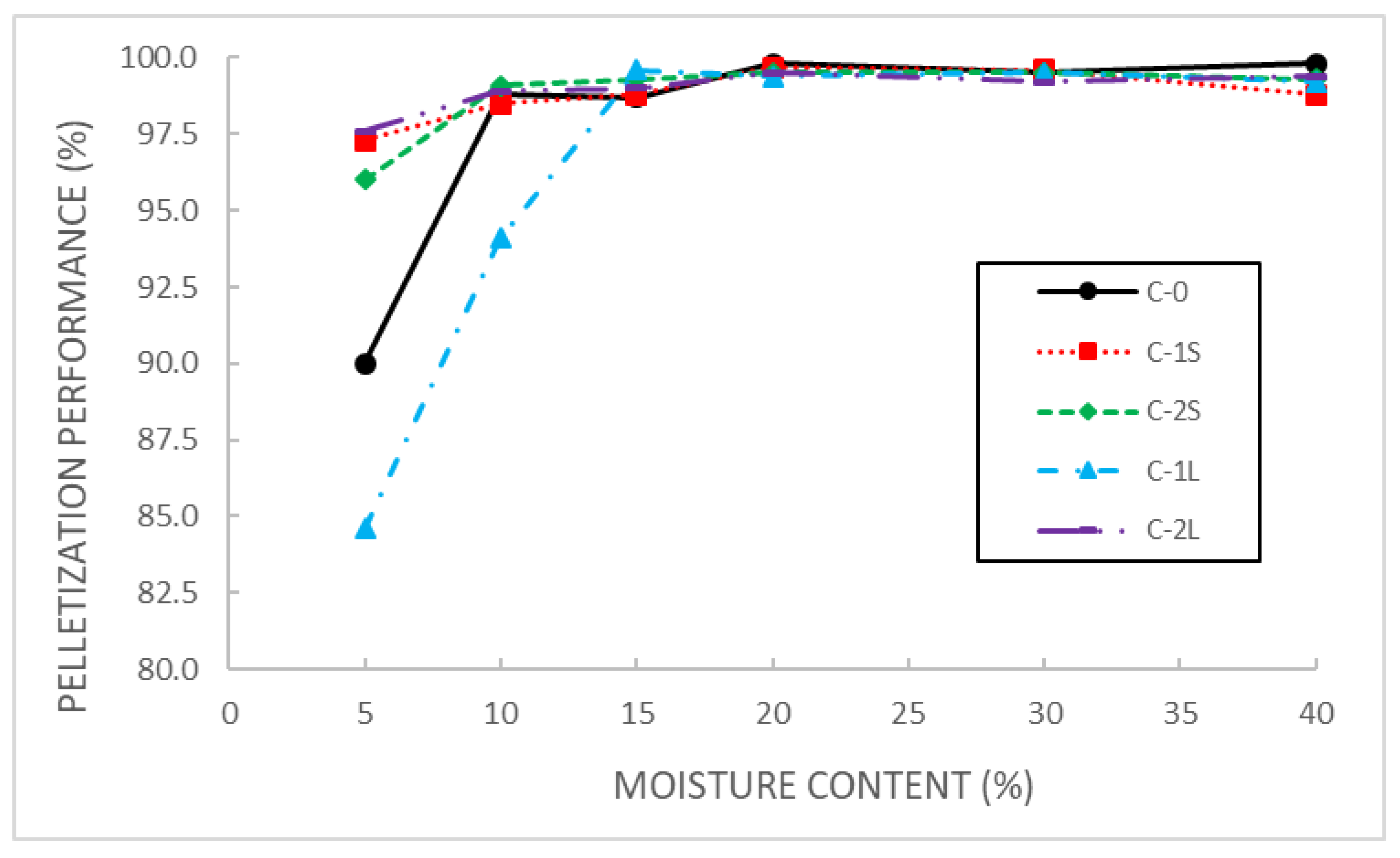

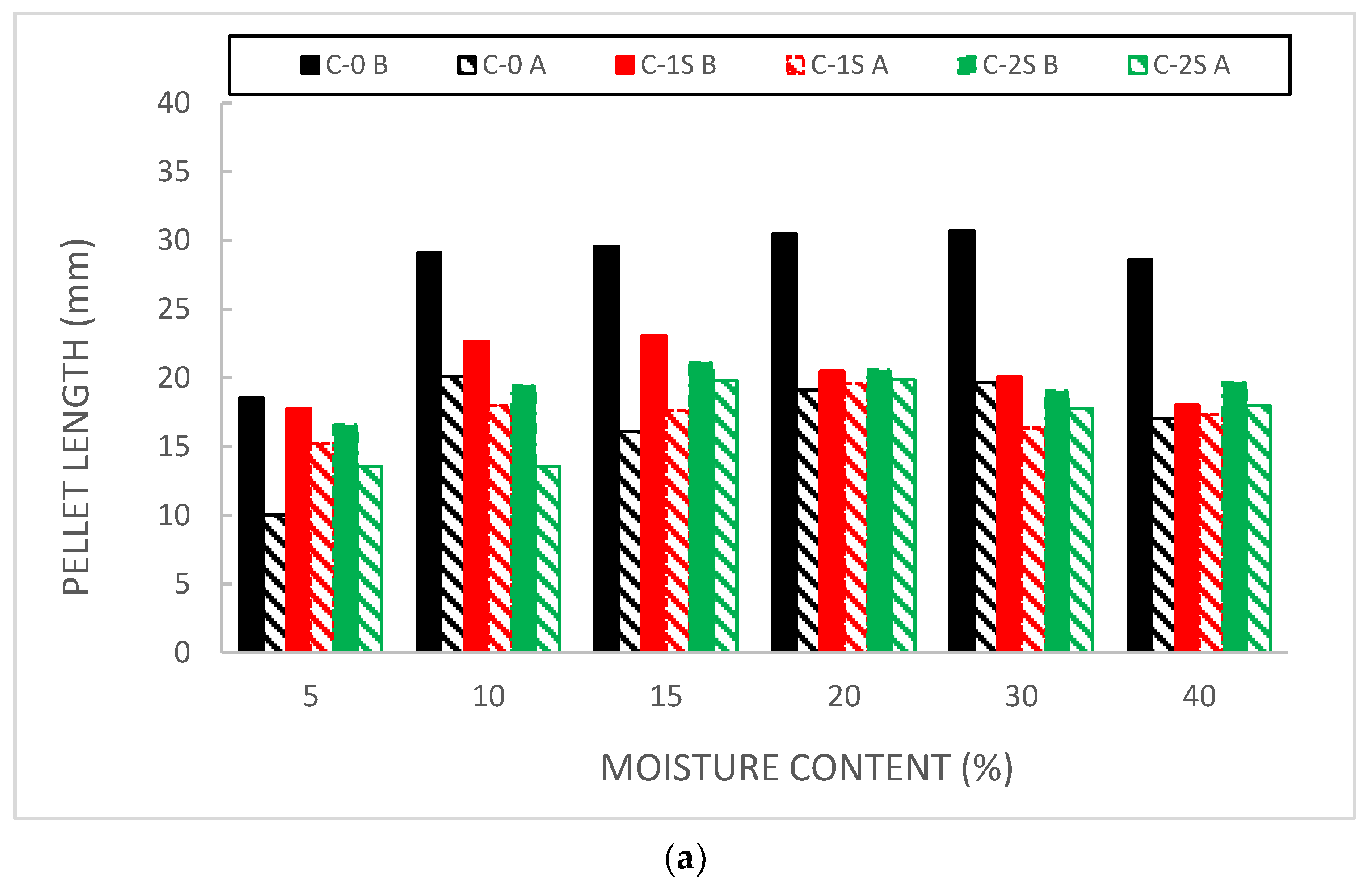

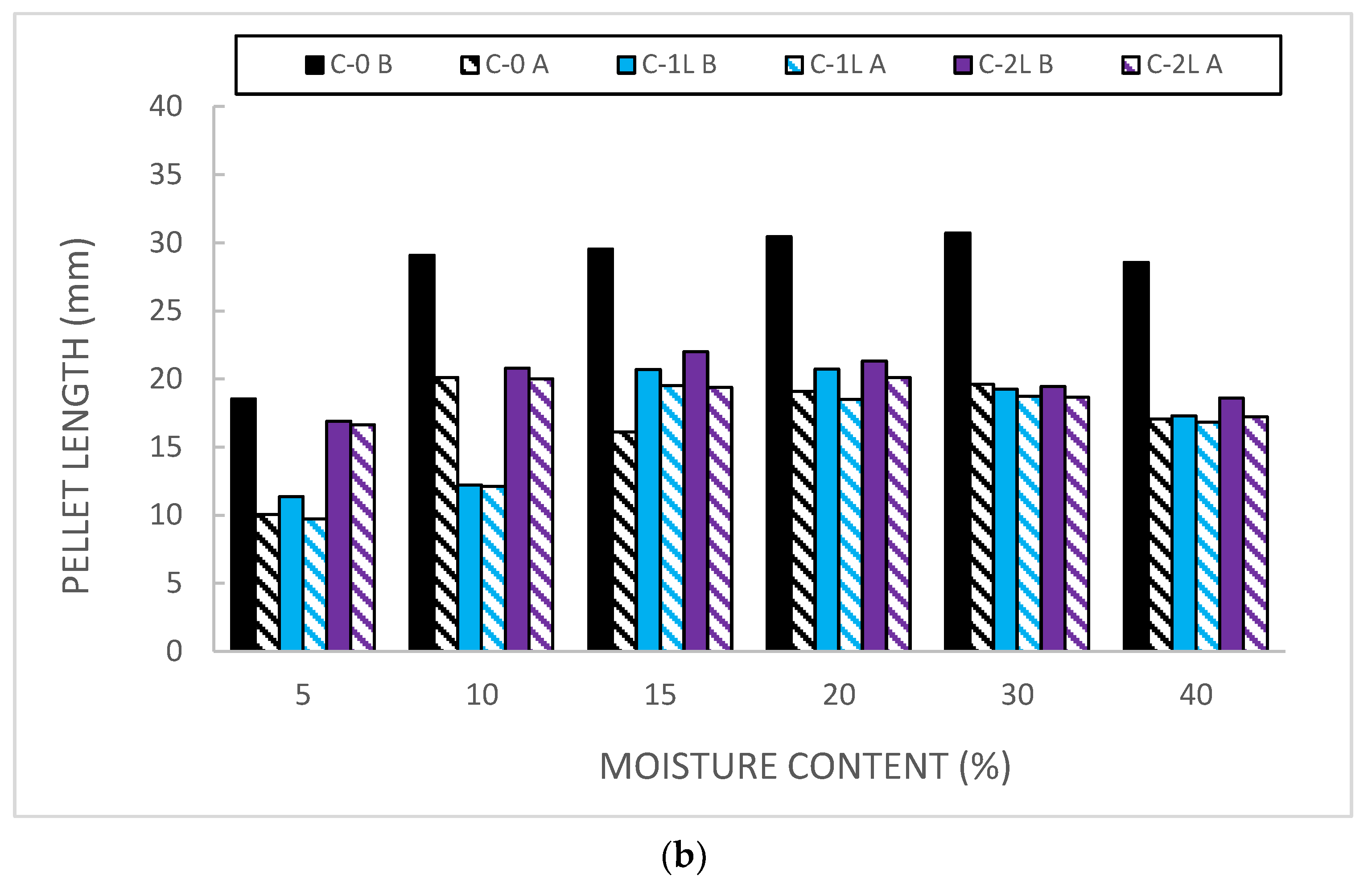

3.1. Manufacturing Performance

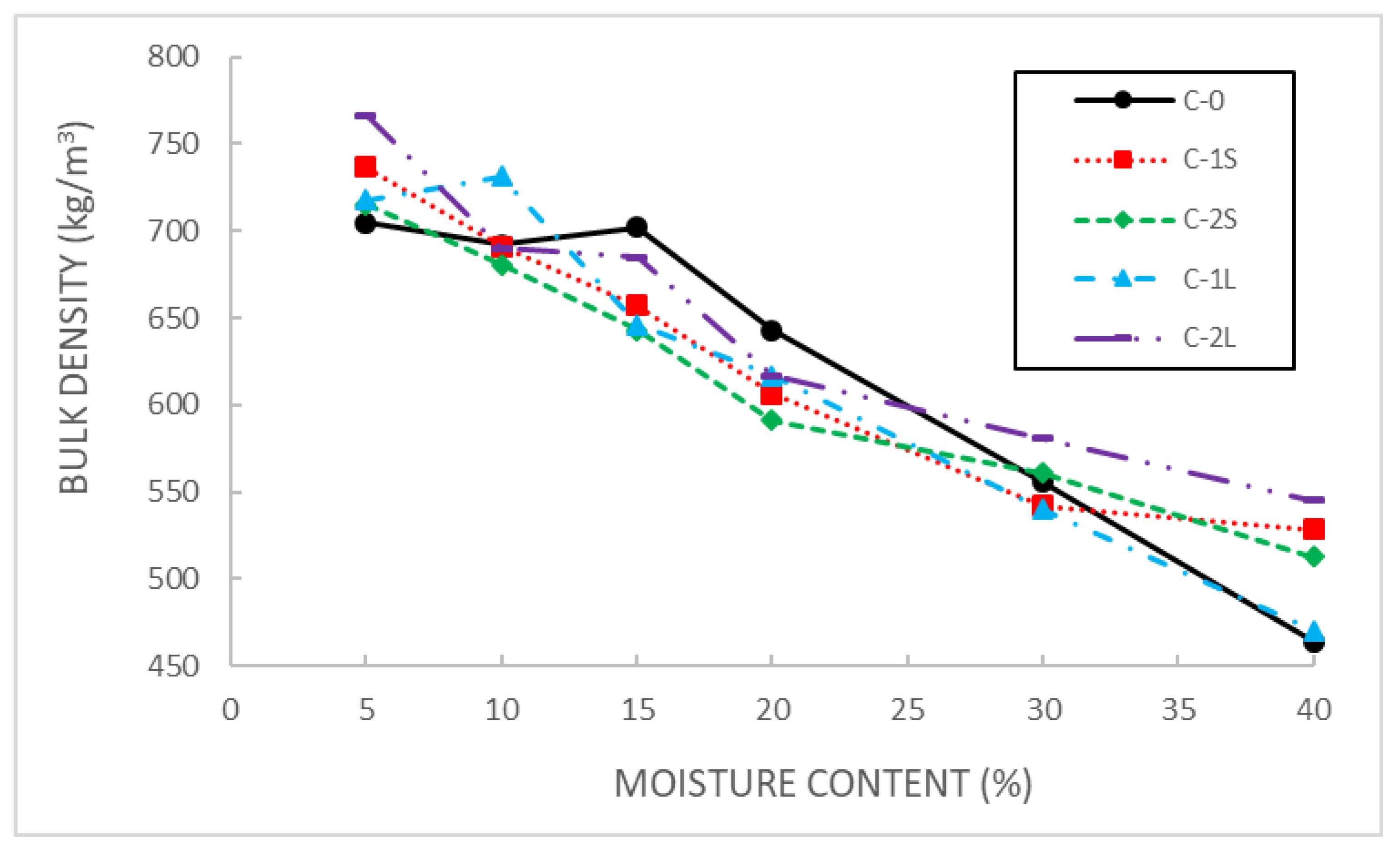

3.2. Pellet Bulk Density

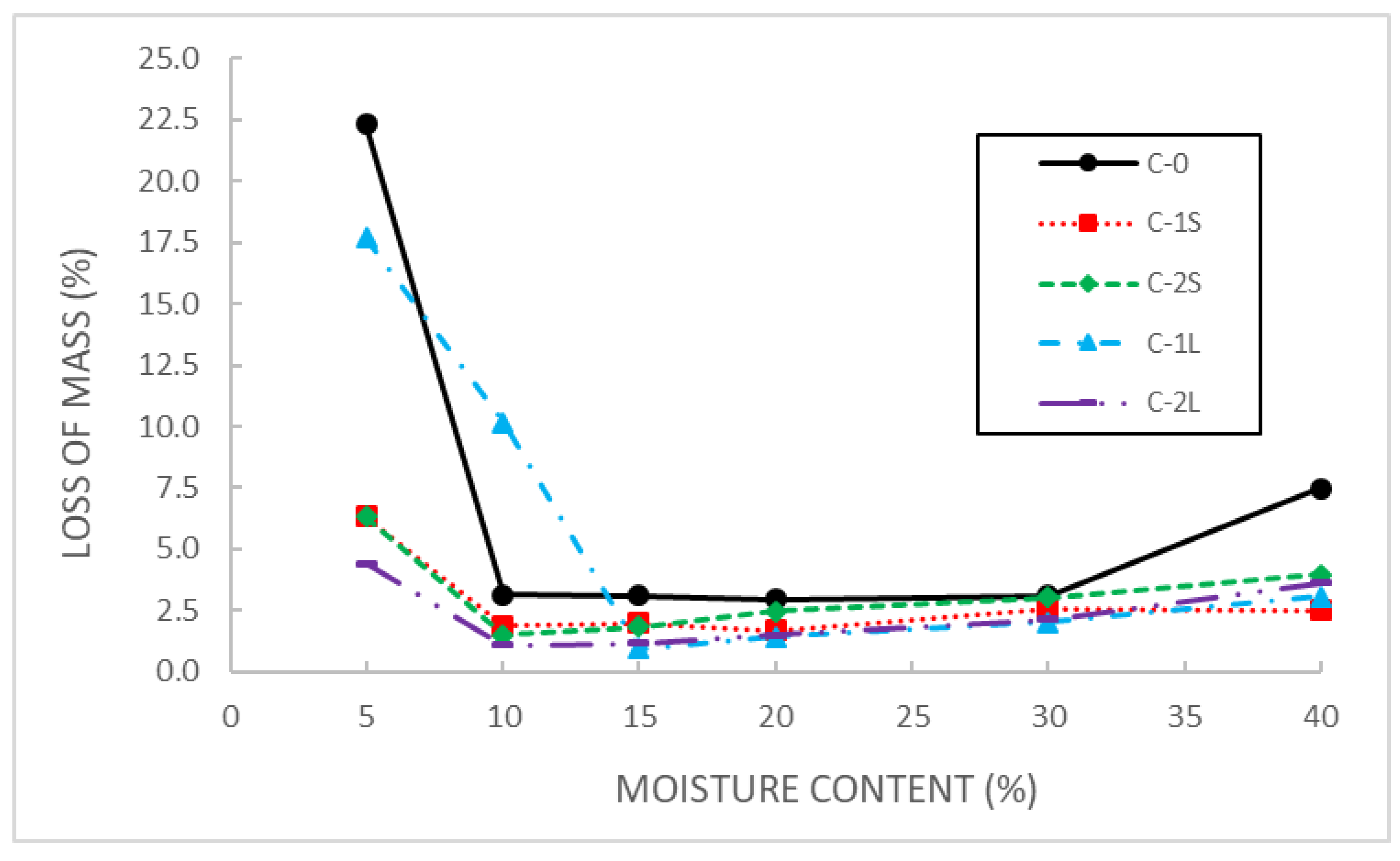

3.3. Mechanical Durability

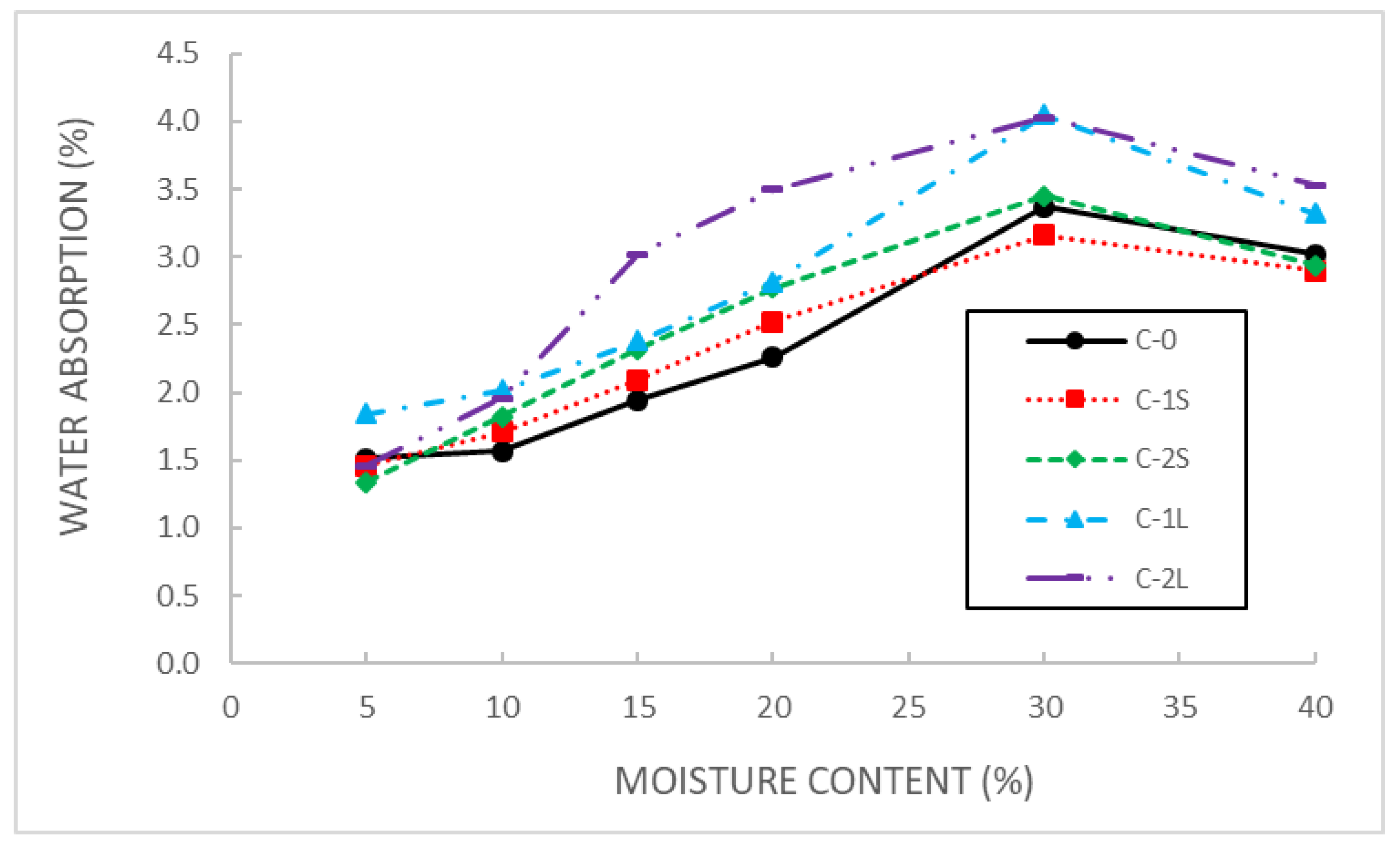

3.4. Water Absorption

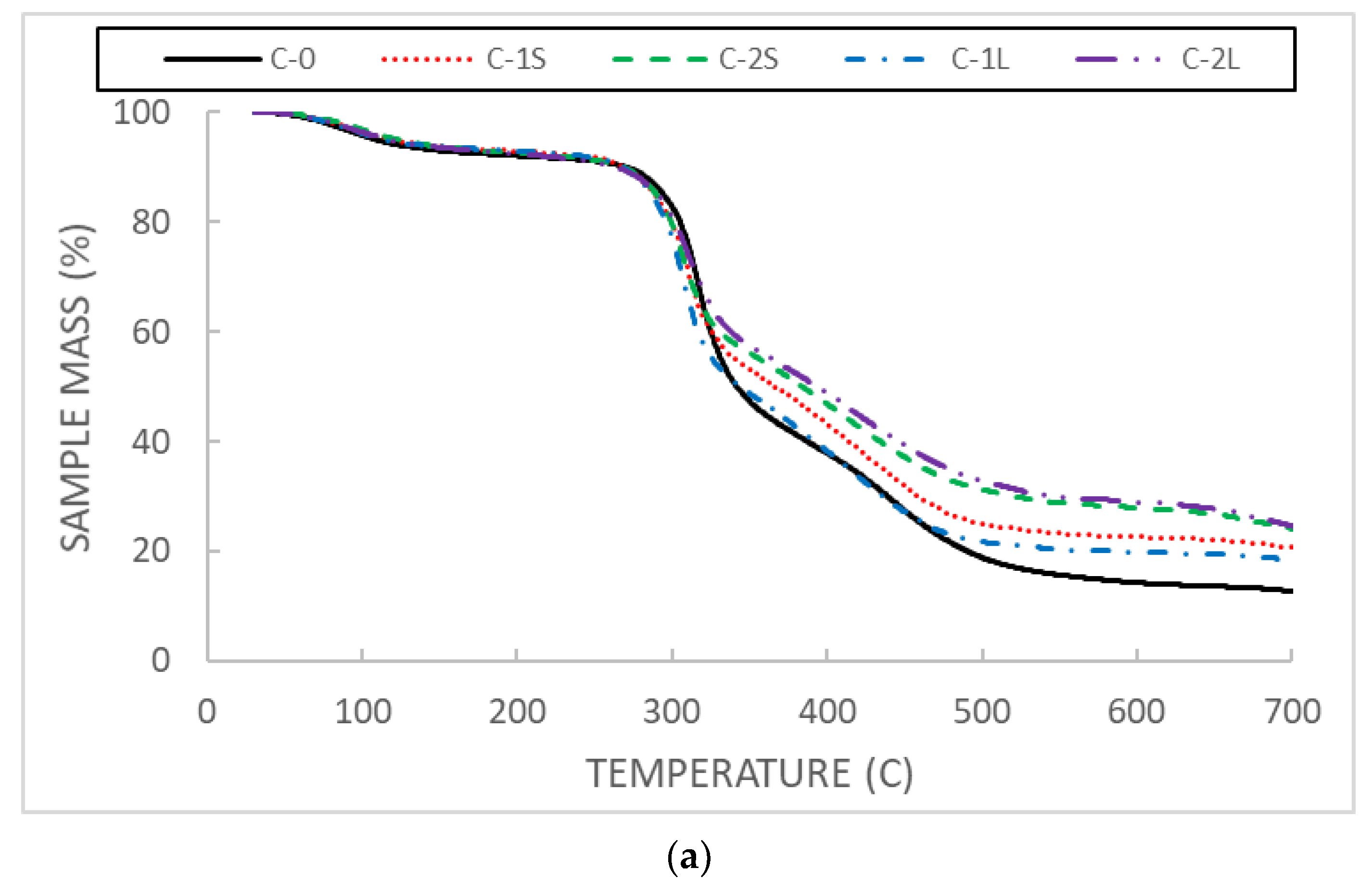

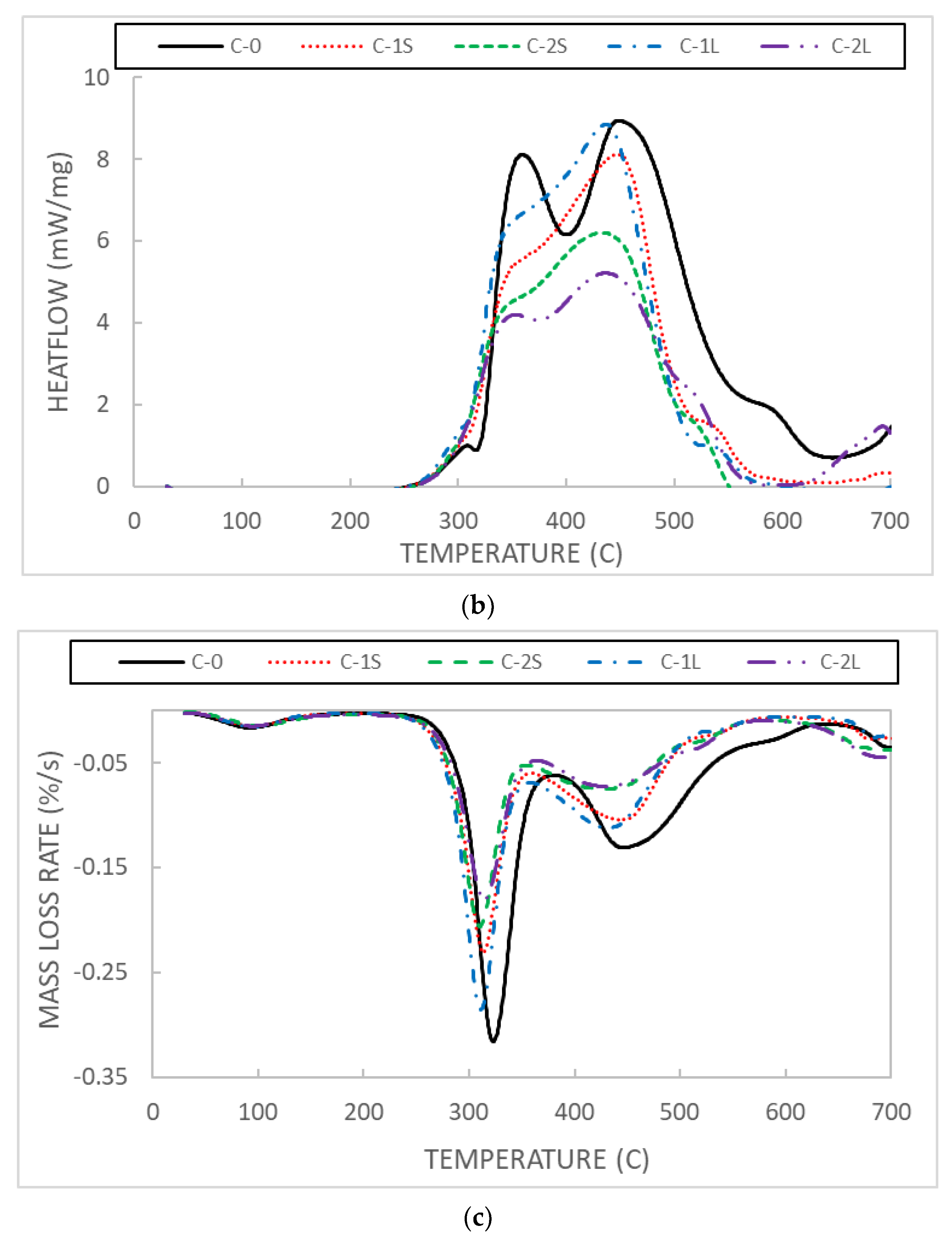

3.5. Chemical Properties and Combustion Characterization

4. Conclusions

- CFP produced pellets with a manufacturing performance higher than 97.5%. The use of sugar or lignosulfonate did not increase this performance except for CFP moisture content below 10%, demonstrating that for higher moisture contents the effect of the binders over the manufacturing performance was negligible.

- Pellet density and moisture content showed an indirect relationship with no evident differences among the combinations, based on the use of additives or the dosages considered.

- Mechanical durability test results were contradictory. Moisture contents between 10% and 30% were optimum to obtain pellets with the lowest loss of fine particles. In this range of moisture contents, no differences were observed between combinations with or without any one of the binders and the dosages tested. On the other hand, the use of binders demonstrated effectiveness in obtaining more resistant pellets against handling cracking.

- The use of binders reduced the resistance of pellets against environmental conditions. This effect was clearer when using lignosulfonate, whose combinations demonstrated a higher hygroscopicity than those of sugar or CFP.

- The use of binders reduced the pellets’ energy power and could increase their pollutant potential and increase the ash content. On the other hand, binders would improve the combustion properties of this biomass fuel.

- Boron remained in the ashes after combustion. This would allow an effective method of valorization for the CFP as well as the recovery of this product from among the ashes generated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dylewski, R.; Adamczyk, J. Study on ecological cost-effectiveness for the thermal insulation of building external vertical walls in Poland. J. Clean. Prod. 2016, 133, 467–478. [Google Scholar] [CrossRef]

- Lopez Hurtado, P.; Rouilly, A.; Raynaud, C.; Vandenbossche, V. The properties of cellulose insulation applied via the wet spray process. Build. Environ. 2016, 107, 43–51. [Google Scholar] [CrossRef]

- Adamczyk, J.; Dylewski, R. Analysis of the sensitivity of the ecological effects for the investment based on the thermal insulation of the building: A Polish case study. J. Clean. Prod. 2017, 162, 856–864. [Google Scholar] [CrossRef]

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Grillet, A.C.; Bui, Q.B.; Diep, T.M.H.; Woloszyn, M. Building bio-insulation materials based on bamboo powder and bio-binders. Constr. Build. Mater. 2018, 186, 686–698. [Google Scholar] [CrossRef]

- Kylili, A.; Christoforou, E.; Fokaides, P.A. Environmental evaluation of biomass pelleting using life cycle assessment. Biomass Bioenergy 2016, 84, 107–117. [Google Scholar] [CrossRef]

- Santolini, E.; Bovo, M.; Barbaresi, A.; Torreggiani, D.; Tassinari, P. Turning agricultural wastes into biomaterials: Assessing the sustainability of scenarios of circular valorization of corn cob in a life-cycle perspective. Appl. Sci. 2021, 11, 6281. [Google Scholar] [CrossRef]

- Haile, M. Integrated volarization of spent coffee grounds to biofuels. Biofuel Res. J. 2014, 1, 65–69. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densifi cation systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Garcia-Maraver, A.; Rodriguez, M.L.; Serrano-Bernardo, F.; Diaz, L.F.; Zamorano, M. Factors affecting the quality of pellets made from residual biomass of olive trees. Fuel Process. Technol. 2015, 129, 1–7. [Google Scholar] [CrossRef]

- Niedziółka, I.; Szpryngiel, M.; Kachel-Jakubowska, M.; Kraszkiewicz, A.; Zawiślak, K.; Sobczak, P.; Nadulski, R. Assessment of the energetic and mechanical properties of pellets produced from agricultural biomass. Renew. Energy 2015, 76, 312–317. [Google Scholar] [CrossRef]

- Espuelas, S.; Marcelino, S.; Echeverría, A.M.; del Castillo, J.M.; Seco, A. Low energy spent coffee grounds briquetting with organic binders for biomass fuel manufacturing. Fuel 2020, 278, 118310. [Google Scholar] [CrossRef]

- Seco, A.; Espuelas, S.; Marcelino, S.; Echeverría, A.M.; Prieto, E. Characterization of biomass briquettes from spent coffee grounds and xanthan gum using low pressure and temperature. Bioenergy Res. 2019, 13, 369–377. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A. Development of groundnut shells and bagasse briquettes as sustainable fuel sources for domestic cooking applications in Uganda. Renew. Energy 2017, 111, 532–542. [Google Scholar] [CrossRef]

- Lerma-Arce, V.; Oliver-Villanueva, J.V.; Segura-Orenga, G. Influence of raw material composition of Mediterranean pinewood on pellet quality. Biomass Bioenergy 2017, 99, 90–96. [Google Scholar] [CrossRef]

- Kang, S.B.; Oh, H.Y.; Kim, J.J.; Choi, K.S. Characteristics of spent coffee ground as a fuel and combustion test in a small boiler (6.5 kW). Renew. Energy 2017, 113, 1208–1214. [Google Scholar] [CrossRef]

- Rajaseenivasan, T.; Srinivasan, V.; Syed Mohamed Qadir, G.; Srithar, K. An investigation on the performance of sawdust briquette blending with neem powder. Alex. Eng. J. 2016, 55, 2833–2838. [Google Scholar] [CrossRef]

- Jiang, L.; Yuan, X.; Xiao, Z.; Liang, J.; Li, H.; Cao, L.; Wang, H.; Chen, X.; Zeng, G. A comparative study of biomass pellet and biomass-sludge mixed pellet: Energy input and pellet properties. Energy Convers. Manag. 2016, 126, 509–515. [Google Scholar] [CrossRef]

- Nosek, R.; Backa, A.; Ďurčanský, P.; Holubčík, M.; Jandačka, J. Effect of paper sludge and dendromass on properties of phytomass pellets. Appl. Sci. 2021, 11, 65. [Google Scholar] [CrossRef]

- Zaharioiu, A.; Bucura, F.; Ionete, E.I.; Ionete, R.E.; Ebrasu, D.; Sandru, C.; Marin, F.; Oancea, S.; Niculescu, V.; Miricioiu, M.G.; et al. Thermochemical decomposition of sewage sludge—An eco-friendly solution for a sustainable energy future by using wastes. Rev. Chim. 2020, 71, 171–181. [Google Scholar] [CrossRef]

- Kong, L.; Xiong, Y.; Liu, T.; Tu, Y.; Tian, S.; Sun, L.; Chen, T. Effect of fiber natures on the formation of “solid bridge” for preparing wood sawdust derived biomass pellet fuel. Fuel Process. Technol. 2016, 144, 79–84. [Google Scholar] [CrossRef]

- Poddar, S.; Kamruzzaman, M.; Sujan, S.M.A.; Hossain, M.; Jamal, M.S.; Gafur, M.A.; Khanam, M. Effect of compression pressure on lignocellulosic biomass pellet to improve fuel properties: Higher heating value. Fuel 2014, 131, 43–48. [Google Scholar] [CrossRef]

- Zeng, T.; Weller, N.; Pollex, A.; Lenz, V. Blended biomass pellets as fuel for small scale combustion appliances: Influence on gaseous and total particulate matter emissions and applicability of fuel indices. Fuel 2016, 184, 689–700. [Google Scholar] [CrossRef]

- Jiang, L.; Liang, J.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Huang, H.; Wang, H.; Zeng, G. Co-pelletization of sewage sludge and biomass: The density and hardness of pellet. Bioresour. Technol. 2014, 166, 435–443. [Google Scholar] [CrossRef]

- Chen, W.; Shi, S.; Chen, M.; Zhou, X. Fast co-pyrolysis of waste newspaper with high-density polyethylene for high yields of alcohols and hydrocarbons. Waste Manag. 2017, 67, 155–162. [Google Scholar] [CrossRef] [PubMed]

- Jackson, J.; Turner, A.; Mark, T.; Montross, M. Densification of biomass using a pilot scale flat ring roller pellet mill. Fuel Process. Technol. 2016, 148, 43–49. [Google Scholar] [CrossRef]

- Nishiguchi, S.; Tabata, T. Assessment of social, economic, and environmental aspects of woody biomass energy utilization: Direct burning and wood pellets. Renew. Sustain. Energy Rev. 2016, 57, 1279–1286. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The significance of pelletization operating conditions: An analysis of physical and mechanical characteristics as well as energy consumption of biomass pellets. Renew. Sustain. Energy Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- Karkania, V.; Fanara, E.; Zabaniotou, A. Review of sustainable biomass pellets production—A study for agricultural residues pellets’ market in Greece. Renew. Sustain. Energy Rev. 2012, 16, 1426–1436. [Google Scholar] [CrossRef]

- Huang, Y.; Finell, M.; Larsson, S.; Wang, X.; Zhang, J.; Wei, R.; Liu, L. Biofuel pellets made at low moisture content—Influence of water in the binding mechanism of densified biomass. Biomass Bioenergy 2017, 98, 8–14. [Google Scholar] [CrossRef]

- Cheng, J.; Zhou, F.; Si, T.; Zhou, J.; Cen, K. Mechanical strength and combustion properties of biomass pellets prepared with coal tar residue as a binder. Fuel Process. Technol. 2018, 179, 229–237. [Google Scholar] [CrossRef]

- Frodeson, S.; Henriksson, G.; Berghel, J. Effects of moisture content during densification of biomass pellets, focusing on polysaccharide substances. Biomass Bioenergy 2019, 122, 322–330. [Google Scholar] [CrossRef]

- Marrugo, G.; Valdés, C.F.; Gómez, C.; Chejne, F. Pelletizing of Colombian agro-industrial biomasses with crude glycerol. Renew. Energy 2019, 134, 558–568. [Google Scholar] [CrossRef]

- Xia, X.; Zhang, K.; Xiao, H.; Xiao, S.; Song, Z.; Yang, Z. Effects of additives and hydrothermal pretreatment on the pelleting process of rice straw: Energy consumption and pellets quality. Ind. Crops Prod. 2019, 133, 178–184. [Google Scholar] [CrossRef]

- Kong, L.; Tian, S.H.; He, C.; Du, C.; Tu, Y.T.; Xiong, Y. Effect of waste wrapping paper fiber as a “solid bridge” on physical characteristics of biomass pellets made from wood sawdust. Appl. Energy 2012, 98, 33–39. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Shang, L.; Sárossy, Z.; Ahrenfeldt, J.; Henriksen, U.B. From a single pellet press to a bench scale pellet mill—Pelletizing six different biomass feedstocks. Fuel Process. Technol. 2016, 142, 27–33. [Google Scholar] [CrossRef]

- Ciolkosz, D.; Jacobson, M.; Heil, N.; Brandau, W. An assessment of farm scale biomass pelleting in the Northeast. Renew. Energy 2017, 108, 85–91. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Iftikhar, M.; Asghar, A.; Ramzan, N.; Sajjadi, B.; Chen, W.-Y. Biomass densification: Effect of cow dung on the physicochemical properties of wheat straw and rice husk based biomass pellets. Biomass Bioenergy 2019, 122, 1–16. [Google Scholar] [CrossRef]

- Muazu, R.I.; Stegemann, J.A. Effects of operating variables on durability of fuel briquettes from rice husks and corn cobs. Fuel Process. Technol. 2015, 133, 137–145. [Google Scholar] [CrossRef]

- Lubwama, M.; Yiga, V.A. Characteristics of briquettes developed from rice and coffee husks for domestic cooking applications in Uganda. Renew. Energy 2018, 118, 43–55. [Google Scholar] [CrossRef]

- Ndindeng, S.A.; Mbassi, J.E.G.; Mbacham, W.F.; Manful, J.; Graham-Acquaah, S.; Moreira, J.; Dossou, J.; Futakuchi, K. Quality optimization in briquettes made from rice milling by-products. Energy Sustain. Dev. 2015, 29, 24–31. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Brand, M.A.; Jacinto, R.C.; Antunes, R.; da Cunha, A.B. Production of briquettes as a tool to optimize the use of waste from rice cultivation and industrial processing. Renew. Energy 2017, 111, 116–123. [Google Scholar] [CrossRef]

| Waste Kind | Higher Heating Value (MJ/kg) | Source | Lower Heating Value (MJ/kg) | Source |

|---|---|---|---|---|

| Agricultural crop residues | 14.64–18.38 | [19] | ||

| Forest biomass | 13.06–20.82 | [23,24] | 16.06–18.01 | [11,16] |

| Wood processing industry residues | 15.86 | [22] | ||

| Other wastes | 15.59–19.67 | [22,25] | ||

| EN 14961-2 | 16.50–19.00 | |||

| EN ISO 17225-6 | >14.50 |

| Number | Code | Additive | Additive Percentage (%) | Water Added (%) |

|---|---|---|---|---|

| 1 | C-0-5W | - | - | 5 |

| 2 | C-0-10W | - | - | 10 |

| 3 | C-0-15W | - | - | 15 |

| 4 | C-0-20W | - | - | 20 |

| 5 | C-0-30W | - | - | 30 |

| 6 | C-0-40W | - | - | 40 |

| 7 | C-1S-5W | Sugar | 1 | 5 |

| 8 | C-1S-10W | Sugar | 1 | 10 |

| 9 | C-1S-15W | Sugar | 1 | 15 |

| 10 | C-1S-20W | Sugar | 1 | 20 |

| 11 | C-1S-30W | Sugar | 1 | 30 |

| 12 | C-1S-40W | Sugar | 1 | 40 |

| 13 | C-2S-5W | Sugar | 2 | 5 |

| 14 | C-2S-10W | Sugar | 2 | 10 |

| 15 | C-2S-15W | Sugar | 2 | 15 |

| 16 | C-2S-20W | Sugar | 2 | 20 |

| 17 | C-2S-30W | Sugar | 2 | 30 |

| 18 | C-2S-40W | Sugar | 2 | 40 |

| 19 | C-1L-5W | Lignosulphonate | 1 | 5 |

| 20 | C-1L-10W | Lignosulphonate | 1 | 10 |

| 21 | C-1L-15W | Lignosulphonate | 1 | 15 |

| 22 | C-1L-20W | Lignosulphonate | 1 | 20 |

| 23 | C-1L-30W | Lignosulphonate | 1 | 30 |

| 24 | C-1L-40W | Lignosulphonate | 1 | 40 |

| 25 | C-2L-5W | Lignosulphonate | 2 | 5 |

| 26 | C-2L-10W | Lignosulphonate | 2 | 10 |

| 27 | C-2L-15W | Lignosulphonate | 2 | 15 |

| 28 | C-2L-20W | Lignosulphonate | 2 | 20 |

| 29 | C-2L-30W | Lignosulphonate | 2 | 30 |

| 30 | C-2L-40W | Lignosulphonate | 2 | 40 |

| Analysis | CFP | CFP + 1% S | CFP + 2% S | CFP + 1% LS | CFP + 2% LS |

|---|---|---|---|---|---|

| Lower heating value (MJ/kg) | 14.984 | 14.185 | 12.718 | 14.294 | 13.741 |

| Ultimate analysis (wt%) | |||||

| N | 0 | 0.11 | 0.17 | 0.13 | 0.88 |

| C | 39.15 | 38.67 | 34.68 | 38.39 | 33.39 |

| H | 5.48 | 5.33 | 5.14 | 5.45 | 5.05 |

| S | 0 | 0 | 0 | 0 | 0 |

| O | 55.38 | 55.89 | 60.01 | 56.04 | 60.69 |

| Proximate analysis (wt%) | |||||

| Moisture | 7.83 | 8.65 | 6.05 | 6.5 | 6.64 |

| Volatiles | 54.49 | 51.17 | 46.59 | 51.59 | 45.81 |

| Fixed carbon | 26.97 | 28.42 | 27.61 | 27.6 | 28.71 |

| Ash | 10.71 | 11.76 | 19.75 | 14.31 | 18.84 |

| Ashes chemical composition (wt%) | |||||

| C | 16.78 | 16.25 | 30.25 | 13.45 | 23.65 |

| O | 57.93 | 56.73 | 49.05 | 59.19 | 52.21 |

| Si | 5.04 | 7.15 | 5.02 | 7.93 | 4.29 |

| B | 16.42 | 13.09 | 10.03 | 14.4 | 15.67 |

| Ca | 3.83 | 6.78 | 5.65 | 5.03 | 4.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Espuelas, S.; Marcelino-Sádaba, S.; del Castillo, J.M.; Garcia, B.; Seco, A. Valorization of Insulation Cellulose Waste as Solid Biomass Fuel. Appl. Sci. 2021, 11, 8223. https://doi.org/10.3390/app11178223

Espuelas S, Marcelino-Sádaba S, del Castillo JM, Garcia B, Seco A. Valorization of Insulation Cellulose Waste as Solid Biomass Fuel. Applied Sciences. 2021; 11(17):8223. https://doi.org/10.3390/app11178223

Chicago/Turabian StyleEspuelas, Sandra, Sara Marcelino-Sádaba, Jesus Maria del Castillo, Benat Garcia, and Andres Seco. 2021. "Valorization of Insulation Cellulose Waste as Solid Biomass Fuel" Applied Sciences 11, no. 17: 8223. https://doi.org/10.3390/app11178223

APA StyleEspuelas, S., Marcelino-Sádaba, S., del Castillo, J. M., Garcia, B., & Seco, A. (2021). Valorization of Insulation Cellulose Waste as Solid Biomass Fuel. Applied Sciences, 11(17), 8223. https://doi.org/10.3390/app11178223