Guidelines for Topology Optimization as Concept Design Tool and Their Application for the Mechanical Design of the Inner Frame to Support an Ancient Bronze Statue

Abstract

:1. Introduction

2. Methods

2.1. Mathematical Formulation and Computation Set-Up

- 1.

- ;

- 2.

- ;

- 3.

- ;

- 4.

- and .

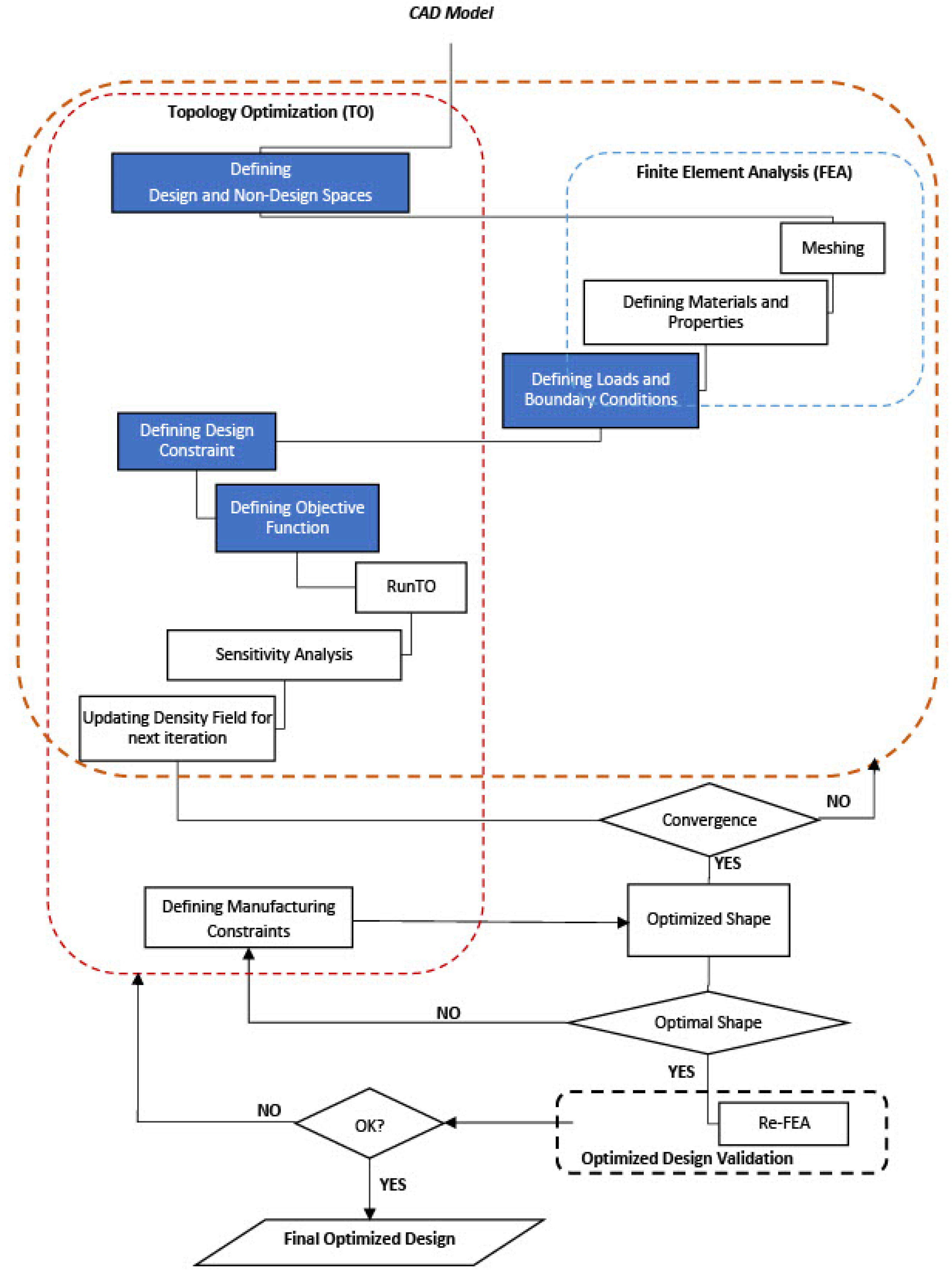

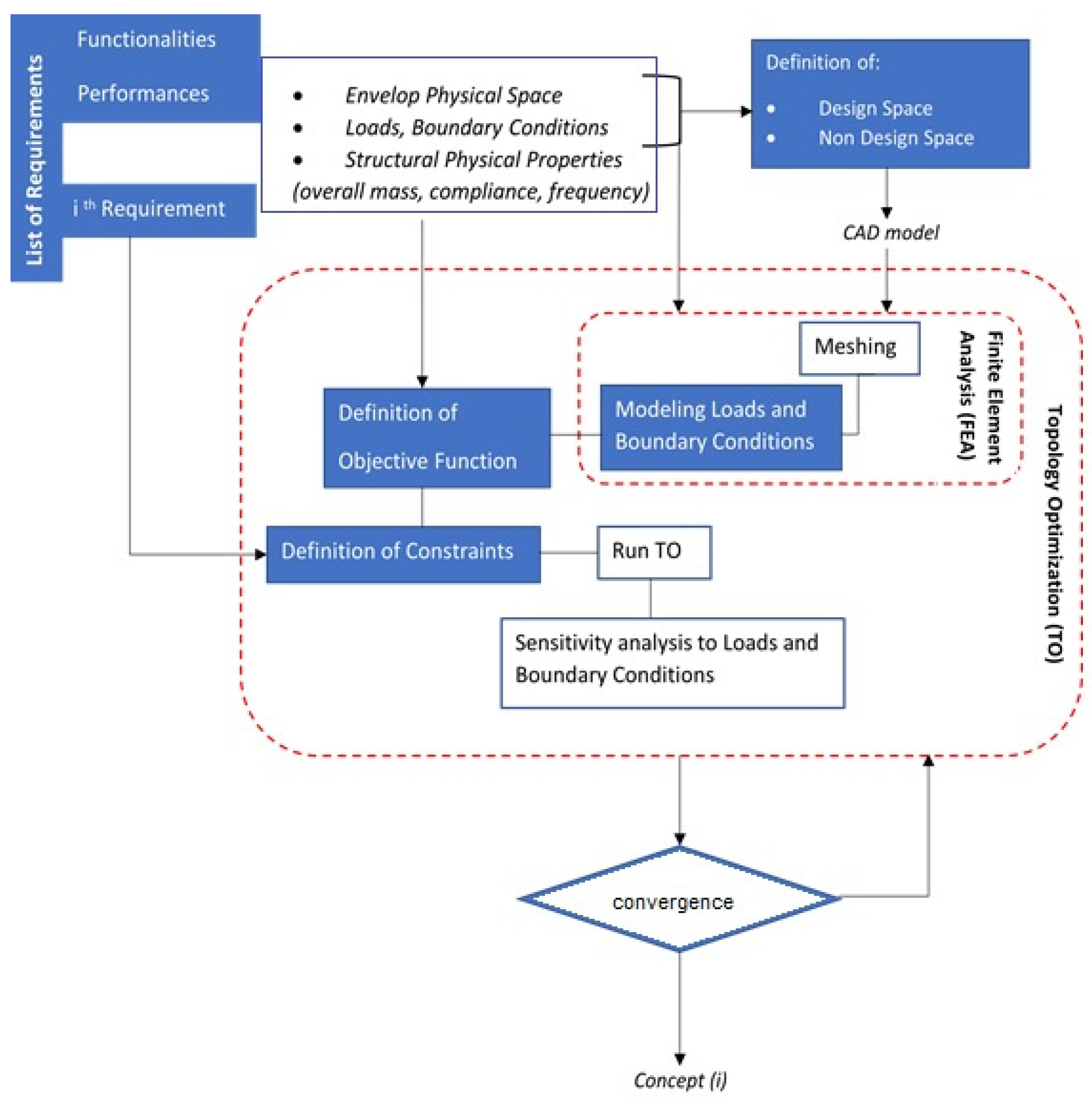

2.2. Design Workflow and Guidelines

- a set of requirements (e.g., aesthetics, ergonomics, transportability, etc.) may constrain the final envelop of the shapes. The definition of design and non-design spaces operatively forces this kind of evaluation, which can be multi-criteria (thus taking into account together many requirements) or not. In this case, requirements may help to define geometrical variants in terms of design space.

- The need for simulating the structural behaviour of the system by FEA requires an anticipated evaluation of the target values, enforcing the physical feasibility of the concept evaluation.

- Looking for optimal topology in assemblies, a clear model of the operative conditions must be defined, so that a preliminary understanding of the worst kinematic/dynamic conditions can be defined. Envelop volumes coupled with multibody analysis such as the equivalent static load method may help the assessing of the problems of flexible multibody assemblies [62].

3. Case Study

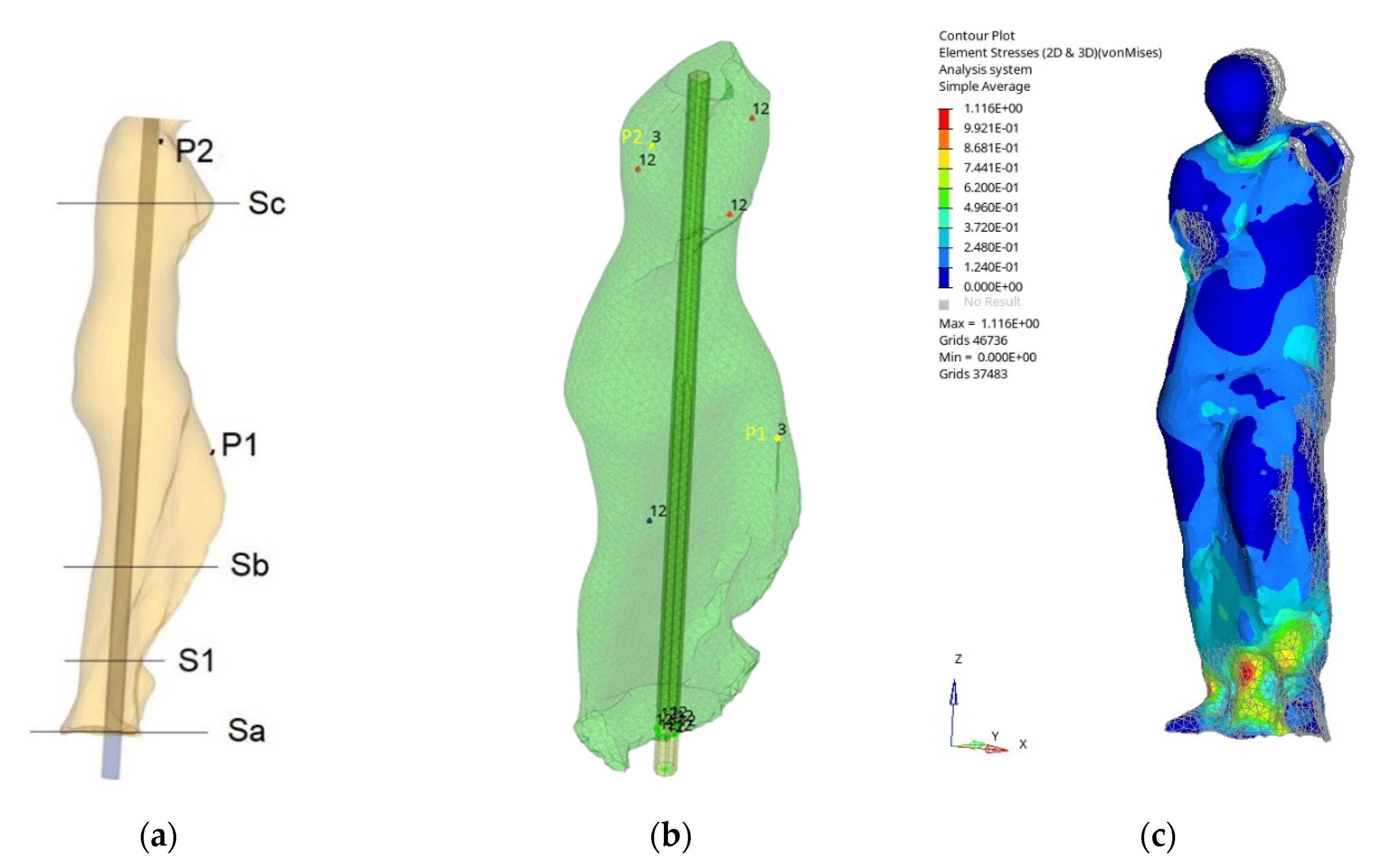

3.1. Design Requirements and the Definition of Design Space and Non-Design Space

3.2. Design Requirements and the Definition of Boundary Constraints and Load Conditions

3.3. Topological Optimization Set-Up

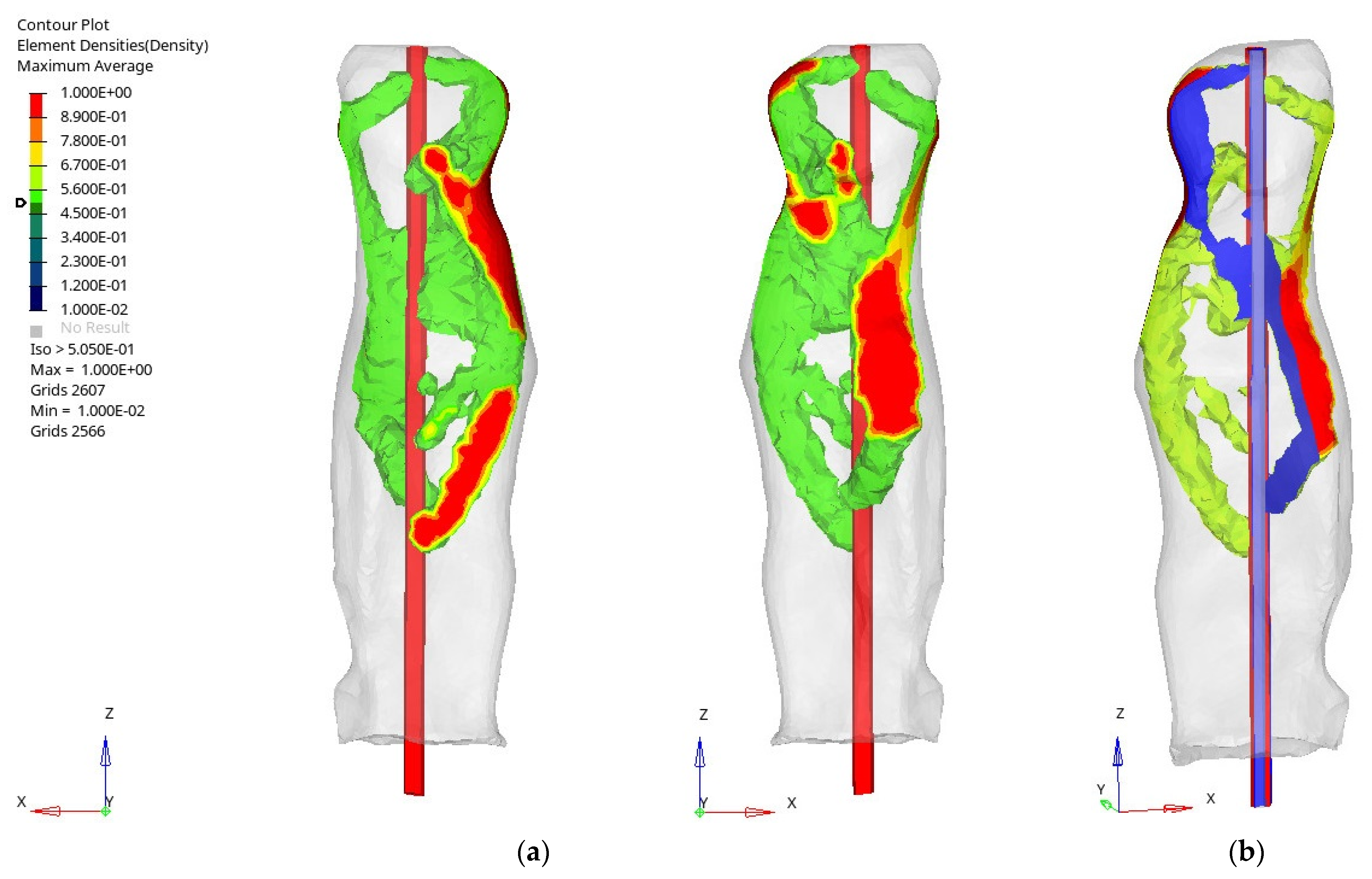

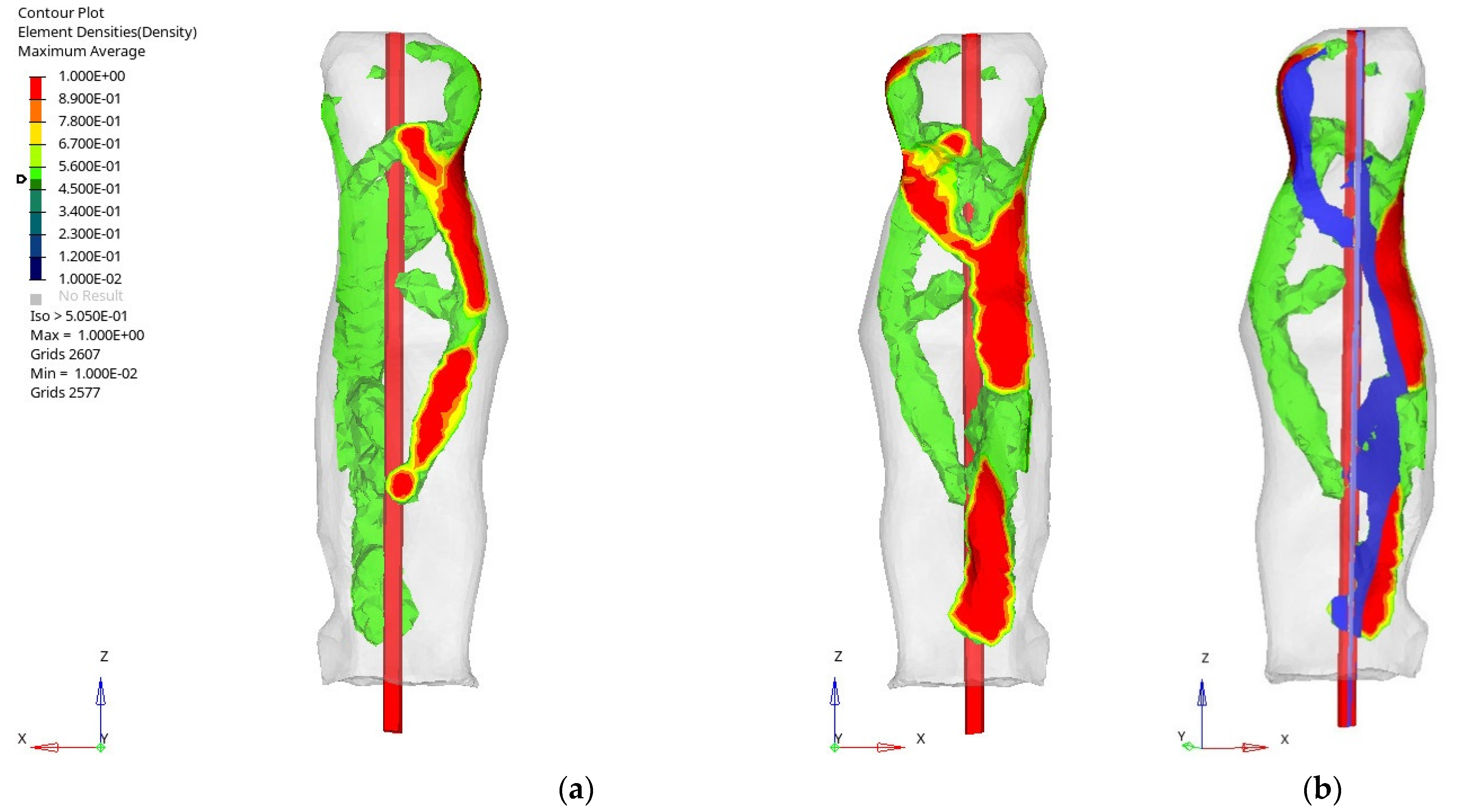

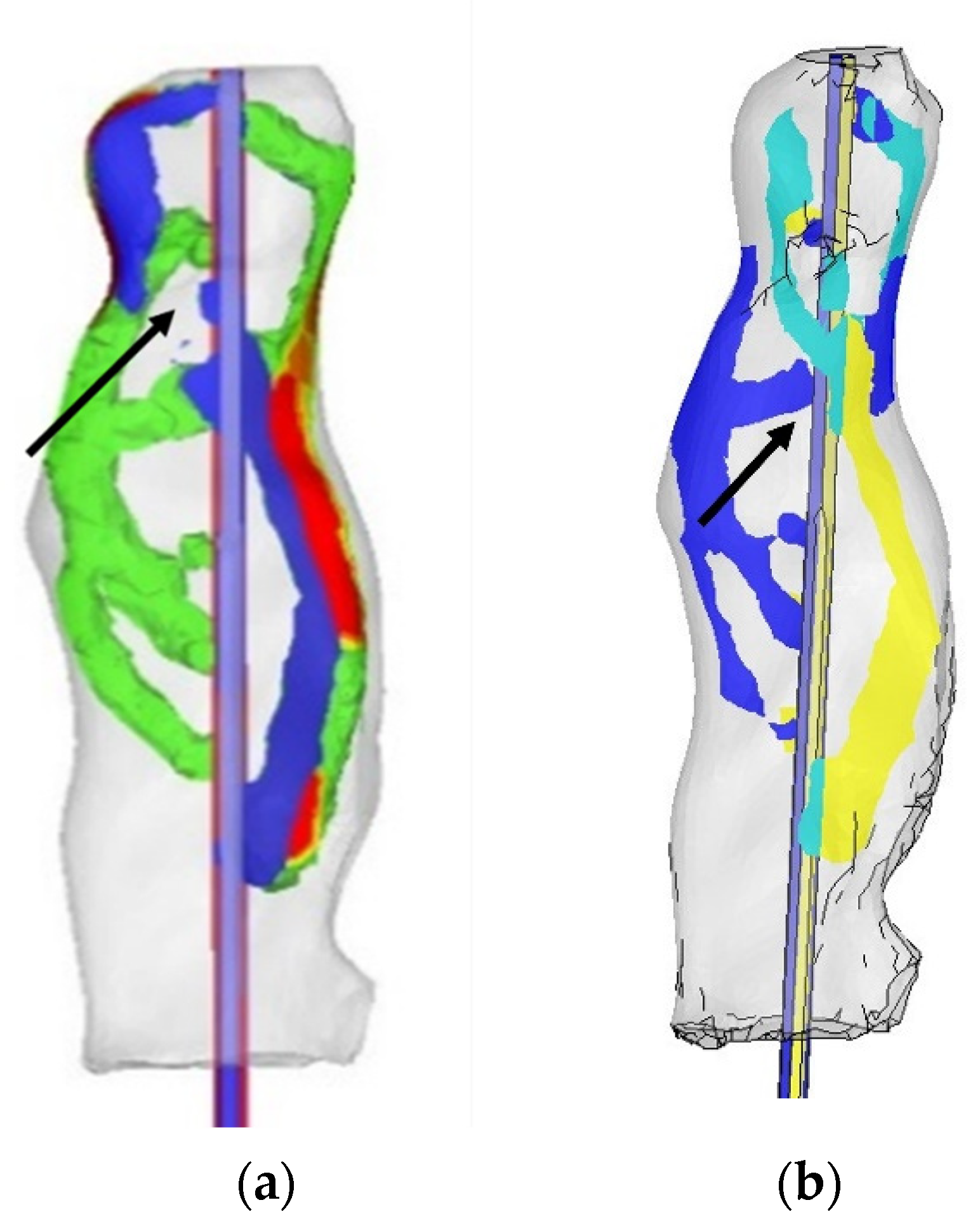

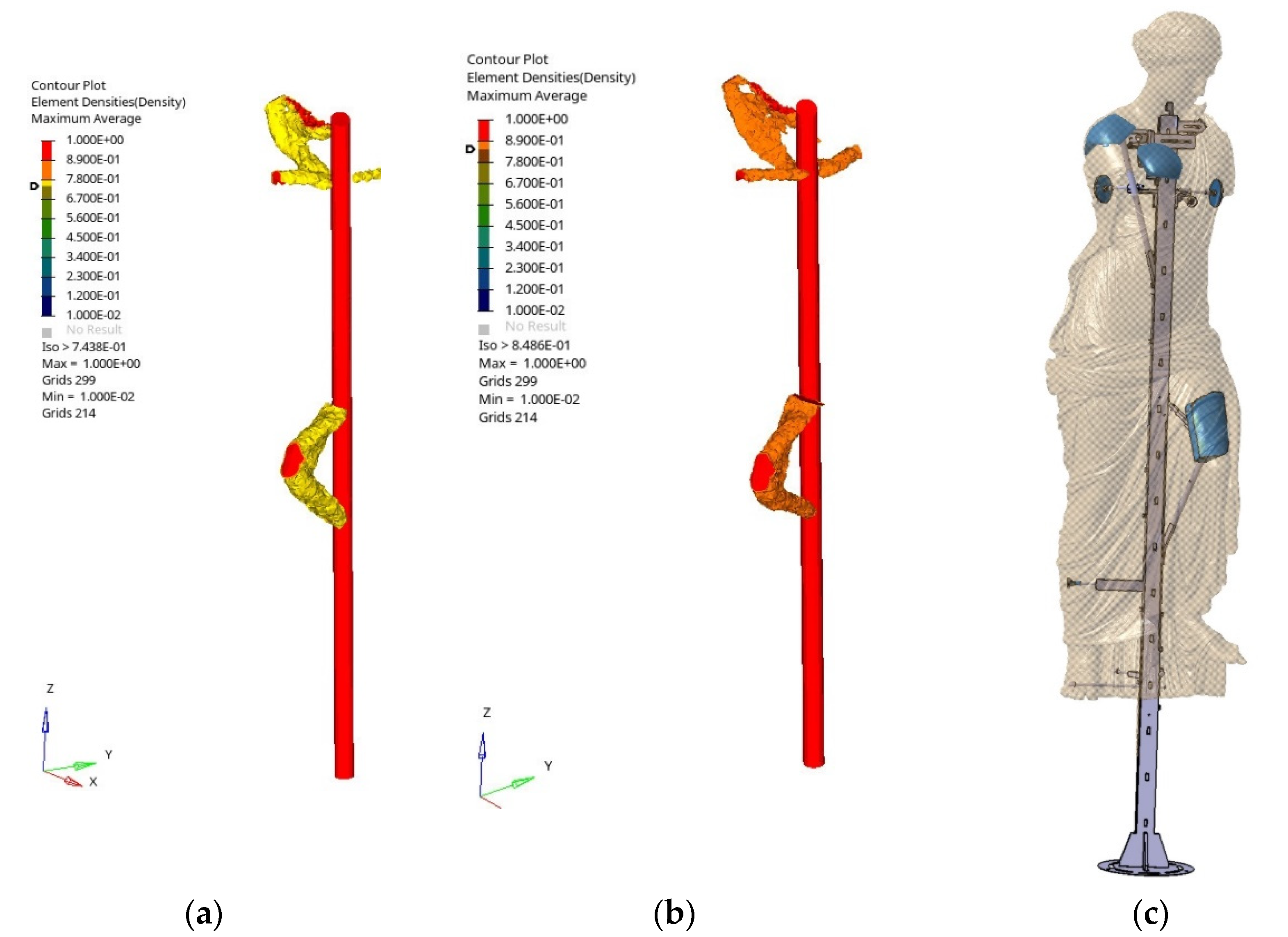

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmad, A.; Raza, M.A.; Campana, F. Simulation Based Topology Optimization Assessment with Manufacturing Constraints. In Proceedings of the 2020 17th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 14–18 January 2020; pp. 174–182. [Google Scholar]

- Beghini, L.L.; Beghini, A.; Katz, N.; Baker, W.F.; Paulino, G.H. Connecting architecture and engineering through structural topology optimization. Eng. Struct. 2014, 59, 716–726. [Google Scholar] [CrossRef]

- Suzuki, K.; Kikuchi, N. A homogenization method for shape and topology optimization. Comput. Methods Appl. Mech. Eng. 1991, 93, 291–318. [Google Scholar] [CrossRef] [Green Version]

- Bendsoe, M.P.; Sigmund, O. Topology Optimization: Theory, Methods, and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Rozvany, G.I.; Zhou, M.; Birker, T. Generalized shape optimization without homogenization. Struct. Optim. 1992, 4, 250–252. [Google Scholar] [CrossRef]

- Yulin, M.; Xiaoming, W. A level set method for structural topology optimization and its applications. Adv. Eng. Softw. 2004, 35, 415–441. [Google Scholar] [CrossRef]

- Allaire, G.; Jouve, F.; Toader, A.M. A level-set method for shape optimization. Comptes Rendus Math. 2002, 334, 1125–1130. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, W.; Zhong, W. Doing topology optimization explicitly and geometrically—A new moving morphable components-based framework. J. Appl. Mech. 2014, 81, 081009. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, J.; Zhu, X.; Zhou, J.; Xue, D.; Lei, X.; Guo, X. Explicit three-dimensional topology optimization via Moving Morphable Void (MMV) approach. Comput. Methods Appl. Mech. Eng. 2017, 322, 590–614. [Google Scholar] [CrossRef] [Green Version]

- Khan, S.A.; Engelbrecht, A.P. A fuzzy particle swarm optimization algorithm for computer communication network topology design. Appl. Intell. 2012, 36, 161–177. [Google Scholar] [CrossRef] [Green Version]

- Blank, L.; Garcke, H.; Sarbu, L.; Srisupattarawanit, T.; Styles, V.; Voigt, A. Phase-field approaches to structural topology optimization. In Constrained Optimization and Optimal Control for Partial Differential Equations; Springer: Berlin/Heidelberg, Germany, 2012; pp. 245–256. [Google Scholar]

- Watanabe, K.; Suga, T.; Kitabatake, S. Topology optimization based on the on/off method for synchronous motor. IEEE Trans. Magn. 2017, 54, 1–4. [Google Scholar] [CrossRef]

- Vlah, D.; Žavbi, R.; Vukašinović, N. Evaluation of topology optimization and generative design tools as support for conceptual design. In Proceedings of the Design Society: DESIGN Conference; Cambridge University Press: Cambridge, UK, 2020; Volume 1, pp. 451–460. [Google Scholar]

- Bici, M.; Broggiato, G.B.; Campana, F. Topological Optimization in Concept Design: Starting approach and a validation case study. In Advances on Mechanics, Design Engineering and Manufacturing; Springer: Berlin/Heidelberg, Germany, 2017; pp. 289–299. [Google Scholar]

- Guirguis, D.; Hamza, K.; Aly, M.; Hegazi, H.; Saitou, K. Multi-objective topology optimization of multi-component continuum structures via a Kriging-interpolated level set approach. Struct. Multidiscip. Optim. 2015, 51, 733–748. [Google Scholar] [CrossRef]

- Sivapuram, R.; Dunning, P.D.; Kim, H.A. Simultaneous material and structural optimization by multiscale topology optimization. Struct. Multidiscip. Optim. 2016, 54, 1267–1281. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Luo, Z.; Xia, L.; Gao, L. Concurrent topology optimization of multiscale composite structures in Matlab. Struct. Multidiscip. Optim. 2019, 60, 2621–2651. [Google Scholar] [CrossRef]

- Hoang, V.N.; Tran, P.; Vu, V.T.; Nguyen-Xuan, H. Design of lattice structures with direct multiscale topology optimization. Compos. Struct. 2020, 252, 112718. [Google Scholar] [CrossRef]

- Zuo, W.; Saitou, K. Multi-material topology optimization using ordered SIMP interpolation. Struct. Multidiscip. Optim. 2017, 55, 477–491. [Google Scholar] [CrossRef]

- Blasques, J.P.; Stolpe, M. Multi-material topology optimization of laminated composite beam cross sections. Compos. Struct. 2012, 94, 3278–3289. [Google Scholar] [CrossRef] [Green Version]

- Radman, A.; Huang, X.; Xie, Y.M. Topology optimization of functionally graded cellular materials. J. Mater. Sci. 2013, 48, 1503–1510. [Google Scholar] [CrossRef]

- Taheri, A.H.; Suresh, K. An isogeometric approach to topology optimization of multi-material and functionally graded structures. Int. J. Numer. Methods Eng. 2017, 109, 668–696. [Google Scholar] [CrossRef]

- Aulig, N.; Nutwell, E.; Menzel, S.; Detwiler, D. A weight balanced multi-objective topology optimization for automotive development. In Proceedings of the 10th European LS-DYNA Conference, Würzburg, Germany, 15–17 June 2015. [Google Scholar]

- Duddeck, F.; Hunkeler, S.; Lozano, P.; Wehrle, E.; Zeng, D. Topology optimization for crashworthiness of thin-walled structures under axial impact using hybrid cellular automata. Struct. Multidiscip. Optim. 2016, 54, 415–428. [Google Scholar] [CrossRef]

- Neves, M.M.; Sigmund, O.; Bendsøe, M.P. Topology optimization of periodic microstructures with a penalization of highly localized buckling modes. Int. J. Numer. Methods Eng. 2002, 54, 809–834. [Google Scholar] [CrossRef]

- Osanov, M.; Guest, J.K. Topology optimization for architected materials design. Annu. Rev. Mater. Res. 2016, 46, 211–233. [Google Scholar] [CrossRef]

- Kingman, J.; Tsavdaridis, K.D.; Toropov, V.V. Applications of topology optimization in structural engineering. In Proceedings of the Civil Engineering for Sustainability and Resilience International Conference (CESARE), Leeds, UK, 24–27 April 2014. [Google Scholar]

- Ahmad, A.; Campana, F.; Bici, M. Application of Topology Optimization to Reduce Automotive Exhaust Emissions. SAE Int. J. Sustain. Transp. Energy Environ. Policy 2021, accepted. [Google Scholar]

- Yi, B.; Zhou, Y.; Yoon, G.H.; Saitou, K. Topology optimization of functionally-graded lattice structures with buckling constraints. Comput. Methods Appl. Mech. Eng. 2019, 354, 593–619. [Google Scholar] [CrossRef]

- Cheng, L.; Bai, J.; To, A.C. Functionally graded lattice structure topology optimization for the design of additive manufactured components with stress constraints. Comput. Methods Appl. Mech. Eng. 2019, 344, 334–359. [Google Scholar] [CrossRef]

- Cheng, L.; Liu, J.; Liang, X.; To, A.C. Coupling lattice structure topology optimization with design-dependent feature evolution for additive manufactured heat conduction design. Comput. Methods Appl. Mech. Eng. 2018, 332, 408–439. [Google Scholar] [CrossRef]

- Karadere, G.; Düzcan, Y.; Yıldız, A.R. Light-weight design of automobile suspension components using topology and shape optimization techniques. Mater. Test. 2020, 62, 454–464. [Google Scholar] [CrossRef]

- Liu, T.; Wang, S.; Li, B.; Gao, L. A level-set-based topology and shape optimization method for continuum structure under geometric constraints. Struct. Multidiscip. Optim. 2014, 50, 253–273. [Google Scholar] [CrossRef]

- Tyflopoulos, E.; Tollnes, F.D.; Steinert, M.; Olsen, A. State of the art of generative design and topology optimization and potential research needs. In Proceedings of the NordDesign 2018, Linköping, Sweden, 14–17 August 2018. [Google Scholar]

- Chen, X.A.; Tao, Y.; Wang, G.; Kang, R.; Grossman, T.; Coros, S.; Hudson, S.E. Forte: User-driven generative design. In Proceedings of the 2018 CHI Conference on Human Factors in Computing Systems, Montréal, QC, Canada, 21–26 April 2018; pp. 1–12. [Google Scholar]

- Dalpadulo, E.; Gherardini, F.; Pini, F.; Leali, F. Integration of topology optimisation and design variants selection for additive manufacturing-based systematic product redesign. Appl. Sci. 2020, 10, 7841. [Google Scholar] [CrossRef]

- Vogiatzis, P.; Chen, S.; Wang, X.; Li, T.; Wang, L. Topology optimization of multi-material negative Poisson’s ratio metamaterials using a reconciled level set method. Comput. Aided Des. 2017, 83, 15–32. [Google Scholar] [CrossRef] [Green Version]

- Takezawa, A.; Kobashi, M. Design methodology for porous composites with tunable thermal expansion produced by multi-material topology optimization and additive manufacturing. Compos. Part. B Eng. 2017, 131, 21–29. [Google Scholar] [CrossRef]

- Joo, Y.; Lee, I.; Kim, S.J. Topology optimization of heat sinks in natural convection considering the effect of shape-dependent heat transfer coefficient. Int. J. Heat Mass Transf. 2017, 109, 123–133. [Google Scholar] [CrossRef]

- Kingman, J.J.; Tsavdaridis, K.; Toropov, V. Applications of topology optimisation in structural engineering: High-rise buildings & steel components. Jordan J. Civ. Eng. 2015, 9, 335–357. [Google Scholar]

- Gaynor, A.T.; Guest, J.K.; Moen, C.D. Reinforced concrete force visualization and design using bilinear truss-continuum topology optimization. J. Struct. Eng. 2013, 139, 607–618. [Google Scholar] [CrossRef]

- Oh, S.; Jung, Y.; Kim, S.; Lee, I.; Kang, N. Deep generative design: Integration of topology optimization and generative models. J. Mech. Des. 2019, 141, 111405. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; To, A.C. Current and future trends in topology optimization for additive manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Cheng, G.; Xu, L. Topology optimization considering overhang constraint in additive manufacturing. Comput. Struct. 2019, 212, 86–100. [Google Scholar] [CrossRef]

- Garaigordobil, A.; Ansola, R.; Santamaría, J.; De Bustos, I.F. A new overhang constraint for topology optimization of self-supporting structures in additive manufacturing. Struct. Multidiscip. Optim. 2018, 58, 2003–2017. [Google Scholar] [CrossRef] [Green Version]

- Gaynor, A.T.; Guest, J.K. Topology optimization considering overhang constraints: Eliminating sacrificial support material in additive manufacturing through design. Struct. Multidiscip. Optim. 2016, 54, 1157–1172. [Google Scholar] [CrossRef]

- Ali Banijamali, S.M.; Oftadeh, R.; Nazarian, A.; Goebel, R.; Vaziri, A.; Nayeb-Hashemi, H. Effects of different loading patterns on the trabecular bone morphology of the proximal femur using adaptive bone remodeling. J. Biomech. Eng. 2015, 137, 011011. [Google Scholar] [CrossRef] [Green Version]

- Xu, S.; Liu, J.; Zou, B.; Li, Q.; Ma, Y. Stress constrained multi-material topology optimization with the ordered SIMP method. Comput. Methods Appl. Mech. Eng. 2021, 373, 113453. [Google Scholar] [CrossRef]

- Lee, E.; James, K.A.; Martins, J.R. Stress-constrained topology optimization with design-dependent loading. Struct. Multidiscip. Optim. 2012, 46, 647–661. [Google Scholar] [CrossRef]

- Holmberg, E.; Torstenfelt, B.; Klarbring, A. Stress constrained topology optimization. Struct. Multidiscip. Optim. 2013, 48, 33–47. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Shen, W.; Xie, H.; Neelamkavil, J.; Pardasani, A. Collaborative conceptual design—State of the art and future trends. Comput. Aided Des. 2002, 34, 981–996. [Google Scholar] [CrossRef]

- Anderson, D.M. Design for Manufacturability: How to Use Concurrent Engineering to Rapidly Develop Low-Cost, High-Quality Products for Lean Production; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Wisthoff, A.; Ferrero, V.; Huynh, T.; DuPont, B. Quantifying the impact of sustainable product design decisions in the early design phase through machine learning. In ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2016. [Google Scholar]

- Zeballos, L.J.; Méndez, C.A.; Povoa, A.P.B. Mixed-integer linear programming approach for product design for life-cycle profit. Comput. Ind. Eng. 2019, 137, 106079. [Google Scholar] [CrossRef]

- Pan, Z.; Wang, X.; Teng, R.; Cao, X. Computer-aided design-while-engineering technology in top-down modeling of mechanical product. Comput. Ind. 2016, 75, 151–161. [Google Scholar] [CrossRef]

- Wu, J.; Quian, X.; Wang, M.Y. Advances in generative design. Comput. Aided Des. 2019, 116, 102733. [Google Scholar] [CrossRef]

- Li, C.; Kim, I.Y. Multi-material topology optimization for automotive design problems. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2018, 232, 1950–1969. [Google Scholar] [CrossRef]

- Zhu, J.H.; Zhang, W.H.; Xia, L. Topology optimization in aircraft and aerospace structures design. Arch. Comput. Methods Eng. 2016, 23, 595–622. [Google Scholar] [CrossRef]

- Chang, C.L.; Chen, C.S.; Huang, C.H.; Hsu, M.L. Finite element analysis of the dental implant using a topology optimization method. Med. Eng. Phys. 2012, 34, 999–1008. [Google Scholar] [CrossRef]

- Feist, S.; Barreto, G.; Ferreira, B.; Leitao, A. Portable Generative Design for Building Information Modelling. In Proceedings of the 21st International Conference on Computer Aided Architectural Design Research in Asia (CAADRIA 2016 Conference), Melbourne, Australia, 30 March–2 April 2016. [Google Scholar]

- Bagassi, S.; Lucchi, F.; De Crescenzio, F.; Persiani, F. Generative design: Advanced design optimization processes for aeronautical applications. In Proceedings of the 30th Congress of the International Council of the Aeronautical Sciences, Daejeon, Korea, 25–30 September 2016. [Google Scholar]

- Yang, Z.-J.; Chen, X.; Kelly, R. A topological optimization method for flexible multi-body dynamic system using epsilon algorithm. Struct. Eng. Mech. 2011, 37, 475–487. [Google Scholar] [CrossRef]

- Bici, M.; Brini, A.; Campana, F.; Capoferri, S.; Guarnieri, R.; Morandini, F.; Patera, A. Design of the new inner frame for the Vittoria Alata di Brescia: How engineering design may support ancient bronze restoration. Lect. Notes Mech. Eng. Proc. ADM2021 Int. Conf. 2021, accepted. [Google Scholar]

- Blösch-Paidosh, A.; Shea, K. Design Heuristics for Additive Manufacturing Validated Through a User Study. ASME J. Mech. Des. 2019, 141, 041101. [Google Scholar] [CrossRef]

- Fu, K.K.; Yang, M.C.; Wood, K.L. Design principles: Literature review, analysis, and future directions. J. Mech. Des. Trans. ASME 2016, 138, 101103. [Google Scholar] [CrossRef] [Green Version]

- Yilmaz, S.; Seifert, C.M. Creativity through design heuristics: A case study of expert product design. Des. Stud. 2011, 32, 384–415. [Google Scholar] [CrossRef]

| Design Requirements (DR) | TO Optimization Requirements (OR) | |

|---|---|---|

| 1 Preserve structural integrity of the ancient material | → | 1.1 Maximize the safety margin for local stress (at least equal to 2) 1.2 Avoid interfaces on thin or weak areas |

| 2 Limit relative displacement at the neck | → | 2.1 Reduce the head displacement 2.2 Minimize bending compliance in the front and lateral planes of the statue |

| 3 Reduce stress at the right part of the hip | → | 3.1 Minimize bending compliance in the front and lateral planes of the statue |

| 4 Do not apply loads on the base of the skirt | → | 4.1 Suspended directly on the inner frame |

| 5 Avoid contact among wings and back of the central body | → | 5.1 Suspended directly on the inner frame |

| 6 Connect the statue as a rigid body to the anti-seismic basement | → | 6.1 Transfer loads to the ground for the static balance 6.2 Reduce relative compliance between central body and arms and wings, making the system as a rigid body |

| 7 Guarantee the position of the arms and the wings in the respect of the central body | → | 7.1 Wings and arms must be connected directly to the central beam through upper openings of the central body |

| 8 Allow assembly and disassembly through the limited areas of the openings i.e., at the base, around the arms and wings connection areas | → | 8.1 Reduction of the design space at the minimum section of the statue to guarantee maneuvering 8.2 Possible manufacturing constraints related to the adoption of a wireframe structures made of beams and mold/machined parts at the interfaces with bronze |

| Loads | Central Body Equivalent loads @ basement | Force: (0, 0, 2111) N Moment: (−53,740, 25,310, 0) Nm |

| Arms and wings Equivalent loads @ basement | Force: (0, 0, 866) N Moment: (203,600, 65,050, −56,890) Nm | |

| Stress-Strain Constraints | Max displacement at neck | <0.9 mm |

| Maximum stress at hip | Less than 40 MPa | |

| Maximum stress at neck | Less than 40 MPa | |

| Mass Constraint | Volume Fraction (%) | Less than 10% |

| Objective Function | Central Body compliance | To be minimized |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, A.; Bici, M.; Campana, F. Guidelines for Topology Optimization as Concept Design Tool and Their Application for the Mechanical Design of the Inner Frame to Support an Ancient Bronze Statue. Appl. Sci. 2021, 11, 7834. https://doi.org/10.3390/app11177834

Ahmad A, Bici M, Campana F. Guidelines for Topology Optimization as Concept Design Tool and Their Application for the Mechanical Design of the Inner Frame to Support an Ancient Bronze Statue. Applied Sciences. 2021; 11(17):7834. https://doi.org/10.3390/app11177834

Chicago/Turabian StyleAhmad, Abas, Michele Bici, and Francesca Campana. 2021. "Guidelines for Topology Optimization as Concept Design Tool and Their Application for the Mechanical Design of the Inner Frame to Support an Ancient Bronze Statue" Applied Sciences 11, no. 17: 7834. https://doi.org/10.3390/app11177834

APA StyleAhmad, A., Bici, M., & Campana, F. (2021). Guidelines for Topology Optimization as Concept Design Tool and Their Application for the Mechanical Design of the Inner Frame to Support an Ancient Bronze Statue. Applied Sciences, 11(17), 7834. https://doi.org/10.3390/app11177834