Wireless Power Transfer Using Harvested Radio Frequency Energy with Magnetic Resonance Coupling to Charge Mobile Device Batteries

Abstract

:1. Introduction

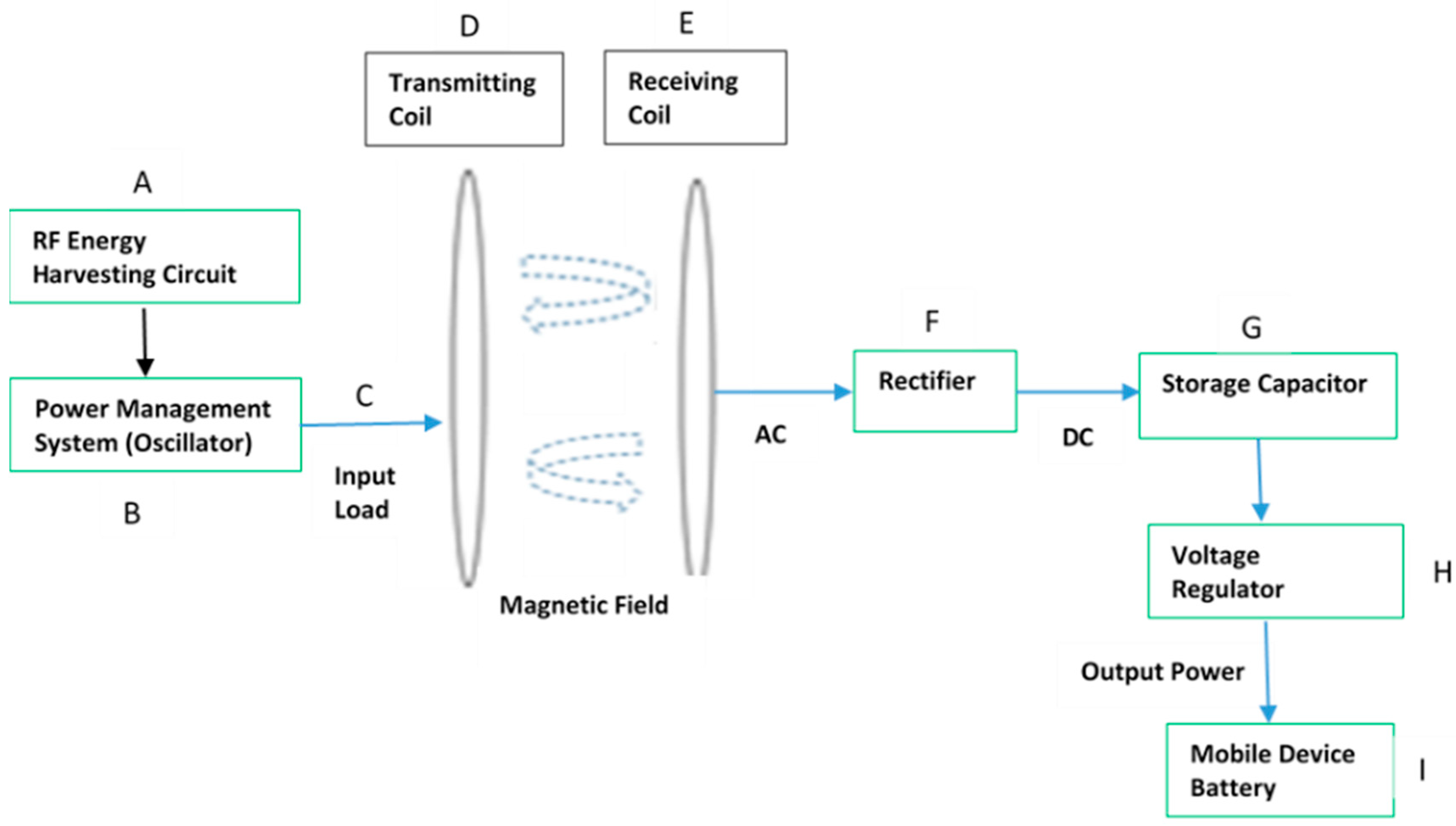

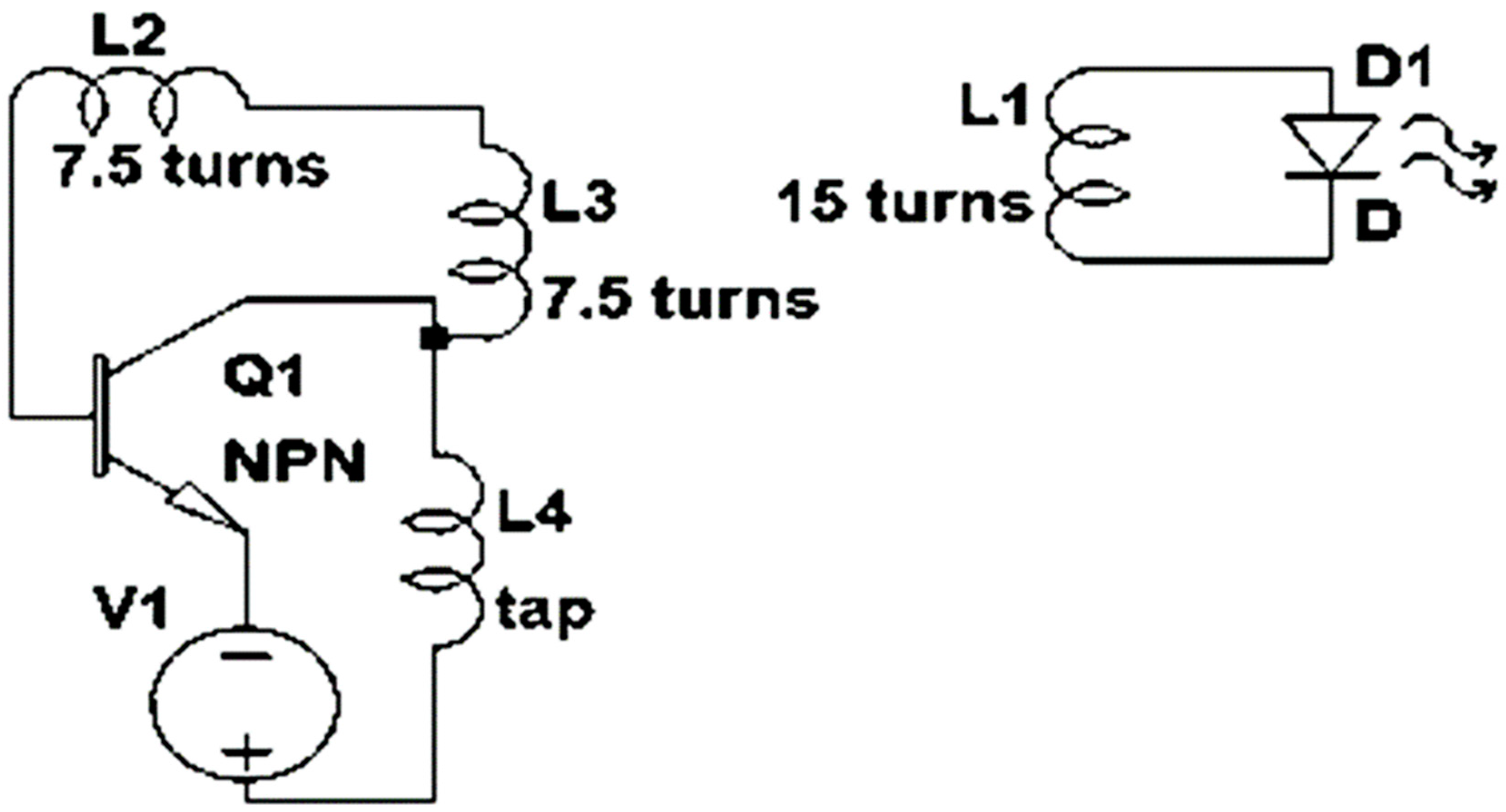

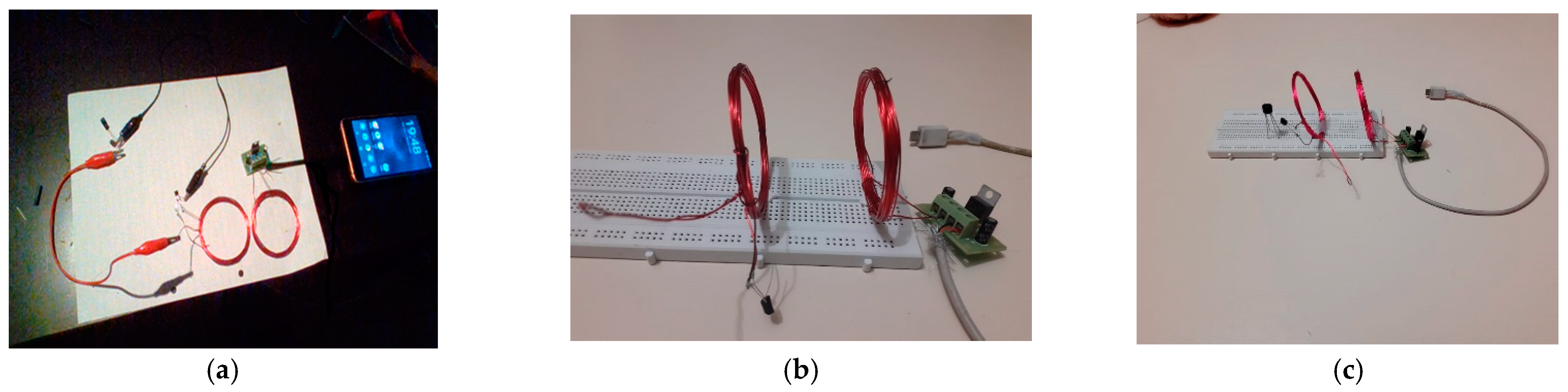

2. Methods

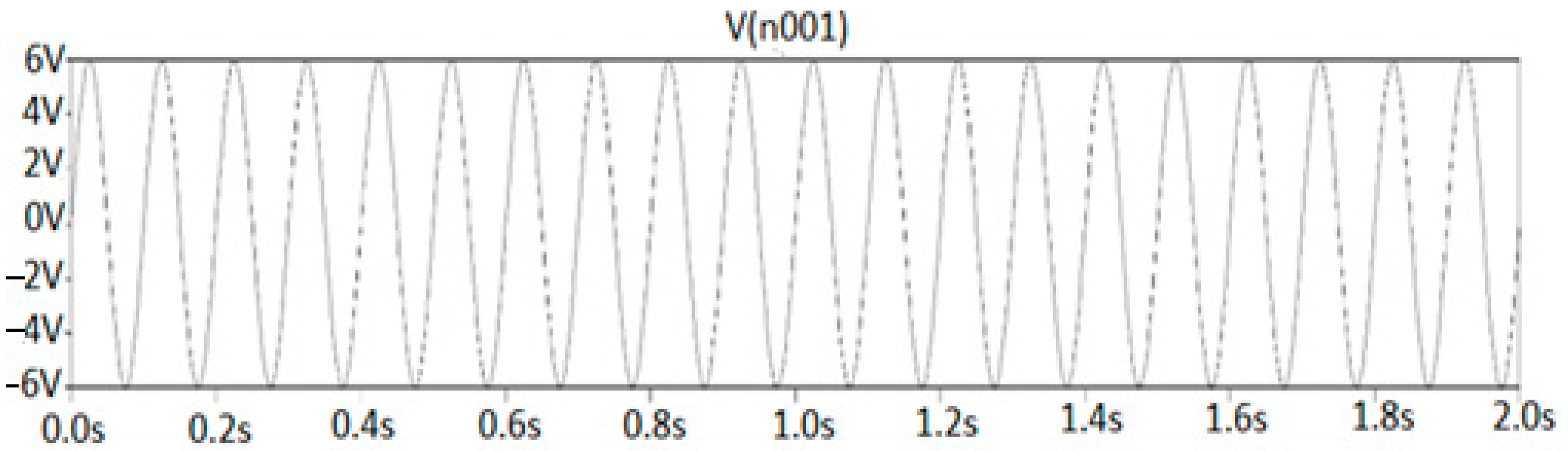

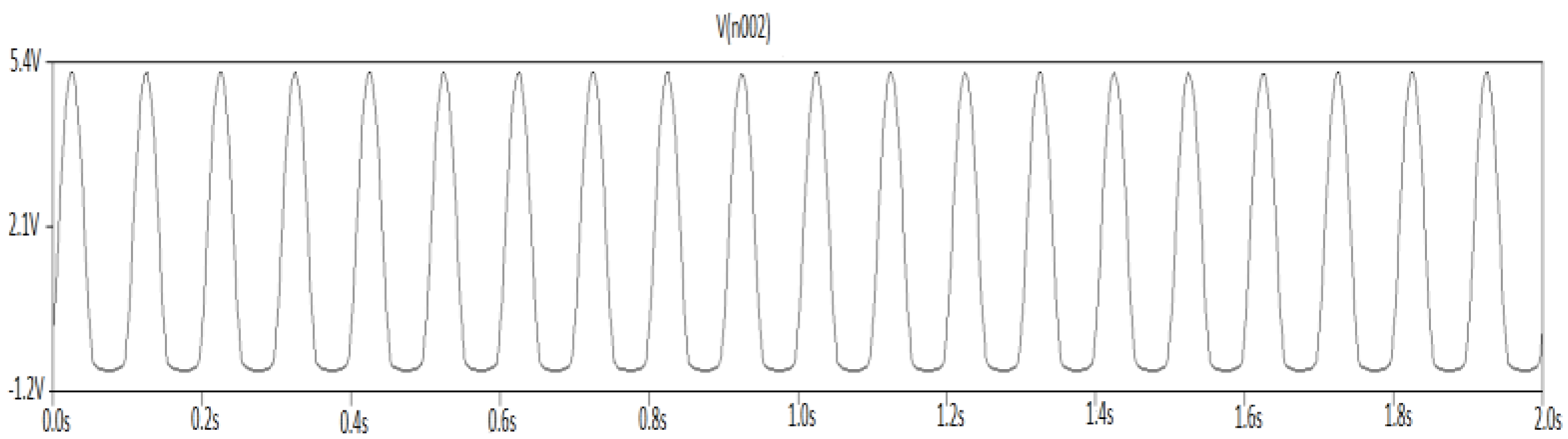

3. Simulation

4. Results and Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, Y.; Shi, W.; Zhang, X. Design of UAV wireless power transmission system based on coupling coil structure optimization. EURASIP JWCN 2020, 67, 1–13. [Google Scholar] [CrossRef]

- Singh, S.K.; Hasarmani, T.S.; Holmukhe, R. Wireless transmission of electrical power overview of recent Research & development. Int. J. Comput. Electr. Eng. 2012, 4, 207–211. [Google Scholar]

- Tfcbooks. Available online: http://www.tfcbooks.com/tesla/1904-03-05.html (accessed on 3 August 2018).

- Maxwell, J.C., VIII. A dynamic theory of the electromagnetic field. Philos. Trans. R. Soc. 1865, 155, 459–512. [Google Scholar]

- Cannon, B.L.; Hoburg, J.F.; Stancil, D.D.; Goldstein, S.C. Magnetic resonant coupling as a potential means for wireless power transfer to multiple small receivers. IEEE Trans. Power Elect. 2009, 24, 1819–1825. [Google Scholar] [CrossRef] [Green Version]

- Introduction to Wireless Power Transfer. Available online: http://www.allaboutcircuits.com/technical-articles/introduction-to-wireless-power-transfer-wpt/ (accessed on 29 August 2018).

- Kod, M.; Zhou, J.; Huang, Y.; Hussein, M.; Sohrab, A.P.; Song, C. An approach to improve the misalignment and wireless power transfer into biomedical implants using meandered wearable loop antenna. Hindawi Wirel. Power Transf. 2021, 1–12. [Google Scholar]

- Moore, J.; Castellanos, S.; Xu, S.; Wood, B.; Ren, H.; Tse, Z.T.H. Applications of wireless power transfer in medicine: State-of-the-art reviews. Ann. Biomed. Eng. 2019, 47, 22–38. [Google Scholar] [CrossRef] [Green Version]

- Kumar, P.; Anand, U.; Chaubey, A.; Ambekar, R.S. Wireless power transfer. Int. Res. J. Eng. Technol. 2017, 4, 1309–1312. [Google Scholar]

- Xing, Y.; Pan, H.; Xu, B.; Tapparello, C.; Shi, W.; Liu, X.; Zhao, T.; Lu, T. Optimal wireless information and power transfer using deep q-network. Hindawi Wirel. Power Transf. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Pratik, U. Design of Capacitive Wireless Power Transfer Systems with Enhanced Power Density and Stray Field Shielding. Master’s Thesis, Utah State University, Logan, UT, USA, 2019. [Google Scholar]

- Yan, Z.; Li, Y.; Zhang, C.; Yang, Q. Influence factors analysis and improvement method on efficiency of wireless power transfer via coupled magnetic resonance. IEEE Trans. Magn. 2014, 50, 83–86. [Google Scholar]

- Beh, T.; Kato, M.; Imura, T.; Hori, Y. Wireless power transfer system via magnetic resonant coupling at fixed resonance frequency-power transfer system based on impedance matching. World Electr. Veh. J. 2010, 4, 744–753. [Google Scholar] [CrossRef] [Green Version]

- Sato, M.; Yamamoto, G.; Gunji, D.; Imura, T.; Fujimoto, H. Development of wireless in-wheel motor using magnetic resonance coupling. IEEE Trans. Power Elect. 2016, 31, 5270–5278. [Google Scholar] [CrossRef]

- Wang, H.; Shi, G.; Han, C. A free-standing electromagnetic energy harvester for condition monitoring in smart grid. Hindawi Wirel. Power Transfer. 2021, 2021, 1–14. [Google Scholar] [CrossRef]

- Paul, J.L.; Sasirekha, S.; Kumar, D.N.D.; Revanth, P.S. A working model for mobile charging using wireless power transmission. Int. J. Eng. Sci. Technol. 2018, 7, 584–588. [Google Scholar]

- Pinto, R.; Bertoluzzo, M.; Lopresto, V.; Mancini, S.; Merla, C.; Pede, G.; Genovese, A.; Buja, G. Exposure assessment of stray electromagnetic fields generated by a wireless power transfer system. In Proceedings of the 9th European Conference on Antennas and Propagation (EuCAP), Lisbon, Portugal, 13–17 April 2015; pp. 1–4. [Google Scholar]

- Pehrman, D.; Liu, Y. Design and stray field evaluation of inductive power transfer in electric vehicle charging. In Proceedings of the 2019 Fourteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 8–10 May 2019; pp. 1–6. [Google Scholar]

- Pichon, L. Electromagnetic analysis and simulation aspects of wireless power transfer in the domain of inductive power transmission technology. J. Electromagn. Waves Appl. 2020, 34, 1719–1755. [Google Scholar] [CrossRef]

- Jaekel, B. Challenges in the EMC standardization of wireless power transfer systems. JET 2019, 12, 11–17. [Google Scholar]

- Brown, W.C. Experiments involving a microwave beam to power and position a helicopter. IEEE Trans. Aerosp. Electron. Syst. 1969, AES-5, 692–702. [Google Scholar] [CrossRef]

- American Association for the Advancement of Science. Available online: https://www.aaas.org/heinrich-hertz-and-electromagnetic-radiation (accessed on 28 July 2021).

- Aparicio, M.P.; Bakkali, A.; Pelegri-Sebastia, J.; Sogorb, T.; Llario, V.; Bou, A. Radio frequency energy harvesting-sources and techniques. In Book Renewable Energy-Utilisation and System Integration; Cao, W., Hu, Y., Eds.; IntechOpen Limited: London, UK, 2016; pp. 155–170. [Google Scholar]

- Zhang, X.; Grajal, J.; López-Vallejo, M.; McVay, E.; Palacios, T. Opportunities and challenges of ambient radio-frequency energy harvesting. Joule 2020, 4, 1148–1152. [Google Scholar] [CrossRef]

- Tran, L.; Cha, H.; Park, W. RF power harvesting: A review on designing methodologies and applications. Micro Nano Syst. Lett. 2017, 5, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Velten, K. Mathematical Modelling and Simulation-Introduction for Scientists and Engineers; Wiley: Weinheim, Germany, 2009; pp. 1–8. [Google Scholar]

- Jayarahini, J.; Udhayavani, M. Modeling and simulation of memristor using LTSPice. IJARECE 2016, 5, 249–2499. [Google Scholar]

- Kato, M.; Imura, T.; Hori, Y. Study on Maximize Efficiency by Secondary Side Control Using DC-DC Converter in Wireless Power Transfer via Magnetic Resonant Coupling. World Electr. Veh. J. 2013, 6, 858–862. [Google Scholar] [CrossRef] [Green Version]

- Power by Proxi. Available online: https://powerbyproxi.com/wireless-power/ (accessed on 18 August 2018).

- Ramsaroop, N.; Olugbara, O.O.; Joubert, E. Exploring energy harvesting technology for wireless charging of mobile device batteries. In Proceedings of the IEEE-ICTAS, Durban, South Africa, 9–10 March 2017. [Google Scholar]

- Panas, A.; Kyarginsky, B.; Maximov, N. Single-transistor microwave chaotic oscillator. In Proceedings of the NOLTA, Dresden, Germany, 17–21 September 2000; pp. 445–448. [Google Scholar]

- Roslia, M.A.; Muradb, S.A.Z.; Norizanc, M.N.; Ramlid, M.M. Design of RF to DC conversion circuit for energy harvesting in CMOS 0.13-μm technology. AIP Conf. Proc. 2018, 1883, 1–8. [Google Scholar]

- Visintini, R. Rectifiers. In CAS CERN Accelerator School Specialized Course on Power Converters; Daniel, B., Ed.; CERN: Geneva, Switzerland, 2006; pp. 133–183. Available online: https://cdsweb.cern.ch/record/705845/files/CERN-2006-010.pdf (accessed on 30 August 2006).

- Collado, A.; Daskalakis, S.N.; Niotaki, K.; Martinez, R.; Bolos, F.; Georgiadis, A. Rectifier Design Challenges for RF Wireless Power Transfer and Energy Harvesting Systems. Radio Eng. 2017, 26, 411–417. [Google Scholar] [CrossRef]

- Xu, H.; Wang, C.; Xia, D.; Liu, Y. Design of Magnetic Coupler for Wireless Power Transfer. Energies 2019, 12, 3000. [Google Scholar] [CrossRef] [Green Version]

- Abou, H.M.; Yang, X.; Chen, W. Magnetically Coupled Resonance WPT: Review of Compensation Topologies, Resonator Structures with Misalignment, and EMI Diagnostics. Electronics 2018, 7, 1–41. [Google Scholar]

- Electronics Tutorials. Available online: https://www.electronics-tutorials.ws/resistor/resistivity.html (accessed on 18 August 2018).

- Diode, Rectifiers, and Power Supplies. Available online: http://uav.ece.nus.edu.sg/~bmchen/courses/EG1108_Rectifiers.pdf (accessed on 18 August 2021).

- Wire Gauge Conversion. Available online: https://www.carreracasting.com/charts/wire-gauge (accessed on 25 July 2021).

| Parameter Symbol | Parameter Definition | Unit of Measurement | Parameter Value |

|---|---|---|---|

| n | Number of turns in coil | n2 | 227 |

| H | Permeability of free space | µ0 | 1.26 |

| A | Cross-sectional area of coil | m2 | 0.05 |

| Le | Length of coil | m | 2.70 |

| M | Mutual inductance | H | 2.62 |

| L | Inductance | H | 2.62 |

| R | Resistance | Ω | 2.29 |

| k | Coupling coefficient | k | 1.00 |

| Vin | Input voltage | V | 6.00 |

| Va | Average voltage | V | 3.82 |

| Φ | Magnetic flux | Wb | 0.05 |

| AWG Wire | Wire Diameter (mm) | Loop Diameter (mm) | Relative Permeability | Inductance (H) |

|---|---|---|---|---|

| 21 | 0.7239 | 50 | 1.256 × 10−6 | 1.70 × 10−13 |

| 22 | 0.6438 | 50 | 1.256 × 10−6 | 1.75 × 10−13 |

| 24 | 0.5106 | 50 | 1.256 × 10−6 | 1.83 × 10−13 |

| 26 | 0.4038 | 50 | 1.256 × 10−6 | 1.93 × 1013 |

| 27 | 0.3606 | 50 | 1.256 × 10−6 | 1.98 × 10−13 |

| 28 | 0.3211 | 50 | 1.256 × 10−6 | 2.02 × 10−13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramsaroop, N.; Olugbara, O.O. Wireless Power Transfer Using Harvested Radio Frequency Energy with Magnetic Resonance Coupling to Charge Mobile Device Batteries. Appl. Sci. 2021, 11, 7707. https://doi.org/10.3390/app11167707

Ramsaroop N, Olugbara OO. Wireless Power Transfer Using Harvested Radio Frequency Energy with Magnetic Resonance Coupling to Charge Mobile Device Batteries. Applied Sciences. 2021; 11(16):7707. https://doi.org/10.3390/app11167707

Chicago/Turabian StyleRamsaroop, Neetu, and Oludayo O. Olugbara. 2021. "Wireless Power Transfer Using Harvested Radio Frequency Energy with Magnetic Resonance Coupling to Charge Mobile Device Batteries" Applied Sciences 11, no. 16: 7707. https://doi.org/10.3390/app11167707

APA StyleRamsaroop, N., & Olugbara, O. O. (2021). Wireless Power Transfer Using Harvested Radio Frequency Energy with Magnetic Resonance Coupling to Charge Mobile Device Batteries. Applied Sciences, 11(16), 7707. https://doi.org/10.3390/app11167707