Application of an Electrical Low Pressure Impactor (ELPI) for Residual Particle Measurement in an Epitaxial Growth Reactor

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

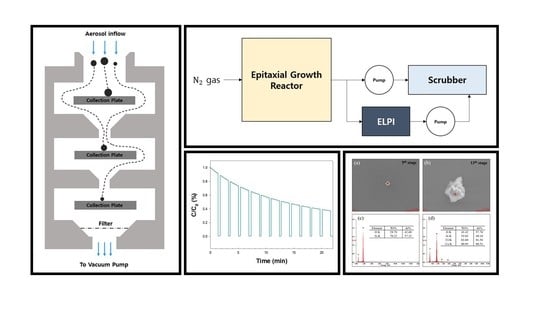

2.1. Test Process Equipment and Experimental Setup

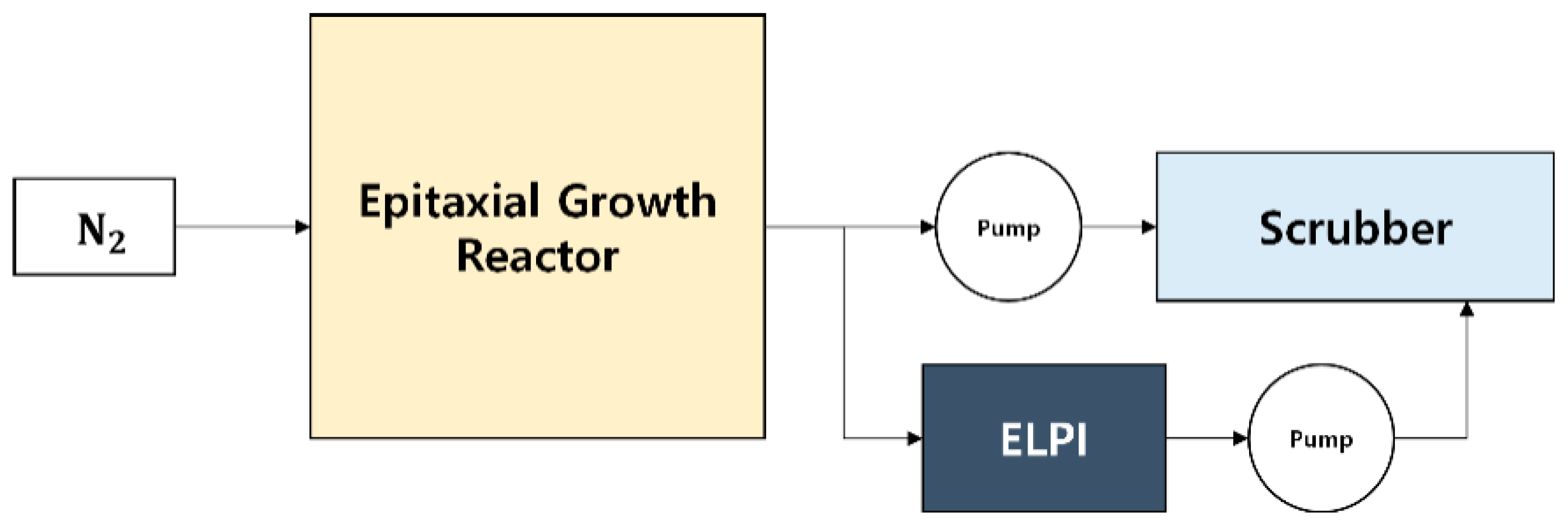

2.2. Instrument for Concentration Measurement of Particles in the Process Chamber: Electrical Low Pressure Impactor (ELPI)

2.3. Additional Analysis after Collecting Particles from the Epitaxial Chamber

3. Results and Discussion

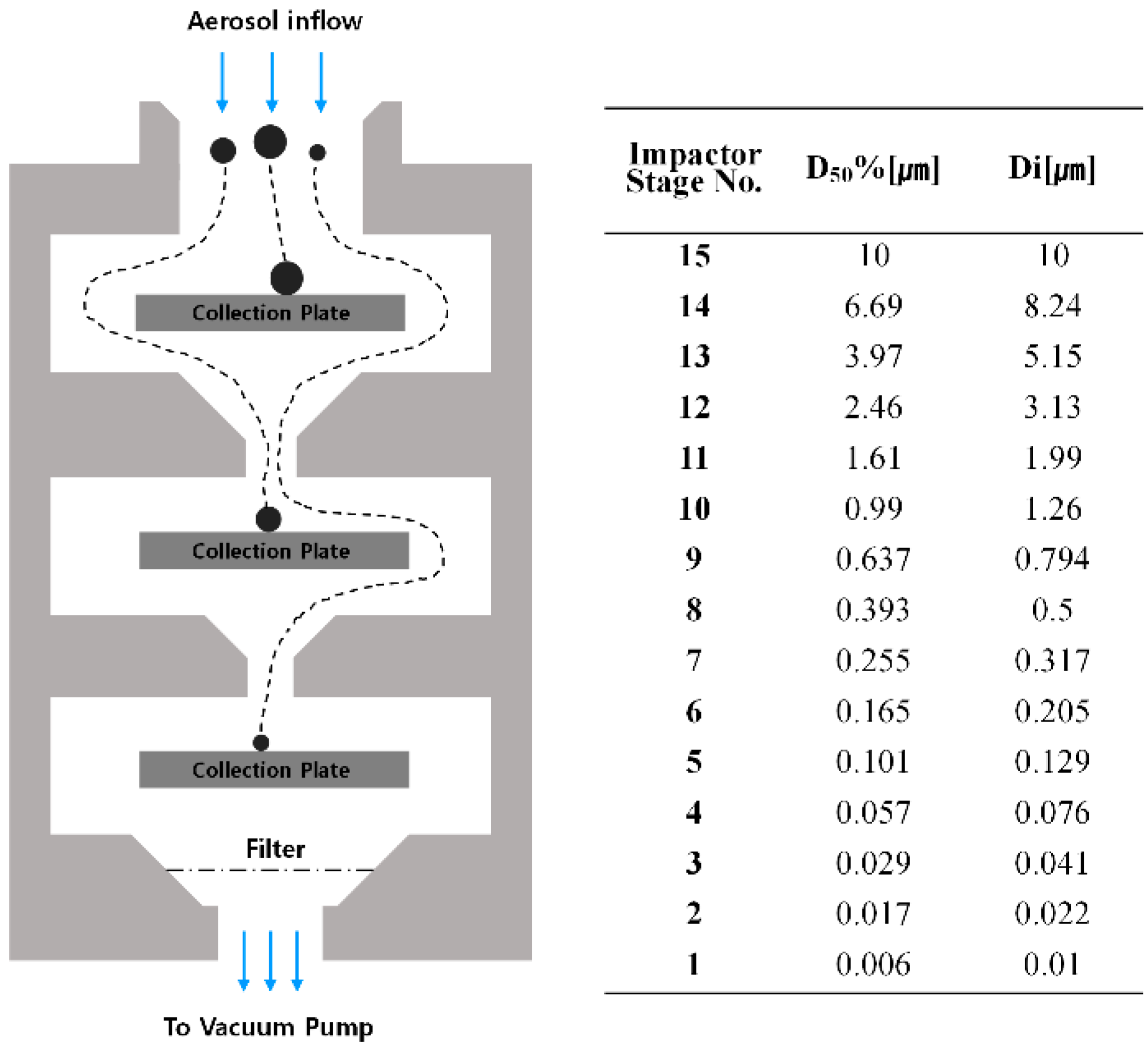

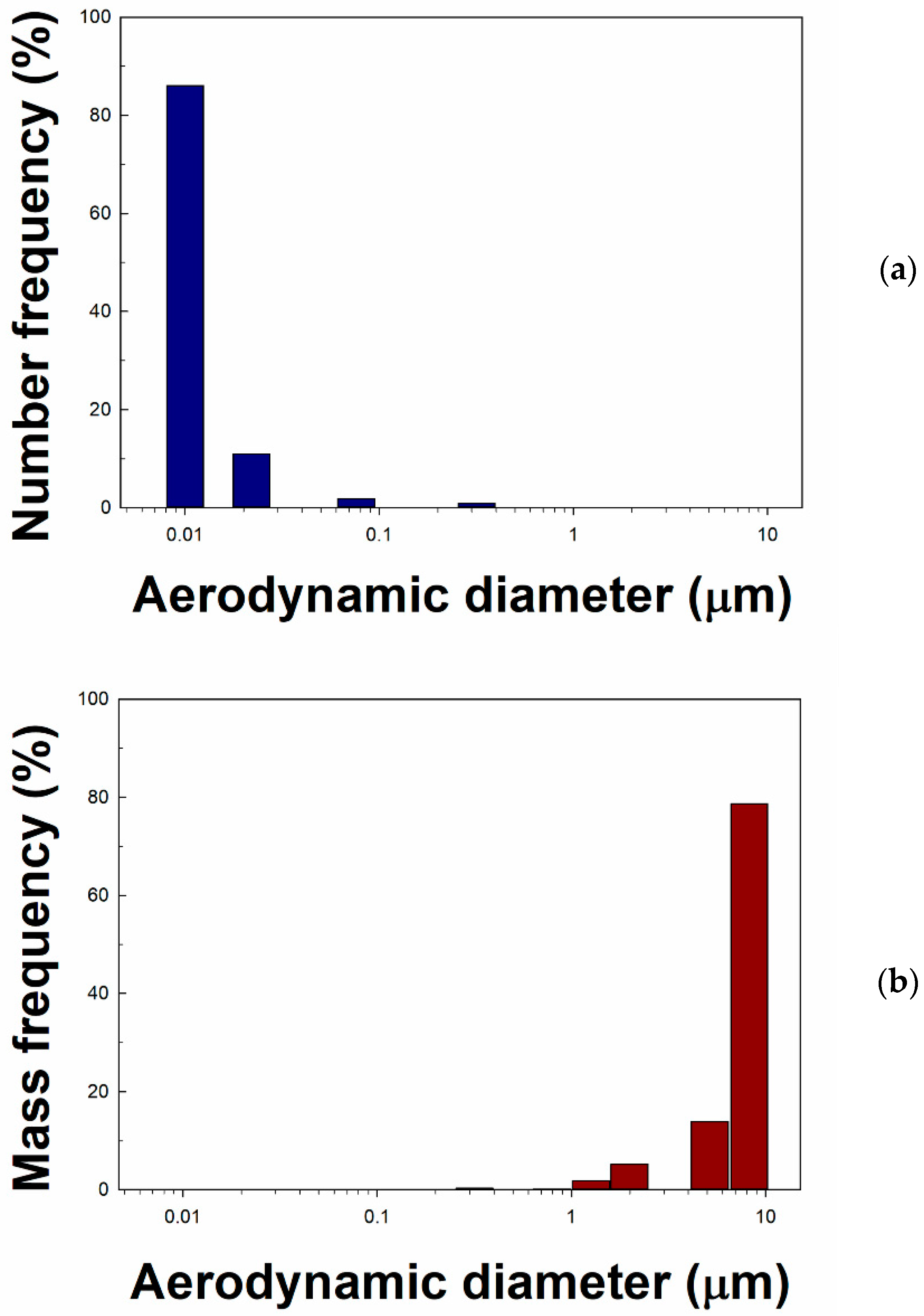

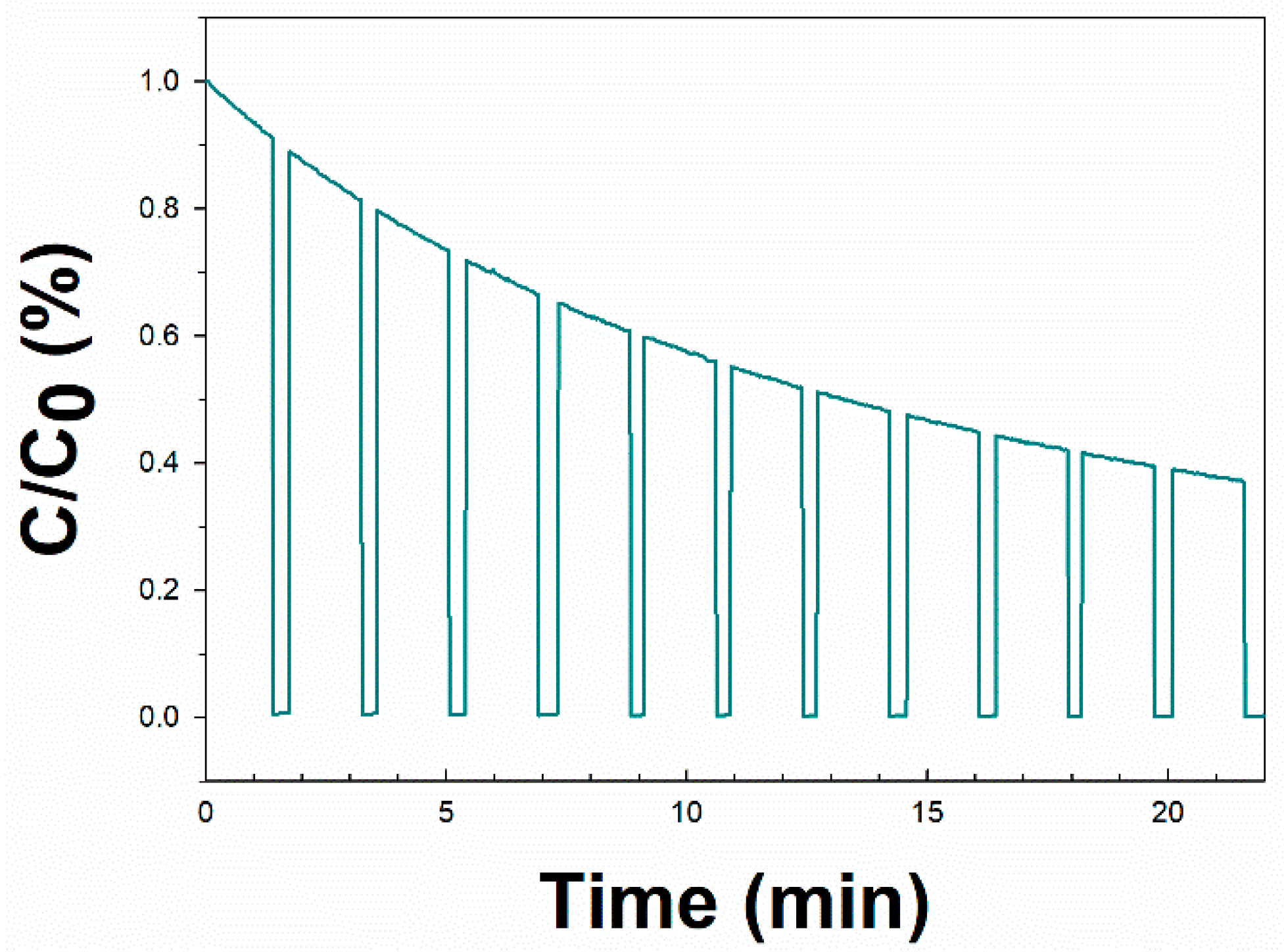

3.1. Number and Mass Concentration

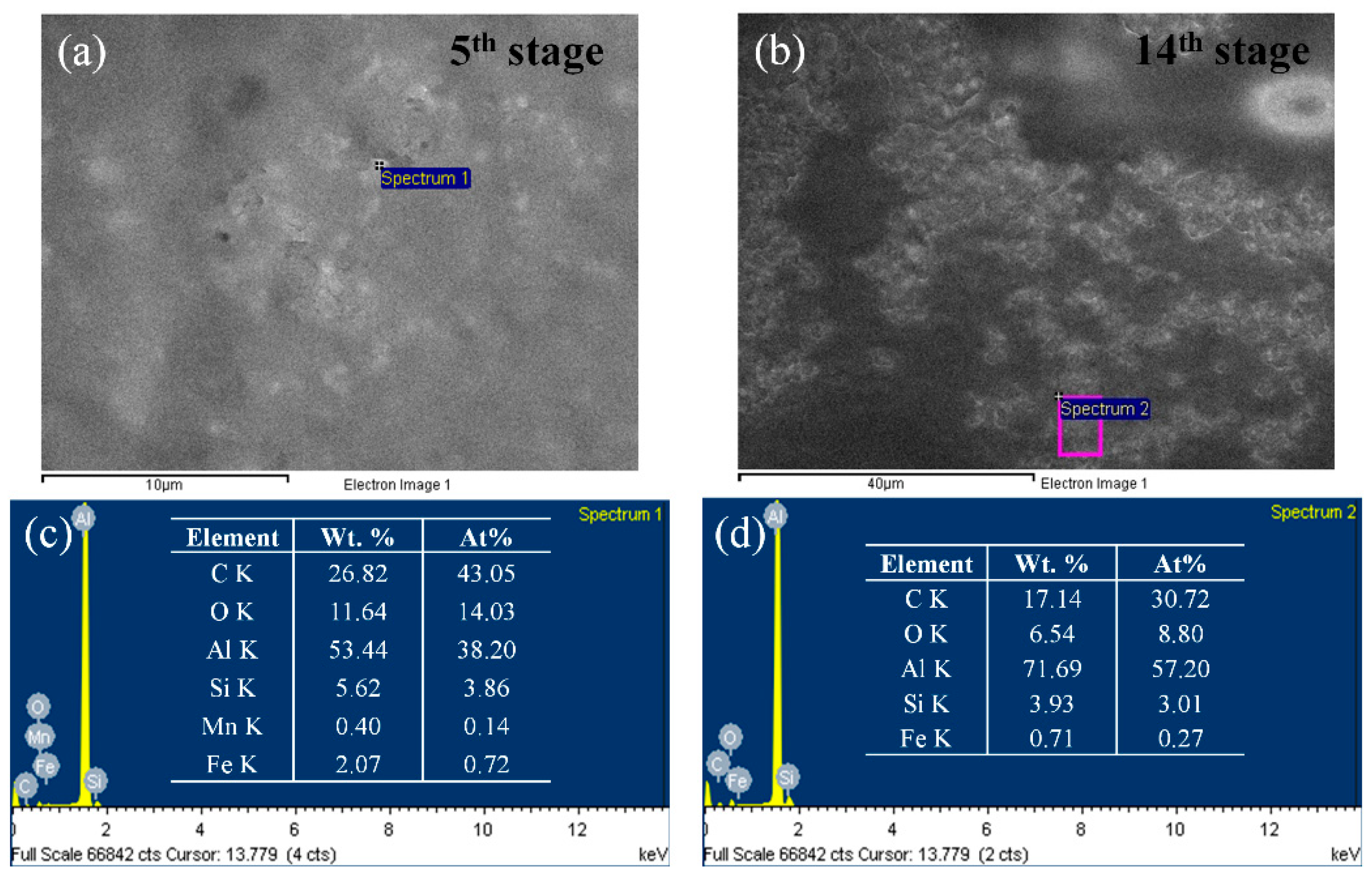

3.2. Image and Element Analysis of Particles Collected by ELPI

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Varas, A.; Varadarajan, R.; Goodrich, J.; Yinug, F. Government incentives and US competitiveness in semiconductor manufacturing. BCG Glob. Sept. 2020, 9, 2. [Google Scholar]

- Müller, S.G.; Sanchez, E.; Hansen, D.; Drachev, R.; Chung, G.; Thomas, B.; Zhang, J.; Loboda, M.; Dudley, M.; Wang, H. Volume production of high quality SiC substrates and epitaxial layers: Defect trends and device applications. J. Cryst. Growth 2012, 352, 39–42. [Google Scholar] [CrossRef]

- Jacobson, H.; Birch, J.; Yakimova, R.; Syväjärvi, M.; Bergman, J.; Ellison, A.; Tuomi, T.; Janzén, E. Dislocation evolution in 4H-SiC epitaxial layers. J. Appl. Phys. 2002, 91, 6354–6360. [Google Scholar] [CrossRef]

- Jean-Luc, B.; Bruno, D. Contamination monitoring and analysis in semiconductor manufacturing. Semicond. Technol. 1999, 1999, 57–78. [Google Scholar]

- Ziemann, P.J.; Liu, P.; Rao, N.P.; Kittelson, D.B.; McMurry, P.H. Particle beam mass spectrometry of submicron particles charged to saturation in an electron beam. J. Aerosol Sci. 1995, 26, 745–756. [Google Scholar] [CrossRef]

- Miyashita, H.; Kikuchi, T.; Kawasaki, Y.; Katakura, Y.; Ohsako, N. Particle measurements in vacuum tools by in situ particle monitor. J. Vac. Sci. Technol. A Vac. Surf. Film. 1999, 17, 1066–1070. [Google Scholar] [CrossRef]

- Takahashi, K.M.; Daugherty, J.E. Current capabilities and limitations of in situ particle monitors in silicon processing equipment. J. Vac. Sci. Technol. A Vac. Surf. Film. 1996, 14, 2983–2993. [Google Scholar] [CrossRef]

- Brundle, C.; Uritsky, Y. Full wafer particle defect characterization. In Proceedings of the AIP Conference, Gaithersburg, MD, USA, 26–29 June 2000; pp. 285–291. [Google Scholar]

- Shen, S.; Jaques, P.A.; Zhu, Y.; Geller, M.D.; Sioutas, C. Evaluation of the SMPS–APS system as a continuous monitor for measuring PM2.5, PM10 and coarse (PM2.5–10) concentrations. Atmos. Environ. 2002, 36, 3939–3950. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, M.; Yao, L.; Kulmala, M.; Zhou, B.; Yang, X.; Chen, J.; Wang, D.; Fu, Q.; Worsnop, D. Strong atmospheric new particle formation in winter in urban Shanghai, China. Atmos. Chem. Phys. 2015, 15, 1769–1781. [Google Scholar] [CrossRef]

- Harrison, R.M.; Jones, M.; Collins, G. Measurements of the physical properties of particles in the urban atmosphere. Atmos. Environ. 1999, 33, 309–321. [Google Scholar] [CrossRef]

- Wiedensohler, A.; Birmili, W.; Nowak, A.; Sonntag, A.; Weinhold, K.; Merkel, M.; Wehner, B.; Tuch, T.; Pfeifer, S.; Fiebig, M. Mobility particle size spectrometers: Harmonization of technical standards and data structure to facilitate high quality long-term observations of atmospheric particle number size distributions. Atmos. Meas. Tech. 2012, 5, 657–685. [Google Scholar] [CrossRef]

- Hogrefe, O.; Lala, G.G.; Frank, B.P.; Schwab, J.J.; Demerjian, K.L. Field evaluation of a TSI model 3034 scanning mobility particle sizer in New York City: Winter 2004 intensive campaign. Aerosol Sci. Technol. 2006, 40, 753–762. [Google Scholar] [CrossRef][Green Version]

- Kheirkhah, P.; Baldelli, A.; Kirchen, P.; Rogak, S. Development and validation of a multi-angle light scattering method for fast engine soot mass and size measurements. Aerosol Sci. Technol. 2020, 54, 1083–1101. [Google Scholar] [CrossRef]

- Jeong, C.-H.; Evans, G.J. Inter-comparison of a fast mobility particle sizer and a scanning mobility particle sizer incorporating an ultrafine water-based condensation particle counter. Aerosol Sci. Technol. 2009, 43, 364–373. [Google Scholar] [CrossRef]

- Jørgensen, R.B. Comparison of four nanoparticle monitoring instruments relevant for occupational hygiene applications. J. Occup. Med. Toxicol. 2019, 14, 28. [Google Scholar] [CrossRef] [PubMed]

- Keskinen, J.; Pietarinen, K.; Lehtimäki, M. Electrical low pressure impactor. J. Aerosol Sci. 1992, 23, 353–360. [Google Scholar] [CrossRef]

- Baron, P.A. Calibration and use of the aerodynamic particle sizer (APS 3300). Aerosol Sci. Technol. 1986, 5, 55–67. [Google Scholar] [CrossRef]

- Jørgensen, R.B.; Kero, I.T. Real-time measurements and characterization of airborne particulate matter from a primary silicon carbide production plant. Int. J. Environ. Res. Public Health 2017, 14, 1611. [Google Scholar] [CrossRef]

- Held, A.; Zerrath, A.; McKeon, U.; Fehrenbach, T.; Niessner, R.; Plass-Dülmer, C.; Kaminski, U.; Berresheim, H.; Pöschl, U. Aerosol size distributions measured in urban, rural and high-alpine air with an electrical low pressure impactor (ELPI). Atmos. Environ. 2008, 42, 8502–8512. [Google Scholar] [CrossRef]

- Hsieh, Y.-K.; Chen, L.-K.; Hsieh, H.-F.; Huang, C.-H.; Wang, C.-F. Elemental analysis of airborne particulate matter using an electrical low-pressure impactor and laser ablation/inductively coupled plasma mass spectrometry. J. Anal. At. Spectrom. 2011, 26, 1502–1508. [Google Scholar] [CrossRef]

- Liu, Z.; Ge, Y.; Johnson, K.C.; Shah, A.N.; Tan, J.; Wang, C.; Yu, L. Real-world operation conditions and on-road emissions of Beijing diesel buses measured by using portable emission measurement system and electric low-pressure impactor. Sci. Total Environ. 2011, 409, 1476–1480. [Google Scholar] [CrossRef]

- Kero, I.; Naess, M.K.; Tranell, G. Particle size distributions of particulate emissions from the ferroalloy industry evaluated by electrical low pressure impactor (ELPI). J. Occup. Environ. Hyg. 2015, 12, 37–44. [Google Scholar] [CrossRef] [PubMed]

- Kero, I.T.; Jørgensen, R.B. Comparison of three real-time measurement methods for airborne ultrafine particles in the silicon alloy industry. Int. J. Environ. Res. Public Health 2016, 13, 871. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.-H.; Yang, W.; Chae, N.; Choi, S. Aerodynamic diameter distribution of aerosols from plasma arc cutting for steels at different cutting power levels. J. Radioanal. Nucl. Chem. 2020, 323, 613–624. [Google Scholar] [CrossRef]

- Glover, W.; Chan, H.-K. Electrostatic charge characterization of pharmaceutical aerosols using electrical low-pressure impaction (ELPI). J. Aerosol Sci. 2004, 35, 755–764. [Google Scholar] [CrossRef]

- Järvinen, A.; Aitomaa, M.; Rostedt, A.; Keskinen, J.; Yli-Ojanperä, J. Calibration of the new electrical low pressure impactor (ELPI+). J. Aerosol Sci. 2014, 69, 150–159. [Google Scholar] [CrossRef]

- Pagels, J.; Gudmundsson, A.; Gustavsson, E.; Asking, L.; Bohgard, M. Evaluation of aerodynamic particle sizer and electrical low-pressure impactor for unimodal and bimodal mass-weighted size distributions. Aerosol Sci. Technol. 2005, 39, 871–887. [Google Scholar] [CrossRef]

- Marjamäki, M.; Keskinen, J.; Chen, D.-R.; Pui, D.Y. Performance evaluation of the electrical low-pressure impactor (ELPI). J. Sci. 2000, 31, 249–261. [Google Scholar] [CrossRef]

- Kim, B.; Lee, J.S.; Choi, B.-S.; Park, S.-Y.; Yoon, J.-H.; Kim, H. Ultrafine particle characteristics in a rubber manufacturing factory. Ann. Occup. Hyg. 2013, 57, 728–739. [Google Scholar]

- Baldelli, A.; Rogak, S.N. Morphology and Raman spectra of aerodynamically classified soot samples. Atmos. Meas. Tech. 2019, 12, 4339–4346. [Google Scholar] [CrossRef]

- Dzubay, T.; Hines, L.; Stevens, R. Particle bounce errors in cascade impactors. Atmos. Environ. 1976, 10, 229–234. [Google Scholar] [CrossRef]

- Lawson, D.R. Impaction surface coatings intercomparison and measurements with cascade impactors. Atmos. Environ. 1980, 14, 195–199. [Google Scholar] [CrossRef]

- Habuka, H.; Aoyama, Y.; Akiyama, S.; Otsuka, T.; Qu, W.-F.; Shimada, M.; Okuyama, K. Chemical process of silicon epitaxial growth in a SiHCl3–H2 system. J. Cryst. Growth 1999, 207, 77–86. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Kim, D.; Cho, Y.; Kim, E.; Liu, P.; Kwak, D.-B.; Keum, S.; Lim, H.; Kim, T. Application of an Electrical Low Pressure Impactor (ELPI) for Residual Particle Measurement in an Epitaxial Growth Reactor. Appl. Sci. 2021, 11, 7680. https://doi.org/10.3390/app11167680

Lee S, Kim D, Cho Y, Kim E, Liu P, Kwak D-B, Keum S, Lim H, Kim T. Application of an Electrical Low Pressure Impactor (ELPI) for Residual Particle Measurement in an Epitaxial Growth Reactor. Applied Sciences. 2021; 11(16):7680. https://doi.org/10.3390/app11167680

Chicago/Turabian StyleLee, Seungjae, Dongbin Kim, Yujin Cho, Eunmi Kim, Pengzhan Liu, Dong-Bin Kwak, Seungho Keum, Hongkang Lim, and Taesung Kim. 2021. "Application of an Electrical Low Pressure Impactor (ELPI) for Residual Particle Measurement in an Epitaxial Growth Reactor" Applied Sciences 11, no. 16: 7680. https://doi.org/10.3390/app11167680

APA StyleLee, S., Kim, D., Cho, Y., Kim, E., Liu, P., Kwak, D.-B., Keum, S., Lim, H., & Kim, T. (2021). Application of an Electrical Low Pressure Impactor (ELPI) for Residual Particle Measurement in an Epitaxial Growth Reactor. Applied Sciences, 11(16), 7680. https://doi.org/10.3390/app11167680