Surface Defect Detection Methods for Industrial Products: A Review

Abstract

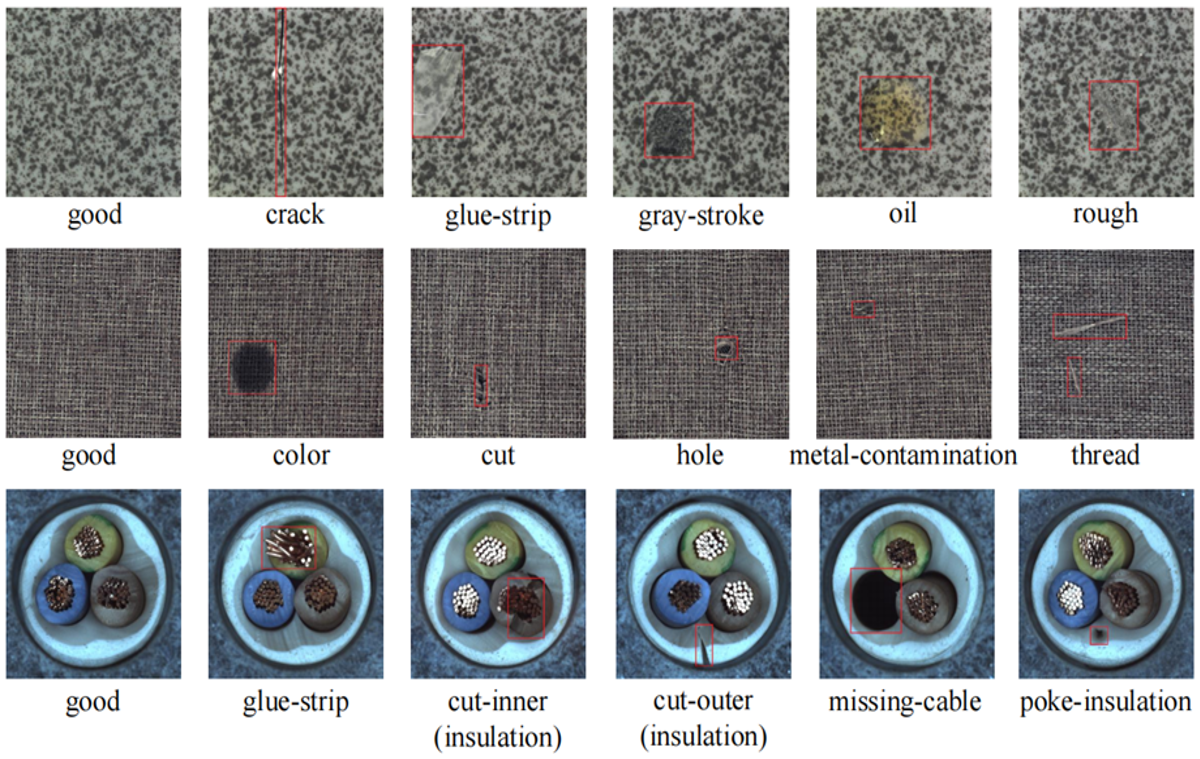

:1. Introduction

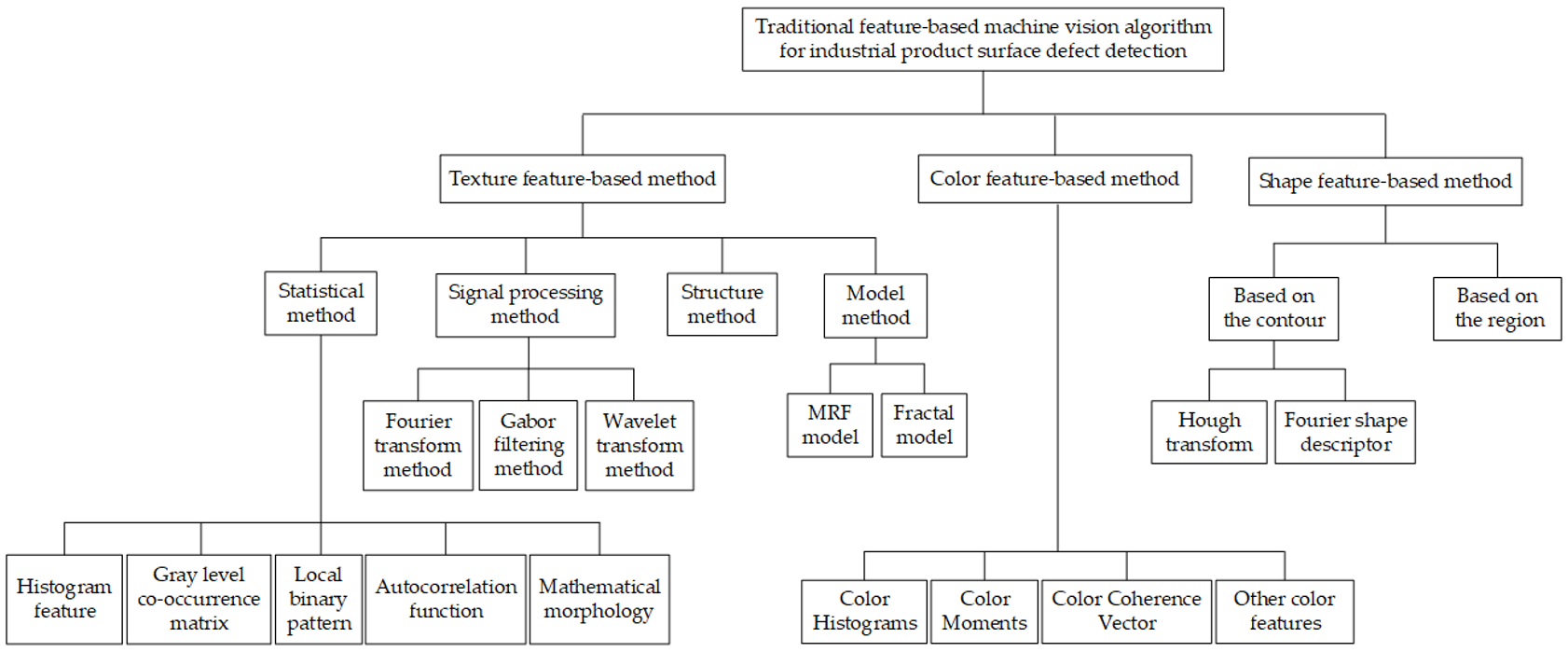

2. Traditional Feature-Based Machine Vision Algorithm for Surface Defect Detection

2.1. Texture Feature-Based Method

2.2. Color Feature-Based Method

2.2.1. Color Histograms

2.2.2. Color Moments

2.2.3. Color Coherence Vector

2.2.4. Other Color Features

2.3. Shape Feature-Based Method

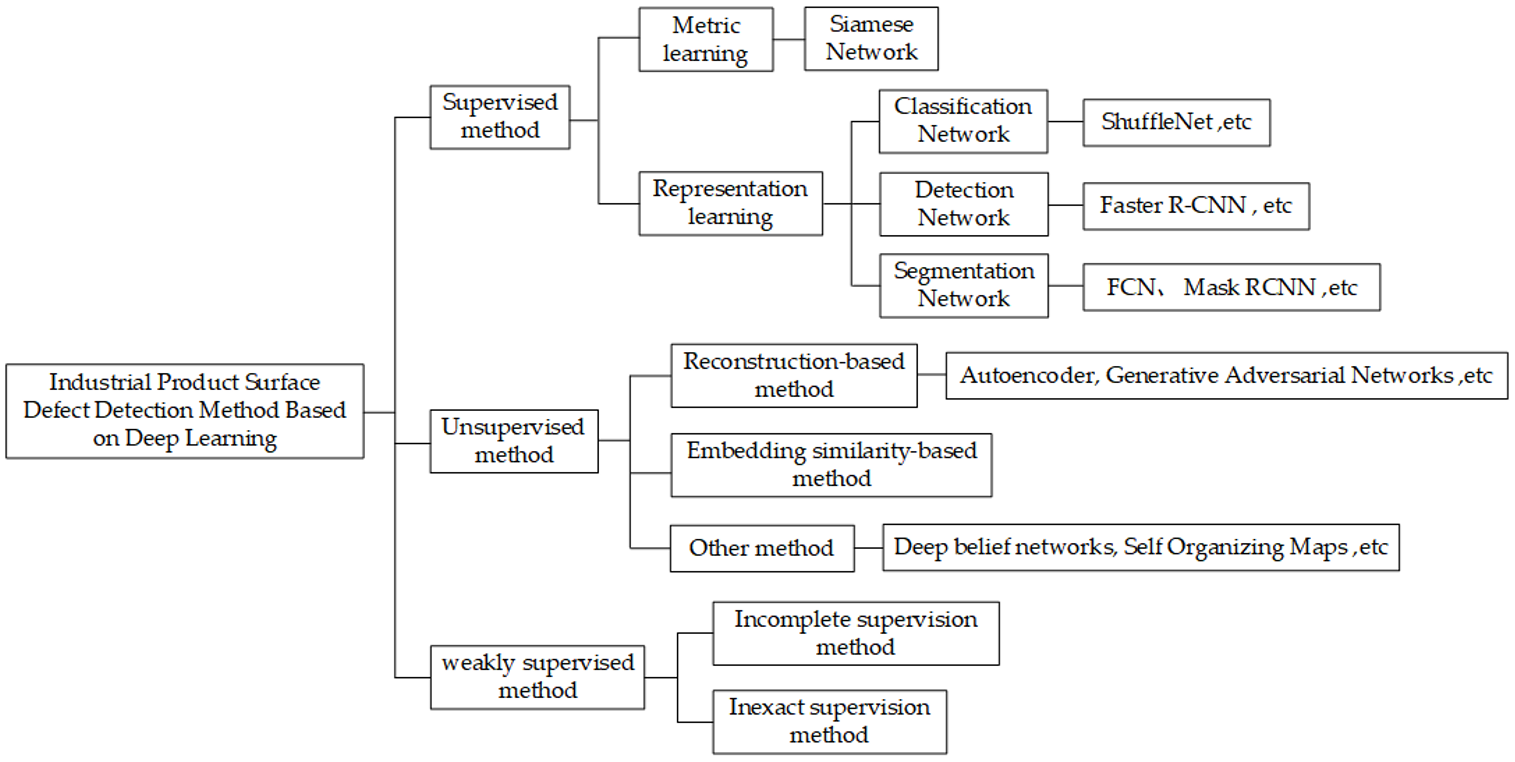

3. Surface Defect Detection Method of Industrial Products Based on Deep Learning

3.1. Supervised Method

3.1.1. Siamese Network

3.1.2. ShuffleNet

3.1.3. Faster R-CNN

3.1.4. Fully Convolutional Networks

3.1.5. Mask RCNN

3.2. Unsupervised Method

3.2.1. Autoencoder

3.2.2. Generative Adversarial Network

3.2.3. Deep Belief Networks

3.2.4. Self-Organizing Map

3.3. Weakly Supervised Method

3.3.1. Incomplete Supervision Method

3.3.2. Inexact Supervision Method

3.4. Summary

4. The Key Problems

4.1. Real-Time Problem

- (1)

- Algorithm: for the network algorithm level, lightweight network can be used to accelerate the model. Commonly used lightweight models include MobileNet, ShuffleNet, SqueezeNet, and EfficientNet. In addition, distillation and pruning can also be used in accelerating the network at algorithm level. In terms of calculation algorithms, the convolution operation can be optimized to achieve the purpose of model acceleration. Typical algorithms include FFT, Winograd, etc.

- (2)

- Hardware: the use of GPU, FPGA, DSP, etc. is the main way to accelerate the model through hardware at present.

4.2. Small Sample Problem

4.2.1. Data Augmentation

4.2.2. Unsupervised/Semi-Supervised Model

4.2.3. Transfer Learning

4.2.4. Optimize Network Structure

4.3. Small Target Detection Problem

- (1)

- Feature fusion: fusion of deep semantic information into shallow feature maps, using deep features to enrich semantic information while using the characteristic of shallow features that to be suitable for detecting small targets;

- (2)

- Data Augmentation: increase the type and number of samples in the small target in the training set;

- (3)

- Image Pyramid + Multi-scale Sliding Window: set different input sizes for images, select a scale randomly from them during training, scale the input image to this scale, and send it to the network;

- (4)

- Reduce the network downsampling rate: by reducing the downsampling rate to reduce the loss of the object on the feature map, a common method is to directly remove the pooling layer and use the hole convolution at the same time;

- (5)

- Reasonable anchor design: the main methods include: border clustering, that is, clustering a set of suitable anchors on the labels of the training set; statistical experiments, that is, putting the anchor and the center point of the label together with using only the width and height information to carry out matching experiment to find a group of anchors with the most consistent aspect to height ratio distribution; set smaller and denser anchors and matching strategies, such as not setting too strict IoU threshold for small objects;

- (6)

- Appropriate training method: use high-resolution images for pre-training while magnifying the input image and then fine-tune on the small-resolution image;

- (7)

- Use GAN to magnify the small objects and then detect them;

- (8)

- Use Context information: establish a connection between the target and its Context.

4.4. Unbalanced Sample Identification Problem

4.4.1. Data Level

4.4.2. Model Level

4.4.3. Feature Level

- Irrelevant to the classifier (typical algorithm: Filter);

- Independent of the classifier (typical algorithm: Wrapper);

- Combined with the classifier (typical algorithm: Embedded).

4.4.4. Evaluation Metric Level

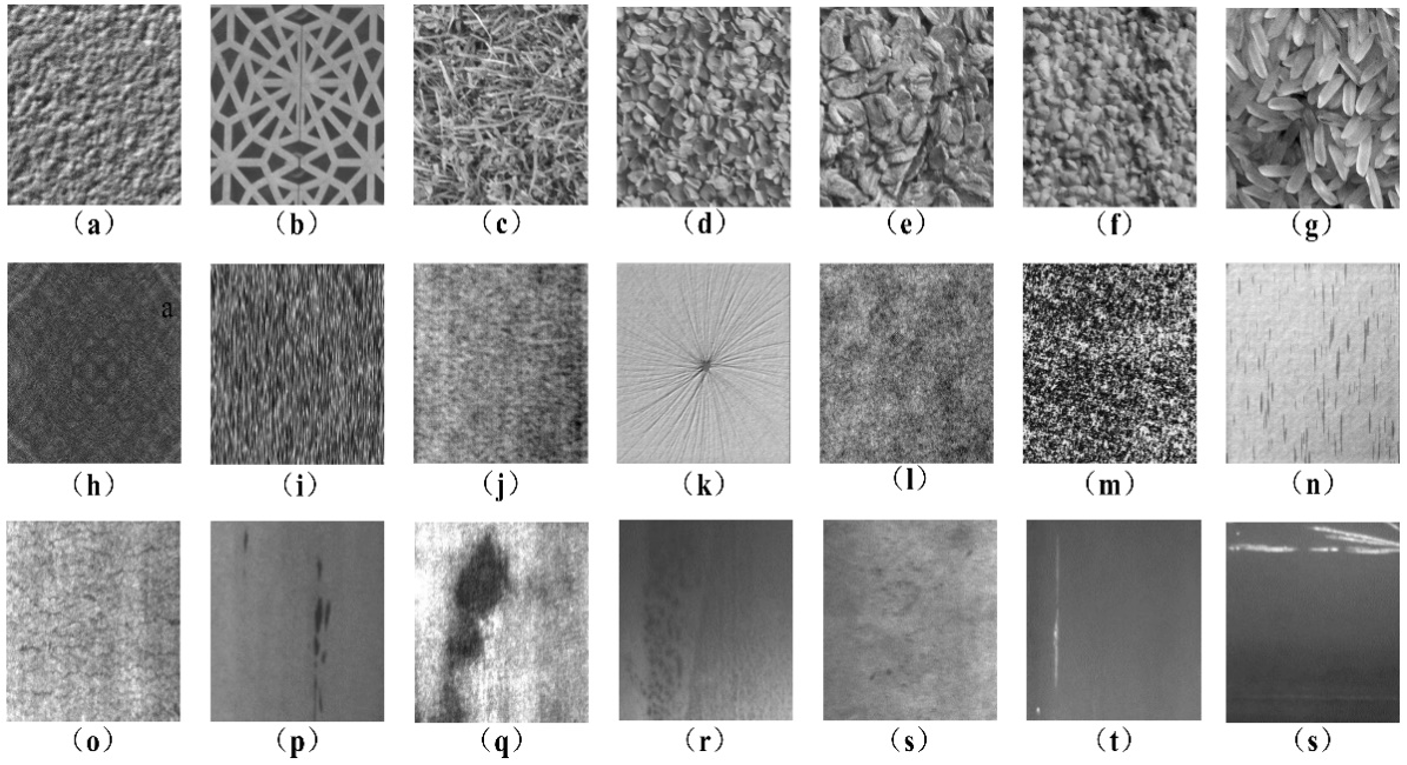

5. Industrial Product Defect Detection Dataset

6. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Vitis, G.A.; Foglia, P.; Prete, C.A. Row-level algorithm to improve real-time performance of glass tube defect detection in the production phase. IET Image Process. 2020, 14, 2911–2921. [Google Scholar] [CrossRef]

- Rasheed, A.; Zafar, B.; Rasheed, A.; Ail, N.; Sajid, M.; Dar, S.H.; Habib, U.; Shehryar, T.; Mahmood, M.T. Fabric Defect Detection Using Computer Vision Techniques: A Comprehensive Review. Math. Probl. Eng. 2020, 2020, 8189403. [Google Scholar] [CrossRef]

- Jain, S.; Seth, G.; Paruthi, A.; Soni, U.; Kumar, G. Synthetic data augmentation for surface defect detection and classification using deep learning. J. Int. Manufact. 2020, in press. [Google Scholar] [CrossRef]

- Ma, Y.; Li, Q.; He, F.; Liu, Y.; Xi, S. Adaptive segmentation algorithm for metal surface defects. Chin. J. Sci. Instrum. 2017, 38, 245–251. [Google Scholar]

- Li, S.; Yang, J.; Wang, Z.; Zhu, S.; Yang, G. Review of Development and Application of Defect Detection Technology. Acta Autom. Sin. 2020, 46, 2319–2336. [Google Scholar]

- Ma, S.; Wu, N.; Li, X. Deep learning with big data: State of the art and development. CAAI Trans. Intell. Syst. 2016, 11, 728–742. [Google Scholar]

- Zhang, Z.; Pang, W.; Xie, W.; Lv, M.; Wang, Y. Deep Learning for Real-time Applications: A Survey. J. Softw. 2020, 31, 2654–2677. [Google Scholar]

- Yu, W.; Zhang, Y.; Yao, H.; Shi, H. Visual inspection of surface defects based on lightweight reconstruction network. Acta Autom. Sin. 2020, 41, 1–12. [Google Scholar]

- Liu, J.; Liu, Y.; Luo, X. Research and development on deep learning. Appl. Res. Comput. 2014, 31, 1921–1930+1942. [Google Scholar]

- Tao, X.; Hou, W.; Xu, D. A Survey of Surface Defect Detection Methods Based on Deep Learning. Acta Autom. Sin. 2020, 47, 1017–1034. [Google Scholar]

- Lu, R.; Wu, A.; Zhang, T.; Wang, Y. Review on Automated Optical (Visual) Inspection and Its Applications in Defect Detection. Acta Opt. Sin. 2018, 38, 23–58. [Google Scholar]

- Yang, J.; Li, S.; Wang, Z.; Dong, H.; Wang, J.; Tang, S. Using Deep Learning to Detect Defects in Manufacturing: A Comprehensive Survey and Current Challenges. Materials 2020, 13, 5755. [Google Scholar] [CrossRef]

- Bergman, P.; Fauser, M.; Sattlegger, D.; Steger, C. MVTec AD—A Comprehensive Real-World Dataset for Unsupervised Anomaly Detection. In Proceedings of the 2019 IEEE/CVF Conference on Computer Vision and Pattern Recognition CVPR), Long Beach, CA, USA, 15–20 June 2019; pp. 9584–9592. [Google Scholar]

- Luo, J.; Dong, T.; Song, D.; Xiu, C. A Review on Surface Defect Detection. J. Front. Comput. Sci. Technol. 2014, 8, 1041–1048. [Google Scholar]

- Tang, B.; Kong, J.; Wu, S. Review of surface defect detection based on machine vision. J. Image Graph. 2017, 22, 1640–1663. [Google Scholar]

- Song, X.; Bai, F.; Wu, J.; Chen, X.; Zhang, T. Wood Knot Defects Recognition with Gray-Scale Histogram Features. Laser Optoelectron. Prog. 2015, 52, 205–210. [Google Scholar]

- Putri, A.P.; Rachmat, H.; Atmaja, D.S.E. Design of Automation System for Ceramic Surface Quality Control Using Fuzzy Logic Method at Balai Besar Keramik (BBK). MATEC Web Conf. 2017, 135, 53. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Xu, K.; Xu, J. An Improved MB-LBP Defect Recognition Approach for the Surface of Steel Plates. Appl. Sci. 2019, 9, 4222. [Google Scholar] [CrossRef] [Green Version]

- Zhu, D.; Pan, R.; Gao, W.; Zhang, J. Yarn-Dyed Fabric Defect Detection Based on Autocorrelation Function And GLCM. Autex Res. J. 2015, 15, 226–232. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.; Kang, Y.; Park, C.; Won, S. Defect Detection Algorithm in Steel Billets Using Morphological Top-Hat filter. IFAC Proc. Vol. 2009, 42, 209–212. [Google Scholar] [CrossRef]

- Tsai, D.M.; Wu, S.C.; Li, W.C. Defect detection of solar cells in electroluminescence images using Fourier image reconstruction. Sol. Energy Mater. Sol. Cells 2012, 99, 250–262. [Google Scholar] [CrossRef]

- Yun, J.P.; Choi, S.H.; Kim, J.W.; Kim, S.W. Automatic detection of cracks in raw steel block using Gabor filter optimized by univariate dynamic encoding algorithm for searches (uDEAS). NDT E Int. 2009, 42, 389–397. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, W.; Kuang, Q.; Cao, L.; Gao, B. Defect detection of IC wafer based on two-dimension wavelet transform. Microelectron. J. 2010, 41, 171–177. [Google Scholar] [CrossRef]

- Lizarraga-Morales, R.A.; Sanchez-Yanez, R.E.; Baeza-Serrato, R. Defect detection on patterned fabrics using texture periodicity and the coordinated clusters representation. Text. Res. J. 2017, 87, 1869–1882. [Google Scholar] [CrossRef]

- Feng, Z.; Zhou, J.; Chen, W.; Yin, J. Mixed-state MRF detection algorithm for ink-jet printing motion texture. J. Zhejiang Univ. (Eng. Sci.) 2015, 49, 1642–1650. [Google Scholar]

- Gao, X.; Xie, Y.; Chen, Z.; You, D. Magneto-optical imaging fractal feature detection for welding defects of high-strength steel. Trans. China Weld. Inst. 2017, 38, 1–4+129. [Google Scholar]

- Ren, H.; Tian, K.; Hong, S.; Dong, B.; Xing, F.; Qin, L. Visualized investigation of defect in cementitious materials with electrical resistance tomography. Constr. Build. Mater. 2019, 196, 428–436. [Google Scholar] [CrossRef]

- Song, W.; Chen, T.; Gu, Z.; Gai, W.; Huang, W.; Wang, B. Wood Materials Defects Detection Using Image Block Percentile Color Histogram and Eigenvector Texture Feature. In Proceedings of the First International Conference on Information Sciences, Machinery, Materials and Energy, Chongqing, China, 11–13 April 2015; Atlantis Press: Paris, France, 2015. [Google Scholar]

- Prasitmeeboon, P.; Yau, H. Defect Detection of Particleboards by Visual Analysis and Machine Learning. In Proceedings of the 2019 5th International Conference on Engineering, Applied Sciences and Technology, Luang Prabang, Laos, 2–5 July 2019; pp. 1–4. [Google Scholar]

- Li, J.; Quan, X.; Wang, Y. Research on Defect Detection Algorithm of Ceramic Tile Surface with Multi-feature Fusion. Comput. Eng. Appl. 2020, 56, 191–198. [Google Scholar]

- Ma, N.; Gao, X.; Wang, C.; Zhang, Y.; You, D.; Zhang, N. Influence of Hysteresis Effect on Contrast of Welding Defects Profile in Magneto-Optical Image. IEEE Sens. J. 2020, 20, 15034–15042. [Google Scholar] [CrossRef]

- Li, Y.; Liu, M. Aerial Image Classification Using Color Coherence Vectors and Rotation & Uniform Invariant LBP Descriptors. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 October 2018; pp. 653–656. [Google Scholar]

- Kshirsagar, D.B.; Kulkarni, U.V. A generalized Neuro-Fuzzy Based Image Retrieval system with modified colour coherence vector and Texture element patterns. In Proceedings of the 2016 IEEE International Conference on Advances in Electronics, Communication and Computer Technology (ICAECCT), New York, NY, USA, 2–3 December 2016; pp. 68–75. [Google Scholar]

- Wang, J.; Fu, P.; Gao, R.X. Machine vision intelligence for product defect inspection based on deep learning and Hough transform. J. Manuf. Syst. 2019, 51, 52–60. [Google Scholar] [CrossRef]

- Li, R.; Tian, F.; Chen, S. Research on Surface Defect Detection Method of E-TPU Midsole Based on Machine Vision. J. Comput. Commun. 2020, 8, 145–160. [Google Scholar] [CrossRef]

- Chang, C.F.; Wu, J.J.; Chen, K.J.; Hsu, M.C. A hybrid defect detection method for compact camera lens. Adv. Mech. Eng. 2017, 9, 287–313. [Google Scholar] [CrossRef] [Green Version]

- Tsai, D.M.; Huang, C.K. Defect Detection in Electronic Surfaces Using Template-Based Fourier Image Reconstruction. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 163–172. [Google Scholar] [CrossRef]

- Wang, F.L.; Zuo, B. Detection of surface cutting defect on magnet using Fourier image reconstruction. J. Cent. South Univ. 2016, 23, 1123–1131. [Google Scholar] [CrossRef]

- Liu, K.; Wang, H.; Chen, H.; Qu, E.; Tian, Y.; Sun, H. Steel Surface Defect Detection Using a New Haar–Weibull-Variance Model in Unsupervised Manner. IEEE Trans. Instrum. Meas. 2017, 66, 2585–2596. [Google Scholar] [CrossRef]

- Kim, M.S.; Park, T.; Park, P. Classification of Steel Surface Defect Using Convolutional Neural Network with Few Images. In Proceedings of the 12th Asian Control Conference (ASCC), Kitakyusyu International Conference Center, Fukuoka, Japan, 9–12 June 2019; pp. 1398–1401. [Google Scholar]

- Ding, R.; Zhang, C.; Zhu, Q.; Liu, H. Unknown defect detection for printed circuit board based on multi-scale deep similarity measure method. J. Eng. 2020, 2020, 388–393. [Google Scholar] [CrossRef]

- Luan, C.; Cui, R.; Sun, L.; Lin, Z. A Siamese Network Utilizing Image Structural Differences for Cross-Category Defect Detection. In Proceedings of the 2020 IEEE International Conference on Image Processing (ICIP), Abu Dhabi, United Arab Emirates, 25–28 October 2020; pp. 778–782. [Google Scholar]

- Liang, Q.; Zhu, W.; Sun, W.; Yu, Z.; Wang, Y.; Zhang, D. In-line inspection solution for codes on complex backgrounds for the plastic container industry. Measurement 2019, 148, 106965. [Google Scholar] [CrossRef]

- Anvar, A.; Cho, Y.I. Automatic Metallic Surface Defect Detection using ShuffleDefectNet. J. Korea Soc. Comput. Inf. 2020, 25, 19–26. [Google Scholar]

- Tao, X.; Zhang, D.; Wang, Z.; Liu, X.; Zhang, H.; Xu, D. Detection of Power Line Insulator Defects Using Aerial Images Analyzed with Convolutional Neural Networks. In IEEE Transactions on Systems, Man, and Cybernetics Systems; IEEE: Piscataway, NJ, USA, 2020; pp. 1486–1498. [Google Scholar]

- Hu, B.; Wang, J. Detection of PCB Surface Defects with Improved Faster-RCNN and Feature Pyramid Network. IEEE Access 2020, 8, 108335–108345. [Google Scholar] [CrossRef]

- Ren, J.; Huang, X. Defect Detection Using Combined Deep Autoencoder and Classifier for Small Sample Size. In Proceedings of the 2020 IEEE 6th International Conference on Control Science and Systems Engineering (ICCSSE), Beijing, China, 17–19 July 2020; pp. 32–35. [Google Scholar]

- Sampedro, C.; Rodriguez-Vazquez, J.; Rodriguez-Ramos, A.; Carrio, A.; Campoy, P. Deep Learning-Based System for Automatic Recognition and Diagnosis of Electrical Insulator Strings. IEEE Access 2019, 7, 101283–101308. [Google Scholar] [CrossRef]

- Balzategui, J.; Eciolaza, L.; Arana-Arexolaleiba, N. Defect detection on Polycrystalline solar cells using Electroluminescence and Fully Convolutional Neural Networks. In Proceedings of the 2020 IEEE/SICE International Symposium on System Integration (SII), Honolulu, HI, USA, 12–15 January 2020; pp. 949–953. [Google Scholar]

- Gao, X.; Jian, M.; Hu, M.; Tanniru, M.; Li, S. Faster multi-defect detection system in shield tunnel using combination of FCN and faster RCNN. Adv. Struct. Eng. 2019, 22, 2907–2921. [Google Scholar] [CrossRef]

- Xiao, L.; Wu, B.; Hu, Y. Surface Defect Detection Using Image Pyramid. IEEE Sens. J. 2020, 20, 7181–7188. [Google Scholar] [CrossRef]

- Mehta, S.; Azad, A.P.; Chemmengath, S.A.; Raykar, V.; Kalyanaraman, S. DeepSolarEye: Power Loss Prediction and Weakly Supervised Soiling Localization via Fully Convolutional Networks for Solar Panels. In Proceedings of the 2018 IEEE Winter Conference on Applications of Computer Vision (WACV), Lake Tahoe, NV, USA, 12–15 March 2018; pp. 333–342. [Google Scholar]

- Dike, H.U.; Zhou, Y.; Deveerasetty, K.K.; Wu, Q. Unsupervised Learning Based on Artificial Neural Network: A Review. In Proceedings of the 2018 IEEE International Conference on Cyborg and Bionic Systems (CBS), Shenzhen, China, 25–27 October 2018; pp. 322–327. [Google Scholar]

- Cohen, N.; Hoshen, Y. Sub-Image Anomaly Detection with Deep Pyramid Correspondences. arXiv 2020, arXiv:2005.02357. [Google Scholar]

- Defard, T.; Setkov, A.; Loesch, A.; Audigier, R. PaDiM: A Patch Distribution Modeling Framework for Anomaly Detection and Localization. arXiv 2020, arXiv:2011.08785. [Google Scholar]

- Roth, K.; Pemula, L.; Zepeda, J.; Schölkopf, B.; Brox, T.; Gehler, P. Towards Total Recall in Industrial Anomaly Detection. arXiv 2021, arXiv:2106.08265. [Google Scholar]

- Bergmann, P.; Löwe, S.; Fauser, M.; Sattlegger, D.; Steger, C. Improving Unsupervised Defect Segmentation by Applying Structural Similarity to Autoencoders. In Proceedings of the International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP), SCITEPRESS, Prague, Czech, 25–27 February 2019. [Google Scholar]

- Pirnay, J.; Chai, K. Inpainting Transformer for Anomaly Detection. arXiv 2021, arXiv:2104.13897. [Google Scholar]

- Haselmann, M.; Gruber, D.P.; Tabatabai, P. Anomaly Detection using Deep Learning based Image Completion. In Proceedings of the 2018 17th IEEE International Conference on Machine Learning and Applications (ICMLA), Orlando, FL, USA, 17–20 December 2018; pp. 1237–1242. [Google Scholar]

- Yang, H.; Chen, Y.; Song, K.; Yin, Z. Multiscale Feature-Clustering-Based Fully Convolutional Autoencoder for Fast Accurate Visual Inspection of Texture Surface Defects. IEEE Trans. Autom. Sci. Eng. 2019, 16, 1450–1467. [Google Scholar] [CrossRef]

- Mei, S.; Yang, H.; Yin, Z. An Unsupervised-Learning-Based Approach for Automated Defect Inspection on Textured Surfaces. IEEE Trans. Instrum. Meas. 2018, 67, 1266–1277. [Google Scholar] [CrossRef]

- Ke, M.; Lin, C.; Huang, Q. Anomaly detection of Logo images in the mobile phone using convolutional autoencoder. In Proceedings of the 2017 4th International Conference on Systems and Informatics (ICSAI), Hangzhou, China, 11–13 November 2018; pp. 1163–1168. [Google Scholar]

- Masci, J.; Meier, U.; Cireşan, D.; Schmidhuber, J. Stacked Convolutional Auto-Encoders for Hierarchical Feature Extraction. In Proceedings of the 21st International Conference on Artificial Neural Networks (ICANN), Espoo, Finland, 14–17 June 2011; pp. 52–59. [Google Scholar]

- Hu, G.; Huang, J.; Wang, Q.; Li, J.; Xu, Z.; Huang, X. Unsupervised fabric defect detection based on a deep convolutional generative adversarial network. Text. Res. J. 2020, 90, 247–270. [Google Scholar] [CrossRef]

- Liu, K.; Li, A.; Wen, X.; Chen, H.; Yang, P. Steel Surface Defect Detection Using GAN and One-Class Classifier. In Proceedings of the 2019 25th International Conference on Automation and Computing (ICAC), Lancaster, UK, 5–7 September 2019; pp. 1–6. [Google Scholar]

- Lai, Y.T.K.; Hu, J.S. A Texture Generation Approach for Detection of Novel Surface Defects. In Proceedings of the 2018 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Miyazaki, Japan, 7–10 October 2018; pp. 4357–4362. [Google Scholar]

- Zhai, W.; Zhu, J.; Cao, Y.; Wang, Z. A Generative Adversarial Network Based Framework for Unsupervised Visual Surface Inspection. In Proceedings of the 2018 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Calgary, AB, Canada, 15–20 April 2018; pp. 1283–1287. [Google Scholar]

- Liu, J.; Wang, C.; Su, H.; Du, B.; Tao, D. Multistage GAN for Fabric Defect Detection. IEEE Trans. Image Process. 2020, 29, 3388–3400. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Yao, M.; He, W.; Qian, Y. Solar Cells Surface Defects Detection Based on Deep Learning. Pattern Recognit. Artif. Intell. 2014, 27, 517–523. [Google Scholar]

- Zheng, H.; Yang, Y.; Sun, X.; Wen, C. Nondestructive Detection of Anchorage Quality of Rock Bolt Based On DS-DBN-SVM. In Proceedings of the 2018 International Conference on Machine Learning and Cybernetics (ICMLC), Chengdu, China, 15–18 July 2018; pp. 288–293. [Google Scholar]

- Silvén, O.; Niskanen, M.; Kauppine, H. Wood inspection with non-supervised clustering. Mach. Vis. Appl. 2003, 13, 275–285. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; Chen, P.; Su, L.; Shi, T.; Tang, Z.; Liao, G. X-ray inspection of TSV defects with self-organizing map network and Otsu algorithm. Microelectron. Reliab. 2016, 67, 129–134. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, H.; Chen, J.; Kong, Y.; Zheng, S. A Generic Semi-Supervised Deep Learning-Based Approach for Automated Surface Inspection. IEEE Access 2020, 8, 114088–114099. [Google Scholar] [CrossRef]

- He, D.; Xu, K.; Zhou, P.; Zhou, D. Surface defect classification of steels with a new semi-supervised learning method. Opt. Lasers Eng. 2019, 117, 40–48. [Google Scholar]

- He, Y.; Song, K.; Dong, H.; Yan, Y. Semi-supervised defect classification of steel surface based on multi-training and generative adversarial network. Opt. Lasers Eng. 2019, 122, 294–302. [Google Scholar] [CrossRef]

- Dai, W.; Mujeeb, A.; Erdt, M.; Sourin, A. Soldering defect detection in automatic optical inspection. Adv. Eng. Inform. 2020, 43, 101004. [Google Scholar] [CrossRef]

- Mayr, M.; Hoffmann, M.; Maier, A.; Christlein, V. Weakly Supervised Segmentation of Cracks on Solar Cells Using Normalized Lp Norm. In Proceedings of the 2019 IEEE International Conference on Image Processing (ICIP), Taipei, Taiwan, 22–25 September 2019; pp. 1885–1889. [Google Scholar]

- Xu, L.; Lv, S.; Deng, Y.; Li, X. A Weakly Supervised Surface Defect Detection Based on Convolutional Neural Network. IEEE Access 2020, 8, 42285–42296. [Google Scholar] [CrossRef]

- Zhang, Z.; Wen, G.; Chen, S. Weld image deep learning-based on-line defects detection using convolutional neural networks for Al alloy in robotic arc welding. J. Manuf. Process. 2019, 45, 208–216. [Google Scholar] [CrossRef]

- Xia, B.; Cao, J.; Wang, C. SSIM-NET: Real-Time PCB Defect Detection Based on SSIM and MobileNet-V3. In Proceedings of the 2019 2nd World Conference on Mechanical Engineering and Intelligent Manufacturing (WCMEIM), Shanghai, China, 22–24 November 2019; pp. 756–759. [Google Scholar]

- Lv, Y.; Ma, L.; Jiang, H. A Mobile Phone Screen Cover Glass Defect Detection MODEL Based on Small Samples Learning. In Proceedings of the 2019 IEEE 4th International Conference on Signal and Image Processing (ICSIP), Wuxi, China, 19–21 July 2019; pp. 1055–1059. [Google Scholar]

- Haselmann, M.; Gruber, D.P. Pixel-Wise Defect Detection by CNNs without Manually Labeled Training Data. Appl. Artif. Intell. 2019, 33, 548–566. [Google Scholar] [CrossRef]

- Mei, S.; Yang, H.; Yin, Z. Unsupervised-Learning-Based Feature-Level Fusion Method for Mura Defect Recognition. IEEE Trans. Semicond. Manuf. 2017, 30, 105–113. [Google Scholar] [CrossRef]

- Zyout, I.; Oatawneh, A. Detection of PV Solar Panel Surface Defects using Transfer Learning of the Deep Convolutional Neural Networks. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 4 February–9 April 2020; pp. 1–4. [Google Scholar]

- Şeker, A. Evaluation of Fabric Defect Detection Based on Transfer Learning with Pre-trained AlexNet. In Proceedings of the 2018 International Conference on Artificial Intelligence and Data Processing (IDAP), Malatya, Turkey, 28–30 September 2018; pp. 1–4. [Google Scholar]

- Zhu, C.; Zhou, W.; Yu, H.; Xiao, S. Defect Detection of Emulsion Pump Body Based on Improved Convolutional Neural Network. In Proceedings of the c2019 International Conference on Advanced Mechatronic Systems (ICAMechS), Kusatsu, Japan, 26–28 August 2019; pp. 349–352. [Google Scholar]

- Volkau, I.; Mujeeb, A.; Dai, W.; Marius, E.; Alexei, S. Detection Defect in Printed Circuit Boards using Unsupervised Feature Extraction Upon Transfer Learning. In Proceedings of the 2019 International Conference on Cyberworlds (CW), Kyoto, Japan, 2–4 October 2019; pp. 101–108. [Google Scholar]

- Liang, H.; Zuo, C.; Wei, W. Detection and Evaluation Method of Transmission Line Defects Based on Deep Learning. IEEE Access 2020, 8, 38448–38458. [Google Scholar] [CrossRef]

- Zeng, W.; You, Z.; Huang, M.; Kong, Z.; Yu, Y.; Le, X. Steel Sheet Defect Detection Based on Deep Learning Method. In Proceedings of the 2019 Tenth International Conference on Intelligent Control and Information Processing (ICICIP), Marrakesh, Morocco, 14–19 December 2019; pp. 152–157. [Google Scholar]

- He, T.; Liu, Y.; Xu, C.; Zhou, X.; Hu, Z.; Fan, J. A Fully Convolutional Neural Network for Wood Defect Location and Identification. IEEE Access 2019, 7, 123453–123462. [Google Scholar] [CrossRef]

- Yang, D. Classification of Fabric Defects Based on Deep Adaptive Transfer Learning. In Proceedings of the 2019 Chinese Automation Congress (CAC), Hangzhou, China, 22–24 November 2019; pp. 5730–5733. [Google Scholar]

- Schlegl, T.; Seeböck, P.; Waldstein, S.M.; Schmidt-Erfurth, U.; Langs, G. Unsupervised Anomaly Detection with Generative Adversarial Networks to Guide Marker Discovery. In International Conference on Information Processing in Medical Imaging; Springer: Philadelphia, PA, USA, 2017; pp. 146–157. [Google Scholar]

- Schlegl, T.; Seeböck, P.; Waldstein, S.M.; Langs, G.; Schmidt-Erfurth, U. f-AnoGAN: Fast unsupervised anomaly detection with generative adversarial networks. Med. Images Anal. 2019, 54, 30–44. [Google Scholar] [CrossRef]

- Akcay, S.; Atapour-Abarghouei, A.; Breckon, T.P. GANomaly: Semi-Supervised Anomaly Detection via Adversarial Training. In Asian Conference on Computer Vision; Springer: Berlin/Heidelberg, Germany, 2018; pp. 622–637. [Google Scholar]

- Jeong, J.; Park, H.; Kwak, N. Enhancement of SSD by concatenating feature maps for object detection. arXiv 2017, arXiv:1705.09587. [Google Scholar]

- Cai, Z.; Vasconcelos, N. Cascade R-CNN: Delving into High Quality Object Detection. In Proceedings of the 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2018; pp. 6154–6162. [Google Scholar]

- Tao, X.; Li, Q.; Ren, C.; Guo, W.; He, Q.; Liu, R.; Zou, J. Affinity and class probability-based fuzzy support vector machine for imbalanced data sets. Neural Netw. 2020, 122, 289–307. [Google Scholar] [CrossRef]

- Ali-Gombe, A.; Elyan, E. MFC-GAN: Class-imbalanced dataset classification using Multiple Fake Class Generative Adversarial Network. Neurocomputing 2019, 361, 212–221. [Google Scholar] [CrossRef]

- Li, M.; Xiong, A.; Wang, L.; Deng, S.; Ye, J. ACO Resampling: Enhancing the performance of oversampling methods for class imbalance classification. Knowl. Based Syst. 2020, 196, 105818. [Google Scholar] [CrossRef]

- Bennin, K.E.; Keung, J.W.; Monden, A. On the relative value of data resampling approaches for software defect prediction. Empir. Softw. Eng. 2019, 24, 602–636. [Google Scholar] [CrossRef]

- Potharaju, S.P.; Sreedevi, M.; Ande, V.K.; Tirandasu, R.K. Data mining approach for accelerating the classification accuracy of cardiotocography. Clin. Epidemiol. Glob. Health 2019, 7, 160–164. [Google Scholar] [CrossRef] [Green Version]

- Dang, L.M.; Hassan, S.I.; Im, S.; Moon, H. Face image manipulation detection based on a convolutional neural network. Expert Syst. Appl. 2019, 129, 156–168. [Google Scholar] [CrossRef]

- Song, K.; Yan, Y. A noise robust method based on completed local binary patterns for hot-rolled steel strip surface defects. Appl. Surf. Sci. 2013, 285, 858–864. [Google Scholar] [CrossRef]

- He, Y.; Song, K.; Meng, Q.; Yan, Y. An End-to-End Steel Surface Defect Detection Approach via Fusing Multiple Hierarchical Features. IEEE Trans. Instrum. Meas. 2020, 69, 1493–1504. [Google Scholar] [CrossRef]

- Bao, Y.; Song, K.; Liu, J.; Wang, Y.; Yan, Y.; Yu, H.; Li, X. Triplet- Graph Reasoning Network for Few-shot Metal Generic Surface Defect Segmentation. IEEE Trans. Instrum. Meas. 2021, 70, 1–11. [Google Scholar]

- Gan, J.; Li, Q.; Wang, J.; Yu, H. A Hierarchical Extractor-Based Visual Rail Surface Inspection System. IEEE Sens. J. 2017, 17, 7935–7944. [Google Scholar] [CrossRef]

- Song, K.; Yan, Y. Micro Surface Defect Detection Method for Silicon Steel Strip Based on Saliency Convex Active Contour Model. Math. Probl. Eng. 2013, 2013, 1–13. [Google Scholar] [CrossRef]

- Buscema, M.; Terzi, S.; Tastle, W. A new meta-classifier. In Proceedings of the 2010 Annual Meeting of the North American Fuzzy Information Processing Society, Toronto, ON, Canada, 12–14 July 2010; pp. 1–7. [Google Scholar]

- Buscema, M. MetaNet: The theory of independent judges. Subst. Use Misuse 1998, 33, 439–461. [Google Scholar] [CrossRef] [PubMed]

- Song, K.; Hu, S.; Yan, Y.; Li, J. Surface Defect Detection Method Using Saliency Linear Scanning Morphology for Silicon Steel Strip under Oil Pollution Interference. ISIJ Int. 2014, 54, 2598–2607. [Google Scholar] [CrossRef] [Green Version]

- Tianchi Aluminum Profile Surface Defect Dataset. Available online: https://tianchi.aliyun.com/competition/entrance/231682/information (accessed on 28 February 2021).

- Tabernik, D.; Šela, S.; Skvarč, J.; Skočaj, D. Segmentation-based deep-learning approach for surface-defect detection. J. Intell. Manuf. 2020, 31, 759–776. [Google Scholar] [CrossRef] [Green Version]

- Lv, X.; Duan, F.; Jiang, J.; Fu, X.; Gan, L. Deep Metallic Surface Defect Detection: The New Benchmark and Detection Network. Sensors 2020, 20, 1562. [Google Scholar] [CrossRef] [Green Version]

- Boracchi, G.; Carrera, D.; Wohlberg, B. Novelty detection in images by sparse representations. In Proceedings of the 2014 IEEE Symposium on Intelligent Embedded Systems (IES), Orlando, FL, USA, 9–12 December 2014; pp. 47–54. [Google Scholar]

- Carrera, D.; Manganini, F.; Boracchi, G.; Lanzarone, E. Defect Detection in SEM Images of Nanofibrous Materials. IEEE Trans. Ind. Inform. 2017, 13, 551–561. [Google Scholar] [CrossRef]

- Buerhop-Lutz, C.; Deitsch, S.; Maier, A.; Gallwitz, F.; Berger, S.; Doll, B.; Hauch, J.; Camus, C.; Brabec, C.J. A Benchmark for Visual Identification of Defective Solar Cells in Electroluminescence Imagery. In Proceedings of the 35th European PV Solar Energy Conference and Exhibition, Brussels, Belgium, 24–27 September 2018; pp. 1287–1289. [Google Scholar]

- Deitsch, S.; Buerhop-Lutz, C.; Sovetkin, E.; Steland, A.; Maier, A.; Gallwitz, F.; Riess, C. Segmentation of Photovoltaic Module Cells in Electroluminescence Images. arXiv 2018, arXiv:1806.06530. [Google Scholar]

- Deitsch, S.; Christlein, V.; Berger, S.; Buerhop-Lutz, C.; Maier, A.; Gallwitz, F.; Riess, C. Automatic classification of defective photovoltaic module cells in electroluminescence images. Sol. Energy 2019, 185, 455–468. [Google Scholar] [CrossRef] [Green Version]

- Mery, D.; Riffo, V.; Zscherpel, U.; Mondragón, G.; Lillo, I.; Zuccar, I.; Lobel, H.; Carrasco, M. GDXray: The Database of X-ray Images for Nondestructive Testing. J. Nondestruct. Eval. 2015, 34, 42. [Google Scholar] [CrossRef]

- Tang, S.; He, F.; Huang, X.; Yang, J. Online PCB Defect Detector on A New PCB Defect Dataset. arXiv 2019, arXiv:1902.06197. [Google Scholar]

- Huang, Y.; Qiu, C.; Guo, Y.; Wang, X.; Yuan, K. Surface Defect Saliency of Magnetic Tile. In Proceedings of the 2018 IEEE 14th International Conference on Automation Science and Engineering (CASE), Munich, Germany, 20–24 August 2018; pp. 612–617. [Google Scholar]

- Dorafshan, S.; Maguire, M. Autonomous Detection of Concrete Cracks on Bridge Decks and Fatigue Cracks on Steel Members. In Proceedings of the Digital Imaging 2017, Mashantucket, CT, USA, 26–28 June 2017; pp. 33–44. [Google Scholar]

- Dorafshan, S.; Maguire, M.; Chang, M. Comparing Automated Image-Based Crack Detection Techniques in the Spatial and Frequency Domains. In Proceedings of the 26th ASNT Research Symposium, Jacksonville, FL, USA, 13–16 March 2017. [Google Scholar]

- Dorafshan, S.; Maguire, M.; Hoffer, N.V.; Coopmans, C. Challenges in bridge inspection using small unmanned aerial systems: Results and lessons learned. In Proceedings of the 2017 International Conference on Unmanned Aircraft Systems (ICUAS), Miami, FL, USA, 13–16 June 2017; pp. 1722–1730. [Google Scholar]

- Dorafshan, S.; Thomas, R.J.; Coopmans, C.; Maguire, M. Deep Learning Neural Networks for sUAS-Assisted Structural Inspections: Feasibility and Application. In Proceedings of the 2018 International Conference on Unmanned Aircraft Systems (ICUAS), Dallas, TX, USA, 12–15 June 2018; pp. 874–882. [Google Scholar]

- Dorafshan, S.; Maguire, M.; Qi, X. Automatic Surface Crack Detection in Concrete Structures Using OTSU Thresholding and Morphological Operations. In Civil and Environmental Engineering Faculty Publications; Paper 1234; Utah State University: Logan, UT, USA, 2016. [Google Scholar]

- Dorafshan, S.; Thomas, R.J.; Maguire, M. Comparison of deep convolutional neural networks and edge detectors for image-based crack detection in concrete. Constr. Build. Mater. 2018, 186, 1031–1045. [Google Scholar] [CrossRef]

- Dorafsha, S.; Thomas, R.J.; Maguire, M. SDNET2018: An annotated image dataset for non-contact concrete crack detection using deep convolutional neural networks. Data in Brief. 2018, 21, 1664–1668. [Google Scholar] [CrossRef]

- Özgenel, Ç.F.; Sorguç, A.G. Performance Comparison of Pretrained Convolutional Neural Networks on Crack Detection in Buildings. In Proceedings of the International Symposium on Automation and Robotics in Construction (IAARC), Berlin, Germany, 20–25 July 2018; pp. 693–700. [Google Scholar]

- Zhang, L.; Yang, F.; Zhang, Y.D.; Zhu, Y.J. Road crack detection using deep convolutional neural network. In Proceedings of the 2016 IEEE International Conference on Image Processing (ICIP), Phoenix, AZ, USA, 25–28 September 2016; IEEE: Washington, DC, USA, 2016; pp. 3708–3712. [Google Scholar]

- Li, L.; Ma, W.; Li, L.; Lu, C. Research on Detection Algorithm for Bridge Cracks Based on Deep Learning. Acta Autom. Sin. 2019, 45, 1727–1742. [Google Scholar]

- Shi, Y.; Cui, L.; Qi, Z.; Meng, F.; Chen, Z. Automatic Road Crack Detection Using Random Structured Forests. IEEE Trans. Intell. Transp. Syst. 2016, 17, 3434–3445. [Google Scholar] [CrossRef]

- Cui, L.; Qi, Z.; Chen, Z.; Meng, F.; Shi, Y. Pavement Distress Detection Using Random Decision Forests; Springer: Sydney, NSW, Australia, 2015; pp. 95–102. [Google Scholar]

- Silvestre-Blanes, J.; Albero-Albero, T.; Miralles, I.; Pérez-Llorens, R.; Moreno, J. A Public Fabric Database for Defect Detection Methods and Results. Autex Res. J. 2019, 19, 363–374. [Google Scholar] [CrossRef] [Green Version]

- Kylberg, G. The Kylberg Texture Dataset, V. 1.0; Technical Report 35; Centre Image Anal., Swedish University of Agricultural Sciences: Uppsala, Sweden, 2011. [Google Scholar]

- DAGM 2007 Datasets. Available online: https://hci.iwr.uni-heidelberg.de/node/3616 (accessed on 25 February 2021).

- Yang, J.; Shi, Y.; Qi, Z. DFR: Deep Feature Reconstruction for Unsupervised Anomaly Segmentation. arXiv 2020, arXiv:2012.07122. [Google Scholar]

- Shi, Y.; Yang, J.; Qi, Z. Unsupervised anomaly segmentation via deep feature reconstruction. Neurocomputing 2021, 424, 9–22. [Google Scholar] [CrossRef]

- Bergmann, P.; Fauser, M.; Sattlegger, D.; Steger, C. Uninformed Students: Student-Teacher Anomaly Detection with Discriminative Latent Embeddings. In Proceedings of the 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Seattle, WA, USA, 13–19 June 2020; pp. 4182–4191. [Google Scholar]

- Ye, F.; Huang, C.; Cao, J.; Li, M.; Zhang, Y.; Lu, C. Attribute Restoration Framework for Anomaly Detection. IEEE Trans. Multimed. 2020. [Google Scholar] [CrossRef]

- Li, J.; Xu, X.; Gao, L.; Wang, Z.; Shao, J. Cognitive visual anomaly detection with constrained latent representations for industrial inspection robot. Appl. Soft. Comput. 2020, 95, 106539. [Google Scholar] [CrossRef]

- Liu, W.; Li, R.; Zheng, M.; Karanam, S.; Wu, Z.; Bhanu, B.; Radke, R.J.; Camps, O. Towards Visually Explaining Variational Autoencoders. In Proceedings of the 2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Seattle, WA, USA, 13–19 June 2020; pp. 8639–8648. [Google Scholar]

- Lin, D.; Li, Y.; Prasad, S.; Nwe, T.L.; Dong, S.; Oo, Z.M. CAM-UNET: Class Activation MAP Guided UNET with Feedback Refinement for Defect Segmentation. In Proceedings of the 2020 IEEE International Conference on Image Processing (ICIP), Abu Dhabi, United Arab Emirates, 25–28 October 2020; pp. 2131–2135. [Google Scholar]

- Tayeh, T.; Aburakhia, S.; Myers, R.; Shami, A. Distance-Based Anomaly Detection for Industrial Surfaces Using Triplet Networks. In Proceedings of the 2020 11th IEEE Annual Information Technology, Electronics and Mobile Communication Conference (IEMCON), Vancouver, BC, Canada, 4–7 November 2020; pp. 372–377. [Google Scholar]

- Chung, H.; Park, J.; Keum, J.; Ki, H.; Kang, S. Unsupervised Anomaly Detection Using Style Distillation. IEEE Access 2020, 8, 221494–221502. [Google Scholar] [CrossRef]

- Rippel, O.; Mertens, P.; Merhof, D. Modeling the Distribution of Normal Data in Pre-Trained Deep Features for Anomaly Detection. arXiv 2020, arXiv:2005.14140. [Google Scholar]

- Reiss, T.; Cohen, N.; Bergaman, L.; Hoshen, Y. PANDA: Adapting Pretrained Features for Anomaly Detection and Segmentation. arXiv 2020, arXiv:2010.05903. [Google Scholar]

- Liu, Y.; Zhuang, C.; Lu, F. Unsupervised Two-Stage Anomaly Detection. arXiv 2021, arXiv:2103.11671. [Google Scholar]

- Wang, G.; Han, S.; Ding, E.; Huang, D. Student-Teacher Feature Pyramid Matching for Unsupervised Anomaly Detection. arXiv 2021, arXiv:2103.04257. [Google Scholar]

| Method | Reference | Feature | Target | Defect Types | Performance |

|---|---|---|---|---|---|

| Statistical method | Song et al. (2015) [16] | Histogram feature | Wood | Knot defect | Recognition rate: 99.8% |

| Putri et al. (2017) [17] | Gray level co-occurrence matrix | Ceramic | Surface with defects or not | Accuracy rate: 92.31% | |

| Liu et al. (2019) [18] | Local binary pattern | Steel plate | Cracks, scratches, indentations, pits, scales | Recognition accuracy: 94.40% | |

| Zhu et al. (2015) [19] | Autocorrelation function and GLCM | Yarn-dyed fabric | Wrong weft, weft crack, oil stain, etc. | Can achieve accurate detection of common defects of yarn-dyed fabric | |

| Lee et al. (2009) [20] | Mathematical morphological | Steel billet | Slender scratches | Detection ratio: 87.5%, can suitable for billet images with scale | |

| Signal processing method | Tsai et al. (2012) [21] | Fourier transform | Solar cell | Small cracks, breaks, and finger interruptions | Can effectively detect various defects and be implemented for online, real-time defect inspection |

| Yun et al. (2009) [22] | Gabor filter method | Steel billet | Crack | Accuracy: corner crack: 93.5%; thin crack: 91.9% | |

| Liu et al. (2010) [23] | Wavelet transform | Integrated circuit chip | Surface defects | Can detect defects of an IC wafer quickly and accurately | |

| Structural method | Lizarraga-Morales et al. (2017) [24] | Texture primitive theory | Patterned fabric | Surface with defects or not | Superior to other advanced algorithms |

| Model method | Feng et al. (2015) [25] | MRF model | Ink-jet printed fabric | Texture defects such as holes, oil drop marks, scratches, etc. | Can effectively detect defect texture from ink-jet printing fabric |

| Gao et al. (2017) [26] | Fractal model | High-strength steel | Welding defects including offset, cracks, and dents | Average recognition rate: 88.33% |

| Name and Reference | Objects | Link |

|---|---|---|

| NEU [103,104,105] | Hot rolled steel belt | http://faculty.neu.edu.cn/yunhyan/NEU_surface_defect_database.html (accessed on 21 June 2021) |

| RSDDs dataset [106] | Rail | http://icn.bjtu.edu.cn/Visint/resources/RSDDs.aspx (accessed on 21 June 2021) |

| Micro surface defect database [107] | Strip steel | http://faculty.neu.edu.cn/yunhyan/SCACM.html (accessed on 21 June 2021) |

| UCI Steel Plates Faults Data Set [108,109] | Strip steel | https://archive.ics.uci.edu/mL/datasets/Steel+Plates+Faults (accessed on 21 June 2021) |

| Severstal: Steel Defect Detection | Strip steel | https://www.kaggle.com/c/severstal-steel-defect-detection/data (accessed on 21 June 2021) |

| Oil pollution defect database [110] | Silicon steel | http://faculty.neu.edu.cn/yunhyan/SLSM.html (accessed on 21 June 2021) |

| Tianchi aluminum profile surface defect dataset [111] | Aluminum profile | https://tianchi.aliyun.com/competition/entrance/231682/information (accessed on 21 June 2021) |

| Kolektor [112] | Electronic commutator | https://www.vicos.si/Downloads/KolektorSDD (accessed on 21 June 2021) |

| Industrial Metallic Surface Dataset | Metal | https://www.kaggle.com/ujik132016/industrial-metallic-surface-dataset (accessed on 21 June 2021) |

| GC10-Det [113] | Metal | https://www.kaggle.com/alex000kim/gc10det (accessed on 21 June 2021) |

| Insulator Data Set—Chinese Power Line Insulator Dataset (CPLID) | Insulator | https://github.com/InsulatorData/InsulatorDataSet (accessed on 21 June 2021) |

| NanoTWICE [114,115] | Scanning tunneling microscope imaging SEM material | http://www.mi.imati.cnr.it/ettore/NanoTWICE/ (accessed on 21 June 2021) |

| elpv-dataset [116,117,118] | Solar panel | https://github.com/zae-bayern/elpv-dataset (accessed on 21 June 2021) |

| GDXray Casting [119] | X-ray image of casting | https://domingomery.ing.puc.cl/material/gdxray/ (accessed on 21 June 2021) |

| DeepPCB dataset [120] | Printed circuit board (PCB) | https://github.com/tangsanli5201/DeepPCB (accessed on 21 June 2021) |

| Magnetic tile surface defects [121] | Tile | https://www.kaggle.com/alex000kim/magnetic-tile-surface-defects (accessed on 21 June 2021) |

| Structural Defects Network (SDNET) 2018 [122,123,124,125,126,127,128] | Crack on concrete surface | https://www.kaggle.com/aniruddhsharma/structural-defects-network-concrete-crack-images (accessed on 21 June 2021) |

| Surface Crack Detection Dataset [129,130] | Crack on concrete surface | https://www.kaggle.com/arunrk7/surface-crack-detection (accessed on 21 June 2021) |

| Bridge Cracks [131] | Bridge crack | https://github.com/Iskysir/Bridge_Crack_Image_Data (accessed on 21 June 2021) |

| Crack Forest Datasets [132,133] | Road crack | https://github.com/cuilimeng/CrackForest-dataset (accessed on 21 June 2021) |

| AITEX [134] | Fabric | https://www.aitex.es/afid/ (accessed on 21 June 2021) |

| Fabric defect dataset | Fabric | https://www.kaggle.com/rmshashi/fabric-defect-dataset (accessed on 21 June 2021) |

| Fabric stain dataset | Dyed fabric | https://www.kaggle.com/priemshpathirana/fabric-stain-dataset (accessed on 21 June 2021) |

| Tianchi cloth defect dataset | Cloth | https://tianchi.aliyun.com/competition/entrance/231666/information (accessed on 21 June 2021) |

| Kylberg Texture Dataset v. 1.0 [135] | Texture images | http://www.cb.uu.se/~gustaf/texture/ (accessed on 21 June 2021) |

| DAGM 2007 [136] | Miscellaneous defects in texture background | https://hci.iwr.uni-heidelberg.de/node/3616 (accessed on 21 June 2021) |

| MVTec AD [13] | Multiple materials | http://www.mvtec.com/company/research/datasets (accessed on 21 June 2021) |

| Reference | Brief Description | Evaluation Index and Its Average Score | The Best Category and Its Evaluation Score | Evaluation Score for the Best Category |

|---|---|---|---|---|

| Yang et al. (2020) [137], (2021) [138] | A multi-scale regional feature generator | PRO-AUC: 0.95 | Objects: Screw | 0.99 |

| Bergmann et al. (2020) [139] | Student-Teacher framework | PRO: 0.91 | Textures: Leather Objects: Capsule, Hazelnut | 0.97 |

| Ye et al. (2020) [140] | Attribute Restoration Network: Attribute Erasing Module (erase certain attributes); the ARNet (restore the original data) | AUROC: 0.839 | Objects: Transistor, Zipper | 1.00 |

| Li et al. (2020) [141] | A cognitive VAD method: introduce a constrained latent space to mimic the cognitive ability of humans | AUC: 0.75 | Objects: Screw | 0.95 |

| Liu et al. (2020) [142] | Explain VAEs visually by means of gradient-based attention | ROC AUC: 0.86 | Objects: Hazelnut | 0.98 |

| Lin et al. (2020) [143] | A class activation map guided UNet with feedback refinement mechanism | IOU: 0.5755 | Textures: Tile | 0.8362 |

| Tayeh et al. (2020) [144] | A deep residual-based triplet network model | AUC: 0.856 | Objects: Hazelnut | 0.979 |

| Cohen et al. (2020) [54] | SPADE: rely on K nearest neighbors of pixel-level feature pyramids extracted by pre-trained deep features | PRO: 0.917 | Textures: Leather | 0.972 |

| Chung et al. (2020) [145] | OE-SDN: outlier-exposed style distillation network | AUROC: 0.91 | Objects: Hazelnut, Toothbrush | 0.98 |

| Rippel et al. (2020) [146] | Fitting a multivariate Gaussian (MVG) to deep feature representations of classification networks trained on ImageNet using normal data only | PRO: 0.958 | Textures: Carpet Objects: Bottle | 1.00 |

| Defard et al. (2020) [55] | PaDim: use a pretrained CNN for patch embedding, and of multivariate Gaussian distributions to get a probabilistic representation of the of the normal class | PRO: 0.921 | Textures: Leather | 0.978 |

| Reiss et al. (2020) [147] | PANDA: the framework consists of three steps: Initial feature extractor, Feature adaptation, and Anomaly scoring. | ROCAUC: 0.962 | Textures: Leather; Objects: Screw | 0.995 |

| Liu et al. (2021) [148] | UTAD: a two-stage framework (include IE-Net and Expert-Net, the two parts are used to generate high-fidelity and anomaly-free reconstructions of the input) | IoU: 0.53 | Textures: Grid | 0.89 |

| Wang et al. (2021) [149] | The student-teacher anomaly detection framework with feature pyramid matching technique | PRO: 0.914 | Objects: Capsule | 0.968 |

| Roth et al. (2021) [56] | PatchCore: combine embeddings from ImageNet models with an outlier detection model and use a maximally representative memory bank of nominal patch-features | AUROC: 0.981 | Objects: Screw | 0.994 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Ding, Y.; Zhao, F.; Zhang, E.; Wu, Z.; Shao, L. Surface Defect Detection Methods for Industrial Products: A Review. Appl. Sci. 2021, 11, 7657. https://doi.org/10.3390/app11167657

Chen Y, Ding Y, Zhao F, Zhang E, Wu Z, Shao L. Surface Defect Detection Methods for Industrial Products: A Review. Applied Sciences. 2021; 11(16):7657. https://doi.org/10.3390/app11167657

Chicago/Turabian StyleChen, Yajun, Yuanyuan Ding, Fan Zhao, Erhu Zhang, Zhangnan Wu, and Linhao Shao. 2021. "Surface Defect Detection Methods for Industrial Products: A Review" Applied Sciences 11, no. 16: 7657. https://doi.org/10.3390/app11167657

APA StyleChen, Y., Ding, Y., Zhao, F., Zhang, E., Wu, Z., & Shao, L. (2021). Surface Defect Detection Methods for Industrial Products: A Review. Applied Sciences, 11(16), 7657. https://doi.org/10.3390/app11167657