Experimental Analysis of Engine Performance and Exhaust Pollutant on a Single-Cylinder Diesel Engine Operated Using Moringa Oleifera Biodiesel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biodiesel Preparation

2.2. Composition of Biodiesel

2.3. Physiochemical Characteristics of Biodiesel

- CCI = calculated cetane index, D = density at 15 °C (g/mL), B = [e(−3.5)(DN)] − 1, DN = D − 0.85, T10N = T10 − 215, T50N = T50 − 260, and T90N = T90 − 310.

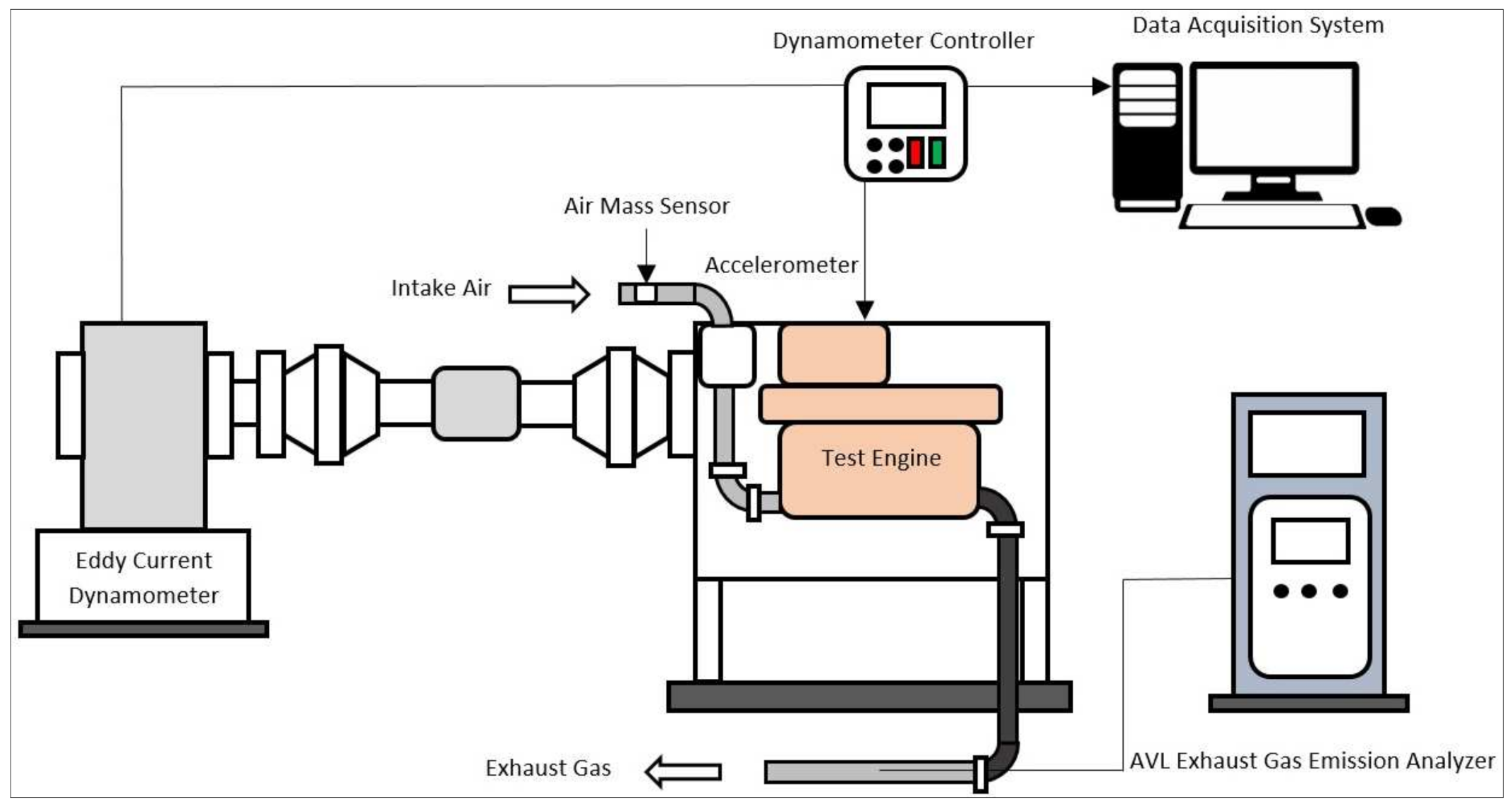

2.4. Engine Setup

2.4.1. BTE and BSFC

2.4.2. Smoke Opacity, HC, CO and NOx

| No. | Description | Specifications | No. | Description | Specifications |

|---|---|---|---|---|---|

| 1 | Engine Model | TF 120M | 5 | Compression ratio | 17.7:1 |

| 2 | Displacement (cm3) | 638 | 6 | Maximum power | 8.8 kW/2400 rpm |

| 3 | Bore (mm) | 92 | 7 | Cooling system | Water cooling |

| 4 | Stroke (mm) | 96 | 8 | Fuel system | Pump line nozzle |

| Equipment | Measurement | Method | Measurement Range | Resolution |

|---|---|---|---|---|

| AVL DiGas 4000/AVL DiCom 4000 | CO | Non-dispersive infrared | 0–10% vol. | 0.01 vol% |

| HC | Non-dispersive infrared | 0–20,000 ppm vol. | 1 ppm | |

| NOx | Electrochemical detector | 0–5000 ppm vol. | 1 ppm | |

| AVL DiSmoke 4000/AVL DiCom 4000 | Opacity | Photodiode receiver | 0–100% vol. | 0.1% |

3. Results

3.1. Engine Performance Characteristics

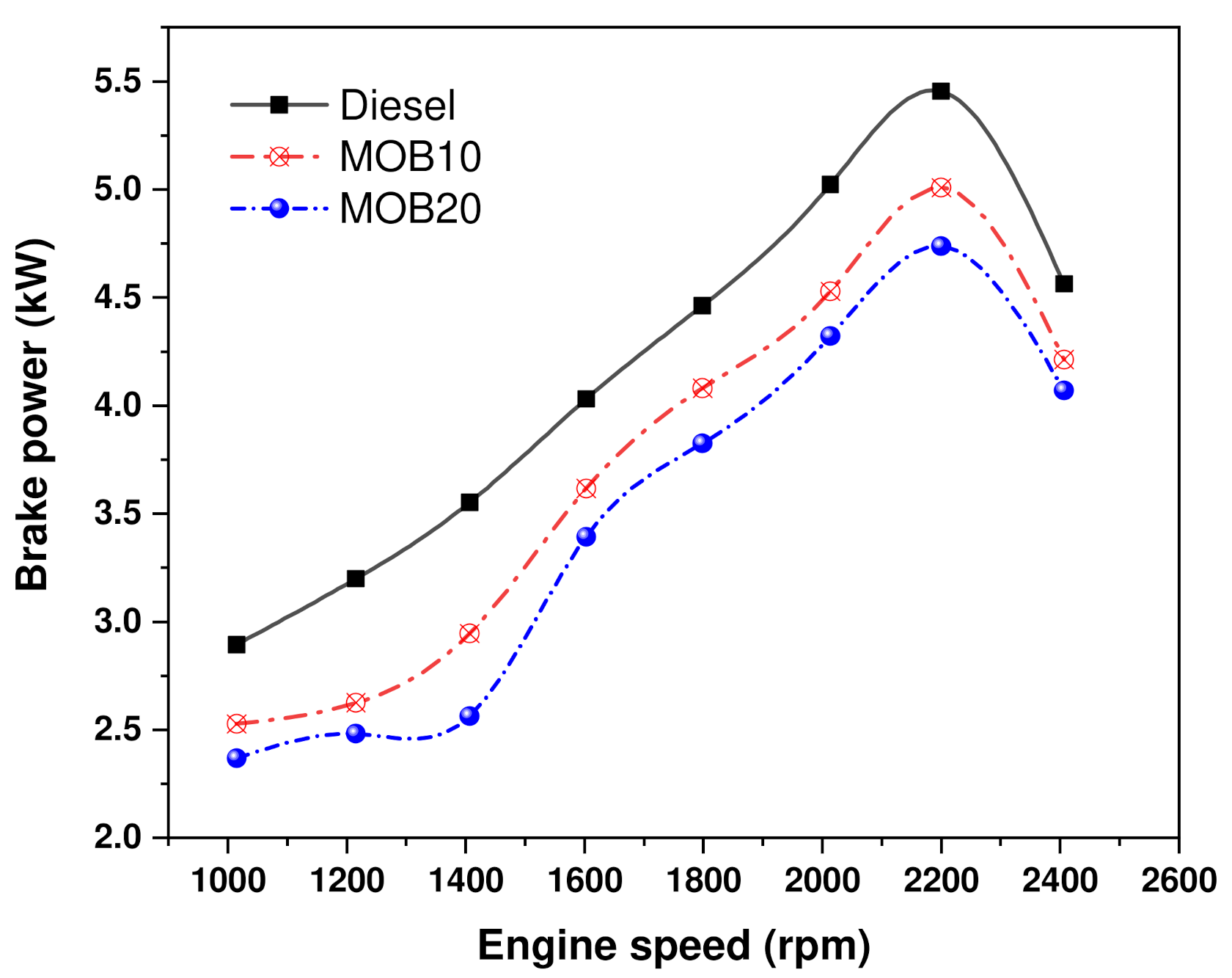

3.1.1. Brake Power (BP)

3.1.2. Brake Specific Fuel Consumption (BSFC)

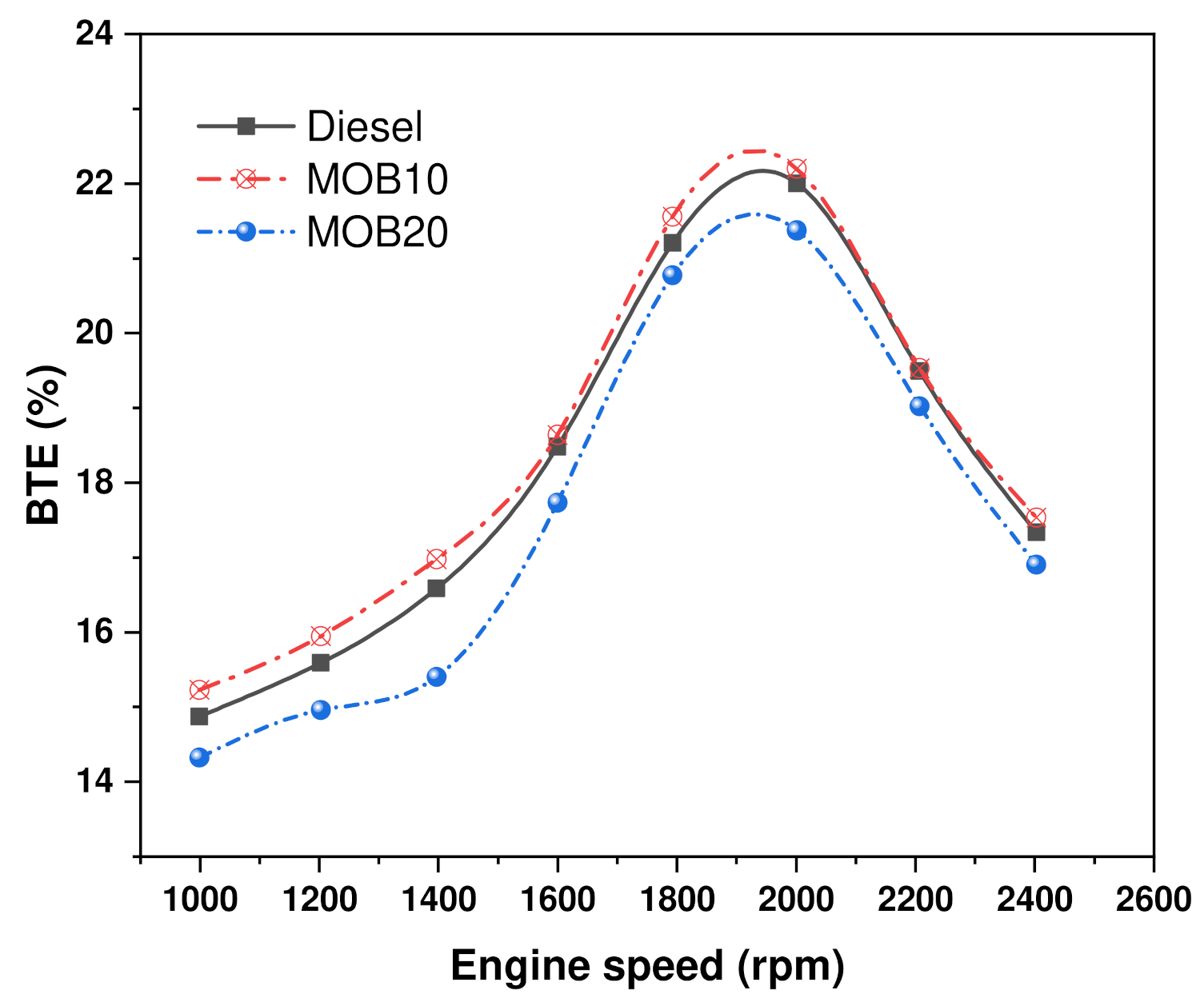

3.1.3. Brake Thermal Efficiency (BTE)

3.2. Emission Characteristics

3.2.1. Unburned Hydrocarbon Emissions (HC)

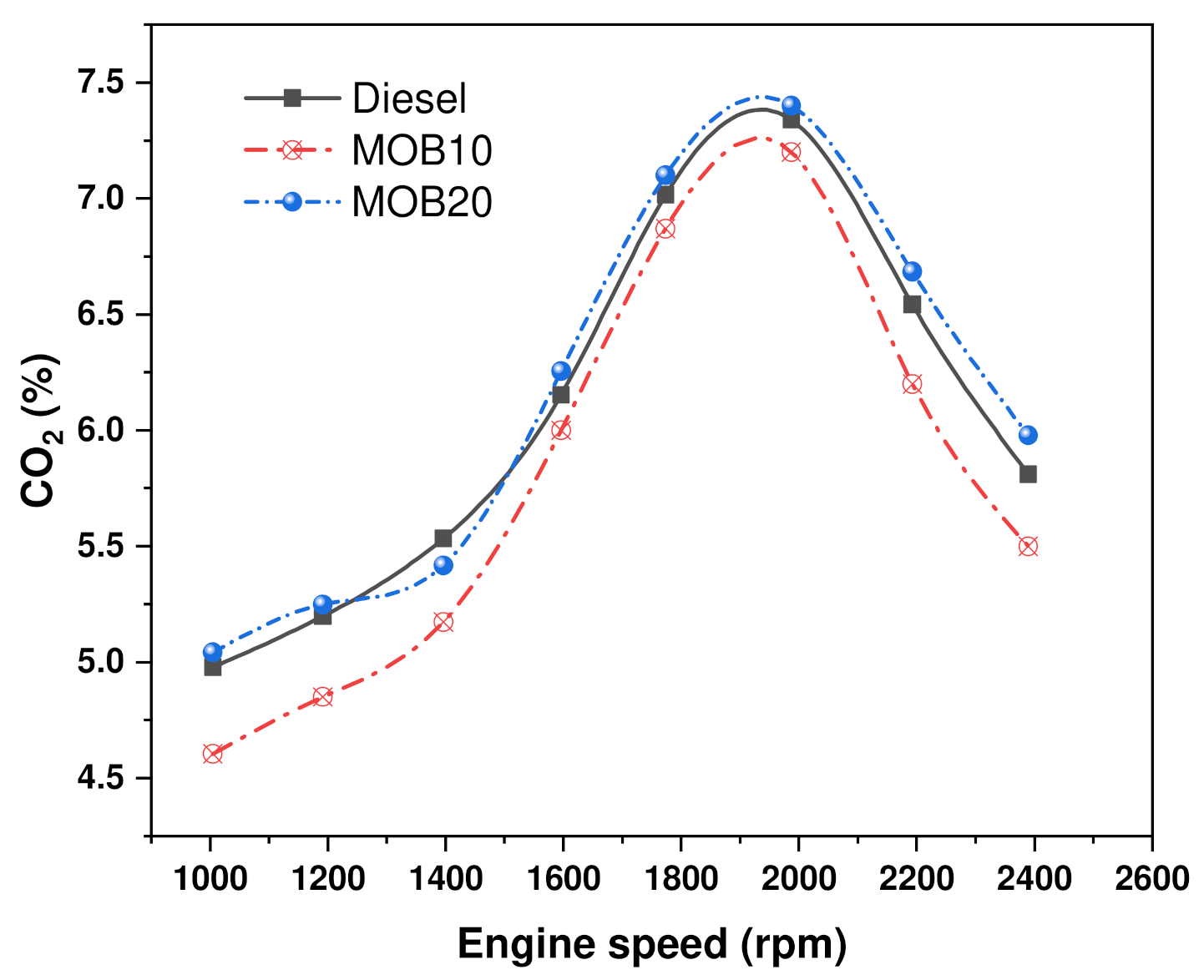

3.2.2. Carbon Dioxide Emissions (CO2)

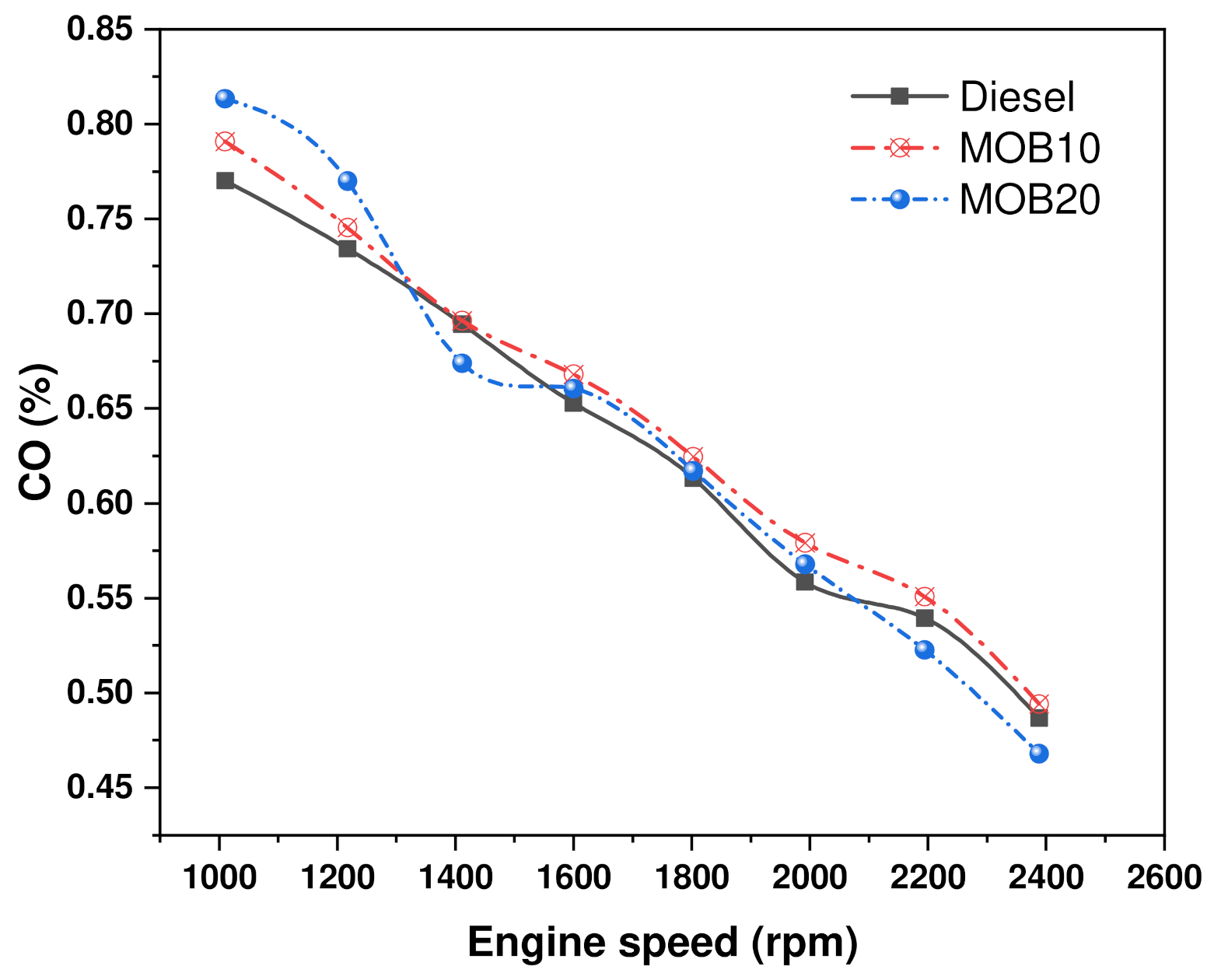

3.2.3. Carbon Monoxide Emissions (CO)

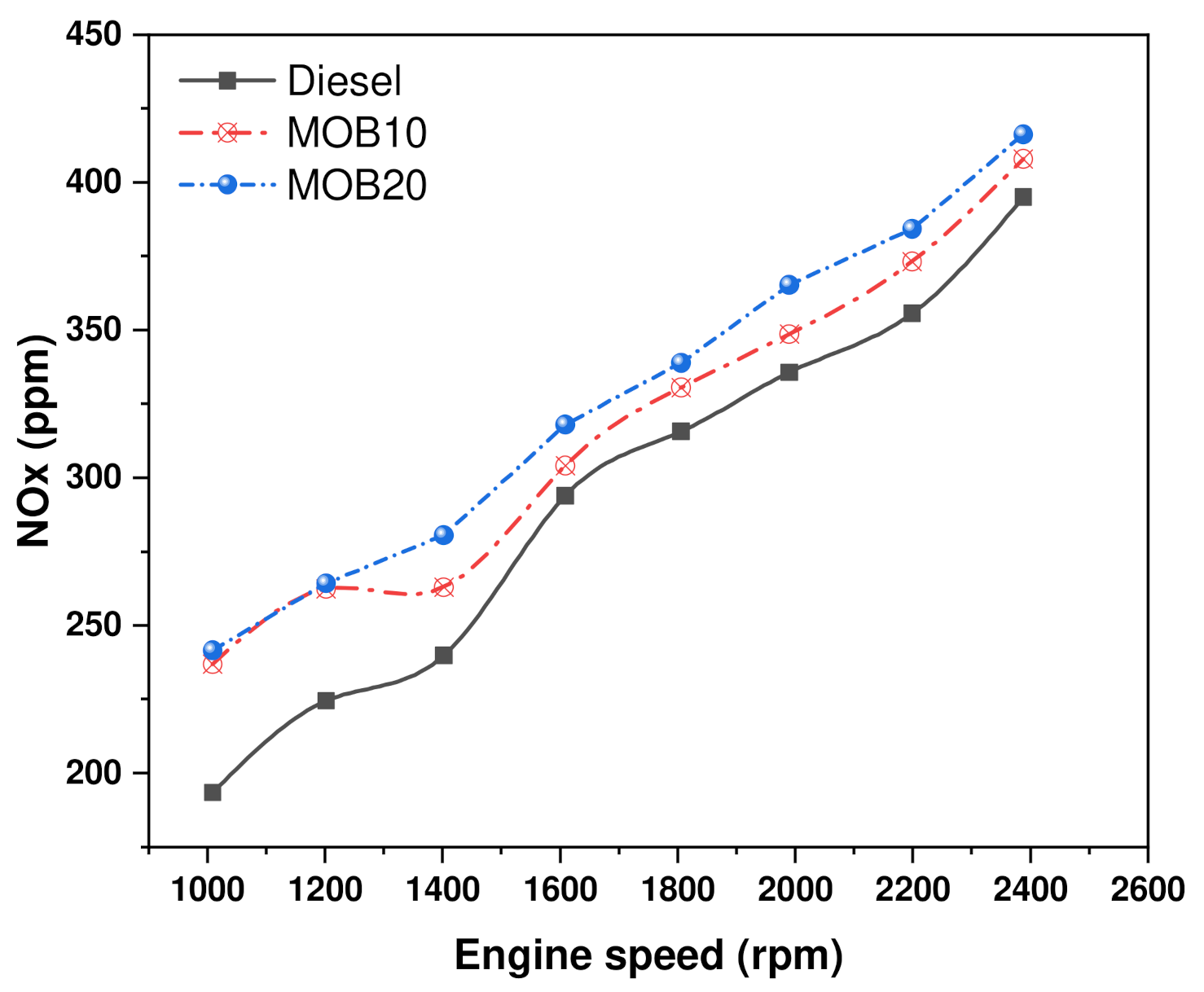

3.2.4. Nitrogen Oxide Emissions (NOx)

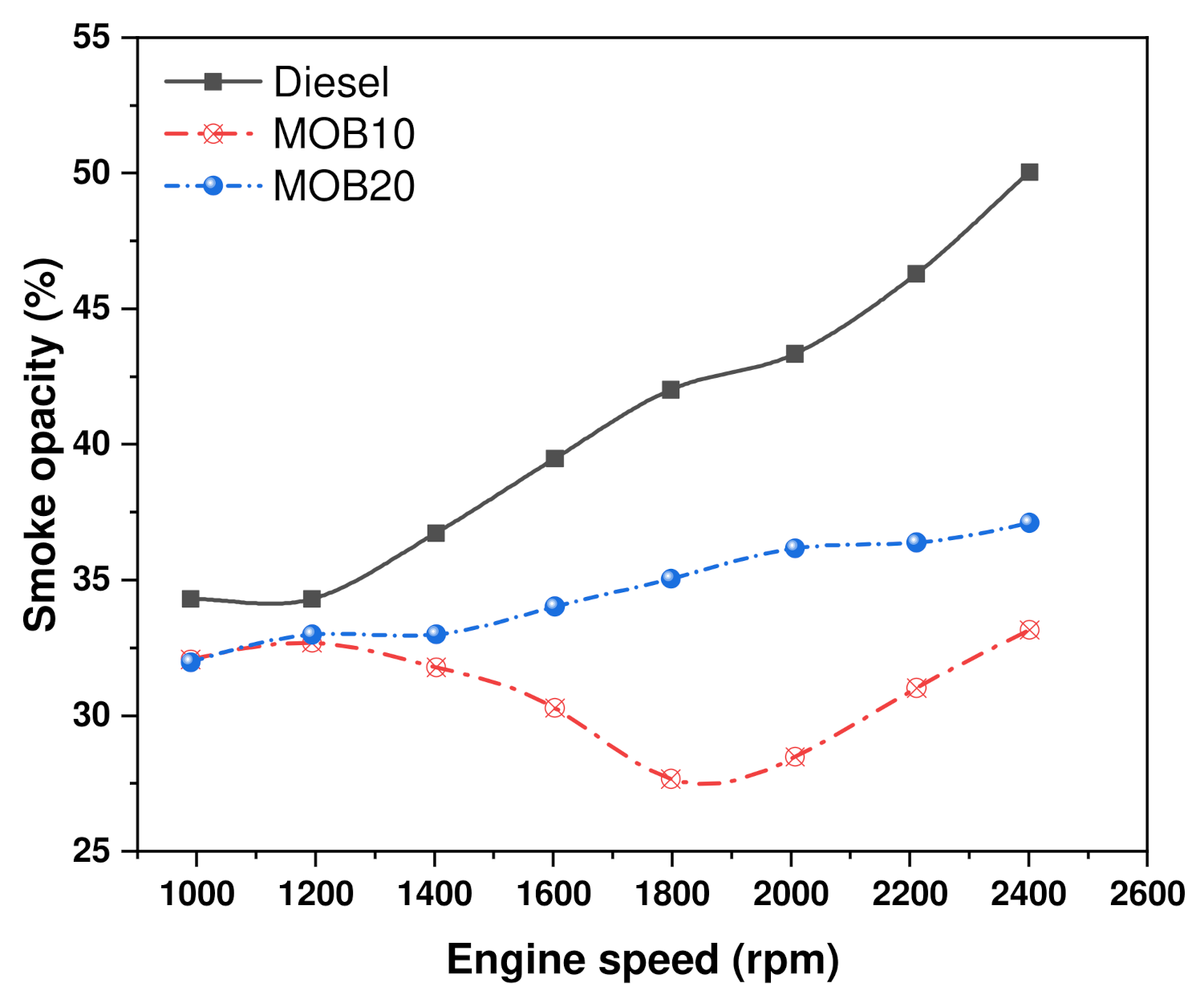

3.2.5. Smoke Opacity

4. Conclusions

- At optimum speed, the BTE for MOB10 and MOB20 was 2.54% higher and 3.45% lower, respectively, than that of pure diesel.

- MOB10 and MOB20 blends had a higher average BSFC than diesel by 7.03% and 12.75%, respectively, due to the higher density and lower calorific values of biodiesel blends.

- MOB10 produced slightly lower BP when compared to diesel, by 0.26 kW. The MOB20 blend was the worst performer, producing less usable power than diesel by 0.36 kW.

- The average HC emission for MOB10 and MOB20 were lower than diesel, with a difference of 8 ppm.

- The average NOx emission for blended fuels was significantly higher than the neat diesel, and the MOB20 blend produces more NOx emissions due to increased oxygen content in fuel blends.

- MOB10 produced lower smoke opacity than those of neat diesel and MOB20 due to good combustion.

- Therefore, MOB10 is suitable to use in conventional compression-ignition diesel engines.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| MOB | Moringa Oleifera Biodiesel |

| CI | Compression Ignition |

| BP | Brake Power |

| BTE | Brake Thermal Efficiency |

| BSFC | Brake Specific Fuel Consumption |

| MOB10 | Moringa Oil Biodiesel 10% + Diesel 90% |

| MOB20 | Moringa Oil Biodiesel 20% + Diesel 80% |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| NOx | Nitrogen Oxides |

| HC | Hydrocarbons |

| EGT | Exhaust Gas Temperature |

| FAC | Fatty Acid Composition |

| MOME | Moringa Oleifera Methyl Ester |

| COME | Canola Oil Methyl Ester |

| SOME | Soybean Oil Methyl Ester |

| SCDE | Single Cylinder Diesel Engine |

| CFPP | Cold Filter Plugging Point |

| HHV | Higher Heating Value |

| DW | Deionized Water |

References

- Wategave, S.; Banapurmath, N.; Sawant, M.; Soudagar, M.E.M.; Mujtaba, M.; Afzal, A.; Basha, J.S.; Alazwari, M.A.; Safaei, M.R.; Elfasakhany, A. Clean combustion and emissions strategy using reactivity controlled compression ignition (RCCI) mode engine powered with CNG-Karanja biodiesel. J. Taiwan Inst. Chem. Eng. 2021, 124, 116–131. [Google Scholar] [CrossRef]

- Li, Z.; Sarafraz, M.; Mazinani, A.; Hayat, T.; Alsulami, H.; Goodarzi, M. Pool boiling heat transfer to CuO-H2O nanofluid on finned surfaces. Int. J. Heat Mass Transf. 2020, 156, 119780. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Christo, F.C. Thermodynamic assessment and techno-economic analysis of a liquid indium-based chemical looping system for biomass gasification. Energy Convers. Manag. 2020, 225, 113428. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, A.A.; Arabbeiki, M.; Ali, H.M.; Goodarzi, M.; Safaei, M.R. Configuration and optimization of a minichannel using water–alumina nanofluid by non-dominated sorting genetic algorithm and response surface method. Nanomaterials 2020, 10, 901. [Google Scholar] [CrossRef] [PubMed]

- Di Sarli, V.; Di Benedetto, A. Combined effects of soot load and catalyst activity on the regeneration dynamics of catalytic diesel particulate filters. AIChE J. 2018, 64, 1714–1722. [Google Scholar] [CrossRef]

- Di Sarli, V.; Landi, G.; Lisi, L.; Di Benedetto, A. Ceria-coated diesel particulate filters for continuous regeneration. AIChE J. 2017, 63, 3442–3449. [Google Scholar] [CrossRef]

- Bala Prasad, K.; Dhana Raju, V.; Ahamad Shaik, A.; Gopidesi, R.K.; Sreekara Reddy, M.B.S.; Soudagar, M.E.M.; Mujtaba, M.A. Impact of injection timings and exhaust gas recirculation rates on the characteristics of diesel engine operated with neat tamarind biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–19. [Google Scholar] [CrossRef]

- Rahmanian, B.; Safaei, M.R.; Kazi, S.N.; Ahmadi, G.; Oztop, H.F.; Vafai, K. Investigation of pollutant reduction by simulation of turbulent non-premixed pulverized coal combustion. Appl. Therm. Eng. 2014, 73, 1222–1235. [Google Scholar] [CrossRef]

- Kang, J.; Chu, S.; Lee, J.; Kim, G.; Min, K. Effect of operating parameters on diesel/propane dual fuel premixed compression ignition in a diesel engine. Int. J. Automot. Technol. 2018, 19, 27–35. [Google Scholar] [CrossRef]

- Hussain, A.; Mehdi, S.M.; Akhtar, M.; Ani, F.N.; Ahmed, I. Combustion Performance of Diesel Palm Olein Fuel: A Combined CFD and Experimental Approach. Arab. J. Sci. Eng. 2018, 43, 1291–1300. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Afzal, A.; Safaei, M.R.; Manokar, A.M.; EL-Seesy, A.I.; Mujtaba, M.; Samuel, O.D.; Badruddin, I.A.; Ahmed, W.; Shahapurkar, K. Investigation on the effect of cottonseed oil blended with different percentages of octanol and suspended MWCNT nanoparticles on diesel engine characteristics. J. Therm. Anal. Calorim. 2020, 1–18. [Google Scholar] [CrossRef]

- Bahiraei, M.; Jamshidmofid, M.; Goodarzi, M. Efficacy of a hybrid nanofluid in a new microchannel heat sink equipped with both secondary channels and ribs. J. Mol. Liq. 2019, 273, 88–98. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Goodarzi, M.; Tlili, I.; Alkanhal, T.A.; Arjomandi, M. Thermodynamic potential of a high-concentration hybrid photovoltaic/thermal plant for co-production of steam and electricity. J. Therm. Anal. Calorim. 2021, 143, 1389–1398. [Google Scholar] [CrossRef]

- Nazari, S.; Karami, A.; Bahiraei, M.; Olfati, M.; Goodarzi, M.; Khorasanizadeh, H. A novel technique based on artificial intelligence for modeling the required temperature of a solar bread cooker equipped with concentrator through experimental data. Food Bioprod. Process. 2020, 123, 437–449. [Google Scholar] [CrossRef]

- Bagherzadeh, S.A.; Jalali, E.; Sarafraz, M.M.; Akbari, O.A.; Karimipour, A.; Goodarzi, M.; Bach, Q.-V. Effects of magnetic field on micro cross jet injection of dispersed nanoparticles in a microchannel. Int. J. Numer. Methods Heat Fluid Flow 2019, 30. [Google Scholar] [CrossRef]

- Bagherzadeh, S.A.; D’Orazio, A.; Karimipour, A.; Goodarzi, M.; Bach, Q.-V. A novel sensitivity analysis model of EANN for F-MWCNTs–Fe3O4/EG nanofluid thermal conductivity: Outputs predicted analytically instead of numerically to more accuracy and less costs. Phys. A Stat. Mech. Appl. 2019, 521, 406–415. [Google Scholar] [CrossRef]

- Akkoli, K.; Banapurmath, N.; Shivashimpi, M.; Soudagar, M.E.M.; Badruddin, I.A.; Alazwari, M.A.; Yaliwal, V.; Mujtaba, M.; Akram, N.; Goodarzi, M. Effect of injection parameters and producer gas derived from redgram stalk on the performance and emission characteristics of a diesel engine. Alex. Eng. J. 2021, 60, 3133–3142. [Google Scholar] [CrossRef]

- Khan, H.M.; Iqbal, T.; Yasin, S.; Irfan, M.; Kazmi, M.; Fayaz, H.; Mujtaba, M.; Ali, C.H.; Kalam, M.; Soudagar, M.E.M. Production and utilization aspects of waste cooking oil based biodiesel in Pakistan. Alex. Eng. J. 2021, 60, 5831–5849. [Google Scholar] [CrossRef]

- Mahdisoozani, H.; Mohsenizadeh, M.; Bahiraei, M.; Kasaeian, A.; Daneshvar, A.; Goodarzi, M.; Safaei, M.R. Performance enhancement of internal combustion engines through vibration control: State of the art and challenges. Appl. Sci. 2019, 9, 406. [Google Scholar] [CrossRef] [Green Version]

- Choudhary, A.K.; Chelladurai, H.; Kannan, C. Optimization of Combustion Performance of Bioethanol (Water Hyacinth) Diesel Blends on Diesel Engine Using Response Surface Methodology. Arab. J. Sci. Eng. 2015, 40, 3675–3695. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Banapurmath, N.; Afzal, A.; Hossain, N.; Abbas, M.M.; Haniffa, M.A.C.M.; Naik, B.; Ahmed, W.; Nizamuddin, S.; Mubarak, N. Study of diesel engine characteristics by adding nanosized zinc oxide and diethyl ether additives in Mahua biodiesel–diesel fuel blend. Sci. Rep. 2020, 10, 1–17. [Google Scholar] [CrossRef]

- Sadeghinezhad, E.; Kazi, S.; Sadeghinejad, F.; Badarudin, A.; Mehrali, M.; Sadri, R.; Safaei, M.R. A comprehensive literature review of bio-fuel performance in internal combustion engine and relevant costs involvement. Renew. Sustain. Energy Rev. 2014, 30, 29–44. [Google Scholar] [CrossRef]

- Goodarzi, M.; Toghraie, D.; Reiszadeh, M.; Afrand, M. Experimental evaluation of dynamic viscosity of ZnO–MWCNTs/engine oil hybrid nanolubricant based on changes in temperature and concentration. J. Therm. Anal. Calorim. 2019, 136, 513–525. [Google Scholar] [CrossRef]

- Hussain, F.; Alshahrani, S.; Abbas, M.M.; Khan, H.M.; Jamil, A.; Yaqoob, H.; Soudagar, M.E.M.; Imran, M.; Ahmad, M.; Munir, M. Waste Animal Bones as Catalysts for Biodiesel Production; A Mini Review. Catalysts 2021, 11, 630. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Safaei, M.R.; Goodarzi, M.; Alrashed, A.A.; Nguyen, T.K. New temperature, interfacial shell dependent dimensionless model for thermal conductivity of nanofluids. Int. J. Heat Mass Transf. 2017, 114, 207–210. [Google Scholar] [CrossRef]

- Senthil, R.; Silambarasan, R. Influence of Injection Timing and Compression Ratio on Performance, Emission and Combustion Characteristics of Jatropha Methyl Ester Operated Di Diesel Engine. Iran. J. Sci. Technol. Trans. Mech. Eng. 2015, 39, 61–76. [Google Scholar]

- Agarwal, A.K. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog. Energ. Combust. 2007, 33, 233–271. [Google Scholar] [CrossRef]

- S Gavhane, R.; M Kate, A.; Pawar, A.; Safaei, M.R.; M Soudagar, M.E.; Mujtaba Abbas, M.; Muhammad Ali, H.; R Banapurmath, N.; Goodarzi, M.; Badruddin, I.A. Effect of zinc oxide nano-additives and soybean biodiesel at varying loads and compression ratios on VCR diesel engine characteristics. Symmetry 2020, 12, 1042. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Rodriguez-Fernandez, J. Effect of biodiesel fuels on diesel engine emissions. Prog. Energ. Combust. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Khan, H.; Soudagar, M.E.M.; Kumar, R.H.; Safaei, M.R.; Farooq, M.; Khidmatgar, A.; Banapurmath, N.R.; Farade, R.A.; Abbas, M.M.; Afzal, A. Effect of nano-graphene oxide and n-butanol fuel additives blended with diesel—Nigella sativa biodiesel fuel emulsion on diesel engine characteristics. Symmetry 2020, 12, 961. [Google Scholar] [CrossRef]

- Mosarof, M.H.; Kalam, M.A.; Masjuki, H.H.; Alabdulkarem, A.; Ashraful, A.M.; Arslan, A.; Rashedul, H.K.; Monirul, I.M. Optimization of performance, emission, friction and wear characteristics of palm and Calophyllum inophyllum biodiesel blends. Energy Convers. Manag. 2016, 118, 119–134. [Google Scholar] [CrossRef]

- Liaquat, A.; Masjuki, H.; Kalam, M.; Fazal, M.; Khan, A.F.; Fayaz, H.; Varman, M. Impact of palm biodiesel blend on injector deposit formation. Appl. Energy 2013, 111, 882–893. [Google Scholar] [CrossRef]

- Ozsezen, A.N.; Canakci, M. Determination of performance and combustion characteristics of a diesel engine fueled with canola and waste palm oil methyl esters. Energy Convers. Manag. 2011, 52, 108–116. [Google Scholar] [CrossRef]

- Sharon, H.; Karuppasamy, K.; Kumar, D.S.; Sundaresan, A. A test on DI diesel engine fueled with methyl esters of used palm oil. Renew. Energy 2012, 47, 160–166. [Google Scholar] [CrossRef]

- Ong, H.C.; Masjuki, H.; Mahlia, T.; Silitonga, A.; Chong, W.; Leong, K. Optimization of biodiesel production and engine performance from high free fatty acid Calophyllum inophyllum oil in CI diesel engine. Energy Convers. Manag. 2014, 81, 30–40. [Google Scholar] [CrossRef]

- Shehata, M.S.; Razek, S.M.A. Experimental investigation of diesel engine performance and emission characteristics using jojoba/diesel blend and sunflower oil. Fuel 2011, 90, 886–897. [Google Scholar] [CrossRef]

- Roy, M.M.; Wang, W.; Bujold, J. Biodiesel production and comparison of emissions of a DI diesel engine fueled by biodiesel–diesel and canola oil—Diesel blends at high idling operations. Appl. Energy 2013, 106, 198–208. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Dhar, A. Experimental investigations of performance, emission and combustion characteristics of Karanja oil blends fuelled DICI engine. Renew. Energy 2013, 52, 283–291. [Google Scholar] [CrossRef]

- Atabani, A.E.; Silitonga, A.S.; Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H.; Badruddin, I.A.; Fayaz, H. Non-edible vegetable oils: A critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production. Renew. Sust. Energ. Rev. 2013, 18, 211–245. [Google Scholar] [CrossRef]

- Azam, M.M.; Waris, A.; Nahar, N.M. Prospects and potential of fatty acid methyl esters of some non-traditional seed oils for use as biodiesel in India. Biomass Bioenerg. 2005, 29, 293–302. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Rasul, M.G.; Atabani, A.E.; Hazrat, M.A.; Mahmudul, H.M. Effect of Biodiesel-Diesel Blending on Physico-Chemical Properties of Biodiesel produced from Moringa oleifera. Procedia Eng. 2015, 105, 665–669. [Google Scholar] [CrossRef]

- Rajaraman, S.; Yashwanth, G.K.; Rajan, T.; Kumaran, R.S.; Raghu, P. Experimental Investigations of Performance and Emission Characteristics of Moringa Oil Methyl Ester and Its Diesel Blends in a Single Cylinder Direct Injection Diesel Engine. In ASME International Mechanical Engineering Congress and Exposition; ASME: Lake Buena Vista, FL, USA, 2010; Volume 3, pp. 27–34. [Google Scholar]

- Aleme, H.G.; Barbeira, P.J. Determination of flash point and cetane index in diesel using distillation curves and multivariate calibration. Fuel 2012, 102, 129–134. [Google Scholar] [CrossRef] [Green Version]

- Sakthivel, G. Prediction of CI engine performance, emission and combustion characteristics using fish oil as a biodiesel at different injection timing using fuzzy logic. Fuel 2016, 183, 214–229. [Google Scholar] [CrossRef]

- Dhamodaran, G.; Krishnan, R.; Pochareddy, Y.K.; Pyarelal, H.M.; Sivasubramanian, H.; Ganeshram, A.K. A comparative study of combustion, emission, and performance characteristics of rice-bran-, neem-, and cottonseed-oil biodiesels with varying degree of unsaturation. Fuel 2017, 187, 296–305. [Google Scholar] [CrossRef]

- Razzaq, L.; Farooq, M.; Mujtaba, M.; Sher, F.; Farhan, M.; Hassan, M.T.; Soudagar, M.E.M.; Atabani, A.; Kalam, M.; Imran, M. Modeling viscosity and density of ethanol-diesel-biodiesel ternary blends for sustainable environment. Sustainability 2020, 12, 5186. [Google Scholar] [CrossRef]

- Nikkhah, V.; Sarafraz, M.; Hormozi, F.; Peyghambarzadeh, S. Particulate fouling of CuO–water nanofluid at isothermal diffusive condition inside the conventional heat exchanger-experimental and modeling. Exp. Therm. Fluid Sci. 2015, 60, 83–95. [Google Scholar] [CrossRef]

- Sarafraz, M.; Hormozi, F.; Peyghambarzadeh, S. Pool boiling heat transfer to aqueous alumina nano-fluids on the plain and concentric circular micro-structured (CCM) surfaces. Exp. Therm. Fluid Sci. 2016, 72, 125–139. [Google Scholar] [CrossRef]

- Salari, E.; Peyghambarzadeh, S.; Sarafraz, M.; Hormozi, F.; Nikkhah, V. Thermal behavior of aqueous iron oxide nano-fluid as a coolant on a flat disc heater under the pool boiling condition. Heat Mass Transf. 2017, 53, 265–275. [Google Scholar] [CrossRef]

- Mujtaba, M.; Kalam, M.; Masjuki, H.; Gul, M.; Soudagar, M.E.M.; Ong, H.C.; Ahmed, W.; Atabani, A.; Razzaq, L.; Yusoff, M. Comparative study of nanoparticles and alcoholic fuel additives-biodiesel-diesel blend for performance and emission improvements. Fuel 2020, 279, 118434. [Google Scholar] [CrossRef]

- Habibullah, M.; Fattah, I.M.R.; Masjuki, H.H.; Kalam, M.A. Effects of Palm-Coconut Biodiesel Blends on the Performance and Emission of a Single-Cylinder Diesel Engine. Energy Fuel 2015, 29, 734–743. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Christo, F. Sustainable three-stage chemical looping ammonia production (3CLAP) process. Energy Convers. Manag. 2021, 229, 113735. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Hsu, K.-H.; Chen, C.-B. Experimental investigation of the performance and emissions of a heavy-duty diesel engine fueled with waste cooking oil biodiesel/ultra-low sulfur diesel blends. Energy 2011, 36, 241–248. [Google Scholar] [CrossRef]

- Murillo, S.; Miguez, J.; Porteiro, J.; Granada, E.; Moran, J. Performance and exhaust emissions in the use of biodiesel in outboard diesel engines. Fuel 2007, 86, 1765–1771. [Google Scholar] [CrossRef]

- Nabi, M.N.; Rahman, M.M.; Akhter, M.S. Biodiesel from cotton seed oil and its effect on engine performance and exhaust emissions. Appl. Therm. Eng. 2009, 29, 2265–2270. [Google Scholar] [CrossRef]

- Gürü, M.; Artukoğlu, B.D.; Keskin, A.; Koca, A. Biodiesel production from waste animal fat and improvement of its characteristics by synthesized nickel and magnesium additive. Energy Convers. Manag. 2009, 50, 498–502. [Google Scholar] [CrossRef]

- Hussain, F.; Soudagar, M.E.M.; Afzal, A.; Mujtaba, M.; Fattah, I.; Naik, B.; Mulla, M.H.; Badruddin, I.A.; Khan, T.; Raju, V.D. Enhancement in Combustion, Performance, and Emission Characteristics of a Diesel Engine Fueled with Ce-ZnO Nanoparticle Additive Added to Soybean Biodiesel Blends. Energies 2020, 13, 4578. [Google Scholar] [CrossRef]

- Teoh, Y.H.; How, H.G.; Masjuki, H.H.; Nguyen, H.T.; Kalam, M.A.; Alabdulkarem, A. Investigation on particulate emissions and combustion characteristics of a common-rail diesel engine fueled with Moringa oleifera biodiesel-diesel blends. Renew. Energy 2019, 136, 521–534. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Arbab, M.I.; Cheng, S.F.; Gouk, S.W. Properties and use of Moringa oleifera biodiesel and diesel fuel blends in a multi-cylinder diesel engine. Energy Convers. Manag. 2014, 82, 169–176. [Google Scholar] [CrossRef]

- Sateesh, K.A.; Yaliwal, V.S.; Soudagar, M.E.M.; Banapurmath, N.R.; Fayaz, H.; Safaei, M.R.; Elfasakhany, A.; El-Seesy, A.I. Utilization of biodiesel/Al2O3 nanoparticles for combustion behavior enhancement of a diesel engine operated on dual fuel mode. J. Therm. Anal. Calorim. 2021, 1–15. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Fattah, I.M.R.; Mobarak, H.M. Comparative evaluation of performance and emission characteristics of Moringa oleifera and Palm oil based biodiesel in a diesel engine. Ind. Crop Prod. 2014, 53, 78–84. [Google Scholar] [CrossRef]

- Rashed, M.M.; Kalam, M.A.; Masjuki, H.H.; Mofijur, M.; Rasul, M.G.; Zulkifli, N.W.M. Performance and emission characteristics of a diesel engine fueled with palm, jatropha, and moringa oil methyl ester. Ind. Crop Prod. 2016, 79, 70–76. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Mujtaba, M.; Safaei, M.R.; Afzal, A.; Ahmed, W.; Banapurmath, N.; Hossain, N.; Bashir, S.; Badruddin, I.A.; Goodarzi, M. Effect of Sr@ ZnO nanoparticles and Ricinus communis biodiesel-diesel fuel blends on modified CRDI diesel engine characteristics. Energy 2021, 215, 119094. [Google Scholar] [CrossRef]

- Nalgundwar, A.; Paul, B.; Sharma, S.K. Comparison of performance and emissions characteristics of DI CI engine fueled with dual biodiesel blends of palm and jatropha. Fuel 2016, 173, 172–179. [Google Scholar] [CrossRef]

- Sarafraz, M.; Hormozi, F.; Peyghambarzadeh, S. Role of nanofluid fouling on thermal performance of a thermosyphon: Are nanofluids reliable working fluid? Appl. Therm. Eng. 2015, 82, 212–224. [Google Scholar] [CrossRef]

- Srithar, K.; Balasubramanian, K.A.; Pavendan, V.; Kumar, B.A. Experimental investigations on mixing of two biodiesels blended with diesel as alternative fuel for diesel engines. J. King Saud Univ. Eng. Sci. 2014, 29, 50–56. [Google Scholar] [CrossRef]

- Harari, P.; Banapurmath, N.; Yaliwal, V.; Soudagar, M.E.M.; Khan, T.Y.; Mujtaba, M.; Safaei, M.R.; Akram, N.; Goodarzi, M.; Elfasakhany, A. Experimental investigation on compression ignition engine powered with pentanol and thevetia peruviana methyl ester under reactivity controlled compression ignition mode of operation. Case Stud. Therm. Eng. 2021, 25, 100921. [Google Scholar] [CrossRef]

- Fayaz, H.; Mujtaba, M.; Soudagar, M.E.M.; Razzaq, L.; Nawaz, S.; Nawaz, M.A.; Farooq, M.; Afzal, A.; Ahmed, W.; Khan, T.Y. Collective effect of ternary nano fuel blends on the diesel engine performance and emissions characteristics. Fuel 2021, 293, 120420. [Google Scholar] [CrossRef]

- Mohammed, E.-K.; Nemit-allah, M.A. Experimental investigations of ignition delay period and performance of a diesel engine operated with Jatropha oil biodiesel. Alex. Eng. J. 2013, 52, 141–149. [Google Scholar]

- Rahman, M.M.; Hassan, M.H.; Kalam, M.A.; Atabani, A.E.; Memon, L.A.; Rahman, S.M.A. Performance and emission analysis of Jatropha curcas and Moringa oleifera methyl ester fuel blends in a multi-cylinder diesel engine. J. Clean. Prod. 2014, 65, 304–310. [Google Scholar] [CrossRef]

- Abedin, M.J.; Masjuki, H.H.; Kalam, M.A.; Sanjid, A.; Rahman, S.M.A.; Fattah, I.M.R. Performance, emissions, and heat losses of palm and jatropha biodiesel blends in a diesel engine. Ind. Crop Prod. 2014, 59, 96–104. [Google Scholar] [CrossRef]

- Yadav, A.K.; Khan, M.E.; Dubey, A.M.; Pal, A. Performance and emission characteristics of a transportation diesel engine operated with non-edible vegetable oils biodiesel. Case Stud. Therm. Eng. 2016, 8, 236–244. [Google Scholar] [CrossRef] [Green Version]

- Gumus, M.; Kasifoglu, S. Performance and emission evaluation of a compression ignition engine using a biodiesel (apricot seed kernel oil methyl ester) and its blends with diesel fuel. Biomass Bioenergy 2010, 34, 134–139. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, G.; Li, L.; Wu, Z.; Hu, Z.; Deng, J. Characteristics of Combustion and Emissions in A DI Engine Fueled with Biodiesel Blends from Soybean Oil; SAE Technical Paper; SAE: Warrendale, PA, USA, 2008; pp. 0148–7191. [Google Scholar]

- Mujtaba, M.A.; Kalam, M.A.; Masjuki, H.H.; Razzaq, L.; Khan, H.M.; Soudagar, M.E.M.; Gul, M.; Ahmed, W.; Raju, V.D.; Kumar, R.; et al. Development of empirical correlations for density and viscosity estimation of ternary biodiesel blends. Renew. Energy 2021. [Google Scholar] [CrossRef]

| Parameters | Specifications |

|---|---|

| Injector | Split type |

| Injection volume | 1 μL |

| Oven temperature | 210 °C, isothermal |

| Split flow | 100 mL/min |

| Carrier gas | Helium, 83 kPa |

| Column | 60 °C for the initial time |

| Column 2 flow | The constant flow of helium at 1 L/min |

| Temperature | Rise from 60 °C to 200 °C at an interval of 10 °C |

| Detector | 250 °C, flame ionization detector with electronic flow control |

| Fatty Acids | Chemical Structure | Molecular Mass (g/mol) | Composition of MOME (w/w %) |

|---|---|---|---|

| Laurate | C12:0 | 214.34 | |

| Myristate | C14:0 | 242.4 | 0.1 |

| Palmitate | C16:0 | 270.45 | 8.1 |

| Palmitoleate | C16:1 | 268.43 | 1.6 |

| Stearate | C18:0 | 298.5 | 5.4 |

| Oleate | C18:1 | 296.49 | 74.3 |

| Linoleate | C18:2 | 294.47 | 4.1 |

| Linolenate | C18:3 | 292.46 | 0.2 |

| Arachidate | C20:0 | 326.56 | 2.3 |

| Eicosenoate | C20:1 | 324.24 | 1.5 |

| Behenate | C22:0 | 354.61 | 2.6 |

| Saturated | 18.7 | ||

| Monounsaturated | 76.9 | ||

| Polyunsaturated | 4.4 |

| Property | Unit | ASTM Standards | Diesel | MOB10 | MOB20 | MOB100 |

|---|---|---|---|---|---|---|

| Density at 15 °C | kg/m3 | D4052 | 856.9 | 860.1 | 861.7 | 877.6 |

| Density at 40 °C | kg/m3 | D4052 | 828.4 | 831.2 | 834.6 | 860.7 |

| Kinematic viscosity at 40 °C | mm2/s | D445 | 3.2525 | 3.5572 | 3.6772 | 4.8338 |

| Viscosity index | – | – | 91 | 101.5 | 112.1 | 185.2 |

| Oxidation stability | h | EN ISO 14112 | 35 | 33.5 | 32.7 | 26.4 |

| Cetane index | – | D4737 | 48.9 | 48.3 | 49.6 | 58.5 |

| Flashpoint | °C | D93 | 68.7 | 80.1 | 82.9 | 151.2 |

| Cloud point | °C | D2500 | 8 | 7 | 8 | 18 |

| Pour point | °C | D97 | 0 | 3 | 6 | 18 |

| Cold filter plugging point | °C | D6371 | 5 | 6 | 6 | 18 |

| Calorific value | MJ/kg | D240 | 45.86 | 44.18 | 43.61 | 39.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soudagar, M.E.M.; Khan, H.M.; Khan, T.M.Y.; Razzaq, L.; Asif, T.; Mujtaba, M.A.; Hussain, A.; Farooq, M.; Ahmed, W.; Shahapurkar, K.; et al. Experimental Analysis of Engine Performance and Exhaust Pollutant on a Single-Cylinder Diesel Engine Operated Using Moringa Oleifera Biodiesel. Appl. Sci. 2021, 11, 7071. https://doi.org/10.3390/app11157071

Soudagar MEM, Khan HM, Khan TMY, Razzaq L, Asif T, Mujtaba MA, Hussain A, Farooq M, Ahmed W, Shahapurkar K, et al. Experimental Analysis of Engine Performance and Exhaust Pollutant on a Single-Cylinder Diesel Engine Operated Using Moringa Oleifera Biodiesel. Applied Sciences. 2021; 11(15):7071. https://doi.org/10.3390/app11157071

Chicago/Turabian StyleSoudagar, Manzoore Elahi M., Haris Mahmood Khan, T. M. Yunus Khan, Luqman Razzaq, Tahir Asif, M. A. Mujtaba, Abrar Hussain, Muhammad Farooq, Waqar Ahmed, Kiran Shahapurkar, and et al. 2021. "Experimental Analysis of Engine Performance and Exhaust Pollutant on a Single-Cylinder Diesel Engine Operated Using Moringa Oleifera Biodiesel" Applied Sciences 11, no. 15: 7071. https://doi.org/10.3390/app11157071

APA StyleSoudagar, M. E. M., Khan, H. M., Khan, T. M. Y., Razzaq, L., Asif, T., Mujtaba, M. A., Hussain, A., Farooq, M., Ahmed, W., Shahapurkar, K., Alwi, A., Ibrahim, T. M., Ishtiaq, U., Elfasakhany, A., Ali Baig, M. A., Goodarzi, M. S., & Safaei, M. R. (2021). Experimental Analysis of Engine Performance and Exhaust Pollutant on a Single-Cylinder Diesel Engine Operated Using Moringa Oleifera Biodiesel. Applied Sciences, 11(15), 7071. https://doi.org/10.3390/app11157071