Proposed Models to Improve Predicting the Operating Temperature of Different Photovoltaic Module Technologies under Various Climatic Conditions

Abstract

:1. Introduction

2. Materials and Methods

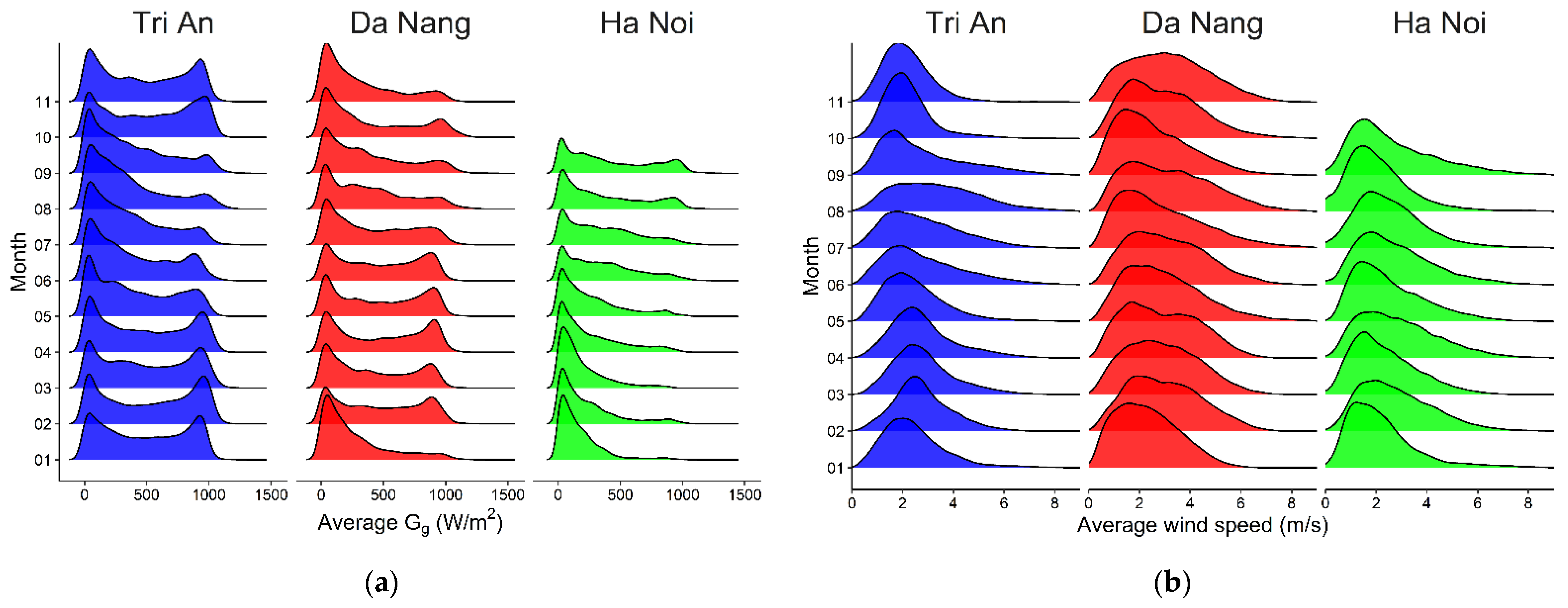

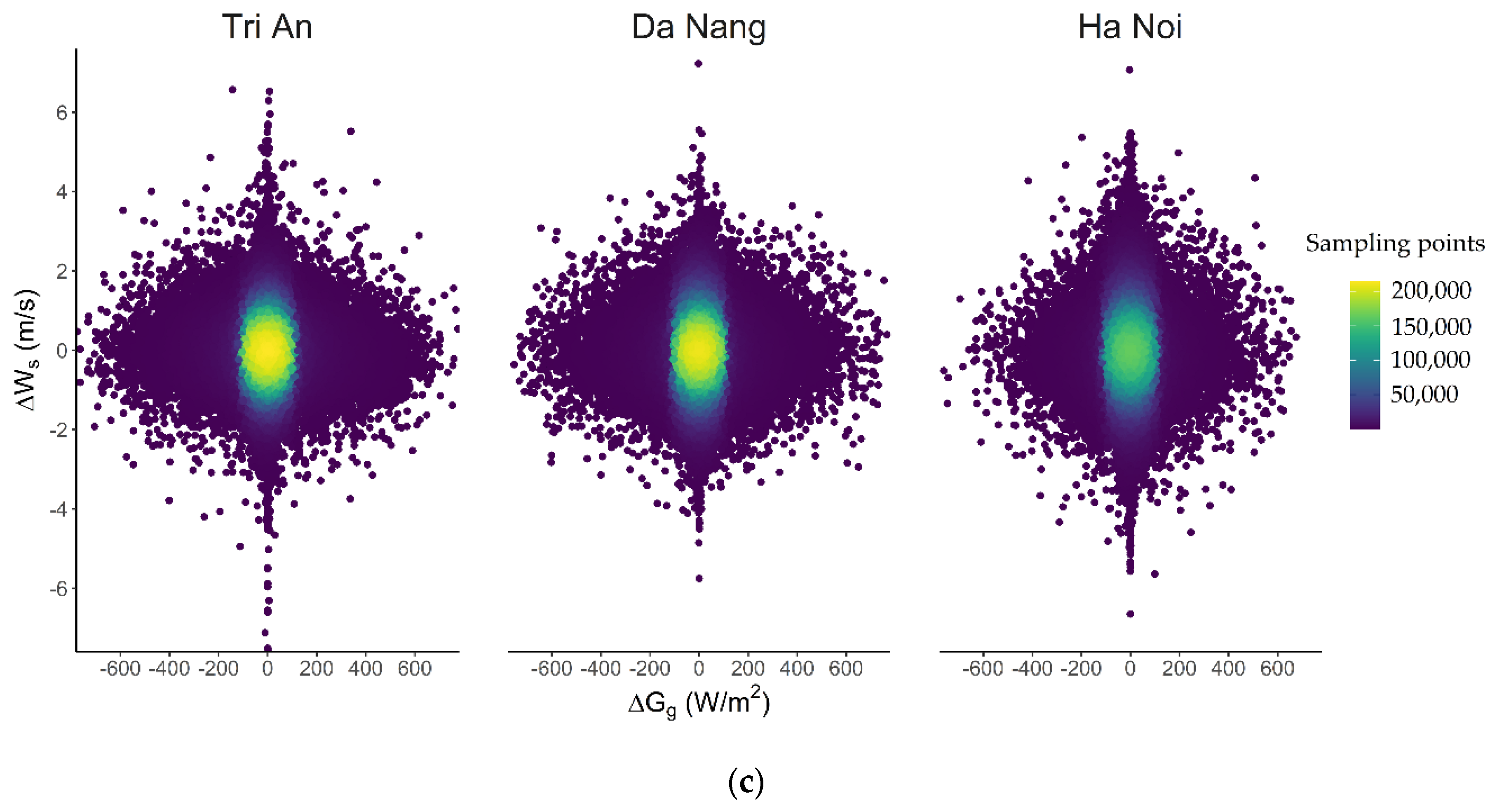

2.1. Data

2.2. Previous Models

2.3. Selected Metrics for Evaluating the Methods

- The correlation coefficient R2 defines the relationship between the estimated and measured data as the following expression:

- The root mean square error, used to evaluate the fluctuations around the model and defined by the expression:

2.4. Proposed Models

2.4.1. Model with Wind

2.4.2. Model without Wind

3. Results and Discussion

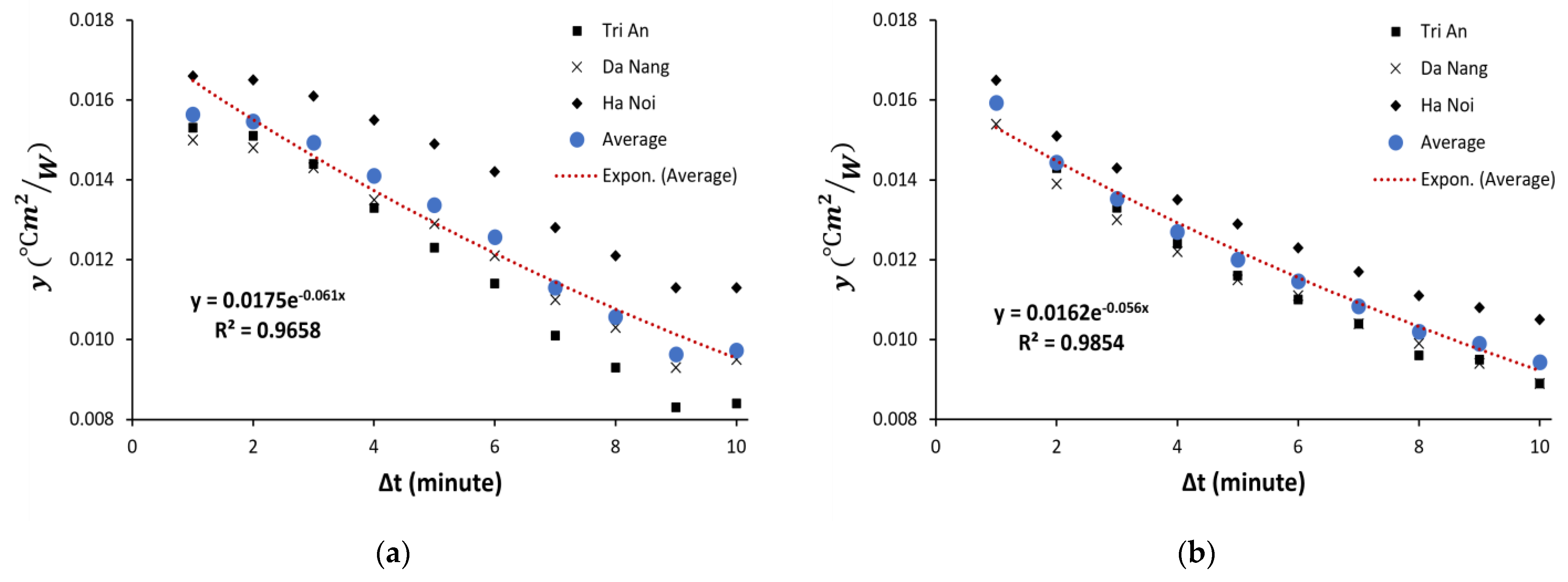

3.1. Parametric Identification

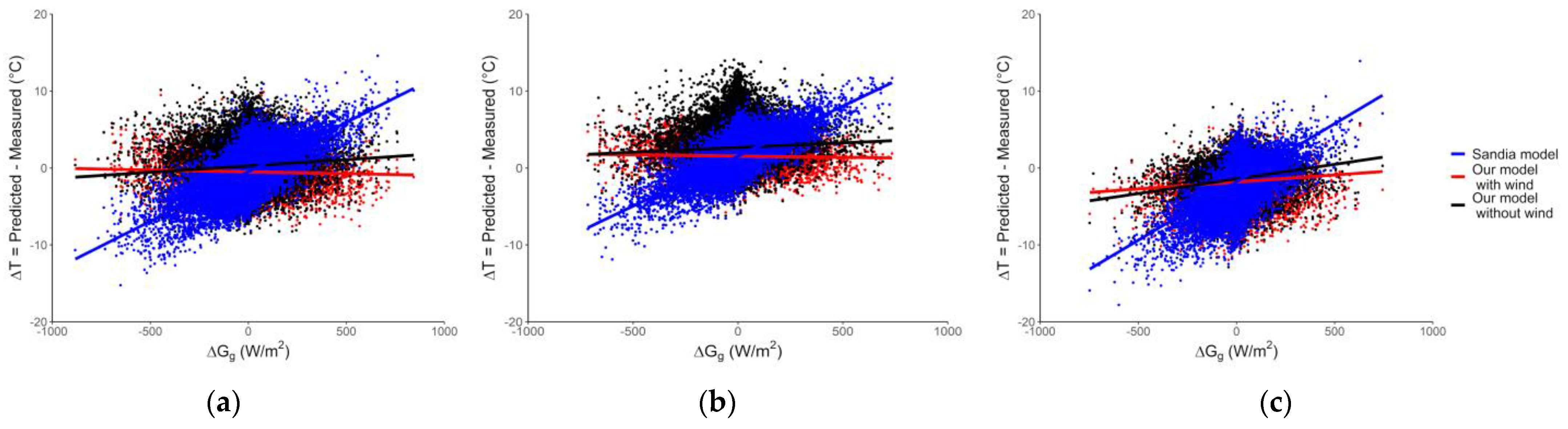

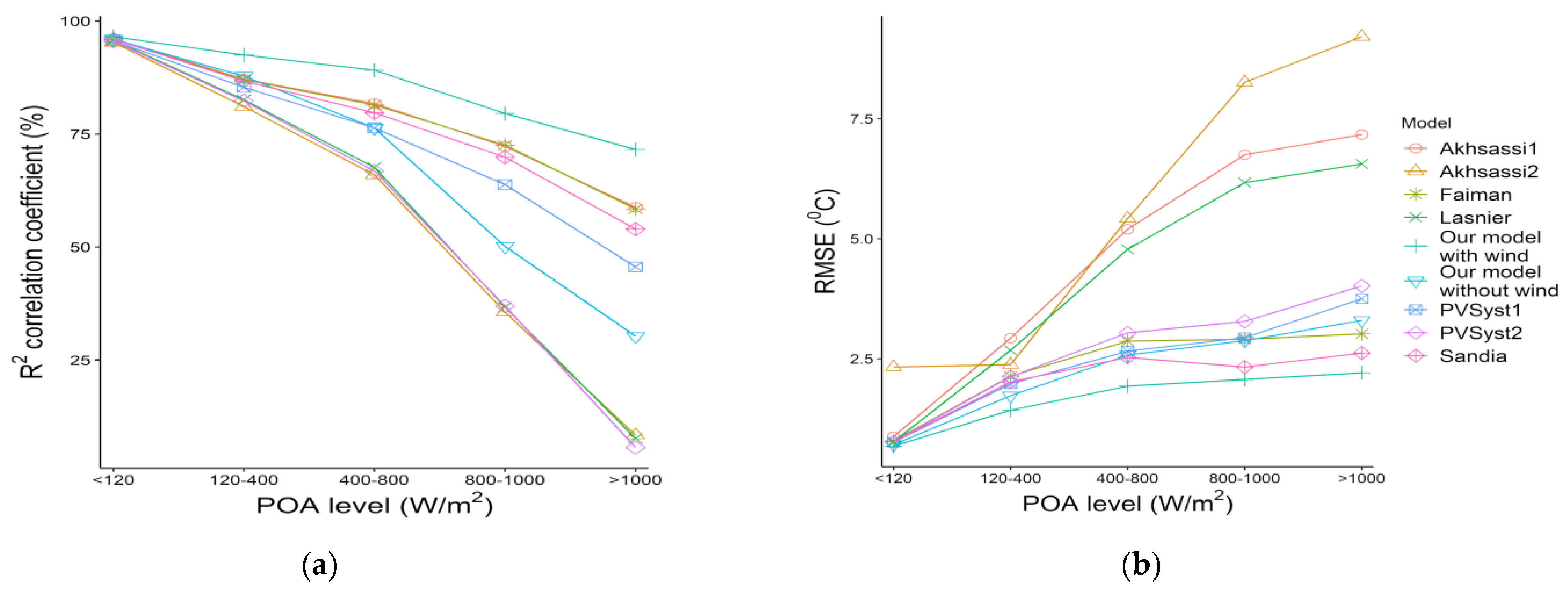

3.2. Models Comparison

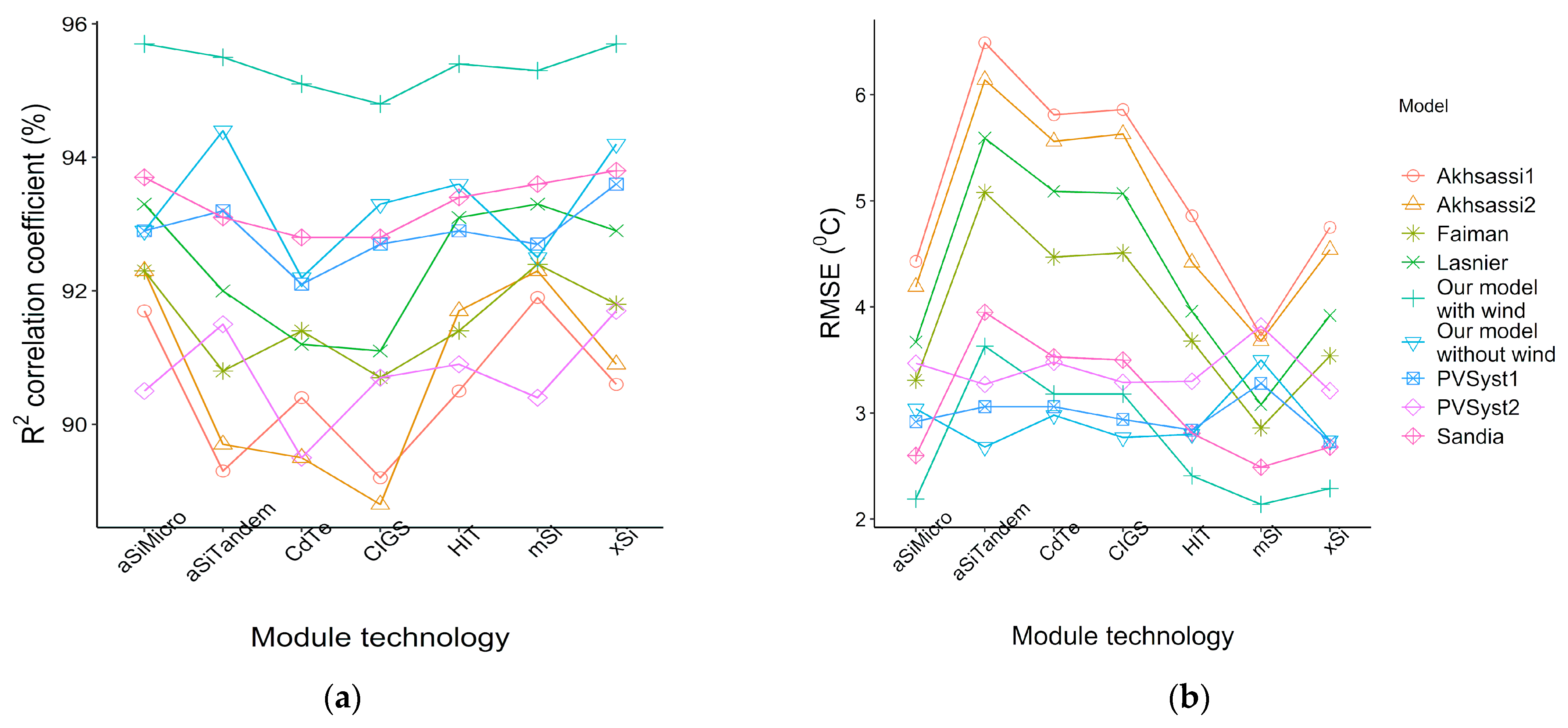

3.3. Comparison between Different PV Technologies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data availability Statement

Conflicts of Interest

Nomenclature

| Module temperature (°C) | |

| Cell temperature (°C) | |

| Ambient temperature (°C) | |

| Reference temperature of 25 °C | |

| Module efficiency coefficient (%) | |

| Module temperature coefficient (%/°C) | |

| Plane Of Array irradiance (POA) (W/m2) | |

| Reference solar irradiance of 1000 W/m2 | |

| Wind speed (m/s) | |

| The constant heat transfer component (W/m2K) | |

| The convective heat transfer component (W/m3sK) | |

| Dimensionless coefficient between 0.03 and 0.12 |

Appendix A

| Location | Model | R2 (%) | RMSE (°C) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Time Step (Minutes) | |||||||||

| 1 | 5 | 10 | 15 | 1 | 5 | 10 | 15 | ||

| Tri An | Sandia * | 94.3 | 96.1 | 97.0 | 97.5 | 2.45 | 2.06 | 1.84 | 1.72 |

| Faiman * | 94.4 | 96.5 | 97.5 | 98.0 | 2.69 | 2.35 | 2.17 | 2.09 | |

| PVSyst1 * | 93.6 | 95.4 | 96.3 | 96.7 | 2.69 | 2.27 | 2.03 | 1.90 | |

| Akhsassi1 * | 94.5 | 96.5 | 97.4 | 97.8 | 4.55 | 4.46 | 4.42 | 4.41 | |

| Our model with wind * | 95.6 | 97.8 | 98.1 | 98.1 | 2.18 | 1.63 | 1.56 | 1.55 | |

| Lasnier | 92.5 | 93.8 | 94.4 | 94.7 | 4.19 | 4.08 | 4.03 | 4.01 | |

| PVSyst2 | 92.0 | 93.7 | 94.6 | 95.0 | 2.88 | 2.53 | 2.33 | 2.22 | |

| Akhsassi2 | 91.4 | 92.5 | 93.0 | 93.2 | 5.12 | 5.08 | 5.06 | 5.05 | |

| Our model without wind | 93.3 | 95.5 | 95.7 | 95.7 | 2.63 | 2.15 | 2.09 | 2.07 | |

| Da Nang | Sandia * | 95.9 | 97.3 | 97.9 | 98.2 | 2.52 | 2.22 | 2.09 | 2.01 |

| Faiman * | 95.2 | 96.9 | 97.6 | 98.0 | 2.20 | 1.82 | 1.64 | 1.55 | |

| PVSyst1 * | 95.4 | 96.7 | 97.3 | 97.6 | 3.63 | 3.41 | 3.31 | 3.26 | |

| Akhsassi1 * | 95.1 | 96.6 | 97.2 | 97.5 | 2.75 | 2.61 | 2.55 | 2.52 | |

| Our model with wind * | 96.7 | 98.5 | 98.7 | 98.8 | 2.35 | 1.95 | 1.88 | 1.87 | |

| Lasnier | 94.6 | 95.4 | 95.8 | 96.0 | 2.21 | 2.05 | 1.96 | 1.92 | |

| PVSyst2 | 94.1 | 95.3 | 95.8 | 96.1 | 3.82 | 3.63 | 3.54 | 3.50 | |

| Akhsassi2 | 93.6 | 94.2 | 94.5 | 94.6 | 3.21 | 3.14 | 3.10 | 3.07 | |

| Our model without wind | 95.0 | 96.4 | 96.5 | 96.5 | 3.72 | 3.49 | 3.46 | 3.46 | |

| Ha Noi | Sandia * | 96.3 | 97.2 | 97.7 | 97.9 | 3.06 | 2.89 | 2.80 | 2.75 |

| Faiman * | 95.8 | 96.9 | 97.5 | 97.8 | 3.39 | 3.24 | 3.16 | 3.13 | |

| PVSyst1 * | 96.2 | 97.1 | 97.7 | 98.0 | 2.60 | 2.36 | 2.22 | 2.14 | |

| Akhsassi1 * | 94.9 | 95.8 | 96.3 | 96.5 | 4.91 | 4.89 | 4.87 | 4.87 | |

| Our model with wind * | 96.9 | 98.2 | 98.4 | 98.5 | 2.94 | 2.66 | 2.63 | 2.63 | |

| Lasnier | 93.7 | 94.2 | 94.5 | 94.7 | 4.84 | 4.80 | 4.78 | 4.77 | |

| PVSyst2 | 95.6 | 96.5 | 97.0 | 97.2 | 2.94 | 2.77 | 2.66 | 2.60 | |

| Akhsassi2 | 91.4 | 91.7 | 91.9 | 92.1 | 5.14 | 5.12 | 5.11 | 5.11 | |

| Our model without wind | 96.3 | 97.5 | 97.7 | 97.8 | 2.79 | 2.49 | 2.45 | 2.45 | |

| Coefficient | Location | Module | Model | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| With Wind | Without Wind | ||||||||||

| Sandia | Faiman | PVSyst1 | Akhsassi1 | Our Model with Wind | Lasnier | PVSyst2 | Akhsassi2 | Our Model without Wind | |||

| R2 (%) | Cocoa | xSi | 93.8 | 91.8 | 93.6 | 90.6 | 95.7 | 92.9 | 91.7 | 90.9 | 94.2 |

| mSi | 93.6 | 92.4 | 92.7 | 91.9 | 95.3 | 93.3 | 90.4 | 92.3 | 92.5 | ||

| CdTe | 92.8 | 91.4 | 92.1 | 90.4 | 95.1 | 91.2 | 89.5 | 89.5 | 92.2 | ||

| CIGS | 92.8 | 90.7 | 92.7 | 89.2 | 94.8 | 91.1 | 90.7 | 88.8 | 93.3 | ||

| HIT | 93.4 | 91.4 | 92.9 | 90.5 | 95.4 | 93.1 | 90.9 | 91.7 | 93.6 | ||

| aSiMicro | 93.7 | 92.3 | 92.9 | 91.7 | 95.7 | 93.3 | 90.5 | 92.3 | 92.9 | ||

| aSiTandem | 93.1 | 90.8 | 93.2 | 89.3 | 95.5 | 92.0 | 91.5 | 89.7 | 94.4 | ||

| Golden | xSi | 96.1 | 95.2 | 96.2 | 93.6 | 96.8 | 91.4 | 95.1 | 87.5 | 95.8 | |

| mSi | 95.9 | 94.5 | 96.3 | 92.8 | 96.8 | 91.7 | 95.6 | 87.7 | 96.5 | ||

| CdTe | 95.4 | 94.5 | 95.6 | 92.8 | 96.5 | 90.9 | 94.7 | 87.1 | 95.7 | ||

| CIGS | 95.0 | 94.5 | 94.8 | 93.1 | 96.1 | 90.3 | 93.4 | 86.8 | 94.4 | ||

| HIT | 94.8 | 93.5 | 95.2 | 91.9 | 96.0 | 91.2 | 94.7 | 87.4 | 95.9 | ||

| aSiMicro | 95.0 | 93.7 | 95.4 | 92.0 | 96.1 | 91.0 | 94.9 | 87.1 | 95.9 | ||

| aSiTandem | 94.7 | 93.3 | 95.2 | 91.5 | 95.9 | 90.2 | 94.6 | 86.2 | 95.8 | ||

| Eugene | xSi | 96.5 | 96.5 | 96.3 | 96.3 | 97.3 | 93.6 | 96.0 | 90.5 | 96.7 | |

| mSi | 96.8 | 96.6 | 96.5 | 96.8 | 97.6 | 95.5 | 96.5 | 93.0 | 97.3 | ||

| CdTe | 95.9 | 95.8 | 95.6 | 95.8 | 96.8 | 93.6 | 95.4 | 90.8 | 96.3 | ||

| CIGS | 95.5 | 95.5 | 95.2 | 95.4 | 96.4 | 92.9 | 95.0 | 90.1 | 95.8 | ||

| HIT | 96.4 | 96.4 | 96.0 | 96.7 | 97.3 | 95.2 | 96.0 | 93.0 | 96.8 | ||

| aSiMicro | 96.2 | 96.1 | 95.8 | 96.2 | 97.0 | 94.4 | 95.7 | 91.8 | 96.5 | ||

| aSiTandem | 96.0 | 96.1 | 95.8 | 95.9 | 97.0 | 93.4 | 95.5 | 90.4 | 96.5 | ||

| RMSE (°C) | Cocoa | xSi | 2.68 | 3.54 | 2.73 | 4.75 | 2.29 | 3.92 | 3.21 | 4.54 | 2.74 |

| mSi | 2.49 | 2.86 | 3.28 | 3.73 | 2.14 | 3.08 | 3.82 | 3.68 | 3.50 | ||

| CdTe | 3.53 | 4.47 | 3.06 | 5.81 | 3.18 | 5.09 | 3.48 | 5.56 | 2.98 | ||

| CIGS | 3.50 | 4.51 | 2.94 | 5.86 | 3.18 | 5.07 | 3.29 | 5.63 | 2.77 | ||

| HIT | 2.81 | 3.68 | 2.84 | 4.86 | 2.41 | 3.96 | 3.30 | 4.42 | 2.80 | ||

| aSiMicro | 2.60 | 3.31 | 2.92 | 4.43 | 2.19 | 3.67 | 3.47 | 4.19 | 3.04 | ||

| aSiTandem | 3.95 | 5.08 | 3.06 | 6.49 | 3.63 | 5.59 | 3.27 | 6.14 | 2.68 | ||

| Golden | xSi | 3.10 | 3.49 | 3.40 | 4.64 | 2.89 | 5.39 | 3.58 | 6.14 | 3.39 | |

| mSi | 3.23 | 3.99 | 2.94 | 5.43 | 2.95 | 6.14 | 3.12 | 6.70 | 2.80 | ||

| CdTe | 3.57 | 4.32 | 3.07 | 5.88 | 3.28 | 6.87 | 3.42 | 7.17 | 3.08 | ||

| CIGS | 3.33 | 3.63 | 3.63 | 4.77 | 3.01 | 5.69 | 3.90 | 6.25 | 3.63 | ||

| HIT | 3.81 | 4.55 | 3.44 | 5.92 | 3.49 | 6.48 | 3.57 | 7.07 | 3.21 | ||

| aSiMicro | 3.58 | 4.29 | 3.30 | 5.66 | 3.29 | 6.30 | 3.45 | 6.89 | 3.12 | ||

| aSiTandem | 3.67 | 4.37 | 3.37 | 5.74 | 3.32 | 6.42 | 3.53 | 6.99 | 3.15 | ||

| Eugene | xSi | 2.43 | 2.33 | 2.88 | 2.74 | 2.15 | 5.23 | 2.66 | 4.61 | 2.42 | |

| mSi | 2.42 | 2.35 | 3.07 | 2.32 | 2.17 | 4.57 | 2.61 | 3.92 | 2.40 | ||

| CdTe | 2.70 | 2.69 | 2.94 | 3.34 | 2.41 | 5.88 | 2.87 | 5.01 | 2.60 | ||

| CIGS | 2.73 | 2.68 | 3.09 | 3.13 | 2.47 | 5.59 | 2.94 | 4.84 | 2.70 | ||

| HIT | 2.65 | 2.51 | 3.30 | 2.40 | 2.40 | 4.78 | 2.88 | 3.79 | 2.67 | ||

| aSiMicro | 2.58 | 2.50 | 3.07 | 2.76 | 2.32 | 5.21 | 2.79 | 4.34 | 2.56 | ||

| aSiTandem | 2.77 | 2.80 | 2.84 | 3.66 | 2.48 | 6.32 | 2.94 | 5.46 | 2.66 | ||

References

- IEA. Solar PV. IEA: Paris, France. Available online: https://www.iea.org/reports/solar-pv (accessed on 24 July 2021).

- Huld, T.; Gracia Amillo, A.M. Estimating PV module performance over large geographical regions: The role of irradiance, air temperature, wind speed and solar spectrum. Energies 2015, 8, 5159–5181. [Google Scholar] [CrossRef] [Green Version]

- Kratochvil, J.A.; Boyson, W.E.; King, D.L. Photovoltaic Array Performance Model; Albuquerque, N.M., Livermore, C.A., Eds.; MDPI: Basel, Switzerland, 2004; Volume 8. [Google Scholar]

- Cañete, C.; Carretero, J.; Sidrach-de-Cardona, M. Energy performance of different photovoltaic module technologies under outdoor conditions. Energy 2014, 65, 295–302. [Google Scholar] [CrossRef]

- Kurnik, J.; Jankovec, M.; Brecl, K.; Topic, M. Outdoor testing of PV module temperature and performance under different mounting and operational conditions. Sol. Energy Mater. Sol. Cells 2011, 95, 373–376. [Google Scholar] [CrossRef]

- Gaglia, A.G.; Lykoudis, S.; Argiriou, A.A.; Balaras, C.A.; Dialynas, E. Energy efficiency of PV panels under real outdoor conditions–An experimental assessment in Athens, Greece. Renew. Energy 2017, 101, 236–243. [Google Scholar] [CrossRef]

- Zsiborács, H.; Pintér, G.; Bai, A.; Popp, J.; Gabnai, Z.; Pályi, B.; Farkas, I.; Baranyai, N.H.; Gützer, C.; Trimmel, H.; et al. Comparison of thermal models for ground-mounted south-facing photovoltaic technologies: A practical case study. Energies 2018, 11, 1114. [Google Scholar] [CrossRef] [Green Version]

- Skoplaki, E.; Palyvos, J.A. Operating temperature of photovoltaic modules: A survey of pertinent correlations. Renew. Energy 2009, 34, 23–29. [Google Scholar] [CrossRef]

- Mora Segado, P.; Carretero, J.; Sidrach-de-Cardona, M. Models to predict the operating temperature of different photovoltaic modules in outdoor conditions. Prog. Photovolt. Res. Appl. 2015, 23, 1267–1282. [Google Scholar] [CrossRef]

- Mattei, M.; Notton, G.; Cristofari, C.; Muselli, M.; Poggi, P. Calculation of the polycrystalline PV module temperature using a simple method of energy balance. Renew. Energy 2006, 31, 553–567. [Google Scholar] [CrossRef]

- Akhsassi, M.; El Fathi, A.; Erraissi, N.; Aarich, N.; Bennouna, A.; Raoufi, M.; Outzourhit, A. Experimental investigation and modeling of the thermal behavior of a solar PV module. Sol. Energy Mater. Sol. Cells 2018, 180, 271–279. [Google Scholar] [CrossRef]

- Faiman, D. Assessing the outdoor operating temperature of photovoltaic modules. Prog. Photovolt. Res. Appl. 2008, 16, 307–315. [Google Scholar] [CrossRef]

- Koehl, M.; Heck, M.; Wiesmeier, S.; Wirth, J. Modeling of the nominal operating cell temperature based on outdoor weathering. Sol. Energy Mater. Sol. Cells 2011, 95, 1638–1646. [Google Scholar] [CrossRef]

- Soteris, A. Kalogirou Solar Energy Engineering: Processes and Systems; Elsevier Inc.: Amsterdam, The Netherlands, 2009; ISBN 9780123745019. [Google Scholar]

- PVsyst 7 Help, Array Thermal Losses. Available online: https://www.pvsyst.com/help/index.html (accessed on 18 March 2021).

- Skoplaki, E.; Boudouvis, A.G.; Palyvos, J.A. A simple correlation for the operating temperature of photovoltaic modules of arbitrary mounting. Sol. Energy Mater. Sol. Cells 2008, 92, 1393–1402. [Google Scholar] [CrossRef]

- Muller, M.; Marion, B.; Rodriguez, J. Evaluating the IEC 61215 Ed.3 NMOT procedure against the existing NOCT procedure with PV modules in a side-by-side configuration. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; pp. 697–702. [Google Scholar] [CrossRef]

- Zouine, M.; Akhsassi, M.; Erraissi, N.; Aarich, N.; Bennouna, A.; Raoufi, M.; Outzourhit, A. Mathematical models calculating PV module temperature using weather data: Experimental study. Lect. Notes Electr. Eng. 2019, 519, 630–639. [Google Scholar] [CrossRef]

- Schwingshackl, C.; Petitta, M.; Wagner, J.E.; Belluardo, G.; Moser, D.; Castelli, M.; Zebisch, M.; Tetzlaff, A. Wind effect on PV module temperature: Analysis of different techniques for an accurate estimation. Energy Procedia 2013, 40, 77–86. [Google Scholar] [CrossRef] [Green Version]

- Vietnam—Solar Radiation Measurement Data obtained from World Bank via ENERGYDATA.info. Available online: https://energydata.info/dataset/vietnam-solar-radiation-measurement-data (accessed on 11 April 2021).

- Polo, J.; Gastón, M.; Vindel, J.M.; Pagola, I. Spatial variability and clustering of global solar irradiation in Vietnam from sunshine duration measurements. Renew. Sustain. Energy Rev. 2015, 42, 1326–1334. [Google Scholar] [CrossRef]

- Marion, B.; Anderberg, A.; Deline, C.; Del Cueto, J.; Muller, M.; Perrin, G.; Rodriguez, J.; Rummel, S.; Silverman, T.J.; Vignola, F.; et al. New data set for validating PV module performance models. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference, Denver, CO, USA, 8–13 June 2014; pp. 1362–1366. [Google Scholar] [CrossRef]

- Lustbader, J.; Afshin, A. NREL Vehicle Testing and Integration Facility (VTIF): Rotating Shadowband Radiometer (RSR). Golden, Colorado (Data); NREL Report No. DA-5500-56490. Available online: https://midcdmz.nrel.gov/apps/sitehome.pl?site=VTIF (accessed on 26 April 2021).

- Global Modeling and Assimilation Office (GMAO). MERRA-2 tavg1_2d_slv_Nx: 2d,1-Hourly, Time-Averaged, Single-Level, Assimilation, Single-Level Diagnostics V5.12.4. Goddard Earth Sciences Data and Information Services Center (GES DISC): Greenbelt, MD, USA, 2015. Available online: https://goldsmr4.gesdisc.eosdis.nasa.gov/data/MERRA2/M2T1NXSLV.5.12.4/ (accessed on 27 January 2021).

- Evans, D.L. Simplified method for predicting photovoltaic array output. Sol. Energy 1981, 27, 555–560. [Google Scholar] [CrossRef]

- Armstrong, S.; Hurley, W.G. A thermal model for photovoltaic panels under varying atmospheric conditions. Appl. Therm. Eng. 2010, 30, 1488–1495. [Google Scholar] [CrossRef]

- Ross, R.G. Interface design considerations for terrestrial solar cell modules. In Proceedings of the 12th Photovoltaic Specialists Conference, Baton Rouge, LA, USA, 15–18 November 1976; pp. 801–806. [Google Scholar]

| Group | Location | Latitude (°N) | Interval Sampling (Minute) | Observed Period |

|---|---|---|---|---|

| 1 | Tri An 1 | 11.01 | 1 | 01/2018–11/2019 |

| Da Nang 1 | 16.01 | 1 | 01/2018–11/2019 | |

| Ha Noi 1 | 21.20 | 1 | 01/2018–09/2019 | |

| 2 | Cocoa 2 | 28.39 | 5 | 01/2011–03/2012 |

| Golden 2 | 39.74 | 15 | 08/2012–09/2013 | |

| Eugene 2 | 44.05 | 5 | 10/2012–01/2014 |

| Module Technology | Characteristics | Sampling Points | |||

|---|---|---|---|---|---|

| ηSTC (%) | Cocoa | Golden | Eugene | ||

| Single-crystalline silicon (xSi) 1 | 13.60 | −0.42 | 29,632 | 10,266 | 37,820 |

| Multi-crystalline silicon (mSi) 2 | 14.00 | −0.41 | 28,248 | 10,268 | 38,016 |

| Cadmium telluride (CdTe) 1 | 8.85 | −0.21 | 29,730 | 10,362 | 37,062 |

| Copper indium gallium selenide (CIGS) 1 | 11.2 | −0.39 | 29,714 | 10,405 | 37,815 |

| Amorphous silicon/crystalline silicon (HIT) 1 | 17.6 | −0.35 | 29,119 | 10,292 | 37,985 |

| Amorphous silicon/microcrystalline silicon (aSiMicro) 1 | 7.5 | −0.36 | 29,701 | 10,578 | 38,022 |

| Amorphous silicon tandem junction (aSiTandem) 1 | 4.47 | −0.25 | 29,853 | 10,413 | 37,970 |

| Groups | Correlations | Comments | Ref. | Equation |

|---|---|---|---|---|

| With wind | Sandia: | [3] | (2) | |

| Faiman: | [12,13] | (3) | ||

| PVSyst1: | [15] | (4) | ||

| Akhsassi1: | [11] | (5) | ||

| Without wind | Lasnier: | [14] | (6) | |

| PVSyst2: | | [15] | (7) | |

| Akhsassi2: | [11] | (8) |

| Time Step (Min.) | Location | Average | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tri An | Da Nang | Ha Noi | |||||||||

| R2 (%) | RMSE (°C) | R2 (%) | RMSE (°C) | R2 (%) | RMSE (°C) | SD | |||||

| 1 | 0.0153 | 91.4 | 2.81 | 0.0150 | 93.6 | 2.73 | 0.0166 | 93.7 | 3.83 | 0.0156 | 0.00085 |

| 2 | 0.0151 | 93.5 | 2.57 | 0.0148 | 95.2 | 2.51 | 0.0165 | 95.1 | 3.66 | 0.0155 | 0.00091 |

| 3 | 0.0144 | 94.6 | 2.43 | 0.0143 | 96.2 | 2.37 | 0.0161 | 95.9 | 3.56 | 0.0149 | 0.00101 |

| 4 | 0.0133 | 95.2 | 2.35 | 0.0135 | 96.7 | 2.29 | 0.0155 | 96.4 | 3.50 | 0.0141 | 0.00122 |

| 5 | 0.0123 | 95.5 | 2.32 | 0.0129 | 96.7 | 2.24 | 0.0149 | 96.7 | 3.46 | 0.0134 | 0.00136 |

| 6 | 0.0114 | 95.7 | 2.30 | 0.0121 | 97.2 | 2.21 | 0.0142 | 96.9 | 3.45 | 0.0126 | 0.00146 |

| 7 | 0.0101 | 95.7 | 2.30 | 0.0110 | 97.2 | 2.20 | 0.0128 | 96.9 | 3.45 | 0.0113 | 0.00137 |

| 8 | 0.0093 | 95.7 | 2.30 | 0.0103 | 97.3 | 2.19 | 0.0121 | 97.0 | 3.44 | 0.0106 | 0.00142 |

| 9 | 0.0083 | 95.7 | 2.31 | 0.0093 | 97.3 | 2.19 | 0.0113 | 97.1 | 3.45 | 0.0096 | 0.00153 |

| 10 | 0.0084 | 95.8 | 2.29 | 0.0095 | 97.4 | 2.17 | 0.0113 | 97.2 | 3.44 | 0.0097 | 0.00146 |

| Time Step (Minute) | Sampling Point | ||

|---|---|---|---|

| Tri An | Da Nang | Ha Noi | |

| 1 | 246,982 | 247,703 | 198,476 |

| 5 | 49,401 | 49,542 | 39,703 |

| 10 | 24,395 | 24,467 | 19,597 |

| 15 | 16,136 | 16,187 | 12,975 |

| Coefficients | Implementing Results | ||

|---|---|---|---|

| Tri An | Da Nang | Ha Noi | |

| 31.4 | 24.7 | 34.7 | |

| Wref (m/s) | 11.1 | 11.8 | 12.8 |

| R2 (%) | 98.0 | 98.4 | 98.4 |

| RMSE (°C) | 1.43 | 1.40 | 1.55 |

| PV Technology | Implementing Results | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cocoa | Golden | Eugenea | ||||||||||

| Wref (m/s) | R2 (%) | RMSE (°C) | Wref (m/s) | R2 (%) | RMSE (°C) | Wref (m/s) | R2 (%) | RMSE (°C) | ||||

| xSi | 27.3 | 21.7 | 96.2 | 2.00 | 29.9 | 12.2 | 97.0 | 2.86 | 29.6 | 8.3 | 97.4 | 2.04 |

| mSi | 25.7 | 18.5 | 95.5 | 2.05 | 29.6 | 18.9 | 97.3 | 2.54 | 27.3 | 9.7 | 97.7 | 1.86 |

| CdTe | 30.8 | 17.5 | 94.9 | 2.47 | 31.7 | 15.2 | 97.0 | 2.54 | 30.8 | 8.5 | 96.9 | 2.37 |

| CIGS | 29.9 | 20.8 | 95.2 | 2.37 | 31.4 | 10.1 | 96.3 | 2.93 | 30.2 | 8.3 | 96.4 | 2.41 |

| HIT | 27.3 | 22.2 | 95.8 | 2.10 | 29.6 | 21.3 | 96.5 | 3.02 | 27.9 | 8.3 | 97.5 | 2.02 |

| aSiMicro | 27.1 | 19.6 | 95.8 | 2.06 | 29.6 | 18.9 | 96.6 | 2.90 | 29.0 | 8.5 | 97.1 | 2.19 |

| aSiTandem | 31.1 | 22.2 | 95.9 | 2.27 | 29.6 | 19.2 | 96.5 | 2.91 | 31.7 | 8.8 | 97.0 | 2.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, D.P.N.; Neyts, K.; Lauwaert, J. Proposed Models to Improve Predicting the Operating Temperature of Different Photovoltaic Module Technologies under Various Climatic Conditions. Appl. Sci. 2021, 11, 7064. https://doi.org/10.3390/app11157064

Nguyen DPN, Neyts K, Lauwaert J. Proposed Models to Improve Predicting the Operating Temperature of Different Photovoltaic Module Technologies under Various Climatic Conditions. Applied Sciences. 2021; 11(15):7064. https://doi.org/10.3390/app11157064

Chicago/Turabian StyleNguyen, Dang Phuc Nguyen, Kristiaan Neyts, and Johan Lauwaert. 2021. "Proposed Models to Improve Predicting the Operating Temperature of Different Photovoltaic Module Technologies under Various Climatic Conditions" Applied Sciences 11, no. 15: 7064. https://doi.org/10.3390/app11157064

APA StyleNguyen, D. P. N., Neyts, K., & Lauwaert, J. (2021). Proposed Models to Improve Predicting the Operating Temperature of Different Photovoltaic Module Technologies under Various Climatic Conditions. Applied Sciences, 11(15), 7064. https://doi.org/10.3390/app11157064