Changes in Crystal Phase, Morphology, and Flexural Strength of As-Sintered Translucent Monolithic Zirconia Ceramic Modified by Femtosecond Laser

Abstract

:1. Introduction

2. Materials and Methods

2.1. Zirconia Specimen Preparation

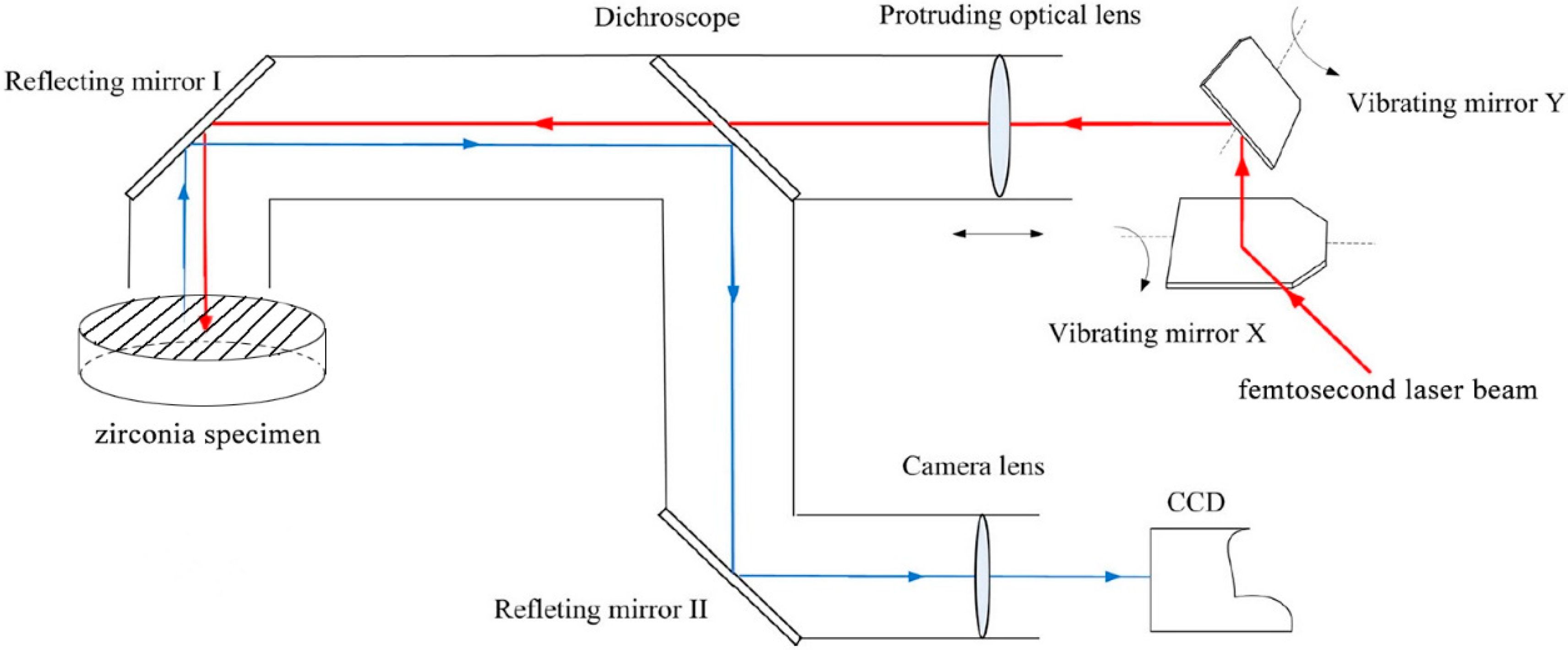

2.2. Zirconia Surface Treatment

2.3. Surface Structure and Roughness Assessment

2.4. X-ray Diffraction Analysis (XRD)

2.5. Flexural Strength Test (Three-Point Bending Test)

2.6. Statistical Analysis

3. Results

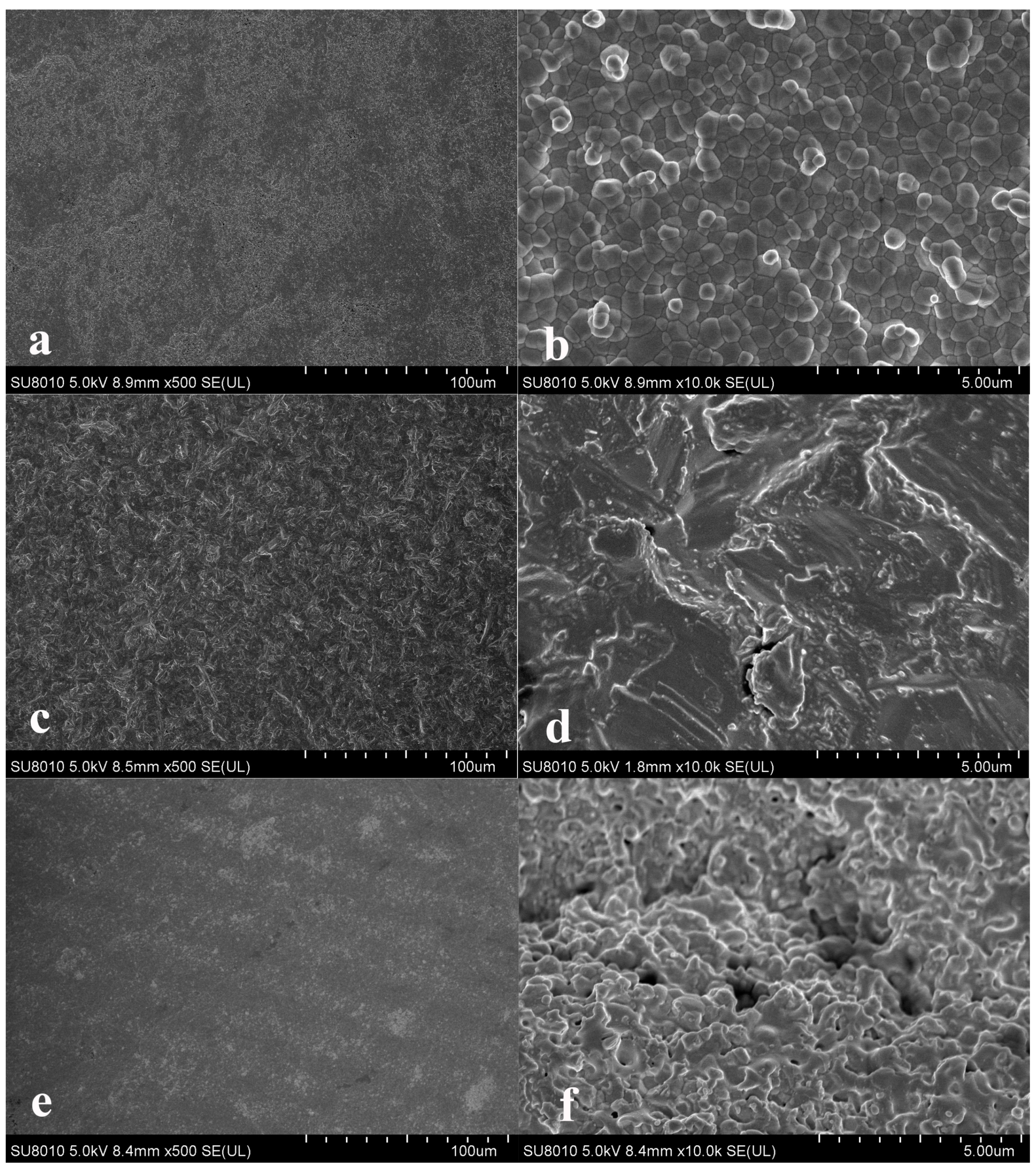

3.1. Scanning Electron Microscopy Observations

3.2. Surface Roughness Evaluation

3.3. Flexural Strength

3.4. XRD

4. Discussion

5. Conclusions

- Femtosecond laser technology offers potential for zirconia surface treatment.

- Through the employment of appropriate parameters, femtosecond laser treatment can be used to modify the surface of zirconia, in order to enhance its roughness without decreasing flexural strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef]

- Gracis, S.; Thompson, V.P.; Ferencz, J.L.; Silva, N.R.; Bonfante, E.A. A new classification system for all-ceramic and ceramic-like restorative materials. Int. J. Prosthodont. 2015, 28, 227–235. [Google Scholar] [CrossRef] [Green Version]

- Scaminaci Russo, D.; Cinelli, F.; Sarti, C.; Giachetti, L. Adhesion to Zirconia: A Systematic review of current conditioning methods and bonding materials. Dent. J. 2019, 7, 74. [Google Scholar] [CrossRef] [Green Version]

- Thompson, J.Y.; Stoner, B.R.; Piascik, J.R.; Smith, R. Adhesion/cementation to zirconia and other non-silicate ceramics: Where are we now? Dent. Mater. 2011, 27, 71–82. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hallmann, L.; Ulmer, P.; Wille, S.; Polonskyi, O.; Köbel, S.; Trottenberg, T.; Bornholdt, S.; Haase, F.; Kersten, H.; Kern, M. Effect of surface treatments on the properties and morphological change of dental zirconia. J. Prosthet. Dent. 2016, 15, 341–349. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, V.V.B., Jr.; Dantas, D.C.B.; Bresciani, E.; Huhtala, M.F.R.L. Evaluation of the bond strength and characteristics of zirconia after different surface treatments. J. Prosthet. Dent. 2018, 120, 955–959. [Google Scholar] [CrossRef]

- Casucci, A.; Monticelli, F.; Goracci, C.; Mazzitelli, C.; Cantoro, A.; Papacchini, F.; Ferrari, M. Effect of surface pre-treatments on the zirconia ceramic–resin cement microtensile bond strength. Dent. Mater. 2011, 27, 1024–1030. [Google Scholar] [CrossRef] [PubMed]

- Lv, P.; Yang, X.; Jiang, T. Influence of hot-etching surface treatment on Zirconia/Resin shear bond strength. Materials 2015, 8, 8087–8096. [Google Scholar] [CrossRef] [Green Version]

- Lükemann, N.; Eichberger, M.; Stawarczyk, B. Different surface modifications combined with universal adhesives: The impact on the bonding properties of zirconia to composite resin cement. Clin. Oral. Investig. 2019, 23, 3941–3950. [Google Scholar] [CrossRef]

- Wu, X.; Xie, H.; Meng, H.; Yang, L.; Chen, B.; Chen, Y.; Chen, C. Effect of tribochemical silica coating or multipurpose products on bonding performance of a CAD/CAM resin-based material. J. Mech. Behav. Biomed. Mater. 2019, 90, 417–425. [Google Scholar] [CrossRef]

- Chen, B.; Yan, Y.; Xie, H.; Meng, H.; Zhang, H.; Chen, C. Effects of tribochemical silica coating and alumina-particle air abrasion on 3Y-TZP and 5Y-TZP: Evaluation of surface hardness, roughness, bonding, and phase transformation. J. Adhes. Dent. 2020, 22, 373–382. [Google Scholar] [CrossRef] [PubMed]

- Bitencourt, S.B.; Ferreira, L.C.; Mazza, L.C.; Dos Santos, D.M.; Pesqueira, A.A.; Theodoro, L.H. Effect of laser irradiation on bond strength between zirconia and resin cement or veneer ceramic: A systematic review and meta-analysis. J. Indian. Prosthodont. Soc. 2021, 21, 125–137. [Google Scholar] [CrossRef] [PubMed]

- Ruja, M.A.; De Souza, G.M.; Finer, Y. Ultrashort-pulse laser as a surface treatment for bonding between zirconia and resin cement. Dent. Mater. 2019, 35, 1545–1556. [Google Scholar] [CrossRef]

- Aboushelib, M.N. Fusion sputtering for bonding to zirconia-based materials. J. Adhes. Dent. 2012, 14, 323–328. [Google Scholar] [CrossRef] [PubMed]

- Hussein, N.A.; El Kady, A.S.; Aboushelib, M.S. The effect of fusion sputtering surface treatment on microshear bond strength of zirconia and MDP-containing resin cement. Dent. Mater. 2019, 35, e107–e112. [Google Scholar] [CrossRef]

- Holthaus, M.G.; Treccani, T.; Rezwan, K. Comparison of micropatterning methods for ceramic surfaces. J. Eur. Ceram. Soc. 2011, 31, 2809–2817. [Google Scholar] [CrossRef]

- Akpinar, Y.Z.; Kepceoglu, A.; Yavuz, T.; Aslan, M.A.; Demirtag, Z.; Kılıc, H.S.; Usumez, A. Effect of femtosecond laser beam angle on bond strength of zirconia-resin cement. Lasers. Med. Sci. 2015, 30, 2123–2128. [Google Scholar] [CrossRef] [PubMed]

- Aivazi, M.; Hossein Fathi, M.; Nejatidanesh, F.; Mortazavi, V.; HashemiBeni, B.; Matinlinna, J.P.; Savabi, O. The evaluation of prepared microgroove pattern by femtosecond laser on alumina-zirconia nano-composite for endosseous dental implant application. Lasers Med. Sci. 2016, 31, 1837–1843. [Google Scholar] [CrossRef]

- Gomes, A.L.; Ramos, J.C.; Santos-del Riego, S.; Montero, J.; Albaladejo, A. Thermocycling effect on microshear bond strength to zirconia ceramic using Er:YAG and tribochemical silica coating as surface conditioning. Lasers Med. Sci. 2015, 20, 787–795. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- International Organization for Standardization. ISO 6872:2015. Dentistry-Ceramic materials. Geneva: International Organization for Standardization. 2015. Available online: https://www.iso.org/standard/59936.html (accessed on 30 June 2015).

- Mao, L.; Kaizer, M.R.; Zhao, M.; Guo, B.; Song, Y.F.; Zhang, Y. Graded ultra-translucent Zirconia (5Y-PSZ) for strength and functionalities. J. Dent. Res. 2018, 97, 1222–1228. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.J.; Lawson, N.C.; McLaren, E.E.; Nejat, A.H.; Burgess, J.O. Comparison of the mechanical properties of translucent zirconia and lithium disilicate. J. Prosthet. Dent. 2018, 120, 132–137. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liang, W.; Jiang, F.; Wang, Z.; Zhao, J.; Zhou, C.; Wu, J. Effects of air-abrasion pressure on mechanical and bonding properties of translucent zirconia. Clin. Oral. Investig. 2021, 25, 1979–1988. [Google Scholar] [CrossRef] [PubMed]

- Vicente, M.; Gomes, A.L.; Montero, J.; Rosel, E.; Seoane, V.; Albaladejo, A. Influence of cyclic loading on the adhesive effectiveness of resin-zirconia interface after femtosecond laser irradiation and conventional surface treatments. Lasers. Surg. Med. 2016, 48, 36–44. [Google Scholar] [CrossRef] [PubMed]

- Okada, M.; Taketa, H.; Torii, Y.; Irie, M.; Matsumoto, T. Optimal sandblasting conditions for conventional-type yttria-stabilized tetragonal zirconia polycrystals. Dent. Mater. 2019, 35, 169–175. [Google Scholar] [CrossRef] [PubMed]

- Guess, P.C.; Zhang, Y.; Kim, J.-W.; Rekow, E.D.; Thompson, V.P. Damage and reliability of Y-TZP after cementation surface treatment. J. Dent. Res. 2010, 89, 592–596. [Google Scholar] [CrossRef] [Green Version]

- Aung, S.S.M.P.; Takagaki, T.; Lyann, S.K.; Ikeda, M.; Inokoshi, M.; Sadr, A.; Nikaido, T.; Tagami, J. Effects of alumina-blasting pressure on the bonding to super/ultra-translucent zirconia. Dent. Mater. 2019, 35, 730–739. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Yu, P.; Xiong, Y.; Yue, L.; Arola, D.; Gao, S. Does the bond strength of highly translucent zirconia show a different dependence on the airborne-particle abrasion parameters in comparison to conventional zirconia? J. Prosthodont. Res. 2020, 64, 60–70. [Google Scholar] [CrossRef] [PubMed]

- Inokoshi, M.; Shimizu, H.; Nozaki, K.; Takagaki, T.; Yoshihara, K.; Nagaoka, N.; Zhang, F.; Vleugels, J.; Van Meerbeek, B.; Minakuchi, S. Crystallographic and morphological analysis of air abraded highly translucent dental zirconia. Dent. Mater. 2018, 34, 508–518. [Google Scholar] [CrossRef]

- Prieto, M.V.; Gomes, A.L.C.; Martín, J.M.; Lorenzo, A.A.; Mato, V.S.; Martínez, A.A. The effect of femtosecond laser treatment on the effectiveness of resin-zirconia adhesive: An in vitro study. J. Lasers Med. Sci. 2016, 7, 214–219. [Google Scholar] [CrossRef] [Green Version]

- Okutan, Y.; Kandemir, B.; Gundogdu, Y.; Kilic, H.S.; Yucel, M.T. Combined application of femtosecond laser and air-abrasion protocols to monolithic zirconia at different sintering stages: Effects on surface roughness and resin bond strength. J. Biomed. Mater. Res. B Appl. Biomater. 2021, 109, 596–605. [Google Scholar] [CrossRef]

- Tonietto, L.; Gonzaga, L., Jr.; Veronez, M.R.; Kazmierczak, C.S.; Arnold, D.C.M.; Costa, C.A.D. New method for evaluating surface roughness parameters acquired by laser scanning. Sci. Rep. 2019, 9, 15038. [Google Scholar] [CrossRef] [Green Version]

- Botelho, M.G.; Dangay, S.; Shih, K.; Lam, W.Y.H. The effect of surface treatments on dental zirconia: An analysis of biaxial flexural strength, surface roughness and phase transformation. J. Dent. 2018, 75, 65–73. [Google Scholar] [CrossRef]

- Ozer, F.; Naden, A.; Turp, V.; Mante, F.; Sen, D.; Blatz, M.B. Effect of thickness and surface modifications on flexural strength of monolithic zirconia. J. Prosthet. Dent. 2018, 119, 987–993. [Google Scholar] [CrossRef]

- Zhang, F.; Spies, B.C.; Vleugels, J.; Reveron, H.; Wesemann, C.; Müller, W.D.; van Meerbeek, B.; Chevalier, J. High-translucent yttria-stabilized zirconia ceramics are wear-resistant and antagonist-friendly. Dent. Mater. 2019, 35, 1776–1790. [Google Scholar] [CrossRef] [PubMed]

- Joglekar, A.P.; Liu, H.H.; Meyhöfer, E.; Mourou, G.; Hunt, A.J. Optics at critical intensity: Applications to nanomorphing. Proc. Natl. Acad. Sci. USA 2004, 101, 5856–5861. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Q.; Fan, Z.; Jiang, G.; Pan, A.; Yan, Z.; Lin, Q.; Cui, J.; Wang, W.; Mei, X. Mechanism and morphology control of underwater femtosecond laser microgrooving of silicon carbide ceramics. Opt. Express. 2019, 27, 26264–26280. [Google Scholar] [CrossRef] [PubMed]

- Okada, M.; Taketa, H.; Hara, E.S.; Torii, Y.; Irie, M.; Matsumoto, T. Improvement of mechanical properties of Y-TZP by thermal annealing with monoclinic zirconia nanoparticle coating. Dent. Mater. 2019, 35, 970–978. [Google Scholar] [CrossRef] [PubMed]

- Qeblawi, D.M.; Muñoz, C.A.; Brewer, J.D.; Monaco, E.A. The effect of zirconia surface treatment on flexural strength and shear bond strength to a resin cement. J. Prosthet. Dent. 2010, 103, 210–220. [Google Scholar] [CrossRef]

- Wang, H.; Aboushelib, M.N.; Feilzer, A.J. Strength influencing variables on CAD/CAM zirconia frameworks. Dent. Mater. 2008, 24, 633–638. [Google Scholar] [CrossRef]

- Song, J.Y.; Park, S.W.; Lee, K.; Yun, K.D.; Lim, H.P. Fracture strength and microstructure of Y-TZP zirconia after different surface treatments. J. Prosthet. Dent. 2013, 110, 274–280. [Google Scholar] [CrossRef]

- Pagano, S.; Lombardo, G.; Caponi, S.; Costanzi, E.; Di Michele, A.; Bruscoli, S.; Xhimitiku, I.; Coniglio, M.; Valenti, C.; Mattarelli, M.; et al. Bio-mechanical characterization of a CAD/CAM PMMA resin for digital removable prostheses. Dent. Mater. 2021, 37, 118–130. [Google Scholar] [CrossRef] [PubMed]

- Roitero, E.; Lasserre, F.; Anglada, M.; Mücklich, F.; Jiménez-Piqué, E. A parametric study of laser interference surface patterning of dental zirconia: Effects of laser parameters on topography and surface quality. Dent. Mater. 2017, 33, e28–e38. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Group | N | Mean | SD | SE | 95% Confidence Interval of the Mean | Minimum | Maximum | |

|---|---|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||||

| NT | 12 | 0.9820 | 0.1821 | 0.0526 | 0.8663 | 1.0977 | 0.71 | 1.28 |

| APA | 12 | 1.1248 | 0.2813 | 0.0812 | 0.9461 | 1.3035 | 0.89 | 1.81 |

| FSL | 12 | 1.4237 | 0.1613 | 0.0466 | 1.3213 | 1.5262 | 1.22 | 1.69 |

| Group | N | Mean | SD | SE | 95% Confidence Interval of the Mean | Minimum | Maximum | |

|---|---|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||||

| NT | 12 | 665.4604 | 82.2518 | 23.7441 | 613.2001 | 717.7207 | 563.78 | 825.14 |

| APA | 12 | 577.0494 | 150.0842 | 43.3256 | 481.6905 | 672.4083 | 415.92 | 927.46 |

| FSL | 12 | 727.7890 | 71.7360 | 20.7084 | 682.2101 | 773.3678 | 611.99 | 887.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, S.; Ye, H.; Yuan, F. Changes in Crystal Phase, Morphology, and Flexural Strength of As-Sintered Translucent Monolithic Zirconia Ceramic Modified by Femtosecond Laser. Appl. Sci. 2021, 11, 6925. https://doi.org/10.3390/app11156925

Liang S, Ye H, Yuan F. Changes in Crystal Phase, Morphology, and Flexural Strength of As-Sintered Translucent Monolithic Zirconia Ceramic Modified by Femtosecond Laser. Applied Sciences. 2021; 11(15):6925. https://doi.org/10.3390/app11156925

Chicago/Turabian StyleLiang, Shanshan, Hongqiang Ye, and Fusong Yuan. 2021. "Changes in Crystal Phase, Morphology, and Flexural Strength of As-Sintered Translucent Monolithic Zirconia Ceramic Modified by Femtosecond Laser" Applied Sciences 11, no. 15: 6925. https://doi.org/10.3390/app11156925

APA StyleLiang, S., Ye, H., & Yuan, F. (2021). Changes in Crystal Phase, Morphology, and Flexural Strength of As-Sintered Translucent Monolithic Zirconia Ceramic Modified by Femtosecond Laser. Applied Sciences, 11(15), 6925. https://doi.org/10.3390/app11156925