Abstract

Industry 4.0 integrates modern technologies into independently functioning units and fundamentally changes established production and non-production processes. Industry 4.0 is also used in the field of logistics with the introduction of automation, robotics or modern warehouse systems with a key element of digitisation. Development based on these principles presents huge challenges for the logistics sector as well as opportunities for further growth. Because the field of logistics is very large, it is important to be more specific. Internal logistics is a very important part of production processes; areas such as storage and supply of production lines with input materials are some of the key processes in a company. The implementation of Industry 4.0 principles is specific and, for many companies, demanding technologically, organisationally and financially. Therefore, companies must know their current level of logistics processes and evaluate the readiness of these elements for automation and digitisation. The company’s management should create a strategy which evaluates internal logistics processes for Industry 4.0. Company readiness will be evaluated on the basis of the tools (methodology) presented in the article. An objective assessment with a multi-level system is needed, and therefore internal logistics is structured into sub-areas. The implementation of this innovative method of evaluation in the industrial environment and a description of the tool development process will also be presented. As these are extensive issues, the initial sections cover the theoretical background of the topics that justify the need and novelty of this tool.

Keywords:

Industry 4.0; internal logistics; readiness model; methodology; dimensions; sub-dimensions; indicators; levels 1. Introduction—Problematics of the Concept of Industry 4.0

Due to the broad scope of Industry 4.0, there are many wide-ranging definitions and views from academics, business representatives, consulting companies and practical associations. The concept originated a few years ago in Germany, where the government and industrial companies began to support the introduction of modern technologies into production. At the heart of the fourth industrial revolution is, very generally speaking, the connection of the virtual cyber world with the world of physical reality [1]. The most mentioned terms within the concept of Industry 4.0—automation, digitisation and robotics—are experiencing the greatest expansion, and therefore are changing the functioning of industry, production and also the thinking and behaviour of society [2,3]. Businesses have to change the processes they have worked with so far and adapt to new ones [4]. The implementation strategy of Industry 4.0 into business sectors means the introduction of independent automation, configuration, diagnostics and problem solving and intelligent decision making [5,6].

Industrial enterprises implement networks in which machines, production equipment, storage systems and other non-production equipment are integrated in the form of Cyber Physical Systems (CPS) [7]. In a production environment, these systems exchange information, trigger actions and control each other independently—their autonomy is important [8,9]. Companies applying the principles of Industry 4.0 use a completely new approach to production and four key components of Industry 4.0 are CPS systems, Internet of Things (IoT), Internet of Services (IoS) in the Intelligent Factory [10]. CPS systems consist of autonomous and cooperative elements and subsystems that are interconnected depending on the situation. The basic idea is the cooperation of independent control units which are able to make autonomous decisions, to manage entrusted technological units and especially to become independent and full members of complex production units [11]. In the industrial field, these units are production equipment and robots that are programmed for specific activities. Additional technology for contactless material identification contributes to this, streamlining communication within production. Internet of Services is a technology that provides a variety of services within an enterprise, addressing a variety of tasks such as organising and coordinating production, data analysis, statistics, access to cloud storage and web services [12].

1.1. Definitions and Principles of Industry 4.0

The following key characteristics of Industry 4.0 show its huge capacity to change traditional production: vertical interconnection of intelligent manufacturing systems, horizontal integration through a new generation of global value chain networks, engineering throughout the value chain and the impact of breakthrough technologies (artificial intelligence, robotics) [13,14]. The principles of intelligent production and logistics are also the basic driving force for maximising the added value of individual processes across a company, which is given by the synergy of the key principles. These principles are in particular interoperability, virtualisation, decentralisation, real-time, service orientation, modularity and reconfigurability [15]. Another way to define Industry 4.0 is in the form of its nine main pillars. These are additive manufacturing, autonomous systems, augmented reality, Internet of Things, simulations, Big Data, cloud storage, cyber security and system integration. Isolated, optimised cells are combined into fully integrated, automated and optimised production flows, leading to greater efficiency and a change in traditional production relationships [16,17,18]. Other pillars that can complement these principles are, for example, autonomous robots. Robotisation of industry is one of the methods aimed at increasing labour productivity. Another important pillar is the use of sensors. Sensors, machines, parts and IT systems will be interconnected [19]. The concept of Industry 4.0 can be further specified using three paradigms: an intelligent product, an intelligent device, and an extended operator [20]. The operator in the Industry 4.0 concept is smart and qualified, and they not only perform cooperative work with robots, but also support machines as needed using human CPS, advanced human–machine interaction technologies and adaptive human-to-machine automatisation of symbiosis of work systems [21].

1.2. Logistics in the Context of Industry 4.0

The integration of CPS, IoT and IoS into logistics promises to enable real-time monitoring of material flows and better handling of manipulation units [10]. Better efficiency of logistics processes can be achieved by implementing Industry 4.0 principles in key areas such as warehousing, transport, packaging, distribution, loading/unloading and information provision [22]. It is important for manufacturing companies to have a perfect overview of where the material is located in the company. This cannot be achieved without perfect information systems, which must ensure process control not only during production, but also during storage operations, material delivery or transport from production to the warehouse [23]. For the main applications of new technologies in the relatively broad field of logistics, Industry 4.0 technologies should be used mainly on the basis of the following four principles [24]:

- Decision support and decision making—refers to the potential of artificial intelligence and big data analysis to automate decision-making processes or support human decisions using a data-based approach;

- Identification and interconnectivity—refers to IoT technologies and intelligent sensors that are able to unambiguously identify products and materials and improve product tracking inside and outside companies, including intercommunication;

- Information flow—refers to the integration of IT systems (vertical integration), which also uses cloud computing to provide access to data from multiple sources in real time to better respond to real-time production planning;

- Automation, robotics and new production technologies—introduction of new equipment and intelligent transport systems capable of replacing or duplicating human labour in manual activities.

Artificial intelligence techniques have shifted the navigation of mobile robots to autonomous control and obstacle avoidance. Automatically Guided Vehicles (AGV) are complemented by Autonomous Mobile Robots (AMR) [25]. The vision of logistics within Industry 4.0 is that the human factor will have a controlling and supervising role. This is a major change in operation, as devices will communicate and cooperate with each other, as well as make their own decisions [26]. Automated logistics facilities using autonomous trucks and robots can automatically adapt to production needs.

1.3. The Potential of Industry 4.0 in the Field of Internal Logistics

Devices for handling robotic elements can work without added infrastructure and are not limited by fixed routes. In order to move as efficiently as possible, they are localised in real time and their data is immediately evaluated and optimised. The use of automated solutions can help address labour shortages, robotic trucks provide greater safety by reducing accidents and eliminating errors, as the vast majority of errors are caused by the human factor. At the same time, automation serves people, who are replaced in demanding or repetitive tasks, enabling them to engage in less physically demanding work with higher added value. A key positive aspect is also the interconnectivity of all the systems, machines and sub-equipment and items in the warehouse. The developments in Industry 4.0 present huge challenges as well as opportunities for logistics [27,28].

One of the pillars of the Industry 4.0 concept is the introduction of its principles and technologies into the area of internal logistics processes. These company processes affect the efficiency and continuity of production processes. They have a large dominance in automated production. The creation of a methodology for evaluating the readiness of internal logistics processes for Industry 4.0 and its implementation in practice can thus be considered highly topical and beneficial for the field of Industrial Engineering.

These advantages and benefits of logistics in combination with Industry 4.0 principles show why it is important to solve logistics processes within this concept. The main principles of smart logistics intersect in many aspects with the principles of the concept, and internal logistics therefore has great potential. The main goal is to design a tool (methodology) for the evaluation of internal logistics processes in terms of readiness for Industry 4.0. Using the methodology, the company will be analysed, evaluated and classified to the appropriate level in terms of readiness for Industry 4.0.

The intention is a detailed evaluation, the methodology must be comprehensive. Therefore, it is appropriate to structure internal logistics into sub-areas and cover the entire area. A system with several levels of readiness is used for evaluation. It is a new and innovative tool that evaluates the support processes of internal logistics.

2. Materials and Methods—Main Topics in the Field of Pre-Research

To achieve this goal, we first wanted to point out the novelty and need for such a proposal. The proposed methodology is therefore also based on findings related to logistics audits, maturity models, internal logistics itself and Industry 4.0. These are the main topics that were part of this research. The first and most important phase was therefore to study and evaluate the literature, current tools and opinions of experts who deal with this field and related research. These are very complex areas; therefore, an evaluation was also prepared with the theoretical foundations on which our proposed methodology is based. The basis of the research is also an empirical method in the form of observation in the real environment. Several industrial companies of different sizes and different industries were visited, focusing on internal logistics processes.

2.1. Logistics Audits with a Focus on Internal Logistics

Internal logistics can be described as a discipline that deals with logistics chains within an industrial plant or between plants within a single company [29,30,31]. Internal logistics covers planning, implementation, control and efficient flow and storage of materials, semi-finished and finished products in a production environment [32,33]. The primary operational functions of internal logistics are handling, receipt and storage, internal transport, picking and packaging [28]. Internal logistics is fully responsible for the internal flow of material and information, thus connecting internal systems, from the entrance warehouse area (goods receipt, warehousing), through internal handling and the supply of production and assembly workplaces to goods dispatch (picking) [34].

A logistics audit is a method for the comprehensive and independent diagnostics of the functionality of the company’s logistics system [35,36]. It includes the determination of a strategy and tactics and a plan for eliminating deficiencies and subsequent improvement of the logistics system [37,38].

A total of three methodologies for logistics audits used in industrial enterprises were analysed—methodologies according to the Chamber of Logistics Auditors (CHLA), VDA 6.3 and MMOG/LE. For the analysis of the logistics audit methodologies, two companies in the automotive industry that use these methodologies were visited in person and special workshops and consultations were conducted. The methodologies of the logistic audits were analysed in detail and Table 1 shows the main attributes of each methodology. The main areas for evaluation are essentially the same, they only differ in their scope. Other analysed attributes are the advantages and disadvantages of each methodology. It is important to focus on a key attribute in the field of logistics as a subject of evaluation according to the audits, where the main parameters sought were specifically the processes of internal logistics (not external logistics within the supply chain). VDA 6.3 and MMOG/LE are used mainly in the automotive field, while the CHLA methodology is more universal. The methodologies also have their own assessment systems for output evaluation, and mainly use numerical point evaluation of the parameters.

Table 1.

Analysed attributes of the logistics audit methods.

The main attributes used for the final evaluation are listed in Table 2. One of the most relevant aspects for research is the definition of areas in internal logistics. In addition to the key attribute of internal logistics evaluation, the Industry 4.0 factor is also important. The potential of internal logistics evaluation corresponding to Industry 4.0, i.e., integration of this concept into audit methodologies, was analysed.

Table 2.

Evaluation methodologies of logistics audits.

Overall assessment of this topic: The main purpose of the analyses related to the logistics audit methodologies was to define the area of internal logistics. The main areas of internal logistics evaluated within the new proposed methodology are:

- Manipulation;

- Storage;

- Packaging;

- Supply;

- Material identification.

However, the areas are general and will be subject to further structuring into sub-areas. For the second analysed attribute—Industry 4.0 and its integration into evaluation and assessment—it can be stated that the methodologies do not work with this attribute and do not evaluate the readiness or level of the internal logistics processes in terms of possible implementation of principles and technologies of Industry 4.0.

2.2. Models Assessing Readiness for Industry 4.0

A readiness model (in some sources called “maturity models”) related to Industry 4.0 can be generally defined as a tool by which we can identify and evaluate the current state of company readiness in various areas for Industry 4.0, or to seek potential for improving the current state and future implementation of Industry 4.0 technologies. The models are based on the same or very similar principles, which are based on CMMI and other alternative standards [46,47]. The analysed parameters are always the areas for evaluation and graded levels. Each model works within different areas (called “dimensions” in the models). For some models, the areas are further extended to sub-areas. The method of evaluation is also important. The similarity in the evaluation method is given by the individual levels of preparedness in given areas. They are arranged logically from the lowest to highest level. Levels have their own names and characteristics for the requirements and properties to meet a given level within a given area. For some models, company readiness is also expressed in a quantitative way in the form of a readiness index [48]. Models have different intentions, some are descriptive or comparative, some are combinations or have a prescriptive character [49]. Models are also categorised into design groups. The main categories of model design are “Roadmaps”, Readiness models, Maturity models or “Frameworks”. They have different ranges and quality [50].

As part of the analysis of Industry 4.0 readiness models, approximately fifty of these “tools” were found to assess the company’s current state. Thirty-six models were analysed in terms of quality and detailed analysis of production areas. Table 3 contains only models that are directly designed for the evaluation of internal logistics. For these models, the most relevant attributes are listed, i.e., dimensions considered in relation to internal logistics and the number of the levels with the names of the lower and upper bounds of the levels that the models use for evaluation. Levels are basically a measuring scale and create a range of ratings.

Table 3.

Readiness models with assessment of internal logistics.

Internal logistics as a dimension itself (evaluation area) occurred in a small number of models, so the area of overall logistics was also examined, in which internal logistics activities were subsequently sought—for example in the fields of warehousing, material handling or material identification.

Another important parameter for the proposed tool is the established scales of models for assessing readiness. The evaluation scale is in various forms and consists of several categories (we use levels within the models). Thus, their determined number and their characteristics for all models were analysed. Readiness models work with different typologies of scales and with different numbers of categories (levels). Of all 36 models analysed, 24 have a set scale with a number of categories (levels) that are characterised. However, this characterisation is usually very brief in the form of a name for a numerical category (for example, level 0 = “without digitisation”). This characteristic therefore only complements the numerical ascending system of levels in most models. The readiness model is one of the few which has set levels numerically from 1 to 5, each with its own name and a brief, but concise description is added to them [57].

Overall assessment of this topic: After reviewing and analysing the readiness models, it can be stated that none of them comprehensively assess company readiness within the concept of Industry 4.0 in the field of internal logistics. The assessment is not comprehensive and neither is it sufficient for the models that are directly designed for internal logistics. Models are more in the form of “frameworks”. For most preparedness models, logistics is generally contained within one dimension, or partial dimensions or isolated questions are addressed in evaluation forms.

Models work with different levels of readiness and each contains the minimum requirements that must be met. Levels are usually defined terminologically from the lowest role of an outsider, through beginner, advanced, experienced, professional to the greatest expert, some models use levels with brief characteristics from digital novice, integrated and interoperable, fully implemented to fully digitally oriented entity. Attitudes are most often ascertained through the direct questioning of respondents. For measuring attitudes based on questioning, the general so-called “scaling” method is used. In standardised questioning, closed questions are mainly used, where a respondent selects from a specified range of answers. The scale is made up of items expressing a certain level of evaluation and a degree of agreement, so it is made up of categories. The levels are usually determined numerically with a brief description

2.3. Summary of Findings

Despite the fact that the area of internal logistics has great potential in the modernisation of most processes, there is no comprehensive methodology that can assess the readiness for this area in detail. The established audit methodologies and maturity models which we analysed and compared, served as the inspiration for a new methodology focused on internal logistics, which includes a new key factor for assessment—Industry 4.0. Based on this research and the above summary evaluation, the researched issues were characterised as follows:

- Logistics audit methodologies are based on hard data and assess internal logistics processes more conservatively and do not evaluate the concept of logistics activities in detail.

- Logistics audit methodologies do not reflect developments in Industry 4.0 and do not evaluate logistics processes with this in mind.

Maturity models provide reference models for scientists and professionals in Industry 4.0 or Logistics 4.0, but models with a focus on internal logistics or logistics are generally not effective (they cover only some parts of this area and very generally—giving biased results). This underlines the need for such a new tool. Further, for this topic, the following main issues were defined:

- Maturity models are in most cases divided into business areas which are then evaluated by a multi-level system, with the highest levels corresponding to Industry 4.0.

- Evaluation in Industry 4.0 readiness models most often corresponds to the scale of measuring attitudes in questionnaires in the form of closed questions (the scale is most often made up of five evaluation categories).

- None of the models comprehensively evaluates the company’s readiness for Industry 4.0 in the area of internal logistics. Several models focus on logistics; however, the evaluation is quite general and without parameters.

At the end of this section, it is important to mention and explain the technical terms that are most worked on in the article, and form the basic pillars of the proposed methodology. The three main parameters are defined as follows:

- Dimension—for this article, a “dimension” is defined as an area. Areas of internal logistics are dimensions. This is also due to the fact that almost all preparedness models in Industry 4.0 work with areas as with the analysed dimensions. The main dimensions of internal logistics for the creation of the methodology are determined from audits and the dimensions in this concept are, for example, “Manipulation”.

- Sub-dimension—the area of internal logistics is extensive; therefore, a prerequisite is its division into sub-areas which will be the subject of the evaluation. Because areas are dimensions, subareas are sub-dimensions. If we use the Manipulation dimension again as an example, we can divide it into sub-areas representing sub-dimensions including, for example: Manipulation technique, Manipulation units, Information security during manipulation.

- Level—level means a numerical expression of readiness related to the dimensions and sub-dimensions of internal logistics. For almost all preparedness models, the word “level” is used, and for some models, the term “degree” is used. The meaning is the same, i.e., level = degree of readiness for Industry 4.0 [48]. Levels are basically categories that make up the degree of consent for evaluation, and it is these categories that make up the scale. The levels are arranged in ascending order on a numerical scale, logically from the lowest to the highest level.

3. Design of a Structure for the Evaluation of Internal Logistics

In order for the final readiness assessment to be objective and to cover the area of internal logistics as much as possible, it first must be structured in a certain way. Therefore, the initial starting point for the proposed methodology is the design of the structure of internal logistics. This area is analysed in several phases and the internal logistics within the company is distributed between main and secondary logistics activities. The structure has three phases and characterises the relationships between the activities of internal logistics, and the principle of a systemic approach is incorporated into its design. The structure of internal logistics is an input element in the design of the methodology and determines the area of the scope of internal logistics for evaluation. Within the structure, these parameters are:

- Main dimensions of internal logistics (hereinafter referred to as “dimensions”).

- Sub-dimensions of main dimensions (hereinafter referred to as “sub-dimensions).

- A set of indicators covering a sub-dimension (hereinafter referred to as “indicators”).

For this reason, the initial phase involves selecting the main areas for analysis in internal logistics determined from the logistics audit analysis, which are manipulation, storage, supply, packaging and material identification. These main activities represent dimensions for the structure that are relatively general, and therefore these dimensions are further broken down into sub-dimensions. For sub-dimensions, a set of indicators is set for even greater detail of the evaluation. By setting a set of indicators, the methodology focuses in detail on the activities and related technologies which are essential for company evaluation. Therefore, the evaluation using this structure is not abstract and the methodology is not just a basic screening. The observation of individual logistics operations within real companies as a form of suitable preliminary research, material flows mapping and their connection to the spatial arrangement, warehouse space analysis and layout, handling and warehouse technology, etc. also helped to determine the complete structure of internal logistics). Practical projects in companies carried out by the author helped to comply with important principles for the structure of internal logistics—practicality and objectivity. Sub-dimensions/indicators are also divided with regard to the applicability of the methodology to automotive, electrical engineering and mechanical engineering companies.

3.1. Determination of Dimensions and Sub-Dimensions

The main starting point for determining the dimensions are the methodologies of the logistics audits, in which we focused on evaluated areas corresponding to internal logistics. Following these logistics audits analyses, the general structure of internal logistics works with five dimensions covering the main logistics activities within the company. Dimensions are further broken down into sub-dimensions because the dimensions are very general and evaluating it all as a single area is inefficient and meaningless. Dimensions cover the entire area of internal logistics, while the sub-dimensions fulfil the given dimension. The basic aspects that were reflected in the determination of sub-dimensions were technological support, human security and information security. Appropriate individual sub-dimensions were defined according to certain criteria. Targeting was the most appropriate coverage of each dimension for evaluation and not creating duplications. These three aspects are further intertwined in the characteristics of the set of the indicators. For the dimensions of handling and storage, the main criterion was, for example, the handling unit, from which the methods of storage and handling were derived. The key criterion for the dimension of the packaging was the material itself, i.e., its character and size of the packaging used. In addition to the five dimensions, a total of 14 sub-dimensions were determined according to the criteria, and Table 4 provides an overview.

Table 4.

Distribution of sub-dimensions.

3.2. A Set of Indicators for Evaluating Individual Dimensions

Selecting the right internal logistics indicators for assessment ensures effective evaluation and can also create an overview of potential locations that have a negative impact on evaluation. By using a set of indicators, the structure is more detailed and places that would not be detected at the level of sub-dimensions are revealed. As with the definition of dimensions and sub-dimensions, indicators are determined according to certain criteria. These criteria need to be justified because each sub-dimension can be characterised by a number of indicators. One of the criteria for determining these indicators is the connection with the concept of Industry 4.0 and its integration into the general structure of internal logistics. It is these set indicators that have the greatest potential for assessing a company’s readiness for this concept and its fulfilment. The second criterion for the appropriate setting of indicators is the fact that, thanks to these indicators, companies can be classified as prepared. These indicators can be characterised for each of the set levels and are therefore suitable for inclusion. These are qualitative indicators, which are then characterised for all specified levels. For each dimension, a table is created for clarity, in which all phases of the internal logistics structure are already recorded, i.e., the relevant sub-dimensions and their indicators with names and numerical designation for further use within the methodology. Table 5 shows the distribution of dimension D2: Storage. The other dimensions are also divided in this way.

Table 5.

Indicators for the dimension of D2: Storage.

Indicators are part of the methodology development process and will also be used in the evaluation process as input data. The determined indicators will be used in the preparatory phase of the proposed methodology. The sub-dimensions contain three to four indicators, and a total of 46 indicators have been set. If more indicators were set, this could lead to a confusing structure and duplicate characteristics.

4. Methodology Design and Internal Logistics Level Evaluating Method

Part of the proposed methodology can be called the “creation process”, as this part was used to prepare generally valid materials that are fixed and their structure does not change. The key parameter in the methodology design is the evaluation of levels. These describe the company maturity depending on specific indicators. Industrial enterprises can vary in size, type of production, repeatability, production sector and their individual logistics conditions. Therefore, the assumptions are defined when and where the methodology is applicable. After a description of the general methodology and the conditions of implementation, levels for evaluation are further described, characterised by indicators according to defined levels, and a mathematically based evaluation system is established, which is used to determine the level of readiness for the sub-dimensions.

4.1. Assumptions and Limitations of Implementing the Methodology

It is assumed that the methodology will be used mainly by medium-sized and large industrial enterprises, which have a profiled extended logistics area. Small businesses are generally not interested in their readiness level because they do not work with Industry 4.0. The methodology implementation has a wide range of uses; however, in connection with the suitability of applying the principles and technologies of Industry 4.0 to industrial areas, it will be used mainly in the automotive, engineering and electrical engineering industries. Companies in the automotive sector are mainly suppliers and subcontractors of components and accessories for automobiles, and the customers are large global automotive companies. The applicability of the methodology to companies according to the type of production is similar to that for defining company size. It is again assumed that the proposed methodology will be applicable mainly to serial and large series types of production. The complexity of logistics processes does not limit the methodology in any way. In summary, the main attributes and their limitations with respect to the application of the proposed methodology to industrial enterprises are presented in Table 6.

Table 6.

Assumptions and limitations of the methodology for its practical application.

4.2. Defining Levels for Evaluation and Characterisation Indicators

Levels for evaluation are set and create an ascending scale for evaluating the indicators. All the indicators are characterised for each level. If we have 46 indicators and 6 levels, we get 276 characteristics. These characteristics are used to evaluate (determine the level of) dimensions and sub-dimensions through the indicators. The defined inputs are:

- (1)

- Levels for evaluation

- (2)

- Characteristics of indicators according to defined levels

4.2.1. Levels for Evaluation

The theoretical foundations (CMMI model and Industry 4.0. readiness models for companies) for two important areas play an important role in determining the number and defining individual levels for evaluation using this methodology. These areas were the most inspiring for defining levels, and the levels of readiness were determined in a similar manner for our methodology.

There are, therefore, a total of six levels for this methodology (five levels of readiness + zero level) which describe the maturity of the company depending on specific indicators. The levels are of an ascending nature. The methodology is designed so that companies can naturally develop the readiness of their internal logistics processes according to the levels. Levels are set to cover a company’s readiness assessment as appropriately as possible. Therefore, as a compromise, they work with a certain set number and definition. Too small a number will not create an objective detailed evaluation, too large a number of levels, on the other hand, will create small variations between the levels and the evaluation becomes unnecessarily complicated. It would be difficult for company employees to answer questions, as the differences in the answers to questions would be minimal and could lead to wrong answers. A zero level is also included in the level design. The main idea for designing a zero level is not only to include it as the worst level, but the primary criterion is that the processes are not defined at all for this level. Furthermore, the levels are graded, the ascending principle is maintained with certain links between them. There are therefore six levels of readiness with the following summarised characteristics:

- Level 0 Uncontrolled Processes not explicitly defined

- Level 1 Controlled Certified process management

- Level 2 Controlled Digitised data collection (from processes), implementation of automation

- Level 3 Controlled Part of processes is automated, connected to an external data source

- Level 4 Controlled Processes are automated, with limited human intervention

- Level 5 Controlled Processes are automated, manually checked only.

More detailed descriptions of each level are provided in Appendix A—Description of the required levels for evaluation.

Set levels and their definitions are designed so that the highest levels, i.e., level 4 and especially level 5, represent the highest readiness and correspond to Industry 4.0. principles. In particular, Level 5 is designed so that it fully fulfils the vision, mission and assumptions of Industry 4.0. That is, the company has not only partially applied technologies, which can be in level 3 or level 4, but a comprehensive coverage of the entire internal logistics area.

4.2.2. Characteristics of Indicators According to Defined Levels

First, links between individual levels were created and then the intersection of the two main parameters was created: a set of indicators, i.e., the lowest phase of the proposed internal logistics structure and levels of readiness.

Levels for evaluating indicators are defined not only numerically on a scale of 0 to 5, but they are mainly defined by a technological description. Each indicator is briefly characterised technologically for all levels. This was processed with regard not only to the currently used technologies, but also to the technologies predicted on the basis of trends and developments in Industry 4.0. This characteristic is a key issue for the whole methodology, as it is an input to the preparedness assessment process. The processed characteristics of all the indicators clearly arranged in tables are basically a method of evaluation and a basis for the calculations in the next phase. These characteristics serve to evaluate (determine the level) of the dimensions and sub-dimensions by means of individual indicators. These indicators are evaluated and are the beginning of the entire evaluation.

Although the intention is to set a number of indicators to cover a large area of internal logistics, three main aspects are intertwined in the characteristics. In addition to technological support, other areas also play an important role. Without provision of information about internal logistics processes and defined organisational structures, the company will not be able to take advantage of the opportunities offered by these technologies. Therefore, the indicators according to the levels contain not only the concept, i.e., the method for carrying out the internal logistics process for a given level such as technological provision, but also an attribute such as information provision and monitoring of these processes and also organisational support, i.e., human provision.

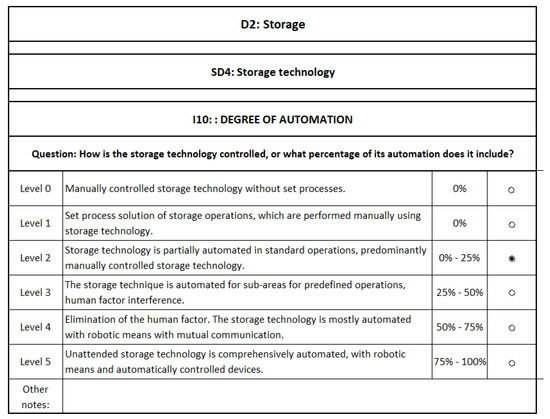

As an illustration, a modified and content-reduced table is included, which represents sub-dimension SD4: Storage technology, which belongs to dimension D2: Storage. Three indicators are characterised, which are I10: Degree of automation, I11: Environmental aspects, I12: Material storage system and I13: Storage technology management. This table is part of Appendix B—Example characteristics of the sub-dimension of Storage technology.

4.3. Evaluation System and Mathematical Equations

An evaluation system and mathematical equations are used when these inputs are known in the form of indicator values. We obtain levels assigned to individual indicators from the answers to structured interviews with company representatives. The answers to the questions are converted into a primary starting numerical value and inserted into the computational equations. Interview questions cover the structure of internal logistics. A question to the employees from the company is always asked, which relates to a specific indicator. The answers are compiled according to the number and definition of levels, i.e., a company employee always chooses one of the optional answers. The goal for the calculations is to determine a “mathematical function” that will determine the level of the subdimensions and the major dimensions from the assigned indicator levels.

Therefore, the main general principles for evaluation in which the mathematical functions are subsequently used are the following evaluation systems:

- Scoring system;

- Interval system with exponential growth of the interval range for levels.

A mathematically based scoring system was used to assess the readiness of the area of internal logistics in Industry 4.0. This was used mainly because we are working with six levels. It is therefore a precisely defined scale, which can also be used as a point evaluation. This scoring system was chosen mainly because the output of the entry phase is, on the basis of the structured interview, an evaluation of the heterogeneous areas that most influence the overall level of preparedness. After the scoring system, another system is used—the assignment system, which places the coefficients of the resulting values in an interval range of respective levels—from the lowest (zero) to the highest (fifth level). In order to be able to classify areas into the appropriate levels according to the results, ranges of intervals for classification must be established. The interval range distribution is based on using an exponential function.

One possible solution is the points proportion. This is the ratio of the achieved and maximum number of points in the examined area. Individual indicators are evaluated by levels from 0 to 5. This means that this ratio is converted into a point system and the individual level values receive assigned points.

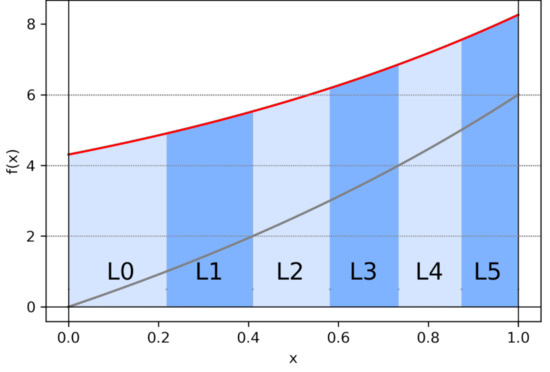

The resulting coefficient has a certain value after calculating the points ratio, which is included in a certain interval, and an exponential function was chosen as the optimal tool for dividing this interval <0;1>. Furthermore, several basic mathematical formulations have been used to determine the ranges by levels in the interval <0;1>, and the geometric interpretation is shown in Figure 1, which shows the interval for readiness levels distribution, and the sizes of the individual levels are colour-coded.

Figure 1.

Interval distribution for readiness levels.

The red curve represents the function f(x). After integrating this function, we get the value of the size of the area under the curve f(x), which is represented in the graph by the green curve. Levels are determined by the size of the area under the red curve in the interval <0; 1>, which is represented by the green curve. Each level is given by an area of size 1. The achieved level is therefore the largest integer multiple of area of size 1, which can be realised on the interval <0,x>. Table 7 shows the calculated range for the interval <0; 1> for each of the six preparedness levels.

Table 7.

Interval ranges and corresponding levels.

5. Basic Evaluation Phases

After obtaining the generally valid documents, the methodology for collecting the input data for analysing and evaluating the companies is applied and this “evaluation process” is divided into the sub-phases of input, calculation and evaluation.

The first input phase is input data collection. The partial goal was to determine how the methodology will actually be applied to the company. All indicators are characterised according to defined levels and the processed characteristics of all the indicators is basically the method of evaluation. However, printed tables and characteristics of indicators are not an ideal way to assess the current state of preparedness in a company. Therefore, a structured interview with questions to provide a better understanding of the indicators was created as a tool for input data collection, where the answers to the questions correspond approximately to the definitions of the characteristics of the indicators and the levels. After conducting a structured interview, the output of this phase is the assignment of levels for all indicators.

The calculation phase follows the first phase. The assigned values of the indicators are the input values to this phase. Based on the proposed evaluation system, in which appropriate mathematical formula are applied, we gradually arrive at partial and overall results. These results are the sub-dimension and dimension readiness levels.

The results of the second phase are the input for the third and last phase, which is the evaluation phase, and its purpose is to report the results. In this phase, outputs from the previous phase are processed to determine the overall level of readiness of the entire internal logistics in the company. Individual dimensions and sub-dimensions are compared. The resulting evaluation should also identify low-level areas.

The proposed methodology is mainly a diagnostic method for determining the level of readiness of the internal logistics processes. It is assumed that the final evaluation will also reveal bottlenecks. These are areas where the evaluation is low and the company should therefore focus on these positions. However, the methodology assesses readiness, reveals weaknesses and problem areas (low level of readiness).

5.1. Materials for Structured Interview and Implementation

The input data is collected using a quantitative approach—a structured interview. There are a total of forty-six questions, that is, one question for one indicator. The questions are therefore of the following nature:

- Closed, i.e., there are several possible answers;

- Selective, i.e., the question has one answer;

- Fixed (they do not change with the rated company).

However, for illustration, the question of the indicator is given in Figure 2 to indicate the form in which questions are created and submitted in the company. This is a question for indicator I10: Degree of automation. This indicator falls into dimension D2: Storage and sub-dimensions SD4: Storage technology.

Figure 2.

Question for I10: Degree of automation.

Company employees answer all the questions asked, in electronic form. The targeted output is therefore the values of the levels of all the indicators and this completes the input phase.

5.2. Evaluation Phase

Results from the evaluation phase are basically the final outputs of the methodology. There is no further evaluation; the proposed methodology does not stipulate any follow-up actions or recommend further action, and this is the end of the evaluation. However, within the evaluation phase, it is possible to obtain the following outputs and two areas of results:

- (a)

- The overall level of readiness of the company, the interconnection of dimensions.

- (b)

- Comparison of individual dimensions and finding the weakest link in the system.

All the results form the following four main groups of results from the methodology:

- The value of the level of individual indicators;

- Sub-dimension level value;

- Dimension level value;

- Overall evaluation of the area of internal logistics and assignment of the final level.

6. Verification of the Proposed Methodology

By applying the methodology, real data are obtained from industrial enterprises and outputs are compared with the assumptions we made during our design of the methodology. To ensure the correctness of the conclusions from the case studies, the industrial enterprises had to be a representative selection. Internal logistics was an extensive area in these companies, so a team solution (several logistics workers) was used in a structured interview for data collection. The main thing was that the evaluation was objective and in a large industrial company the team evaluation proved to be successful, which unifies both the knowledge and differences in the opinions of the experts. Consultations took place with experts in warehouse management, but also with the department for packaging processes. The head of the logistics department or their deputy was always a part of it.

To maintain the representativeness of the verification of a smaller study, the methodology was applied to a total of 29 different industrial enterprises in the Czech Republic. The evaluated companies are either Czech or international companies that have several branches here. The verification deals with data analysis from the applied methodology (especially values of the overall readiness, values of dimensions, sub-dimensions and their indicators), which it compares with general characteristics of the company. The characteristics that created the diversity of the evaluated companies include:

- Industries

- o

- Automotive (13 companies), engineering (11 companies), electrical engineering (5 companies).

- Company size and number of employees

- o

- Small and medium-sized enterprises, large enterprises.

- Type of production according to repeatability degree

- o

- Piece/small series (8 companies), serial (14 companies), large series (7 companies).

- Manufacturing programme

The sample analysed and evaluated includes large and medium-sized enterprises, but also several small enterprises with a small number of employees. The automotive sector is represented as a core industry. Engineering companies are also represented. For efficient production, for example, CNC machines can cooperate with industrial robots in the field of manipulation.

6.1. Application Outputs

One of the first values that we receive after data analysis is the overall average value of level of readiness of the entire area of internal logistics for the concept of Industry 4.0 across all the evaluated industrial enterprises. The value is 2.24 and it includes all the evaluated indicators. The core of the proposed methodology is a three-level structure of internal logistics, and average values of dimensions, sub-dimensions and indicators are also calculated. The average values of the five dimensions give the overall average value of readiness level. Given the scope of the resulting data, it is only possible to state without graphical form that the weakest analysed dimension for all the analysed industrial enterprises is dimension D3: Packaging (value 2.02). The best rated dimensions are D4: Supply (value 2.43). The remaining three dimensions have very similar values with minimal differences, and the values of the sub-dimensions also follow this pattern. Each sub-dimension consists of 3–4 indicators and is the most detailed output of the average values for all the enterprises. Logically, some indicators from dimension D3: Packaging have the lowest average value, specifically indicator I21: Degree of automation, I27: Attitude of the company to packaging management, and I29: Environmental aspects. Other sites that have a lower readiness level and are therefore potential sites for increased readiness are the areas in dimension D2: Storage, indicators I15: Material localizability and I18: Receipt and storage process. Lower values are also shown by all the indicators that relate to the environmental aspect of manipulation and storage technology, as well as information security, which appears in the fields of both manipulation and storage.

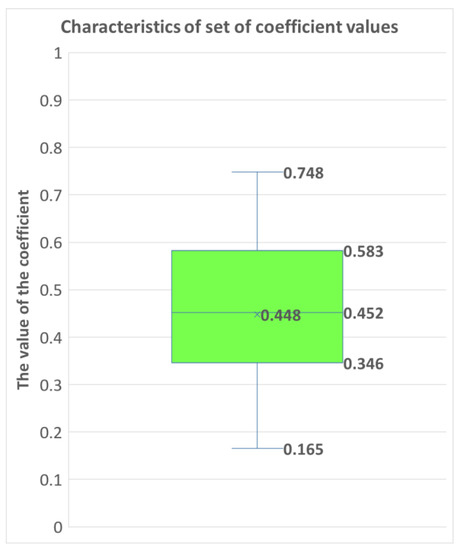

The box plot in Figure 3 shows the characteristics of the set of values of the resulting coefficients using quartiles. Coefficient values correspond to level values. Minimum and maximum are the boundary lines, upper and lower quartiles are the edges of rectangles, the median is the line and the diameter is the cross. The value of coefficient 0.748 is the highest (only 1 company), for which the overall readiness of internal logistics was level 4. The average value of the coefficient for all companies is 0.448 (this corresponds to a value of 2.24).

Figure 3.

Characteristics of set of coefficient values.

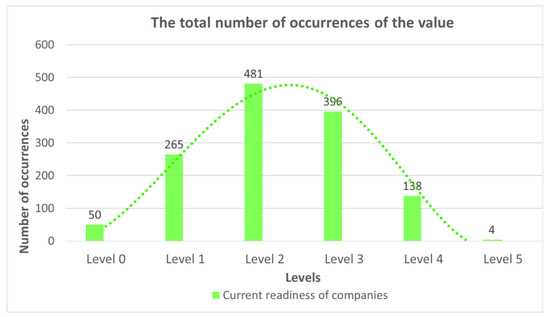

The analysed methodology outputs represent aggregated data that indicate only the average value of the level of readiness of internal logistics. Therefore, these average values were supplemented by the results of frequencies, i.e., number of occurrences of values within the analysed area. Figure 4 shows the total number of occurrences of the value of one of the levels for all evaluated companies for the entire area of internal logistics. The current level is shown in a bar graph, including regression curve interpolation. Level 2 (481 times) was most assigned during the input data collection and structured interview, followed by level 3 (396 times). As expected, the absolute minimum is level 5 and also level 0. This means that it is mainly a selection of lower levels. Level 4, already representing principles of Industry 4.0, contains only 138 assignments. Level 5 corresponding to full fulfilment of Industry 4.0 vision is practically non-existent.

Figure 4.

The number of occurrences of the current readiness level.

Table 8 provides summary data on the results of the overall levels of the enterprises evaluated as a percentage.

Table 8.

Summary data on the number of enterprises and their levels in the current variant.

Out of the total of 29 companies, the largest representation according to the results is in three levels, i.e., in level 1, level 2 and level 3. The smallest percentage is in level 0, in which there are only two companies. The main idea for designing a zero level is not only to include it as the worst level, but for this level it is also the primary criterion that the internal logistics processes are not defined at all and are not managed. The minimum representation is in level 4, in which there is only one enterprise. The representation of companies is therefore evenly distributed over at least three levels. The extremes are level 0 and especially level 5, in which companies are expected to occur minimally in order to fulfil the vision of Industry 4.0

6.2. Summary Verification of the Functionality of the Methodology

Data from the companies can be analysed according to other aspects, and the resulting values of the levels can be compared according to criteria such as type of industry (automotive, mechanical engineering, electrical engineering), company size according to number of employees (small, medium, large) and according to production type according to repeatability (piece/small series, serial, large series). Within the data analysis, company output data were compared and on the basis of the outputs from the analyses using the methodology it is possible to state the following:

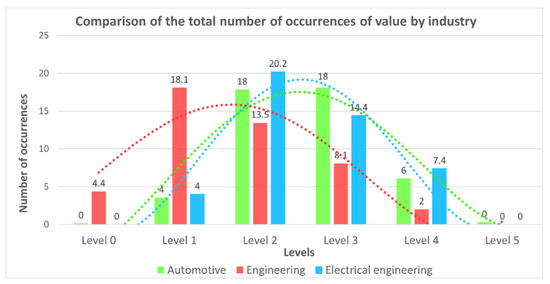

The best rated industry is the automotive industry. The electrical engineering sector also shows a similar value; the worst rated is the mechanical engineering sector. The average value of readiness level for automotive companies is 2.59, companies in engineering have a value of 1.68. Enterprises in the field of electrical engineering have 2.55. As the number of enterprises is not the same in each sector, frequencies are based on the same base so that they can be compared. This comparison with the numerical data is shown in Figure 5. The red bars represent the field of engineering and it can be seen from the graph that this sector scores mainly at lower levels, especially at level 1, and then the number of occurrences decreases. Green bars are for the automotive industry, which scores mainly in level 2 and level 3. The blue bars represent the field of electrical engineering. Industries are shown in a group bar graph, including the interpolation of regression curves for all industries.

Figure 5.

Comparison of the total number of occurrences of values for automotive, mechanical engineering and electrical engineering industries.

Automotive companies have established certified process equipment, which contains several standards that they must meet for customers, and due to serial production, they also have basic automation in place, especially in the field of supply and storage. Automotive companies also have digitised data collection with their structuring and properly functioning supply chain operations. Across all five dimensions, preparedness levels are clearly better than companies in the engineering sector.

- The level of readiness of internal logistics depends on the size of the company. The lowest levels of readiness were achieved by smaller companies. As the size of the company increases, the level of readiness of its internal logistics increases. The total average value of readiness for smaller companies with up to 250 employees is 1.42. Medium-sized companies with 250–900 employees have an average value of level of 2.23, and the best evaluation is, in line with our assumptions, for large companies, which have an average value for the entire area of internal logistics of 2.79.

- The level of readiness of internal logistics depends on the type of production according to repeatability. At the same time, with increasing repeatability, the level of readiness of internal logistics increases, and companies with large-scale production have the highest readiness. The average value of the level of readiness of piece/small series production was 1.37 after analysis. Mass production has an average level of 2.47. Large-scale production has an average value of 2.77.

- At present, companies in the Czech Republic are mainly in the lower levels of Industry 4.0 readiness assessment, which we consider to be level 0–3.

The results of the verification of the methodology are compared with data from the Czech Statistical Office (CZSO). In 2020, the CZSO published the publication “Innovative Activities of Enterprises” and in one of several parts of this publication they are also the subject of a survey of technologies related to Industry 4.0 and digitisation of business processes with possible implementation in internal logistics [58].

One of the surveys is innovation activities that used technologies associated with Industry 4.0 and digitisation of business processes. Most technologies correspond to the technologies that are used and defined within the methodology. The verification of the methodology leads to the conclusion that large companies have the highest readiness—the average value is 2.55. According to the CZSO, large companies have the largest share in the total number of companies with innovation activities in the given group for all technologies of Industry 4.0.

Another survey to demonstrate objectivity concerned the innovation of internal processes according to the area of their implementation. One of the areas is also logistics activities (storage, manipulation) and business information processing. According to the output data, large companies have the largest share in the implementation of innovated internal processes, then small companies have the medium and lowest values. The size of the company affects the intensity of innovation activities and large companies innovate most intensively [58].

The results from the application of the methodology were compared with data from the CZSO and according to the criterion of company size are the same and the application of the methodology provides an objective evaluation and it can be assumed that the methodology is fully functional and the set indicators are functional. Investment activities in large companies are in line with investments in modern technologies, where the emphasis is on logistics processes. The methodology has corresponding outputs.

7. Discussion

The first and most important phase for the development of the methodology was a literature evaluation and finding the opinions of experts who deal with this field and related research. Comprehensive research revealed the theoretical basis on which the proposed methodology is based and therefore it is based on solid foundations and pillars. For example, two companies were personally visited for consultation to analyse logistics audit methodologies. The already established audit methodologies and readiness models which were analysed and compared served as inspiration for creating a new methodology focused on the company’s internal logistics, which included a new key factor for assessment—Industry 4.0. Preparedness models provide reference models for scientists and professionals in Industry 4.0 or Logistics 4.0. However, models with a focus on internal logistics or logistics are generally not effective (they cover only some parts of this area and very generally leading to biased results). This underlines the need for such a tool.

The second phase was creating data that will be unchanged in the methodology application, and one of the key parts comprises the characteristics of the indicators from the structure of internal logistics with defined levels. The evaluation subject is the proposed structure of internal logistics, where the whole area is divided. One of the partial goals was that the methodology is not just a basic screening, so internal logistics is structured into sub-dimensions, etc. It is worth mentioning that this division is also determined on the basis of observations of individual logistics operations within a company in the real environment as a form of appropriate preliminary research. Consultations were also held with a mathematical analysis expert concerning the assessment method with a tier system.

In the third phase, the methodology was first tested for its feasibility on a real case study and after subsequent validation applied in 29 industrial companies. More than 50 industrial companies were contacted to verify it; however, some of them were not interested and did not want to be analysed and evaluated, because apart from CNC machines, which are already part of all workplaces focused on engineering production, these companies do not have any other automation or do not plan to have it in the future. Some companies were not interested in the results, and in addition, they are private entities that did not want to have their results published. The application of the methodology in real companies has shown its effectiveness in an industrial context and the results show the strengths and weaknesses of companies with regard to their readiness to implement Industry 4.0 technologies. In general, research in this area and design of a methodology represent important steps towards strengthening the transition to Industry 4.0 in a company’s logistics processes.

After application, the methodology’s basic properties were profiled and among the main ones it is possible to state that the evaluation results are summative, data collection takes in the order of hours, and repeatability of evaluation (periodicity) is possible. Knowledge of logistics processes and existing technological equipment, and the level of evaluation of logistics processes using qualitative indicators is medium. The main feature is its diagnostic character. The methodology assesses readiness, reveals weaknesses and problematic areas (low level of readiness), but does not give precise procedures for design measures that could increase the level of problem areas.

The aspects related to the reliability and practicality of the proposal are summarized:

- The methodology focuses only on the readiness of internal logistics processes for Industry 4.0. The methodology is not an alternative to a logistics audit. The structure of internal logistics is therefore designed to optimally cover the largest possible field of these processes. Therefore, a total of 46 indicators are proposed. The paper contains only examples of one dimension of D2: Storage. There are no more indicators, because duplications would be created and it would not be possible to define the indicator into 6 levels.

- For the indicators to be appropriate and the proposal to be practical, the author uses the experience from companies. In companies, the author worked on projects for internal logistics related to continuous improvement and implementation of new technologies. For practicality, the methodology used for medium-sized and large companies with serial production is also limited. Small companies with piece production do not have to have the proposed indicators (or sub-dimensions) in the company and the evaluation will not be objective.

- Another aspect for practicality is that the methodology was applied to 29 companies. That is enough businesses for smaller research studies. The companies were interviewed by a team of experts to collect input data.

- Data from CSZO were only compared according to the criterion of company size. The results agree because large companies innovate more than small companies.

8. Conclusions

Evaluation according to the methodology provides two areas of results—an overall assessment of readiness for the entire area and detection of weaknesses in the internal logistics structure which cause low evaluation. The methodology is applied to all types of companies in terms of size, but mainly medium and large ones. The overall level of preparedness for Industry 4.0 depends to some extent on business size. It is very similar for companies with different types of production according to the size of the series. From the point of view of the industrial sector, the assumption was met and the methodology was applied to automotive, engineering and electrical engineering industries. Because it is a structured interview with a technologically and numerically defined scale, individual evaluations are not mutually influenced and the evaluation can be performed at any time and this evaluation can be repeated. In addition, if similar companies are evaluated according to aspects such as type of production and company size, the evaluation allows comparison in key areas of internal logistics.

The methodology described in this article thus provides an innovative view of evaluation of a company’s internal logistics readiness, which, moreover, combines the integration of Industry 4.0 into this corporate area. On the basis of all the acquired knowledge, it is possible to summarise the benefits for business practice, but also for the scientific field.

In summary, the application of the developed methodology provides companies with the following benefits:

- It makes it possible to determine the readiness level of internal logistics in the company, including sub-areas and their interconnection.

- It compares the individual main dimensions with a detailed analysis and identifies the weakest points in any dimension, obtaining the worst-rated sub-areas.

- It identifies strong and weak areas of internal logistics.

- There is possible re-use of the evaluation and subsequent comparison tool.

- It includes structured and detailed analysis of internal logistics in the company with determination of a set of indicators that affect the level.

- Awareness can be gained of the potential of internal logistics within the concept of Industry 4.0 and possible implementation of principles in this area.

- It enables identification of the situation in which a company finds itself in relation to issues of Industry 4.0, whether they are aware of the principles of Industry 4.0, and whether companies are able to respond to these challenges.

The theoretical benefits of this work can be summarised in several basic points for each topic, where the main advantages are the creation of an internal logistics structure to cover the entire field of logistics in the company and the methodology of innovative evaluation based on a points system divided into six intervals using an exponential function.

Internal logistics and Industry 4.0 are very large areas in a company that intersect with processes across the company and create a lot of space for further work and make recommendations for future scientific work. The methodology focuses primarily on the technical and technological readiness of a company’s logistics. This methodology could also, for example, serve as the basis for a future knowledge system that would not only measure the current state, but also suggest ways to improve. The methodology would therefore be not only a diagnostic tool, but a complete methodology also enabling design measures. For such a complete methodology, it would be part of establishing company strategy and tactics and a plan to eliminate deficiencies and subsequently improve the internal logistics system and increase the level of the company.

Author Contributions

Conceptualization, Z.M.; Methodology, Z.M.; Validation, S.M.; Writing—original draft preparation, Z.M.; Writing—review and editing, S.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was created by the support of the project SGS-2021-028 “Developmental and training tools for the interaction of man and the Cyber-Physical Production System”. This project is under the Internal Grant Agency of the University of West Bohemia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. General Description of Levels

Table A1.

Description of the required levels for evaluation.

Table A1.

Description of the required levels for evaluation.

| Level | Level Description |

|---|---|

| Level 0 | This is the basic lowest level, in which processes are not explicitly defined, and there is no connection be tween them. This is the primary criterion. Information systems and simple software for data collection and processing are not used at this level—only in paper form. Data is not processed and recorded. The basic handling and storage technology is used, where there is a minimal share of mechanization, and performed activities are controlled manually. The technology is not guided and controlled in any way, it is not inter connected. The process is poorly managed or not controlled at all, process management does not have the right organizational and technological “tools” to build infrastructure for logistics processes that will allow repeatability/usability/extensibility of used. |

| Level 1 | At this level, documentation, certification, ISO and other similar representatives of the classic process management are prescribed. It uses simple software, classic tools and basic information systems, ineffi cient processing and non-use of data. It includes manual data collection and subsequent entry into PC. Handling and storage technology is controlled manually and is mechanized. The process is planned and implemented. However, process management is worse due to lack of organization. Basic offline communi cation of handling and storage technology (communication according to sorted data). Standard industrial methods. |

| Level 2 | Internal logistics processes are fixed and managed. The process is defined through planning and imple mentation of best practices and management practices. The use of basic automated elements in standard ized activities is beginning; however, mechanised methods prevail in cooperation with the worker. Data collection is partially digitised. Periodic data processing into various internal information systems that are not interconnected. Internal information systems, which are specifically profiled, have basic functionalities according to the sub-area of internal logistics and data are not structured in them. Basic connection of han dling and storage technology, introduction of communication system. |

| Level 3 | Manipulation and storage technology is more automated for predefined tasks with human cooperation. Digitised technologies and information systems are used for data collection, which are also connected to external data sources, where mutual communication takes place. There is data processing into information systems that are interconnected. It is possible to automate processing locally, including automatic collec tion into data warehouses. It involves interconnection, transportation technologies and planning software; and partial automatic control of processes and technology using advanced IS. |

| Level 4 | Processes are digitised and automated, with limited human intervention, which usually acts as a control ler. At this level, therefore, most processes are automated; however, it is not yet complex automation. The process is digitally oriented and based on a solid technological infrastructure. It uses information systems that connect all company areas, including external sources, and there is automatic processing. Information systems are shared across the enterprise. There is integration of structured and unstructured data; data processing from all areas; use of advanced predictive analytics; autonomous synchronization of produc tion and logistics processes. |

| Level 5 | Processes are fully automated and only human-checked. It is therefore a complex automation, where over all process is automated and humans takes over only the role of planning and strategic management. The control of all systems is autonomous. Handling, storage and packaging technology is controlled by an in formation system. The company is fully equipped with sensors. Creation of a unified data model, and fully automated data processing are available. There are online communications and automatic infor mation systems that are fully interconnected, compatible, interconnected with production systems and managing the entire logistics part of the company, including external resources. It involves comprehensive business coverage using wireless technology (optical fibre), low-energy technology; real-time data ex change, M2M communication based on control systems with AI. |

Appendix B. Exemplary Characteristics of the Subdimension of Storage Technology

| Levels | 0 | 1 | 2 | 3 | 4 | 5 | ||

| D2: Storage | SD4: Subdimension—Storage technology | I10: Degree of automation | Manually controlled storage technology without set processes. | Set process solution of storage operations, which are performed manually using storage technology. | Storage technology is partially automated in standard operations, predominantly manually controlled storage technology. | The storage technique is automated for sub-areas for predefined operations, human factor interference. | Elimination of the human factor. The storage technology is mostly automated with robotic means with mutual communication. | Unattended storage technology is comprehensively automated, with robotic means and automatically controlled devices. |

| 0% | 0% | 0–25% | 25–50% | 50–75% | 75–100% | |||

| I11: Environmental aspects | Use of non-ecological internal combustion engines without emission limits. | Implementation of propulsion units reducing CO2, NO and airborne particles. Power units for CNG, LPG. | Implementation of electric power units. | Implementation of electric power units with possible recycling. | Implementation of storage facilities for electric drives from renewable sources with partial recycling. | Storage technology uses renewable energy sources. The device can be completely recycled, including the battery. | ||

| I12: Material storage system | Storage items without system, no storage technology used. | Stock items are stored in shelving systems with marked locations with defined rules. | Stock items stored in shelving systems with efficient management of stock positions. | Stock items on the shelves, dynamic racks and elevator systems with partial automation. | Automated storage system for all items (incl. size), with robotic storage and picking of items, equipped with sensors for operating status. | Self-organizable closed storage system— autonomous warehouse with robotic storage and picking of items, completely sensory equipped for the detection of operating and fault conditions. | ||

| I13: Storage technology management | Basic method of storage technology without the use of information technology and set management processes. Unmanaged storage. | Storage technologies automatically provide data in a given process certification. Partial identifiable movements and actions. Partially controlled storage | Storage technology with tools for data collection. Advanced human-machine interface with set control and identifiable movements. Controlled storage | Storage technology more comprehensively connected to IS in combination with automated robotic devices and equipment. Automated storage | Storage technologies are integrated into the information environment. Operational control according to predefined rules and autonomous algorithms. Intelligently managed storage | Storage technologies are automatically controlled by IS. The complex warehouse system is controlled by artificial intelligence or advanced algorithms, online and is fully digitised. Autonomous storage | ||

References

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Final Report of the Industrie 4.0 Working Group; Acatech National Academy of Science and Engineering: München, Germany, 2013. [Google Scholar]

- Sarvari, P.A.; Ustundag, A.; Cevikcan, E.; Kaya, I.; Cebi, S. Technology Roadmap for Industry 4.0. In Industry 4.0: Managing the Digital Transformation; Springer International Publishing: Basel, Switzerland, 2018; pp. 95–103. ISSN 1860-5168. [Google Scholar]

- Cioffi, R.; Travaglioni, M.; Piscitelli, G.; Petrillo, A.; Parmentola, A. Smart Manufacturing Systems and Applied Industrial Technologies for a Sustainable Industry: A Systematic Literature Review. Appl. Sci. 2020, 10, 2897. [Google Scholar] [CrossRef]

- Muhuri, P.K.; Shukla, A.K.; Abraham, A. Industry 4.0: A Bibliometric Analysis and Detailed Overview. Eng. Appl. Artif. Intel. 2019, 78, 218–235. [Google Scholar] [CrossRef]

- Botlíková, M.; Botlík, J. Local Extremes of Selected Industry 4.0 Indicators in the European Space—Structure for Autonomous Systems. J. Risk Financ. Manag. 2020, 13, 13. [Google Scholar] [CrossRef]

- Felsberger, A.; Reiner, G. Sustainable Industry 4.0 in Production and Operations Management: A Systematic Literature Review. Sustainability 2020, 12, 7982. [Google Scholar] [CrossRef]

- Brozzi, R.; Forti, D.; Rauch, E.; Matt, D.T. The Advantages of Industry 4.0 Applications for Sustainability: Results from a Sample of Manufacturing Companies. Sustainability 2020, 12, 3647. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; De Freitas Rocha Loures, E.; Ramos, L.F.P. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Buer, S.V.; Strandhagen, J.O.; Chan, F.T.S. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Monostori, L. Cyber-physical production systems: Roots, expectations and R&D challenges. Variety Management in Manufacturing. In Proceedings of the 47th CIRP Conference on Manufacturing Systems, Windsor, ON, Canada, 28–30 April 2014. [Google Scholar]

- Kopetz, H. Real-Time Systems: Design Principles for Distributed Embedded Applications; Kluwer International Series in Engineering and Computer Science, SECS 395; Kluwer Academic Publishers: Boston, MA, USA, 1997; ISBN 0-792-39894-7. [Google Scholar]