A Presentation of Ionic Liquids as Lubricants: Some Critical Comments

Abstract

1. Introduction

- (1)

- the achievement of the desired friction coefficient;

- (2)

- the lubricant has to be able to withstand the pressure without being squeezed out;

- (3)

- the lubrication performance should be as independent as possible of changes in the environment [3].

- Section 2 will give a general description of the properties of ionic liquids which allow their use as lubricants;

- Section 3 will show the mechanism of action of ILs as lubricants;

- Section 4 will give some hints on how to probe the IL structure;

- Section 5 will report some examples of the use of ILs as lubricants;

- Section 6, finally, will give some perspectives.

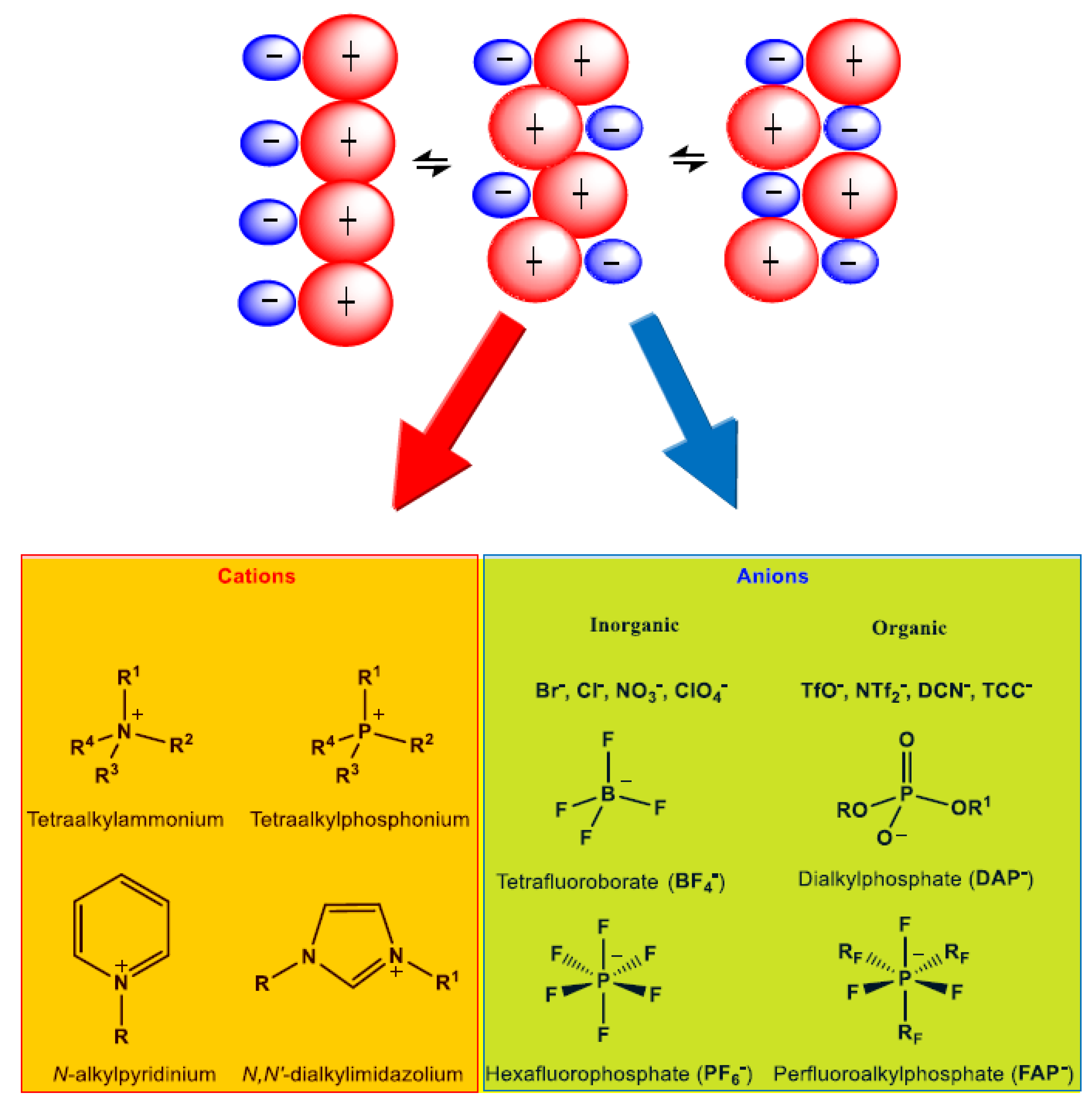

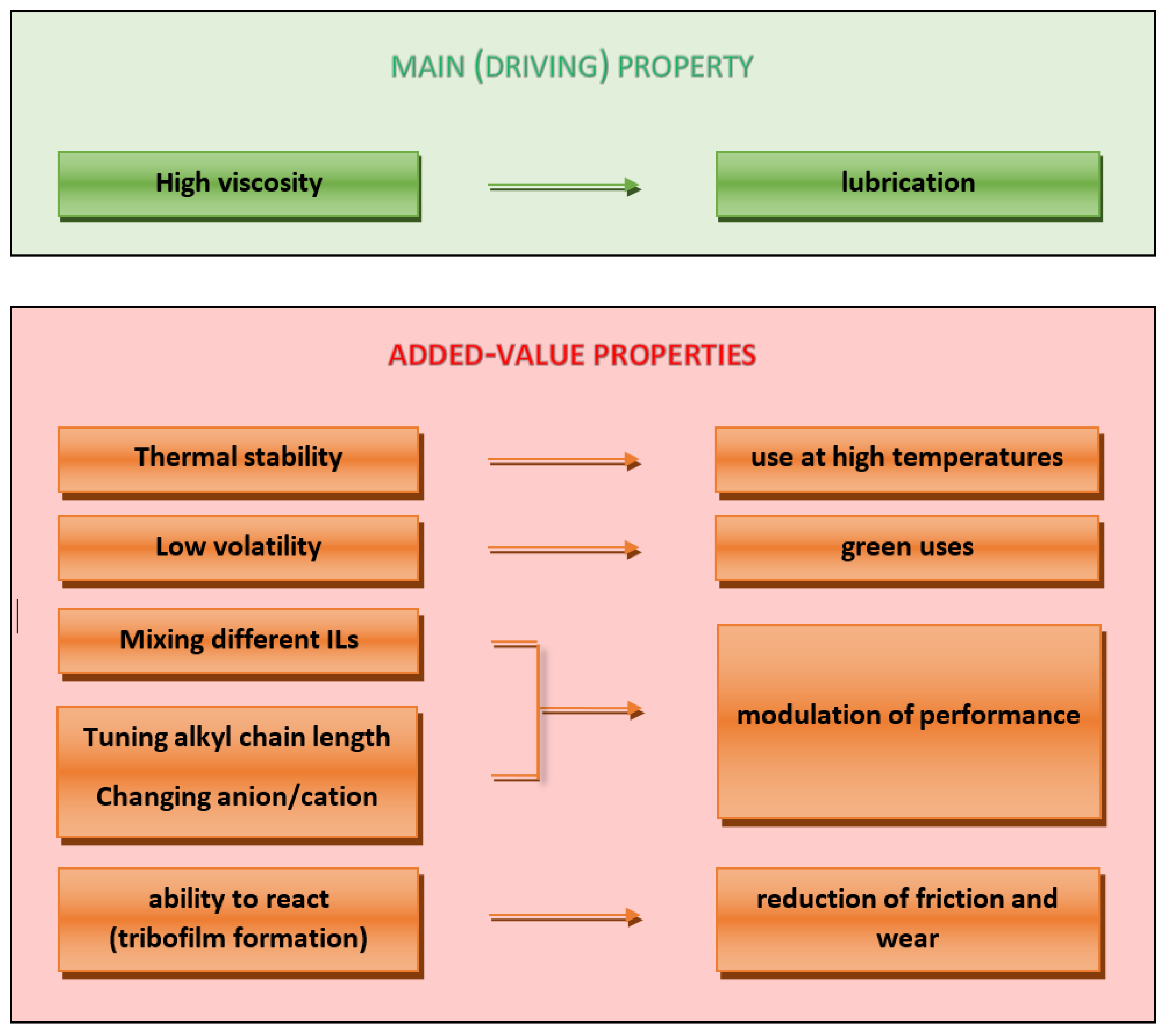

2. Why Should ILs Be Used as Lubricants?

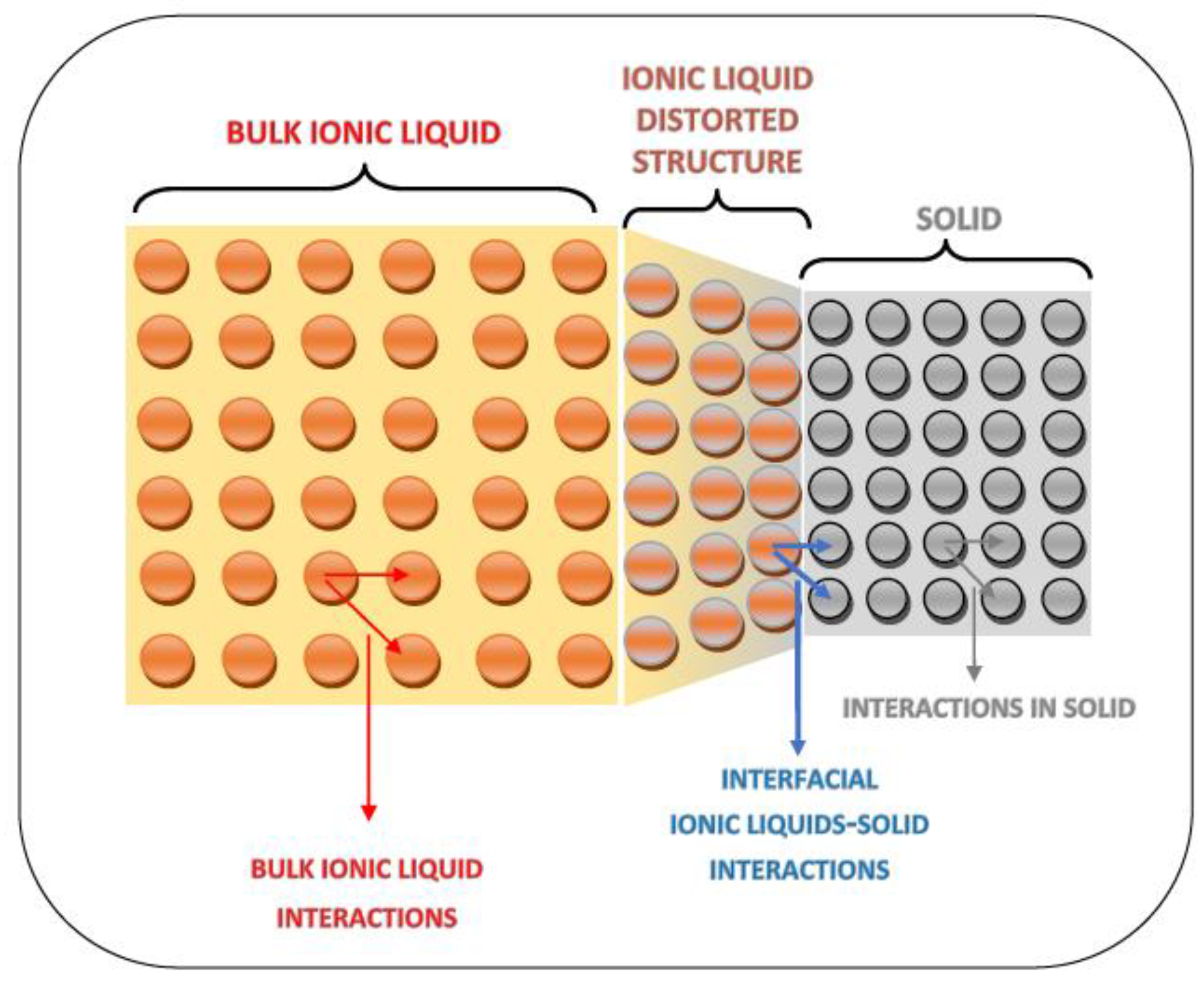

2.1. Surface-Dependent IL Structure

2.2. Moving Closer to the Surface

2.3. Specificity of Surfaces

3. Mechanism of Action of ILs as Lubricants

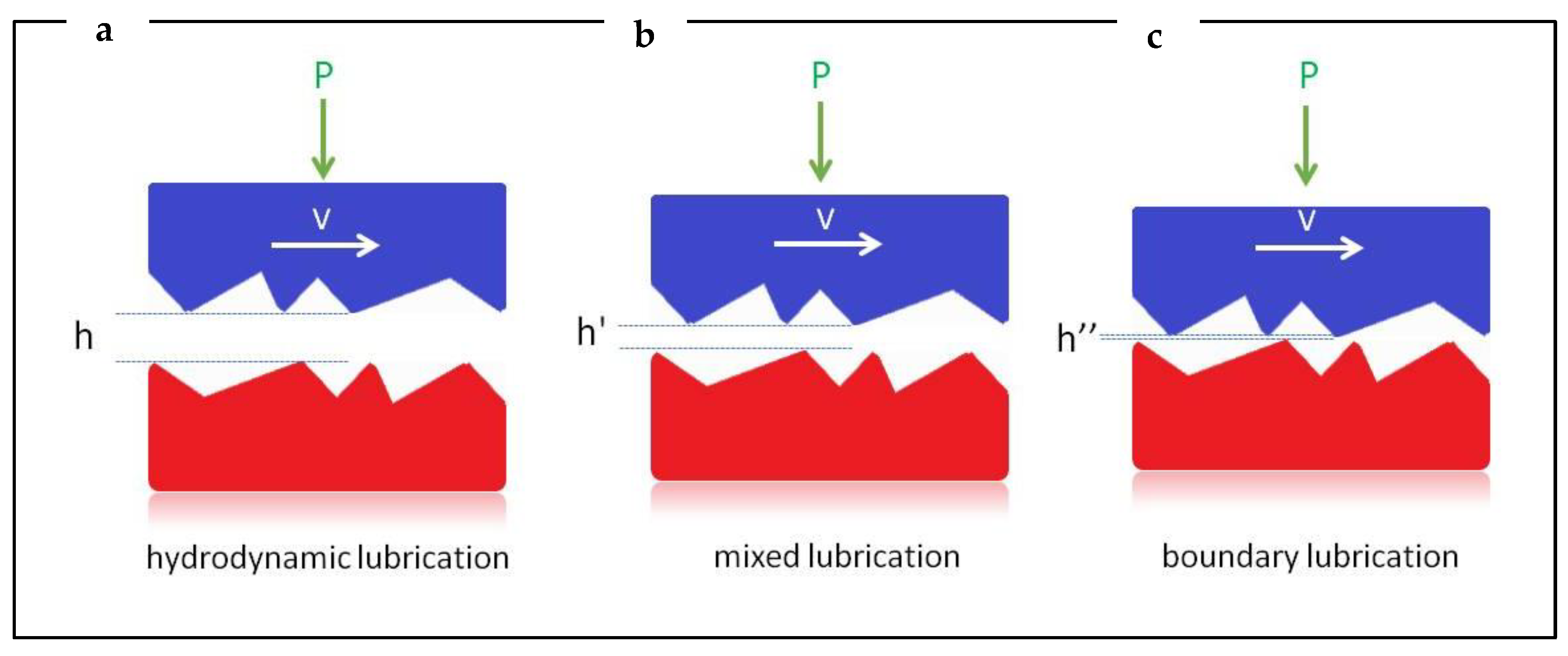

3.1. Hydrodynamic Lubrication (HL)

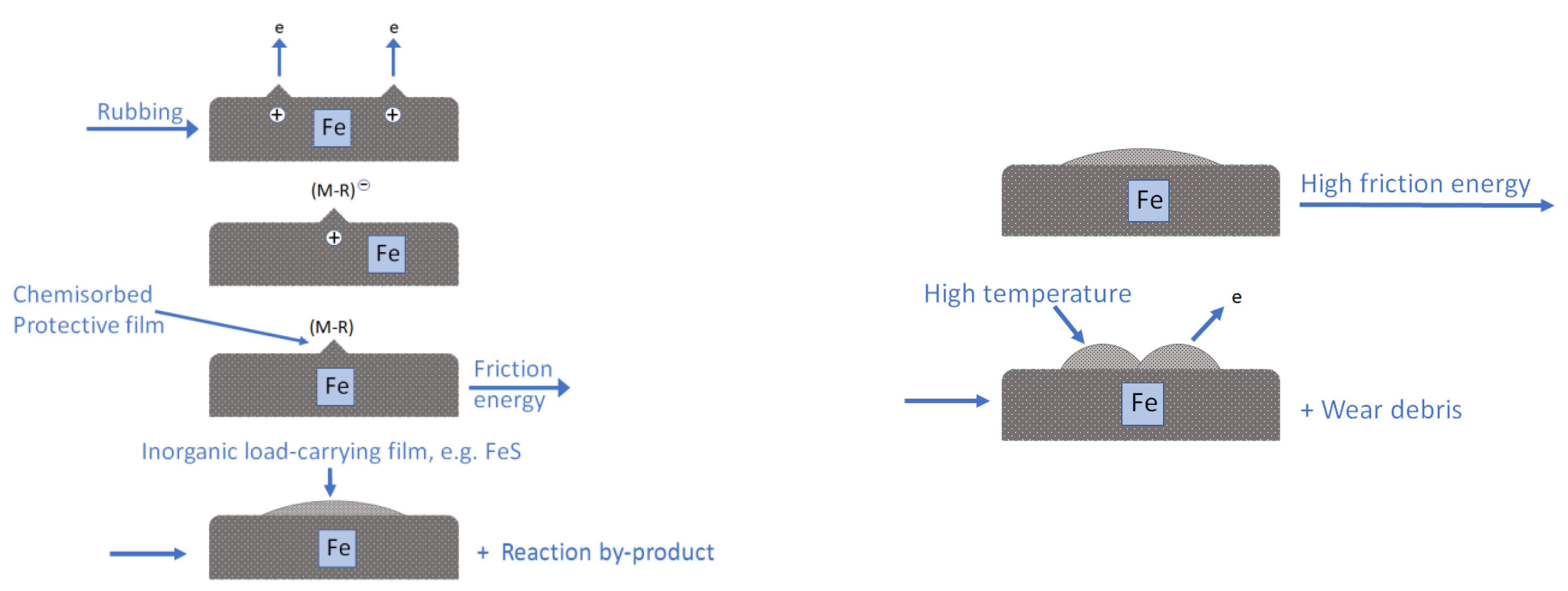

3.2. Boundary Lubrication (BL)

3.3. Mixed Lubrication (ML)

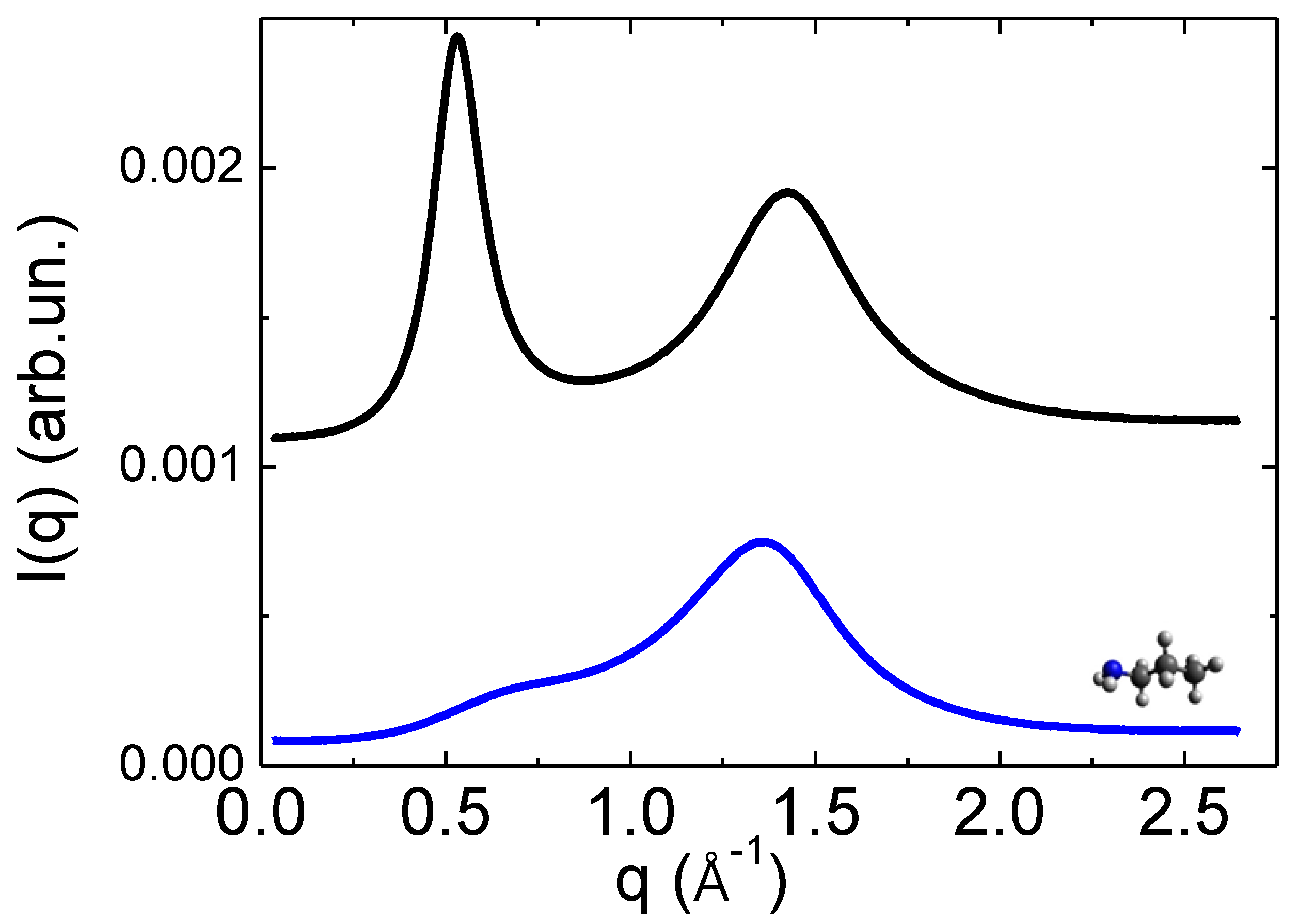

4. Intermolecular Distances as Probes for Structure: How to Measure Them

4.1. Scattering

4.2. Atomic Force Microscopy (AFM)

4.3. Purity Dictates Structure

5. Some Applications

5.1. Steel Surfaces

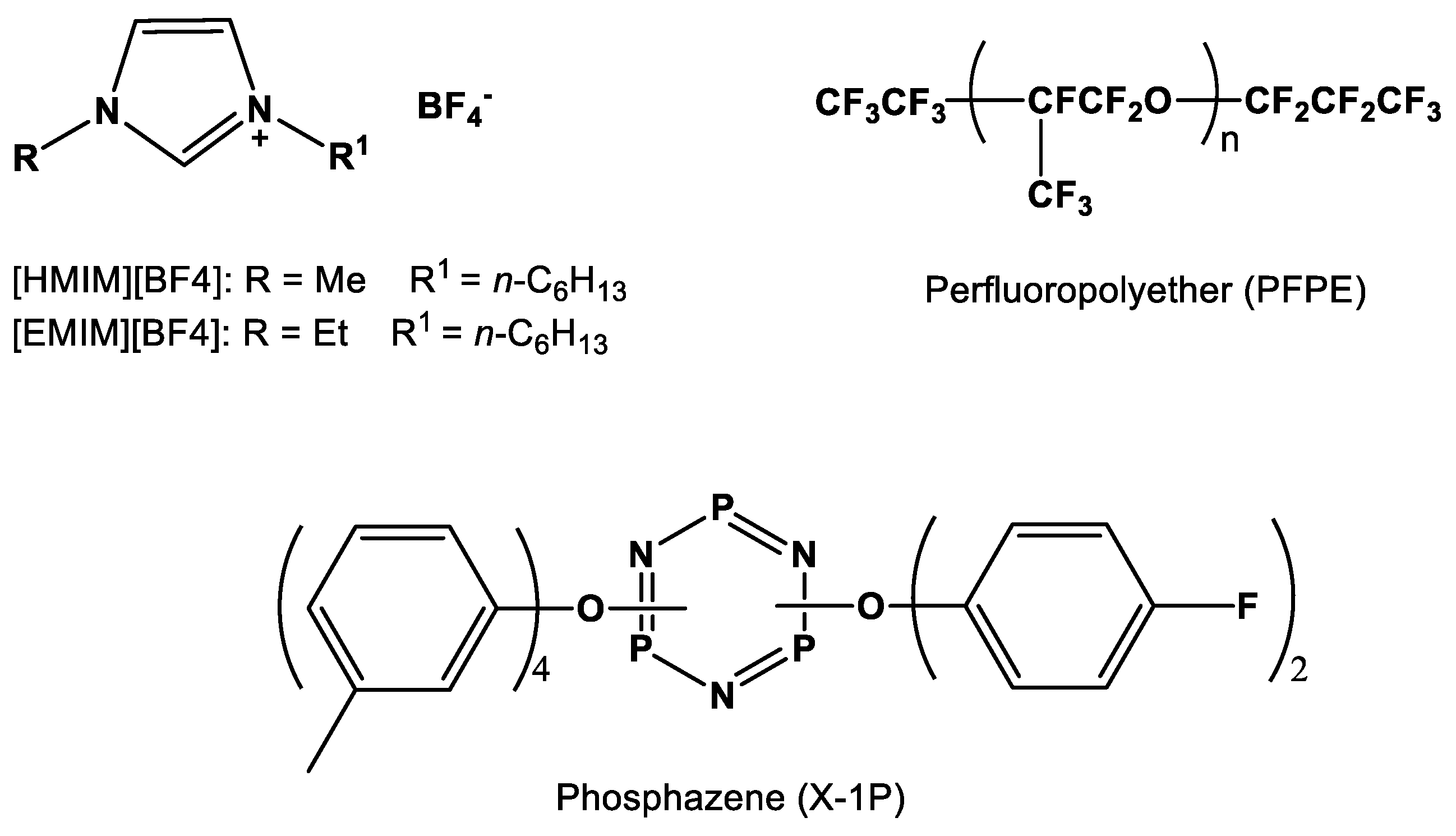

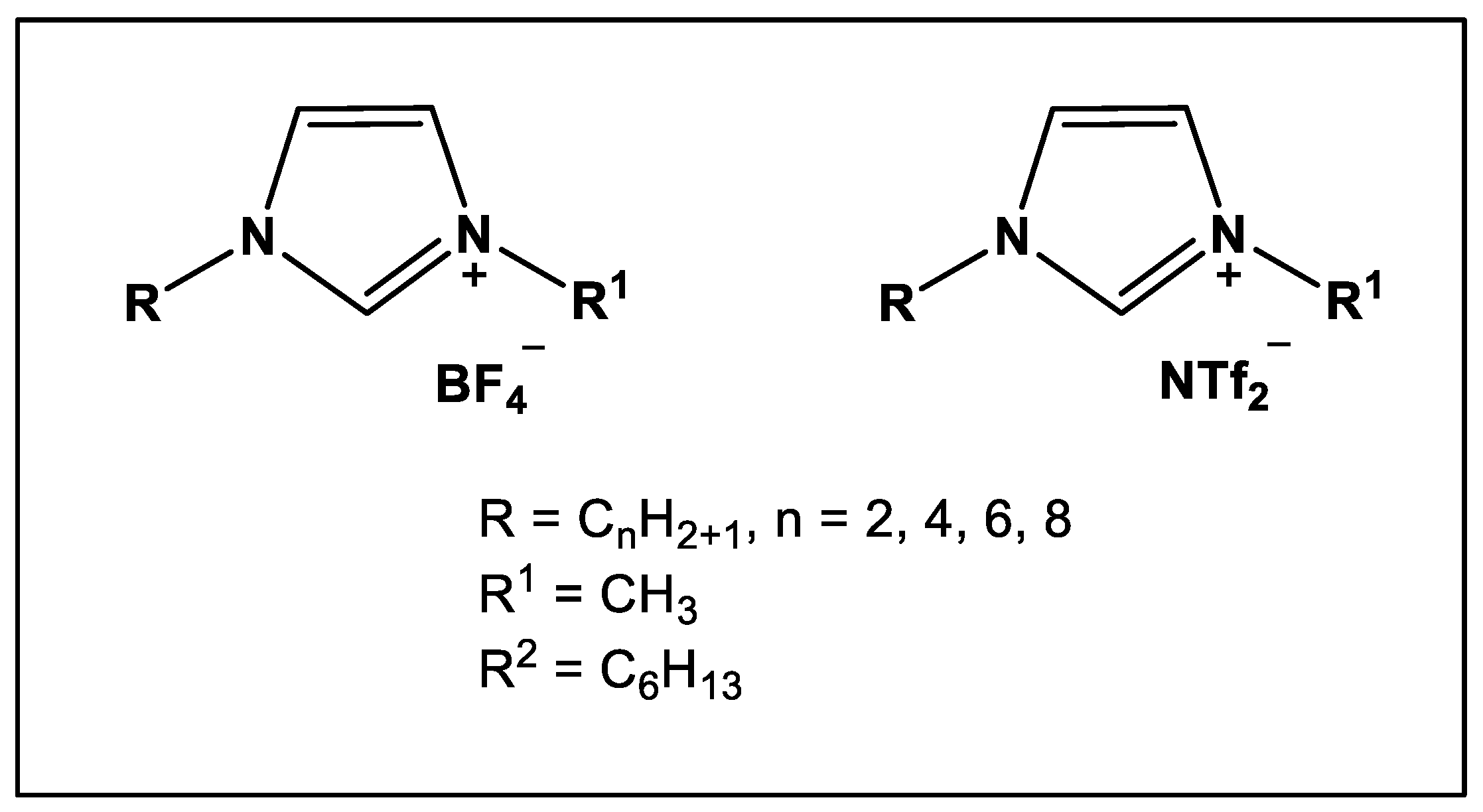

5.1.1. The Initial Efforts to Find Performing ILs as Lubricants

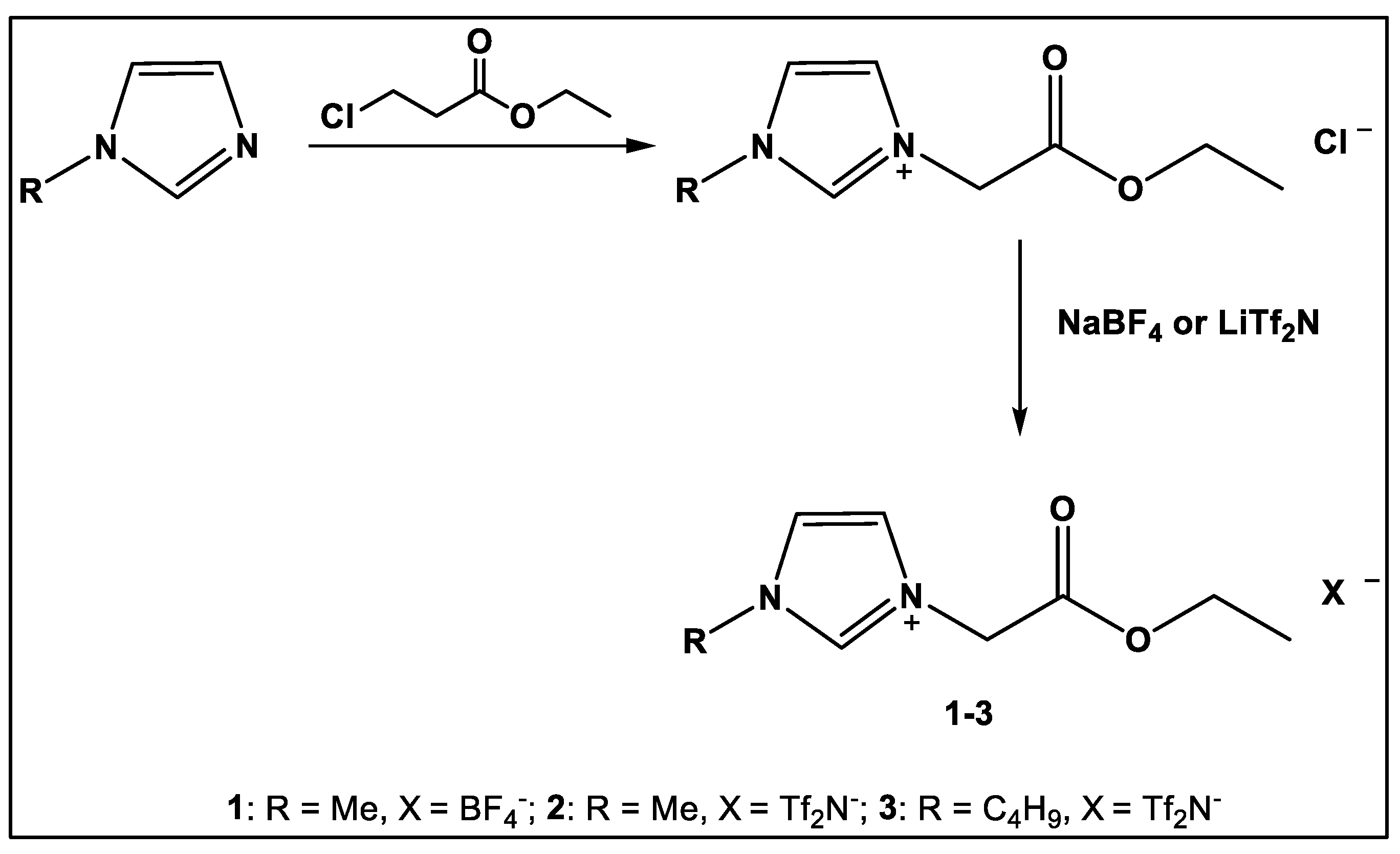

5.1.2. Developments through Preparation of ad hoc ILs

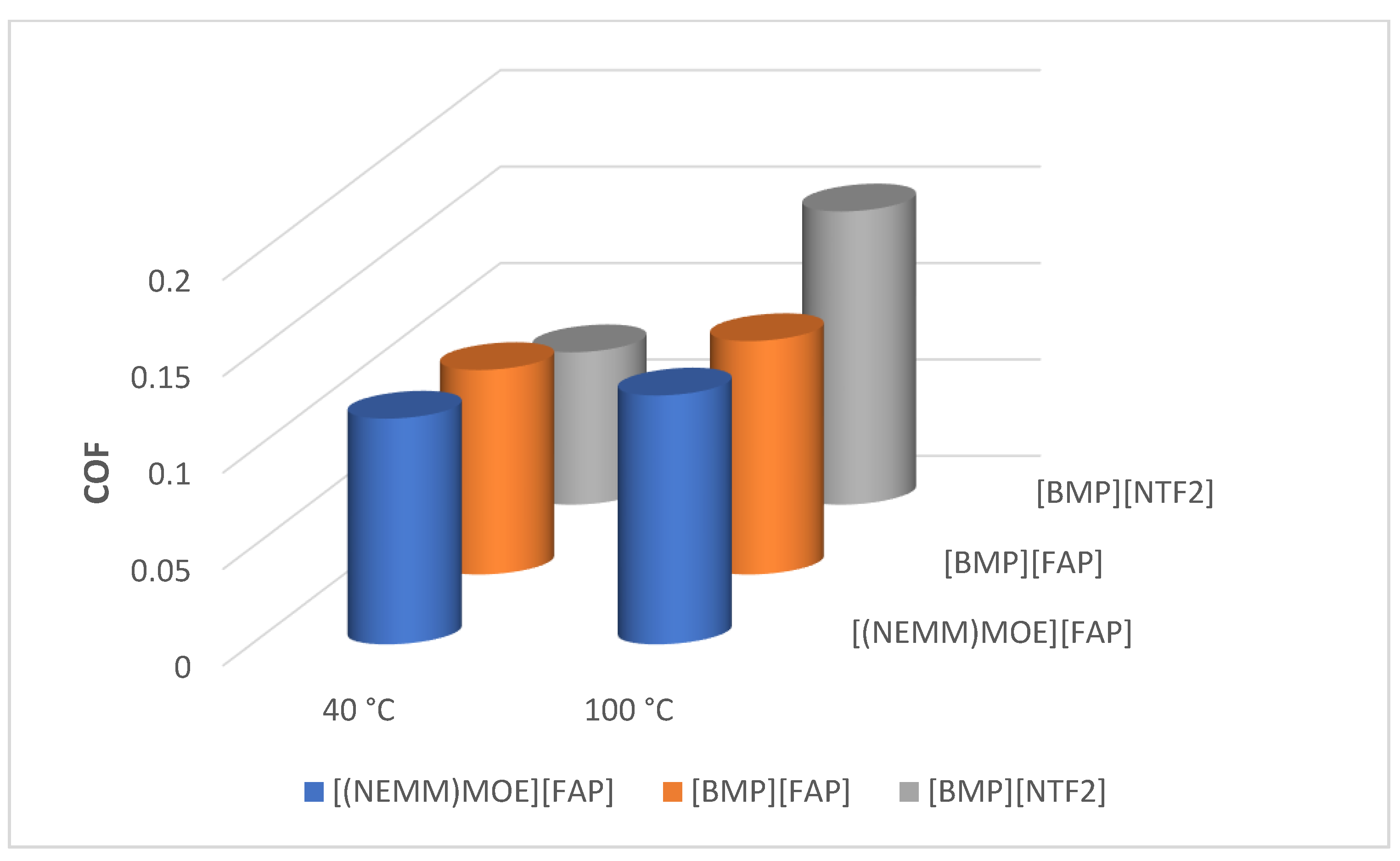

5.1.3. Anion Effects

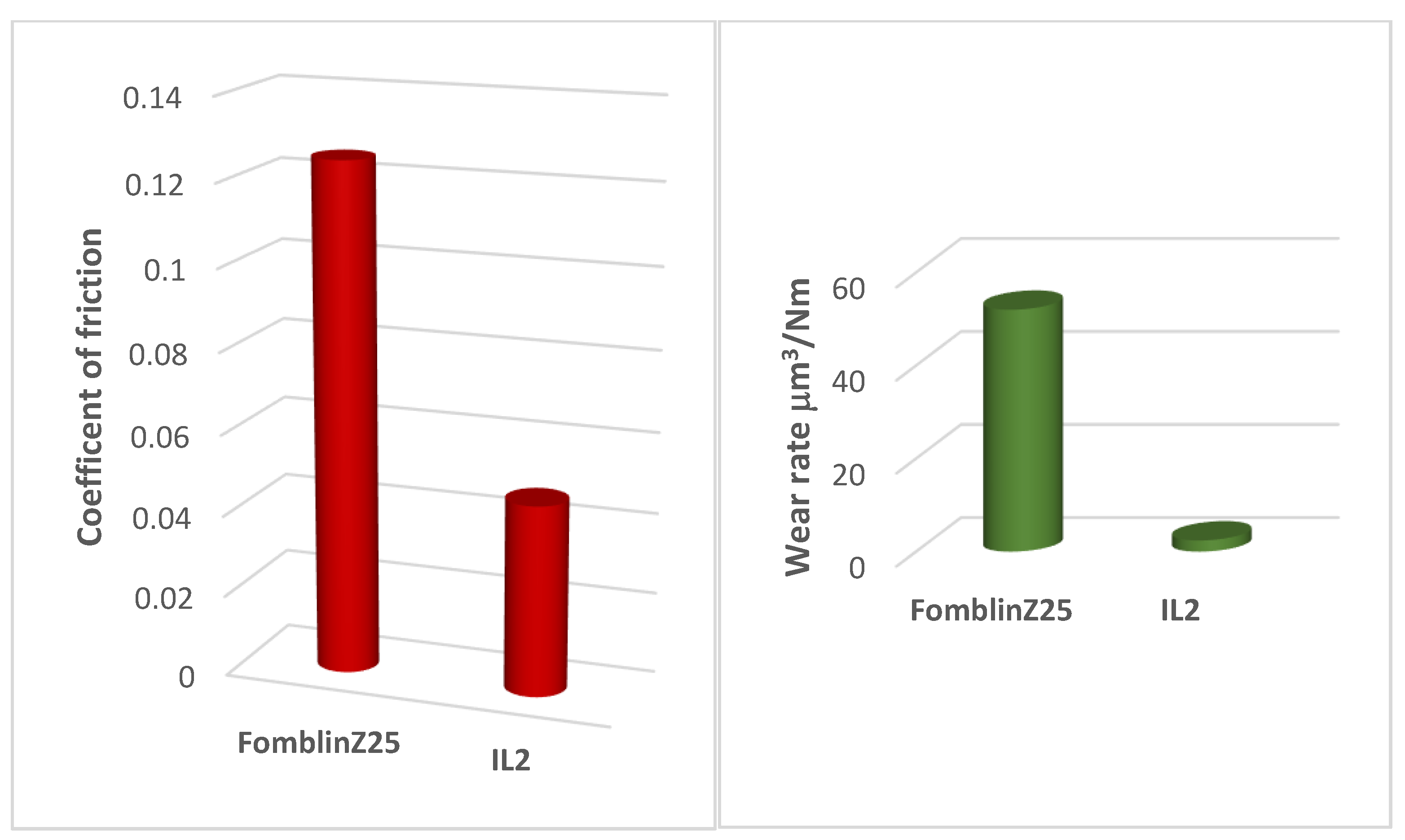

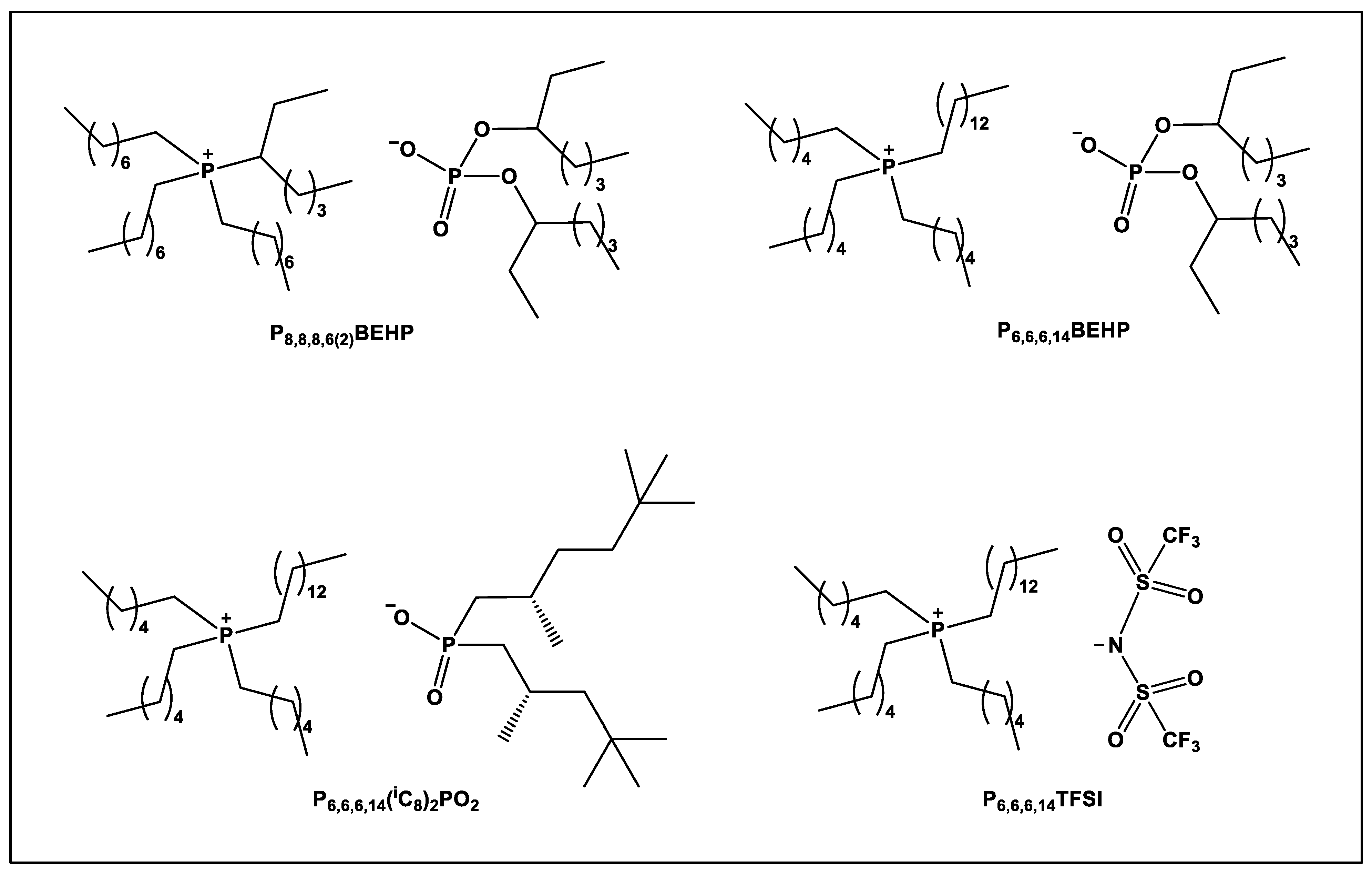

5.1.4. Low-Vapour Pressure

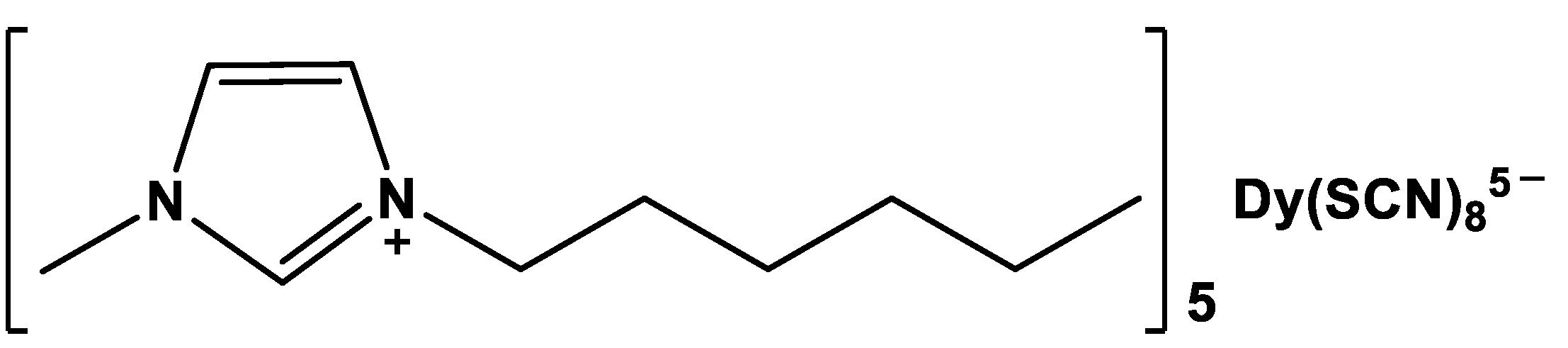

5.1.5. Magnetic Ionic Liquids

5.2. Aluminium Surfaces

5.3. Titanium

5.4. Other Applications I: Magnetic Media

5.5. Other Applications II: Human Body Joints Antifriction

6. Perspectives

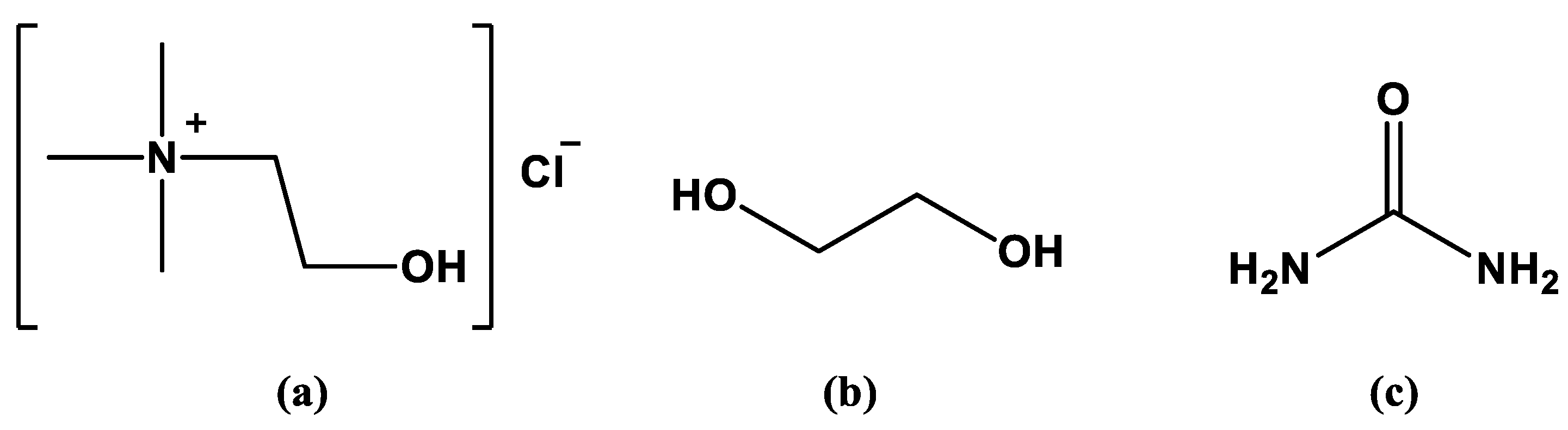

6.1. Novel Approaches to Overcome the High Costs

6.2. Some Attention to Avoid the Possibility of Corrosion

6.3. Novel Structures

6.4. IL-Metals

6.5. Commercialization

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Bowden, F.P.; Tabor, D. The Friction and Lubrication of Solids; Oxford University Press: Oxford, UK, 1950; pp. 1–337. [Google Scholar]

- Kardar, M.; Golestanian, R. The “friction” of vacuum, and other fluctuation-induced forces. Rev. Mod. Phys. 1999, 71, 1233–1245. [Google Scholar] [CrossRef]

- Lhermerout, R.; Diederichs, C.; Perkin, S. Are Ionic Liquids Good Boundary Lubricants? A Molecular Perspective. Lubricants 2018, 6, 9. [Google Scholar] [CrossRef]

- Ye, C.F.; Liu, W.M.; Chen, Y.X.; Yu, L.G. Room-temperature ionic liquids: A novel versatile lubricant. Chem. Commun. 2001, 2244–2245. [Google Scholar] [CrossRef]

- Earle, M.J.; Seddon, K.R. Ionic liquids. Green solvents for the future. Pure Appl. Chem. 2000, 72, 1391–1398. [Google Scholar] [CrossRef]

- Somers, A.E.; Howlett, P.C.; MacFarlane, D.R.; Forsyth, M.A. Review of Ionic Liquid Lubricants. Lubricants 2013, 1, 3–21. [Google Scholar] [CrossRef]

- Bhushan, B.; Palacio, M.; Kinzig, B. AFM-Based Nanotribological and Electrical Characterization of Ultrathin Wear-Resistant Ionic Liquid Films. J. Colloid Interface Sci. 2008, 317, 275–287. [Google Scholar] [CrossRef]

- Goossens, K.; Lava, K.; Bielawski, C.W.; Binnemans, K. Ionic Liquid Crystals: Versatile Materials. Chem. Rev. 2016, 116, 4643–4807. [Google Scholar] [CrossRef]

- Calandra, P.; Caponetti, E.; Martino, D.C.; D’Angelo, P.; Minore, A.; Turco Liveri, V. FT-IR and Dielectric study of water/AOT liquid crystals. J. Mol. Struct. 2000, 522, 165–178. [Google Scholar] [CrossRef]

- Donato, M.T.; Colaço, R.; Branc, L.C.; Saramago, B. A review on alternative lubricants: Ionic liquids as additives and deep eutectic solvents. J. Mol. Liq. 2021, 333, 116004–116029. [Google Scholar] [CrossRef]

- Li, Z.; Mangolini, F. Recent Advances in Nanotribology of Ionic Liquids. Exp. Mech. 2021. [Google Scholar] [CrossRef]

- Xiao, H. Ionic Liquid Lubricants: Basics and Applications. Tribol. Trans. 2017, 60, 20–30. [Google Scholar] [CrossRef]

- Bermúdez, M.-D.; Jiménez, A.-E.; Sanes, J.; Carrión, F.-J. Ionic Liquids as Advanced Lubricant Fluids. Molecules 2009, 14, 2888–2908. [Google Scholar] [CrossRef]

- Amiri, S.A.S.; Rahim, E.A.; Syahrullail, S. A review on ionic liquids as sustainable lubricants in manufacturing and engineering: Recent research, performance, and application. J. Clean. Prod. 2017, 168, 1571–1589. [Google Scholar] [CrossRef]

- Kondo, Y.; Koyama, T.; Sasaki, S. Tribological Properties of Ionic Liquids in Ionic Liquids—New Aspects for the Future. IntechOpen 2013, 5, 127–141. [Google Scholar]

- Perkin, S.; Albrecht, T.; Klein, J. Layering and shear properties of an ionic liquid, 1-ethyl-3-methylimidazolium ethylsulfate, confined to nano-films between mica surfaces. Phys. Chem. Chem. Phys. 2010, 12, 1243–1247. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.-H.; Hsu, L.-W.; Chang, H.-C. Structural Reorganization of Imidazolium Ionic Liquids Induced by Pressure-Enhanced Ionic Liquid—Polyethylene Oxide Interactions. Int. J. Mol. Sci. 2021, 22, 981. [Google Scholar] [CrossRef]

- Chang, H.-C.; Wang, T.-H.; Burba, C.M. Probing Structures of Interfacial 1-Butyl-3-Methylimidazolium Trifluoromethanesulfonate Ionic Liquid on Nano-Aluminum Oxide Surfaces Using High-Pressure Infrared Spectroscopy. Appl. Sci. 2017, 7, 855. [Google Scholar] [CrossRef]

- Han, M.; Espinosa-Marzal, R.M. Molecular Mechanisms Underlying Lubrication by Ionic Liquids: Activated Slip and Flow. Lubricants 2018, 6, 64. [Google Scholar] [CrossRef]

- Li, H.; Cooper, P.K.; Somers, A.E.; Rutland, M.W.; Howlett, P.C.; Forsyth, M.; Atkin, R. Ionic Liquid Adsorption and Nanotribology at the Silica–Oil Interface: Hundred-Fold Dilution in Oil Lubricates as Effectively as the Pure Ionic Liquid. J. Phys. Chem. Lett. 2014, 5, 4095–4099. [Google Scholar] [CrossRef]

- Welton, T. Ionic liquids: A brief history. Biophys. Rev. 2018, 10, 691–706. [Google Scholar] [CrossRef]

- Maiuolo, L.; Algieri, V.; Olivito, F.; De Nino, A. Recent Developments on 1,3-Dipolar Cycloaddition Reactions by Catalysis in Green Solvents. Catalysts 2020, 10, 65. [Google Scholar] [CrossRef]

- Welton, T. Room-Temperature Ionic Liquids. Solvents for Synthesis and Catalysis. Chem. Rev. 1999, 99, 2071–2084. [Google Scholar] [CrossRef] [PubMed]

- De Nino, A.; Merino, P.; Algieri, V.; Nardi, M.; Di Gioia, M.L.; Russo, B.; Tallarida, M.A.; Maiuolo, L. Synthesis of 1,5-Functionalized 1,2,3-Triazoles Using Ionic Liquid/Iron (III) Chloride as an Efficient and Reusable Homogeneous Catalyst. Catalysts 2018, 8, 364–376. [Google Scholar]

- Hallett, J.P.; Welton, T. Room-Temperature Ionic Liquids: Solvents for Synthesis and Catalysis 2. Chem. Rev. 2011, 111, 3508–3576. [Google Scholar] [CrossRef]

- De Nino, A.; Algieri, V.; Tallarida, M.A.; Costanzo, P.; Pedrón, M.; Tejero, T.; Merino, P.; Maiuolo, L. Regioselective Synthesis of 1,4,5-Trisubstituted-1,2,3-Triazoles from Aryl Azides and Enaminones. Eur. J. Org. Chem. 2019, 33, 5725–5731. [Google Scholar] [CrossRef]

- De Nino, A.; Maiuolo, L.; Merino, P.; Nardi, M.; Procopio, A.; Roca-Lopez, D.; Russo, B.; Algieri, V. Efficient Organocatalyst Supported on a Simple Ionic Liquid as a Recoverable System for the Asymmetric Diels-Alder Reaction in the Presence of Water. ChemCatChem 2015, 7, 830–835. [Google Scholar] [CrossRef]

- Mu, Z.; Zhou, F.; Zhang, S.; Liang, Y.; Liu, W. Effect of the Functional Groups in Ionic Liquid Molecules on the Friction and Wear Behavior of Aluminum Alloy in Lubricated Aluminum-on Steel Contact. Tribol. Int. 2005, 38, 725–731. [Google Scholar] [CrossRef]

- Itoh, T.; Watanabe, N.; Inada, K.; Ishioka, A.; Hayase, S.; Kawatsura, M.; Minami, I.; Mori, S. Design of Alkanesulfonate Ionic Liquids for Lubricants. Chem. Lett. 2009, 38, 64–65. [Google Scholar] [CrossRef]

- Zhou, F.; Liang, Y.; Liu, W. Ionic Liquid Lubricants: Designed Chemistry for Engineering Applications. Chem. Soc. Rev. 2009, 38, 2590–2599. [Google Scholar] [CrossRef]

- Xie, G.; Luo, J.; Guo, D.; Liu, S. Nanoconfined Ionic Liquids under Electric Fields. Appl. Phys. Lett. 2010, 96, 043112. [Google Scholar] [CrossRef]

- Hansen, J.-P.; McDonald, I.R. Theory of Simple Liquids with Applications to Soft Matter, 4th ed.; Academic Press: Cambridge, MA, USA, 2013; pp. 1–619. [Google Scholar]

- Triolo, A.; Russina, O.; Bleif, H.-J.; Di Cola, E. Nanoscale Segregation in Room Temperature Ionic Liquids. J. Phys. Chem. B 2007, 111, 4641–4644. [Google Scholar] [CrossRef]

- Triolo, A.; Russina, O.; Fazio, B.; Appetecchi, G.B.; Carewska, M.; Passerini, S. Nanoscale organization in piperidinium-based room temperature ionic liquids. J. Chem. Phys. 2009, 130, 164521. [Google Scholar] [CrossRef] [PubMed]

- Triolo, A.; Russina, O.; Fazio, B.; Triolo, R.; Di Cola, E. Morphology of 1-alkyl-3-methylimidazolium hexafluorophosphate room temperature ionic liquids Chem. Phys. Lett. 2008, 457, 362–365. [Google Scholar]

- Canongia Lopes, J.N.; Costa Gomes, M.F.; Pádua, A.A.H. Nonpolar, Polar, and Associating Solutes in Ionic Liquids. J. Phys. Chem. B 2006, 110, 16816–16818. [Google Scholar] [CrossRef]

- Granick, S. Motions and Relaxations of Confined Liquids. Science 1991, 253, 1374–1379. [Google Scholar] [CrossRef] [PubMed]

- Zaera, F. Probing Liquid/Solid Interfaces at the Molecular Level. Chem. Rev. 2012, 112, 2920–2986. [Google Scholar] [CrossRef]

- Bain, C.D. Sum-frequency vibrational spectroscopy of the solid/liquid interface. J. Chem. Soc. Faraday Trans. 1995, 91, 1281–1296. [Google Scholar] [CrossRef]

- Voïtchovsky, K. Anharmonicity, solvation forces, and resolution in atomic force microscopy at the solid-liquid interface. Phys. Rev. E 2013, 88, 022407. [Google Scholar] [CrossRef]

- Voïtchovsky, K.; Kuna, J.J.; Contera, S.A.; Tosatti, E.; Stellacci, F. Direct mapping of the solid-liquid adhesion energy with sub-nanometre resolution. Nat. Nanotechnol. 2010, 5, 401–405. [Google Scholar] [CrossRef]

- Kuna, J.J.; Voïtchovsky, K.; Singh, C.; Jiang, H.; Mwenifumbo, S.; Ghorai, P.K.; Stevens, M.M.; Glotzer, S.C.; Stellacci, F. The effect of nanometre-scale structure on interfacial energy. Nat. Mater. 2009, 8, 837–842. [Google Scholar] [CrossRef] [PubMed]

- Ricci, M.; Spijker, P.; Voïtchovsky, K. Water-induced correlation between single ions imaged at the solid–liquid interface. Nat. Commun. 2014, 5, 4400. [Google Scholar] [CrossRef]

- Gómez-Márquez, J. What are the principles that govern life? Commun. Integr. Biol. 2020, 13, 97–107. [Google Scholar] [CrossRef] [PubMed]

- Hayes, R.; Warr, G.G.; Atkin, R. Structure and Nanostructure in Ionic Liquids. Chem. Rev. 2015, 115, 6357–6426. [Google Scholar] [CrossRef] [PubMed]

- Hayes, R.; Wakeham, D.; Atkin, R. Interfaces of Ionic Liquids in Ionic Liquids UnCOILed: Critical Expert Overviews; Seddon, K.R., Plechkova, N., Eds.; John Wiley & Sons: New York, NY, USA, 2012; pp. 51–86. [Google Scholar]

- Atkin, R.; El Abedin, S.Z.; Hayes, R.; Gasparotto, L.H.S.; Borisenko, N.; Endres, F. AFM and STM Studies on the Surface Interaction of [BMP]TFSA and [EMIm]TFSA Ionic Liquids with Au(111) F. J. Phys. Chem. C 2009, 113, 13266–13272. [Google Scholar] [CrossRef]

- Hayes, R.; El Abedin, S.Z.; Atkin, R. Pronounced Structure in Confined Aprotic Room-Temperature Ionic Liquids. J. Phys. Chem. B 2009, 113, 7049–7052. [Google Scholar] [CrossRef] [PubMed]

- Wakeham, D.; Hayes, R.; Warr, G.G.; Atkin, R. Influence of Temperature and Molecular Structure on Ionic Liquid Solvation Layers. J. Phys. Chem. B 2009, 113, 5961–5966. [Google Scholar] [CrossRef] [PubMed]

- Horn, R.G.; Evans, D.F.; Ninham, B.W. Double-layer and solvation forces measured in a molten salt and its mixtures with water. J. Phys. Chem. 1988, 92, 3531–3537. [Google Scholar] [CrossRef]

- Israelachvili, J.N. Intermolecular and Surface Forces, 3rd ed.; Elsevier: London, UK, 2011; pp. 1–704. [Google Scholar]

- Lim, R.; O’Shea, S. Solvation Forces in Branched Molecular Liquids. J. Phys. Rev. Lett. 2002, 88, 246101. [Google Scholar] [CrossRef] [PubMed]

- Israelachvili, J. Solvation forces and liquid structure, as probed by direct force measurements. Acc. Chem. Res. 1987, 20, 415–421. [Google Scholar] [CrossRef]

- Meusel, M.; Lexow, M.; Gezmis, A.; Schötz, S.; Wagner, M.; Bayer, A.; Maier, F. Steinrück H-P. Atomic Force and Scanning Tunneling Microscopy of Ordered Ionic Liquid Wetting Layers from 110 K up to Room Temperature. ACS Nano 2020, 14, 9000–9010. [Google Scholar] [CrossRef] [PubMed]

- Graves, A.D. The electrical double layer in molten salts: Part 1—The potential of zero charge. Electroanal. Chem. 1970, 25, 349–356. [Google Scholar] [CrossRef]

- Graves, A.D. The electrical double layer in molten salts: Part 2—The double-layer capacitance. Electroanal. Chem. 1970, 25, 357–372. [Google Scholar] [CrossRef]

- Heyes, D.M.; Clarke, J.H. Computer simulation of molten-salt interphases—Effect of a rigid boundary and an applied electric field. J. Chem. Soc. Faraday Trans. 2 1981, 77, 1089–1100. [Google Scholar] [CrossRef]

- Atkin, R.; Craig, V.S.J.; Wanless, E.J.; Biggs, S. Mechanism of cationic surfactant adsorption at the solid-aqueous interface. Adv. Colloid Interface Sci. 2003, 103, 219–304. [Google Scholar] [CrossRef]

- Warr, G.G. Surfactant adsorbed layer structure at solid/solution interfaces: Impact and implications of AFM imaging studies. Curr. Opin. Colloid Interface Sci. 2000, 5, 88–94. [Google Scholar] [CrossRef]

- Halling, J. Hydrodynamic Lubrication. In Principles of Tribology; Palgrave: London, UK, 1978. [Google Scholar]

- Koyama, T.; Tsuboi, R.; Sasaki, S. Research on lubricity of ionic liquid for metal alloys. In Proceedings of the JAST Tribology Conference, Tokyo, Japan, 30 October–3 November 2011; pp. 47–48. [Google Scholar]

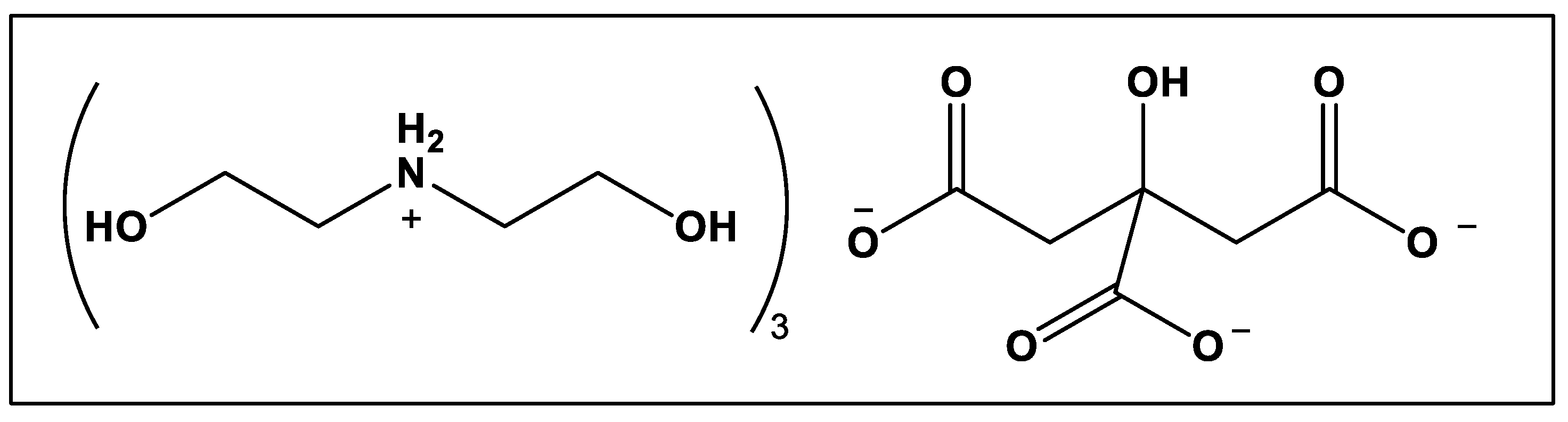

- Avilés, M.D.; Pamies, R.; Sanes, J.; Carrión, F.J.; Bermúdez, M.D. Fatty acid-derived ionic liquid lubricant: Protic ionic liquid additives. Coatings 2019, 9, 710. [Google Scholar] [CrossRef]

- Avilés, M.D.; Pamies, R.; Sanes, J.; Arias-Pardilla, J.; Carrión, F.J.; Bermúdez, M.D. Protic ammonium bio-based ionic liquid crystal lubricants. Tribol. Int. 2021, 158, 106917–106925. [Google Scholar] [CrossRef]

- Mia, S.; Tomozawa, K.; Morita, S.; Ohno, N. High-pressure rheology of ionic liquid. In Proceedings of the World Tribology Congress IV, Kyoto, Japan, 6–11 September 2009; p. 572. [Google Scholar]

- Rosenblum, B.; Brauelich, P.; Mimmel, L. Spontaneous emission of charged particles and photons during tensile deformation of oxide-covered metals under ultrahigh-vacuum conditions, J. Appl. Phys. 1977, 48, 5262–5273. [Google Scholar] [CrossRef]

- Kajdas, C. Importance of Anionic Reactive Intermediates for Lubricant Component Reactions with Friction Surfaces. Lubr. Sci. 1994, 6, 203–228. [Google Scholar] [CrossRef]

- Elbourne, A.; Sweeney, J.; Webber, G.B.; Wanless, E.J.; Warr, G.G.; Rutland, M.W.; Atkin, R. Adsorbed and near-surface structure of ionic liquids determines nanoscale friction. Chem. Commun. 2013, 49, 6797–6799. [Google Scholar] [CrossRef]

- Yanga, S.; Wong, J.S.S.; Zhoub, F. Ionic Liquid Additives for Mixed and Elastohydrodynamic Lubrication. Tribol. Trans. 2018, 61, 816–826. [Google Scholar] [CrossRef]

- Li, Q. Functional Organic and Hybrid Nanostructured Materials: Fabrication, Properties, and Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2018; pp. 1–638. [Google Scholar]

- Bonaccorsi, L.; Calandra, P.; Amenitsch, H.; Proverbio, E.; Lombardo, D. Growth of fractal aggregates during template directed SAPO-34 zeolite formation. Microporous Mesoporous Mater. 2013, 167, 3–9. [Google Scholar] [CrossRef]

- Chen, C.; Wylie, R.A.L.; Klinger, D.; Connal, L.A. Shape Control of Soft Nanoparticles and Their Assemblies. Chem. Mater. 2017, 29, 1918–1945. [Google Scholar] [CrossRef]

- Lombardo, D.; Calandra, P.; Magazù, S.; Wanderlingh, U.; Barreca, D. Soft nanoparticles charge expression within lipid membranes: The case of amino terminated dendrimers in bilayers vesicles. Colloids Surf. B Biointerfaces 2018, 170, 609–616. [Google Scholar] [CrossRef]

- Lombardo, D.; Munaò, G.; Calandra, P.; Pasqua, L.; Caccamo, M.T. Evidence of pre-micellar aggregates in aqueous solution of amphiphilic PDMS–PEO block copolymer. Phys. Chem. Chem. Phys. 2019, 21, 11983–11991. [Google Scholar] [CrossRef] [PubMed]

- Lombardo, D.; Calandra, P.; Caccamo, M.T.; Magazu, S.; Kiselev, M.A. Colloidal stability of liposomes. AIMS Mater. Sci. 2019, 6, 200–213. [Google Scholar] [CrossRef]

- Lombardo, D.; Calandra, P.; Kiselev, M.A. Structural Characterization of Biomaterials by Means of Small Angle X-rays and Neutron Scattering (SAXS and SANS), and Light Scattering Experiments. Molecules 2020, 25, 5624. [Google Scholar] [CrossRef] [PubMed]

- Zemb, T.; Lindner, P. Neutron, X-rays and Light Scattering Methods Applied to Soft Condensed Matter; North-Holland Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Kiselev, M.A.; Lombardo, D. Structural characterization in mixed lipid membrane systems by neutron and X-ray scattering. Biochim. Biophys. Acta 2017, 1861, 3700–3717. [Google Scholar] [CrossRef]

- Bonaccorsi, L.; Calandra, P.; Kiselev, M.A.; Amenitsch, H.; Proverbio, E.; Lombardo, D. Self-assembly in poly(dimethylsiloxane)-poly(ethylene oxide) block copolymer template directed synthesis of linde type A zeolite. Langmuir 2013, 29, 7079–7086. [Google Scholar] [CrossRef] [PubMed]

- Nagana Gowda, G.A.; Chen, H.; Khetrapal, C.L.; Weiss, R.G. Amphotropic Ionic Liquid Crystals with Low Order Parameters. Chem. Mater. 2004, 16, 2101–2106. [Google Scholar] [CrossRef]

- Tomšič, M.; Jamnik, A.; Fritz-Popovski, G.; Glatter, O.; Vlček, L. Structural Properties of Pure Simple Alcohols from Ethanol, Propanol, Butanol, Pentanol, to Hexanol: Comparing Monte Carlo Simulations with Experimental SAXS Data. J. Phys. Chem. B 2007, 111, 1738–1751. [Google Scholar] [CrossRef]

- Mariani, A.; Ballirano, P.; Angiolari, F.; Caminiti, R.; Gontrani, L. Does High Pressure Induce Structural Reorganization in Linear Alcohols? A Computational Answer. ChemPhysChem 2016, 17, 3023–3029. [Google Scholar] [CrossRef]

- Calandra, P.; Ruggirello, A.; Mele, A.; Liveri, V.T. Self-assembly in surfactant-based liquid mixtures: Bis(2-ethylhexyl)phosphoric acid/bis(2-ethylhexyl)amine systems. J. Colloid Interface Sci. 2010, 348, 183–188. [Google Scholar] [CrossRef] [PubMed]

- Calandra, P.; Turco Liveri, V.; Riello, P.; Freris, I.; Mandanici, A. Self-assembly in surfactant-based liquid mixtures: Octanoic acid/Bis(2-ethylhexyl)amine systems. J. Colloid Interface Sci. 2012, 367, 280–285. [Google Scholar] [CrossRef]

- Calandra, P.; Mandanici, A.; Turco Liveri, V. Self-assembly in surfactant-based mixtures driven by acid–base reactions: Bis(2-ethylhexyl) phosphoric acid–n-octylamine systems. RSC Adv. 2013, 3, 5148. [Google Scholar] [CrossRef]

- Mariani, A.; Caminiti, R.; Campetella, M.; Gontrani, L. Pressure-induced mesoscopic disorder in protic ionic liquids: First computational study Phys. Chem. Chem. Phys. 2016, 18, 2297–2302. [Google Scholar] [CrossRef] [PubMed]

- Atkin, R.; Warr, G.G. The Smallest Amphiphiles: Nanostructure in Protic Room-Temperature Ionic Liquids with Short Alkyl Groups. J. Chem. Phys. B Lett. 2008, 112, 4164–4166. [Google Scholar] [CrossRef] [PubMed]

- Russina, O.; Sferrazza, A.; Caminiti, R.; Triolo, A. Amphiphile Meets Amphiphile: Beyond the Polar-Apolar Dualism in Ionic Liquid/Alcohol Mixtures. J. Phys. Chem. Lett. 2014, 5, 1738–1742. [Google Scholar] [CrossRef] [PubMed]

- Turco Liveri, V.; Lombardo, D.; Pochylski, M.; Calandra, P. Molecular association of small amphiphiles: Origin of ionic liquid properties in dibutyl phosphate/propylamine binary mixtures. J. Mol. Liq. 2018, 263, 274–281. [Google Scholar] [CrossRef]

- Castner, E.W.; Wishart, J.F. Spotlight on ionic liquids J. Chem. Phys. 2010, 132, 120901. [Google Scholar] [CrossRef]

- Hayes, R.; Imberti, S.; Warr, G.G.; Atkin, R. Pronounced sponge-like nanostructure in propylammonium nitrate. Phys. Chem. Chem. Phys. 2011, 13, 13544–13551. [Google Scholar] [CrossRef] [PubMed]

- Ricci, M.; Spijker, P.; Stellacci, F.; Molinari, J.-F.; Voïtchovsky, K. Direct visualization of single ions in the Stern layer of calcite. Langmuir 2013, 29, 2207–2216. [Google Scholar] [CrossRef] [PubMed]

- Elbourne, A.; Voitchovsky, K.; Warr, G.; Atkin, R. Ion structure controls ionic liquid near-surface and interfacial nanostructure. Chem. Sci. 2015, 6, 527–536. [Google Scholar] [CrossRef] [PubMed]

- Segura, J.J.; Elbourne, A.; Wanless, E.J.; Warr, G.G.; Voïtchovsky, K.; Atkin, R. Adsorbed and near surface structure of ionic liquids at a solid interface. Phys. Chem. Chem. Phys. 2013, 15, 3320. [Google Scholar] [CrossRef] [PubMed]

- Seddon, J.R.T. Conservative and Dissipative Interactions of Ionic Liquids in Nanoconfinement. J. Phys. Chem. C 2014, 118, 22197–22201. [Google Scholar] [CrossRef]

- Chen, C.J. Introduction to Scanning Tunnelling Microscopy; Oxford University Press: New York, NY, USA, 1993; pp. 1–488. [Google Scholar]

- Muller, E.A.; Strader, M.L.; Johns, J.E.; Yang, A.; Caplins, B.W.; Shearer, A.J.; Suich, D.E.; Harris, C.B. Femtosecond Electron Solvation at the Ionic Liquid/Metal Electrode Interface. J. Am. Chem. Soc. 2013, 135, 10646–10653. [Google Scholar] [CrossRef]

- Aliaga, C.; Baldelli, S. A Sum Frequency Generation Study of the Room-Temperature Ionic Liquid-Titanium Dioxide Interface. J. Phys. Chem. C 2008, 112, 3064–3072. [Google Scholar] [CrossRef]

- Mariani, A.; Bonomo, M.; Wu, B.; Centrella, B.; Dini, D.; Castner, E.W., Jr.; Gontrani, L. Intriguing transport dynamics of ethylammonium nitrate–acetonitrile binary mixtures arising from nano-inhomogeneity. Phys. Chem. Chem. Phys. 2017, 19, 27212–27220. [Google Scholar] [CrossRef]

- Seddon, K.R.; Stark, A.; Torres, M.-J. Influence of chloride, water, and organic solvents on the physical properties of ionic liquids. Appl. Chem. 2000, 72, 2275–2287. [Google Scholar] [CrossRef]

- Lawes, S.D.A.; Hainsworth, S.V.; Blake, P.; Ryder, K.S.; Abbott, A.P. Lubrication of Steel/Steel Contacts by Choline Chloride Ionic Liquids. Tribol. Lett. 2010, 37, 103–110. [Google Scholar] [CrossRef]

- Zhu, L.-Y.; Chen, L.-G.; Yang, X.; Song, H.-B. Functionalized Ionic Liquids as Lubricants for Steel-Steel Contact. Appl. Mech. Mater. 2012, 138, 630–634. [Google Scholar] [CrossRef]

- García, A.; González, R.; HernándezBattez, A.; Viesca, J.L.; Monge, R.; Fernández-González, A.M. Hadfield Ionic liquids as a neat lubricant applied to steel-steel contacts. Tribol. Int. 2014, 72, 42–50. [Google Scholar] [CrossRef]

- Matweb. Solvay Specialty Polymers Fomblin® Z25 PFPE Lubricant. Available online: http://www.matweb.com/search/datasheet_print.aspx?matguid=0fe558c6e3c941f5b7a4168fa2d26fee (accessed on 12 April 2019).

- Dörr, N.; Merstallinger, A.; Holzbauer, R.; Pejaković, V.; Brenner, J.; Pisarova, L.; Stelzl, J.; Frauscher, M. Five-Stage Selection Procedure of Ionic Liquids for Lubrication of Steel–Steel Contacts in Space Mechanisms. Tribol. Lett. 2019, 67, 1–18. [Google Scholar] [CrossRef]

- Nie, L.R.; Song, H.; Yohannes, A.; Liang, S.W.; Yao, S. Extraction in cholinium-based magnetic ionic liquid aqueous two-phase system for the determination of berberine hydrochloride in Rhizomacoptidis. RSC Adv. 2018, 8, 44–25201. [Google Scholar] [CrossRef]

- Jia, J.; Yang, G.; Zhang, C.; Zhang, S.; Zhang, Y.; Zhang, P. Effects of magnetic ionic liquid as a lubricant on the friction andwear behavior of a steel-steel sliding contact under elevated temperatures. Friction 2021, 9, 61–74. [Google Scholar] [CrossRef]

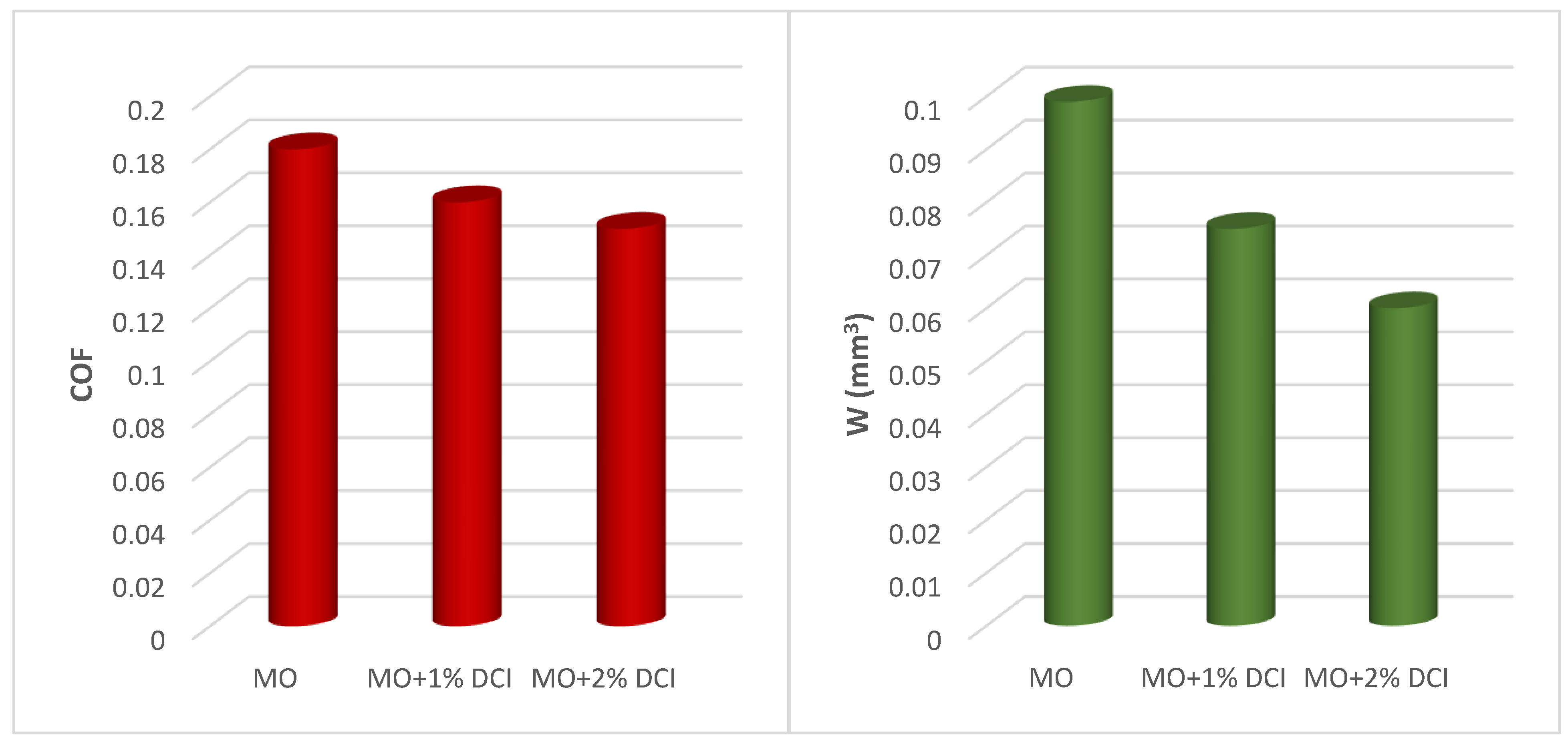

- Singh, K.K.; Singh, S.; Shrivastava, A.K. Study of Tribological Behavior of Silicon Carbide Based Aluminum Metal Matrix Composites under Dry and Lubricated Environment. Adv. Mater. Sci. Eng. 2016, 2016, 3813412–3813422. [Google Scholar] [CrossRef]

- Espinosa, T.; Sanes, J.; Jiménez, A.E.; Bermúdez, M.D. Protic ammonium carboxylate ionic liquid lubricants of OFHC copper. Wear 2013, 303, 495–509. [Google Scholar] [CrossRef]

- Ortega Vega, M.R.; Parise, K.; Ramos, L.B.; Boff, U.; Mattedi, S.; Schaeffer, L.; Malfatti, C.F. Protic Ionic Liquids Used as Metal-Forming Green Lubricants for Aluminum: Effect of Anion Chain Length. Mater. Res. 2017, 20, 675–687. [Google Scholar] [CrossRef]

- Zhang, H.-b.; Chen, H.; Shi, X.-n.; Liu, X.; Duan, G.-j. Tribological properties of ionic liquids for steel/aluminum, steel/copper and steel/Si3N4 ceramic contacts under boundary lubrication. Ind. Lubr. Tribol. 2018, 70, 1158–1168. [Google Scholar] [CrossRef]

- Patel, A.; Guo, H.; Iglesias, P. Study of the Lubricating Ability of Protic Ionic Liquid on an Aluminum-Steel Contact. Lubricants 2018, 6, 66. [Google Scholar] [CrossRef]

- An, R.; Zhu, Y.; Wu, N.; Xie, W.; Lu, J.; Feng, X.; Lu, X. Wetting Behavior of Ionic Liquid on Mesoporous Titanium Dioxide Surface by Atomic Force Microscopy. ACS Appl. Mater. Interfaces 2013, 5, 2692–2698. [Google Scholar] [CrossRef]

- Li, H.; Somers, A.E.; Rutland, M.W.; Howlett, P.C.; Atkin, R. Combined Nano- and Macrotribology Studies of Titania Lubrication Using the Oil-Ionic Liquid Mixtures. ACS Sustain. Chem. Eng. 2016, 4, 5005–5012. [Google Scholar] [CrossRef]

- Cooper, P.K.; Staddon, J.; Zhang, S.; Aman, Z.M.; Atkin, R.; Li, H. Nano- and Macroscale Study of the Lubrication of Titania Using Pure and Diluted Ionic Liquids. Front. Chem. 2019, 7, 287–295. [Google Scholar] [CrossRef] [PubMed]

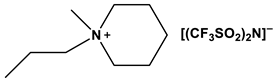

- Kondo, H. Tribochemistry of Ionic Liquid Lubricant on Magnetic Media. Adv. Tribol. 2012, 1–20. [Google Scholar] [CrossRef][Green Version]

- Kondo, H. Ionic Liquid Lubricant with Ammonium Salts for Magnetic Media in Applications of Ionic Liquids in Science and Technology; InTech Publisher: London, UK, 2011; pp. 1–516. [Google Scholar]

- Gong, J.P.; Kurokawa, T.; Narita, T.; Kagata, G.; Osada, Y.; Nishimura, G.; Kinjo, M. Synthesis of hydrogels with extremely low surface friction. J. Am. Chem. Soc. 2001, 123, 5582–5583. [Google Scholar] [CrossRef] [PubMed]

- Ren, H.-Y.; Mizukami, M.; Tanabe, T.; Furukawa, H.; Kurihara, K. Friction of polymer hydrogels studied by resonance shear measurements. Soft Matter 2015, 11, 6192–6200. [Google Scholar] [CrossRef]

- Okumura, Y.; Ito, K. The polyrotaxane gels: A topological gel by figure-of eight cross-links. Adv. Mater. 2001, 13, 485–487. [Google Scholar] [CrossRef]

- Sakai, T.; Matsunaga, T.; Yamamoto, Y.; Ito, C.; Yoshida, R.; Suzuki, S.; Sasaki, N.; Shibayama, M.; Chung, U. Design and Fabrication of a High-Strength Hydrogel with Ideally Homogeneous Network Structure from Tetrahedron-like Macromonomers. Macromolecules 2008, 41, 5379–5384. [Google Scholar] [CrossRef]

- Gong, J.P.; Katsuyama, Y.; Kurokawa, T.; Osada, Y. Double-Network Hydrogels with Extremely High Mechanical Strength. Adv. Mater. 2003, 15, 1155–1158. [Google Scholar] [CrossRef]

- Arafune, H.; Honma, S.; Morinaga, T.; Kamijo, T.; Miura, M.; Furukawa, H.; Sato, T. Highly Robust and Low Frictional Double-Network Ion Gel. Adv. Mater. Interfaces 2017, 4, 1700074–1700078. [Google Scholar] [CrossRef]

- Arafune, H.; Muto, F.; Kamijo, T.; Honma, S.; Morinaga, T.; Sato, T. Tribological Properties of Double-Network Gels Substituted by Ionic Liquids. Lubricants 2018, 6, 89. [Google Scholar] [CrossRef]

- Ratti, R. Ionic Liquids: Synthesis and Applications in Catalysis Advances in Chemistry Adv. Chem. 2014, 729842. [Google Scholar] [CrossRef]

- Calandra, P.; Turco Liveri, V.; Proietti, N.; Capitani, D.; Lombardo, D.; Gainaru, C.; Böhmer, R.; Kozak, M.; Dobies, M.; Fojud, Z.; et al. Non-ideal mixing behavior in dibutyl phosphate-propylamine binary liquids: Dielectric and nuclear magnetic resonance investigations. J. Mol. Liq. 2021, 323, 114963. [Google Scholar] [CrossRef]

- Calandra, P. On the physico-chemical basis of self-nanosegregation giving magnetically-induced birefringence in dibutyl phosphate/bis(2-ethylhexyl) amine systems. J. Mol. Liq. 2020, 310, 113186. [Google Scholar] [CrossRef]

- Pochylski, M.; Lombardo, D.; Calandra, P. Optical Birefringence Growth Driven by Magnetic Field in Liquids: The Case of Dibutyl Phosphate/Propylamine System. Appl. Sci. 2020, 10, 164. [Google Scholar] [CrossRef]

- Calandra, P.; Turco Liveri, P.; Ruggirello, A.M.; Licciardi, M.; Lombardo, M.; Mandanici, A. Anti-Arrhenian behaviour of conductivity in octanoic acid–bis(2-ethylhexyl)amine systems: A physico-chemical study. J. Mater. Chem. C 2015, 3, 3198–3210. [Google Scholar] [CrossRef]

- Uerdingen, M.; Treber, C.; Balser, M.; Schmittc, G.; Wernerb, C. Corrosion behaviour of ionic liquids. Green Chem. 2005, 7, 321–325. [Google Scholar] [CrossRef]

- Jimenez, A.E.; Bermudez, M.D.; Carrion, F.J.; Martinez-Nicolas, G. Room temperature ionic liquids as lubricant additives in steel-aluminium contacts: Influence of sliding velocity, normal load and temperature. Wear 2006, 261, 347–359. [Google Scholar] [CrossRef]

- Qu, J. Tribological characteristics of aluminum alloys sliding against steel lubricated by ammonium and imidazolium ionic liquids. Wear 2009, 267, 1226–1231. [Google Scholar] [CrossRef]

- Bermudez, M.D.; Jimenez, A.E.; Martinez-Nicolas, G. Study of surface interactions of ionic liquids with aluminium alloys in corrosion and erosion-corrosion processes. Appl. Surf. Sci. 2007, 253, 7295–7302. [Google Scholar] [CrossRef]

- Gabler, C.; Tomastik, C.; Brenner, J.; Pisarova, L.; Doerra, N.; Allmaierb, G. Corrosion properties of ammonium based ionic liquids evaluated by SEM-EDX, XPS and ICP-OES. Green Chem. 2011, 13, 2869–2877. [Google Scholar] [CrossRef]

- Jimenez, A.E.; Bermudez, M.D. Ionic liquids as lubricants of titanium-steel contact part 2: Friction, wear and surface interactions at high temperature. Tribol. Lett. 2010, 37, 431–443. [Google Scholar] [CrossRef]

- Kawada, S.; Watanabe, S.; Tsuboi, R.; Sasaki, S.; Prakash, B. Lubrication mechanism of halogen-free ionic liquids. Tribol. Online 2017, 12, 155–161. [Google Scholar] [CrossRef][Green Version]

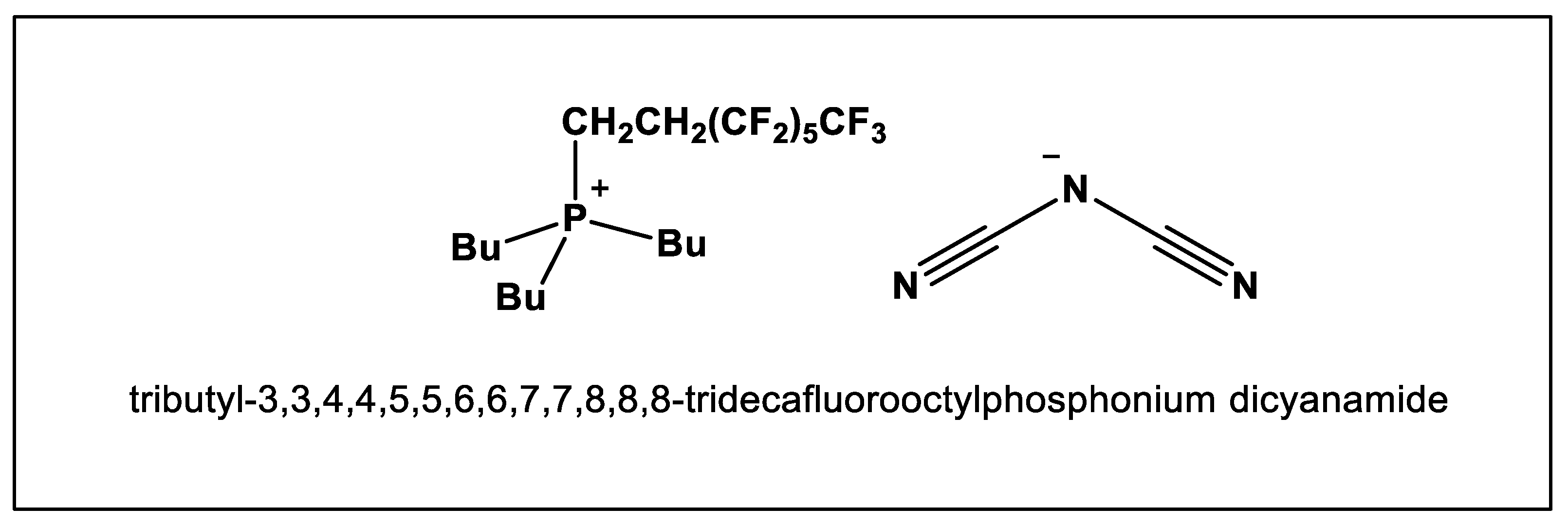

- Urtis, L.A.; Arcifa, A.; Zhang, P.; Du, J.; Fantauzzi, M.; Rauber, D.; Hempelmann, R.; Kraus, T.; Rossi, A.; Spencer, N.D. Influence of Water on Tribolayer Growth When Lubricating Steel with a Fluorinated Phosphonium Dicyanamide Ionic Liquid. Lubricants 2019, 7, 27. [Google Scholar] [CrossRef]

- Smirnova, N.A.; Safonova, E.A. Ionic Liquids as Surfactants. Russ. J. Phys. Chem. A 2010, 84, 1695–1704. [Google Scholar] [CrossRef]

- Qi, X.; Zhang, X.; Luo, G.; Han, C.; Liu, C.; Zhang, S. Mixing Behavior of Conventional Cationic Surfactants and Ionic Liquid Surfactant 1-Tetradecyl-3-methylimidazolium Bromide ([C14mim]Br) in Aqueous Medium. J. Dispers. Sci. Technol. 2013, 34, 125–133. [Google Scholar] [CrossRef]

- Farooq, U.; Ali, A.; Patel, R.; Malik, N.A. Self-aggregation of ionic liquid-cationic surfactant mixed micelles in water and in diethylene glycol–water mixtures: Conductometric, tensiometric, and spectroscopic studies. J. Mol. Liq. 2017, 234, 452–462. [Google Scholar] [CrossRef]

- Calandra, P.; Caschera, D.; Turco Liveri, V.; Lombardo, D. How self-assembly of amphiphilic molecules can generate complexity in the nanoscale. Colloids Surf. A Physicochem. Eng. Asp. 2015, 484, 164–183. [Google Scholar] [CrossRef]

- Jinaga, R.; Jagadeesha, T.; Kolekar, S.; Choi, S.-B. The Synthesis of Organic Oils Blended Magnetorheological Fluids with the Field-Dependent Material Characterization. Int. J. Mol. Sci. 2019, 20, 5766. [Google Scholar] [CrossRef]

- Schwartz, M. Smart Materials; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2008; pp. 1–554. [Google Scholar]

- Fan, X.; Xia, Y.; Wang, L. Tribological properties of conductive lubricating greases. Friction 2014, 2, 343–353. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, L.; Si, L.; Ren, X.; Wu, S. Study on the Friction Behaviors of Copper Nanowires in Ionic Liquids under External Voltages. J. Mater. Eng. Perform. 2020, 29, 5718–5727. [Google Scholar] [CrossRef]

- Si, L.; Pan, Y.; Zhang, X.; Wang, J.; Yao, J.; Wang, Y.; Liu, F.; He, F. Tribological properties of metallic nanoparticles as lubricant additives under the applied electric currents. Ind. Lubr. Tribol. 2018, 70, 1714–1720. [Google Scholar] [CrossRef]

- Gusain, R.; Khatri, O.P. Ultrasound assisted shape regulation of CuO nanorods in ionic liquids and their use as energy efficient lubricant additives. Mater. Chem. A 2013, 1, 5612–5619. [Google Scholar] [CrossRef]

- Carrión, F.J.; Sanes, J.; Bermúdez, M.-D. Effect of the addition of room temperature ionic liquid and ZnO nanoparticles on the wear and scratch resistance of epoxy resin. Wear 2010, 268, 1295–1302. [Google Scholar]

- Bermúdez, M.-D.; Brostow, W.; Carrión-Vilches, F.-J.; Sanes, J. Scratch Resistance of Polycarbonate Containing ZnO Nanoparticles: Effects of Sliding Direction. J. Nanosci. Nanotechnol. 2010, 10, 6683–6689. [Google Scholar] [CrossRef] [PubMed]

- Rogers, R.D.; Seddon, K.R. Ionic Liquids—Solvents of the Future? Science 2003, 302, 792–793. [Google Scholar] [CrossRef]

- European Chemicals Agency (ECHA). Substances Restricted under REACH (Last Updated 10 August 2020). Available online: https://echa.europa.eu/substances-restricted-under-reach (accessed on 1 September 2020).

- Welton, T. Ionic liquids in Green Chemistry. Green Chem. 2011, 13, 225. [Google Scholar] [CrossRef]

- Plechkova, N.V.; Seddon, K.R. Applications of ionic liquids in the chemical industry. Chem. Soc. Rev. 2008, 37, 123–150. [Google Scholar] [CrossRef] [PubMed]

- Greer, A.J.; Jacquemin, J.; Hardacre, C. Industrial Applications of Ionic Liquids. Molecules 2020, 25, 5207. [Google Scholar] [CrossRef] [PubMed]

- Shiflett, M.B. Commercial Applications of Ionic Liquids; Springer: Cham, Switzerland, 2020; pp. 1–282. [Google Scholar]

| Frictional Pair (Ball/Disk) | Friction Coefficient | ||

|---|---|---|---|

| [HMIM][BF4] | X-1P | PFPE | |

| Steel/Steel | 0.065 | 0.098 | 0.145 |

| Steel/Al | 0.040 | 0.128 | - |

| Steel/Cu | 0.025 | 0.117 | 0.145 |

| Steel/SiO2 | 0.060 | 0.110 | 0.132 |

| Steel/sialon | 0.065 | 0.100 | 0.120 |

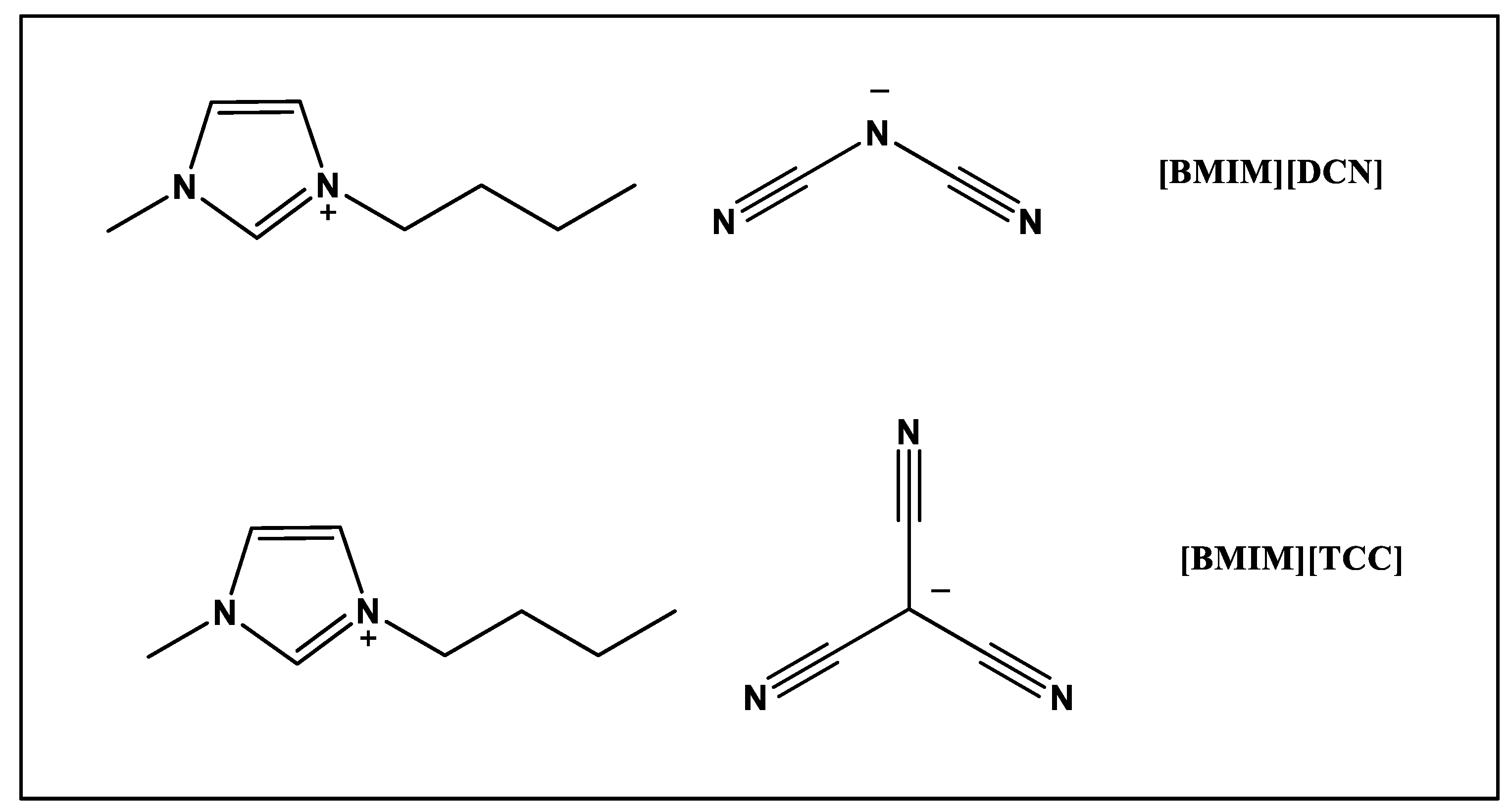

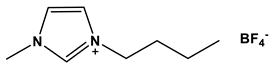

| Fluid | Kinematic Viscosity (mm2/s) | Viscosity Index | |||

|---|---|---|---|---|---|

| 40 °C | 100 °C | ||||

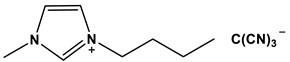

| Ioni liquid | (PP13)[TFSI] |  | 52.5 | 10.0 | 181 |

| [P(h3)t][TFSI] |  | 118 | 15.4 | 137 | |

| [BMIM][PF4] |  | 44.5 | 9.01 | 189 | |

| [BMIM][PF6] |  | 81.0 | 13.6 | 172 | |

| [BMIM][TFSI] |  | 29.0 | 6.88 | 211 | |

| [BMIM][I] |  | 203 | 21.0 | 122 | |

| [BMIM][TCC] |  | 14.6 | 3.7 | 146 | |

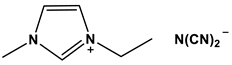

| [EMIM][DCN] |  | 8.6 | 3.01 | 252 | |

| oil | Synthetic oil (PAO4) | 16.8 | 3.9 | 129 | |

| Synthetic oil (PAO6) | 30.5 | 5.79 | 135 | ||

| Mineral base oil | 30.1 | 5.28 | 106 | ||

| Load/N | Friction Coefficient | |||

|---|---|---|---|---|

| IL 1 | IL 2 | IL 3 | PFPE | |

| 100 | 0.086 | 0.094 | 0.095 | 0.131 |

| 200 | 0.077 | 0.081 | 0.085 | 0.138 |

| 400 | 0.076 | 0.082 | 0.077 | 0.122 |

| 600 | 0.082 | 0.085 | 0.074 | - b |

| 800 | 0.079 | 0.082 | 0.075 | - b |

| Lubricant | Cefficient of Friction |

|---|---|

| Commercial | 0.08 ± 0.011 |

| 2HEAPe | 0.14 ± 0.026 |

| 2HEAF | 0.35 ± 0.12 |

| Dry | 0.64 ± 0.10 |

| Lubricant | Friction Coefficient | |

|---|---|---|

| 2N | 10N | |

| Hexadecane (HD) | 0.45 ± 0.05 | 0.46 ± 0.05 |

| HD + 0.01% IL | 0.46± 0.04 | 0.47 ± 0.04 |

| HD + 0.1% IL | 0.47± 0.05 | 0.48 ± 0.04 |

| HD + 1% IL | 0.45 ± 0.05 | 0.46 ± 0.05 |

| HD + 2% IL | 0.11 ± 0.02 | 0.45± 0.06 |

| HD + 10% IL | 0.12 ± 0.02 | 0.47± 0.05 |

| Pure IL | 0.09 ± 0.01 | 0.09± 0.01 |

| 2% ZDDP | 0.42 ± 0.06 | 0.45± 0.04 |

| IL | Friction Coefficient |

|---|---|

| P8,8,8,6(2) BEHP | 0.08 |

| P6,6,6,6,14 BEHP | 0.33 |

| P6,6,6,6,14(iC8)2PO2 | 0.16 |

| P6,6,6,6,14 TFSI | 0.17 |

| RF-CO-Y-R | ||

|---|---|---|

| RF | Y | R |

| C7F15 | O | C18H37 |

| C7F15 | O | C18H37 |

| C7F15 | NH | C18H37 |

| C7F15 | NH | C18H37 |

| C7F15 | O-NH3+ | C18H37 |

| C7F15 | O-NH3+ | C18H37 |

| C9F19 | O-NH3+ | C18H37 |

| C9F19 | O-NH3+ | C18H37 |

| C9F19 | O-NH3+ | C18H37 |

| C9F19 | O-NH3+ | C18H37 |

| -CF2O-(CF2O)m-(CF2CF2O)n-CF2O- | O-NH3+ | C18H37 |

| -CF2O-(CF2O)m-(CF2CF2O)n-CF2O- | O-NH3+ | C18H37 |

| -CF2O-(CF2O)m-(CF2CF2O)n-CF2O- | O-NH3+ | C18H37 |

| -CF2O-(CF2O)m-(CF2CF2O)n-CF2O- | O-NH2(CH3)+ | C18H37 |

| -CF2O-(CF2O)m-(CF2CF2O)n-CF2O- | O-NH(CH3)2+ | C18H37 |

| -CF2O-(CF2O)m-(CF2CF2O)n-CF2O- | O-NH2(C18H37)+ | C18H37 |

| -CF2O-(CF2O)m-(CF2CF2O)n-CF2O- | O-NH2(C6H5)+ | C18H37 |

| F-(CF2CF2CF2O)n-CF2CF2- | O-NH3+ | C18H37 |

| O-NH3+ | C18H37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calandra, P.; Szerb, E.I.; Lombardo, D.; Algieri, V.; De Nino, A.; Maiuolo, L. A Presentation of Ionic Liquids as Lubricants: Some Critical Comments. Appl. Sci. 2021, 11, 5677. https://doi.org/10.3390/app11125677

Calandra P, Szerb EI, Lombardo D, Algieri V, De Nino A, Maiuolo L. A Presentation of Ionic Liquids as Lubricants: Some Critical Comments. Applied Sciences. 2021; 11(12):5677. https://doi.org/10.3390/app11125677

Chicago/Turabian StyleCalandra, Pietro, Elisabeta I. Szerb, Domenico Lombardo, Vincenzo Algieri, Antonio De Nino, and Loredana Maiuolo. 2021. "A Presentation of Ionic Liquids as Lubricants: Some Critical Comments" Applied Sciences 11, no. 12: 5677. https://doi.org/10.3390/app11125677

APA StyleCalandra, P., Szerb, E. I., Lombardo, D., Algieri, V., De Nino, A., & Maiuolo, L. (2021). A Presentation of Ionic Liquids as Lubricants: Some Critical Comments. Applied Sciences, 11(12), 5677. https://doi.org/10.3390/app11125677