Design and Simulation of a Vision-Based Automatic Trout Fish-Processing Robot

Abstract

:Featured Application

Abstract

1. Introduction

- Designing a trout fish-processing system capable of processing the fish in different dimensions.

- Developing the system into a machine at which different cleaning steps can be performed in one integrated system (belly-cutting, beheading, gutting, and cleaning processes).

- Designing a system that is adapted with online data extracted from the online image processing technique.

- Extracting the required forces, torques, and displacements by simulating the real movements.

- Finally, fabricating and selecting the proper functioning motors and pneumatic jacks of the system based on the applied tools (mechanical design, machine vision, control algorithms, and simulation).

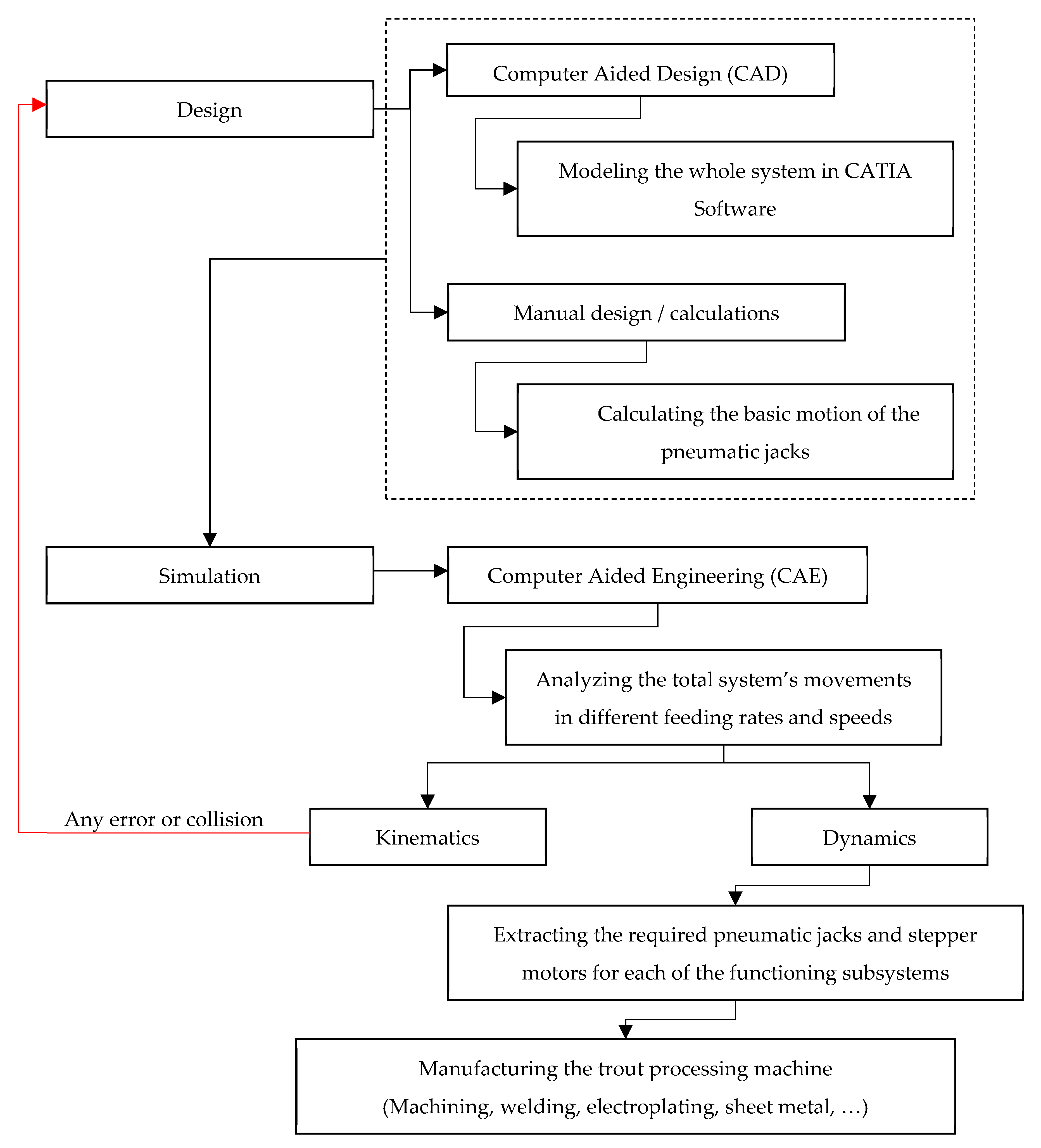

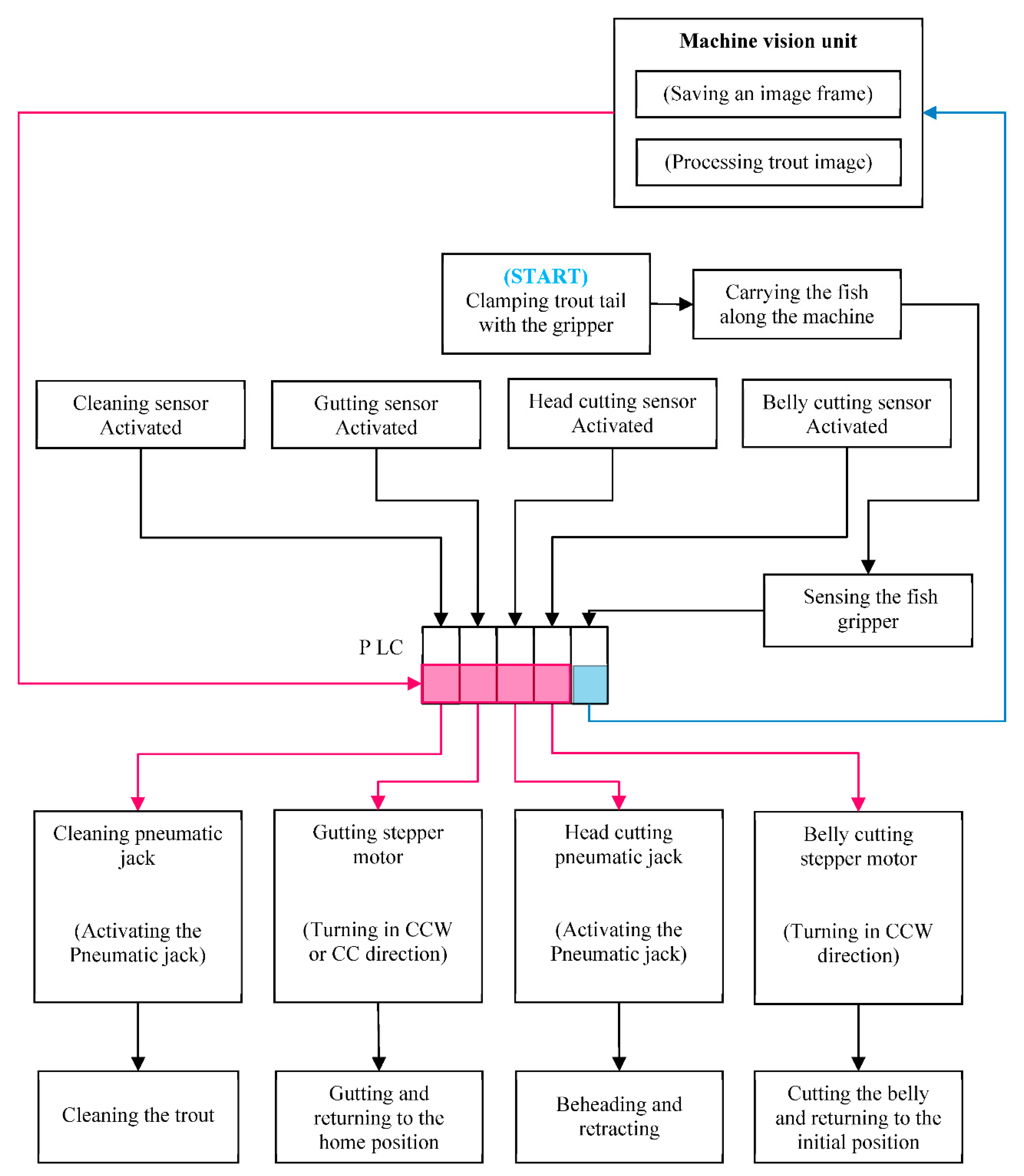

2. Material and Methods

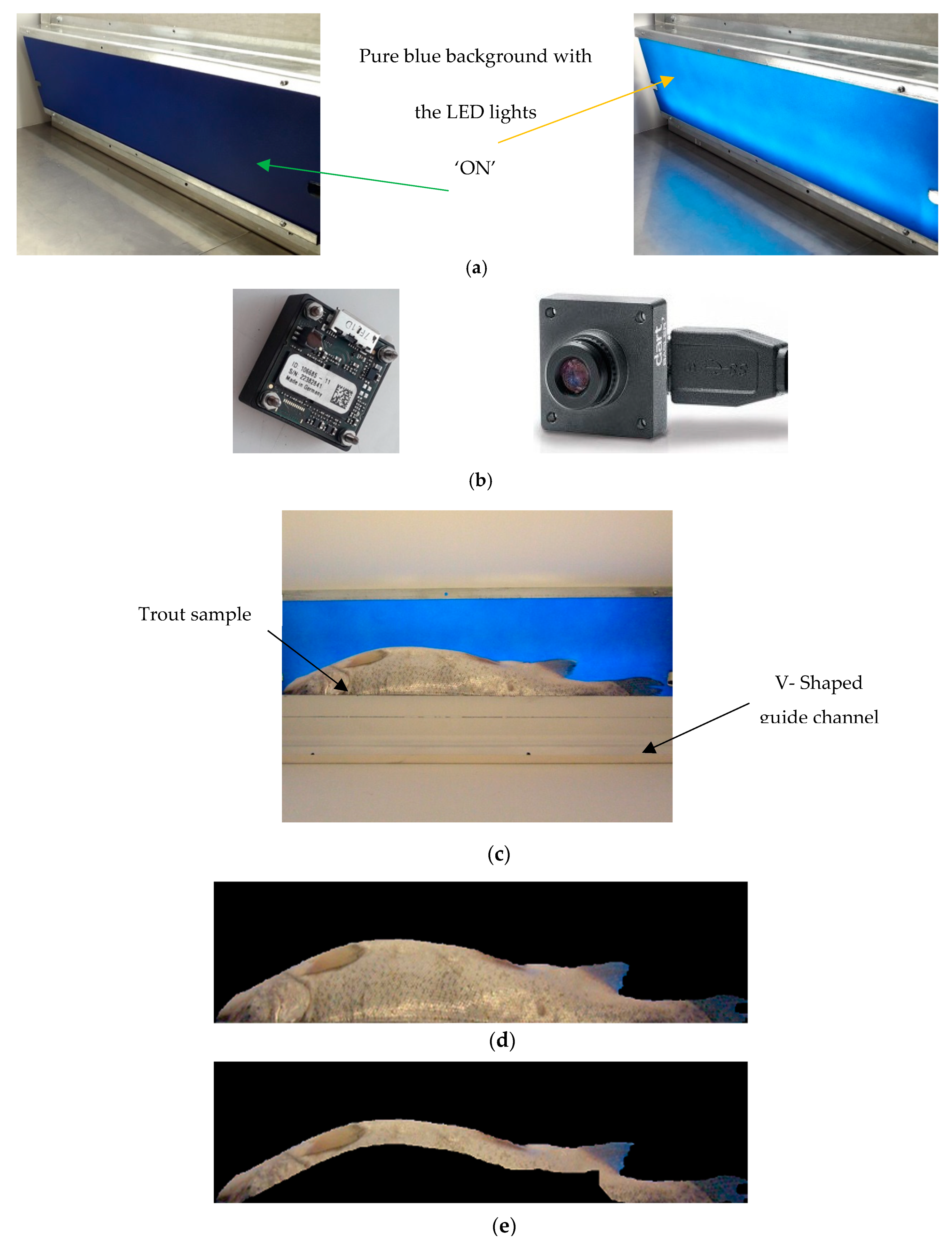

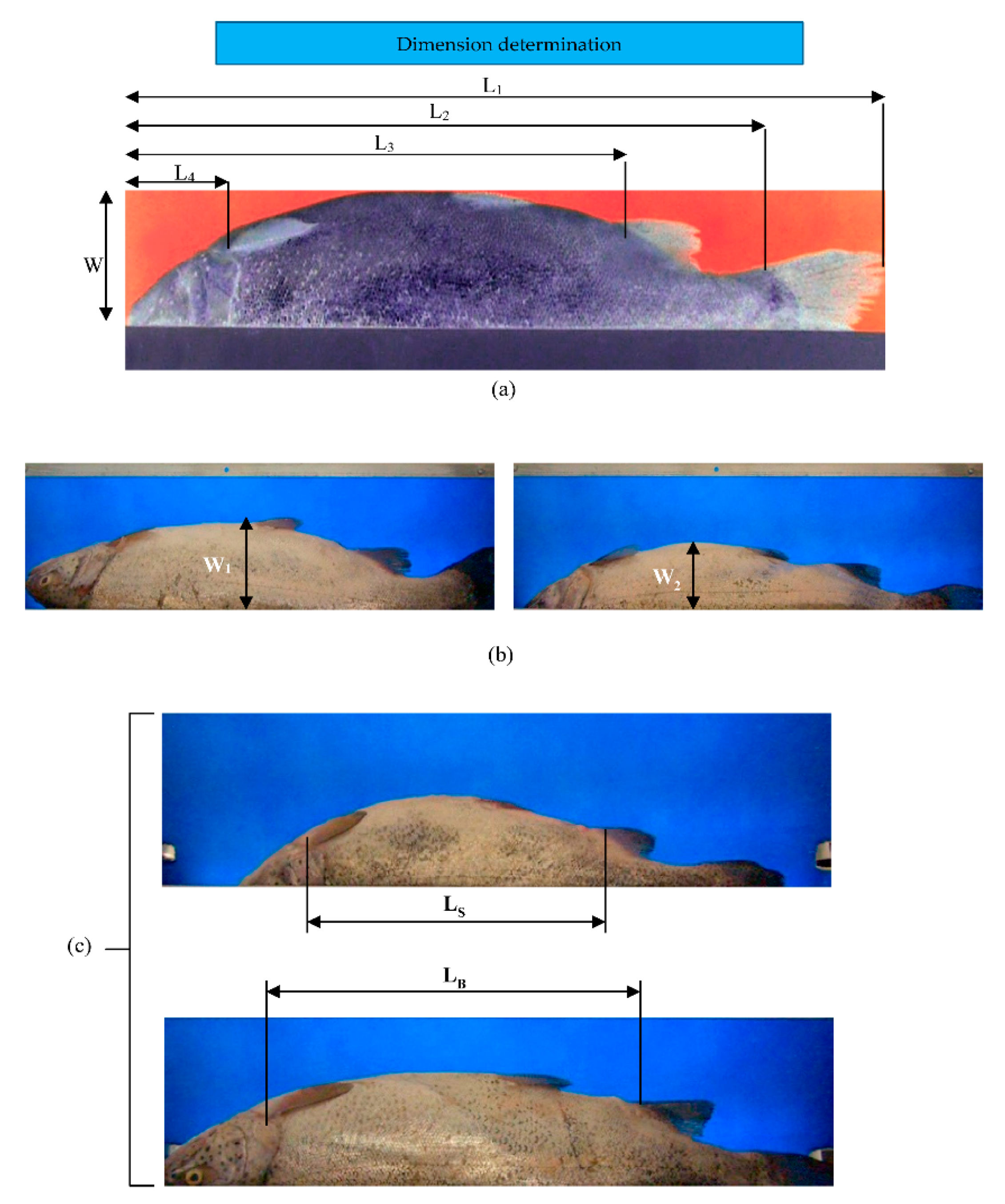

2.1. Machine Vision and Dimension Determination

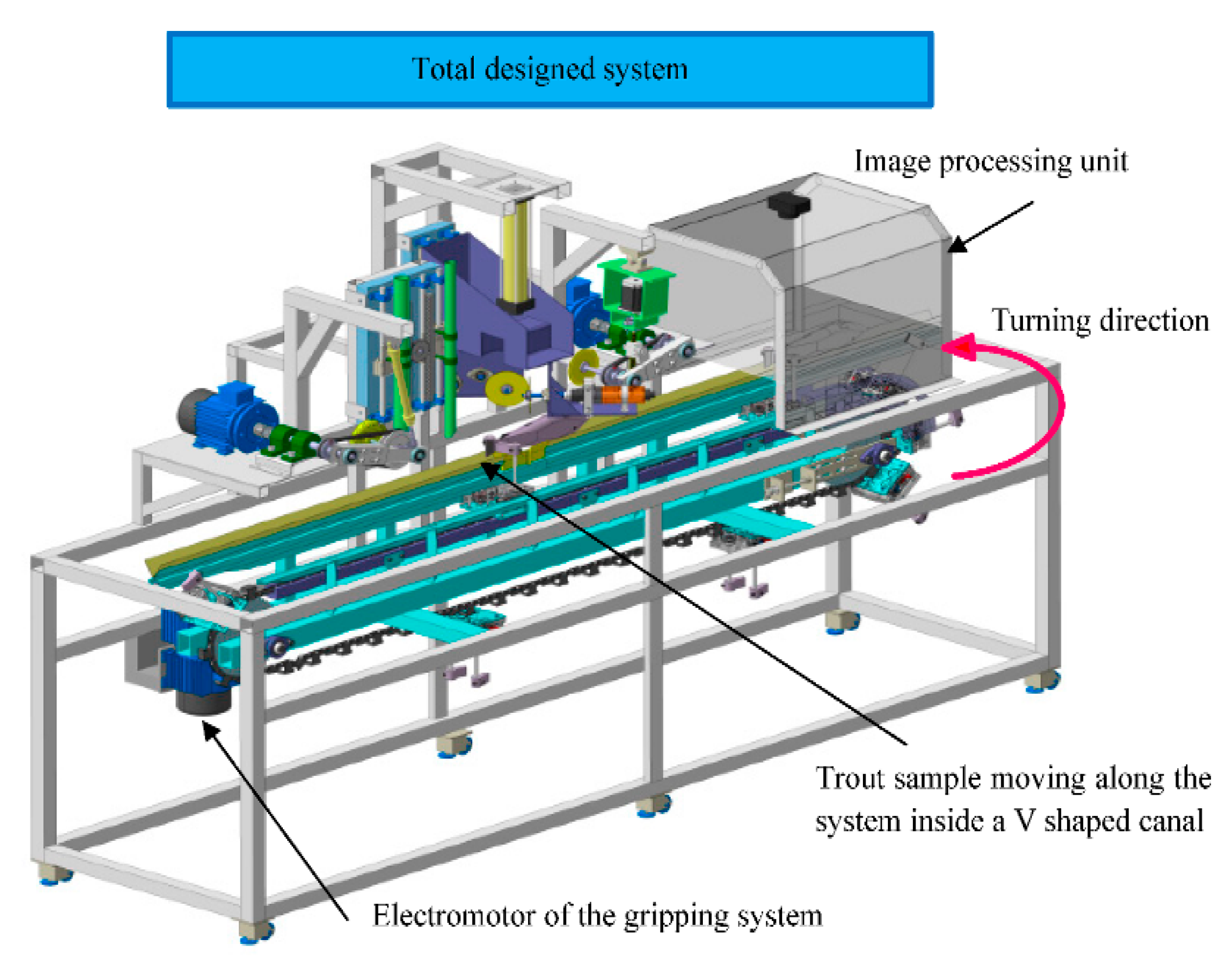

2.2. Designing the Mechanical Parts

2.2.1. Fish-Carrying Subsystem

- Fish grippers;

- Gripper guides and fish canal;

- Driver AC motor;

- Gripper conveyer.

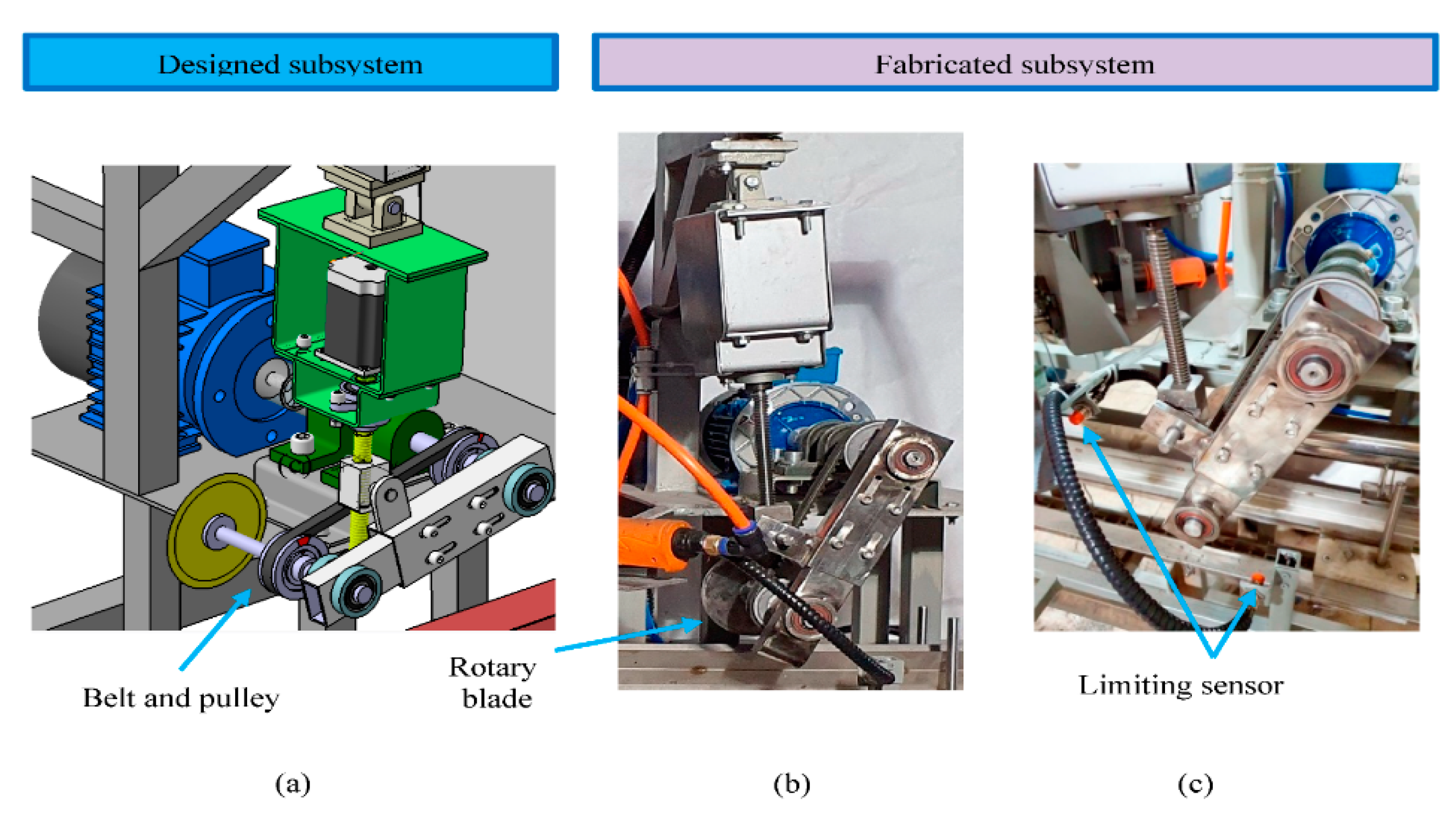

2.2.2. Belly-Cutting Subsystem

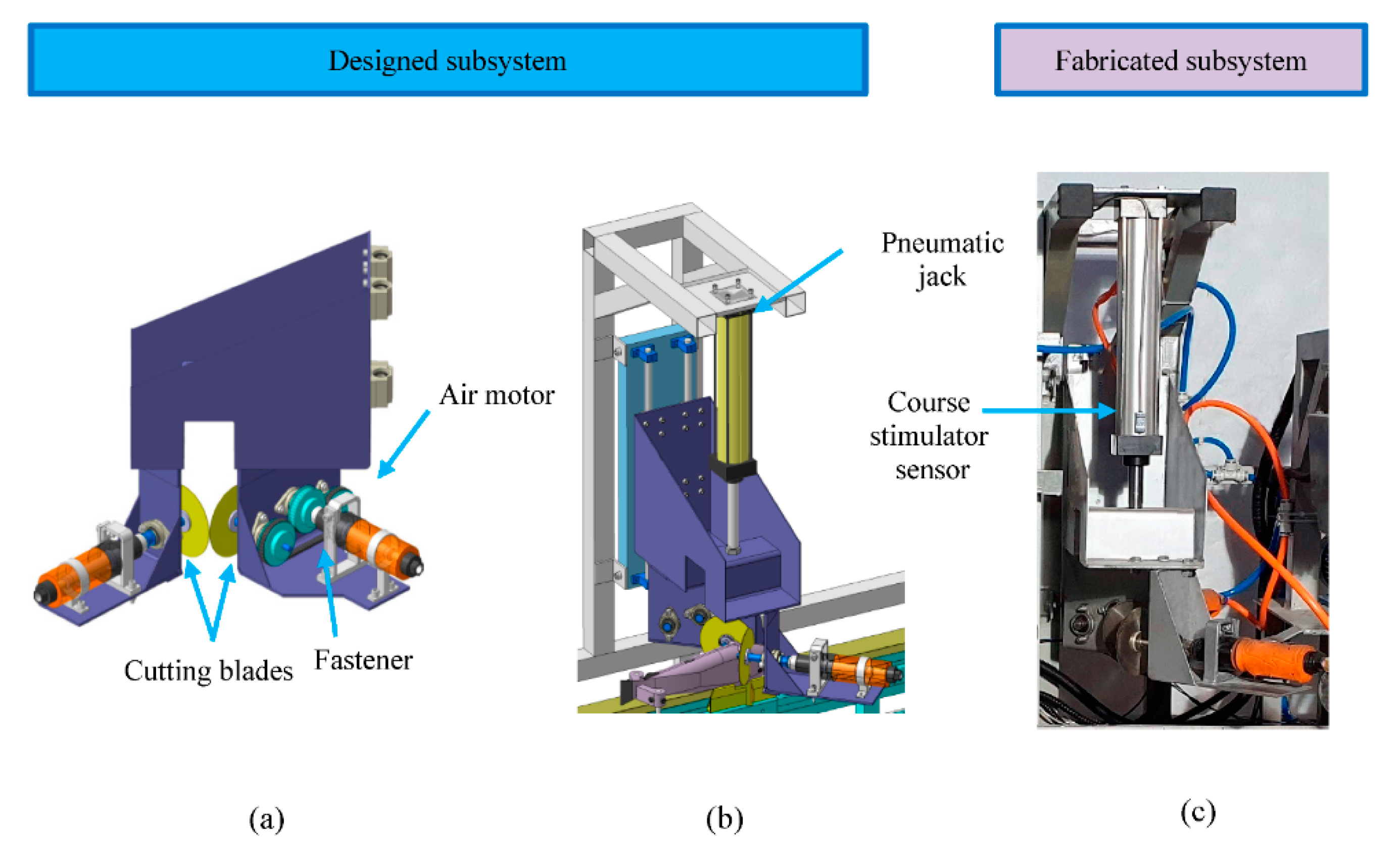

2.2.3. Head-Cutting Subsets

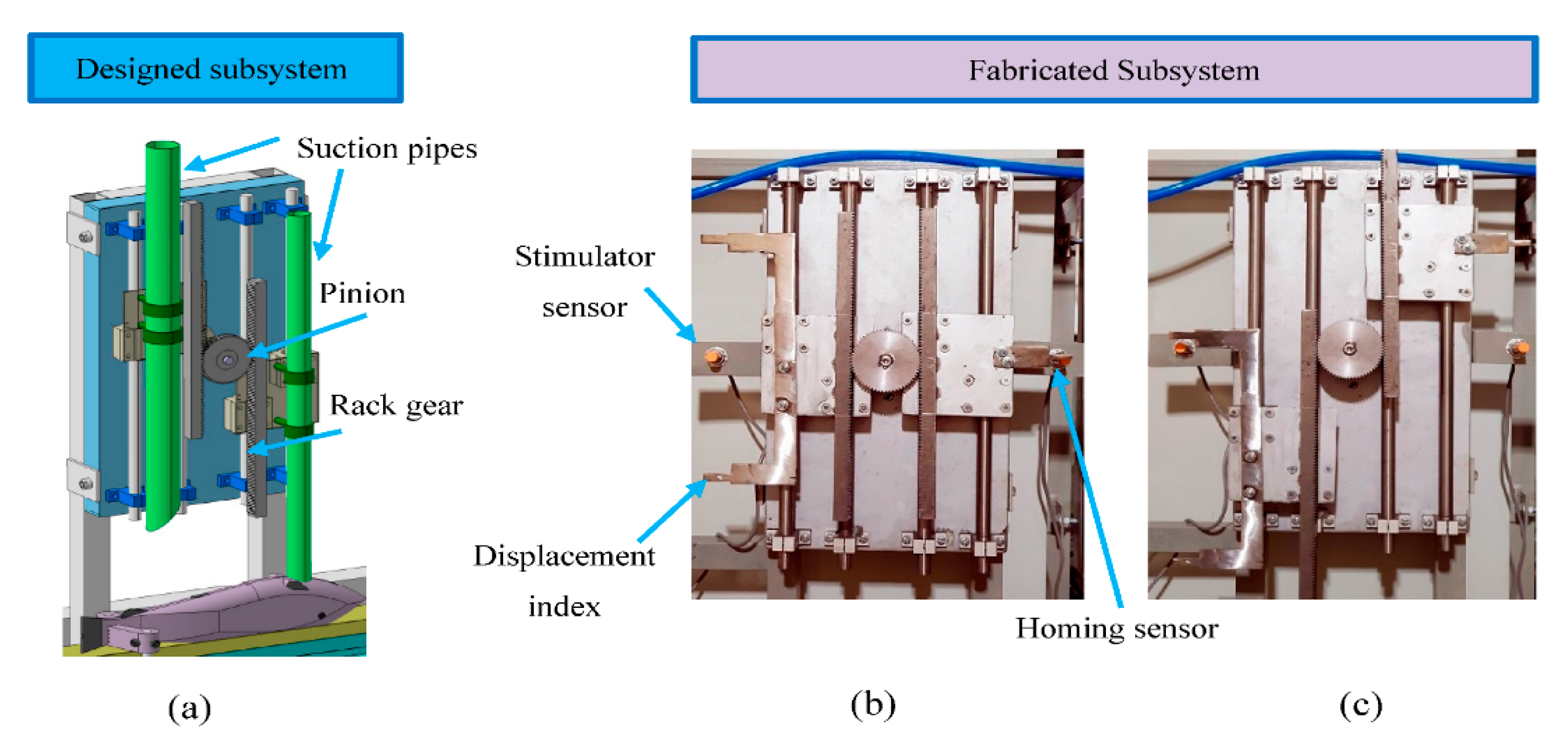

2.2.4. Gutting Subsystem

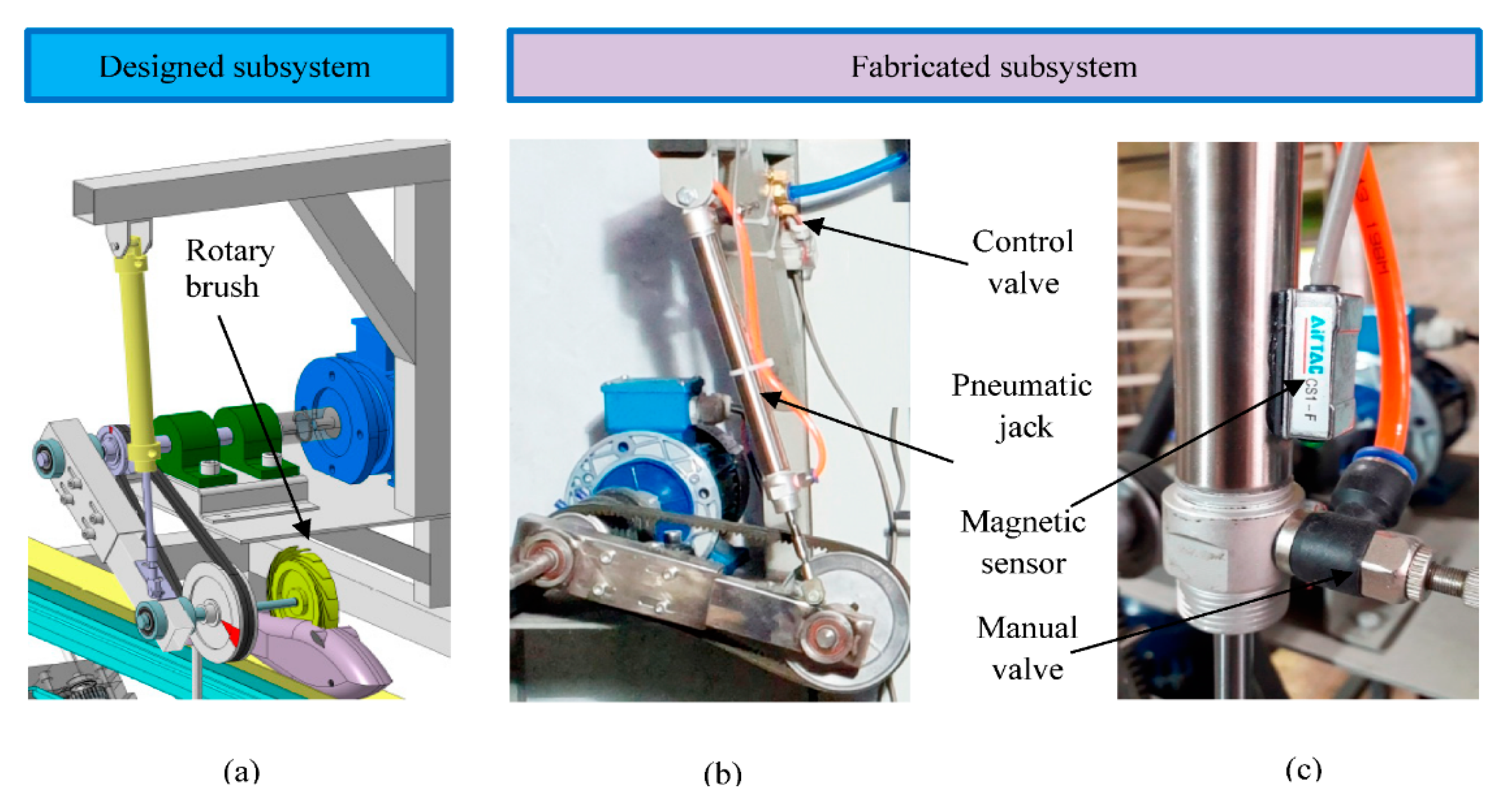

2.2.5. Cleaner Subsystem

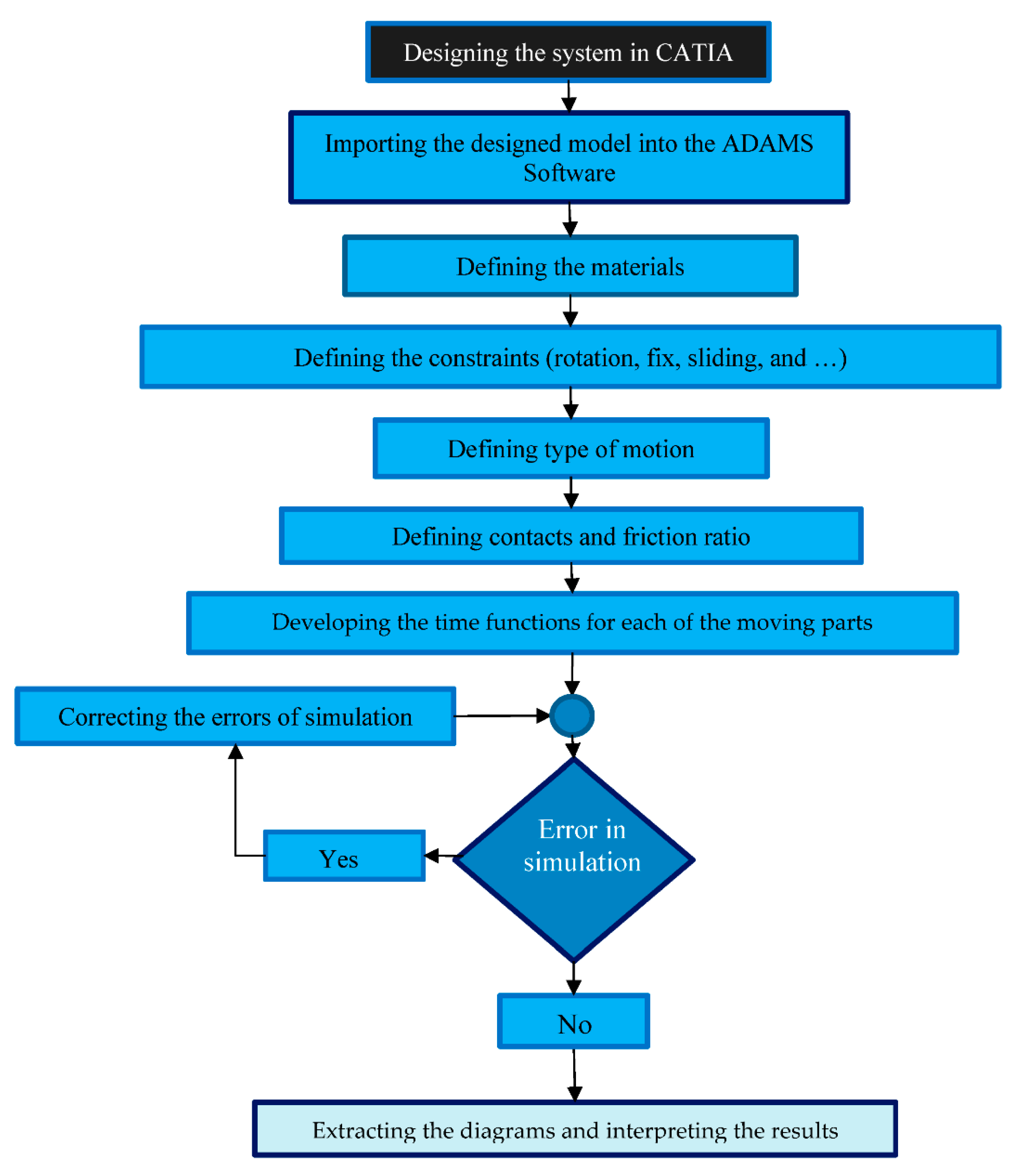

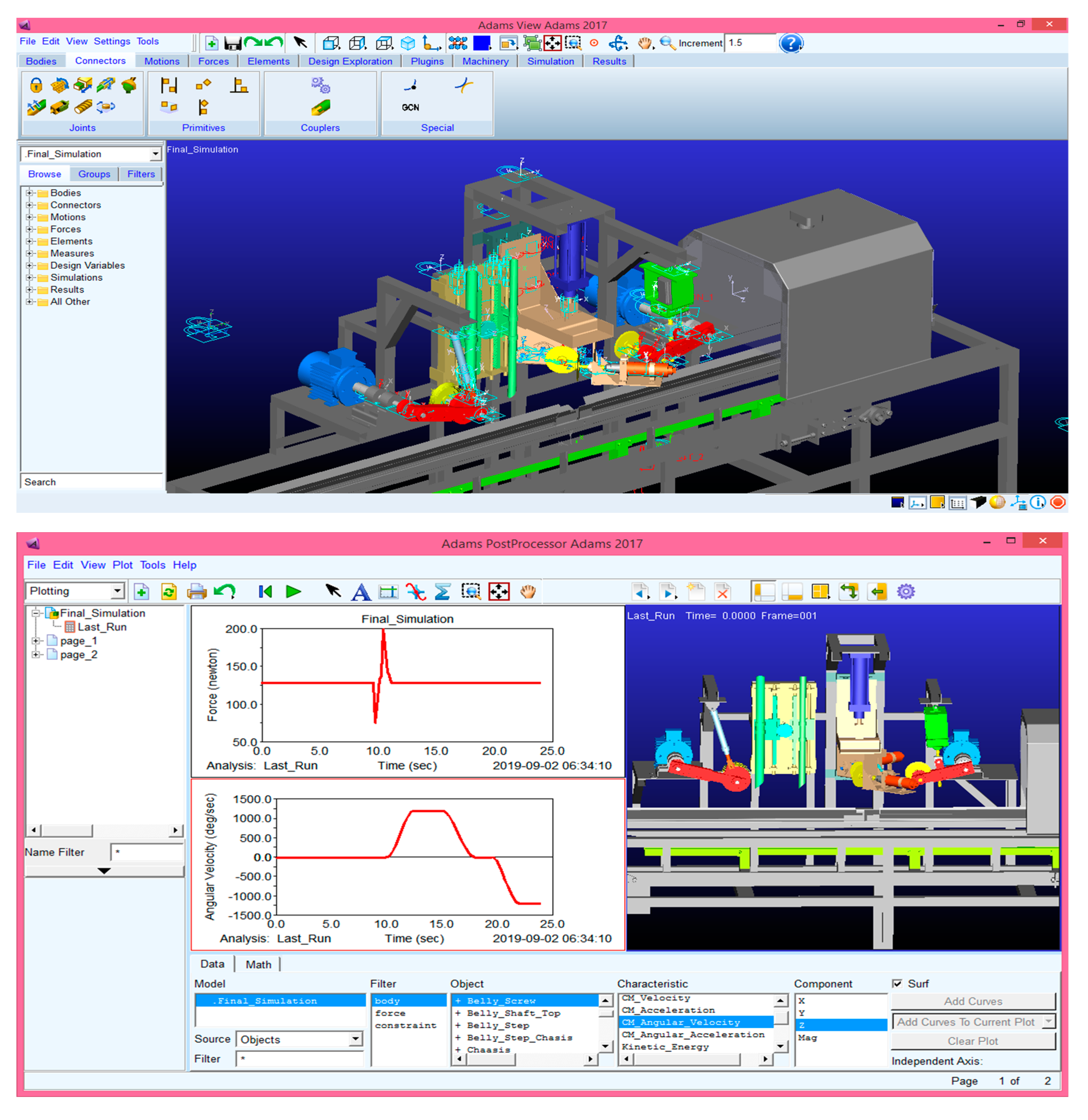

2.3. Device Simulation, Kinetic and Dynamic Analysis and Extracting the Torques of the Motors and Forces of the Pneumatic Jacks

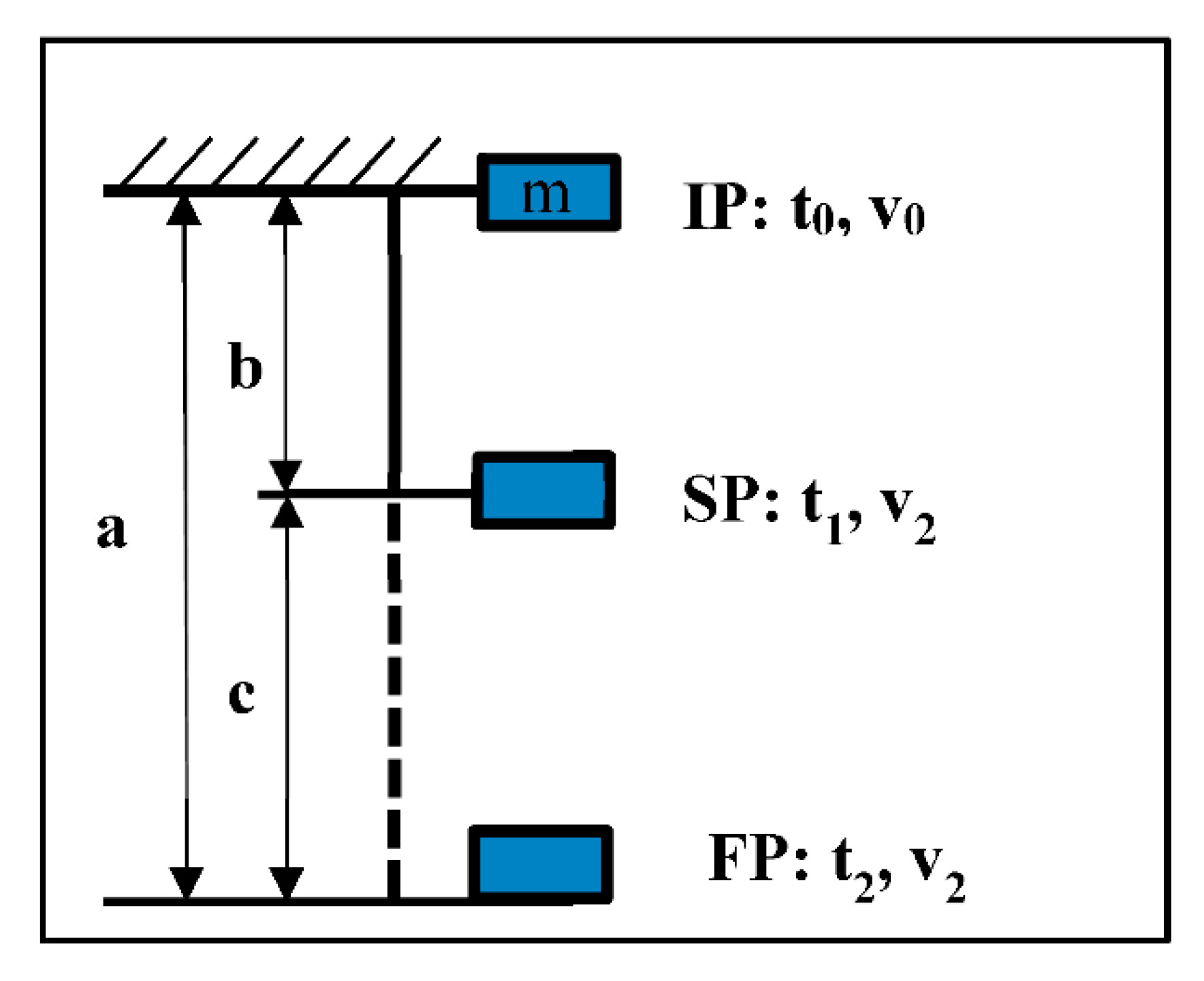

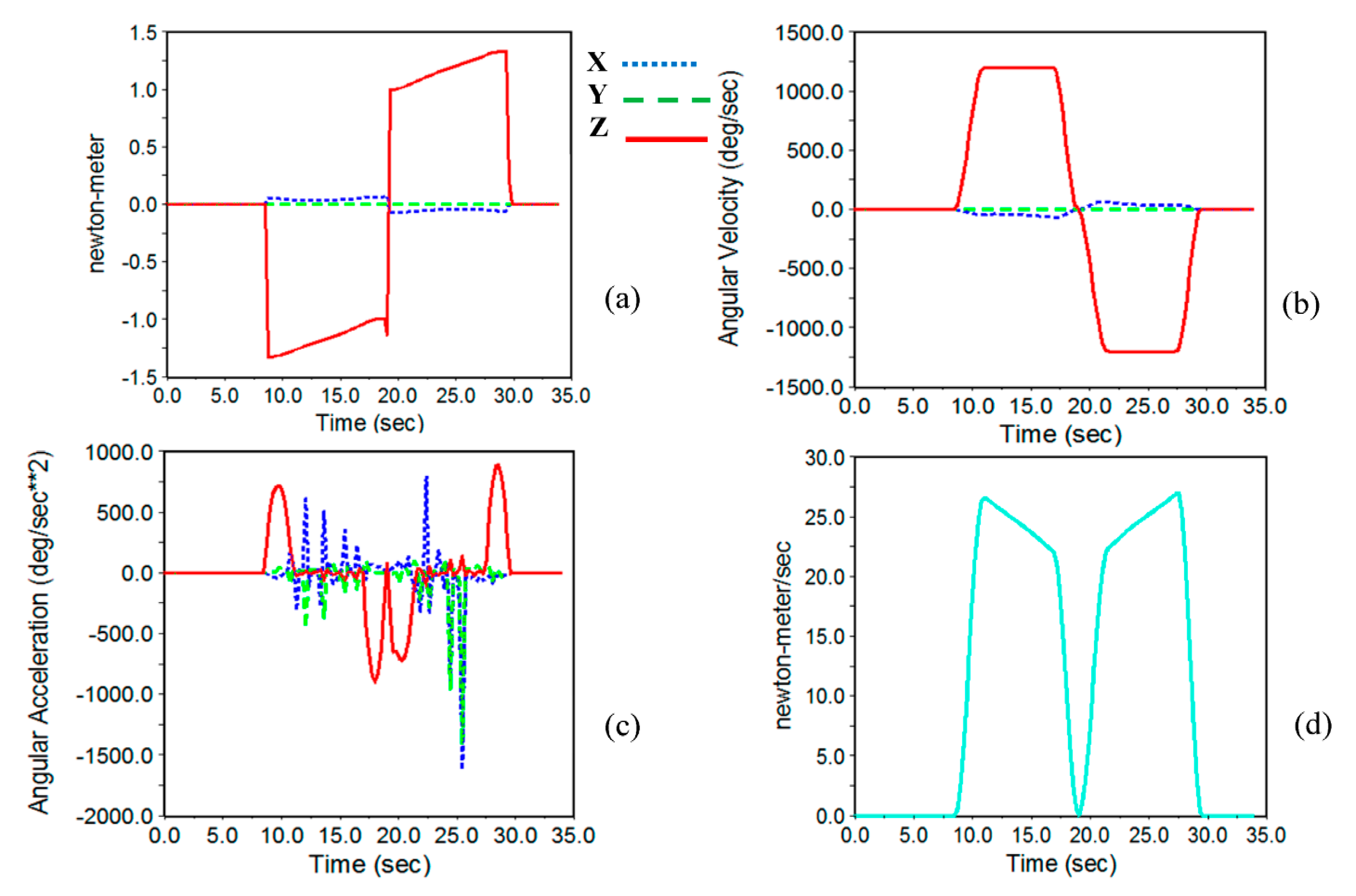

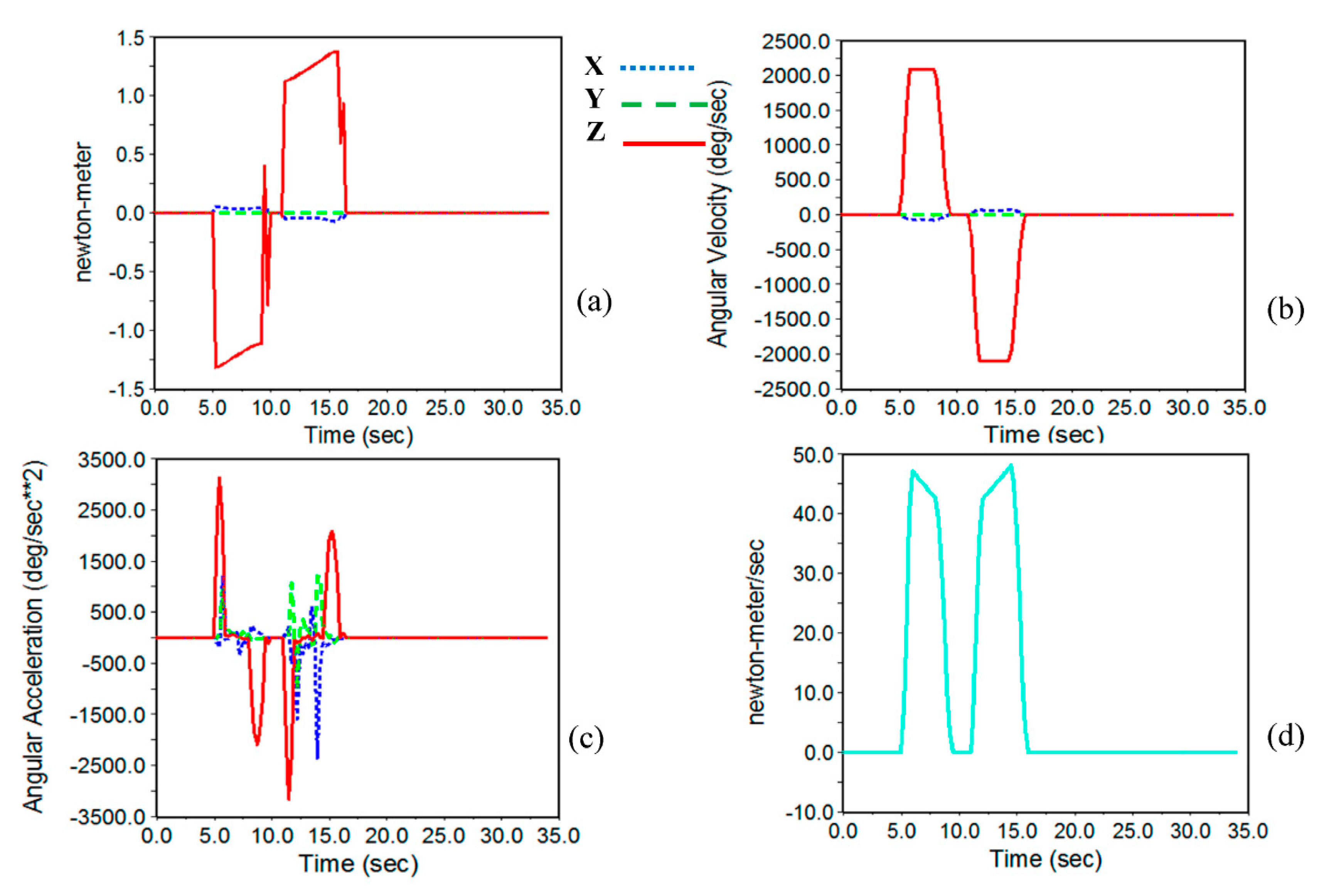

2.3.1. Calculations Related to the Stepper Motors of the Belly-Cutting and Gutting Subsystems

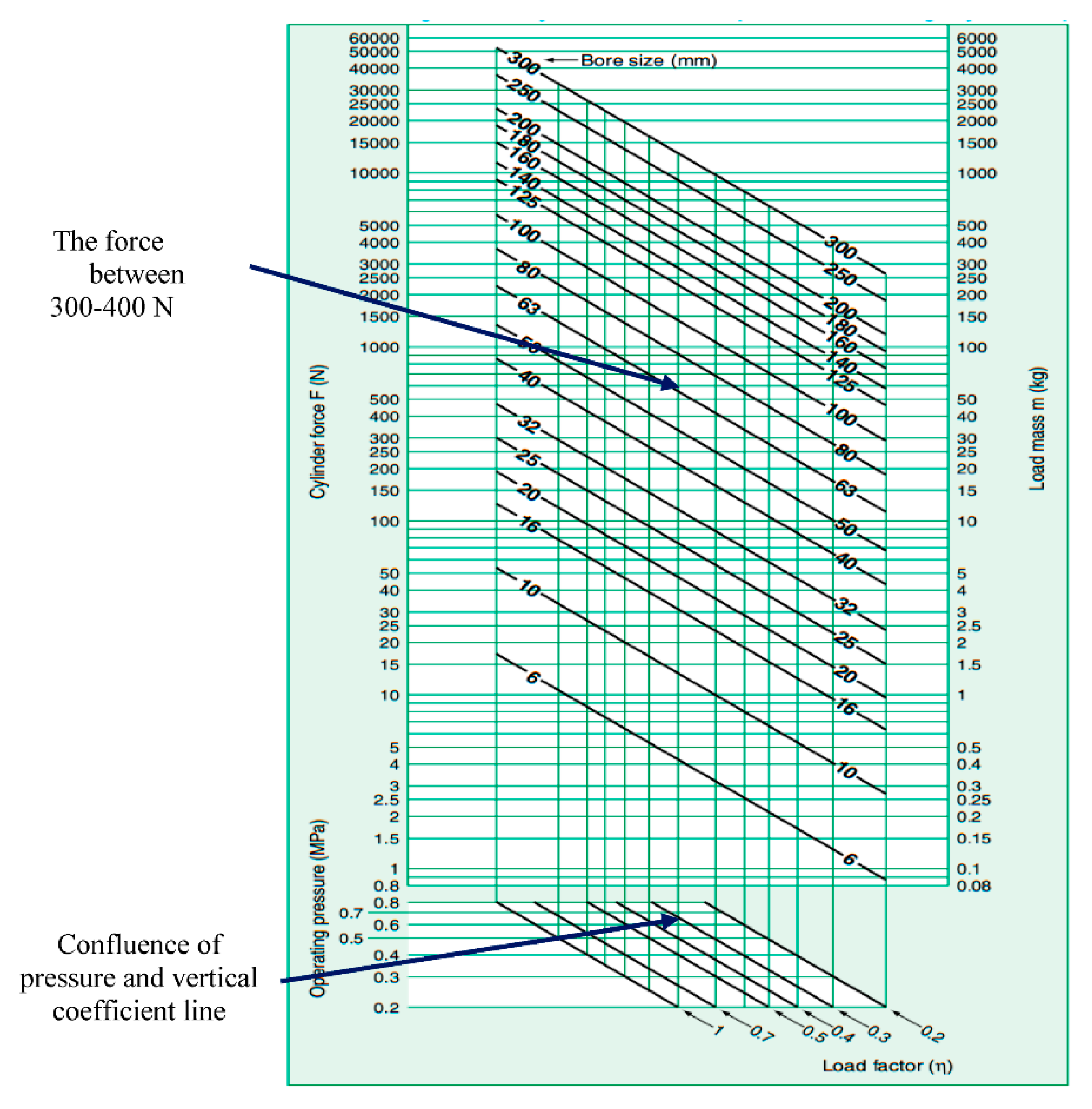

2.3.2. Calculations Related to Pneumatic Jacks of Head-Cutting and Cleaner Subsystems

- Design factor;

- Jack force;

- Load coefficient in vertical operation mode;

- Air pressure;

- Speed coefficient.

2.4. Fabricated System

3. Results and Discussion

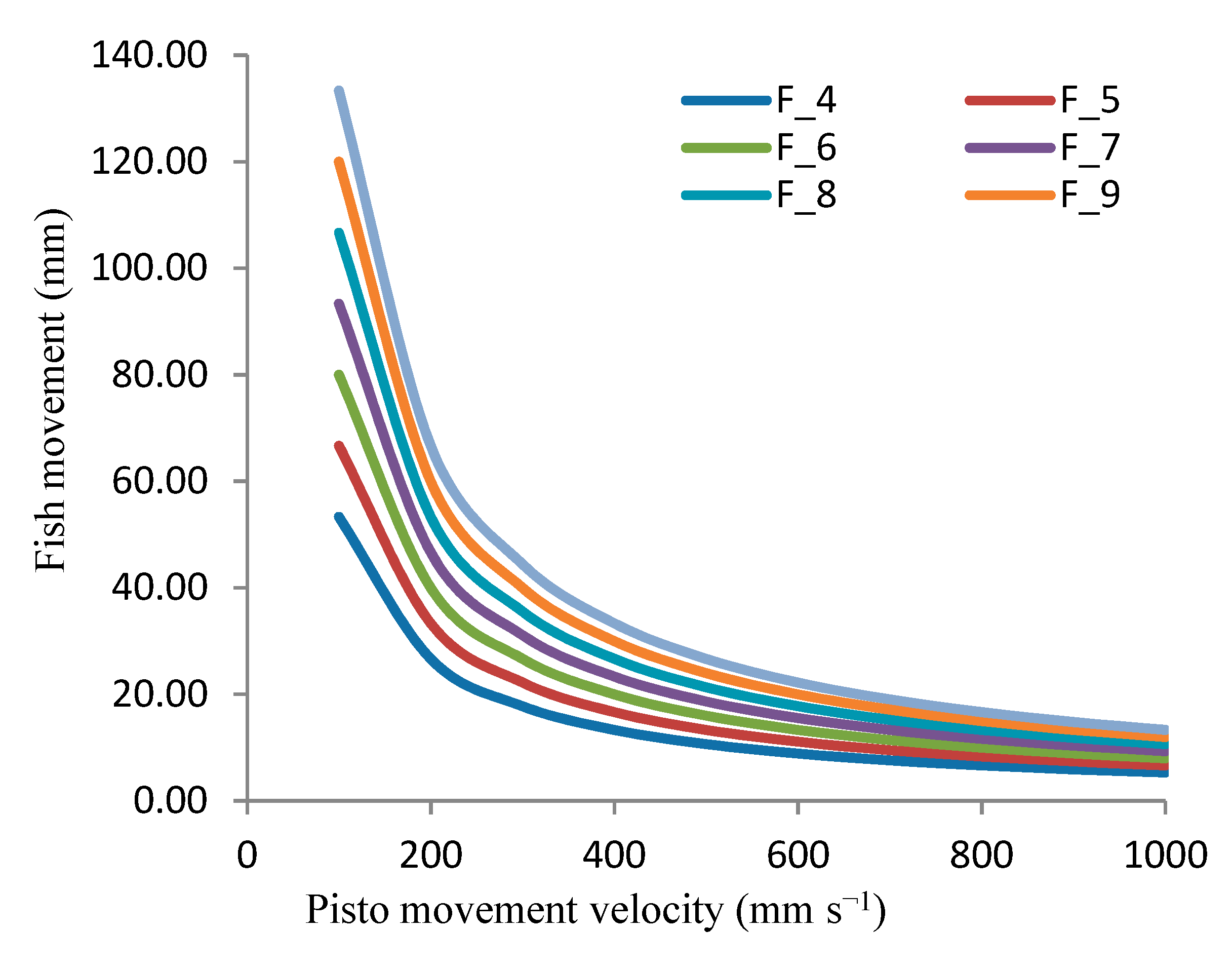

3.1. Piston Speed Calculations

3.2. Results of Simulation

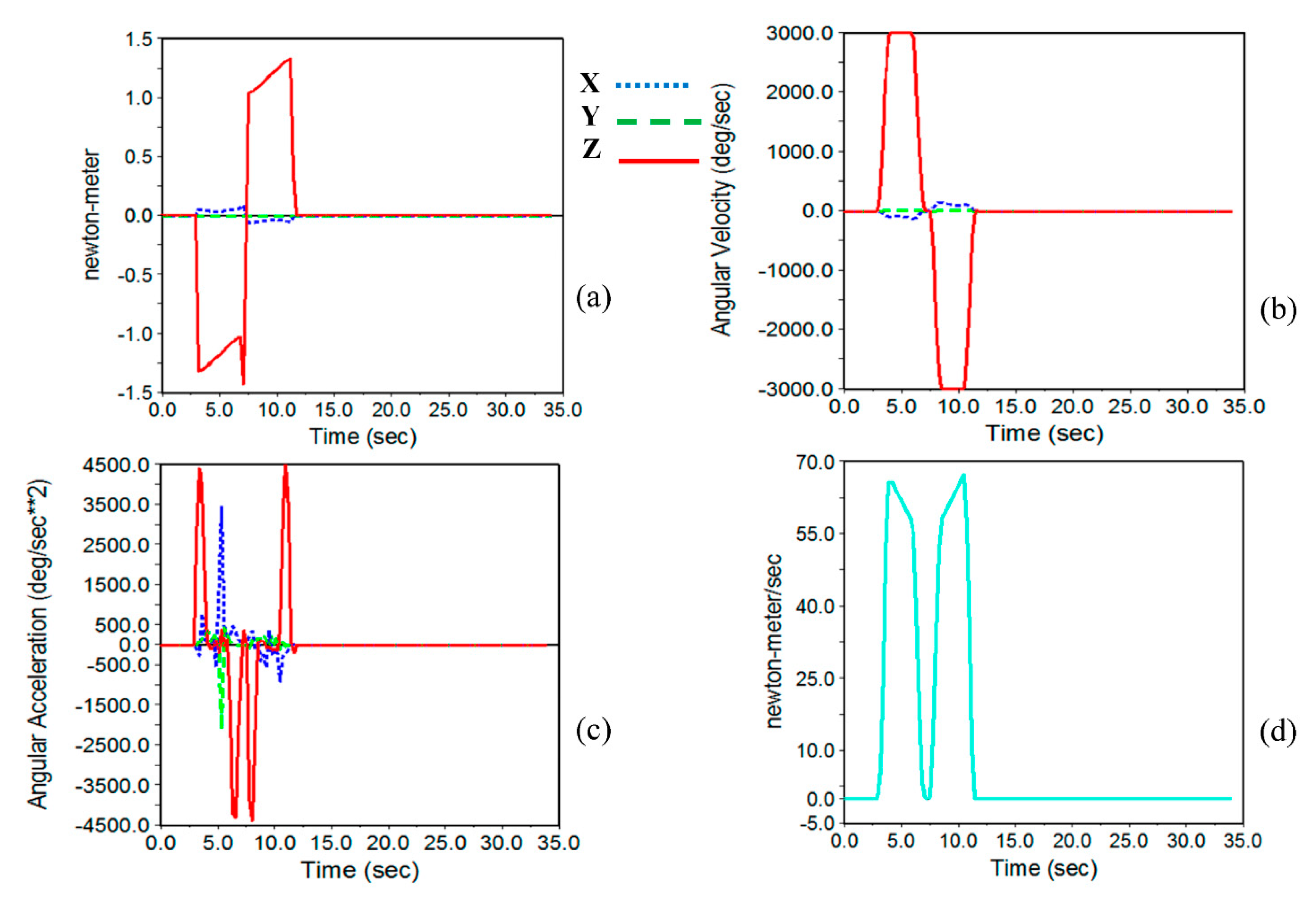

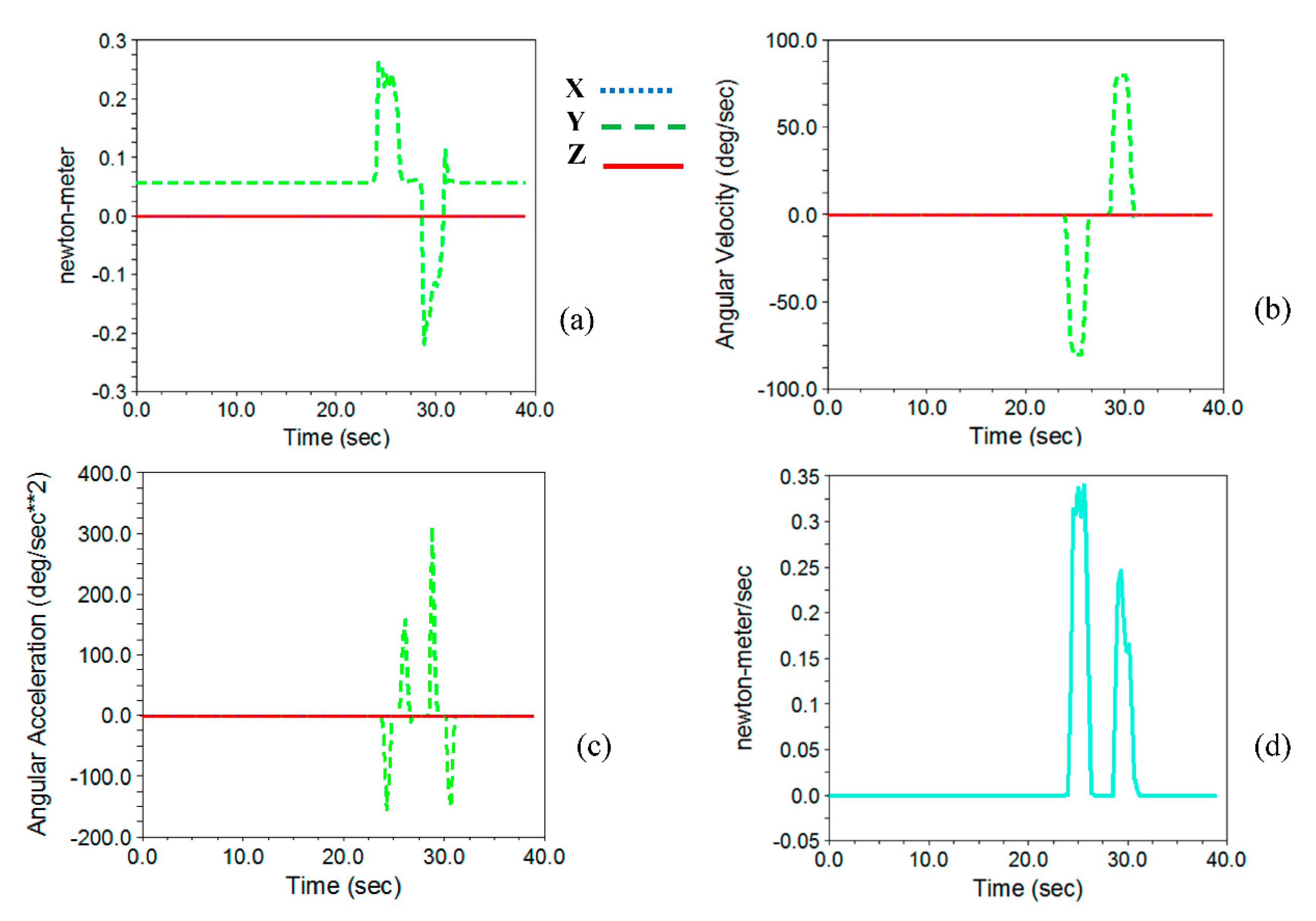

3.2.1. Selecting the Stepper Motor of the Belly-Cutting Subsystem

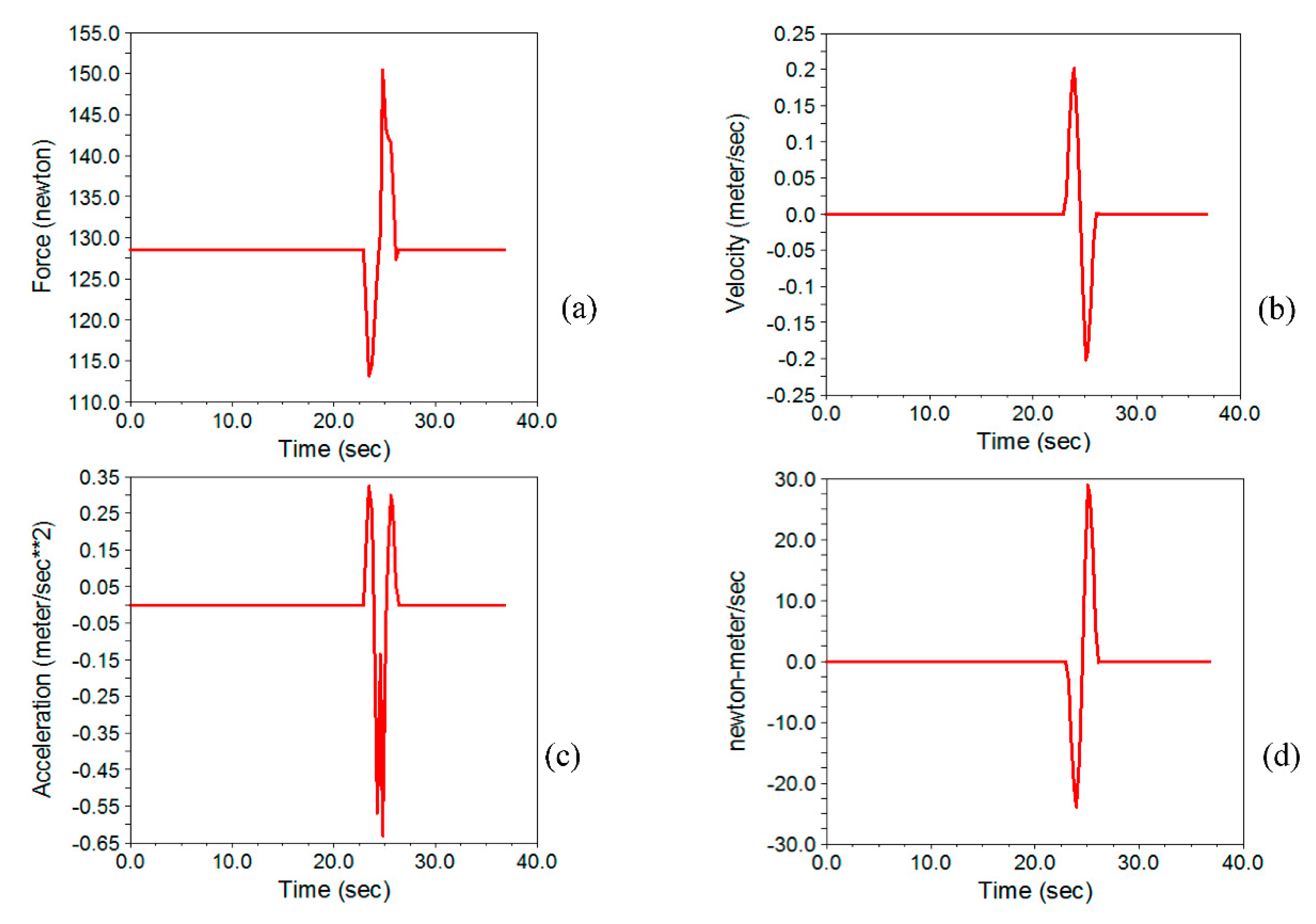

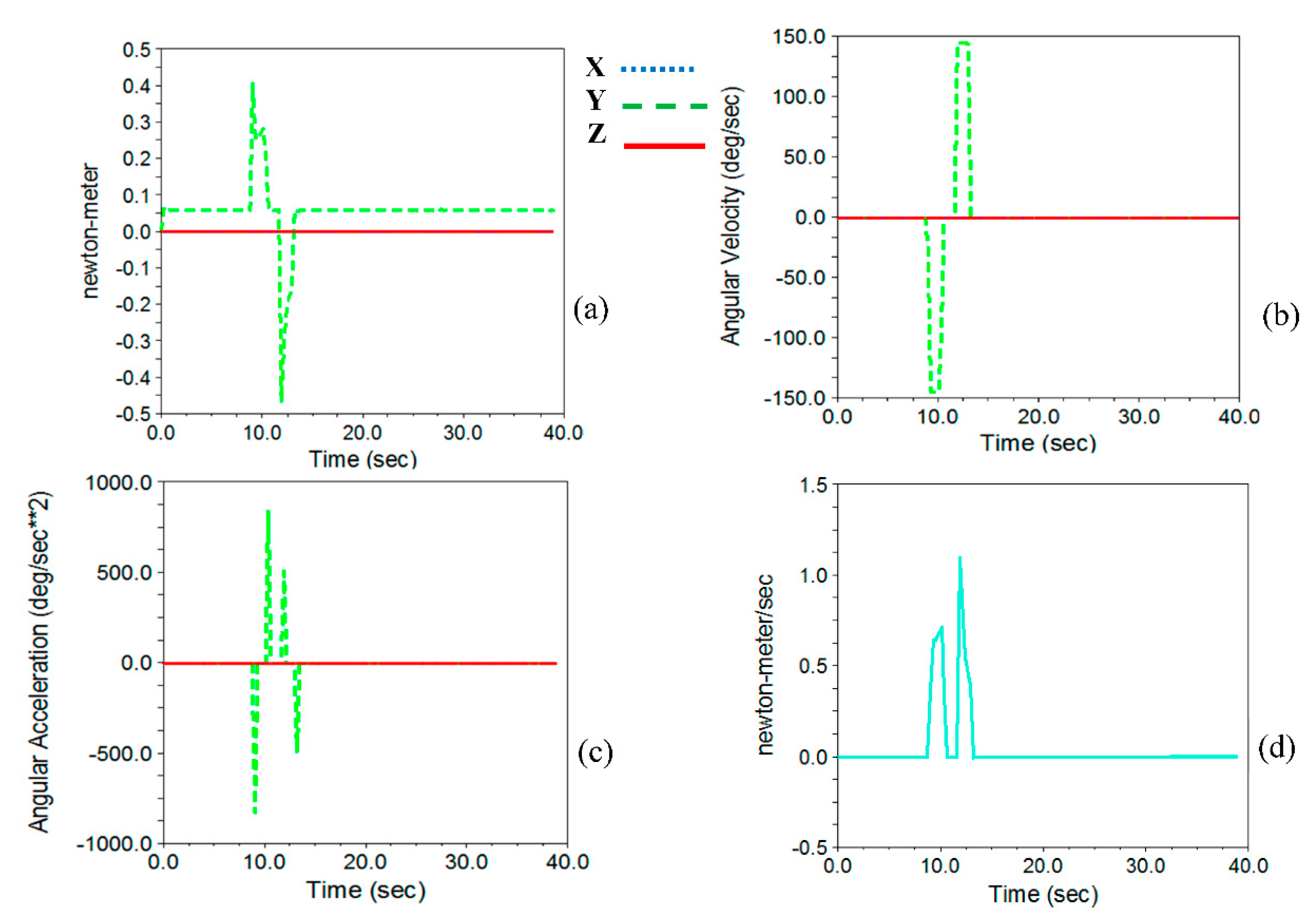

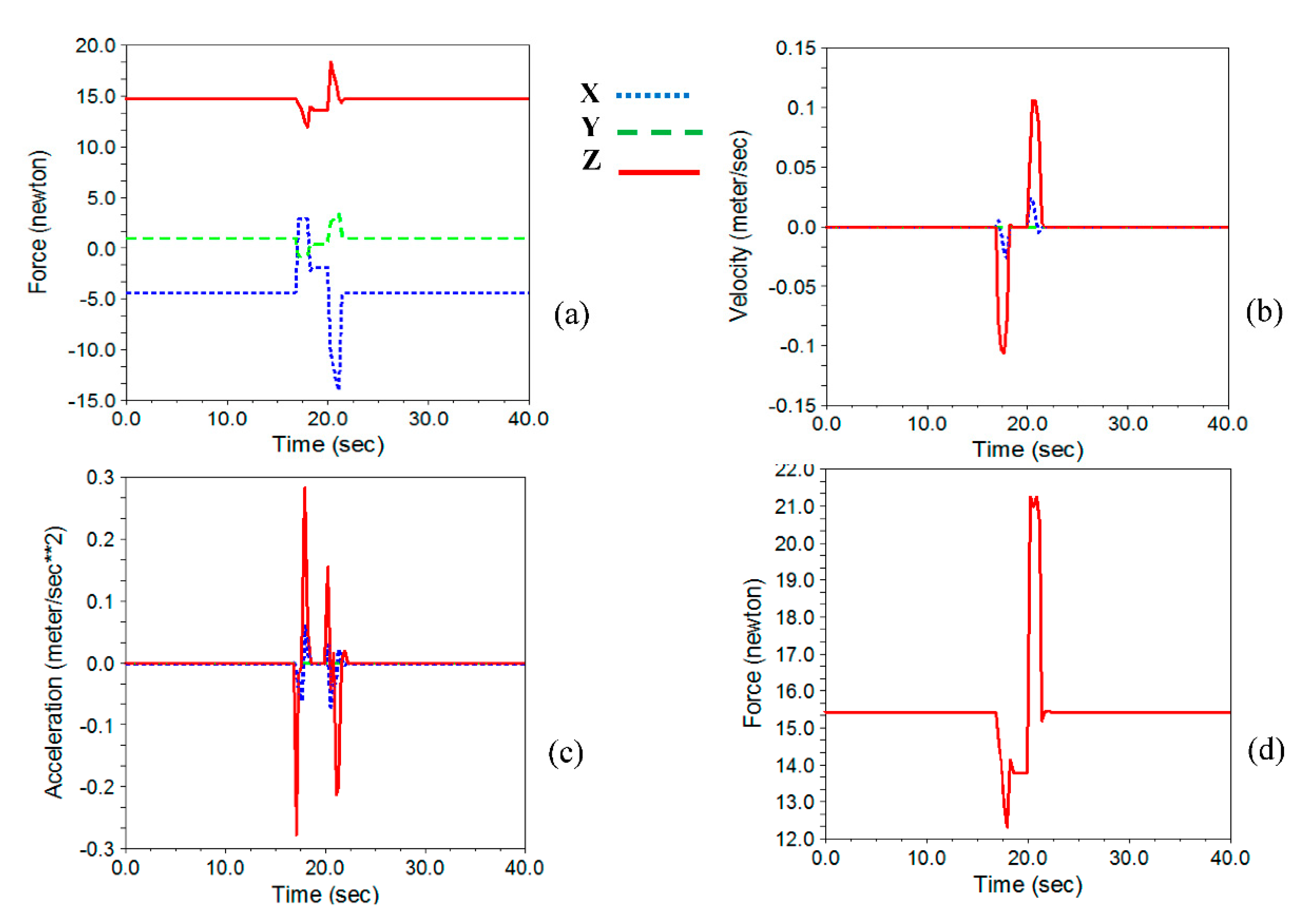

3.2.2. Selecting the Pneumatic Jack of the Head-Cutting Subsystem

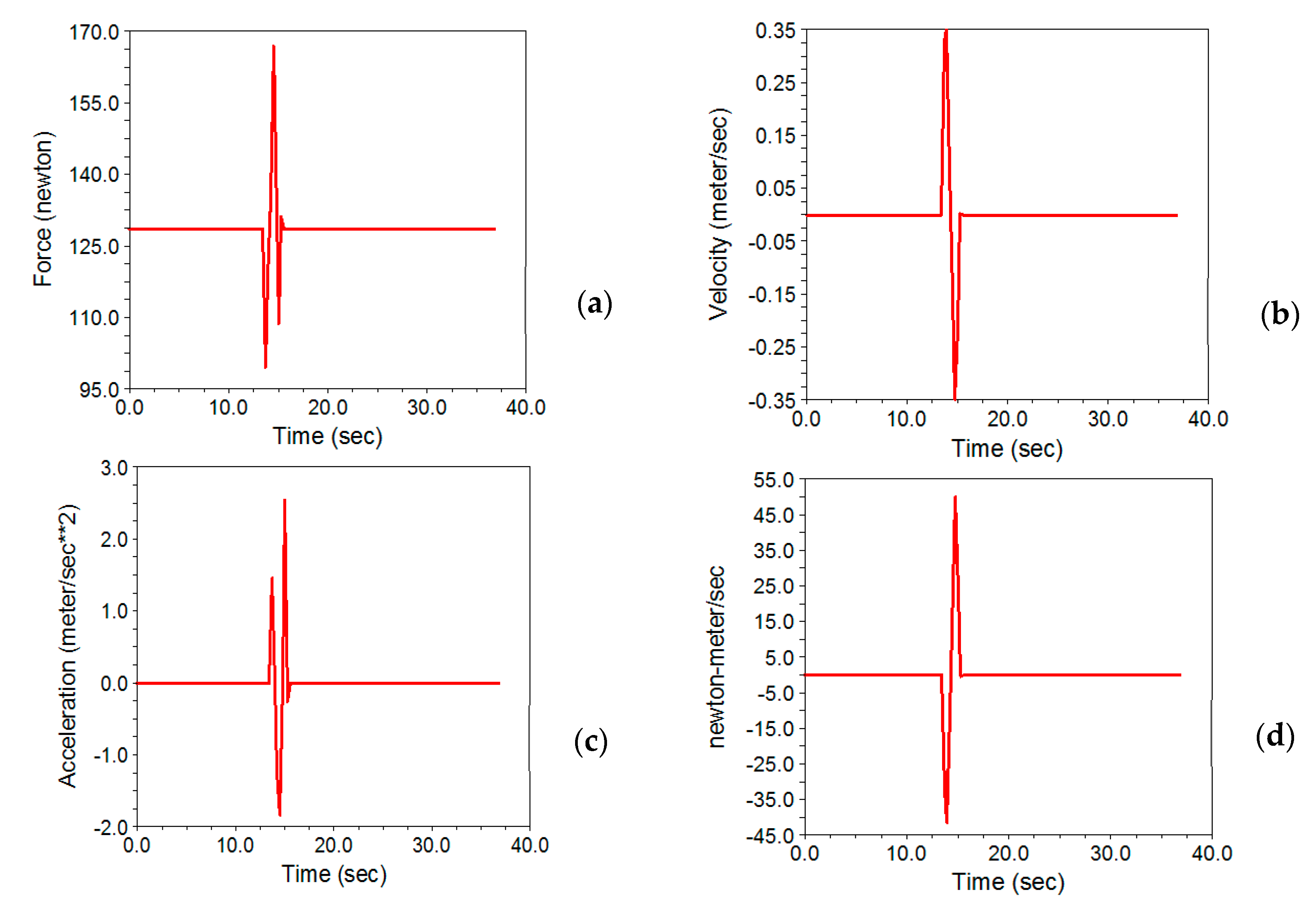

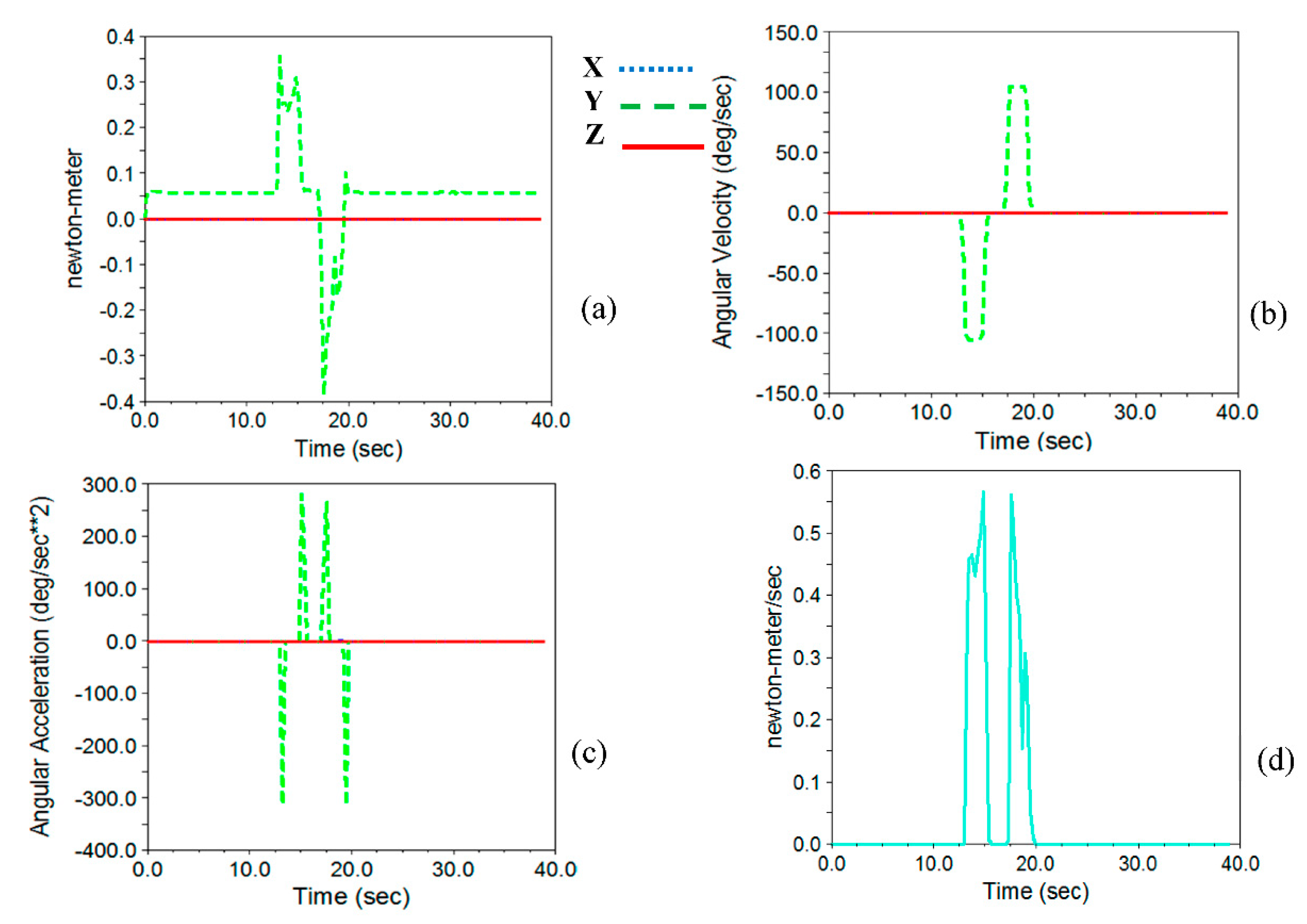

3.2.3. Selecting the Stepper Motor of the Gutting Subsystem

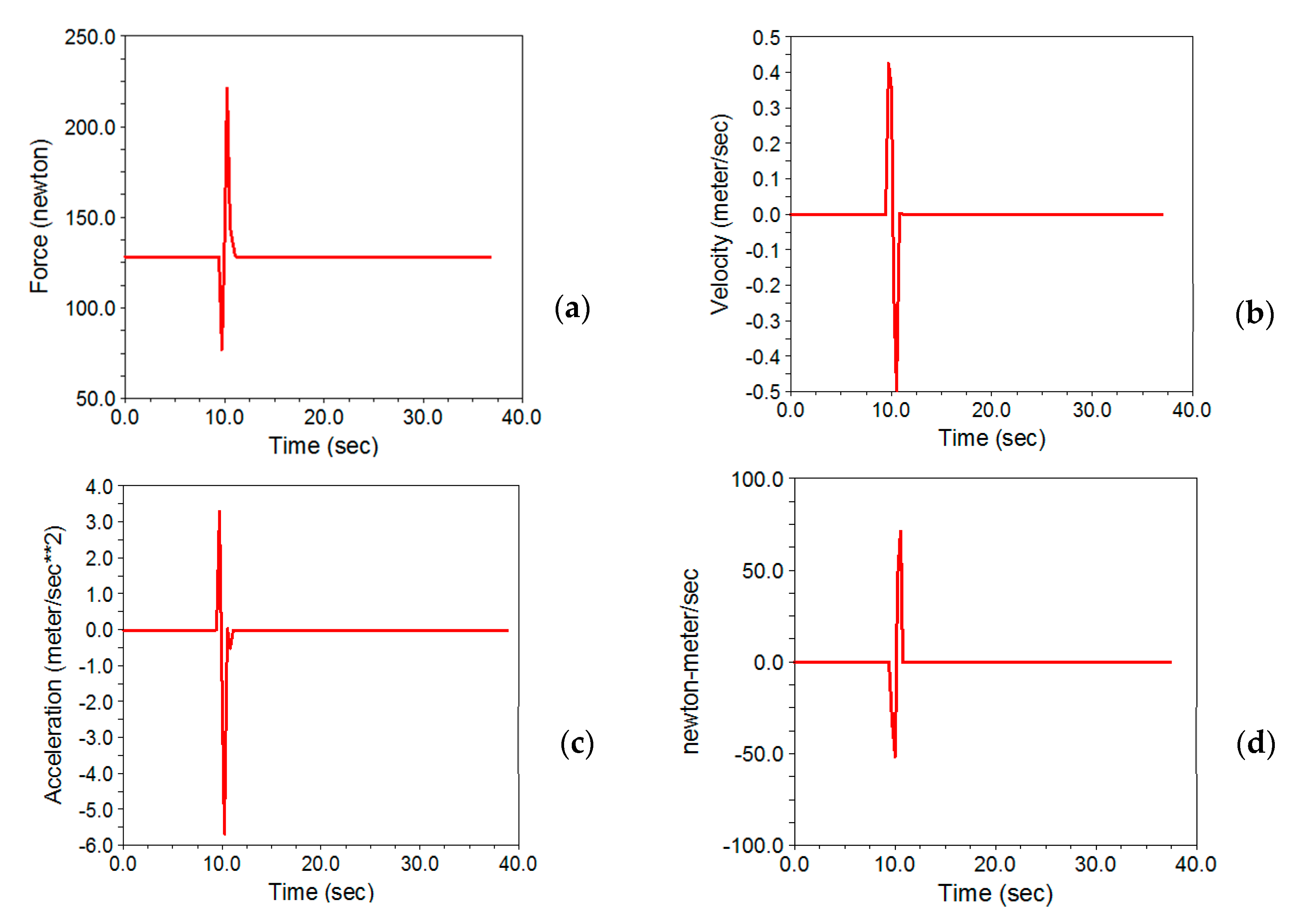

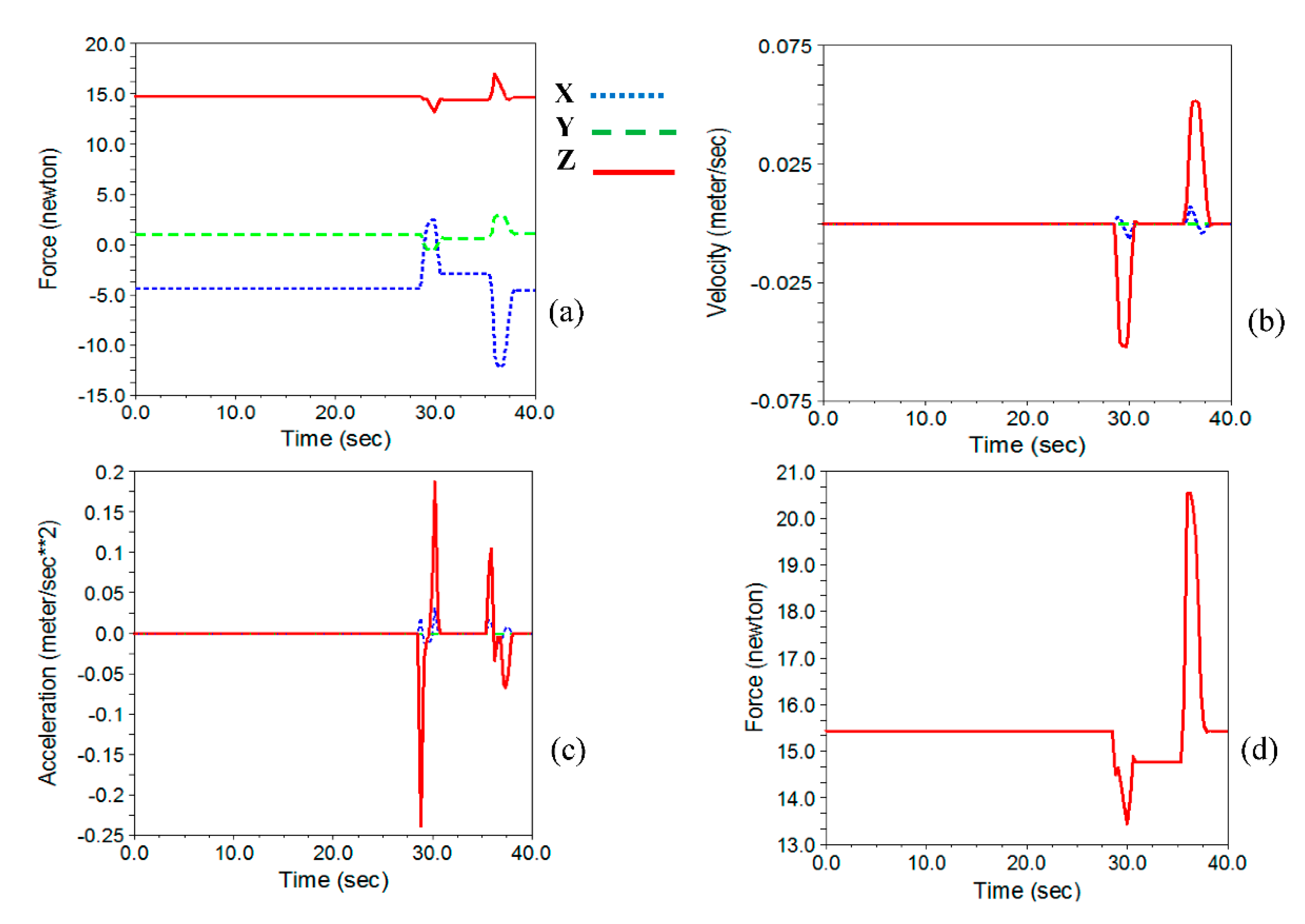

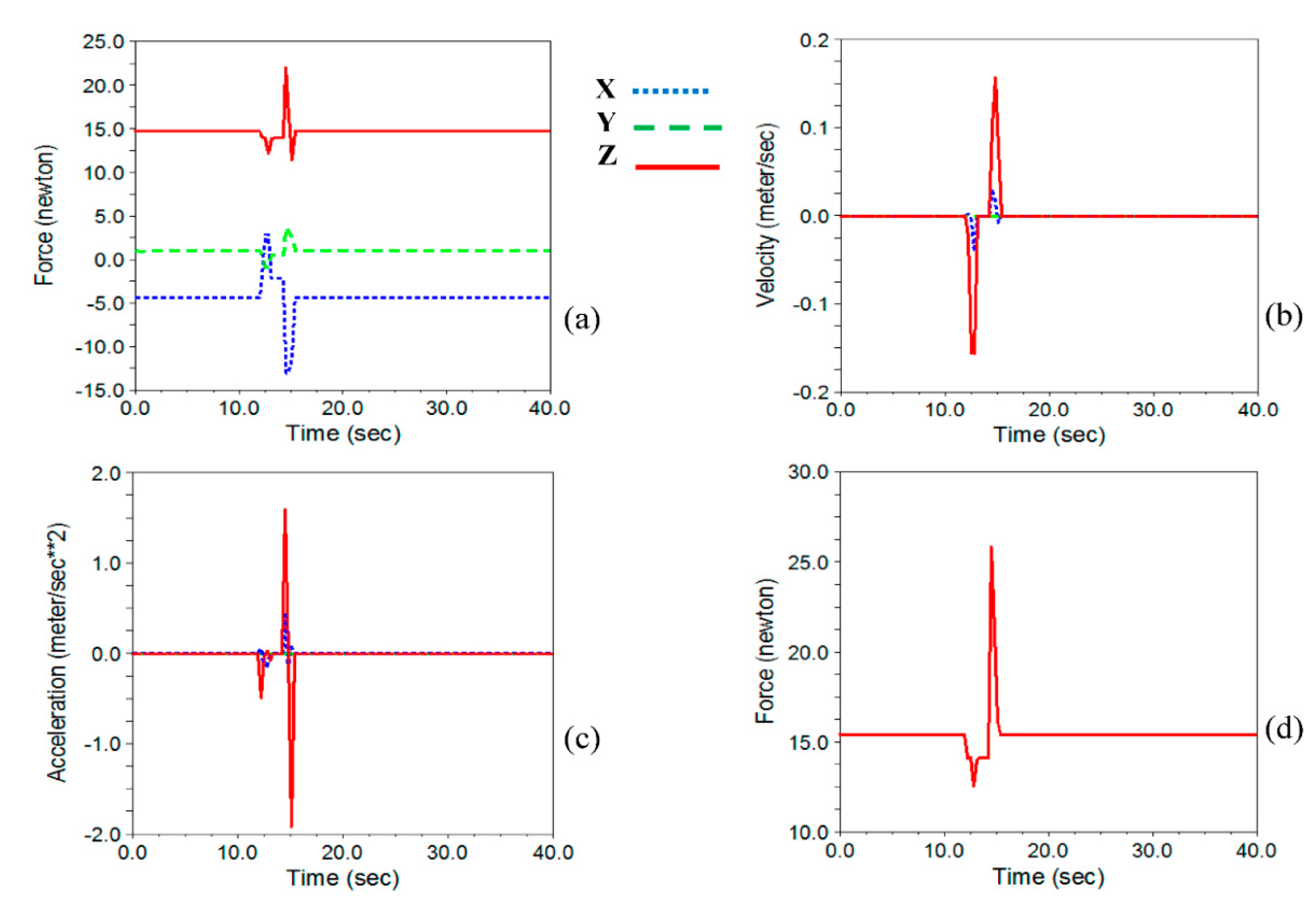

3.2.4. Selecting the Pneumatic Jack of the Cleaning Subsystem

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Booman, A.; Parin, M.; Zugarramurdi, A. Efficiency of size sorting of fish. IJPE 1997, 48, 259–2652. [Google Scholar] [CrossRef]

- Beiranvand, A.; Kalhor, A.; Masouleh, M.T. Modeling, identification and minimum length integral sliding mode control of a 3-DOF cartesian parallel robot by considering virtual flexible links. Mech. Mach. Theory 2021, 157, 104183. [Google Scholar] [CrossRef]

- Xu, K.; Liu, H.; Yue, W.; Xiao, J.; Ding, Y.; Wang, G. Kinematic modeling and optimal design of a partially compliant four-bar linkage using elliptic integral solution. Mech. Mach. Theory 2021, 157, 104214. [Google Scholar] [CrossRef]

- Hao, G.; He, X.; Awtar, S. Design and analytical model of a compact flexure mechanism for translational motion. Mech. Mach. Theory 2019, 142, 103593. [Google Scholar] [CrossRef]

- Hong, H.; Yang, X.; You, Z.; Cheng, F. Visual quality detection of aquatic products using machine vision. Aquac. Eng. 2014, 63, 62–71. [Google Scholar] [CrossRef]

- Atienza-Vanacloig, V.; Andreu-García, G.; López-García, F.; Valiente-González, J.M.; Puig-Pons, V. Vision-based discrimination of tuna individuals in grow-out cages through a fish bending model. Comput. Electron. Agric. 2016, 130, 142–150. [Google Scholar] [CrossRef]

- Hernández-Ontiveros, J.M.; Inzunza-González, E.; García-Guerrero, E.E.; López-Bonilla, O.R.; Infante-Prieto, S.O.; Cárdenas-Valdez, J.R.; Tlelo-Cuautle, E. Development and implementation of a fish counter by using an embedded system. Comput. Electron. Agric. 2018, 145, 53–62. [Google Scholar] [CrossRef]

- Issac, A.; Dutta, M.K.; Sarkar, B. Computer vision based method for quality and freshness check for fish from segmented gills. Comput. Electron. Agric. 2017, 139, 10–21. [Google Scholar] [CrossRef]

- Lalabadi, H.M.; Sadeghi, M.; Mireei, S.A. Fish freshness categorization from eyes and gills color features using multi-class artificial neural network and support vector machines. Aquacult. Eng. 2020, 90, 102076. [Google Scholar] [CrossRef]

- Miranda, J.M.; Romero, M. A prototype to measure rainbow trout’s length using image processing. Aquacult. Eng. 2017, 76, 41–49. [Google Scholar] [CrossRef]

- Muñoz-Benavent, P.; Andreu-García, G.; Valiente-González, J.M.; Atienza-Vanacloig, V.; Puig-Pons, V.; Espinosa, V. Enhanced fish bending model for automatic tuna sizing using computer vision. Comput. Electron. Agric. 2018, 150, 52–61. [Google Scholar] [CrossRef]

- Costa, C.; Antonucci, F.; Boglione, C.; Menesatti, P.; Vandeputte, M.; Chatain, B. Automated sorting for size, sex and skeletal anomalies of cultured seabass using external shape analysis. Aquacult. Eng. 2013, 52, 58–64. [Google Scholar] [CrossRef]

- Buckingham, R.; Graham, A.; Arnarson, H.; Snaeland, P.; Davey, P. Robotics for de-heading fish–a case study. Ind. Robot. 2001, 24, 302–309. [Google Scholar] [CrossRef]

- De Silva, C.; Wickramarachchi, N. An innovative machine for automated cutting of fish. IEEE-ASME T Mech. 1997, 2, 86–98. [Google Scholar] [CrossRef]

- Lang, H.; Wang, Y.; de Silva, C.W. (Eds.) An automated industrial fish cutting machine: Control, fault diagnosis and remote monitoring. In Proceedings of the 2008 IEEE International Conference on Automation and Logistics, Qingdao, China, 1–3 September 2008. [Google Scholar]

- Ketels, D. Apparatus for Positioning Fish for Heading. U.S. Patent 7467995, 23 December 2008. [Google Scholar]

- Kragh, H. Fish Processing Machine with Alignment Devices and Methods for Realigning Fish during Processing. U.S. Patents US20100240289A1, 13 April 2007. [Google Scholar]

- Urushibara, S.; Yusa, K. Method and Apparatus for Gutting Fish. U.S. Patents CA2007425A1, 1 September 1991. [Google Scholar]

- Ryan, R.M. Fish Processing System and Method. U.S. Patent 20130316632, 6 August 2013. [Google Scholar]

- Paulsohn, C.; Dann, A.; Rüsch, R.; Brandt, M. Tool, Device, and Method for Gutting Fish Opened at the Stomach Cavity. U.S. Patents , CA2650073C, 12 November 2010. [Google Scholar]

- Kowalski, W. Method for Removing Blood Released during Filleting from the Backbone of Fish, and Device for Removing such Blood. U.S. Patent 8956205B2, 17 February 2015. [Google Scholar]

- Braeger, H. Method and Device for Automatically Extracting Flesh from Fish. U.S. Patent 9888697B2, 13 February 2018. [Google Scholar]

- Finke, H.; Jurs, M.; Grabau, T. Apparatus and Method for Automatically Obtaining Flesh from Beheaded and Gutted Fish. U.S. Patent US8814637B2, 26 August 2018. [Google Scholar]

- Bondø, M.S.; Mathiassen, J.R.; Vebenstad, P.A.; Misimi, E.; Bar, E.M.S.; Toldnes, B.; Ove østvik, S. An automated salmonid slaughter line using machine vision. Ind. Robot. 2011, 38, 399–405. [Google Scholar] [CrossRef]

- Storbeck, F.; Daan, B. Fish species recognition using computer vision and a neural network. Fish Res. 2001, 51, 11–15. [Google Scholar] [CrossRef]

- Godfrey, D. Friction of greases and grease components during boundary lubrication. Asle Trans. 1964, 7, 24–31. [Google Scholar] [CrossRef]

- Gray, D.E. American institute of physics handbook. Am. J. Phys. 1964, 32, 389. [Google Scholar] [CrossRef]

| Fish Cleaning Machine Capacity (MF) | |||||||

|---|---|---|---|---|---|---|---|

| System capacity (fish/minute) | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Linear velocity of the conveyer chain (mm s−1) | 53.33 | 66.66 | 80 | 93.33 | 106.66 | 120 | 133.33 |

| Pneumatic Cylinder | Fish Movement along the Machine Based on the Feeding Rate (Fish Per Minute) | |||||||

|---|---|---|---|---|---|---|---|---|

| Speed (mm s−1) | t (s) | MF-4 | MF-5 | MF-6 | MF-7 | MF-8 | MF-9 | MF-10 |

| 100 | 1 | 53.33 | 66.67 | 80.00 | 93.33 | 106.67 | 120.00 | 133.33 |

| 200 | 0.50 | 26.67 | 33.33 | 40.00 | 46.67 | 53.33 | 60.00 | 66.67 |

| 300 | 0.32 | 17.78 | 22.22 | 26.67 | 31.11 | 35.56 | 40.00 | 44.44 |

| 400 | 0.25 | 13.33 | 16.76 | 20.00 | 23.33 | 26.67 | 30.00 | 33.33 |

| 500 | 0.20 | 10.67 | 13.33 | 16.20 | 18.67 | 21.33 | 24.80 | 26.67 |

| 600 | 0.17 | 8.89 | 11.11 | 13.33 | 15.56 | 17.78 | 20.00 | 22.22 |

| 700 | 0.14 | 7.62 | 9.52 | 11.43 | 13.33 | 15.24 | 17.14 | 19.05 |

| 800 | 0.13 | 6.67 | 8.33 | 10.00 | 11.67 | 11.85 | 15.00 | 16.67 |

| 900 | 0.11 | 5.93 | 7.41 | 8.89 | 10.37 | 14.22 | 13.33 | 14.81 |

| Free fall | 0.06 | 3.20 | 4.00 | 4.80 | 5.60 | 6.40 | 7.20 | 8.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azarmdel, H.; Mohtasebi, S.S.; Jafary, A.; Behfar, H.; Rosado Muñoz, A. Design and Simulation of a Vision-Based Automatic Trout Fish-Processing Robot. Appl. Sci. 2021, 11, 5602. https://doi.org/10.3390/app11125602

Azarmdel H, Mohtasebi SS, Jafary A, Behfar H, Rosado Muñoz A. Design and Simulation of a Vision-Based Automatic Trout Fish-Processing Robot. Applied Sciences. 2021; 11(12):5602. https://doi.org/10.3390/app11125602

Chicago/Turabian StyleAzarmdel, Hossein, Seyed Saeid Mohtasebi, Ali Jafary, Hossein Behfar, and Alfredo Rosado Muñoz. 2021. "Design and Simulation of a Vision-Based Automatic Trout Fish-Processing Robot" Applied Sciences 11, no. 12: 5602. https://doi.org/10.3390/app11125602

APA StyleAzarmdel, H., Mohtasebi, S. S., Jafary, A., Behfar, H., & Rosado Muñoz, A. (2021). Design and Simulation of a Vision-Based Automatic Trout Fish-Processing Robot. Applied Sciences, 11(12), 5602. https://doi.org/10.3390/app11125602