Abstract

Prefabricated buildings are the direction of the future development of the construction industry and have received widespread attention. The effective execution of prefabricated construction project scheduling should consider resource constraints and the supply arrangement of prefabricated components. However, the traditional construction resource-constrained project scheduling implementation method cannot simultaneously consider the characteristics of the linkage between component production and on-site assembly construction. It cannot also fully adapt to the scheduling implementation method of the prefabricated construction projects. It is difficult to work out a reasonable project schedule and resource allocation table. In order to determine the relevant schedule parameters that can reflect the actual construction situation of the prefabricated building and meet the scheduling requirements of the prefabricated project, this study proposes a prefabricated construction project scheduling model that considers project resource constraints and prefabricated component supply constraints. Additionally, it improves the design of traditional genetic algorithms (GAs). Research results of the experimental calculation and engineering application show that the proposed project scheduling optimization model and GA are effective and practical, which can help project managers in effectively formulating prefabricated construction project scheduling plans, reasonably allocating resources, reducing completion time, and improving project performance.

1. Introduction

In recent years, the construction industry has paid increasing attention to the use of modular prefabricated parts. In China, prefabricated buildings have recently become a popular form of construction [1,2,3]. The prefabricated building transfers part of the traditional on-site construction work to the factory for completion [4]. The modular components are completed in the factory manufacturing center, and then transported to the final project location to form the building [5]. The prefabricated building splits the construction process into two parts, namely, the off-site prefabricated component production process and the on-site assembly construction process; thus, the on-site construction scheduling arrangement of the prefabricated building project must consider the production and supply of prefabricated components [6,7]. Related studies have found that project scheduling has relatively high value in theoretical research and specific applications. It not only promotes the development of engineering projects but also serves as an important reference for engineering project decision-making, especially under resource-constrained conditions. An effective scheduling plan is a necessary condition for successfully completing the entire project [8,9]. The unreasonable project scheduling plan formulated due to the failure to fully consider the characteristics of the prefabricated building will make it difficult for on-site construction activities to be implemented as planned, resulting in a series of negative ripple consequences; hence, prefabricated construction projects cannot be completed on time and the cost increases [10].

In the past few decades, Critical Path Method (CPM) and Program Evaluation and Review Technique (PERT) are the main planning methods to solve project scheduling [11]. The two methods of CPM and PERT usually assume unlimited resources [12,13]. However, resource supply is generally limited in an actual project implementation, and the project schedule generated by CPM or PERT usually needs to be further optimized after considering resource constraints. Accordingly, scholars began to consider the resource-constrained project scheduling problem (RCPSP). In the past 10 years, many researchers have devoted themselves to solving RCPSP through various meta-heuristic methods. At present, researchers mainly focus on enhancing the performance of meta-heuristic algorithms by using the knowledge of genetic algorithms (GAs) [14]. However, the resource-constrained project scheduling implementation method of traditional buildings cannot be completely adapted to the realization of prefabricated construction project scheduling for the problem of prefabricated construction project scheduling. The project scheduling method of conventional buildings is only adequate for scheduling repetitive tasks in prefabricated building schedules [15,16]. Assembly construction is constrained by a variety of limited renewable resources, such as management personnel, lifting equipment (crane, flatbed truck) and labor workers (crane driver, installer), etc. Although the project scheduling of prefabricated buildings still belongs to the scope of the resource-constrained project scheduling problem, it is significantly different from the traditional building that the construction site activities of prefabricated buildings can only start after the required prefabricated components arrive on time. Under normal circumstances, the production of prefabricated components is scheduled according to the schedule of on-site construction. However, the business of manufacturing companies is usually operated under the condition of multiproject execution. Resource sharing and competition exist between projects, and the failure to timely supply prefabricated components is often an important reason for the failure to complete prefabricated construction projects [17]. Accordingly, it is difficult to directly apply the traditional scheduling method to the scheduling research of prefabricated buildings [18]. Some studies have tried to develop an effective assembly-type construction project scheduling method, including mathematical modeling optimization and simulation modeling [19,20,21,22]. However, these previous studies show that the traditional project scheduling technology often ignores the impact of untimely component supply on site construction, or model optimization is usually carried out on the premise of timely and quantitative supply of components. These studies cannot simultaneously consider the two essential construction processes of prefabricated component production and field assembly construction. The project schedule and resource allocation table are often inconsistent with the actual construction demand, and the availability of the schedule is not very high. Although the solution of simulation modeling can fully display the project scheduling process, the workload of simulation modeling is often large, and the solution efficiency is relatively low.

This study has developed a prefabricated construction project scheduling optimization model that is more intuitive and easy to solve to make up for the failure to fully consider the impact of the supply of prefabricated components on the scheduling model and the limitations of simulation modeling in the previous research [16,23]. The model considers the priority and resource occupation constraints of project activities and transforms the constraints of production and transportation of prefabricated components into supply time constraints into the optimization model. The priority relationship between prefabricated construction project activities is complex, and it is constrained by a variety of resources and the supply of prefabricated components. Due to the core genetic operations of the genetic algorithm (including selection, crossover and mutation) will not be greatly affected by project changes. Therefore, this study introduces a GA that is easy to express project-related constraints to solve the prefabricated construction project scheduling problem and designs the genetic operation of GA correspondingly. The study verifies the effectiveness of the algorithm proposed in this paper through experimental calculations on the Project Scheduling Problem Library (PSPLIB) data set, and then applies the developed model and algorithm to actual prefabricated projects. This study has two important research contributions compared with previous studies that failed to consider the prefabrication characteristics of prefabricated buildings well or use simulation modeling [16,24]. First, this work provides a prefabricated construction project scheduling optimization model which can consider the supply conditions of prefabricated components. Moreover, this work determines the relevant parameters of the prefabricated construction schedule, such as the delivery time of prefabricated components, resource occupation, and supply restrictions. In contrast with previous studies that ignore the influencing factors of precast components [25], this study can better reflect the actual construction situation of prefabricated buildings and meet the needs of project scheduling arrangements. To a certain extent, it fills the blank that current prefabricated construction project scheduling research results are less or the key factors of the model are not fully considered. Second, in view of the shortcomings of the GA proposed in the past, this research improves the related genetic operation and designs a GA with a stable solution quality, scalability, and high practicability to solve the prefabricated construction project scheduling optimization model. The superiority and practicability of the proposed model and algorithm are verified through experimental calculation, algorithm comparison, and actual engineering case application.

The remaining sections of this study are arranged as follows: the Section 2 reviews the related research; the Section 3 establishes the mathematical model of the prefabricated construction project scheduling problem; the Section 4 introduces the designed GA in detail; the Section 5 provides a series of calculation results by using PSPLIB test examples to verify the effectiveness of the algorithm; the Section 6 applies the proposed model and algorithm to the actual application. Finally, the Section 7 is the conclusion of this study.

2. Literature Review

2.1. Resource-Constrained Project Scheduling Problem

Project scheduling is a complex process involving multiple resources and activities that need to be optimized. Resource constraints have a wide range of impacts and inevitable obstacles during a project implementation because unreasonable resource allocation can easily lead to certain problems such as construction delays and budget overruns [26]. Therefore, RCPSP is an important and challenging problem in theoretical and practical application research [3,27]. RCPSP is defined as scheduling a set of activities linked by priority relationships to minimize project duration while meeting priority and resource constraints [28]. This issue is a typical combinatorial optimization problem and belongs to the NP-hard problem [29,30].

In previous research, the resource-constrained project scheduling problem has received great attention [31,32,33]. Dodin et al. [34] used mixed integer programming to optimize the integration of project scheduling and material supply by taking the material and project related costs of a single project as the objective functions. Zhang et al. [35] proposed a new algorithm for the rush problem of repetitive construction projects. The calculation examples show that the algorithm can easily identify various types of control subprocesses and obtain the exact solution of the corresponding minimum total cost with a small amount of calculation. Zoraghi et al. [36] studied the combination of a multimode project scheduling problem and material ordering, and used multiobjective evolutionary algorithms, including intensity Pareto evolution II, multiobjective particle swarm optimization and multiobjective evolution based on decomposition, to solve the developed three-objective problem. Tian et al. [37] proposed an improved critical chain technology for solving resource-constrained multiproject scheduling by studying the resource flow characteristics of single project, multiproject and activity. GAs are based on biological evolution compared with the other algorithms. As a meta-heuristic search optimization method to effectively solve RCPSP, GA has good convergence, and its search space is not limited. When the calculation accuracy requirements are clear, GA calculation time is less. Therefore, GA is more widely favored by research scholars. Zoraghi et al. [38] established a multimode material ordering resource constrained project scheduling model based on the reward and punishment mechanism, and designed a hierarchical search hybrid GA to solve the problem. The result of the model showed good performance. Goncharov et al. [39] proposed a GA with two crossover operators to solve the problem based on the technical constraints and resource constraints of project activities for effectively shortening the project duration. The GA considers the critical degree of resources and improves the resource utilization rate on the premise of ensuring the completion quality.

With the development of resource-constrained project scheduling problem, many research results have been obtained. The GA, which is widely used in the field of project scheduling, has many excellent characteristics. The spatial solution search performance and calculation ability of GA are excellent, and its robustness is high. It provides a new and effective way to solve complex optimization problems [40,41]. However, the traditional GA often has the defects of premature convergence and local optimum. In some previous studies, the initial population is often random for the design of GA, regardless of the priority logic relationship between project activities, resulting in a large number of infeasible solutions, which greatly increases the calculation time of the algorithm. The unreasonable design of genetic operation mode also reduces the efficiency of the algorithm to a certain extent. Therefore, it is necessary to use GA to solve the project scheduling problem and explore more efficient and reasonable genetic operation design to solve the actual engineering project scheduling problem under resource constraints.

2.2. Prefabricated Building Scheduling Problem

In the study of prefabricated buildings, scholars found that a reasonable scheduling plan has an important impact on the successful implementation of the entire prefabricated building project in the construction process of prefabricated concrete residential construction [42]. The scheduling problem of prefabricated construction projects belongs to RCPSP. Thus, the resource constraints must be considered. In contrast with the traditional resource-constrained project scheduling problem, the target modeling and solution of the scheduling problem need to consider the supply of prefabricated components [10,43]. Drawing on the traditional resource-constrained construction project scheduling solution model, the project scheduling research of prefabricated building mainly adopts algorithm optimization. Taghaddos et al. [16] constructed a system to optimize the allocation of humans, space resources and meet various constraints, and generated scheduling management charts through model and algorithm simulation to guide project managers to carry out resource scheduling practice of prefabricated buildings. However, this resource library is aimed at previous research and has certain limitations for the complex real-world environment of prefabricated buildings. Arashpour et al. [25] used integer and probability optimization models to develop a method to minimize the cost of resources by using multiple skills in off-site construction to cope with the change of demand and resource availability in off-site assembly construction process. However, the study did not consider the supply constraints of prefabricated components for the construction of prefabricated buildings. Lee et al. [24] proposed three assembly-type construction project classification and scheduling strategies: manufacturing-driven, field-driven, and comprehensive. On this basis, they established a discrete event simulation conceptual model. However, some uncertainties are observed in the simulation results, and further research is needed in using the model to guide engineering practice. Wang and Lian [23] established a multiobjective and multimode resource constrained project scheduling model with time/robustness considering various possible situations in the process of assembly project construction. The adjusted nondominated GA is designed to solve the model. However, the premise of the research model is that the prefabricated components can arrive at the site one day in advance to avoid affecting the assembly work, ignoring the fact that the prefabricated components may be delayed in delivery.

The above-mentioned research results on prefabricated construction project scheduling are mostly borrowed from traditional resource-constrained project scheduling. Most established scheduling models are based on the premise that the on-site construction scheduling plan dominates the production scheduling plan of prefabricated components, ignoring the occurrence of untimely supply and delayed delivery of prefabricated components, which cannot truly reflect the linkage between on-site construction and component production in the actual construction process of prefabricated construction projects. In the actual implementation of a prefabricated construction project, the overall project process and project resource demand and supply of prefabricated components must be fully considered to formulate its scheduling plan [7]. Therefore, directly learning from the traditional resource-constrained project scheduling model and applying it to the scheduling research of prefabricated buildings are unreasonable. In the previous research [16,24], simulation modeling is also a common way to solve scheduling problems in addition to using algorithm optimization. Through this method, the whole project construction process model oriented to scheduling problems can be established. However, the cost of simulation modeling is high, the modeling workload is large, and the scalability is poor. The operability of using simulation models to guide engineering practice scheduling is poor. The objective function, constraint conditions, and other elements of the scheduling problem can be transformed into the form of digital expression, which has the characteristics of intuitive description and easy solution, through mathematical modeling. In this study, we will establish a mathematical optimization model of construction scheduling that can reflect the complex constraints of a prefabricated construction project simultaneously considering the characteristics of component production and field assembly construction process. The improved GA is applied to solve the model to make a reasonable and effective project scheduling plan.

2.3. Solution Algorithm

The construction scheduling of prefabricated concrete residential building projects needs to consider resource constraints, which belongs to the resource-constrained project scheduling problem. The solution to resource-constrained project scheduling mainly includes three types of algorithms, namely exact algorithm, heuristic algorithm and meta-heuristic algorithm.

2.3.1. Exact Algorithm

Among the exact algorithms, PERT [44], CPM [45], linear and integer programming [46], branch and bound [47] are the commonly used solutions. However, the exact algorithms can only find the optimal solution for small-scale projects. When encountering a problem with a large project scale, exact algorithms will lose their application significance due to the long calculation time. PERT and CPM give the shortest possible critical path value ignoring resource constraints, and it is difficult to optimize restricted resources and construction time [18]. The assumption of unlimited resources in prefabricated construction scheduling will lead to the failure to fully reflect the periodic working environment. In the past, some studies using exact algorithms cannot effectively deal with the limited resources [48,49], and the calculation scale is limited. Thus, it is difficult to apply to prefabricated construction projects.

2.3.2. Heuristic Algorithm

Compared with exact algorithms, heuristic algorithms are more flexible than accurate algorithms in terms of balancing computational efficiency and quality. However, the disadvantage of heuristic algorithms is that the optimal solution cannot be directly obtained [50]. The main content of heuristic algorithms is the priority rule and the generation mechanism. Among simple heuristic algorithms based on priority rules, the commonly recognized rules mainly include resource scheduling methods, the latest completion time, the smallest time difference, the shortest processing time, the latest start time, and the worst-case relaxation time [51]. The generation mechanism mainly adopts the serial generation mechanism and the parallel generation mechanism proposed by Kolisch [52].

2.3.3. Meta-Heuristic Algorithm

Meta-heuristic algorithm is based on heuristic algorithm, uses sampling algorithm to generate initial population, and optimizes based on the search mechanism of the evolutionary algorithm itself. It can quickly obtain the (approximate) optimal solution of the problem, which can make up for the shortcomings of the exact algorithm and heuristic algorithm. This type of algorithm is a research hotspot [53]. The meta-heuristic algorithms include particle swarm optimization algorithm [54], tabu search algorithm [55], GA [56], and ant colony algorithm [57]. Among the many complex meta-heuristic algorithms, GA has the advantages of good convergence, short simulation calculation time, high calculation accuracy, and is not restricted by the search space. From the perspective of design ability and application effect, GA is considered to be the best solution among many solutions [58,59]. Since the introduction of GA by John Holland [60] in 1975, GA has been widely used to solve engineering planning problems [60], such as flow operation [61], construction projects [62], and highway construction [63]. The proposal of GA provides an effective solution for complex project scheduling optimization problems, and its good search and computing capabilities are generally recognized by researchers. However, the traditional GA is prone to premature convergence or fall into local optimization [58]. Therefore, the following research will improve the design of the traditional GA to meet the needs of model solving.

3. Problem Statement and Mathematical Formulation

3.1. Assumptions

In this study, we consider a prefabricated construction project with n activities, whose activities are constrained by renewable resources and supply of prefabricated components to minimize the project duration. The following hypotheses are introduced to facilitate the research:

- (1)

- Assume that the first activity 1 at the beginning of the project and the last activity n at the end of the project are dummy work, which does not consume any time and resources.

- (2)

- The process activity adopts the end-to-start (F-S type) logic relationship to express the sequence relationship between the activities. Assume that the time lag between the processes is zero.

- (3)

- Assume that each activity is executed in a non-preemptive manner, once each process activity starts, it will be executed uninterrupted to the end.

- (4)

- Assume that each activity has only one execution mode, and the time consumption and resource requirements of each activity during the execution process remain unchanged.

- (5)

- In order to save inventory costs and ensure the smooth progress of construction, it is assumed that the maximum stacking volume of prefabricated components on site each time shall not exceed the on-site inventory space, and the stock volume is sufficient for the assembly construction of the next process.

3.2. Notations

The notations used in this study are shown in Table 1 to establish the mathematical model of the prefabricated construction project scheduling problem.

Table 1.

Notation description.

3.3. Formulation of Mathematical Model

In this research, the prefabricated construction project scheduling problem will minimize the project completion time as the goal, while considering the main constraints that affect the prefabricated construction project scheduling problem, including the predecessor’s logical relationship constraint, the renewable resource limit and the impact of prefabricated component supply. Representing the problem with some math models, the established scheduling mathematical model is as follows:

In the model established above, Formula (1) is the goal to be achieved by the problem, which is to minimize the duration of the project, expressed in terms of the completion time of the last dummy activity n. Formula (2) is the logical relationship before and after the implementation of the activity, that is, the activity cannot start before the end of its predecessor activities. Formula (3) represents that at the same time, the demand of renewable resources (such as manpower, machinery, equipment, etc.) required by the activities being implemented cannot exceed the maximum supply of resources. Formula (4) converts the production and transportation constraints of prefabricated components in prefabricated building construction into the supply time limit of prefabricated components, that is, the maximum on-site delivery time of prefabricated components required for the execution of the activity needs to be less than the start execution time of the activity.

4. The Proposed Genetic Algorithm

4.1. Brief Introduction of Genetic Algorithm for Scheduling Problem of Prefabricated Building

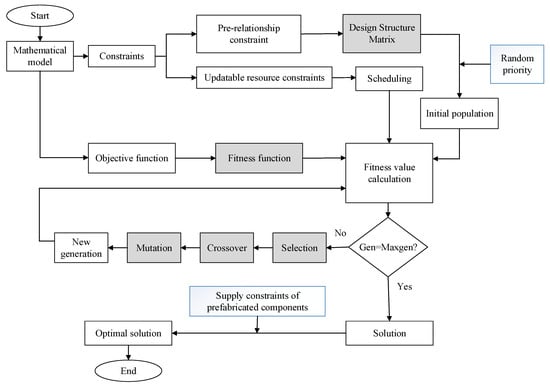

Figure 1 shows the solution process of the proposed GA in this research problem. In Figure 1, the first step is to transform the objective function of the model into a fitness function and use it as a basis for judging the adaptability of the population. With regard to the constraints of the predecessor relationship shown by the model, the Design Structure Matrix (DSM) is introduced to generate the initial population that satisfies the predecessor relationship required to execute the GA. In terms of the updatable resource constraints, the execution time of the sequence activities corresponding to each initial population individual will be arranged one by one according to the resource occupancy. Next, the GA selection operation is performed to screen and retain the better individuals according to the fitness calculation results of each initial population individual. To find better individuals, crossover and mutation operations of GA are performed on the selected parents to produce better offspring than the parents. The generated offspring also need to undergo a new round of fitness evaluation and selection. The designed algorithm takes the number of iterations as the criterion for loop termination. When the number of iterations reaches the maximum, the algorithm stops iterating and outputs the optimal individual of the group, that is, the optimal feasible solution under the current number of iterations. However, the obtained optimal scheduling plan needs to be further adjusted according to the supply of prefabricated components, and then the actual optimal scheduling plan of the prefabricated construction project can be obtained. In this process, the algorithm coding, fitness function, selection operator, crossover operator, and mutation operator design are the keys to determine whether the algorithm can be effectively applied to solve the prefabricated construction project scheduling problem.

Figure 1.

Flow chart of GA for solving the scheduling problem of prefabricated construction projects.

4.2. Genetic Algorithm Design for Scheduling Problem of Prefabricated Building

4.2.1. Coding

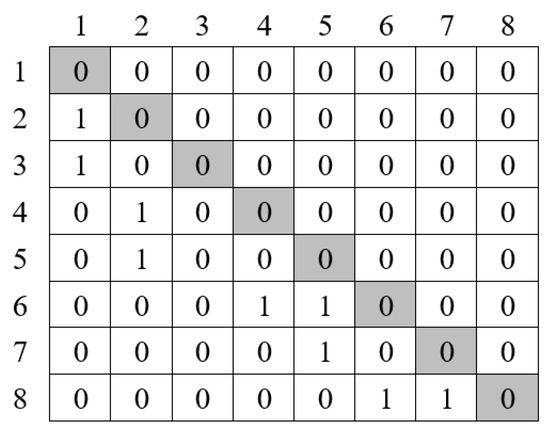

Coding is a bridge between the algorithm and the research problem. Encoding the solution of the problem into a chromosome is a prerequisite for the remaining steps of the GA. In the field of project scheduling, how to deal with the logical relationship of activities and effectively generate codes that can deal with the constraints of the predecessors of the activities are the key and difficult points [64]. At present, the common coding methods in this field include task list, random key, task priority rule, shift vector and so on. This study adopted a real-numbered representation of the task list based on priority. For example, a chromosome p = (1, 2, 3, …, n) with n genes, and each gene of the chromosome represents every activity of the project. This notion means that the project has a total of n activities, among which activities 1 and n are dummy activities. The gene sequence of chromosome p is the corresponding activity execution arrangement sequence. In order to facilitate the algorithm coding and visual analysis of the project, the DSM is introduced as an expression of the predecessor relationship between activities. DSM is a representation method that reflects the logical relationship between activities in the form of a matrix. The project Active On the Node network diagram can be expressed in computer operations through DSM [65,66]. The scheduling generated in this way not only satisfies the predecessor relationship constraints of the activity, but also guarantees the randomness of the performed activities, thereby expanding the space for solution. For example, eight activities are present in a project. According to the DSM shown in Figure 2, the predecessor activities of activities 2 and 3 are activity 1, the predecessor activities of activities 4 and 5 are activity 2, and so on.

Figure 2.

DSM.

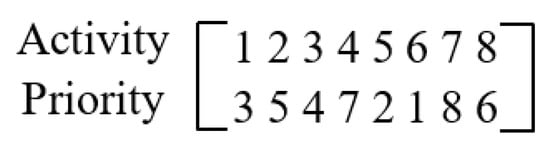

The priority of an activity is set to be randomly generated to ensure the randomness of the individual. Each activity is assigned a unique activity priority, and the priority values are not repeated, as shown in Figure 3. In the aforementioned figure, the random priorities corresponding to the eight activities are 35472186. Activity 6 will be prioritized for execution, followed by activity 5, to satisfy the predecessor’s relationship, and the remaining activities can be arranged according to the priority given. Especially for new projects that lack historical and empirical data, random priority is more maneuverable. Combining DSM and random priority can generate an activity list that satisfies the constraint relationship between activities.

Figure 3.

Distribution of random priority of activities.

4.2.2. Fitness Function

In GA, the expression of fitness function determines the direction of population evolution, and the survival ability of an individual generally corresponds to its fitness value. The mathematical model established in this research is to minimize the project completion time under the limited renewable resources and the supply constraints of prefabricated components. Therefore, it is necessary to convert the target value of the construction period of the problem into a fitness value. The design of the fitness function in this study is shown in Formula (5).

where, Fit(j) is the fitness function of individual j, which can be used as a criterion to evaluate the individual’s adaptability; is the target value of individual j, and the value is the corresponding project completion time; and are the maximum and minimum target values of individuals in the current population, respectively; w is a positive real number in the interval (0,1). On the one hand, w can ensure that Equation (5) will not be divided by zero. On the other hand, w can adjust the selection behavior from fitness proportional selection to pure random selection. In the next section of this study, the value of w is 0.5.

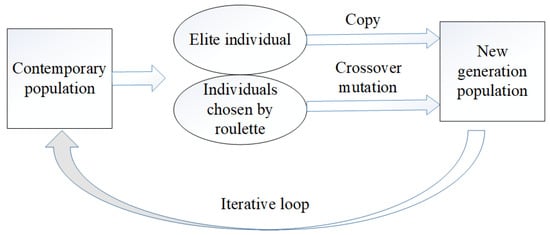

4.2.3. Selection Operator

The selection operation of GA generally has several methods such as proportional selection, ranking selection, and elite selection [67]. Roulette is the most commonly used method among the proportional selection strategies. The idea of the roulette method is to determine the individual’s choice based on the proportion of each individual’s fitness value in the population fitness value. The method requires multiple rounds of random numbers between [0, 1]. The larger the individual’s fitness value is, the more likely it will be retained under roulette selection. Due to the uncertainty brought by random operation, the individual with the highest fitness only can be easily eliminated by roulette selection method. The elite selection method can ensure that the best individuals that have appeared to date will not be eliminated or destroyed during the algorithm evolution due to selection, crossover, and mutation operations. In order to select a better project scheduling scheme, this study adopts the combination of roulette and elite selection methods for the design of GA selection operator, as shown in Figure 4. The algorithm divides the current population individuals (scheduling solution) into two parts. One part directly copies the contemporary individuals with the highest fitness (current optimal scheduling solution) to the next generation through elite selection. In the other part, some individuals were selected by roulette selection method to produce new individuals through crossover and mutation. The newly generated individuals and the copied individuals form a new offspring population. The new generation will repeat the selection and iterate until it reaches the stop standard. The combination of roulette and elite selection methods plays an important role in enhancing the global convergence ability of traditional GA.

Figure 4.

Combination of roulette and elite selection.

4.2.4. Crossover Operator

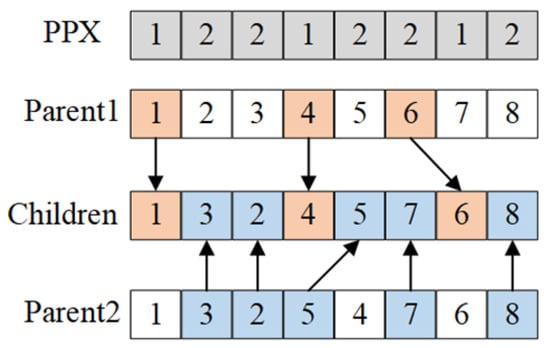

In the field of project scheduling, the design of the GA crossover operator must not only inherit the excellent characteristics of the parent population, but also ensure that the newly generated algorithm solution (scheduling scheme) after the crossover is still feasible. How to ensure that new individuals after the crossover still meet the constraints of the predecessor relationship between activities is one of the difficulties in algorithm design. In comparison with the other crossover operators, the Precedence Preservative Crossover (PPX) does not destroy the predecessor constraint relationship between activities when performing the crossover operation and ensures the validity of the corresponding solution of the new offspring. Therefore, this study uses PPX to perform crossover operations. PPX is composed of randomly generated 1 or 2 values, and the number of values is consistent with the number of genes in the parent generation. Figure 5 illustrates the process of using PPX to perform crossover operations. If the corresponding value in PPX is 1, then the gene of the offspring selects the gene at the corresponding position of the parent 1; otherwise, the gene at the corresponding position of the parent 2 is selected. In Figure 5, in the newly generated offspring gene sequencing, the genes corresponding to parent 1 are selected at positions 1, 4, and 7, and the genes of parent 2 are selected at other positions. Through the cross-operation of GA, a new activity scheduling scheme can be generated.

Figure 5.

Schematic of PPX performing cross-operation.

4.2.5. Mutation Operator

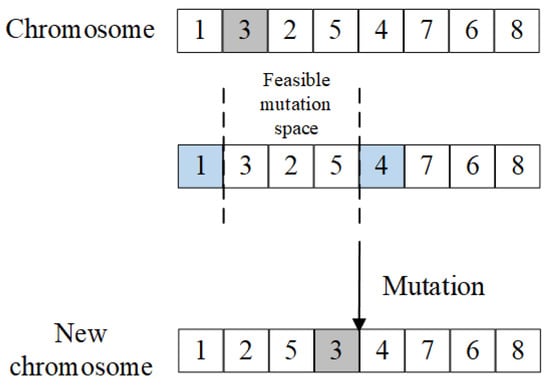

Similar to the crossover operator, the design of the GA mutation operator also needs to ensure that the newly generated algorithm solution after the mutation is still feasible. The difference is that the biggest role of the mutation operator is to prevent the algorithm from converging locally and to maintain the diversity of the population. The operation diagram of the mutation operator designed in this study is shown in Figure 6. The mutation individual (the new scheduling scheme) obtained by this way of operation satisfies the predecessor relationship constraint. In Figure 6, the gene on chromosome 3 is randomly selected. The feasible variation space of gene 3 can be obtained by searching for the activity represented by the gene in DSM, the latest to complete predecessor activity 1 and the earliest to start follow-up activity 4, which are the loci 2, 3, and 4 between activities 1 and 4. Then, a new variant individual that satisfies the logical relationship constraint can be obtained by randomly inserting gene 3 into locus 4.

Figure 6.

Schematic of mutation operation.

5. Computational Experiments

5.1. Tested Instances and Parameter Setting

In this section the single execution mode project scheduling problem data set in the international general project scheduling standard problem library PSPLIB [68] was used as a test example to verify the effectiveness of the proposed algorithm. The PSPLIB question library is generated by the ProGen program under strict parameter control. The single-execution model project scheduling problem data set consists of four data sets, namely, J30, J60, J90, and J120, which contain 32, 62, 92, and 122 activities (including start and end virtual activities), respectively. The four data sets have four types of renewable resources. Each data set of J30, J60, and J90 has a total of 480 examples, which can be divided into 48 groups according to the different parameter combinations. Every group contains 10 problem examples. The J120 data set has a total of 600 examples, which can be divided into 60 groups, and each group is also composed of 10 problem examples. The optimal solution of J30 data set was obtained by exact algorithm. J60, J90, and J120 did not yet obtain the optimal solution, but PSPLIB provides the lower bound of the solution and the best solution at present. These data can be obtained from the website http://www.om-db.wi.tum.de/psplib/ accessed on 12 April 2021. The problem sets of J30, J60, and J120 were selected for experimental calculation, and the experimental results were compared with the other algorithms in recent years. The algorithm in this section is implemented using Matlab2014a. The operating environment is a computer with Windows10 system, 8 GB memory, 1.80 GHz CPU frequency, and Intel(R) Core(TM) i5-8265U processor.

For the convenience of comparison, the number of generated scheduling schemes was set to 50,000, and the algorithm related parameters were set as shown in Table 2. Pop_size represents the size of the population, Max_gen is the maximum number of iterations of the algorithm, Pc represents the crossover probability, and Pm represents the mutation probability.

Table 2.

Algorithm parameter setting.

5.2. Experimental Results

5.2.1. Evaluation Method

This study adopts the most widely used evaluation method for the three types of test sets J30, J60, and J120, to determine the deviation of the designed algorithm solution from the (approximate) optimal solution of a given test problem. This method was proposed by Kolisch [69], as shown in Equations (6) and (7). According to the evaluation standard, the average deviation between the optimal solution obtained by the algorithm and the exact solution of the problem set (given the lower bound solution) or the length of the critical path is taken as the standard to measure the performance of the algorithm. The lower the average deviation rate, the better the performance of the algorithm.

where, means the objective value of an optimal solution of example i in the test problem set by algorithm; means the known lower bound solution of example i; means the solution of example i obtained by CPM; n represents the number of examples contained in the test problem set; Ave_DeV_lb and Ave_DeV_mpm represent the average deviation rate between the optimal solution obtained by the algorithm and the lower bound solution or the critical path solution, respectively.

5.2.2. Results

Three subproblem sets of J30, J60 and J120 were selected for numerical experiments, 48 examples were randomly selected from the J30 and J60 question sets, and 60 examples were randomly selected from the J120 question set for algorithm testing. Table 3 shows the calculation results of the J30, J60 and J120 test cases using the GA proposed in this research.

Table 3.

Optimization results of PSPLIB instance.

The performance of other excellent algorithms in the J30, J60 and J120 data sets in recent years is compared to illustrate the effectiveness of the algorithm. In previous studies, the effectiveness of the algorithm was mostly measured by calculating the deviation rate between the optimal solution and the solution of the CPM. The comparison of the average deviation of the algorithm is shown in Table 4, except for J30 which is measured by the Avg_DeV_lb standard, J60 and J120 are measured by the Avg_DeV_mpm standard. The symbol “_” in the table indicates that the corresponding index results were not available in the original text.

Table 4.

Comparison of the average deviation between the proposed algorithm and the other algorithms.

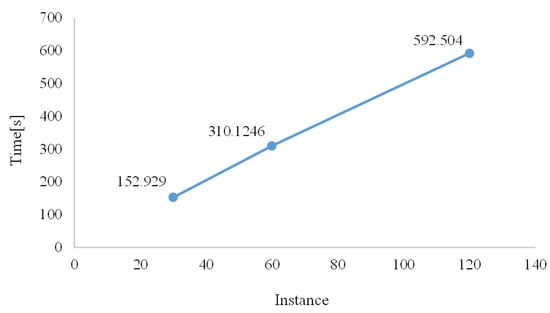

Table 4 illustrates that the average deviation rate increases as the scale of the problem increases, which indicates that the difficulty of solving the problem gradually increases with the scale increase. The average deviation rate of the algorithm proposed in this study in the J30, J60 and J120 problem sets are 0.00%, 9.32% and 30.16%, and the rankings are, respectively, the first, the first and the second in the compared algorithms. The J30 problem set has been accurately solved. In the previous research, many scholars’ algorithms have been able to achieve a test accuracy of 0.00%. The performance of the algorithm proposed in this study on the J30 test case shows that the algorithm is effective and has certain advantages in solution stability and accuracy. The performance of the J60 test case further shows that the proposed algorithm still has high solution accuracy and stability in solving medium-scale resource-constrained project scheduling problems. The results on the J120 test case show that the proposed algorithm is still effective and relatively stable when solving large-scale solutions. Figure 7 shows the average computing time performance of the algorithm on the J30, J60, and J120 problem sets. It can be seen from Figure 7 that the calculation time of the proposed algorithm of the research increases approximately linearly with the increase in project activities. The algorithm in this study is more efficient in terms of time compared with the other algorithms that have exponentially increasing computing time [80,87,88]. Therefore, the algorithm has more advantages in solving large-scale project scheduling problems.

Figure 7.

Average operation time of the algorithm.

The analysis of the above results indicated that the proposed algorithm shows a good computing performance in small and medium-scale problem sets or large-scale problem set tests. The algorithm has more stable and efficient advantages in solution quality and calculation time. The main reason is that in the design of GA, DSM and random priority are used to generate the initial population for ensuring that the initial individuals (the activity sequence of project scheduling) satisfy the constraints of predecessor logical relationship. In the genetic evolution operation of the algorithm, the design of the crossover operator and the mutation operator in this study ensures that the newly generated offspring conforms to the constraints of a predecessor logical relationship. In contrast with the method of randomly generating a certain number of population in some literature, then selecting better individuals to enter the initial population, and even screening out the infeasible solution after genetic operation, the method adopted in this study reduces the generation of infeasible individuals to a large extent, reduces the search space and improves the efficiency of operation. In addition, in the design of the selection operation, the proposed algorithm applies an elite strategy based on the roulette method, which ensures that the optimal individual is not eliminated, and enhances the global convergence ability of the algorithm.

6. Case Study

6.1. Project Description

For verifying the practicability of the proposed algorithm in solving practical engineering problems, this section applies the designed GA to the project scheduling problem of actual engineering cases. The selected case is adapted from the study of Wang and Lian, and it is used to analyze the trade-off between the duration and the robustness of a multimode prefabricated construction project [23]. The project is a new prefabricated industrial plant in Shaanxi Province, China. The prefabricated structure of the whole production building is divided into three areas, and each area is divided into two construction sections. According to the research objective of this study, the case is designed as a single mode project with a total of 25 activities, taking one area of the project as the analysis object. The project is constrained by three renewable resources, namely, manager R1, available lifting equipment (crane and flatbed truck) R2, and labor (crane driver, installation personnel, drilling personnel, and grouting personnel) R3. The maximum daily supply of renewable resources R1, R2, and R3 are 8, 36, and 18, respectively. Activities 1 and 25 are dummy activities that do not consume any time and resources. Table 5 provides for the specific information of the project.

Table 5.

Project activity information.

6.2. Simulation Results

In this section, the project scheduling mathematical model established in Section 3 and the GA proposed in Section 4 are used to optimize the duration of the case. The relevant parameters of the algorithm are set as follows: population size = 40, maximum number of iterations = 100, crossover rate = 0.9, mutation rate = 0.03, and w = 0.5. Under normal circumstances, the prefabricated components required for project construction will be timely delivered to the site before the start of the activity to ensure the smooth progress of on-site assembly and construction. Generally, on-site construction arrangements are the leading factor, which governs the production and transportation arrangements of factory prefabricated components [89]. Wang and Lian’s research was based on the analysis on the assumption that the prefabricated components arrived on time [23]. However, delays in the delivery of prefabricated components are not rare in the construction process of prefabricated construction projects, which is also an important reason for the deviation of the project schedule [90]. Therefore, the case study in this section will be analyzed from the two situations of on-time supply and delayed supply of prefabricated components.

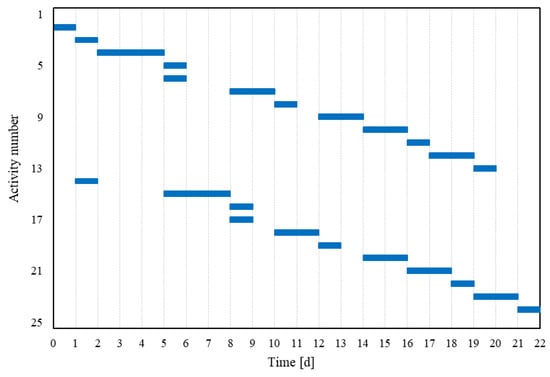

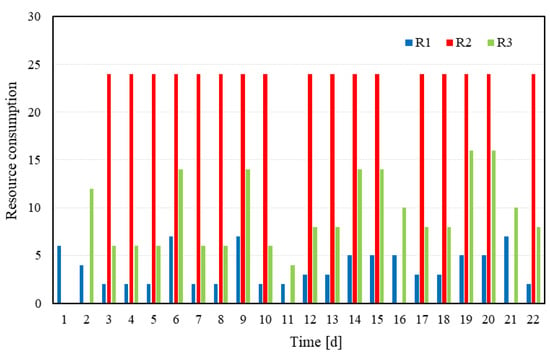

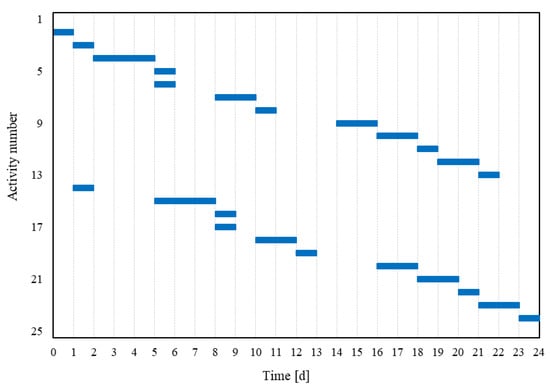

In the case that the prefabricated components can supply on-site construction requirements on time, the optimal activity sequence of the project is obtained by using the algorithm as [1 2 14 3 4 15 17 6 5 16 7 18 8 9 19 10 11 12 13 20 21 22 23 24 25]. The Gantt chart and resource consumption distribution chart of project scheduling are shown in Figure 8 and Figure 9, respectively. Figure 8 shows that under the condition of punctual supply of prefabricated components, subject to the constraints of three limited renewable resources, the maximum completion time of the project is 22 days. During the project construction, the resource allocation is well-distributed under this scheduling arrangement (Figure 9).

Figure 8.

Gantt chart under the on-time supply of prefabricated components.

Figure 9.

Distribution of resource consumption under the on-time supply of prefabricated components. manager R1, available lifting equipment (crane and flatbed truck) R2, and labor (crane driver, installation personnel, drilling personnel, and grouting personnel) R3.

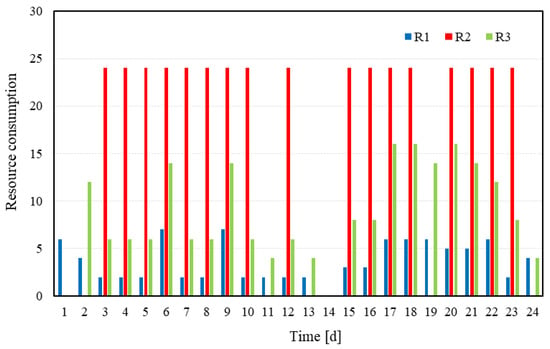

On the other hand, considering the situation that prefabricated components cannot supply on-site construction requirements on time, the optimal sequence of activities is still [1 2 14 3 4 15 17 6 5 16 7 18 8 9 19 10 11 12 13 20 21 22 23 24 25]. We assume that the prefabricated components required for the construction of activity 9 are delayed by 2 days. Originally planned to start on the 12th day, activity 9 needs to be adjusted to start on the 14th day at the earliest. The delay of activity 9 will have a certain effect on the schedule of the subsequent activities, and the unexecuted activities need to be readjusted. The updated project scheduling Gantt chart and resource consumption distribution diagram are shown in Figure 10 and Figure 11. Figure 10 demonstrates that in the event that the delivery of the prefabricated components required in activity 9 is delayed by 2 days, the maximum completion time of the project is delayed by 24 days. Activities 10, 11, 12, 13, 20, 21, 22, 23, and 24 all delayed the start time compared with the schedule in Figure 8. Especially for activity 20, even if all its predecessors have been executed on the 13th day, due to the constraints of renewable resources, activity 20 has to wait until the 16th day to start work. It is worth noting that due to the rescheduling of the delayed delivery of the prefabricated components, according to Figure 11, the resource consumption of 0 occurred on the 14th day. The project manager needs to pay attention to this situation. It is necessary to focus on the losses caused by the delayed delivery of prefabricated components and make timely adjustments. In addition, according to the resource consumption distribution maps in Figure 9 and Figure 11, project managers can predict the peak point of project resource usage and take the corresponding preventive measures to avoid project delays caused by resource allocation.

Figure 10.

Gantt chart for delayed delivery of prefabricated components.

Figure 11.

Distribution of resource consumption under delay delivery of prefabricated components. manager R1, available lifting equipment (crane and flatbed truck) R2, and labor (crane driver, installation personnel, drilling personnel, and grouting personnel) R3.

7. Conclusions

A prefabricated building has the advantages of rapid construction, clean and environmental protection, which is the main way to realize the development of building industrialization in the future. Unreasonable project scheduling plans will make it difficult to implement on-site assembly activities as planned. This is likely to lead to failure of prefabricated construction projects and affect project performance. At present, project managers usually only make time schedules based on their experience, which has a great subjectivity. In addition, since the prefabricated components of the prefabricated construction project need to be manufactured in the factory, for a reasonable prefabricated construction scheduling plan, the supply of prefabricated components needs to be considered in particular while considering general constraints such as activity priority and renewable resources. However, traditional scheduling methods are difficult to directly apply to the scheduling research of prefabricated buildings. Accordingly, this research proposes an optimization model for prefabricated construction project scheduling based on the characteristics of assembly construction. In view of the shortcomings of traditional GAs, a corresponding genetic operation improvement design is carried out. The designed GA used PSPLIB data sets J30, J60 and J120 for experimental calculation, and their average deviations are 0.00%, 9.32% and 30.16%, respectively. Compared with some algorithms in recent years, the proposed algorithm has advantages in accuracy and stability. Furthermore, the proposed model and algorithm were applied to practical engineering cases. The application results also show that the proposed project scheduling model and algorithm are practical and effective. The research results will help project managers formulate reasonable prefabricated-type project scheduling arrangements and implement effective decision-making arrangements, including schedule arrangements and resource allocation under resource constraint and the supply constraint of prefabricated components. Compared with previous studies, this study provides a prefabricated building project scheduling optimization model that can consider the supply conditions of prefabricated components, which can better reflect the actual construction situation of prefabricated buildings and meet the needs of project scheduling arrangements. In the future research, the proposed single-mode resource constrained prefabricated construction project scheduling optimization model and the designed GA may be extended to other interesting project scheduling problems in the field of prefabricated construction engineering. Such as stochastic activity duration and multimode resource constrained prefabricated construction project scheduling problem. Furthermore, we consider multiple conflicting objectives of the project, including minimizing completion time and cost. In practical application optimization, it is worth studying and interesting to extend the proposed model and algorithm to analyze these real cases.

Author Contributions

Conceptualization, L.X. and Y.C.; methodology, L.X.; software, Y.C.; validation, L.X., Y.C. and R.C.; formal analysis, R.C.; data curation, Y.C.; writing—original draft preparation, Y.C.; writing—review and editing, L.X. and R.C.; visualization, Y.C.; supervision, R.C.; project administration, L.X.; funding acquisition, L.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (grant number 71871096).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data generated or used during the study are available from the corresponding author by request.

Acknowledgments

The authors gratefully acknowledge the funding and support provided by the National Natural Science Foundation of China (Grant no. 71871096).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, L.-K.; Yuan, R.-P.; Ji, X.-J.; Lu, X.-Y.; Xiao, J.; Tao, J.-B.; Kang, X.; Li, X.; He, Z.-H.; Quan, S.; et al. Modular Composite Building in Urgent Emergency Engineering Projects: A Case Study of Accelerated Design and Construction of Wuhan Thunder God Mountain/Leishenshan Hospital to COVID-19 Pandemic. Autom. Constr. 2021, 124, 103555. [Google Scholar] [CrossRef]

- Jiang, R.; Mao, C.; Hou, L.; Wu, C.; Tan, J. A SWOT Analysis for Promoting Off-Site Construction under the Backdrop of China’s New Urbanisation. J. Clean. Prod. 2018, 173, 225–234. [Google Scholar] [CrossRef]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative Analysis of Modular Construction Practices in Mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical Review of the Research on the Management of Prefabricated Construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Kawecki, L.R. Environmental Performance Of Modular Fabrication: Calculating the Carbon Footprint of Energy Used in the Construction of a Modular Home. Ph.D. Dissertations & Theses Gradworks, Arizona State University, Tempe, AZ, USA, 2010. [Google Scholar]

- Alvanchi, A.; Azimi, R.; Lee, S.; AbouRizk, S.M.; Zubick, P. Off-Site Construction Planning Using Discrete Event Simulation. J. Archit. Eng. 2012, 18, 114–122. [Google Scholar] [CrossRef]

- Lee, J.; Hyun, H. Multiple Modular Building Construction Project Scheduling Using Genetic Algorithms. J. Constr. Eng. Manag. 2019, 145, 04018116. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Shi, Y.; Li, J. Solving Resource-Constrained Project Scheduling Problem via Genetic Algorithm. J. Comput. Civ. Eng. 2020, 34, 04019055. [Google Scholar] [CrossRef]

- Liu, S.; Feng, S. Disruption Management Simulation for Multi-Mode Resource-Constrained Project Scheduling Problem. J. Syst. Simul. 2017, 29, 662–668. [Google Scholar]

- Arashpour, M.; Wakefield, R.; Lee, E.W.M.; Chan, R.; Hosseini, M.R. Analysis of Interacting Uncertainties in On-Site and off-Site Activities: Implications for Hybrid Construction. Int. J. Proj. Manag. 2016, 34, 1393–1402. [Google Scholar] [CrossRef]

- Jain, V.; Sethi, P.; Arya, S.; Verma, R.; Chawla, C. Project Evaluation Using Critical Path Method & Project Evaluation Review Technique. Wesleyan J. Res. 2020, 13, 1–9. [Google Scholar]

- Bettemir, Ö.H.; Sonmez, R. Hybrid Genetic Algorithm with Simulated Annealing for Resource-Constrained Project Scheduling. J. Manag. Eng. 2015, 31, 04014082. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Tran, D.-H.; Wu, Y.-W. Using a Fuzzy Clustering Chaotic-Based Differential Evolution with Serial Method to Solve Resource-Constrained Project Scheduling Problems. Autom. Constr. 2014, 37, 88–97. [Google Scholar] [CrossRef]

- Xie, F.; Li, H.; Xu, Z. Multi-Mode Resource-Constrained Project Scheduling with Uncertain Activity Cost. Expert Syst. Appl. 2021, 168, 114475. [Google Scholar] [CrossRef]

- Chan, W.T.; Hu, H. Production Scheduling for Precast Plants Using a Flow Shop Sequencing Model. J. Comput. Civ. Eng. 2002, 16, 165–174. [Google Scholar] [CrossRef]

- Taghaddos, H.; Hermann, U.; AbouRizk, S.; Mohamed, Y. Simulation-Based Multiagent Approach for Scheduling Modular Construction. J. Comput. Civ. Eng. 2014, 28, 263–274. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H.; Gong, J. Simulation Based Multiple Disturbances Evaluation in the Precast Supply Chain for Improved Disturbance Prevention. J. Clean. Prod. 2018, 177, 232–244. [Google Scholar] [CrossRef]

- Mohamed, Y.; Borrego, D.; Francisco, L.; Al-Hussein, M.; AbouRizk, S.; Hermann, U. Simulation-based Scheduling of Module Assembly Yards: Case Study. Eng. Constr. Archit. Manag. 2007, 14, 293–311. [Google Scholar] [CrossRef]

- Abu Hammad, A.; Salem, O.; Hastak, M.; Syal, M. Decision Support System for Manufactured Housing Facility Layout. J. Archit. Eng. 2008, 14, 36–46. [Google Scholar] [CrossRef]

- Jeong, J.G.; Hastak, M.; Syal, M. Supply Chain Simulation Modeling for the Manufactured Housing Industry. J. Urban Plan. Dev. 2006, 132, 217–225. [Google Scholar] [CrossRef]

- Ma, Z.; Li, S.; Wang, Y.; Yang, Z. Component-Level Construction Schedule Optimization for Hybrid Concrete Structures. Autom. Constr. 2021, 125, 103607. [Google Scholar] [CrossRef]

- Nasereddin, M.; Mullens, M.A.; Cope, D. Automated Simulator Development: A Strategy for Modeling Modular Housing Production. Autom. Constr. 2007, 16, 212–223. [Google Scholar] [CrossRef]

- Wang, R.; Lian, J. Research on Construction Schedule Optimization of Assembly Building Based on NSGA-II. E3S Web Conf. 2020, 165, 06055. [Google Scholar] [CrossRef]

- Lee, J.; Park, M.; Lee, H.-S.; Hyun, H. Classification of Modular Building Construction Projects Based on Schedule-Driven Approach. J. Constr. Eng. Manag. 2019, 145, 04019031. [Google Scholar] [CrossRef]

- Arashpour, M.; Kamat, V.; Bai, Y.; Wakefield, R.; Abbasi, B. Optimization Modeling of Multi-Skilled Resources in Prefabrication: Theorizing Cost Analysis of Process Integration in off-Site Construction. Autom. Constr. 2018, 95, 1–9. [Google Scholar] [CrossRef]

- Sheng, B.; Wang, H.; Xiao, Z.; Zhang, C.; Zhao, F.; Yin, X. A Novel Heuristic Algorithm with Activity Back-Shift Response Model for Resource-Constrained Project Scheduling Problem. Soft Comput. 2019, 23, 7805–7819. [Google Scholar] [CrossRef]

- Su, Z.X.; Wei, H.Y.; Zou, X.; Qi, J.X. Zero-One Formulation for a Partial Resource-Constrained Project Scheduling Problem with Generalized Precedence Relations. J. Constr. Eng. Manag. 2019, 145. [Google Scholar] [CrossRef]

- Hartmann, S.; Briskorn, D. A Survey of Variants and Extensions of the Resource-Constrained Project Scheduling Problem. Eur. J. Oper. Res. 2010, 207, 1–14. [Google Scholar] [CrossRef]

- Jia, Q.; Guo, Y. Hybridization of ABC and PSO Algorithms for Improved Solutions of RCPSP. J. Chin. Inst. Eng. 2016, 39, 727–734. [Google Scholar] [CrossRef]

- Möhring, R.H.; Schulz, A.S.; Stork, F.; Uetz, M. Solving Project Scheduling Problems by Minimum Cut Computations. Manag. Sci. 2003, 49, 330–350. [Google Scholar] [CrossRef]

- Messelis, T.; De Causmaecker, P. An Automatic Algorithm Selection Approach for the Multi-Mode Resource-Constrained Project Scheduling Problem. Eur. J. Oper. Res. 2014, 233, 511–528. [Google Scholar] [CrossRef]

- Moradi, H.; Shadrokh, S. A Robust Scheduling for the Multi-Mode Project Scheduling Problem with a given Deadline under Uncertainty of Activity Duration. Int. J. Prod. Res. 2019, 57, 3138–3167. [Google Scholar] [CrossRef]

- Shariatmadari, M.; Nahavandi, N.; Zegordi, S.H.; Sobhiyah, M.H. Integrated Resource Management for Simultaneous Project Selection and Scheduling. Comput. Ind. Eng. 2017, 109, 39–47. [Google Scholar] [CrossRef]

- Dodin, B.; Elimam, A.A. Integrated Project Scheduling and Material Planning with Variable Activity Duration and Rewards. IIE Trans. 2001, 33, 1005–1018. [Google Scholar] [CrossRef]

- Zhang, L.; Liang, H. Repetitive Construction Project Deadline Constraint Satisfaction Problem. J. Civ. Eng. Manag. 2016, 33, 22–29. [Google Scholar]

- Zoraghi, N.; Shahsavar, A.; Niaki, S.T.A. A Hybrid Project Scheduling and Material Ordering Problem: Modeling and Solution Algorithms. Appl. Soft Comput. 2017, 58, 700–713. [Google Scholar] [CrossRef]

- Tian, M.; Liu, R.J.; Zhang, G.J. Solving the Resource-Constrained Multi-Project Scheduling Problem with an Improved Critical Chain Method. J. Oper. Res. Soc. 2020, 71, 1243–1258. [Google Scholar] [CrossRef]

- Zoraghi, N.; Shahsavar, A.; Abbasi, B.; Van Peteghem, V. Multi-Mode Resource-Constrained Project Scheduling Problem with Material Ordering under Bonus–Penalty Policies. TOP 2017, 25, 49–79. [Google Scholar] [CrossRef]

- Goncharov, E.N.; Leonov, V.V. Genetic Algorithm for the Resource-Constrained Project Scheduling Problem. Autom Remote Control 2017, 78, 1101–1114. [Google Scholar] [CrossRef]

- Armentano, V.A.; Mazzini, R. A Genetic Algorithm for Scheduling on a Single Machine with Set-up Times and Due Dates. Prod. Plan. Control 2000, 11, 713–720. [Google Scholar] [CrossRef]

- Zahmani, M.H.; Atmani, B. Extraction of Dispatching Rules for Single Machine Total Weighted Tardiness Using a Modified Genetic Algorithm and Data Mining. Int. J. Manuf. Res. 2018, 13, 1–25. [Google Scholar] [CrossRef]

- Sabeghi, N.; Tareghian, H.R.; Demeulemeester, E.; Taheri, H. Determining the Timing of Project Control Points Using a Facility Location Model and Simulation. Comput. Oper. Res. 2015, 61, 69–80. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, J.; HU, Z. Review and Thinking on Development of Building Industrialization in China. China Civ. Eng. J. 2016, 49, 1–8. [Google Scholar]

- Malcolm, D.G.; Roseboom, J.H.; Clark, C.E.; Fazar, W. Application of a Technique for Research and Development Program Evaluation. Oper. Res. 1959, 7, 646–669. [Google Scholar] [CrossRef]

- Kelley, J.E.; Walker, M.R. Critical-Path Planning and Scheduling. In Papers Presented at the December 1–3, 1959, Eastern Joint IRE-AIEE-ACM Computer Conference; Association for Computing Machinery: Boston, MA, USA, 1 December 1959; pp. 160–173. [Google Scholar]

- Berthold, T.; Heinz, S.; Lübbecke, M.E.; Möhring, R.H.; Schulz, J. A Constraint Integer Programming Approach for Resource-Constrained Project Scheduling. In Integration of AI and OR Techniques in Constraint Programming for Combinatorial Optimization Problems; Lodi, A., Milano, M., Toth, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 313–317. [Google Scholar]

- Chakrabortty, R.; Sarker, R.; Essam, D. Resource Constrained Project Scheduling: A Branch and Cut Approach. In Proceedings of the 45th International Conference on Computers and Industrial Engineering, Metz, Paris, 28–30 October 2015. [Google Scholar]

- Buddhakulsomsiri, J.; Kim, D.S. Priority Rule-Based Heuristic for Multi-Mode Resource-Constrained Project Scheduling Problems with Resource Vacations and Activity Splitting. Eur. J. Oper. Res. 2007, 178, 374–390. [Google Scholar] [CrossRef]

- Shen, W.; Wang, L.; Hao, Q. Agent-Based Distributed Manufacturing Process Planning and Scheduling: A State-of-the-Art Survey. IEEE Trans. Syst. Mancybern. Part C (Appl. Rev.) 2006, 36, 563–577. [Google Scholar] [CrossRef]

- Roy, B.; Sen, A.K. Meta-Heuristic Techniques to Solve Resource-Constrained Project Scheduling Problem. In Proceedings of the International Conference on Innovative Computing and Communications; Bhattacharyya, S., Hassanien, A.E., Gupta, D., Khanna, A., Pan, I., Eds.; Springer: Singapore, 2019; pp. 93–99. [Google Scholar]

- Demeulemeester, E.L.; Herroelen, W.S. An Efficient Optimal Solution Procedure for the Preemptive Resource-Constrained Project Scheduling Problem. Eur. J. Oper. Res. 1996, 90, 334–348. [Google Scholar] [CrossRef]

- Kolisch, R. Efficient Priority Rules for the Resource-Constrained Project Scheduling Problem. J. Oper. Manag. 1996, 14, 179–192. [Google Scholar] [CrossRef]

- Salhi, S. Handbook of Metaheuristics (2nd Edition). J. Oper. Res. Soc. 2014, 65, 320. [Google Scholar] [CrossRef]

- Zhang, Y.; Gong, D.; Hu, Y.; Zhang, W. Feature Selection Algorithm Based on Bare Bones Particle Swarm Optimization. Neurocomputing 2015, 148, 150–157. [Google Scholar] [CrossRef]

- Yu, X.; Liang, G.; Dong, Z. Multi-Objective Flexible Job Shop Scheduling Based on Hybrid Genetic Tabu Search Algorithm. Machinery 2016, 54, 90–93. [Google Scholar]

- Oh, I.S.; Lee, J.S.; Moon, B.R. Hybrid Genetic Algorithms for Feature Selection. IEEE Trans. Pattern Anal. Mach. Intell. 2004, 26, 1424–1437. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ji, D. Data- and Rule-Based Integrated Mechanism for Job Shop Scheduling. Int. J. Comput. Commun. Eng. 2015, 4, 180–186. [Google Scholar] [CrossRef]

- Su, Y.; Han, L.; Wang, H.; Wang, J. The Workshop Scheduling Problems Based on Data Mining and Particle Swarm Optimisation Algorithm in Machine Learning Areas. Enterp. Inf. Syst. 2019, 1–16. [Google Scholar] [CrossRef]

- Weckman, G.R.; Ganduri, C.V.; Koonce, D.A. A Neural Network Job-Shop Scheduler. J. Intell. Manuf. 2008, 19, 191–201. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial Systems; University of Michigan Press: Ann Arbor, MI, USA, 1975. [Google Scholar]

- He, F.; Wang, M.; Tang, Y. Application of Genetic Algorithm in Workshop Flow Job Scheduling. J. Comput. Appl. 2010, 30, 274–276. [Google Scholar]

- Ma, Z.; He, Z.; Wang, N.; Yang, Z.; Demeulemeester, E. A Genetic Algorithm for the Proactive Resource-Constrained Project Scheduling Problem With Activity Splitting. IEEE Trans. Eng. Manag. 2019, 66, 459–474. [Google Scholar] [CrossRef]

- El-Rayes, K.; Kandil, A. Time-Cost-Quality Trade-Off Analysis for Highway Construction. J. Constr. Eng. Manag. 2005, 131, 477–486. [Google Scholar] [CrossRef]

- Xuan, G.; Cheng, R. Genetic Algorithm and Engineering Optimization; Tsinghua University Press: Beijing, China, 2004; ISBN 978-7-302-07482-3. [Google Scholar]

- Chai, C. Modeling Resource-Constrained Project Scheduling Problem and Its Solution by Genetic Algorithm. J. Digit. Inf. Manag. 2013, 11, 87–96. [Google Scholar]

- Le, Y.; Sun, Q.; Chen, J.; Tang, K. Pre-Project Schedule Optimization of Airport Based on Design Structure Matrix. J. Tongji Univ. (Nat. Sci.) 2020, 48, 1523–1529. [Google Scholar]

- Shukla, A.; Pandey, H.M.; Mehrotra, D. Comparative Review of Selection Techniques in Genetic Algorithm. In Proceedings of the 2015 International Conference on Futuristic Trends on Computational Analysis and Knowledge Management (ABLAZE), Greater Noida, India, 25–27 February 2015; pp. 515–519. [Google Scholar]

- Kolisch, R.; Sprecher, A.; Drexl, A. Characterization and Generation of a General Class of Resource-Constrained Project Scheduling Problems. Manag. Sci. 1995, 41, 1693–1703. [Google Scholar] [CrossRef]

- Kolisch, R.; Hartmann, S. Experimental Investigation of Heuristics for Resource-Constrained Project Scheduling: An Update. Eur. J. Oper. Res. 2006, 174, 23–37. [Google Scholar] [CrossRef]

- Rahman, H.F.; Chakrabortty, R.K.; Ryan, M.J. Memetic Algorithm for Solving Resource Constrained Project Scheduling Problems. Autom. Constr. 2020, 111, 103052. [Google Scholar] [CrossRef]

- Berthaut, F.; Pellerin, R.; Hajji, A.; Perrier, N. A Path Relinking-Based Scatter Search for the Resource-Constrained Project Scheduling Problem. Int. J. Proj. Organ. Manag. 2018, 10, 1–36. [Google Scholar] [CrossRef]

- Elsayed, S.; Sarker, R.; Ray, T.; Coello, C.C. Consolidated Optimization Algorithm for Resource-Constrained Project Scheduling Problems. Inf. Sci. 2017, 418–419, 346–362. [Google Scholar] [CrossRef]

- Chand, S.; Singh, H.K.; Ray, T. A Heuristic Algorithm for Solving Resource Constrained Project Scheduling Problems. In Proceedings of the 2017 IEEE Congress on Evolutionary Computation (CEC), San Sebastián, Spain, 5–8 June 2017; pp. 225–232. [Google Scholar]

- Zamani, R. An Evolutionary Implicit Enumeration Procedure for Solving the Resource-Constrained Project Scheduling Problem. Int. Trans. Oper. Res. 2017, 24, 1525–1547. [Google Scholar] [CrossRef]

- Gonzalez-Pardo, A.; Del Ser, J.; Camacho, D. Comparative Study of Pheromone Control Heuristics in ACO Algorithms for Solving RCPSP Problems. Appl. Soft Comput. 2017, 60, 241–255. [Google Scholar] [CrossRef]

- Munlin, M.; Anantathanavit, M. Hybrid Radius Particle Swarm Optimization. In Proceedings of the 2016 IEEE Region 10 Conference (TENCON), Singapore, 22–25 November 2016; pp. 2180–2184. [Google Scholar]

- Paraskevopoulos, D.C.; Tarantilis, C.D.; Ioannou, G. An Adaptive Memory Programming Framework for the Resource-Constrained Project Scheduling Problem. Int. J. Prod. Res. 2016, 54, 4938–4956. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, L. A Multi-Agent Optimization Algorithm for Resource Constrained Project Scheduling Problem. Expert Syst. Appl. 2015, 42, 6039–6049. [Google Scholar] [CrossRef]

- Fahmy, A.; Hassan, T.M.; Bassioni, H. Improving RCPSP Solutions Quality with Stacking Justification—Application with Particle Swarm Optimization. Expert Syst. Appl. 2014, 41, 5870–5881. [Google Scholar] [CrossRef]

- Koulinas, G.; Kotsikas, L.; Anagnostopoulos, K. A Particle Swarm Optimization Based Hyper-Heuristic Algorithm for the Classic Resource Constrained Project Scheduling Problem. Inf. Sci. 2014, 277, 680–693. [Google Scholar] [CrossRef]

- Zamani, R. A Competitive Magnet-Based Genetic Algorithm for Solving the Resource-Constrained Project Scheduling Problem. Eur. J. Oper. Res. 2013, 229, 552–559. [Google Scholar] [CrossRef]

- Lim, A.; Ma, H.; Rodrigues, B.; Tan, S.T.; Xiao, F. New Meta-Heuristics for the Resource-Constrained Project Scheduling Problem. Flex. Serv. Manuf. J. 2013, 25, 48–73. [Google Scholar] [CrossRef]

- Mobini, M.; Mobini, Z.; Rabbani, M. An Artificial Immune Algorithm for the Project Scheduling Problem under Resource Constraints. Appl. Soft Comput. 2011, 11, 1975–1982. [Google Scholar] [CrossRef]

- Chen, R.-M. Particle Swarm Optimization with Justification and Designed Mechanisms for Resource-Constrained Project Scheduling Problem. Expert Syst. Appl. 2011, 38, 7102–7111. [Google Scholar] [CrossRef]

- Chen, W.; Shi, Y.; Teng, H.; Lan, X.; Hu, L. An Efficient Hybrid Algorithm for Resource-Constrained Project Scheduling. Inf. Sci. 2010, 180, 1031–1039. [Google Scholar] [CrossRef]

- Debels, D.; Vanhoucke, M. A Decomposition-Based Genetic Algorithm for the Resource-Constrained Project-Scheduling Problem. Oper. Res. 2007, 55, 457–469. [Google Scholar] [CrossRef]

- Gonçalves, J.F.; Resende, M.G.C.; Mendes, J.J.M. A Biased Random-Key Genetic Algorithm with Forward-Backward Improvement for the Resource Constrained Project Scheduling Problem. J. Heuristics 2011, 17, 467–486. [Google Scholar] [CrossRef]

- Mahdi Mobini, M.D.; Rabbani, M.; Amalnik, M.S.; Razmi, J.; Rahimi-Vahed, A.R. Using an Enhanced Scatter Search Algorithm for a Resource-Constrained Project Scheduling Problem. Soft Comput. 2009, 13, 597–610. [Google Scholar] [CrossRef]

- Hsu, P.-Y.; Angeloudis, P.; Aurisicchio, M. Optimal Logistics Planning for Modular Construction Using Two-Stage Stochastic Programming. Autom. Constr. 2018, 94, 47–61. [Google Scholar] [CrossRef]

- Hsu, P.-Y.; Aurisicchio, M.; Angeloudis, P. Risk-Averse Supply Chain for Modular Construction Projects. Autom. Constr. 2019, 106, 102898. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).