Evaluation of Maturity and Odor Emissions in the Process of Combined Composting of Kitchen Waste and Garden Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Composting Materials

2.2. Experimental Protocol

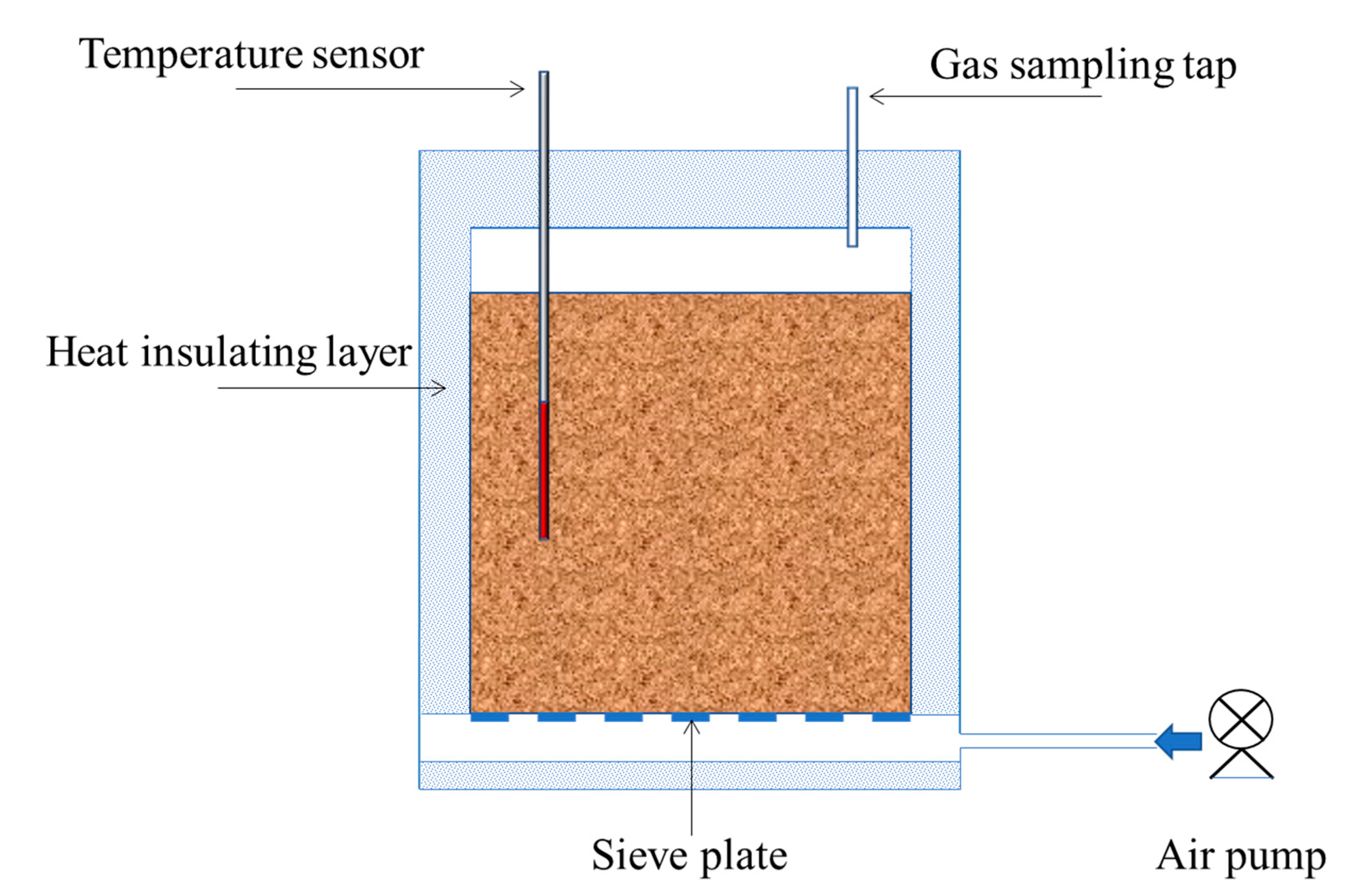

2.3. Experimental Device

2.4. Analytic Methods

3. Results and Discussion

3.1. Temperature

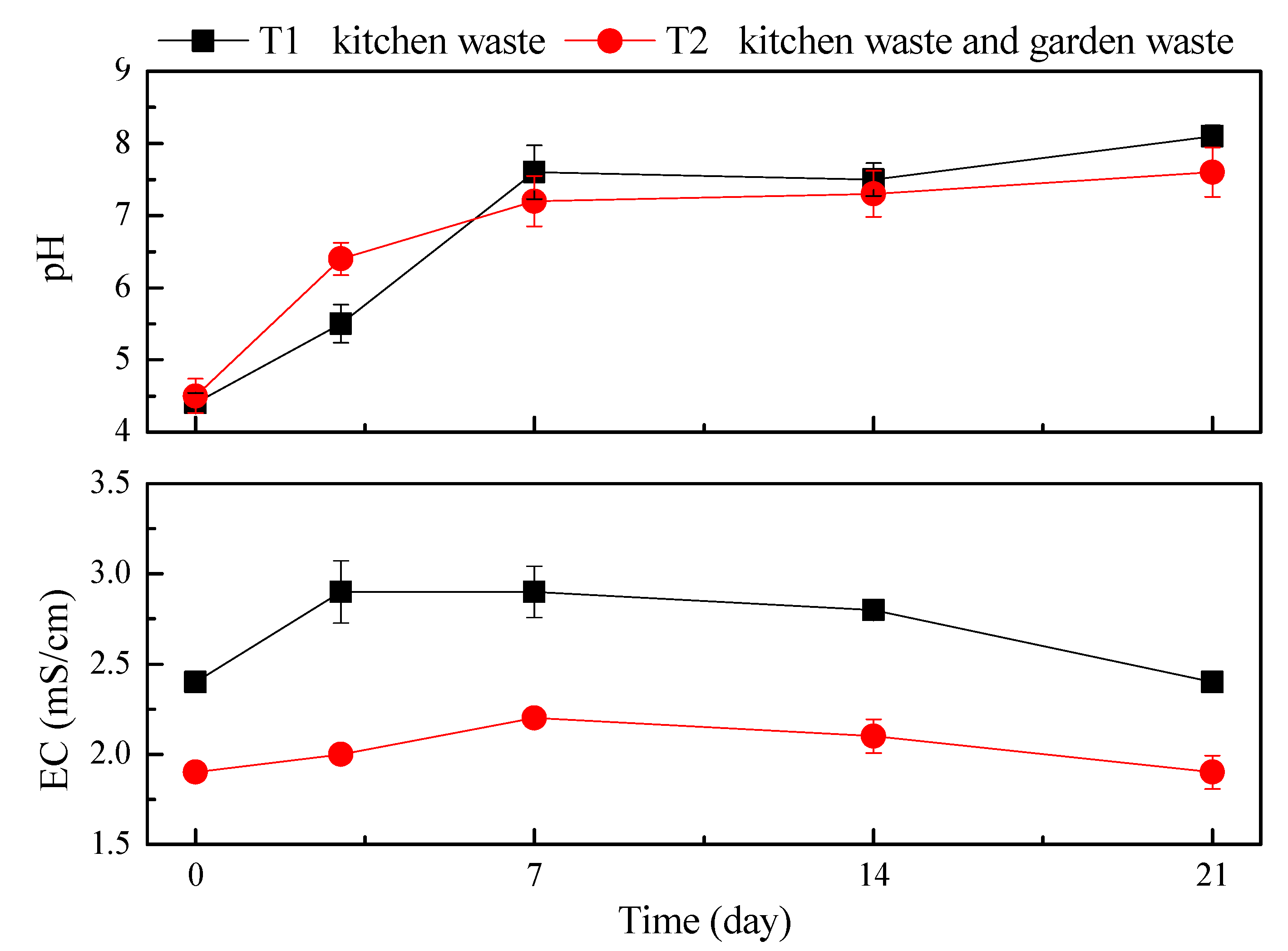

3.2. pH and EC

3.3. Germination Index (GI)

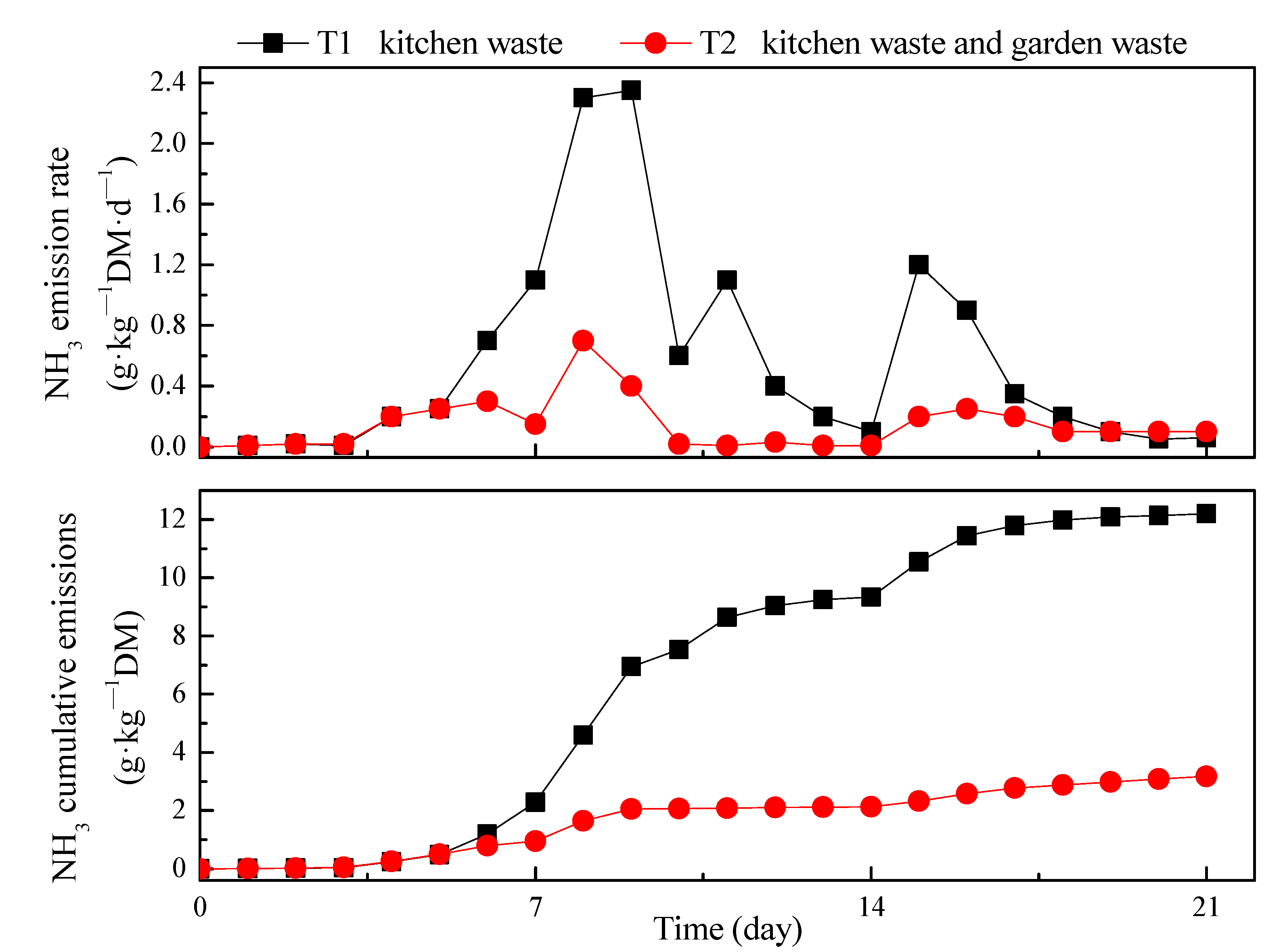

3.4. NH3 Emission

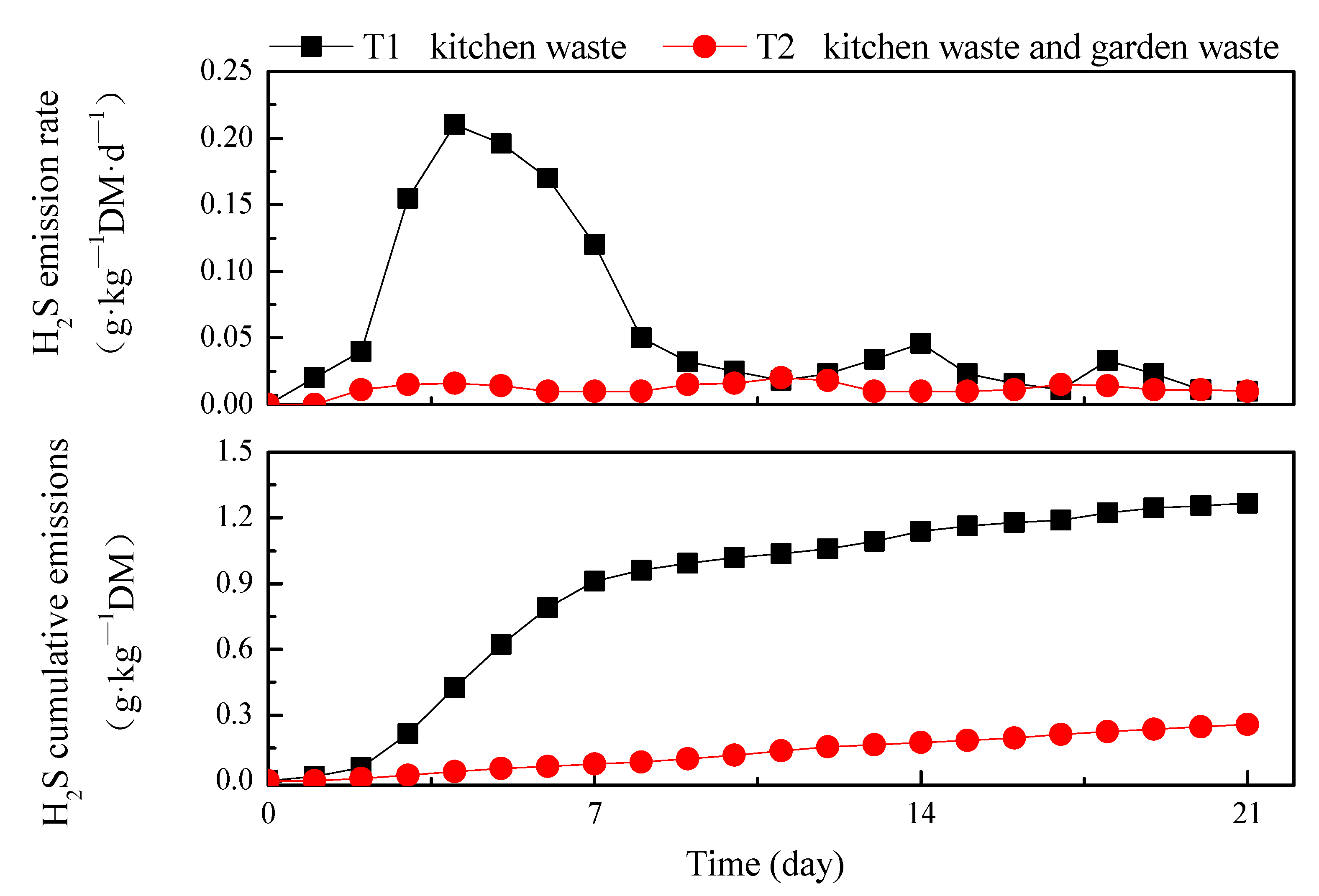

3.5. H2S Emission

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hafid, H.; Rahman, N.; Shah, U.; Baharuddin, A.; Ariff, A. Feasibility of Using Kitchen Waste as Future Substrate for Bioethanol Production: A Review. Renew. Sustain. Energy Rev. 2017, 74, 671–686. [Google Scholar] [CrossRef]

- Karimi, S.; Karimi, K. Efficient ethanol production from kitchen and garden wastes and biogas from the residues. J. Clean. Prod. 2018, 187, 37–45. [Google Scholar] [CrossRef]

- Yuan, J.; Yang, Q.; Zhang, Z.; Li, G.; Luo, W.; Zhang, D. Use of additive and pretreatment to control odors in municipal kitchen waste during aerobic composting. J. Environ. Sci. 2015, 37, 83–90. [Google Scholar] [CrossRef]

- Zhu, N. Effect of low initial C/N ratio on aerobic composting of swine manure with rice straw. Bioresour. Technol. 2007, 98, 9–13. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, M.; Wang, Z.; She, Z.; Hu, B.; Wang, Y.; Zhao, C. Comparison of physicochemical parameters during the forced-aeration composting of sewage sludge and maize straw at different initial C/N ratios. J. Air Waste Manag. Assoc. 2013, 63, 1130–1136. [Google Scholar] [CrossRef]

- Domingo, J.L.; Nadal, M. Domestic waste composting facilities: A review of human health risks. Environ. Int. 2009, 35, 382–389. [Google Scholar] [CrossRef]

- Yang, F.; Li, G.; Yang, Q.; Luo, W. Effect of bulking agents on maturity and gaseous emissions during kitchen waste composting. Chemosphere 2013, 93, 1393–1399. [Google Scholar] [CrossRef]

- Jiang, T.; Schuchardt, F.; Li, G.; Guo, R.; Zhao, Y. Effect of C/N ratio, aeration rate and moisture content on ammonia and greenhouse gas emission during the composting. J. Environ. Sci. 2011, 23, 1754–1760. [Google Scholar] [CrossRef]

- Zang, B.; Li, S.; Michel, F.; Li, G.; Luo, Y.; Zhang, D.; Li, Y. Effects of mix ratio, moisture content and aeration rate on sulfur odor emissions during pig manure composting. Waste Manag. 2016, 56, 498–505. [Google Scholar] [CrossRef]

- Pagans, E.; Barrena, R.; Font, X.; Sanchez, A. Ammonia emissions from the composting of different organic wastes. Dependency on process temperature. Chemosphere 2006, 62, 1534–1542. [Google Scholar] [CrossRef]

- Drennan, M.F.; Distefano, T.D. Characterization of the curing process from high-solids anaerobic digestion. Bioresour. Technol. 2010, 101, 537–544. [Google Scholar] [CrossRef]

- Wu, T.; Wang, X.; Li, D.; Yi, Z. Emission of volatile organic sulfur compounds (VOSCs) during aerobic decomposition of food wastes. Atmos. Environ. 2010, 44, 5065–5071. [Google Scholar] [CrossRef]

- Zhang, H.; Schuchardt, F.; Li, G.; Yang, J.; Yang, Q. Emission of volatile sulfur compounds during composting of municipal solid waste (MSW). Waste Manag. 2013, 33, 957–963. [Google Scholar] [CrossRef]

- Toledo, M.; Marquez, P.; Siles, J.; Chica, A.; Martin, M. Co-composting of sewage sludge and eggplant waste at full scale: Feasibility study to valorize eggplant waste and minimize the odoriferous impact of sewage sludge. J. Environ. Manag. 2019, 247, 205–213. [Google Scholar] [CrossRef]

- Zhou, J.-M. The Effect of Different C/N Ratios on the Composting of Pig Manure and Edible Fungus Residue with Rice Bran. Compos. Sci. Util. 2016, 25, 120–129. [Google Scholar] [CrossRef]

- Yuan, J.; Li, Y.; Wang, G.; Zhang, D.; Shen, Y.; Ma, R.; Li, D.; Li, S.; Li, G. Biodrying performance and combustion characteristics related to bulking agent amendments during kitchen waste biodrying. Bioresour. Technol. 2019, 284, 56–64. [Google Scholar] [CrossRef]

- Jolanun, B.; Towprayoon, S.; Chiemchaisri, C. Aeration improvement in fed batch composting of vegetable and fruit wastes. Environ. Prog. 2008, 27, 250–256. [Google Scholar] [CrossRef]

- Toledo, M.; Gutierrez, M.C.; Siles, J.A.; Martin, M.A. Full-scale composting of sewage sludge and market waste: Stability monitoring and odor dispersion modeling. Environ. Res. 2018, 167, 739–750. [Google Scholar] [CrossRef]

- Masó, M.; Blasi, A.B. Evaluation of composting as a strategy for managing organic wastes from a municipal market in Nicaragua. Bioresour. Technol. 2008, 99, 5120–5124. [Google Scholar] [CrossRef]

- Wang, G.; Kong, Y.; Liu, Y.; Li, D.; Zhang, X.; Yuan, J.; Li, G. Evolution of phytotoxicity during the active phase of co-composting of chicken manure, tobacco powder and mushroom substrate. Waste Manag. 2020, 114, 25–32. [Google Scholar] [CrossRef]

- Sellami, F.; Hachicha, S.; Chtourou, M.; Medhioub, K.; Ammar, E. Maturity assessment of composted olive mill wastes using UV spectra and humification parameters. Bioresour. Technol. 2008, 99, 6900–6907. [Google Scholar] [CrossRef]

- Lin, C. A negative-pressure aeration system for composting food wastes. Bioresour. Technol. 2008, 99, 7651–7656. [Google Scholar] [CrossRef]

- Huang, G.F.; Wu, Q.T.; Wong, J.C.; Nagar, B.B. Transformation of organic matter during co-composting of pig manure with sawdust. Bioresour. Technol. 2006, 97, 1834–1842. [Google Scholar] [CrossRef]

- Yuan, J.; Chadwick, D.; Zhang, D.; Li, G.; Chen, S.; Luo, W.; Du, L.; He, S.; Peng, S. Effects of aeration rate on maturity and gaseous emissions during sewage sludge composting. Waste Manag. 2016, 56, 403–410. [Google Scholar] [CrossRef]

- Neyla, S.; Soulwene, K.; Fadhel, M.; Naceur, J.; Meriam, M.; Abdennaceur, H.; Hadda, O. Microbiological parameters and maturity degree during composting of Posidonia oceanica residues mixed with vegetable wastes in semi-arid pedo-climatic condition. J. Environ. Sci. 2009, 21, 1452–1458. [Google Scholar]

- Dhar, B.R.; Youssef, E.; Nakhla, G.; Ray, M.B. Pretreatment of municipal waste activated sludge for volatile sulfur compounds control in anaerobic digestion. Bioresour. Technol. 2011, 102, 3776–3782. [Google Scholar] [CrossRef]

- Toledo, M.; Gutierrez, M.C.; Pena, A.; Siles, J.A.; Martin, M.A. Co-composting of chicken manure, alperujo, olive leaves/pruning and cereal straw at full-scale: Compost quality assessment and odour emission. Process Saf. Environ. Prot. 2020, 139, 362–370. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Fan, F.; Guo, C.; Yu, M.; Zhao, M.; Song, Y.; Li, Y. Evaluation of Maturity and Odor Emissions in the Process of Combined Composting of Kitchen Waste and Garden Waste. Appl. Sci. 2021, 11, 5500. https://doi.org/10.3390/app11125500

Zhang B, Fan F, Guo C, Yu M, Zhao M, Song Y, Li Y. Evaluation of Maturity and Odor Emissions in the Process of Combined Composting of Kitchen Waste and Garden Waste. Applied Sciences. 2021; 11(12):5500. https://doi.org/10.3390/app11125500

Chicago/Turabian StyleZhang, Bangxi, Feifei Fan, Chao Guo, Mingji Yu, Mingcan Zhao, Yuan Song, and Yun Li. 2021. "Evaluation of Maturity and Odor Emissions in the Process of Combined Composting of Kitchen Waste and Garden Waste" Applied Sciences 11, no. 12: 5500. https://doi.org/10.3390/app11125500

APA StyleZhang, B., Fan, F., Guo, C., Yu, M., Zhao, M., Song, Y., & Li, Y. (2021). Evaluation of Maturity and Odor Emissions in the Process of Combined Composting of Kitchen Waste and Garden Waste. Applied Sciences, 11(12), 5500. https://doi.org/10.3390/app11125500