A Parametric Product Design Framework for the Development of Mass Customized Head/Face (Eyewear) Products

Abstract

1. Introduction

2. Related Works

2.1. Mass Customisation, Personalisation and Design

2.2. Customer-Driven Design and Manufacture at the Core of MC Systems

- Agile manufacturing is the ability to thrive and prosper in a competitive environment of continuous and unanticipated change in order to respond quickly to rapidly changing markets driven by customer-based valuing of products [19]. Here, it is important to truly capture user preferences and requirements based on attitudes and emotions, which may imply further challenges [17].

- Customer-driven design and manufacture at the core of MC systems [22] “actively considers the market trends and individual customer requirements during the design, manufacturing and delivery of the products”. Some authors call this practice “One-of-a-Kind Production” (OKP). The application of customer-driven practices in MC systems aims at providing the conditions for the customer to take part in the design process, and for the company to build an infrastructure to develop such customer-driven products, hence the relevance of defining customer preferences though a robust design requirement specification [15].

2.3. The Ergonomic-Anthropometric-Good Fit Relationship

2.4. 3D Scanning Technology

2.5. Wearable Product Design

3. Methodology

3.1. Parametric Modelling Strategy

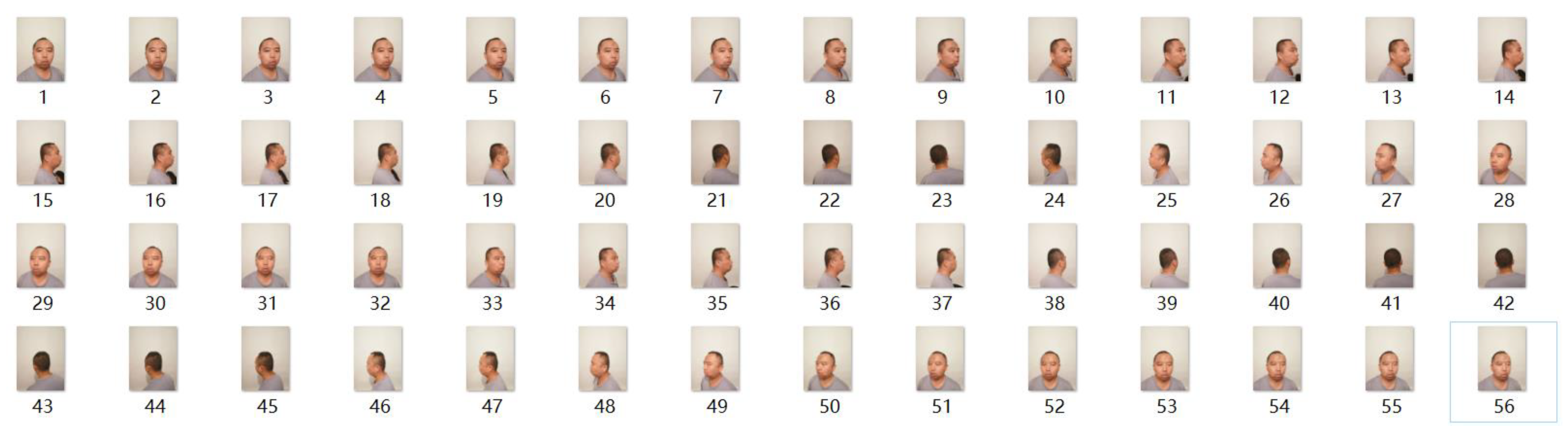

3.2. Head/Face Scanning

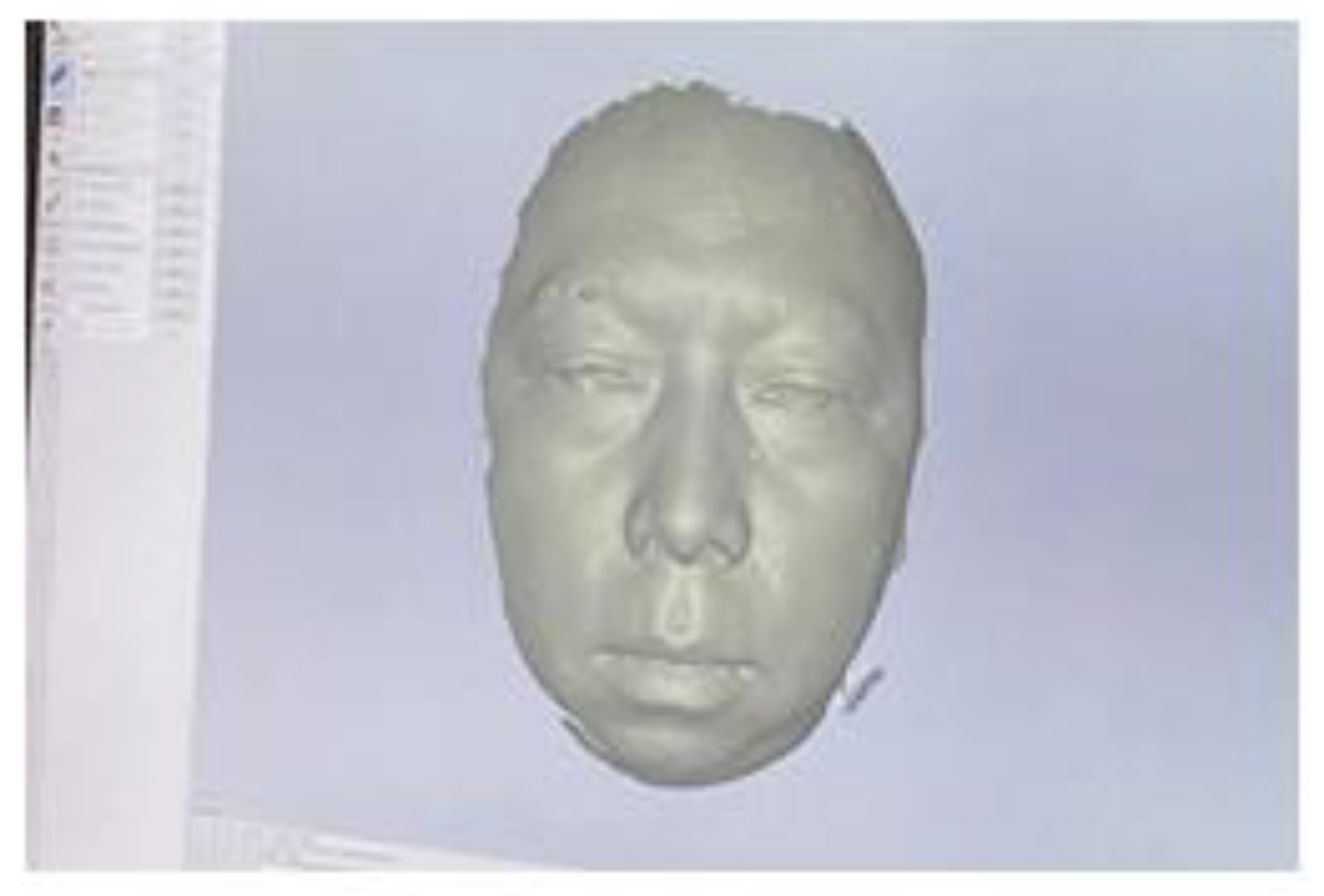

3.2.1. Photogrammetry

3.2.2. Somatosensory Camera Scan

3.2.3. Laser Scanning

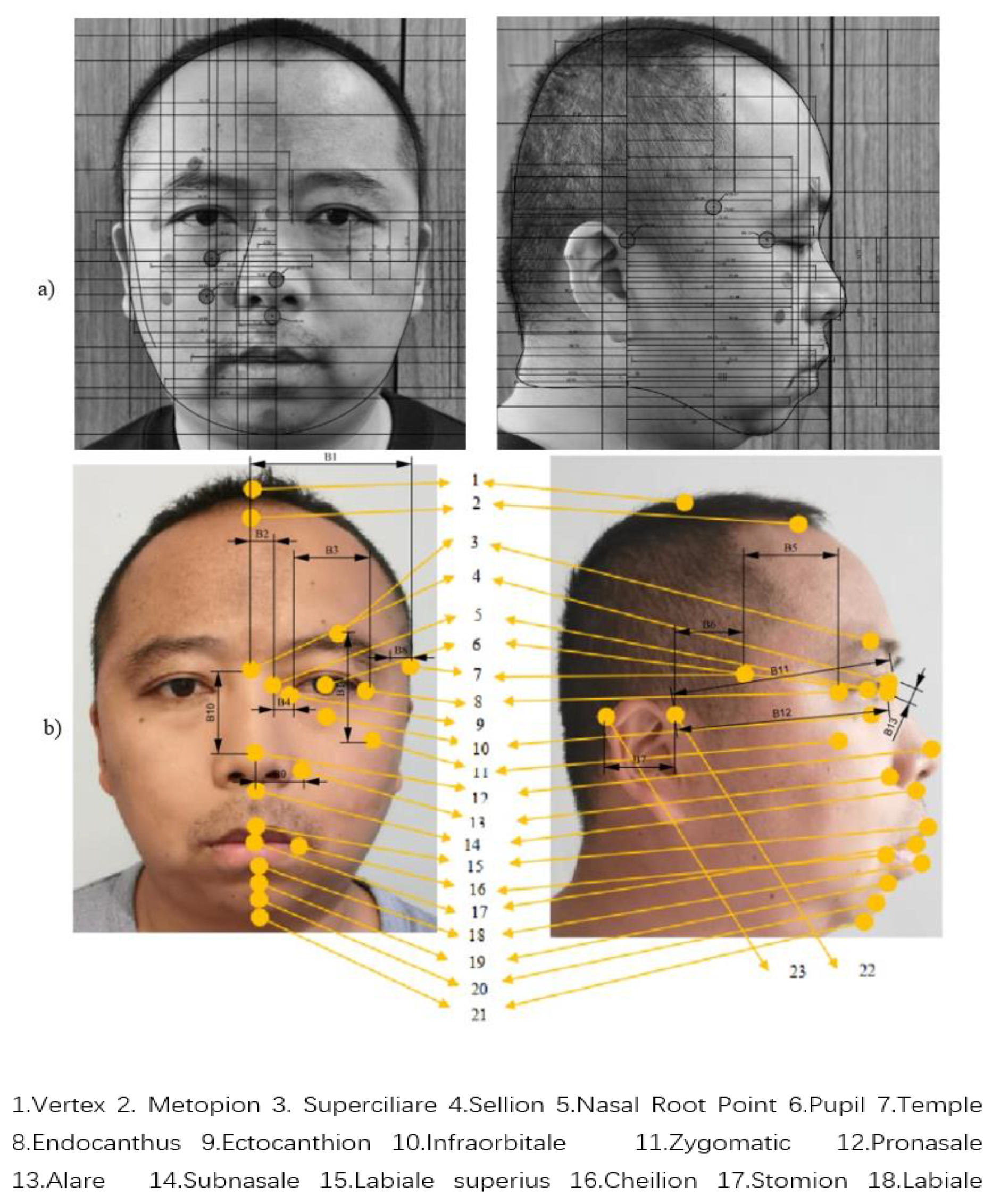

3.3. Determining the Head/Face Required Dimensions

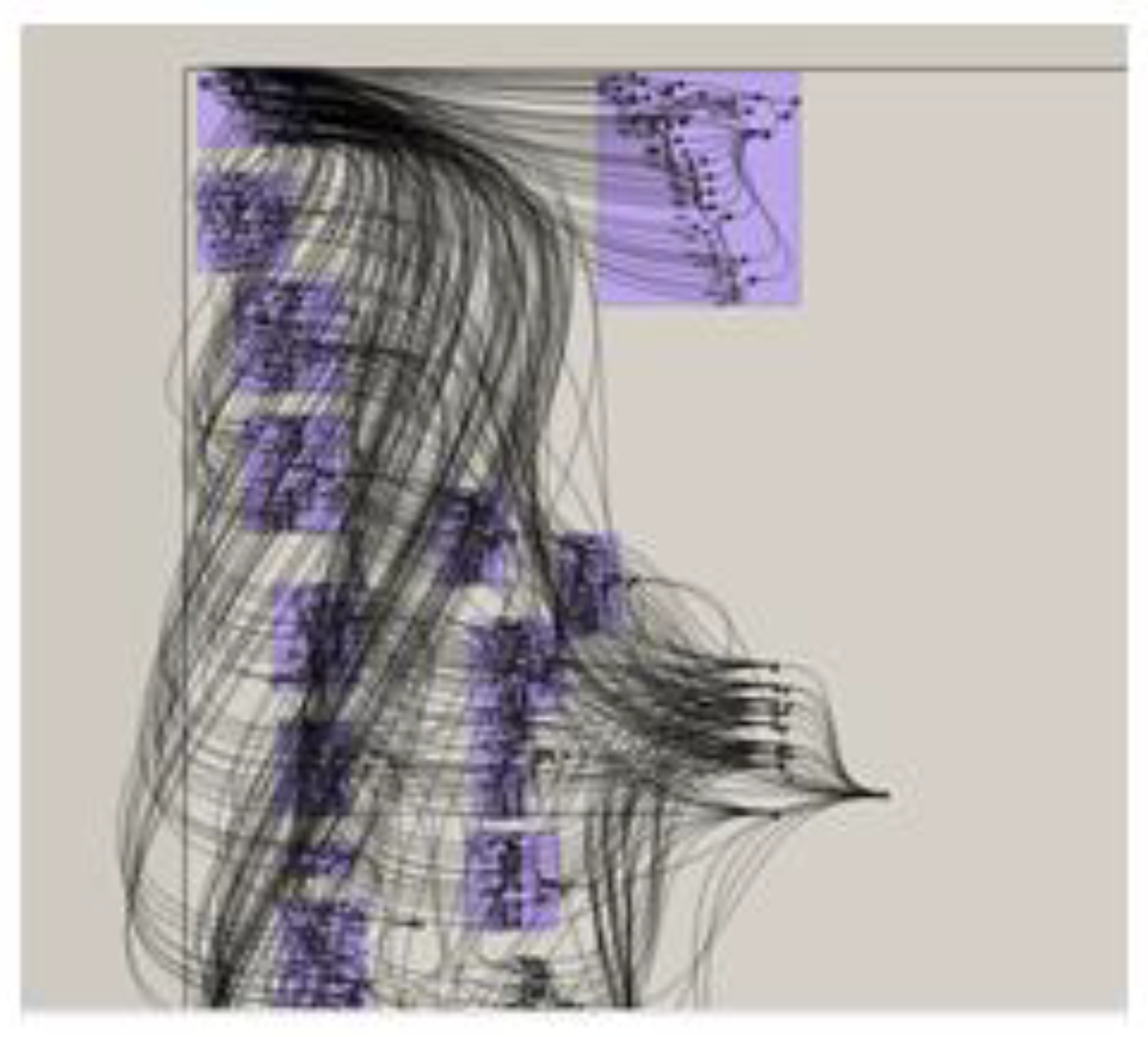

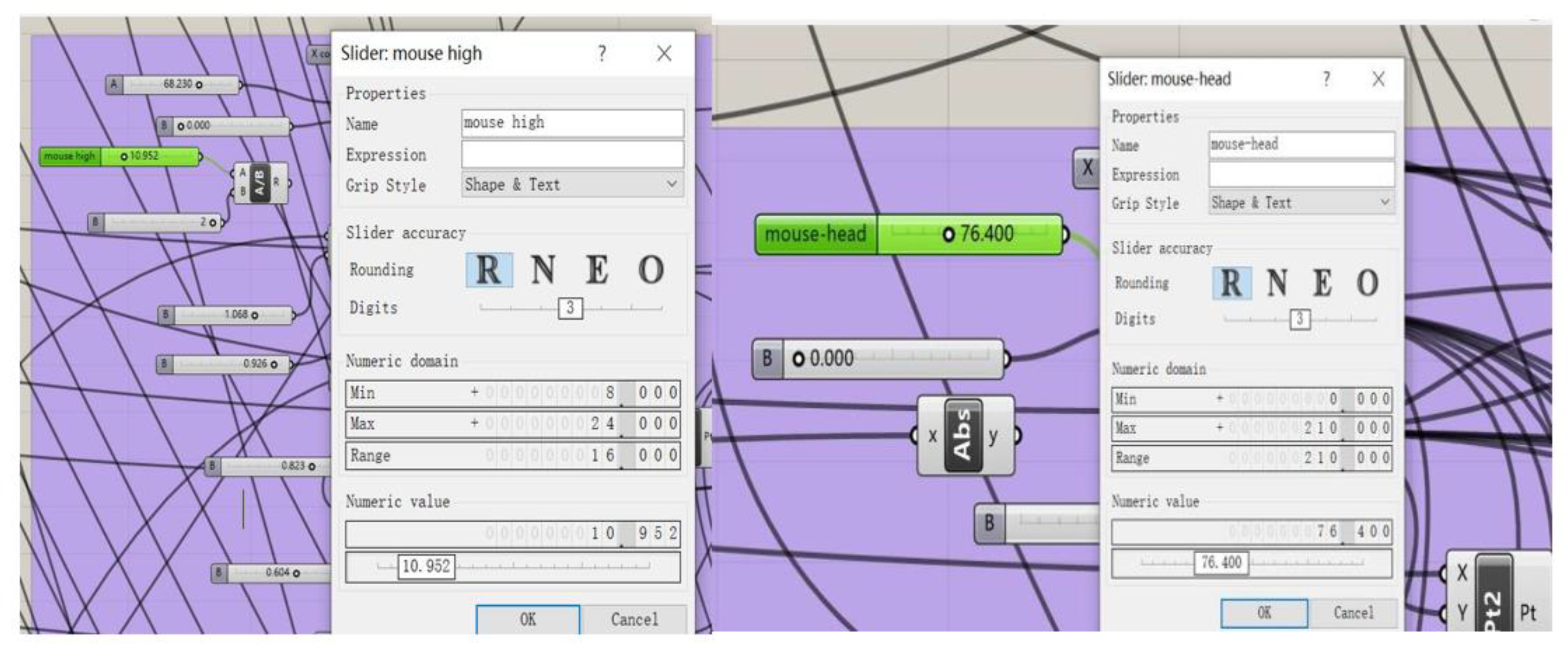

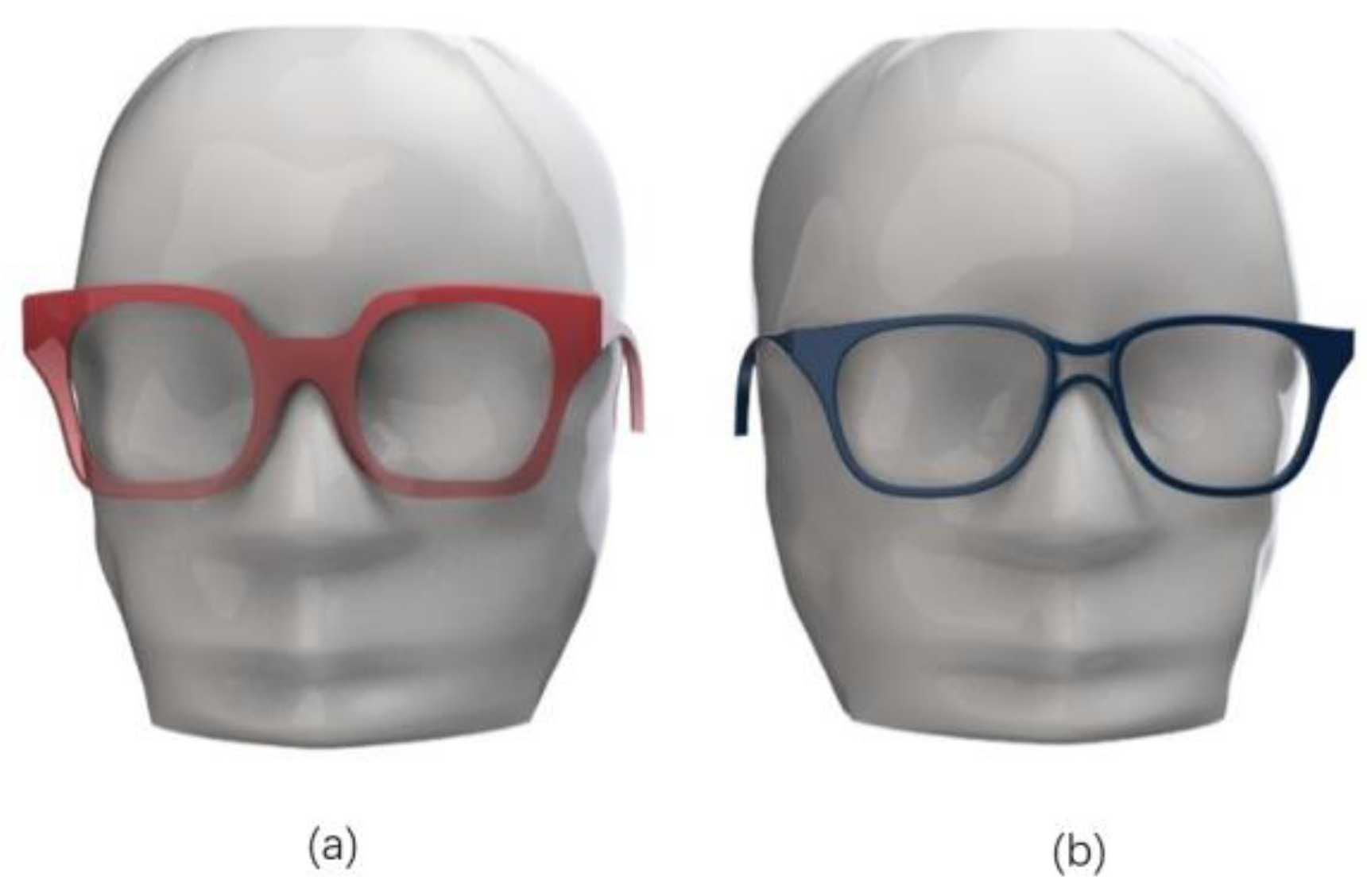

3.4. Algorithm Development, Parametric Design, and Good Fit Test

4. Results

4.1. 3D Full Head/Face Scanning and Parametric Head Model

4.1.1. Photogrammetry

4.1.2. Somatosensory Camera Scanning

4.1.3. Laser Scanning

4.1.4. Scanning Comparison

4.2. Algorithm Development, Parametric Design, and Good Fit Test

5. Conclusions

- Human centred-based approach: Within a complex MC system, the uncovering of user and other stakeholders needs (e.g., designer) poses one of the biggest challenges. Therefore, human-centred design methods may bring a better understanding of the user needs in order to ease the implementation of MC strategies.

- Technology appropriateness: In the process of personalised and mass customisation design of wearable products, convenient and accurate acquisition of users’ body data has become a key factor for customisation design. The quality of this data relies mostly on technology appropriateness, setup, and user expertise. The user experience of the data acquisition in commercial setups is a factor that requires further research.

- Real-time feedback: In the process of personalisation and mass customisation of eyewear, parametric design is an effective and flexible tool to quickly realise product design iterations and explore the meeting of some of the needs of different users by adjusting design parameters and getting users’ real-time feedback.

- Clear communication strategy with consumers/end-users: this could facilitate the identification of needs to be met and clearly define the project scope.

- Inclusive co-design process: A clear co-design strategy with well-defined roles and requirements could ease the decision-making process that is involved in the personalisation or customisation process.

- Technical and aesthetic requirements: personalised and customised products, in particular eyewear, are expected to meet the basic personal needs of consumers in terms of comfort, functionality, and aesthetics. These can be fully defined during the inclusive co-design process.

- User experience and human-centred focus: the development of a user-friendly Software/Visual Programming tool that enables the above tasks should be at the core of this type of work. A human-centred approach for the development of these tools is necessary for a seamless co-design experience.

- Agile manufacturing: having the ability to adapt and to respond quickly to rapidly changing markets driven by customer-based needs is important for MC strategies. For eyewear products, current 3D printing technologies and available materials have reached a level of maturity that provides a good alternative.

- Integration of new technologies: having a flexible framework that allows the integration of new technologies or strategies could increase the potential of this type of MC framework. For example, machine learning and artificial intelligence could be used to collect and analyse users’ data to pre-identify patterns in preferences to help determine the design requirements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Simpson, T.W. Product platform design and customization: Status and promise. Artif. Intell. Eng. Des. Anal. Manuf. 2004, 18, 3–20. [Google Scholar] [CrossRef]

- Ali, K.; Smadi, H.; Salhieh, S.M. Two-phase methodology for customized product design and manufacturing. J. Manuf. Technol. Manag. 2012, 23, 370–401. [Google Scholar]

- Tseng, M.M.; Jiao, J. Mass Customization. In Handbook of Industrial Engineering, 3rd ed.; Salvendy, G., Ed.; Wiley: Hoboken, NJ, USA, 2001; pp. 684–709. [Google Scholar]

- Herstatt, C.; Verworn, B. The ‘fuzzy front end’ of innovation. In Bringing Technology and Innovation into the Boardroom; Palgrave Macmillan: London, UK, 2004; pp. 347–372. [Google Scholar]

- Oliveira, M.G.; Phaal, R.; Probert, D.; Cunha, V.P.; Rozenfeld, H. A starting point for addressing product innovativeness in the fuzzy front-end. Int. J. Technol. Intell. Plan. 2011, 7, 309–326. [Google Scholar] [CrossRef]

- Dean, L.; Unver, E.; Campbell, I.; De Beer, D. Making it real: Virtual tools in 3D creative practice. In Proceedings of the Making: An International Conference on Materiality and Knowledge, Book of Abstracts, NordFo, Nordic Research Network, Notodden, Norway, 24–27 September 2012; p. 76. [Google Scholar]

- O’Sullivan, M.; Sheahan, C. Using Innovation Games to Assess Mass Customisation Potential from the Fuzzy Front-End. In Proceedings of the ECIE 2019 14th European Conference on Innovation and Entrepreneurship, Kalamata, Greece, 19–20 September 2019; p. 2. [Google Scholar]

- Jitpaiboon, T.; Dobrzykowski, D.D.; Ragu-Nathan, T.S.; Vonderembse, M.A. Unpacking IT use and integration for mass customisation: A service-dominant logic view. Int. J. Prod. Res. 2013, 51, 2527–2547. [Google Scholar] [CrossRef]

- Kristal, M.M.; Huang, R.; Schroeder, R.G. The effect of quality management on mass customization capability. Int. J. Oper. Prod. Manag. 2010, 30, 900–920. [Google Scholar] [CrossRef]

- Gilmore, J.H.; Pine, B.J. The four faces of mass customization. Harv. Bus. Rev. 1997, 75, 91–102. [Google Scholar]

- Montalto, A.; Graziosi, S.; Bordegoni, M. An approach to design reconfigurable manufacturing tools to manage product variability: The mass customisation of eyewear. J. Intell. Manuf. 2018, 31, 1–16. [Google Scholar] [CrossRef]

- Da Silveira, G.; Borenstein, D.; Fogliatto, F.S. Mass customization: Literature review and research directions. Int. J. Prod. Econ. 2001, 72, 1–13. [Google Scholar] [CrossRef]

- Spira, J.S. Mass customization through training at Lutron Electronics. Plan. Rev. 1993, 21, 23–24. [Google Scholar] [CrossRef]

- Berger, C.; Moslein, K.; Piller, F.; Reichwald, R. Cooperation between manufacturers, retailers, and customers for user co-design: Learning from exploratory research. Eur. Manag. Rev. 2005, 1, 70–87. [Google Scholar] [CrossRef]

- Pedersen, S.N.; Christensen, M.E.; Howard, T.J. Robust Design Requirements Specification: A Quantitative Method for Requirements Development Using Quality Loss Functions. J. Eng. Des. 2016, 27, 544–567. [Google Scholar] [CrossRef]

- Desmet, P.; Pohlmeyer, A. Positive Design: An Introduction to Design for Subjective Well-Being. Int. J. Des. 2013, 7, 5–19. [Google Scholar]

- Zöller, S.G.; Wartzack, S. Considering Users’ Emotions in Product Development Processes and the Need to Design for Attitudes. Emot. Eng. 2017, 5, 69–97. [Google Scholar]

- Chong, Y.T.; Chen, C.H. Customer needs as moving targets of product development: A review. Int. J. Adv. Manuf. Technol. 2010, 48, 395–406. [Google Scholar] [CrossRef]

- Ulrich, K.T. The role of product architecture in the manufacturing firm. Res. Policy 1995, 24, 419–440. [Google Scholar] [CrossRef]

- Dove, R. The 21s Century Manufacturing Enterprise Strategy; AD-A257176; Iacocca Institute, Lehigh University Press: Bethlehem, PA, USA, 1991. [Google Scholar]

- Rinaldi, M.; Caterino, M.; Manco, P.; Fera, M.; Macchiaroli, R. The impact of Additive Manufacturing on Supply Chain design: A simulation study. Procedia Comput. Sci. 2021, 180, 446–455. [Google Scholar] [CrossRef]

- Jagdev, H.S.; Browne, J. The extended enterprise a context for manufacturing. Prod. Plan. Control 1998, 9, 216–229. [Google Scholar] [CrossRef]

- Storch, R.L.; Lim, S. Improving flow to achieve lean manufacturing in shipbuilding. Prod. Plan. Control 1999, 10, 127–137. [Google Scholar] [CrossRef]

- Warnecke, H.J.; Hüser, M. Lean production. Int. J. Prod. Econ. 1995, 41, 37–43. [Google Scholar] [CrossRef]

- Deradjat, D.; Minshall, T. Implementation of rapid manufacturing for mass customisation. J. Manuf. Technol. Manag. 2017, 28, 95–121. [Google Scholar] [CrossRef]

- Mehrabi, M.G.; Ulsoy, A.G.; Koren, Y. Reconfigurable manufacturing systems: Key to future manufacturing. J. Intell. Manuf. 2000, 11, 403–419. [Google Scholar] [CrossRef]

- Kaiser, C.; Fischer, T.V.; Schmeltzpfenning, T.; Stöhr, M.; Artschwager, A. Case study: Mass customisation of individualized orthotics–the fashion-able virtual development and production framework. Procedia CIRP 2014, 21, 105–110. [Google Scholar] [CrossRef][Green Version]

- Hirsch, B.E.; Thoben, K.D.; Hoheisel, J. Requirements upon human competencies in globally distributed manufacturing. Comput. Ind. 1998, 36, 49–54. [Google Scholar] [CrossRef]

- Kouchi, M. Secular changes in the Japanese head form viewed from somatometric data. Anthropol. Sci. 2004, 112, 41–52. [Google Scholar] [CrossRef]

- Ziqing, Z.; Douglas, L.; Stacey, B.; Raymond, R.; Ronald, S. Facial Anthropometric Differences among Gender, Ethnicity, and Age Groups. Ann. Occup. Hyg. 2010, 54, 391–402. [Google Scholar]

- Lee, H.J.; Park, S.J. Comparison of korean and japanese head and face anthropometric characteristics. Hum. Biol. 2008, 80, 313–330. [Google Scholar] [CrossRef]

- Ball, R.; Shu, C.; Xi, P.; Rioux, M.; Luximon, Y.; Molenbroek, J. A comparison between Chinese and Caucasian head shapes. Appl. Ergon. 2010, 41, 832–839. [Google Scholar] [CrossRef]

- Hanson, L.; Sperling, L.; Gard, G.; Ipsen, S.; Vergara, C.O. Swedish anthropometrics for product and workplace design. Appl. Ergon. 2009, 40, 797–806. [Google Scholar] [CrossRef]

- Purkait, R.; Singh, P. Anthropometry of the normal human auricle: A study of adult indian men. Aesthetic Plast. Surg. 2017, 31, 372–379. [Google Scholar] [CrossRef]

- Fan, H.; Yu, S.; Chu, J.; Wang, M.; Wang, N. Anthropometric characteristics and product categorization of chinese auricles for ergonomic design. Int. J. Ind. Ergon. 2019, 69, 118–141. [Google Scholar] [CrossRef]

- Zhu, Z.; Ji, X.; Gao, Z.; Hu, G. A morphometric study of auricular concha in the population of young chinese adults. Int. J. Morphol. 2017, 35, 1451–1458. [Google Scholar] [CrossRef][Green Version]

- Lee, W.; Lee, B.; Yang, X.; Jung, H.; Bok, I.; Kim, C.; You, H. A 3D anthropometric sizing analysis system based on North American CAESAR 3D scan data for design of head wearable products. Comput. Ind. Eng. 2018, 117, 121–130. [Google Scholar] [CrossRef]

- Perret-Ellena, T.; Skals, S.L.; Subic, A.; Mustafa, H.; Pang, T.Y. 3D Anthropometric investigation of Head and Face characteristics of Australian Cyclists. Procedia Eng. 2015, 112, 98–103. [Google Scholar] [CrossRef]

- Montalto, A.; Graziosi, S.; Bordegoni, M.; Landro, L.D. Combining aesthetics and engineering specifications for fashion-driven product design: A case study on spectacle frames. Comput. Ind. 2018, 95, 102–112. [Google Scholar] [CrossRef]

- Brodie, F.L.; Nattagh, K.; Shah, V.; Swarnakar, V.; Lin, S.; Kelil, T.; de Alba Campomanes, A.G. Computed tomography–based 3D modeling to provide custom 3D-printed glasses for children with craniofacial abnormalities. J. Am. Assoc. Pediatr. Ophthalmol. Strabismus 2019, 23, 165–167. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, Z.; Shu, C.; Xi, P.; Bergman, M.; Joseph, M. Head-and-face shape variations of U.S. civilian workers. Appl. Ergon. 2013, 44, 775–784. [Google Scholar] [CrossRef] [PubMed]

- Ball, R.M. SizeChina: A 3D Anthropometric Survey of the Chinese Head. Ph.D. Thesis, The Hong Kong Polytechnic University, Hong Kong, China, 2011. [Google Scholar]

- Luximon, Y.; Ball, R.; Justice, L. The 3D Chinese head and face modeling. Comput. Aided Des. 2012, 44, 40–47. [Google Scholar] [CrossRef]

- Zheng, R.; Yu, W.; Fan, J. Development of a new chinese bra sizing system based on breast anthropometric measurements. Int. J. Ind. Ergon. 2007, 37, 697–705. [Google Scholar] [CrossRef]

- Ji, X.; Zhu, Z.; Gao, Z.; Bai, X.; Hu, G. Anthropometry and classification of auricular concha for the ergonomic design of earphones. Hum. Factors Ergon. Manuf. Serv. Ind. 2017, 28, 90–99. [Google Scholar] [CrossRef]

- Perret-Ellena, T.; Mustafa, H.; Subic, A.; Pang, T.Y. A design framework for the mass customisation of custom-fit bicycle helmet models. Int. J. Ind. Ergon. 2018, 64, 122–133. [Google Scholar] [CrossRef]

- Pang, T.Y.; Lo, T.S.T.; Ellena, T.; Mustafa, H.; Babalija, J.; Subic, A. Fit, stability and comfort assessment of custom-fitted bicycle helmet inner liner designs, based on 3d anthropometric data. Appl. Ergon. 2018, 68, 240–248. [Google Scholar] [CrossRef]

- Li, J.; Ye, J.; Wang, Y.; Bai, L.; Lu, G. Fitting 3d garment models onto individual human models. Comput. Graph. 2010, 34, 742–755. [Google Scholar] [CrossRef]

- Lu, L.G. Customizing 3d garments based on volumetric deformation. Comput. Ind. 2011, 62, 693–707. [Google Scholar]

- Liu, H.; Li, Z.; Zheng, L. Rapid preliminary helmet shell design based on three-dimensional anthropometric head data. J. Eng. Des. 2008, 19, 45–54. [Google Scholar] [CrossRef]

- Hsu, M.C.; Wang, C.; Herrema, A.J.; Schillinger, D.; Ghoshal, A.; Bazilevs, Y. An interactive geometry modeling and parametric design platform for isogeometric analysis. Comput. Math. Appl. 2015, 70, 1481–1500. [Google Scholar] [CrossRef]

- Chu, C.H.; Wang, I.J.; Wang, J.B.; Luh, Y.P. 3D parametric human face modeling for personalized product design: Eyeglasses frame design case. Adv. Eng. Inform. 2017, 32, 202–223. [Google Scholar] [CrossRef]

- Huang, S.H.; Yang, Y.I.; Chu, C.H. Human-centric design personalization of 3d glasses frame in markerless augmented reality. Adv. Eng. Inform. 2012, 26, 35–45. [Google Scholar] [CrossRef]

- Lu, W.; Petiot, J.F. Affective design of products using an audio-based protocol: Application to eyeglass frame. Int. J. Ind. Ergon. 2014, 44, 383–394. [Google Scholar] [CrossRef]

- Shintaku, H.; Yamaguchi, M.; Toru, S.; Kitagawa, M.; Hirokawa, K.; Yokota, T.; Uchihara, T. Three-dimensional surface models of autopsied human brains constructed from multiple photographs by photogrammetry. PLoS ONE 2019, 14, e0219619. [Google Scholar] [CrossRef]

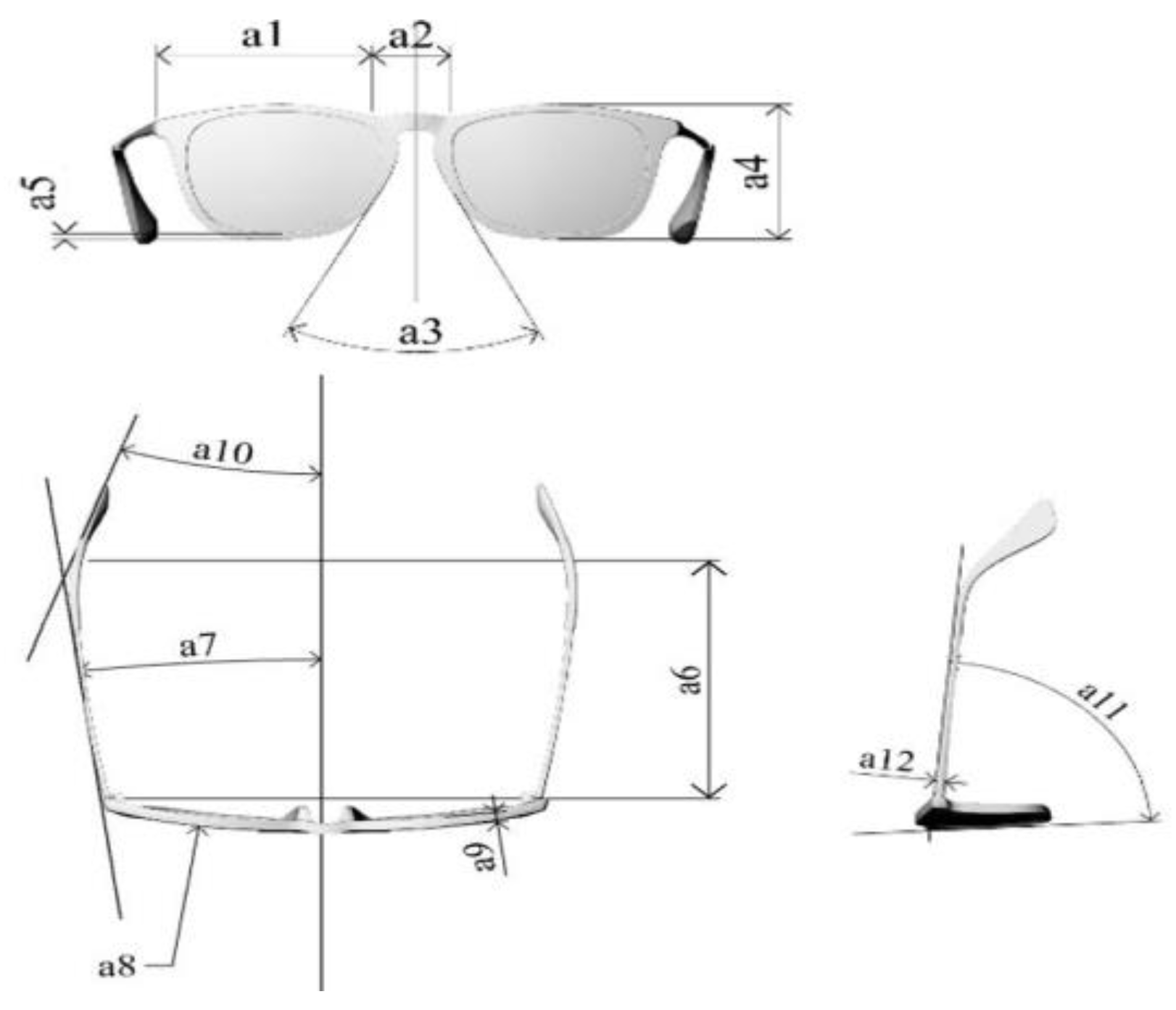

| Eyewear Size Parameters (Figure 4) | Size Name | Explanation of Size | Head Feature Points Related to the Eyewear Size (Figure 5b) |

|---|---|---|---|

| a1 | Eye size | Indicates the width of the lens | 6,8,9 |

| a2 | Bridge width | Connection section of lens | 4,5,6 |

| a3 | Nose angle | Decide where to contact the eyewear and nose | 4,5,12,13,14 |

| a4 | Lens height | Height of glasses, determined by appearance | 3,5,8,10,11 |

| a5 | Height of frame | Height of eyeglasses frame section, determined by appearance | |

| a6 | The temple size | Distance from eyewear frame to ear | 7,22 |

| a7 | Angle of temple | The angle between the temple and the symmetrical plane of head | 7,22 |

| a8 | Curvature of eyewear frame | Curvature of the eyewear frame | 3,4,6,7,8,9,22 |

| a9 | Thickness of frame | Thickness of eyewear frame section, determined by appearance | |

| a10 | Back leg angle of eyewear | Back leg angle of glasses | 22,23 |

| a11 | Angle of eyewear frame | Angle between frame and temple | 4,5,7,11 |

| a12 | Thickness of temple | Thickness of temple |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, X.; Huerta, O.; Unver, E.; Allen, J.; Clayton, J.E. A Parametric Product Design Framework for the Development of Mass Customized Head/Face (Eyewear) Products. Appl. Sci. 2021, 11, 5382. https://doi.org/10.3390/app11125382

Bai X, Huerta O, Unver E, Allen J, Clayton JE. A Parametric Product Design Framework for the Development of Mass Customized Head/Face (Eyewear) Products. Applied Sciences. 2021; 11(12):5382. https://doi.org/10.3390/app11125382

Chicago/Turabian StyleBai, Xiaobo, Omar Huerta, Ertu Unver, James Allen, and Jane E. Clayton. 2021. "A Parametric Product Design Framework for the Development of Mass Customized Head/Face (Eyewear) Products" Applied Sciences 11, no. 12: 5382. https://doi.org/10.3390/app11125382

APA StyleBai, X., Huerta, O., Unver, E., Allen, J., & Clayton, J. E. (2021). A Parametric Product Design Framework for the Development of Mass Customized Head/Face (Eyewear) Products. Applied Sciences, 11(12), 5382. https://doi.org/10.3390/app11125382