Neural Network-Based Prediction: The Case of Reinforced Concrete Members under Simple and Complex Loading

Abstract

1. Introduction

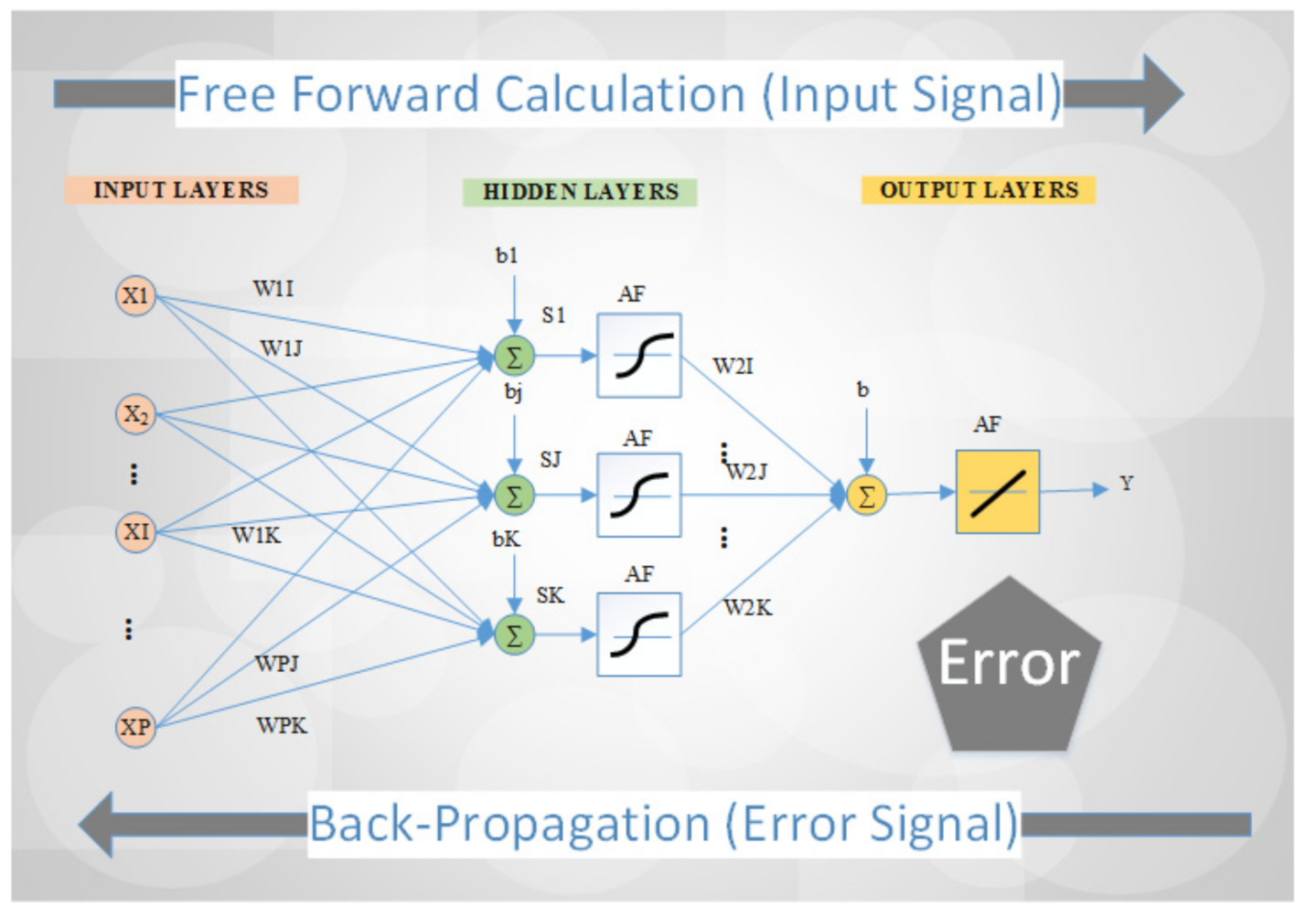

2. Function of Artificial Neural Network (ANN)

2.1. Pre Processing Phase

2.2. The Features of ANN Model

- The database is divided by the random method into three sub-sets: 70% for the training purpose, 15% for validation purpose and the remaining 15% for the testing purposes.

- Each ANN models is calibrated for 1000 epochs/cycles.

- The training is stopped if any one of the following conditions is achieved: (a) a maximum of 100 validation failures occur, and (b) the minimum performance learning slope becomes 10−8.

3. Database-I: BWOS and BWS

3.1. ANN Models for DB-I

3.2. Comparative Studies for DB-I

4. Database-II: CWA

4.1. ANN Models for DB-II

4.2. Comparative Studies for DB-II

5. Database-III: TBWOS and TBWS

5.1. Development of ANN Models for DB-III

5.2. Comparative Studies for DB-III

6. Database-IV: SCS

6.1. Development of ANN Models for DB-IV

6.2. Comparative Studies for DB-IV

7. Conclusions

Future Directions of the Current Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EC2. Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules And Rules For Buildings. In EN 1992-1-1; Management Centre: Brussels, Belgium, 2004. [Google Scholar]

- ACI. Building Code Requirements for Structural Concrete (ACI 318-08) and Commentary. In Aci-318-08; American Concrete Institute: Farmington Hills, MI, USA, 2008; pp. 1–471. [Google Scholar]

- JSCE. Standard Specifications for Concrete Structures-2007. In JSCE Guideline for Concrete No. 15; JSCE: Tokyo, Japan, 2007; pp. 1–503. [Google Scholar]

- CSA. Design of Concrete Structures. In A23.3-04; CSA: Mississauga, ON, Canada, 2004; pp. 1–232. [Google Scholar]

- NZS. Concrete Structures Standard Part-1. In NZS 3101; New Zealand Standard: Wellington, New Zealand, 2006; Volume Part 1, pp. 1–309. [Google Scholar]

- KBCS. Korean Building Code-Structural (KBCS); Architectural Institute of Korea: Kimoondang, Korea, 2005. [Google Scholar]

- T. S. SarmaSTAAD. Pro V8i; Bentley Systems, Inc.: Exton, PA, USA, 2008; Volume 8.

- CSI Group. SACS Import Manual; Computers and Structures Inc.: Berkeley, CA, USA, 2013. [Google Scholar]

- Ahmad, A.; Kotsovou, G.; Cotsovos, D.M.; Lagaros, N.D. Assessing the accuracy of RC design code predictions through the use of artificial neural networks. Int. J. Adv. Struct. Eng. 2018, 10, 349–365. [Google Scholar] [CrossRef]

- Ahmad, A.; Cotsovos, D.M.; Lagaros, N.D. Framework for the development of artificial neural networks for predicting the load carrying capacity of RC members. SN Appl. Sci. 2020, 2, 1–21. [Google Scholar] [CrossRef]

- Ahmad, A.; Cotsovos, D.M. Reliability analysis of models for predicting T-beam response at ultimate limit response. Proc. Inst. Civ. Eng. Struct. Build. 2020, 1–23. [Google Scholar] [CrossRef]

- Kotsovou, G.M.; Ahmad, A.; Cotsovos, D.M.; Lagaros, N.D. Reappraisal of methods for calculating flexural capacity of reinforced concrete members. Proc. Inst. Civ. Eng. Struct. Build. 2020, 173, 279–290. [Google Scholar] [CrossRef]

- Ahmad, A. Reinforced Concrete (RC) Structures Analysis and Assessment with Artificial Neural Networks (ANNs); Heriot-Watt University: Edinburgh, Scotland, 2018. [Google Scholar]

- Kotsovos, M.D. Compressive Force-Path Method; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Papadrakakis, M.; Lagaros, N.D. Reliability-based structural optimization using neural networks and Monte Carlo simulation. Comput. Methods Appl. Mech. Eng. 2002, 191, 3491–3507. [Google Scholar] [CrossRef]

- Lagaros, N.D.; Papadrakakis, M. Learning improvement of neural networks used in structural optimization. Adv. Eng. Softw. 2004, 35, 9–25. [Google Scholar] [CrossRef]

- Lagaros, N.D.; Charmpis, D.C.; Papadrakakis, M. An adaptive neural network strategy for improving the computational performance of evolutionary structural optimization. Comput. Methods Appl. Mech. Eng. 2005, 194, 3374–3393. [Google Scholar] [CrossRef]

- Lagaros, N.D.; Plevris, V.; Papadrakakis, M. Multi-objective design optimization using cascade evolutionary computations. Comput. Methods Appl. Mech. Eng. 2005, 194, 3496–3515. [Google Scholar] [CrossRef]

- Lagaros, N.D.; Fragiadakis, M. Fragility assessment of steel frames using neural networks. Earthq. Spectra 2007, 23, 735–752. [Google Scholar] [CrossRef]

- Ahmad, A.; Plevris, V.; Khan, Q.-U.-Z. Prediction of Properties of FRP-Confined Concrete Cylinders Based on Artificial Neural Networks. Crystals 2020, 10, 811. [Google Scholar] [CrossRef]

- Almuhaylan, M.R.; Ghumman, A.R.; Al-Salamah, I.S.; Ahmad, A.; Ghazaw, Y.M.; Haider, H.; Shafiquzzaman, M.J.W. Evaluating the Impacts of Pumping on Aquifer Depletion in Arid Regions Using MODFLOW, ANFIS and ANN. Water 2020, 12, 2297. [Google Scholar] [CrossRef]

- Iqbal, M.; Naeem, U.A.; Ahmad, A.; Ghani, U.; Farid, T.J.M. Relating groundwater levels with meteorological parameters using ANN technique. Measurement 2020, 166, 108163. [Google Scholar] [CrossRef]

- Raza, A.; Khan, Q.U.Z.; Ahmad, A. Prediction of axial compressive strength for FRP-confined concrete compression members. Ksce J. Civ. Eng. 2020, 24, 2099–2109. [Google Scholar] [CrossRef]

- Manfredi, V.; Masi, A.; Nicodemo, G.; Digrisolo, A.; Santarsiero, G. The Role of Damage Extent in the Estimation of Direct Economic Losses of Existing RC Buildings; Pisa University Press: PISA, Italy, 2019; pp. 36–45. [Google Scholar]

- Nigro, D.; Digrisolo, A.; Ventura, G.; Santarsiero, G.; Masi, A.; Manfredi, V. Development of Integrated Techniques to Improve Seismic Performance and Energy Efficiency of Buildings: Preliminary Results of the Experimental Campaign on RC Portal Frames; Pisa University Press: PISA, Italy, 2019; pp. 128–137. [Google Scholar]

- Shakya, A.; Mishra, M.; Maity, D.; Santarsiero, G. Structural health monitoring based on the hybrid ant colony algorithm by using Hooke–Jeeves pattern search. SN Appl. Sci. 2019, 1, 1–14. [Google Scholar] [CrossRef]

- Volna, E. Introduction to Soft Computing, 1st ed.; Dept. of Computer Science University of Ostrava: Ostrava, Czechia, 2013; p. 137. [Google Scholar]

- Sadrmomtazi, A.; Sobhani, J.; Mirgozar, M.A. Modeling Compressive Strength of Eps Lightweight Concrete Using Regression, Neural Network And Anfis. Constr. Build. Mater. 2013, 42, 205–216. [Google Scholar] [CrossRef]

- Chandwani, V.; Agrawal, V.; Nagar, R. Modeling Slump of Ready Mix Concrete Using Genetic Algorithms Assisted Training of Artificial Neural Networks. Expert Syst. Appl. 2015, 42, 885–893. [Google Scholar] [CrossRef]

- Alshihri, M.M.; Azmy, A.M.; El-Bisy, M.S. Neural Networks For Predicting Compressive Strength of Structural Light Weight Concrete. Constr. Build. Mater. 2009, 23, 2214–2219. [Google Scholar] [CrossRef]

- Prasad, B.K.R.; Eskandari, H.; Reddy, B.V.V. Prediction of Compressive Strength of Scc And Hpc With High Volume Fly Ash Using ANN. Constr. Build. Mater. 2009, 23, 117–128. [Google Scholar] [CrossRef]

- Diab, A.M.; Elyamany, H.E.; Abd Elmoaty, A.E.M.; Shalan, A.H. Prediction of Concrete Compressive Strength Due To Long Term Sulfate Attack Using Neural Network. Alex. Eng. J. 2014, 53, 627–642. [Google Scholar] [CrossRef]

- Caglar, N.; Elmas, M.; Yaman, Z.D.; Saribiyik, M. Neural Networks In 3-Dimensional Dynamic Analysis of Reinforced Concrete Buildings. Constr. Build. Mater. 2008, 22, 788–800. [Google Scholar] [CrossRef]

- Jenkins, W.M. A Neural Network For Structural Re-Analysis. Comput. Struct. 1999, 72, 687–698. [Google Scholar] [CrossRef]

- Chang, C.C.; Chang, T.Y.P.; Xu, Y.G.; Wang, M.L. Structural Damage Detection Using An Iterative Neural Network. J. Intell. Mater. Syst. Struct. 2000, 11, 32–42. [Google Scholar] [CrossRef]

- Kim, J.T.; Ryu, Y.S.; Cho, H.M.; Stubbs, N. Damage Identification In Beam-Type Structures: Frequency-Based Method Vs Mode-Shape-Based Method. Eng. Struct. 2003, 25, 57–67. [Google Scholar] [CrossRef]

- Bakhary, N.; Hao, H.; Deeks, A.J. Damage Detection Using Artificial Neural Network With Consideration of Uncertainties. Eng. Struct. 2007, 29, 2806–2815. [Google Scholar] [CrossRef]

- Sahoo, B.; Maity, D. Damage Assessment Of Structures Using Hybrid Neuro-Genetic Algorithm. Appl. Soft Comput. 2007, 7, 89–104. [Google Scholar] [CrossRef]

- Günaydın, H.M.; Doğan, S.Z. A Neural Network Approach For Early Cost Estimation of Structural Systems of Buildings. Int. J. Proj. Manag. 2004, 22, 595–602. [Google Scholar] [CrossRef]

- Nyarko, M.H.; Nyarko, E.K.; Moric, D. A Neural Network Based Modelling And Sensitivity Analysis of Damage Ratio Coefficient. Expert Syst. Appl. 2011, 38, 13405–13413. [Google Scholar] [CrossRef]

- Hadi, M.N.S. Neural Networks Applications In Concrete Structures. Comput. Struct. 2003, 81, 373–381. [Google Scholar] [CrossRef]

- Zapico, J.L.; Gonzalez, M.P. Numerical Simulation of A Method For Seismic Damage Identification In Buildings. Eng. Struct. 2006, 28, 255–263. [Google Scholar] [CrossRef]

- Zhang, J.; Foschi, R.O. Performance-Based Design And Seismic Reliability Analysis Using Designed Experiments And Neural Networks. Probabilistic Eng. Mech. 2004, 19, 259–267. [Google Scholar] [CrossRef]

- Gonzalez, M.P.; Zapico, J.L. Seismic Damage Identification In Buildings Using Neural Networks And Modal Data. Comput. Struct. 2008, 86, 416–426. [Google Scholar] [CrossRef]

- Cheng, J. Serviceability Reliability Analysis of Prestressed Concrete Bridges. Ksce J. Civ. Eng. 2013, 17, 415–425. [Google Scholar] [CrossRef]

- Giordano, F.; Rocca, M.L.; Perna, C. Input Variable Selection in Neural Network Models. Commun. Stat. Theory Methods 2014, 43, 735–750. [Google Scholar] [CrossRef]

- Hammer, B. Neural Networks; Elsevier: Amsterdam, The Netherlands, 2014; Volume 1, pp. 817–855. [Google Scholar]

- Basheer, I.A.; Hajmeer, M. Artificial Neural Networks: Fundamentals, Computing, Design, And Application. J. Microbiol. Methods 2000, 43, 3–31. [Google Scholar] [CrossRef]

- Castellano, G.; Fanelli, A.M. Variable Selection Using Neural-Network Models. Neurocomputing 2000, 31, 1–13. [Google Scholar] [CrossRef]

- Beale, M.H.; Hagan, M.T.; Demuth, H.B. Neural Network Toolbox™—User’s Guide; The MathWorks, Inc.: Natick, MA, USA, 2015. [Google Scholar]

- Krogh, A.; Vedelsby, J. Neural Network Ensembles, Cross Validation, and Active Learning. Adv. Neyral Inf. Process. Syst. 1995, 7, 21–238. [Google Scholar]

- Utans, J.; Moody, J.; Rehfuss, S.; Siegelmannt, H. Input Variable Selection for Neural Networks: Application to Predicting the U.S. Business Cycle; IEEE Transactions on Knowledge and Data Engineering: New York, NY, USA, 1995; pp. 118–122. [Google Scholar]

- Kotsovos, G.M.; Kotsovos, M.D. Flat slabs without shear reinforcement: Criteria for punching. Struct. Eng. 2010, 87, 1–8. [Google Scholar]

- Kotsovos, G.M.; Kotsovos, M.D. A new approach to designing reinforcement to resist punching shear. Struct. Eng. 2010, 89, 20–25. [Google Scholar]

- Pendharkar, U.; Chaudhary, S.; Nagpal, A.K. Neural network for bending moment in continuous composite beams considering cracking and time effects in concrete. Eng. Struct. 2007, 29, 2069–2079. [Google Scholar] [CrossRef]

- Yang, K.H.; Ashour, A.F.; Song, J.K. Shear Capacity of Reinforced Concrete Beams Using Neural Network. Int. J. Concr. Struct. Mater. 2007, 1, 66–73. [Google Scholar]

- Cladera, A.; Mari, A.R. Shear Design Procedure For Reinforced Normal And High-Strength Concrete Beams Using Artificial Neural Networks. Part I: Beams Without Stirrups. Eng. Struct. 2004, 26, 917–926. [Google Scholar] [CrossRef]

- Cladera, A.; Mari, A.R. Shear Design Procedure For Reinforced Normal And High-Strength Concrete Beams Using Artificial Neural Networks. Part II: Beams With Stirrups. Eng. Struct. 2004, 26, 927–936. [Google Scholar] [CrossRef]

- Wei, W.W.; Che, Y.; Gong, J.X. Shear Strength Prediction For Reinforced Concrete Beams Without Stirrups. Mag. Concr. Res. 2011, 63, 433–440. [Google Scholar] [CrossRef]

| Beams without Stirrups (BWOS) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| b | d | av/d | ρl | fyl | fc | Mf | Vu | |||

| Unit | Mm | Mm | (%) | MPa | MPa | kN-mm | kN | |||

| Min | 52 | 70 | 0.329 | 0.25 | 122 | 13 | 2000 | 7.25 | ||

| Max | 500 | 556 | 9.76 | 7.46 | 555 | 112 | 844,000 | 585 | ||

| Avg. | 170 | 264 | 3.75 | 2.21 | 390 | 38 | 104,147 | 72 | ||

| St. Dev | 68 | 85 | 1.55 | 1.1 | 87.26 | 21 | 120,894 | 56 | ||

| COV | 0.4 | 0.35 | 0.45 | 0.55 | 0.25 | 0.57 | 1.2 | 0.82 | ||

| Beams with Stirrups (BWS) | ||||||||||

| b | d | av/d | ρl | fyl | fc | ρw | fyw | Mf | Vu | |

| Unit | mm | mm | (%) | MPa | MPa | (%) | MPa | kN-mm | kN | |

| Min | 100 | 113 | 1 | 0.18 | 250 | 13.8 | 0.08 | 224 | 2648 | 4.097 |

| Max | 510 | 975 | 7.25 | 5.6 | 890 | 126 | 2.25 | 875 | 1,738,423 | 760.194 |

| Avg. | 208 | 343 | 3.5 | 2.4 | 415 | 45 | 0.6 | 400 | 283,485 | 185.54 |

| St. Dev | 68 | 158 | 1.5 | 1.1 | 78 | 25 | 0.5 | 115 | 378,729 | 134.25 |

| COV | 0.34 | 0.48 | 0.4 | 0.46 | 0.2 | 0.55 | 0.9 | 0.3 | 1.35 | 0.75 |

| Vu | |

|---|---|

| BWOS | |

| EXP | b, d, ρl, fyl, fc, av/d, |

| BWOS-1 | b, d, ρl, fyl, fc, av/d |

| BWOS-2 | b, d, Mf, fc, av/d |

| BWOS-3 | b/d, Mf/fcbd2, av/d |

| BWOS-4 | d, Mf/bd2, fc, av/d |

| BWOS-5 | d, b/d, Mf/fcbd2, av/d |

| BWOS-6 | d, b/d, Mf/fcbd2 fc, av/d |

| BWS | |

| EXP | b, d, ρl, fyl, fc, ρw, fyw, av/d |

| BWS-1 | b, d, ρl, fyl, fc, ρw, fyw, av/d |

| BWS-2 | b, d, Mf, fc, ρw, fyw, av/d |

| BWS-3 | b/d, Mf/fcbd2, ρw, fyw, av/d |

| BWS-4 | b/d, ρw/ρl, fc/fyw, av/d |

| BWS-5 | d, Mf/bd2, fc, ρwfyw, av/d |

| BWS-6 | d, b/d, Mf/fcbd2, ρw, fyw, av/d |

| BWS-7 | d, b/d, Mf/fcbd2, fc, ρw, fyw, av/d |

| BWS-8 | d, b/d, Mf/fcbd2, fc, ρwfyw, av/d |

| b | d | av/d | ρl | fyl | fc | ρw | fyw | N | Mf | Vu | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (%) | (MPa) | (MPa) | (%) | (MPa) | (kN) | kN-mm | (kN) | ||

| Min | 150 | 110.5 | 2.647 | 0.87 | 313 | 17.9 | 0.1 | 255 | 111 | 15 | 33 |

| Max | 550 | 470 | 8.73362 | 6.16 | 559.5 | 118 | 2.8 | 1424 | 5373 | 1590 | 812 |

| Avg. | 323.03 | 241.22 | 5.1 | 3.19 | 463.16 | 49.09 | 0.82 | 497.46 | 1445.62 | 366.91 | 244.04 |

| St. Dev | 117.16 | 77.37 | 1.57 | 1.15 | 50.13 | 28.23 | 0.58 | 246.1 | 1270.2 | 337.62 | 177.62 |

| COV | 0.36 | 0.32 | 0.31 | 0.36 | 0.11 | 0.58 | 0.71 | 0.49 | 0.88 | 0.92 | 0.73 |

| Parameters | |

|---|---|

| DB-II | |

| CWA:1 | b, d, ρl, N, fyl, fc, ρw, fyw, av/d, |

| CWA:2 | b, d, Mf, N, fc, ρw, fyw, av/d, |

| CWA:3 | b/d, N/bdfc, ρw, fyw, Mf/fcbd2, av/d, |

| CWA:4 | b/d, N/bdfc, fc/fyw, ρw/ρl, av/d, |

| CWA:5 | d, N/bdfc, ρwfyw, Mf/fcbd2, fc, av/d, |

| CWA:6 | d, b/d, N/bdfc, ρw, fyw, Mf/fcbd2, av/d, |

| CWA:7 | d, b/d, N/fcbd, ρw, fyw, Mf/fcbd2, fc, av/d, |

| CWA:8 | d, b/d, N/fcbd, ρwfyw, Mf/fcbd2, fc, av/d |

| CWA:9 | d, b/d, ρw, fyw, Mf/fcbd2, fc, av/d, |

| Detail of the Database TBWOS | ||||||

|---|---|---|---|---|---|---|

| Min | Max | Mean | St. Dev | COV | ||

| fc | MPa | 18 | 47 | 31 | 7.56 | 0.23 |

| bw | mm | 52 | 175 | 123 | 35.74 | 0.28 |

| hf | mm | 39 | 105 | 58.78 | 19.69 | 0.35 |

| bf | mm | 153 | 918 | 419 | 182 | 0.48 |

| d | mm | 175 | 354 | 232 | 39 | 0.14 |

| ρlfyl | MPa | 5..69 | 28.36 | 12.97 | 7.40 | 0.53 |

| bw/d | Ratio | 0.23 | 0.82 | 0.54 | 0.14 | 0.32 |

| bf/hf | Ratio | 2.3 | 12.62 | 8.25 | 3.75 | 0.52 |

| ρtfyt | MPa | 0 | 7.45 | 0.72 | 1.95 | 2.56 |

| av/d | Ratio | 2.48 | 10.39 | 4.35 | 1.65 | 0.42 |

| Mf | kN-mm | 26998 | 407489 | 79278 | 75478 | 0.91 |

| Vu | kN | 18.8 | 81.45 | 40.43 | 15.89 | 0.35 |

| Details of the Database TBWS | ||||||

| Min | Max | Mean | St. Dev | COV | ||

| fc | MPa | 12 | 57 | 28.85 | 8.46 | 0.29 |

| bw | mm | 53 | 305 | 145 | 30.23 | 0.24 |

| hf | mm | 78 | 108 | 79.4 | 6.48 | 0.07 |

| bf | mm | 304 | 964 | 564 | 173.24 | 0.36 |

| d | mm | 259 | 379 | 289 | 43.19 | 0.14 |

| ρtfyt | MPa | 0 | 14.79 | 1.69 | 2.44 | 2.31 |

| bw/d | Ratio | 0.145 | 1.45 | 0.55 | 0.13 | 0.27 |

| bf/hf | Ratio | 3.36 | 12.74 | 7.19 | 2.27 | 0.33 |

| ρlfyl | MPa | 5.45 | 36.75 | 18.71 | 6.54 | 0.39 |

| ρwfyw | MPa | 0.378 | 4.89 | 1.59 | 1.02 | 0.78 |

| av/d | Ratio | 1.54 | 7.35 | 3.86 | 1.82 | 0.22 |

| Mf | kN-mm | 74358 | 407729 | 207263 | 90839 | 0.46 |

| Vu | kN | 72.69 | 378.5 | 167.59 | 74.58 | 0.43 |

| Details of the Database for TBWOS | |

|---|---|

| VEXP | bw, hf, bf, d, fc, ρlfyl, av/d, |

| TBWOS:01 | bw, hf, bf, d, fc, ρlfyl, av/d, |

| TBWOS:02 | bw, hf, bf, d, fc, Mf/fcbwd2, av/d, |

| TBWOS:03 | bw/d, bf/hf, ρlfyl, fc/fyl, av/d, |

| TBWOS:04 | bw/d, bf/hf, Mf/fcbwd2, fc/fyl, av/d, |

| Details of the Database for TBWS | |

| VEXP | bw, hf, bf, d, fc, ρlfyl, ρwfyw, av/d, |

| TBWS:01 | bw, hf, bf, d, fc, ρlfyl, ρwfyw, av/d, |

| TBWS:02 | bw, hf, bf, d, fc, Mf/fcbwd2, ρwfyw, av/d, |

| TBWS:03 | bw/d, bf/hf, ρvfyv/ρlfyl, fc/fyl, av/d, |

| TBWS:04 | bw/d, bf/hf, Mf/fcbwd2, ρwfyw, fc/fyl, av/d, |

| c | d | αv/d | ρl | fyl | fc | Mf | Vu | |

|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (%) | (MPa) | (MPa) | kN-mm | (kN) | ||

| Min | 54 | 64 | 4.5 | 0.3 | 294 | 9.52 | 39,000 | 105 |

| Max | 600 | 275 | 14.02 | 6.9 | 749 | 118.7 | 1,951,000 | 2450 |

| Avg. | 206.34 | 122.32 | 7.81 | 1.31 | 496.88 | 41.3 | 252,655 | 458.7 |

| St. Dev | 87 | 44.82 | 2.4 | 0.89 | 117.68 | 24.85 | 292,121 | 436.88 |

| COV | 0.42 | 0.37 | 0.31 | 0.68 | 0.24 | 0.6 | 1.16 | 0.95 |

| Model | Parameters |

|---|---|

| SCS:01 | c, d, ρl, fyl, fc, av/d, |

| SCS:02 | c, d, Mf, fc, av/d, |

| SCS:03 | c/d, Mf/fcbd2, av/d, |

| SCS:04 | c/d, ρl, fc/fyl, av/d, |

| SCS:05 | d, Mf/bd2, fc, av/d, |

| SCS:06 | d, c/d, Mf/fcbd2, av/d, |

| SCS:07 | d, c/d, Mf/fcbd2, fc, av/d, |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, A.; Lagaros, N.D.; Cotsovos, D.M. Neural Network-Based Prediction: The Case of Reinforced Concrete Members under Simple and Complex Loading. Appl. Sci. 2021, 11, 4975. https://doi.org/10.3390/app11114975

Ahmad A, Lagaros ND, Cotsovos DM. Neural Network-Based Prediction: The Case of Reinforced Concrete Members under Simple and Complex Loading. Applied Sciences. 2021; 11(11):4975. https://doi.org/10.3390/app11114975

Chicago/Turabian StyleAhmad, Afaq, Nikos D. Lagaros, and Demetrios M. Cotsovos. 2021. "Neural Network-Based Prediction: The Case of Reinforced Concrete Members under Simple and Complex Loading" Applied Sciences 11, no. 11: 4975. https://doi.org/10.3390/app11114975

APA StyleAhmad, A., Lagaros, N. D., & Cotsovos, D. M. (2021). Neural Network-Based Prediction: The Case of Reinforced Concrete Members under Simple and Complex Loading. Applied Sciences, 11(11), 4975. https://doi.org/10.3390/app11114975