A Hybrid Nanofluid of Alumina and Tungsten Oxide for Performance Enhancement of a Parabolic Trough Collector under the Weather Conditions of Budapest

Abstract

:1. Introduction

2. Model Specifications

Parabolic Trough Collector

3. Mathematical Model Description

3.1. Radiation Model

3.2. Thermal Model

3.3. Thermal Fluid Specifications

4. Results and Discussions

4.1. Thermal Model Validation

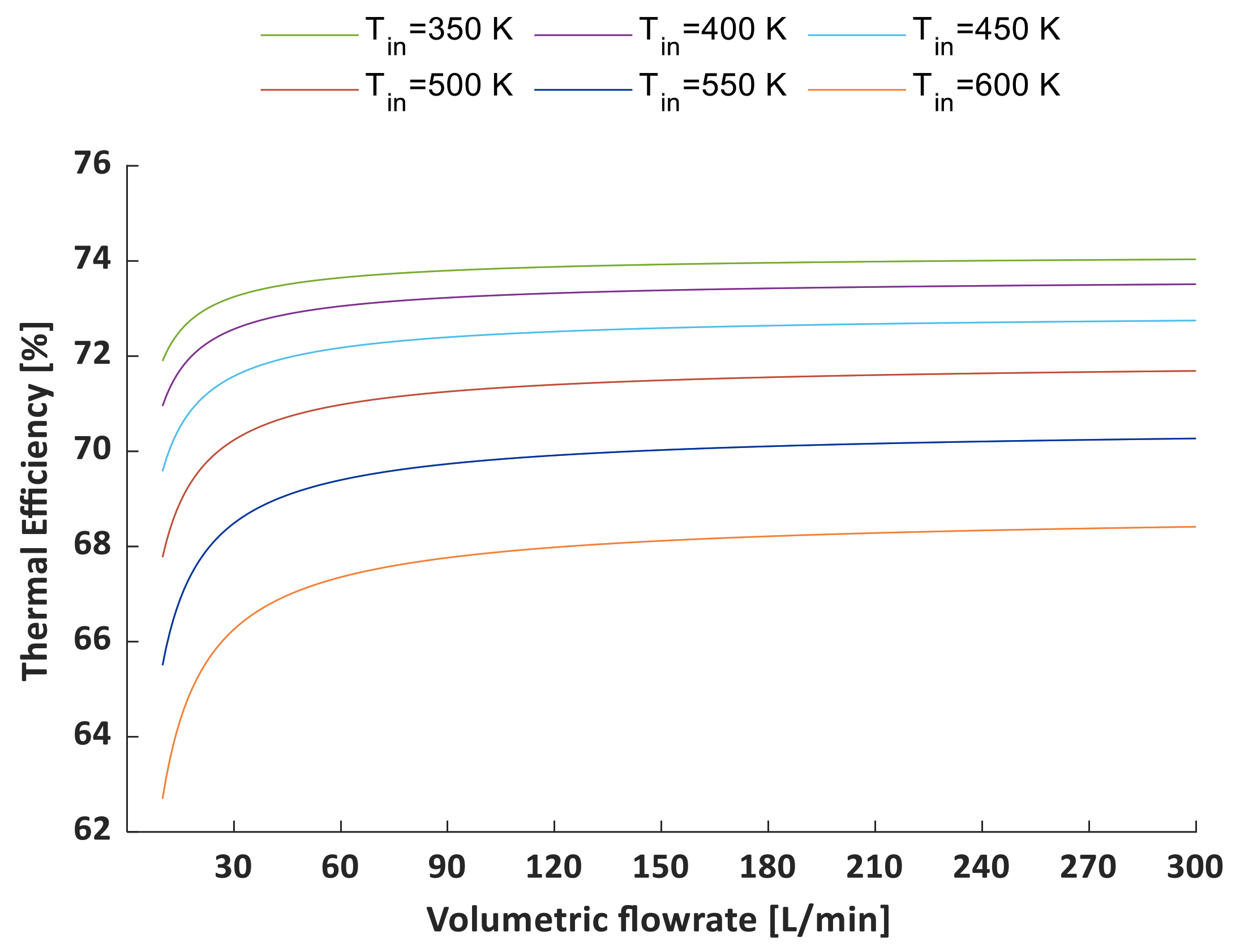

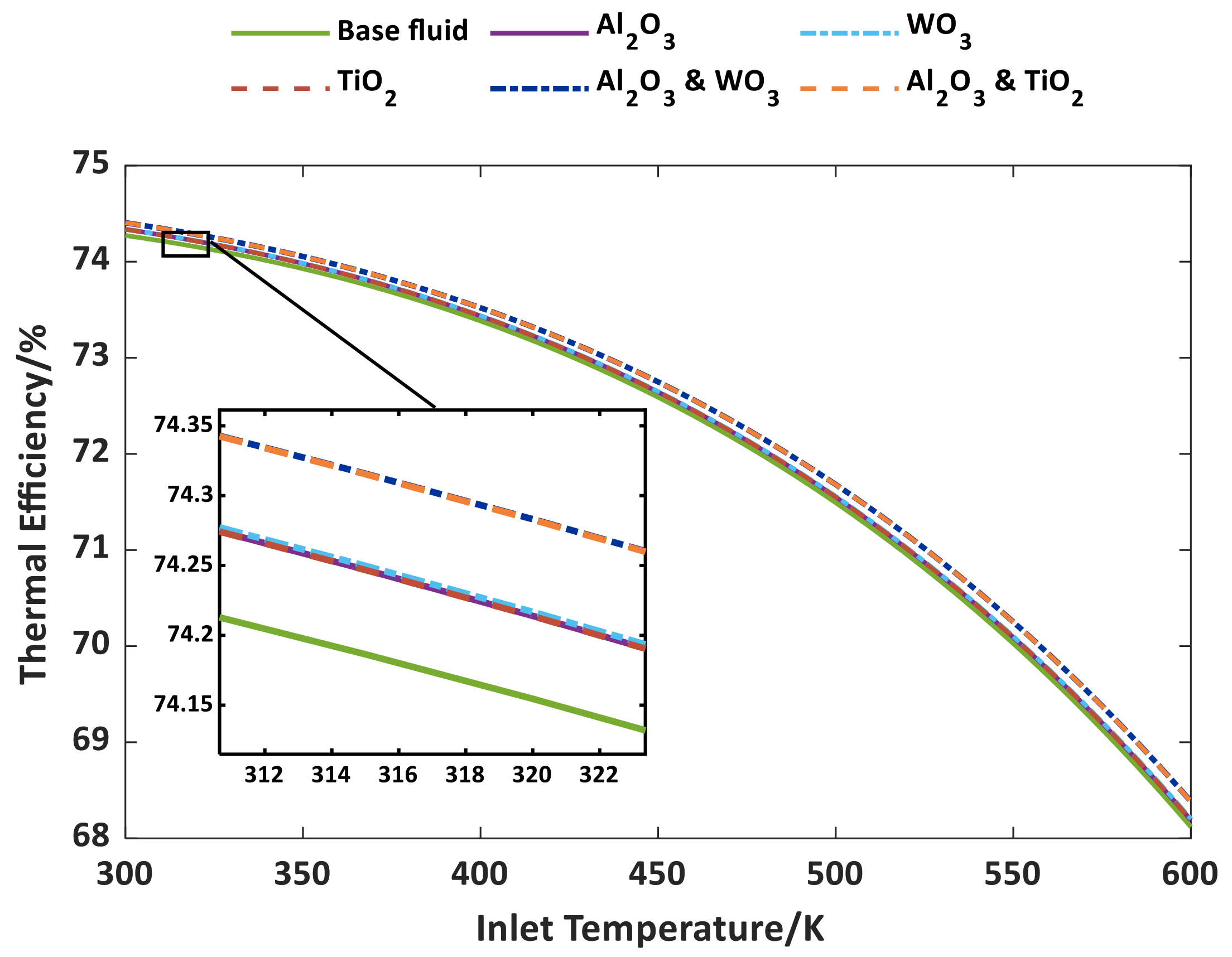

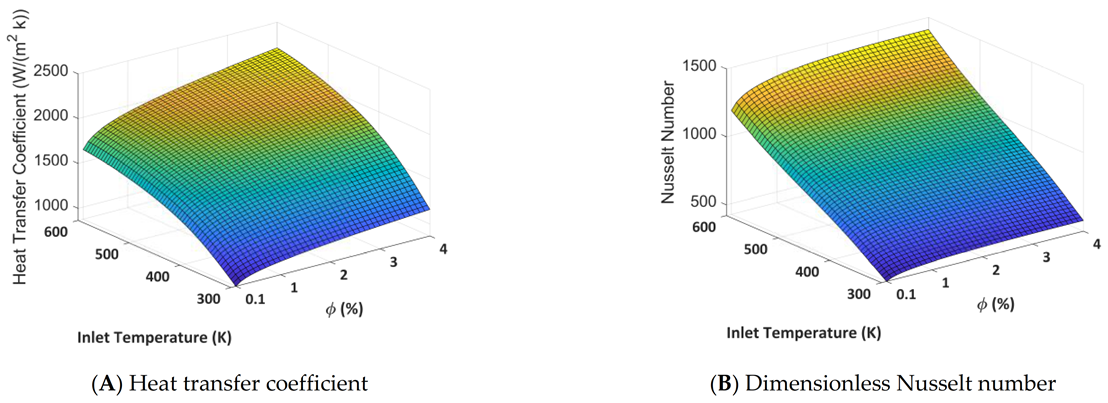

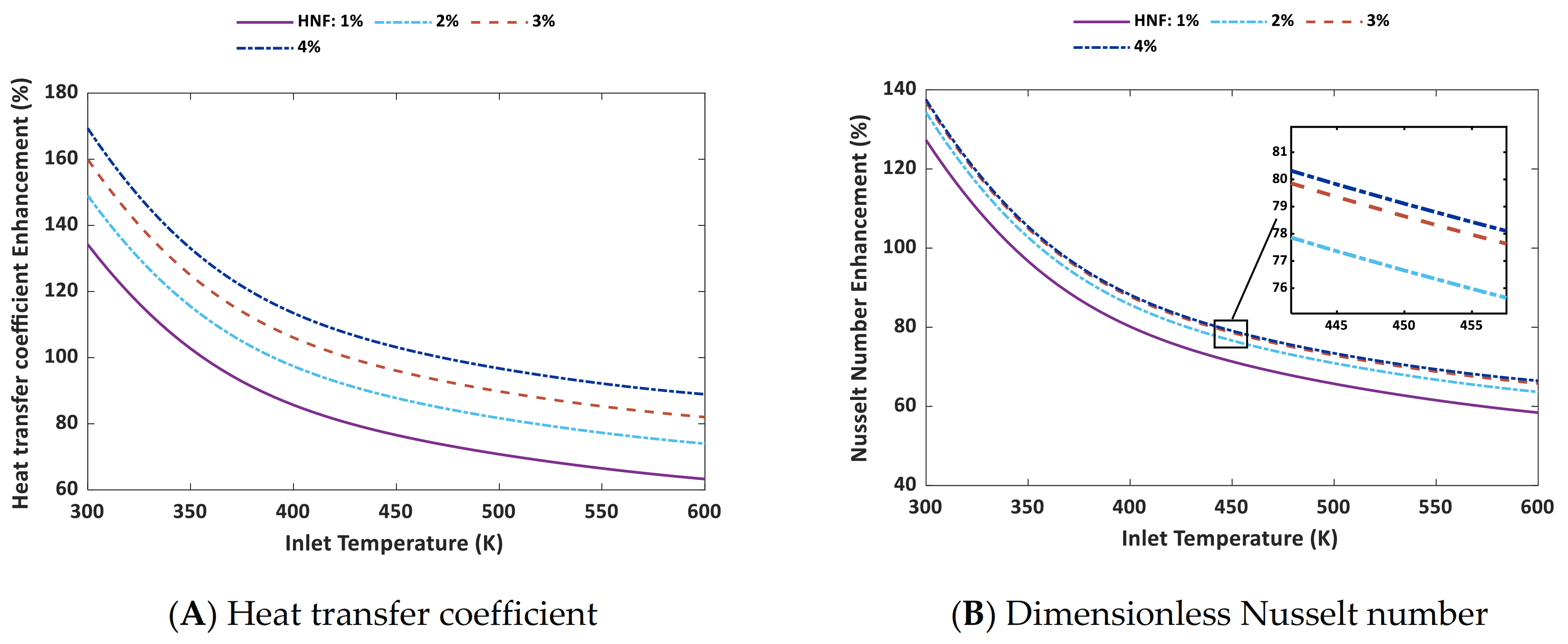

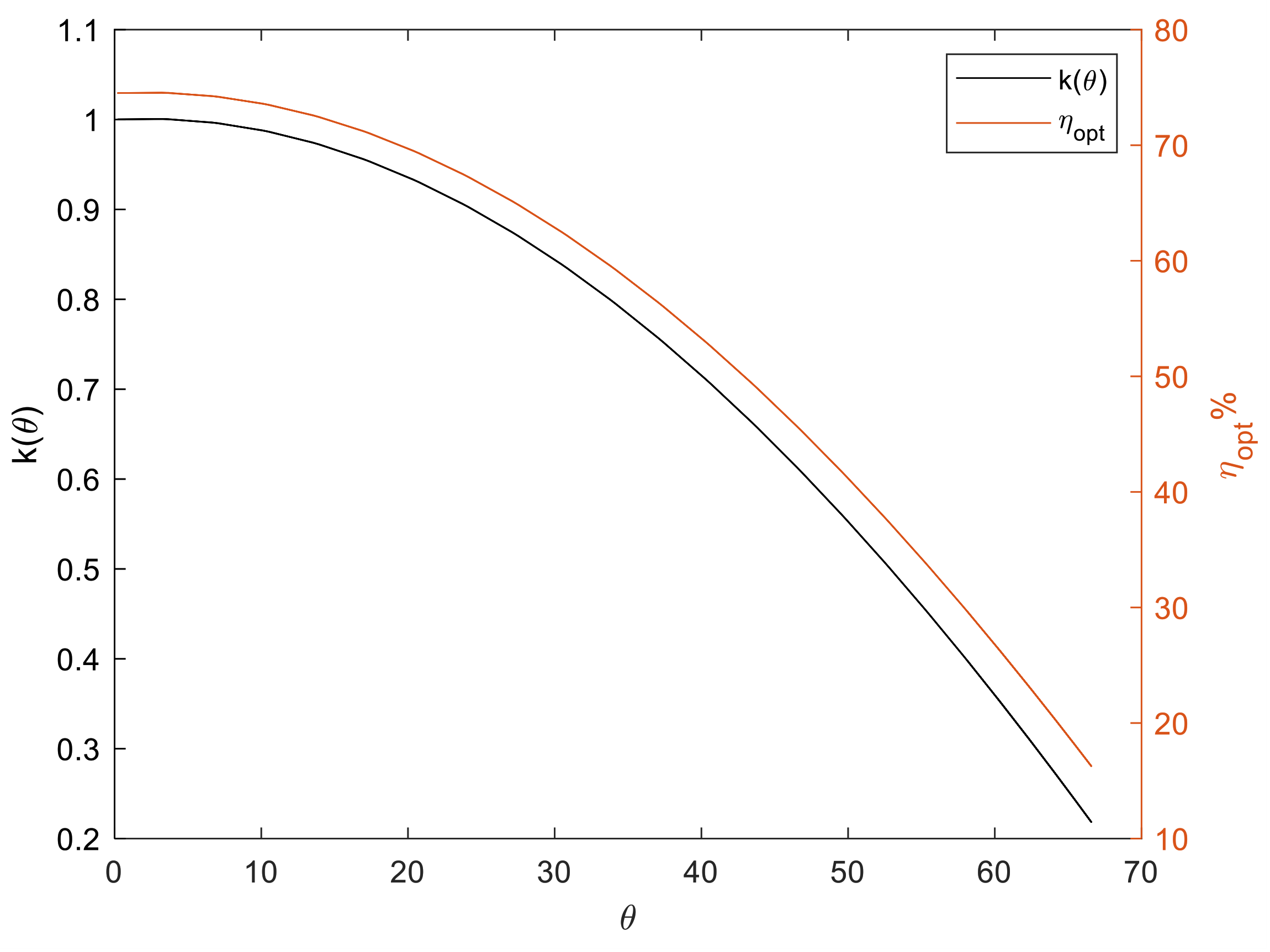

4.2. Thermal Performance Results and Discussions

4.3. Thermal and Exergy Efficiencies Assessment under the Weather Conditions of Budapest

5. Conclusions

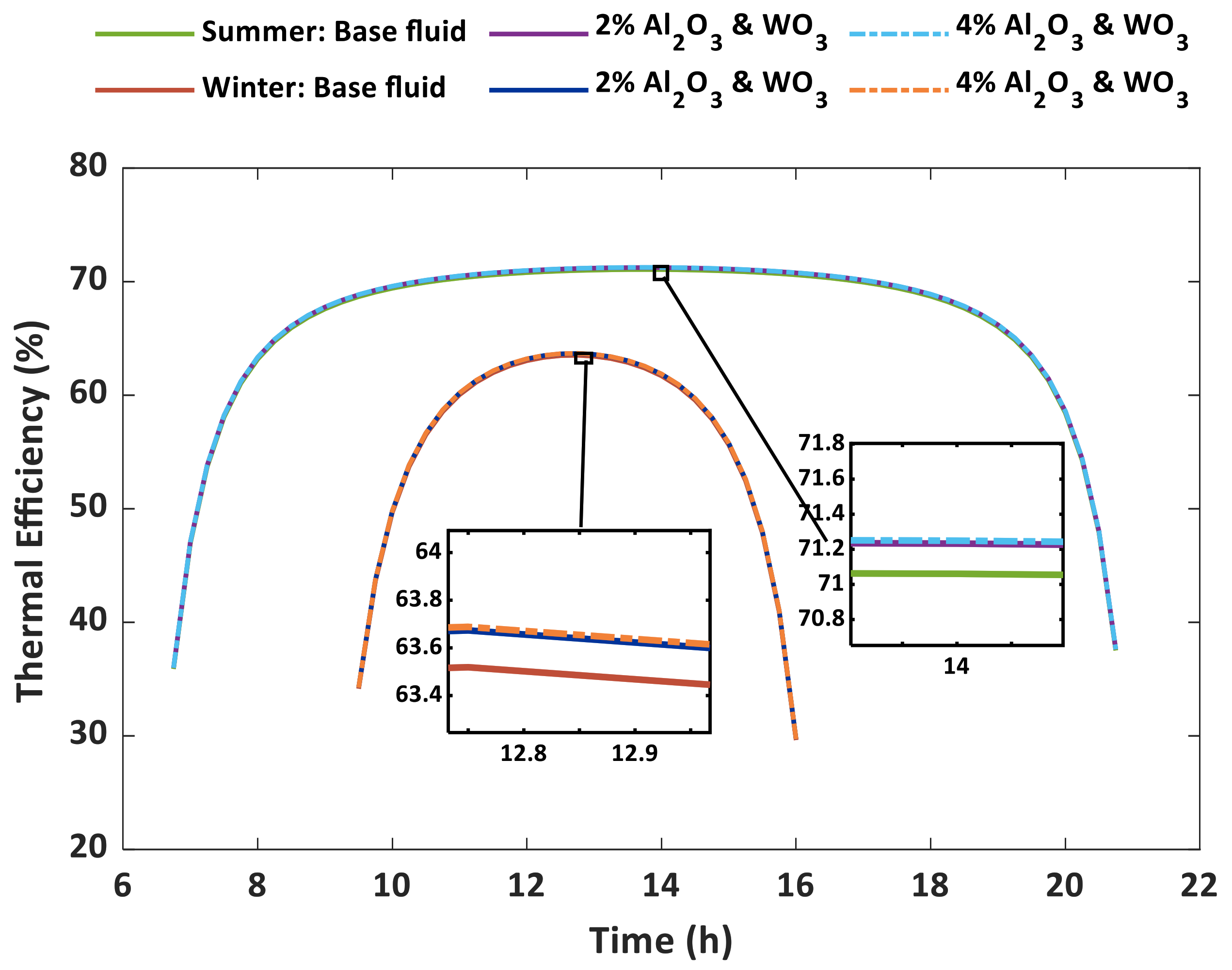

- Utilizing concentrated solar applications (PTC) under Budapest’s weather conditions showed their ability to produce energy, especially in summer. The maximum intensity of the beam radiation reaching the parabolic reflectors approached 880 W/m2 on typical sunny days, and it reaches 260 W/m2 on typical winter days.

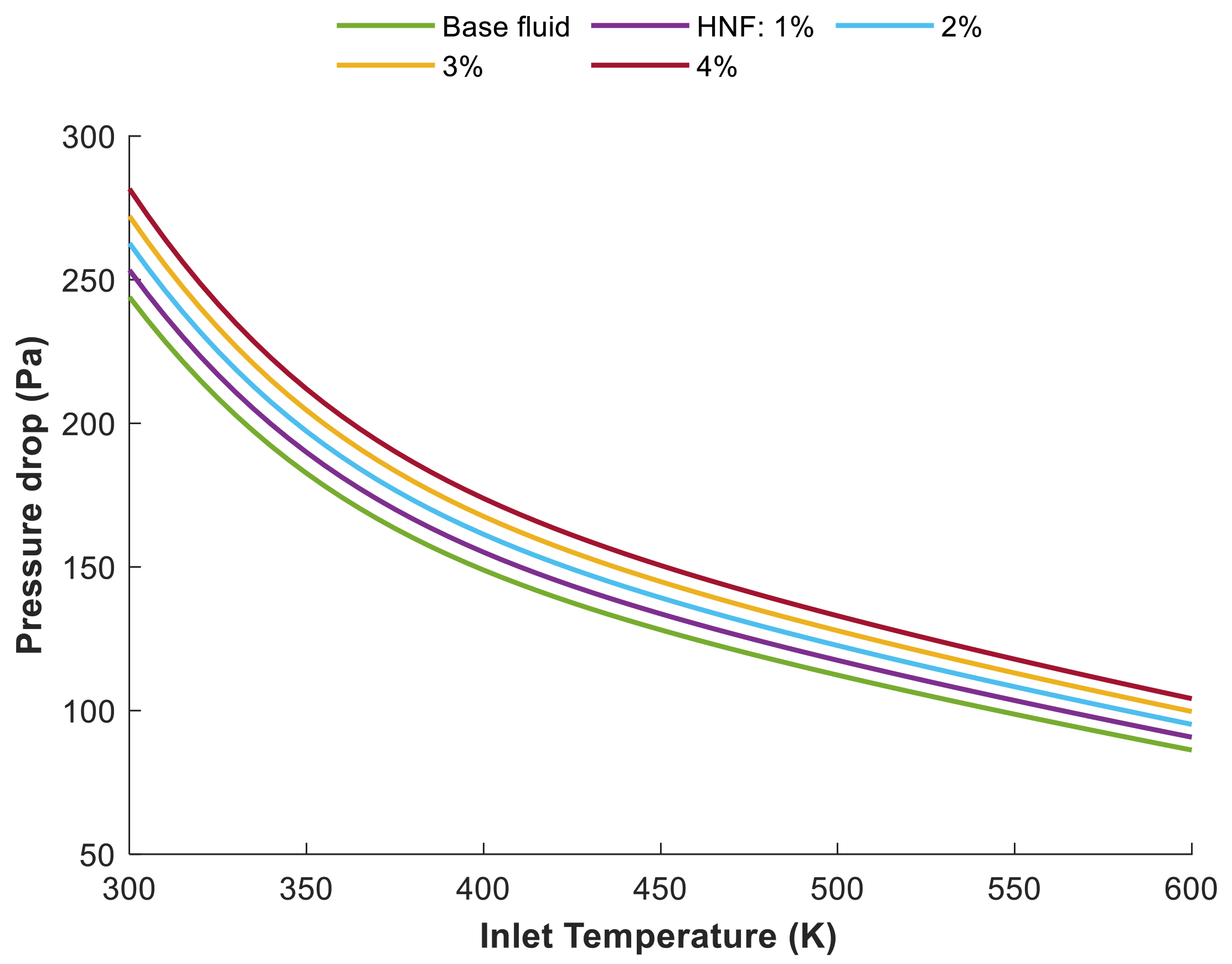

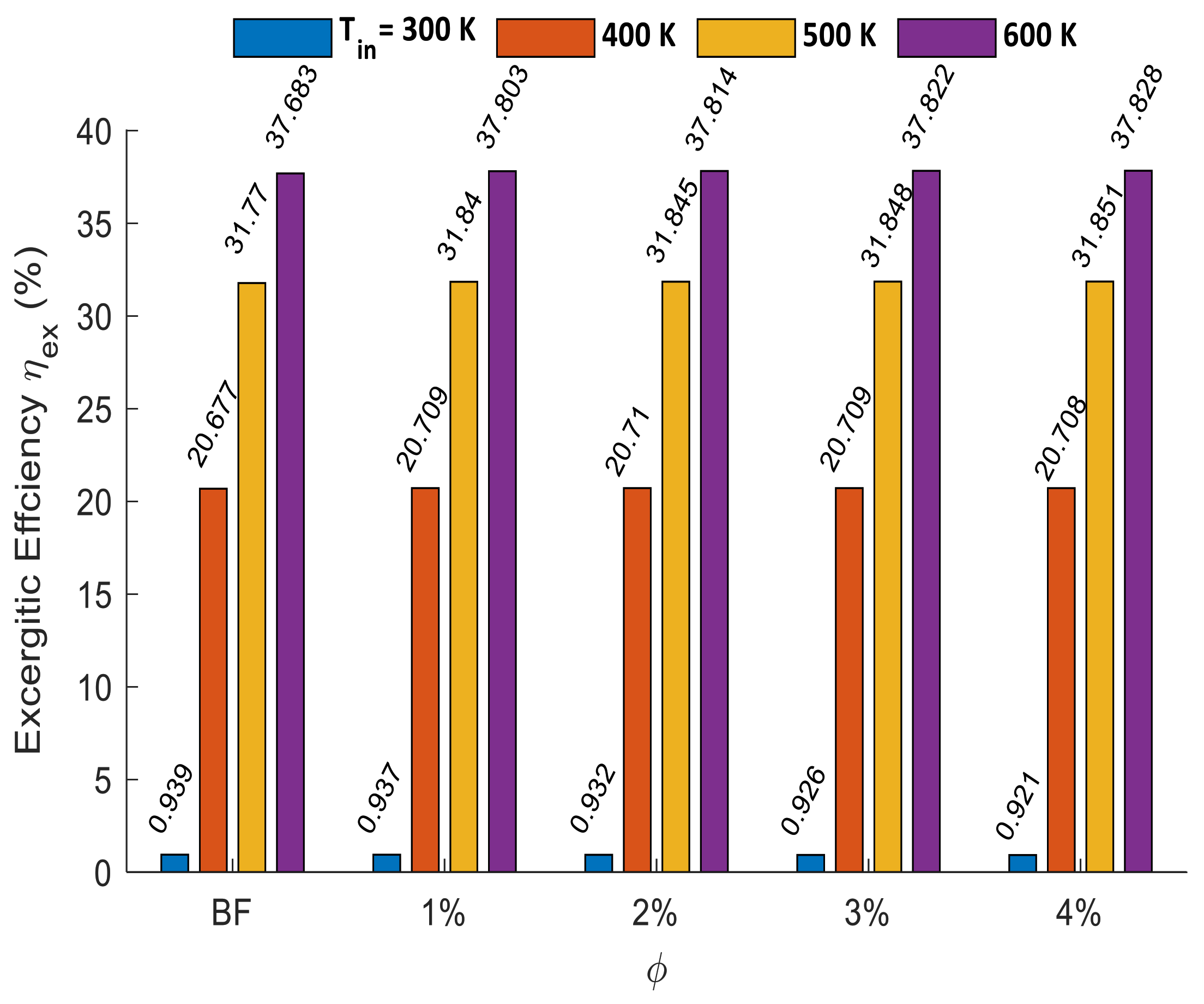

- In order to explain the effect of the dimensionless Nusselt number and heat transfer coefficient in increasing exergy and energy efficiencies, experiments were performed for HNFs under different concentrations (0–4%) and temperatures (300–600 K) at a constant volume flow rate of 150 L/min. Using a 2% volume concentration yielded 1402 W/m2∙K for the Nusselt number and 2060 W/m2∙K for the heat transfer coefficient. In comparison, a maximum Nusselt number of 1427 W/m2∙K and a heat transfer coefficient of 2236 W/m2∙K were obtained using a 4% volume concentration with a maximum temperature of 600 K.

- Thermal and exergy efficiencies achieved the highest improvement using high concentrations and high temperatures, reaching 68.384% and 37.828%, respectively; this means that the enhancement ratio equaled 0.39% for the thermal efficiency and 0.38% for the exergy efficiency.

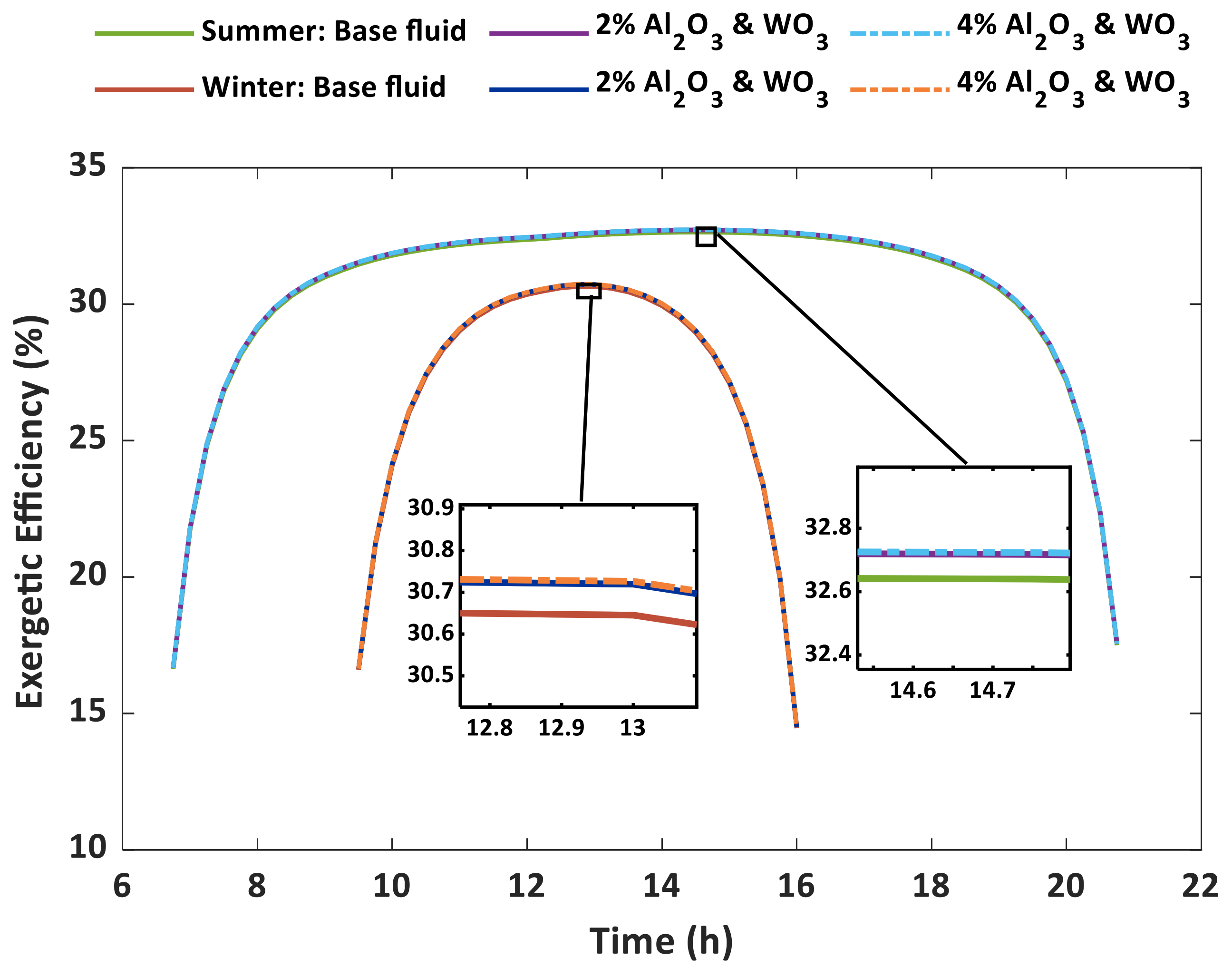

- For HNFs, the maximum exergy and energy values were recorded at midday under Budapest’s summer climatic conditions, and reach 32.728% and 71.255%, respectively, under the optimum temperature of 500 K and flow rate 150 L/min. These results and the low impact of increasing the concentrations, in this case, can be attributed to simulating the effects under high volume flow rates and using a highly efficient commercial PTC (which has an evacuated tube). Despite the low enhancement results (0.25%), which were attributed to the reasons mentioned above, it was acceptable and justified [31]. On the other hand, there were promising findings on the financial feasibility in the literature for the effects of nanofluid prices. For example, Ehyaei et al. [64] found that nanofluid use did not contribute to a major increase in the overall cost of PTCs. In addition, Kasaiean et al. [38] found in their research that the payback period of nanofluid-based PTC usage is lower than the payback period of nanofluid-free PTCs.

6. Limitations and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Falahi, A.; Alobaid, F.; Epple, B. Thermo-Economic Comparisons of Environmentally Friendly Solar Assisted Absorption Air Conditioning Systems. Appl. Sci. 2021, 11, 2442. [Google Scholar] [CrossRef]

- Al-Ghussain, L.; Al-Oran, O.; Lezsovits, F. Statistical estimation of hourly diffuse radiation intensity of Budapest City. Environ. Prog. Sustain. Energy 2021, 40, e13464. [Google Scholar] [CrossRef]

- Tsoutsos, T.; Frantzeskaki, N.; Gekas, V. Environmental impacts from the solar energy technologies. Energy Policy 2005, 33, 289–296. [Google Scholar] [CrossRef]

- Caraballo, A.; Galán-Casado, S.; Caballero, Á.; Serena, S. Molten Salts for Sensible Thermal Energy Storage: A Review and an Energy Performance Analysis. Energies 2021, 14, 1197. [Google Scholar] [CrossRef]

- Luna, G.Y.R.; Gómez Franco, W.R.; Carrasco, D.U.; Domínguez, R.R.J.; García, J.J.C. Integration of the experimental results of a parabolic trough collector (PTC) solar plant to an absorption air-conditioning system. J. Appl. Sci. 2018, 8, 2163. [Google Scholar] [CrossRef] [Green Version]

- Tzuc, O.M.; Bassam, A.; Ricalde, L.J.; Jaramillo, O.; Flota-Bañuelos, M.; Soberanis, M.E. Environmental-economic optimization for implementation of parabolic collectors in the industrial process heat generation: Case study of Mexico. J. Clean. Prod. 2020, 242, 118538. [Google Scholar] [CrossRef]

- González-Mora, E.; García, M.D.D. Methodology for an Opto-Geometric Optimization of a Linear Fresnel Reflector for Direct Steam Generation. Energies 2020, 13, 355. [Google Scholar] [CrossRef] [Green Version]

- Bellos, E.; Tzivanidis, C. Polynomial Expressions for the Thermal Efficiency of the Parabolic Trough Solar Collector. Appl. Sci. 2020, 10, 6901. [Google Scholar] [CrossRef]

- Zhuang, X.; Xu, X.; Liu, W.; Xu, W. LCOE Analysis of Tower Concentrating Solar Power Plants Using Different Molten-Salts for Thermal Energy Storage in China. Energies 2019, 12, 1394. [Google Scholar] [CrossRef] [Green Version]

- Manikandan, G.; Iniyan, S.; Goic, R. Enhancing the optical and thermal efficiency of a parabolic trough collector: A review. Appl. Energy 2019, 235, 1524–1540. [Google Scholar] [CrossRef]

- Al-Oran, O.; Lezsovits, F. Recent experimental enhancement techniques applied in the receiver part of the parabolic trough collector: A review. Int. Rev. Appl. Sci. Eng. 2020, 209–219. [Google Scholar] [CrossRef]

- Abed, N.; Afgan, I. An extensive review of various technologies for enhancing the thermal and optical performances of parabolic trough collectors. J. Int. J. Energy Res. 2020, 44, 5117–5164. [Google Scholar] [CrossRef] [Green Version]

- Abed, N.; Afgan, I. Enhancement techniques of parabolic trough collectors: A review of past and recent technologies. J. Adv. Civil Eng. Technol. 2019, 3, 1. [Google Scholar]

- Olia, H.; Torabi, M.; Bahiraei, M.; Ahmadi, M.H.; Goodarzi, M.; Safaei, M.R. Application of nanofluids in thermal performance enhancement of parabolic trough solar collector: State-of-the-art. J. Appl. Sci. 2019, 9, 463. [Google Scholar] [CrossRef] [Green Version]

- Abubakr, M.; Amein, H.; Akoush, B.M.; El-Bakry, M.M.; Hassan, M.A. An intuitive framework for optimizing energetic and exergetic performances of parabolic trough solar collectors operating with nanofluids. Renew. Energy 2020, 157, 130–149. [Google Scholar] [CrossRef]

- Al-Oran, O.; Lezsovits, F. Thermal performance of inserting hybrid nanofluid in parabolic trough collector. Pollack Period. 2021. [Google Scholar] [CrossRef]

- Kumar, K.R.; Reddy, K.S. Effect of porous disc receiver configurations on performance of solar parabolic trough concentrator. Heat Mass Transf. 2012, 48, 555–571. [Google Scholar] [CrossRef]

- Jamal-Abad, M.T.; Saedodin, S.; Aminy, M. Experimental investigation on a solar parabolic trough collector for absorber tube filled with porous media. Renew. Energy 2017, 107, 156–163. [Google Scholar] [CrossRef]

- Kamel, M.S.; Al-Oran, O.; Lezsovits, F. Thermal Conductivity of Al2O3 and CeO2 Nanoparticles and Their Hybrid Based Water Nanofluids: An Experimental Study. Period. Polytech. Chem. Eng. 2020, 65, 50–60. [Google Scholar] [CrossRef]

- Mahian, O.; Kolsi, L.; Amani, M.; Estellé, P.; Ahmadi, G.; Kleinstreuer, C.; Marshall, J.S.; Siavashi, M.; Taylor, R.A.; Niazmand, H.; et al. Recent advances in modeling and simulation of nanofluid flows-Part I: Fundamentals and theory. Phys. Rep. 2019, 790, 1–48. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Tlili, I.; Baseer, M.A.; Safaei, M.R. Potential of Solar Collectors for Clean Thermal Energy Production in Smart Cities using Nanofluids: Experimental Assessment and Efficiency Improvement. Appl. Sci. 2019, 9, 1877. [Google Scholar] [CrossRef] [Green Version]

- Peng, Y.; Zahedidastjerdi, A.; Abdollahi, A.; Amindoust, A.; Bahrami, M.; Karimipour, A.; Goodarzi, M. Investigation of energy performance in a U-shaped evacuated solar tube collector using oxide added nanoparticles through the emitter, absorber and transmittal environments via discrete ordinates radiation method. J. Therm. Anal. Calorim. 2020, 139, 2623–2631. [Google Scholar] [CrossRef]

- Sarafraz, M.; Safaei, M.R. Diurnal thermal evaluation of an evacuated tube solar collector (ETSC) charged with graphene nanoplatelets-methanol nano-suspension. J. Renew. Energy 2019, 142, 364–372. [Google Scholar] [CrossRef]

- Abed, N.; Afgan, I.; Nasser, A.; Iacovides, H.; Cioncolini, A.; Mekhail, T. Numerical Investigations of parabolic trough collectors using different nanofluids. Int. J. Appl. Energy Syst. 2020, 2, 88–94. [Google Scholar] [CrossRef]

- Abed, N.; Afgan, I.; Cioncolini, A.; Iacovides, H.; Nasser, A.; Mekhail, T. Thermal performance evaluation of various nanofluids with non-uniform heating for parabolic trough collectors. Case Stud. Therm. Eng. 2020, 22, 100769. [Google Scholar] [CrossRef]

- Abed, N.; Afgan, I.; Iacovides, H.; Cioncolini, A.; Khurshid, I.; Nasser, A. Thermal-Hydraulic Analysis of Parabolic Trough Collectors Using Straight Conical Strip Inserts with Nanofluids. J. Nanomat. 2021, 11, 853. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A.; Worek, W.M. Solar Engineering of Thermal Processes, 2nd ed. J. Sol. Energy Eng. 1994, 116, 67–68. [Google Scholar] [CrossRef]

- Forristall, R. Heat Transfer Analysis and Modeling of a Parabolic Trough Solar Receiver Implemented in Engineering Equation Solver; National Renewable Energy Lab.: Golden, CO, USA, 2003. [Google Scholar]

- Rostami, S.; Shahsavar, A.; Kefayati, G.; Goldanlou, A.S. Energy and Exergy Analysis of Using Turbulator in a Parabolic Trough Solar Collector Filled with Mesoporous Silica Modified with Copper Nanoparticles Hybrid Nanofluid. Energies 2020, 13, 2946. [Google Scholar] [CrossRef]

- Toghyani, S.; Baniasadi, E.; Afshari, E. Thermodynamic analysis and optimization of an integrated Rankine power cycle and nano-fluid based parabolic trough solar collector. Energy Convers. Manag. 2016, 121, 93–104. [Google Scholar] [CrossRef]

- Allouhi, A.; Amine, M.B.; Saidur, R.; Kousksou, T.; Jamil, A. Energy and exergy analyses of a parabolic trough collector operated with nanofluids for medium and high temperature applications. Energy Convers. Manag. 2018, 155, 201–217. [Google Scholar] [CrossRef] [Green Version]

- Khullar, V.; Tyagi, H.; Phelan, P.E.; Otanicar, T.; Singh, H.; Taylor, R.A. Solar Energy Harvesting Using Nanofluids-Based Concentrating Solar Collector. J. Nanotechnol. Eng. Med. 2012, 3, 031003. [Google Scholar] [CrossRef]

- Mwesigye, A.; Yılmaz, I.H.; Meyer, J.P. Numerical analysis of the thermal and thermodynamic performance of a parabolic trough solar collector using SWCNTs-Therminol®VP-1 nanofluid. Renew. Energy 2018, 119, 844–862. [Google Scholar] [CrossRef] [Green Version]

- Benabderrahmane, A.; Benazza, A.; Aminallah, M.; Laouedj, S. Heat transfer behaviors in parabolic trough solar collector tube with compound technique. Int. J. Sci. Res. Eng. Technol. 2016, 5, 568–575. [Google Scholar]

- Mwesigye, A.; Huan, Z.; Meyer, J.P. Thermal performance and entropy generation analysis of a high concentration ratio parabolic trough solar collector with Cu-Therminol® VP-1 nanofluid. J. Energy Convers. Manag. 2016, 120, 449–465. [Google Scholar] [CrossRef] [Green Version]

- Okonkwo, E.C.; Abid, M.; Ratlamwala, T.A.H. Numerical Analysis of Heat Transfer Enhancement in a Parabolic Trough Collector Based on Geometry Modifications and Working Fluid Usage. J. Sol. Energy Eng. 2018, 140, 051009. [Google Scholar] [CrossRef]

- Mwesigye, A.; Meyer, J.P. Optimal thermal and thermodynamic performance of a solar parabolic trough receiver with different nanofluids and at different concentration ratios. J. Appl. Energy 2017, 193, 393–413. [Google Scholar] [CrossRef] [Green Version]

- Kasaiean, A.; Sameti, M.; Daneshazarian, R.; Noori, Z.; Adamian, A.; Ming, T. Heat transfer network for a parabolic trough collector as a heat collecting element using nanofluid. Renew. Energy 2018, 123, 439–449. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Thermal efficiency enhancement of nanofluid-based parabolic trough collectors. J. Therm. Anal. Calorim. 2018, 135, 597–608. [Google Scholar] [CrossRef]

- Basbous, N.; Taqi, M.; Janan, M.A. Thermal performances analysis of a parabolic trough solar collector using different nanofluids. In Proceedings of the 2016 International Renewable and Sustainable Energy Conference (IRSEC), Marrakesh, Morocco, 14–17 November 2016; pp. 322–326. [Google Scholar]

- Bellos, E.; Tzivanidis, C. Parametric investigation of nanofluids utilization in parabolic trough collectors. Therm. Sci. Eng. Prog. 2017, 2, 71–79. [Google Scholar] [CrossRef]

- Al-Oran, O.; Lezsovits, F.; Aljawabrah, A. Exergy and energy amelioration for parabolic trough collector using mono and hybrid nanofluids. J. Therm. Anal. Calorim. 2020, 140, 1579–1596. [Google Scholar] [CrossRef] [Green Version]

- Bellos, E.; Tzivanidis, C. Thermal analysis of parabolic trough collector operating with mono and hybrid nanofluids. Sustain. Energy Technol. Assess. 2018, 26, 105–115. [Google Scholar] [CrossRef]

- Dudley, V.E.; Evans, L.R.; Matthews, C.W. Test results, Industrial Solar Technology Parabolic trough Solar Collector; Sandia National Labs.: Albuquerque, NM, USA, 1995. [Google Scholar]

- Giwa, S.O.; Sharifpur, M.; Goodarzi, M.; Alsulami, H.; Meyer, J.P. Influence of base fluid, temperature, and concentration on the thermophysical properties of hybrid nanofluids of alumina-ferrofluid: Experimental data, modeling through enhanced ANN, ANFIS, and curve fitting. J. Therm. Anal. Calorim. 2021, 143, 4149–4167. [Google Scholar] [CrossRef]

- Sharafeldin, M.; Gróf, G. Efficiency of evacuated tube solar collector using WO3/Water nanofluid. Renew. Energy 2019, 134, 453–460. [Google Scholar] [CrossRef]

- Al-Oran, O.; Lezsovits, F. Enhance thermal efficiency of parabolic trough collector using Tungsten oxide/Syltherm 800 nanofluid. Pollack Period. 2020, 15, 187–198. [Google Scholar] [CrossRef]

- Coccia, G.; Di Nicola, G.; Colla, L.; Fedele, L.; Scattolini, M. Adoption of nanofluids in low-enthalpy parabolic trough solar collectors: Numerical simulation of the yearly yield. Energy Convers. Manag. 2016, 118, 306–319. [Google Scholar] [CrossRef]

- Mokheimer, E.M.; Dabwan, Y.N.; Habib, M.A.; Said, S.A.; Al-Sulaiman, F.A. Techno-economic performance analysis of parabolic trough collector in Dhahran, Saudi Arabia. Energy Convers. Manag. 2014, 86, 622–633. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Analytical Expression of Parabolic Trough Solar Collector Performance. J. Des. 2018, 2, 9. [Google Scholar] [CrossRef] [Green Version]

- Minea, A.A. Hybrid nanofluids based on Al2O3, TiO2 and SiO2: Numerical evaluation of different approaches. Int. J. Heat Mass Transf. 2017, 104, 852–860. [Google Scholar] [CrossRef]

- Khan, M.S.; Abid, M.; Bashir, M.A.; Amber, K.P.; Khanmohammadi, S.; Yan, M. Thermodynamic and exergoeconomic analysis of a novel solar-assisted multigenerational system utilizing high temperature phase change material and hybrid nanofluid. Energy Convers. Manag. 2021, 236, 113948. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. A detailed exergetic analysis of parabolic trough collectors. Energy Convers. Manag. 2017, 149, 275–292. [Google Scholar] [CrossRef]

- Petela, R. Exergy of undiluted thermal radiation. Sol. Energy 2003, 74, 469–488. [Google Scholar] [CrossRef]

- Incropera, F.P.; Lavine, A.S.; Bergman, T.L.; De Witt, D.P. Fundamentals of Heat and Mass Transfer; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Minea, A.A.; Buonomo, B.; Burggraf, J.; Ercole, D.; Karpaiya, K.R.; Di Pasqua, A.; Sekrani, G.; Steffens, J.; Tibaut, J.; Wichmann, N.; et al. NanoRound: A benchmark study on the numerical approach in nanofluids’ simulation. Int. Commun. Heat Mass Transf. 2019, 108, 104292. [Google Scholar] [CrossRef]

- Takabi, B.; Salehi, S. Augmentation of the Heat Transfer Performance of a Sinusoidal Corrugated Enclosure by Employing Hybrid Nanofluid. Adv. Mech. Eng. 2014, 6, 147059. [Google Scholar] [CrossRef]

- Rasih, R.A.; Sidik, N.A.C.; Samion, S. Recent progress on concentrating direct absorption solar collector using nanofluids. J. Therm. Anal. Calorim. 2019, 137, 903–922. [Google Scholar] [CrossRef]

- Bozorg, M.V.; Doranehgard, M.H.; Hong, K.; Xiong, Q. CFD study of heat transfer and fluid flow in a parabolic trough solar receiver with internal annular porous structure and synthetic oil–Al2O3 nanofluid. Renew. Energy 2020, 145, 2598–2614. [Google Scholar] [CrossRef]

- Abdullatif, Y.M.; Okonkwo, E.C.; Al-Ansari, T. Thermal Performance Optimization of a Parabolic Trough Collector Operating with Various Working Fluids Using Copper Nanoparticles. J. Therm. Sci. Eng. Appl. 2021, 13, 1–35. [Google Scholar] [CrossRef]

- Brinkman, H.C. The Viscosity of Concentrated Suspensions and Solutions. J. Chem. Phys. 1952, 20, 571. [Google Scholar] [CrossRef]

- Abed, N.; Afgan, I.; Cioncolini, A.; Iacovides, H.; Nasser, A. Assessment and Evaluation of the Thermal Performance of Various Working Fluids in Parabolic trough Collectors of Solar Thermal Power Plants under Non-Uniform Heat Flux Distribution Conditions. Energies 2020, 13, 3776. [Google Scholar] [CrossRef]

- Tagle-Salazar, P.D.; Nigam, K.; Rivera-Solorio, C.I. Heat transfer model for thermal performance analysis of parabolic trough solar collectors using nanofluids. Renew. Energy 2018, 125, 334–343. [Google Scholar] [CrossRef]

- Ehyaei, M.; Ahmadi, A.; Assad, M.E.H.; Hachicha, A.; Said, Z. Energy, exergy and economic analyses for the selection of working fluid and metal oxide nanofluids in a parabolic trough collector. Sol. Energy 2019, 187, 175–184. [Google Scholar] [CrossRef]

| Author Ref. | PTC Model L,W/m do,di/ | Nanofluids | Max, Increase% | ||||

|---|---|---|---|---|---|---|---|

| mm | |||||||

| bf | np | φc | ηeff | ηex | h | ||

| Max | |||||||

| Allouhi et al. [31] | LS3 PTC | Therminol Vp-1 | TiO2, CuO, Al2O3 | 5% v | ~0% | 9% | 83% CuO |

| Khular et al. [32] | (7.84,5) (70,66) | Therminol Vp-1 | Al2O3 | 0.05% | ~10% | - | - |

| Mwesigye et al. [33] | (5,9) (80,76) | Therminol Vp-1 | SWCNT | 2.5% v | 4.4% | 234% | |

| Benabderrahmane et al. [34] | (2,-) (32,35) | Therminol Vp-1 | CNT | 1% v | - | - | - |

| Mwesigye et al. [35] | (5,9) (80,76) | Therminol Vp-1 | Cu | 0–6% v | 12.5% | - | 32% |

| Okonkwo et al. [36] | LS2 | Therminol Vp-1 | Fe2O4, CuO, Al2O3 | 3% v | 0.22% Al2O3 | - | - |

| Mwesigye et al. [37] | (5,7–9) (80,76) | Therminol Vp-1 | Ag, Cu, Al2O3 | 0–6% v | 13.9% | - | 7.9% |

| Kasaiean et al. [38] | (2,0.7) (28,26) | Thermal-oil | MWCNT | 6% v | 0.5% | - | 15% |

| Bellos and Tzivanidis [39] | LS2 PTC | Syltherm-800 | CuO, Cu, Fe2O3, TiO2, Al2O3, SiO2 | 6% v | 2.2% Cu | - | ~24% Cu |

| Basbous et al. [40] | LS2 PTC | Syltherm-800 | CuO, Cu, Ag, Al2O3 | 5% v | - | - | 36% Ag |

| Bellos and Tzivanidis [41] | Euro trough ET-150 | Syltherm-800 | CuO, Al2O3 | 4% v | 1.26% CuO | - | 40.9% |

| Al-Oran et al. [42] | LS2 PTC | Syltherm-800 | CeO2, Al2O3, CuO, CeO2 + Al2O3, CuO + Al2O3 | 4% v | 1.09% CeO2 + Al2O3 | 1.03% CeO2 + Al2O3 | 200.7% CeO2 + Al2O3 |

| Bellos and Tzivanidis [43] | LS2 PTC | Syltherm-800 | Tio2, Al2O3/Hybrid | 3% v | Mono 0.7% Hyb 1.8% | - | Mono 56% Hyb 204% |

| LS2 Parameter [Symbols] | Specifications | Parameter [Symbols] | Specifications |

|---|---|---|---|

| Length of the PTC [L] | 7.8 m | Emittance of glass cover [εc] | 0.9 |

| Aperture width of the PTC [Wa] | 5 m | Max optical efficiency [ηopt] | 74.5% |

| Aperture area [Aa] | 39 m2 | Glass cover absorbance [αc] | 0.02 |

| Absorber inner diameter [dri] | 0.066 m | Glass cover transmittance [τc] | 0.95 |

| Absorber outer diameter [dro] | 0.07 m | Absorber absorbance [αr] | 0.96 |

| Glass inner diameter [dci] | 0.115 m | Concentrator reflectance [ρc] | 0.94 |

| Glass outer diameter [dco] | 0.121 m | Intercept factor [γ] | 0.93 |

| Emittance of the absorber [εr] | 0.2 | Concentration ratio [C] | 22.74 |

| Parameter | Symbols | Case (1) | Case (2) | |

|---|---|---|---|---|

| Radiation intensity | Gb | 1000 W/m2 | Summer | Winter |

| 880 | 260 | |||

| Surrounding convection | hout | 10 W/m2·K | 10 W/m2·K | |

| Ambient temperature | Tamb | 300 K | Variable with time | |

| Inlet temperature | Tin | 300 K–600 K | 500 K | |

| Volume flow rate | Vflow | 150 L/min | 150 L/min | |

| Nanoparticle volume fractions | φ | 0–4% | 0–4% | |

| Symbols | Definition |

|---|---|

| K1 | |

| K2 | |

| K3 | |

| K4 | |

| K5 | |

| Property/Nanoparticles | Aluminum Oxide Nanoparticle Al2O3 | Tungsten Oxide Nanoparticle WO3 |

|---|---|---|

| Specific heat Cpnp/J·kg−1 K−1 | 765 | 315.4 |

| Density ρnp/kg m−3 | 3970 | 7160 |

| Thermal conductivity knp/W m−1 K−1 | 40 | 16 |

| Cases | Gb (W/m2) | Tamb (C) | Tin (C) | Vf (L/min) | Tout (C) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dudley [21] | Model | Deviation % | Dudley [21] | Model | Deviation % | |||||

| 1 | 933.7 | 21.2 | 102 | 47.7 | 124 | 124.36 | 0.29 | 72.51 | 73.6 | 1.51 |

| 2 | 968.2 | 22.4 | 151 | 47.8 | 173 | 174.04 | 0.6 | 72.1 | 72.91 | 1.13 |

| 3 | 962.3 | 24.3 | 197 | 49.1 | 219 | 219.28 | 0.13 | 71.6 | 72.06 | 0.65 |

| 4 | 909.5 | 26.2 | 250 | 54.7 | 259 | 268.99 | 3.86 | 70.4 | 70.74 | 0.48 |

| 5 | 937.9 | 28.8 | 297 | 55.5 | 316 | 316.52 | 0.16 | 69.1 | 69.3 | 0.29 |

| 6 | 880.6 | 27.5 | 299 | 55.6 | 317 | 317.24 | 0.08 | 68.7 | 68.99 | 0.42 |

| 7 | 920.9 | 29.5 | 379 | 56.8 | 398 | 398.43 | 0.11 | 64.8 | 65.64 | 1.02 |

| 8 | 903.2 | 31.1 | 355 | 56.3 | 374 | 373.92 | 0.02 | 66.1 | 66.63 | 0.8 |

| Mean | 0.64 | 0.78 | ||||||||

| Therminol VP1 | 1% | 2% | 3% | 4% | |

|---|---|---|---|---|---|

| 71.065 | 71.224 | 71.238 | 71.246 | 71.255 | |

| 63.528 | 63.66 | 63.672 | 63.682 | 63.688 | |

| 32.64 | 32.712 | 32.718 | 32.72 | 32.728 | |

| 30.65 | 30.718 | 30.724 | 30.728 | 30.732 | |

| W | 1306 | 1249 | 1245 | 1241 | 1239 |

| W | 25,300 | 25,357 | 25,360 | 25,365 | 25,371 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Oran, O.; Lezsovits, F. A Hybrid Nanofluid of Alumina and Tungsten Oxide for Performance Enhancement of a Parabolic Trough Collector under the Weather Conditions of Budapest. Appl. Sci. 2021, 11, 4946. https://doi.org/10.3390/app11114946

Al-Oran O, Lezsovits F. A Hybrid Nanofluid of Alumina and Tungsten Oxide for Performance Enhancement of a Parabolic Trough Collector under the Weather Conditions of Budapest. Applied Sciences. 2021; 11(11):4946. https://doi.org/10.3390/app11114946

Chicago/Turabian StyleAl-Oran, Otabeh, and Ferenc Lezsovits. 2021. "A Hybrid Nanofluid of Alumina and Tungsten Oxide for Performance Enhancement of a Parabolic Trough Collector under the Weather Conditions of Budapest" Applied Sciences 11, no. 11: 4946. https://doi.org/10.3390/app11114946