Evaluation of Heating Technique of Deformed Reinforcement Using High-Frequency Induction Heating System

Abstract

:1. Introduction

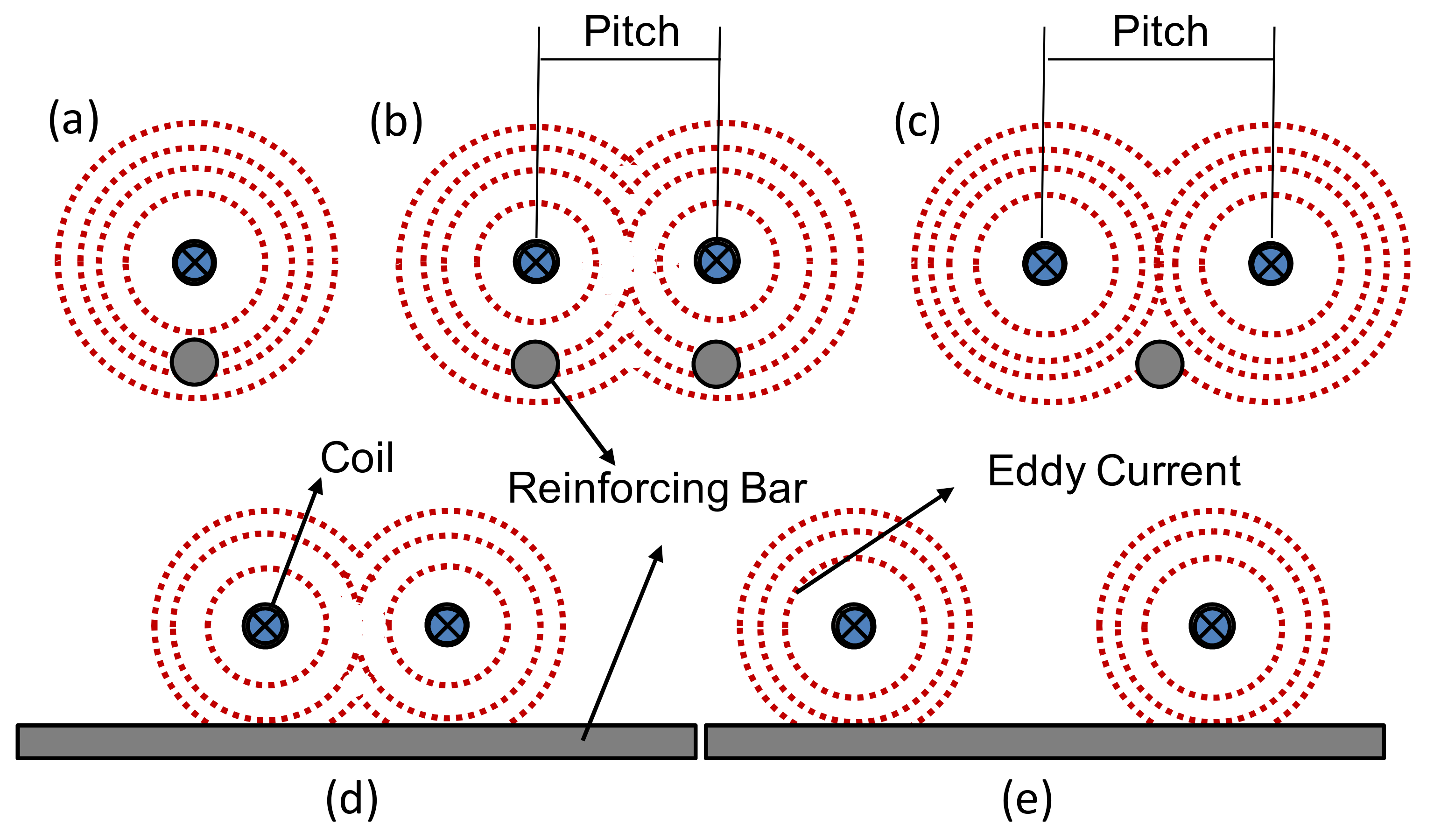

2. Heat Generation Model for Reinforcing Steel

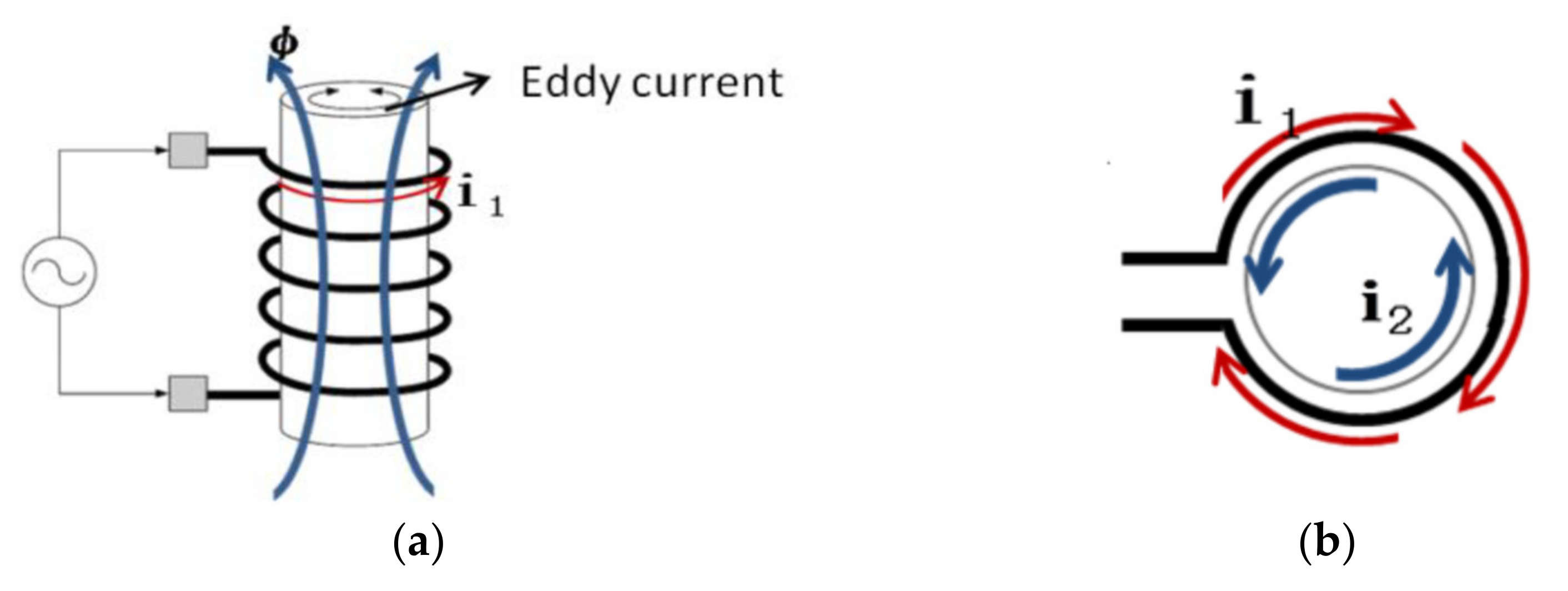

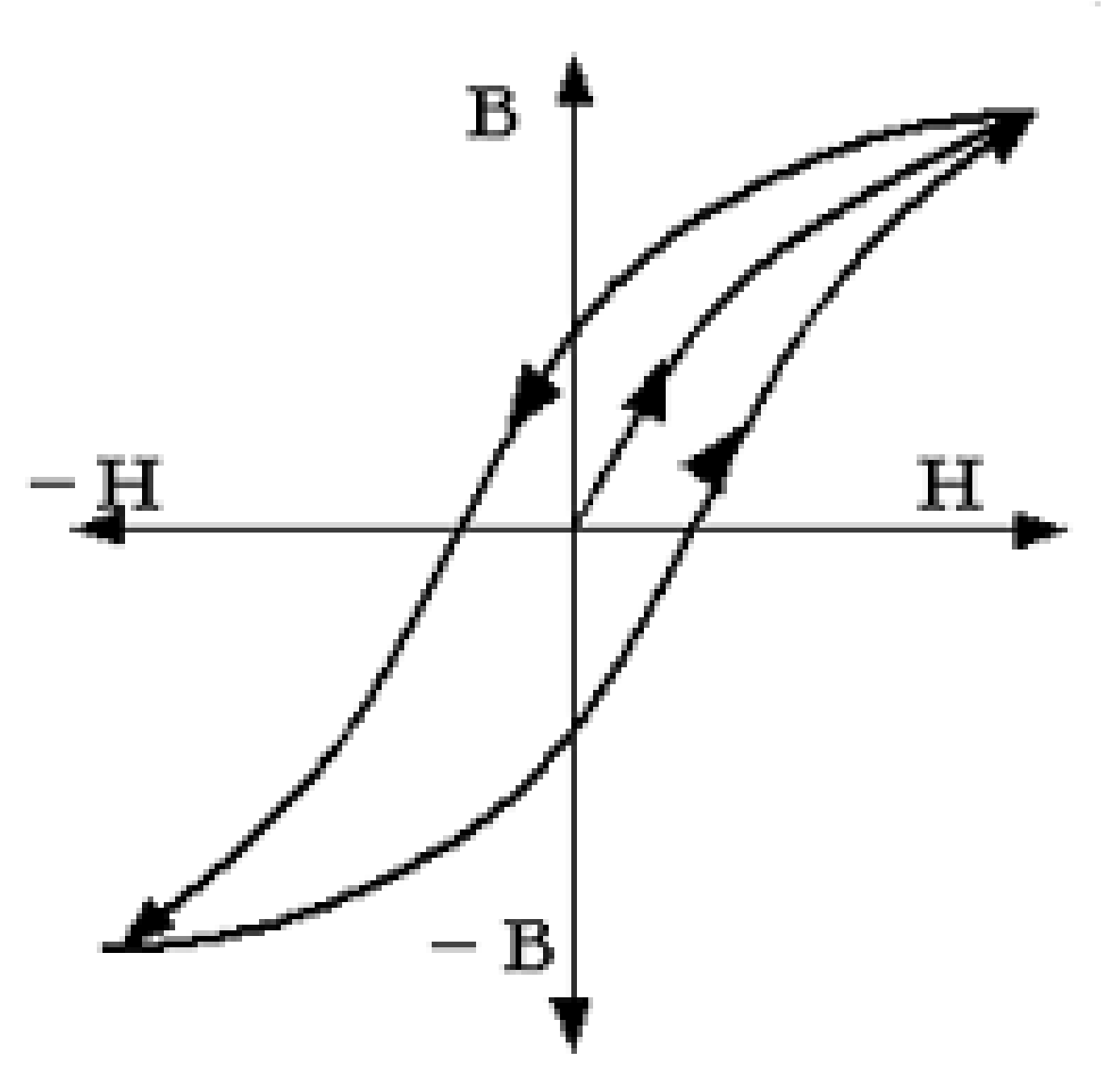

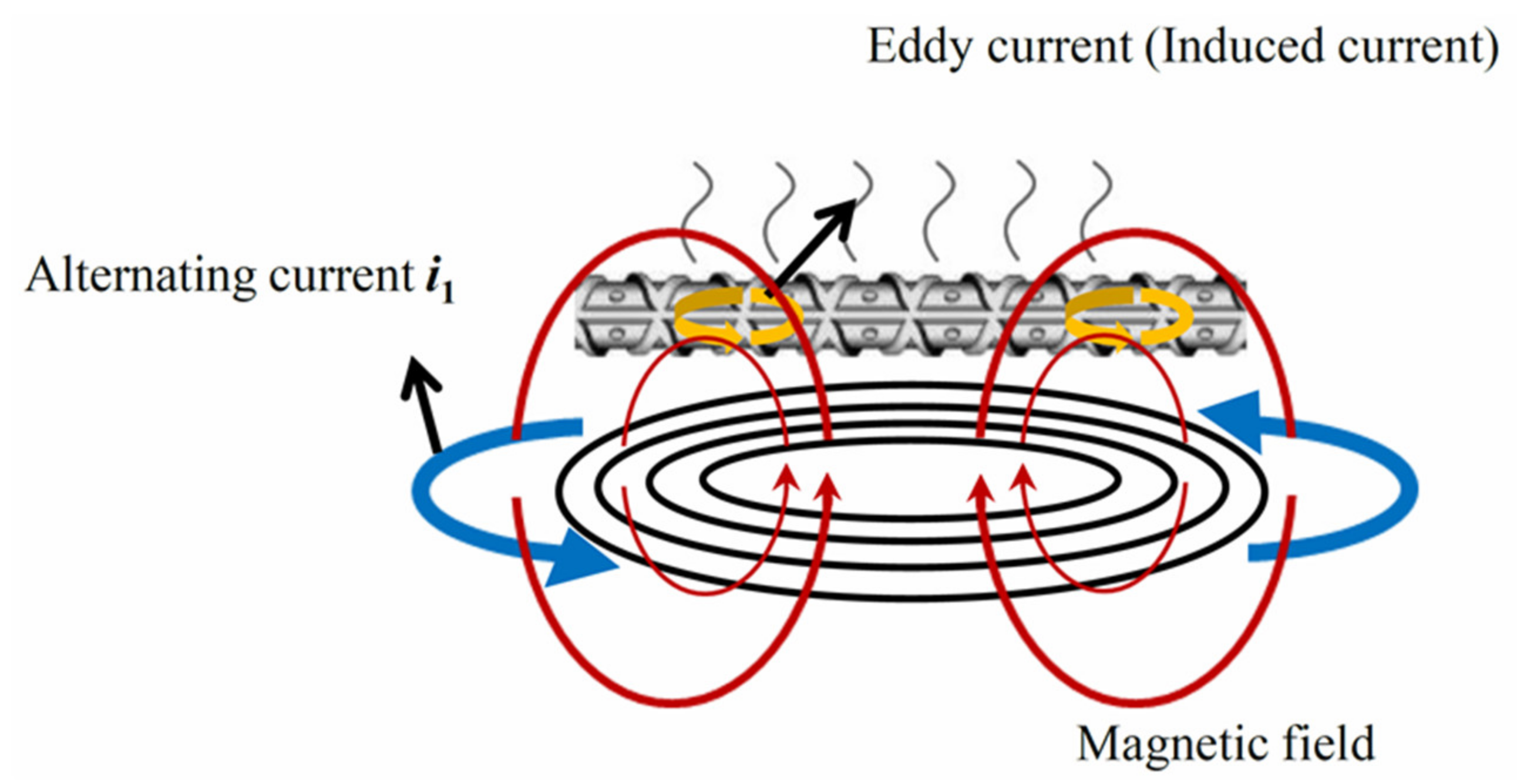

2.1. Definition and Mechanism of High-Frequency Induction Heating

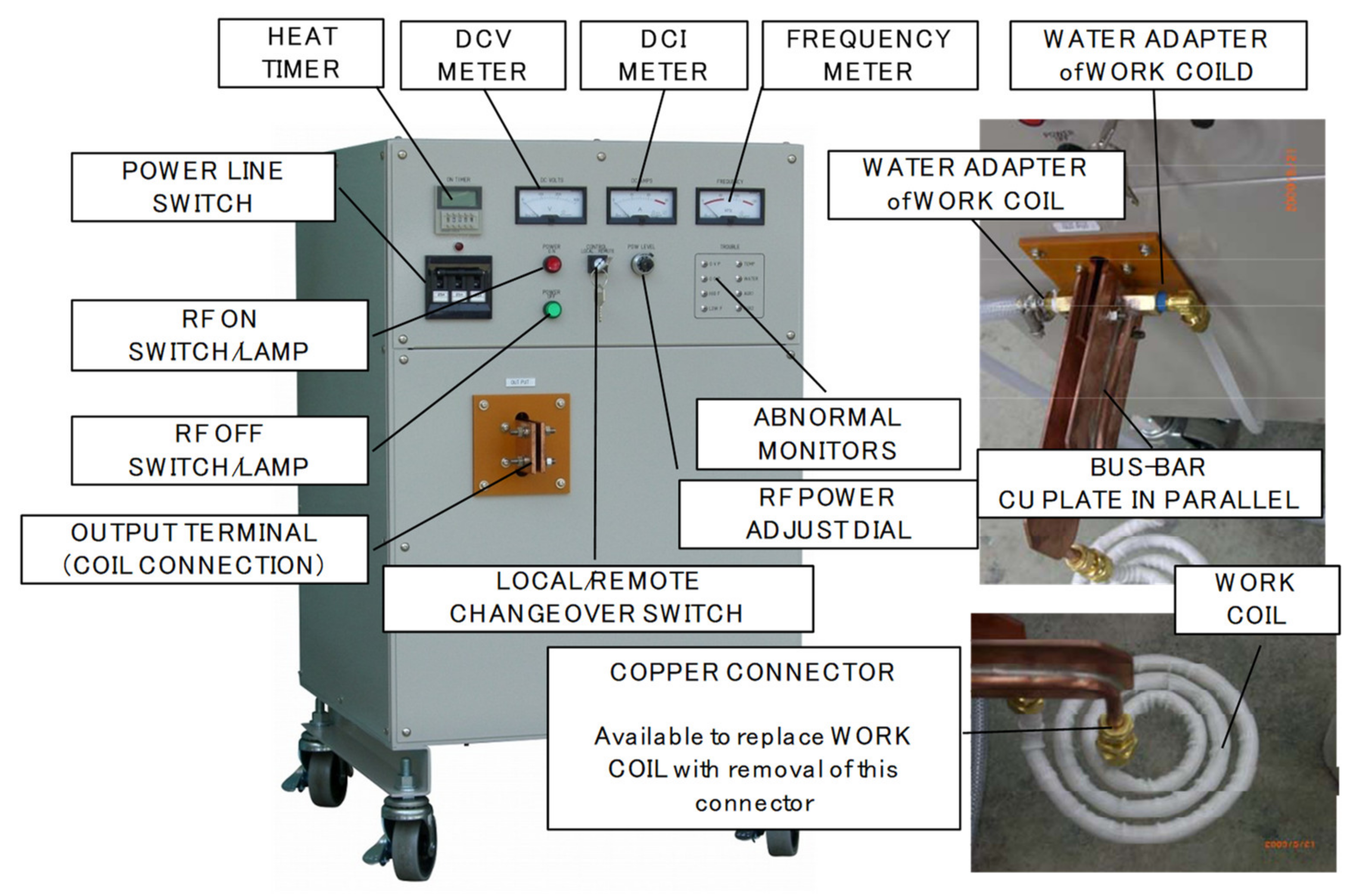

2.2. Heating Model of Reinforcement Using High-Frequency Induction Heating

3. Results and Investigation

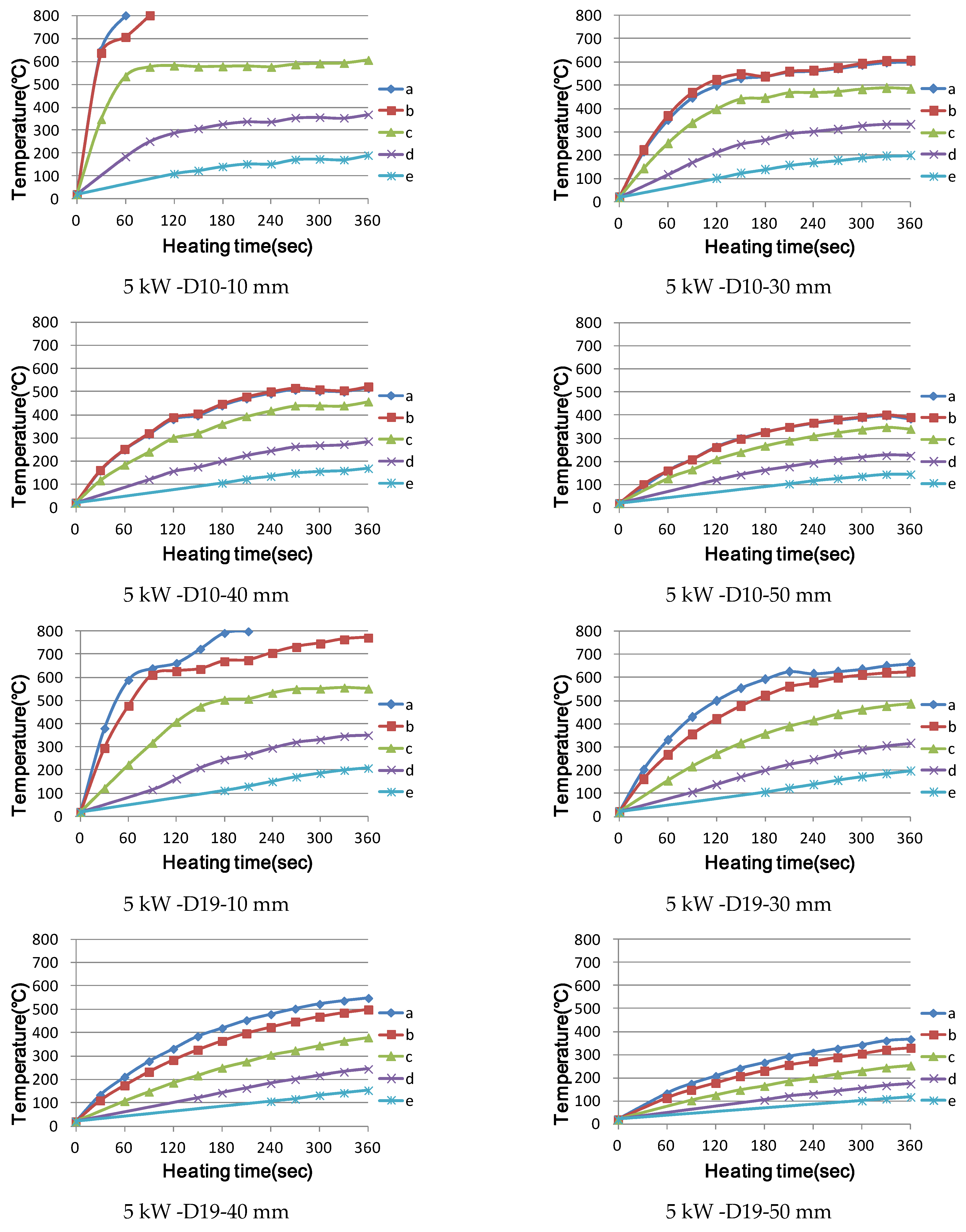

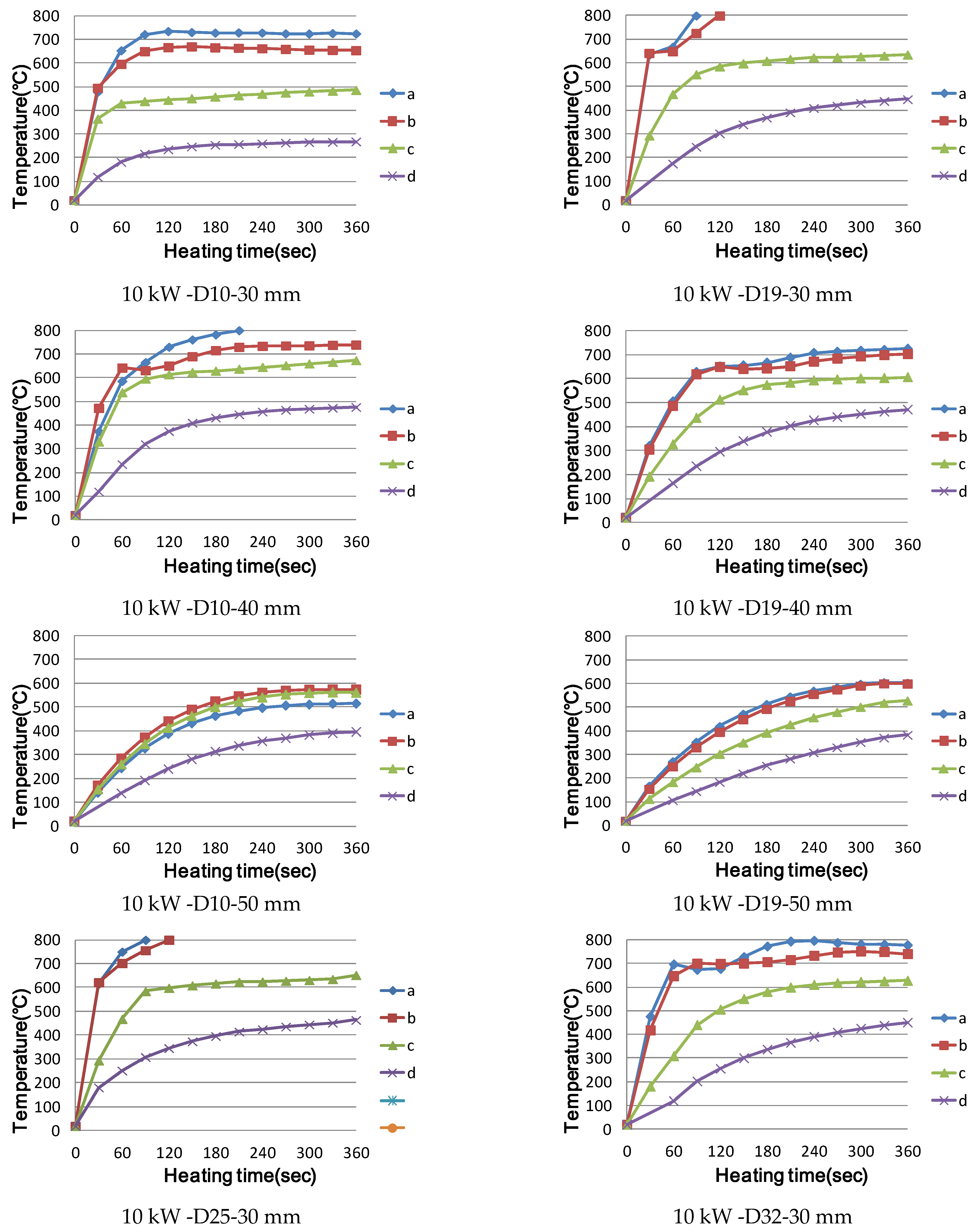

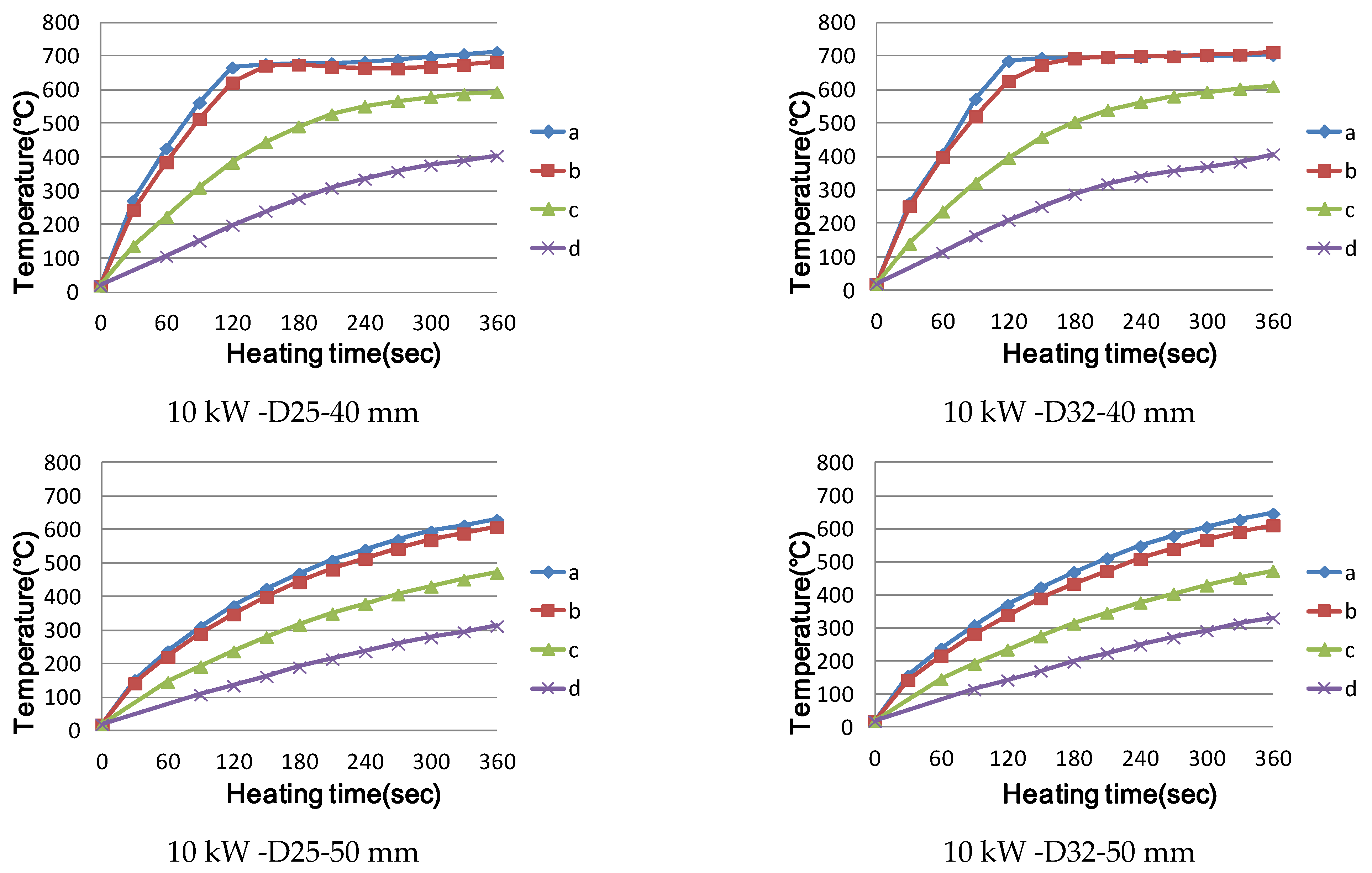

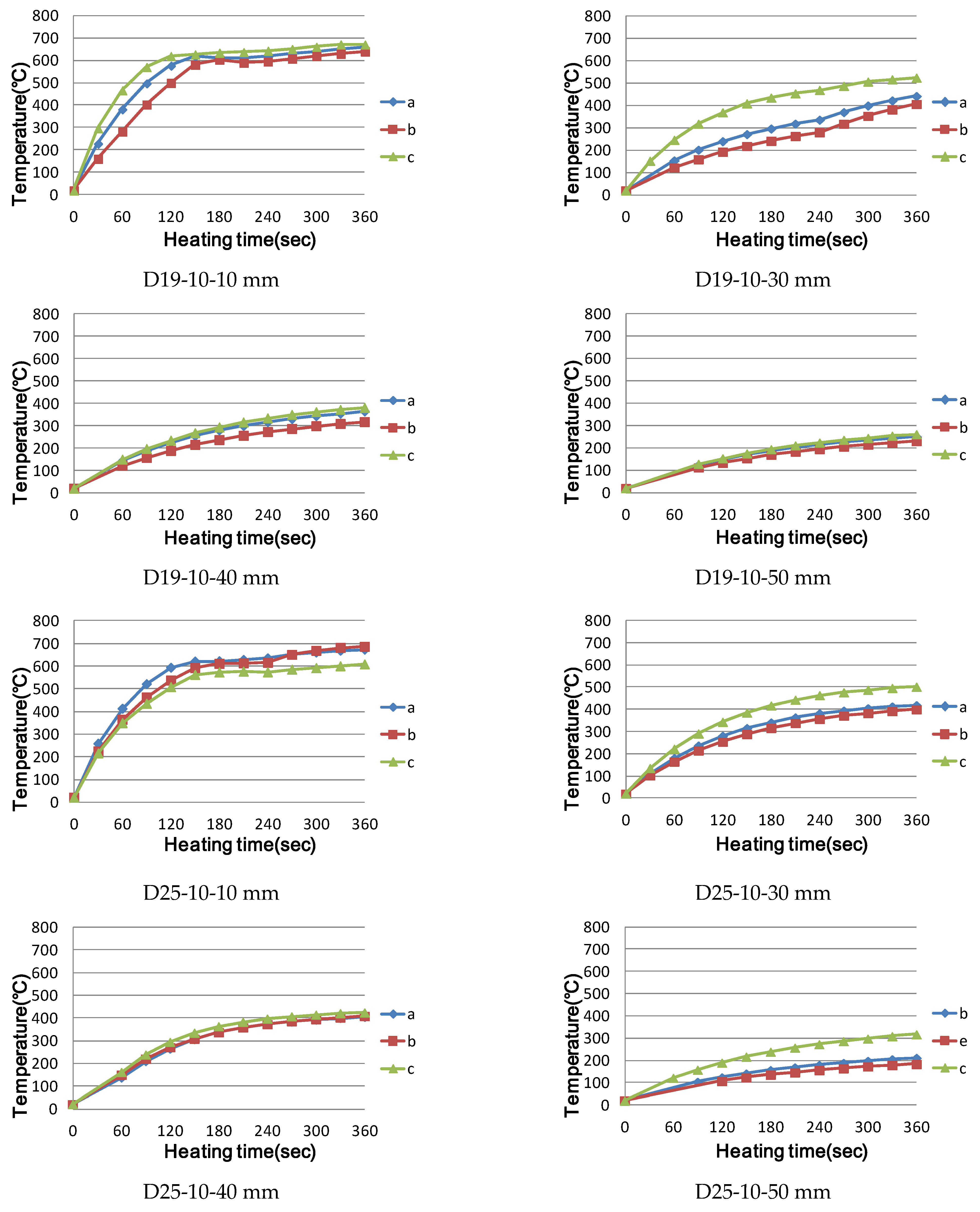

3.1. Temperature Characteristics of Single Reinforcement by Induction Heating

3.1.1. Materials Used

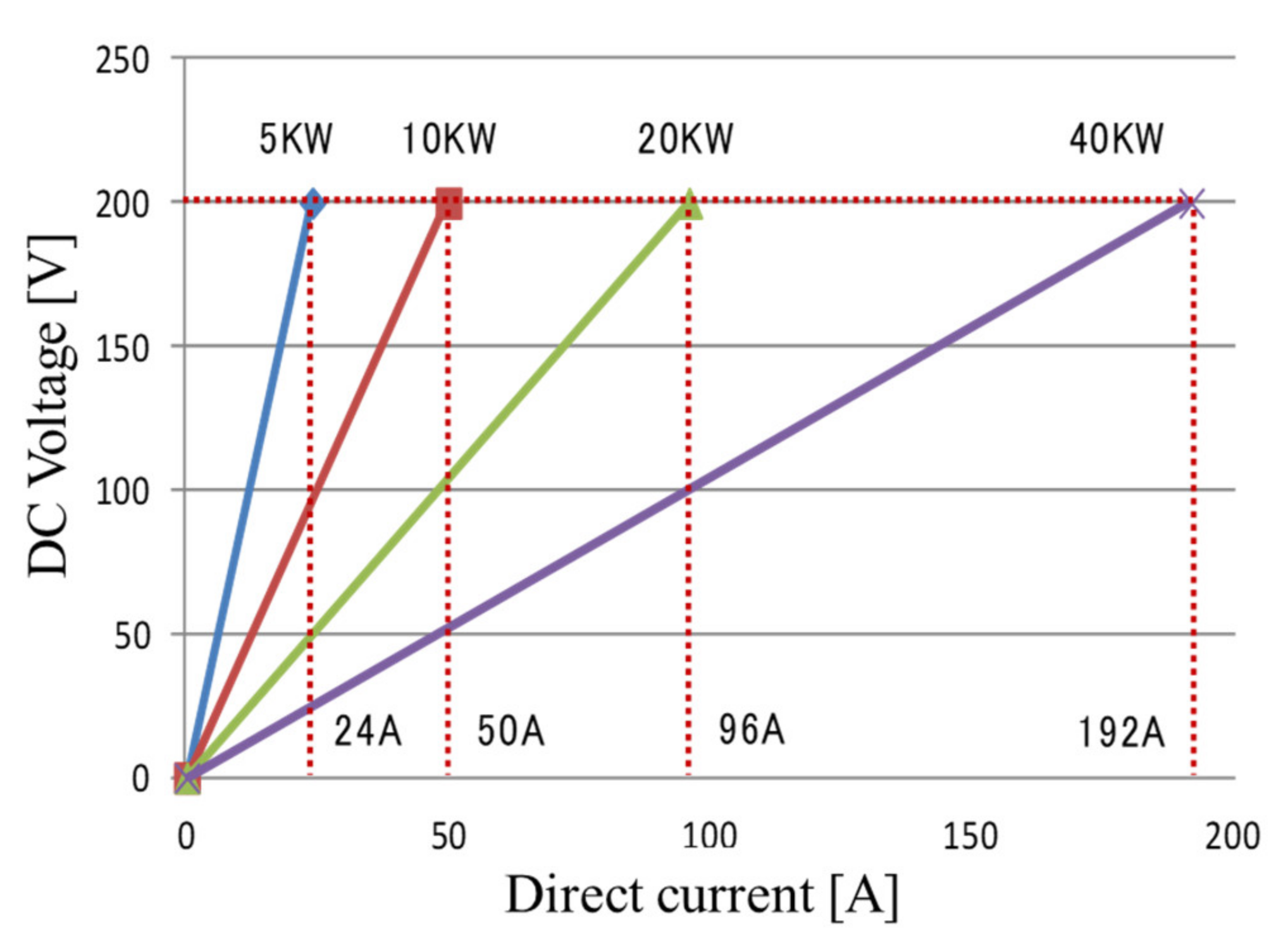

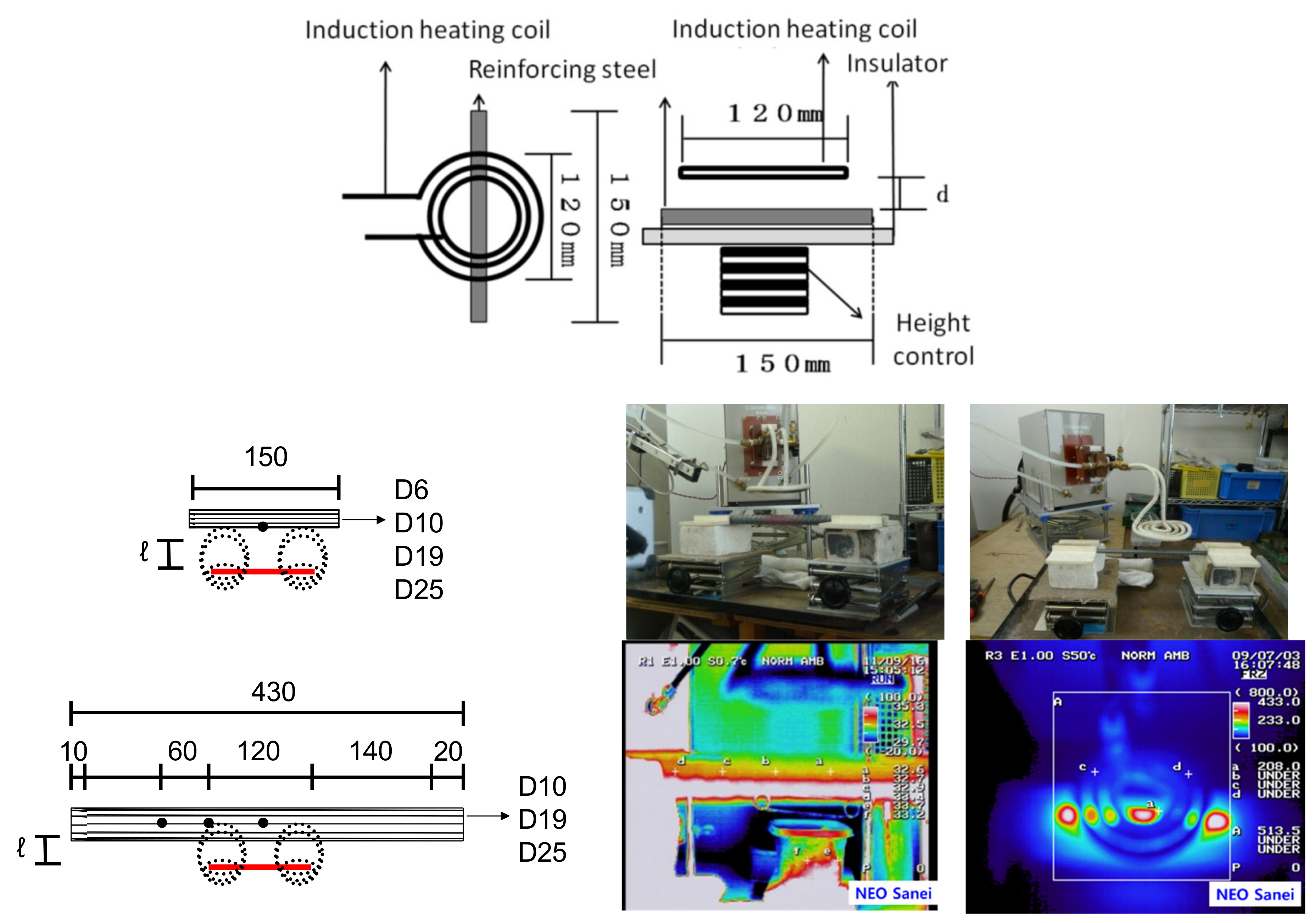

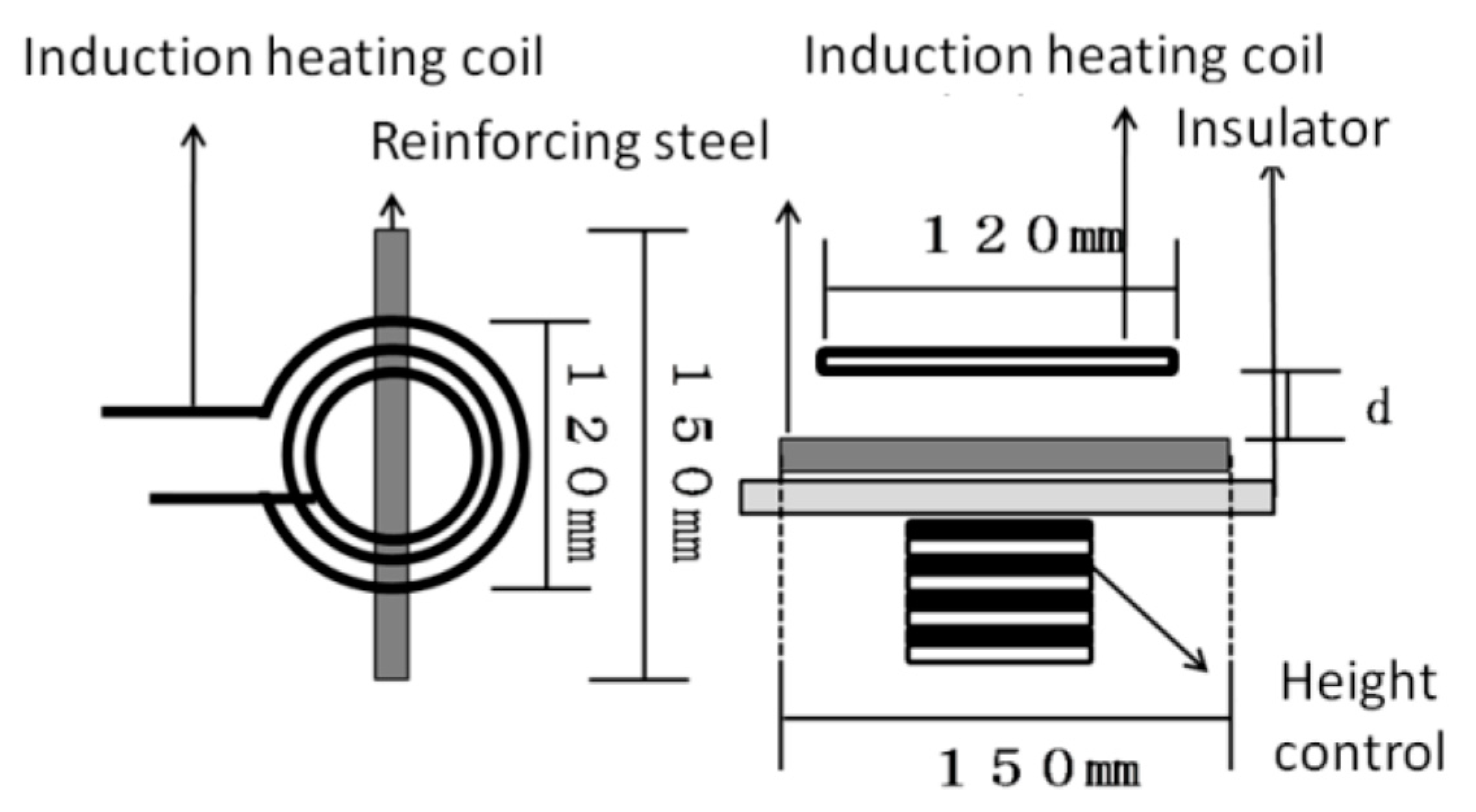

3.1.2. Experimental Methodology

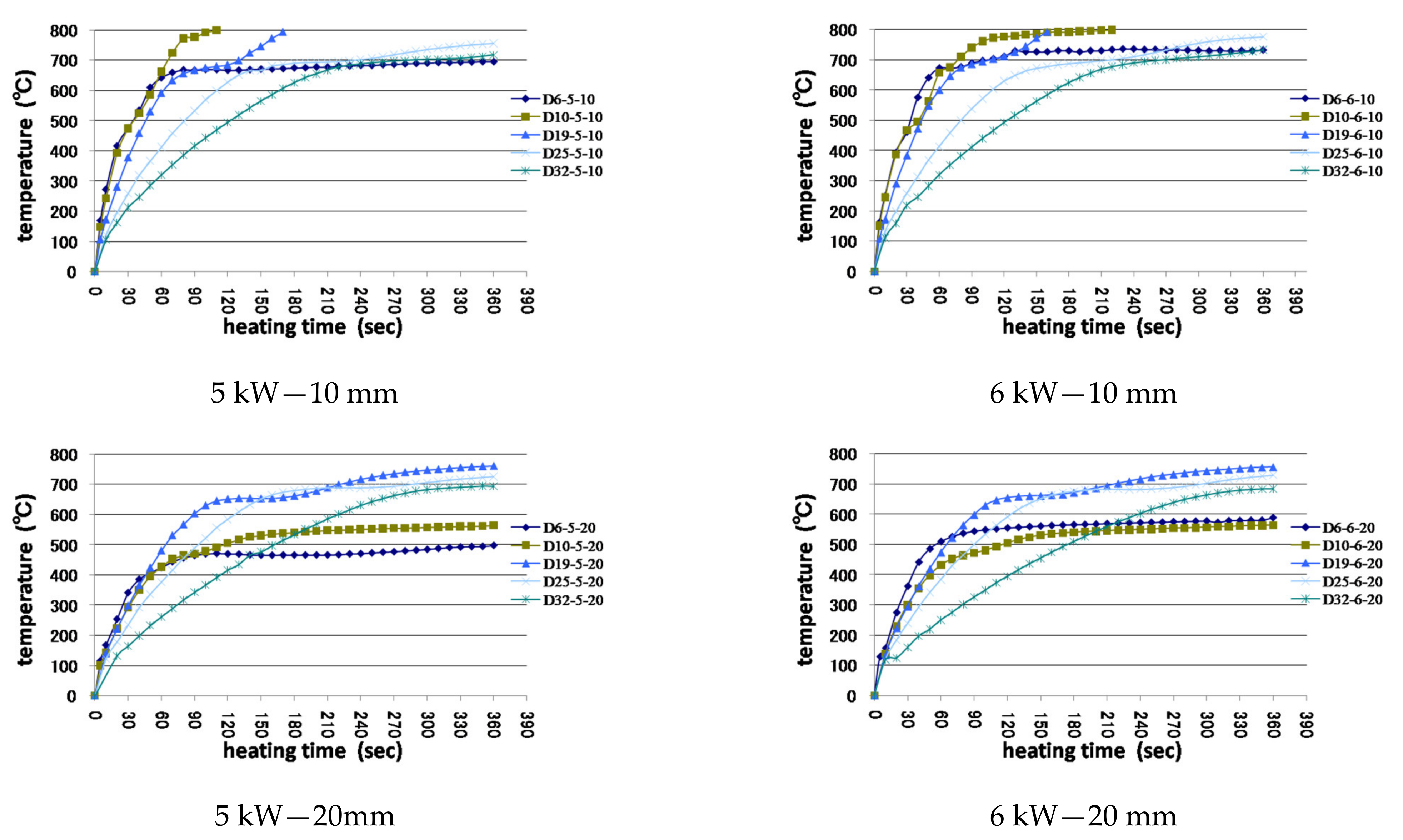

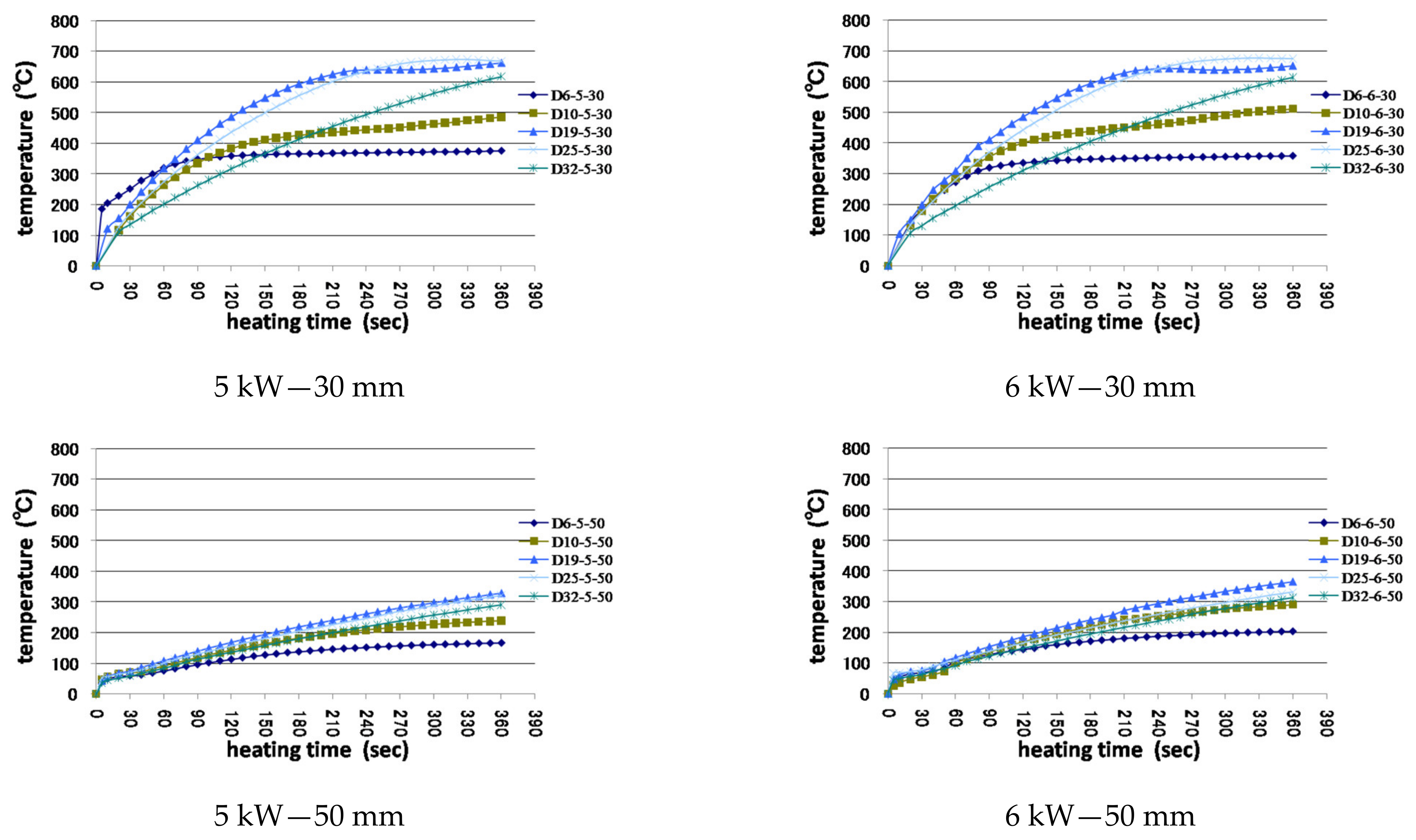

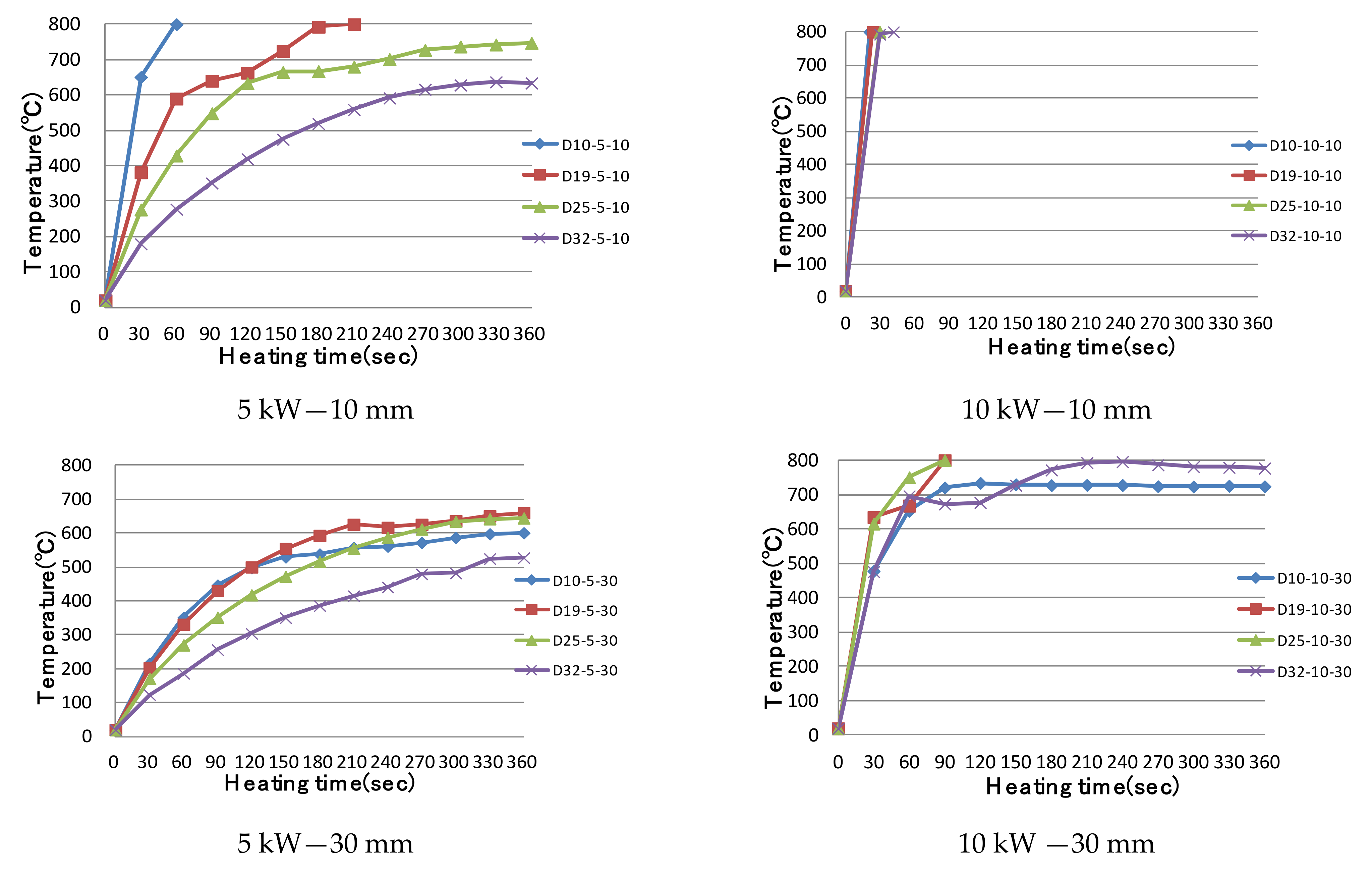

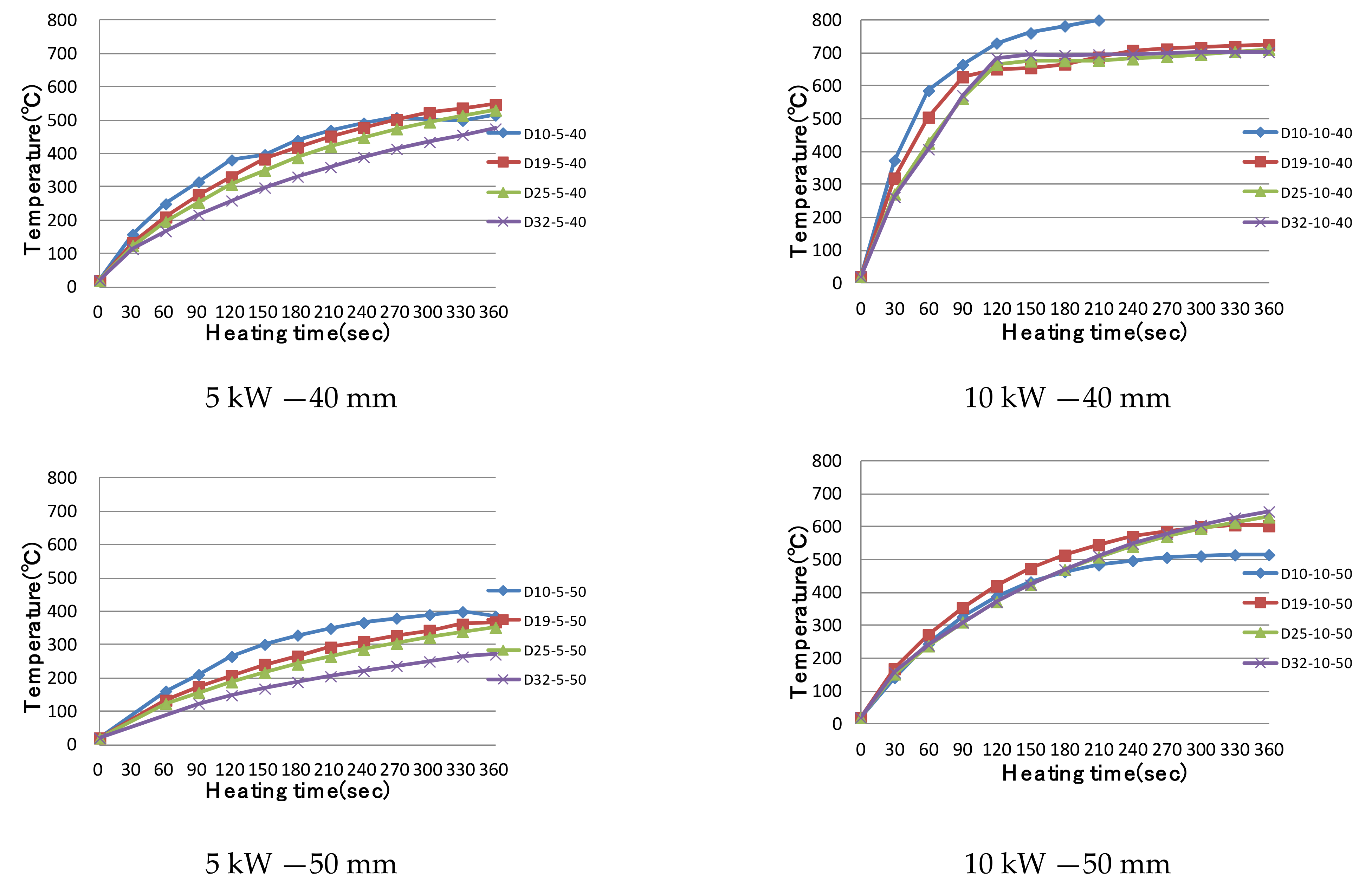

3.1.3. Experimental Results and Investigation

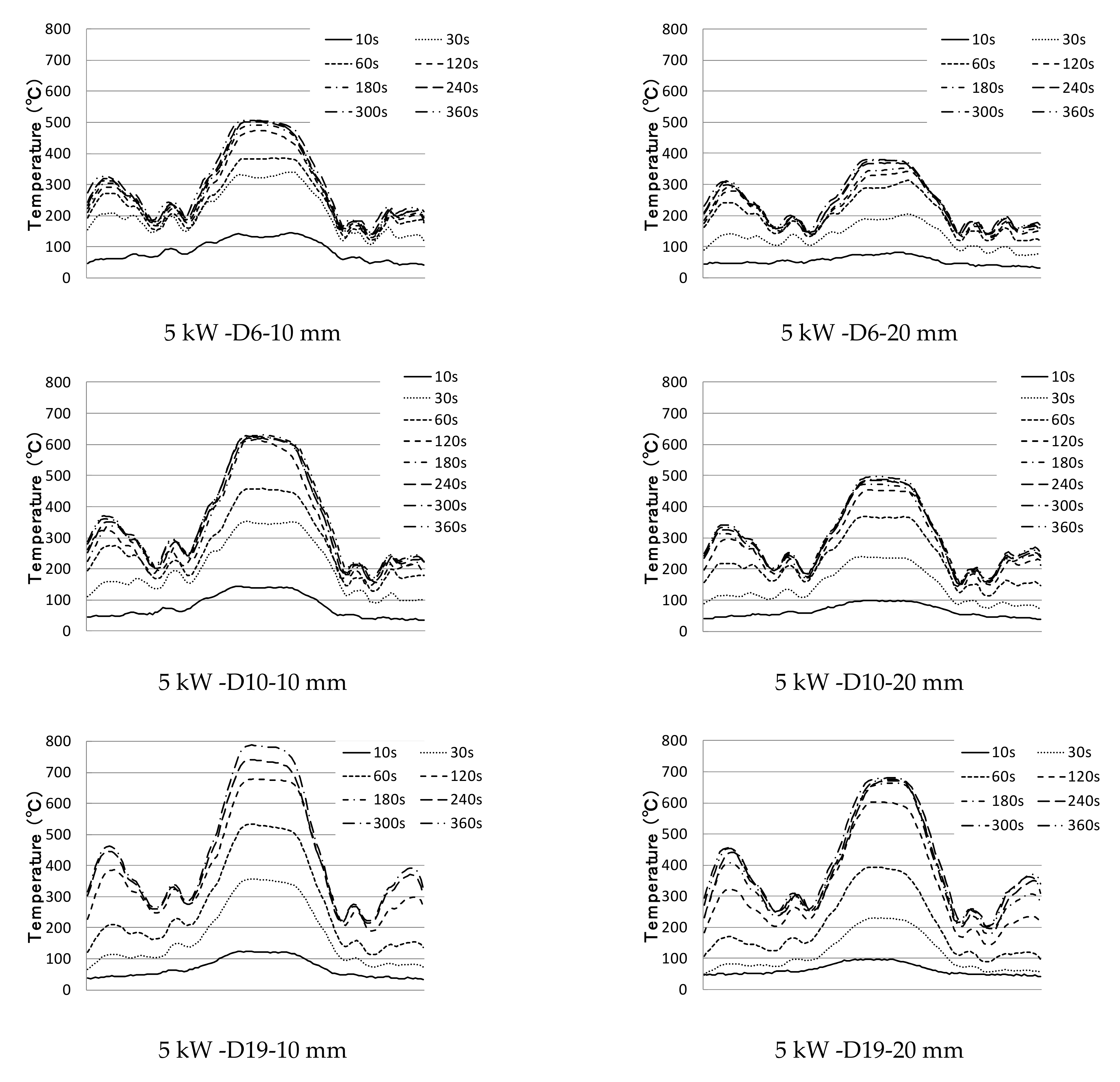

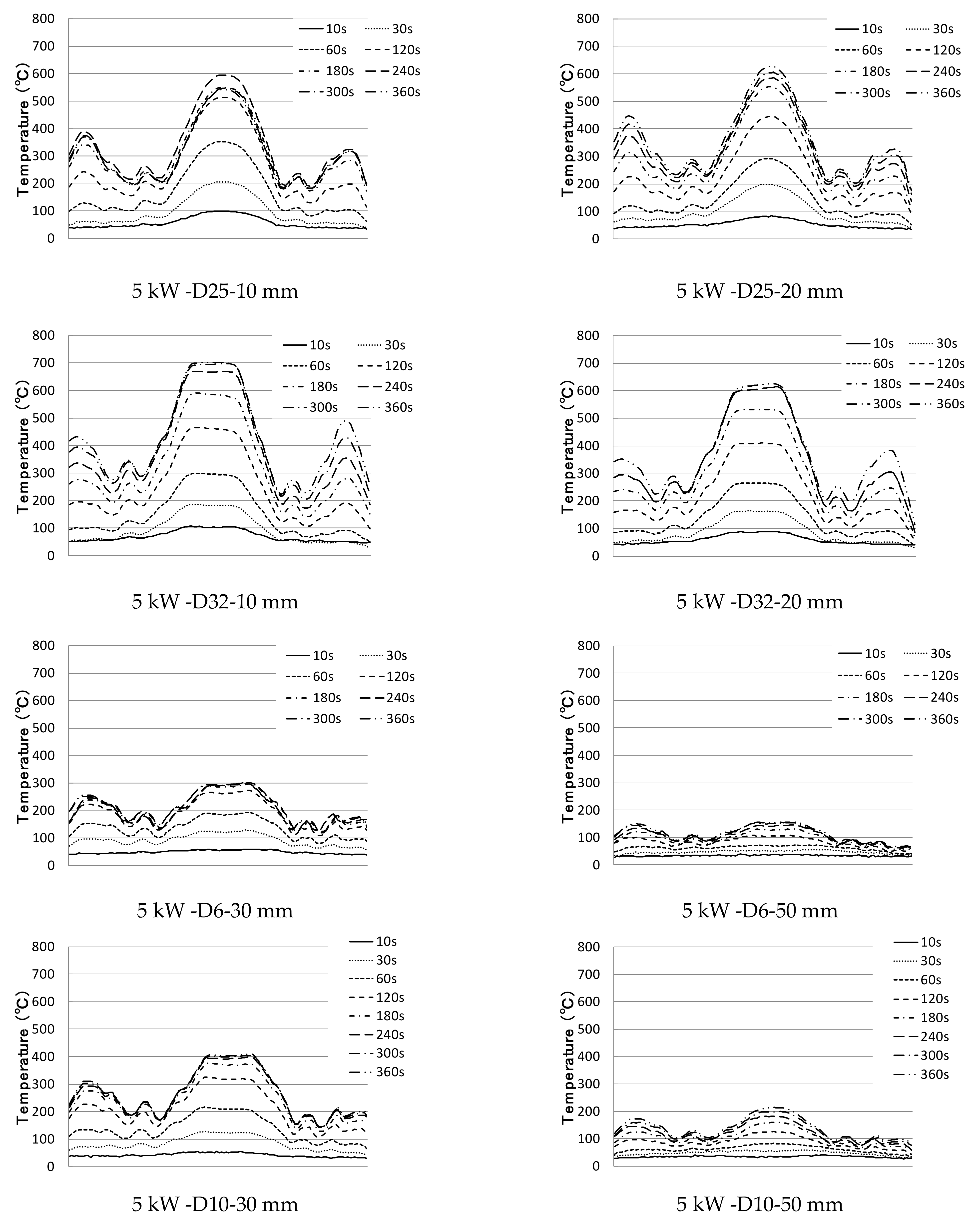

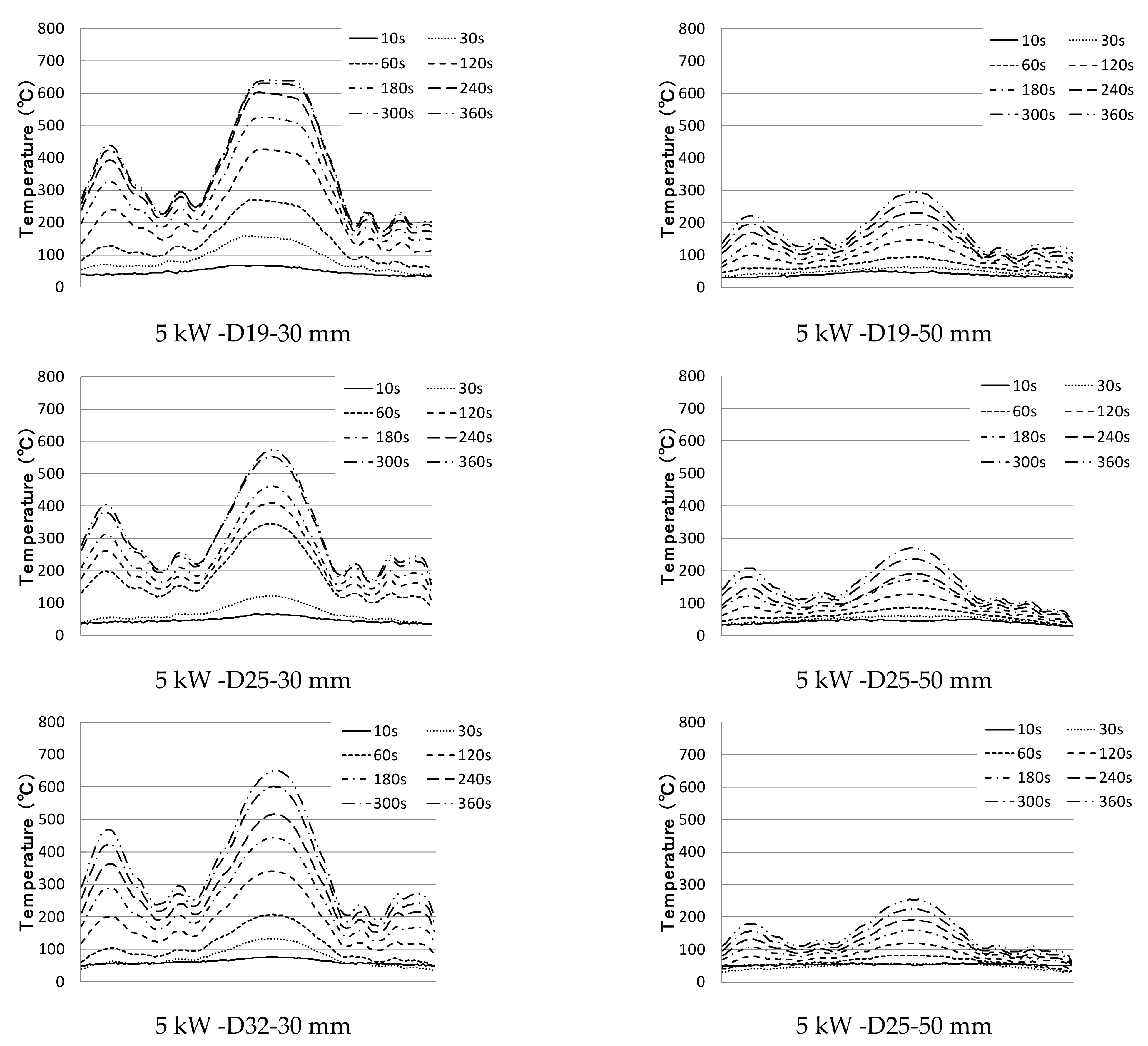

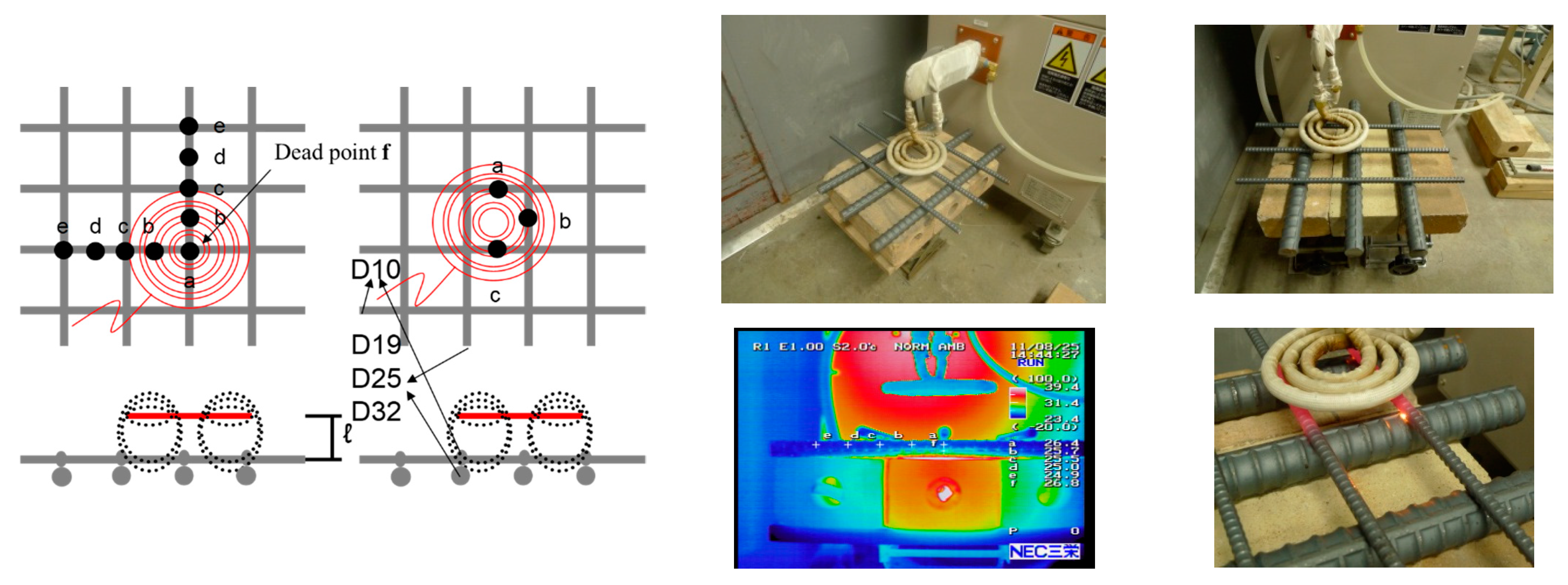

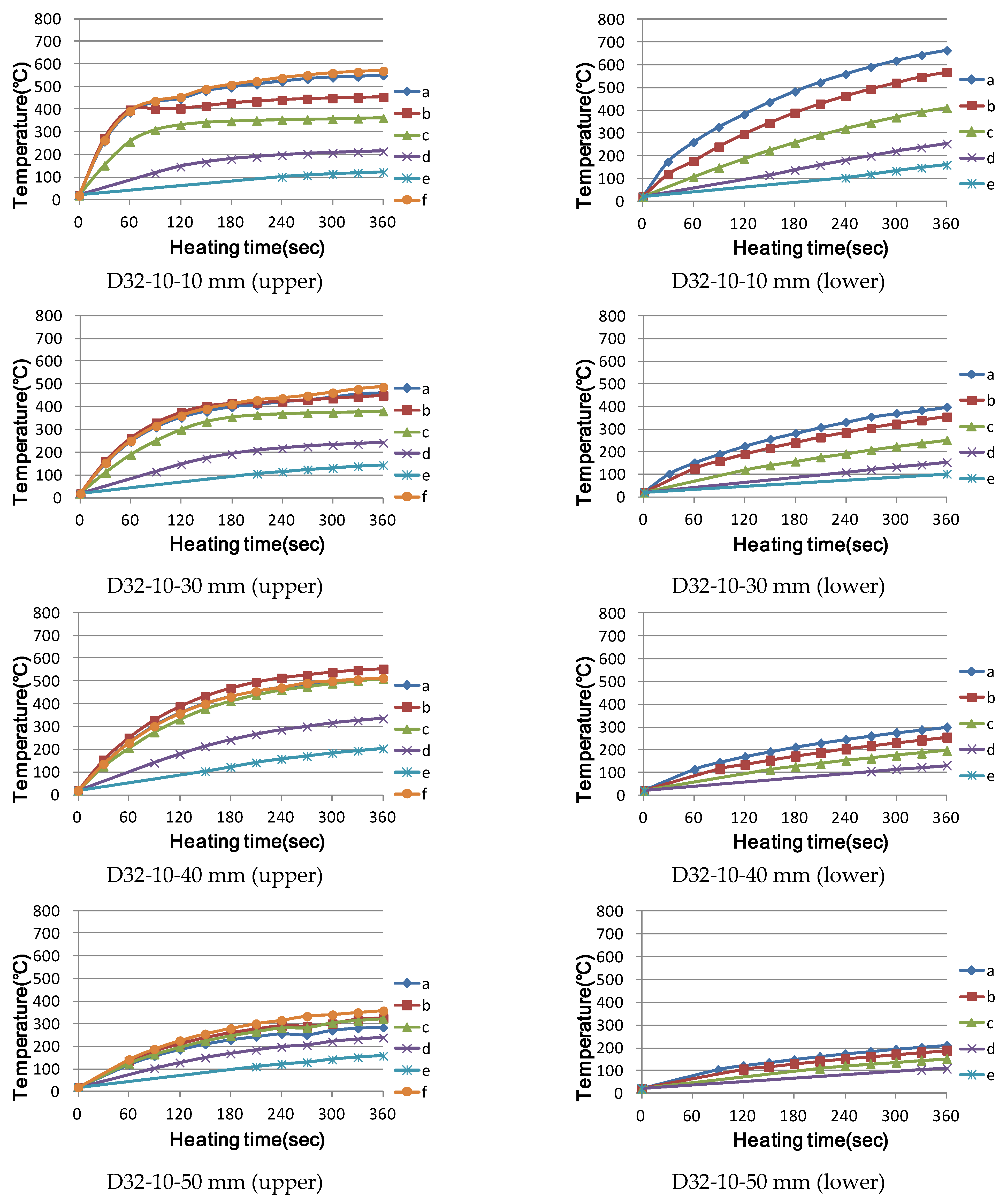

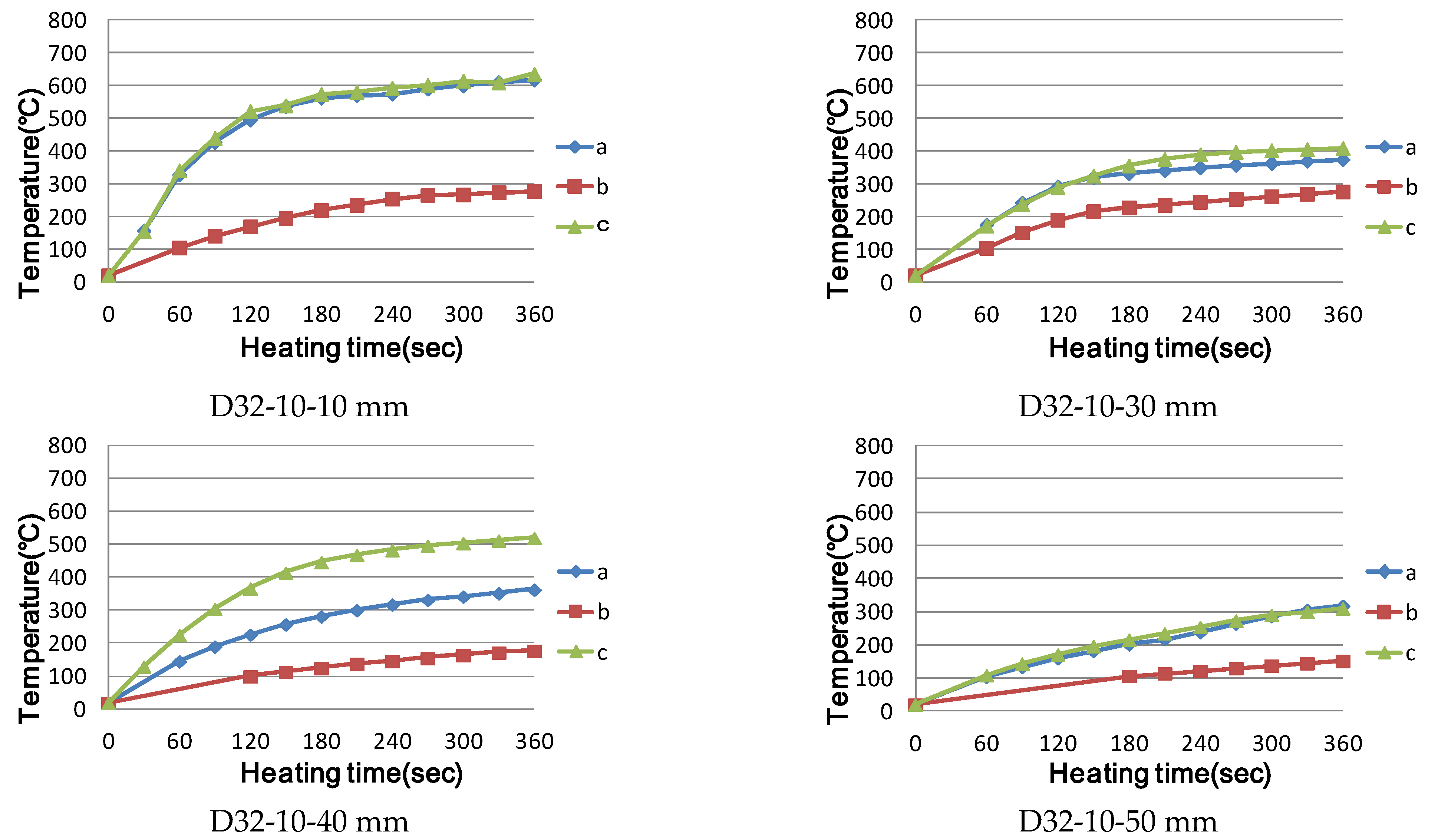

3.2. Temperature Characteristics of a Cross-Bar during Induction Heating

3.2.1. Experimental Methodology

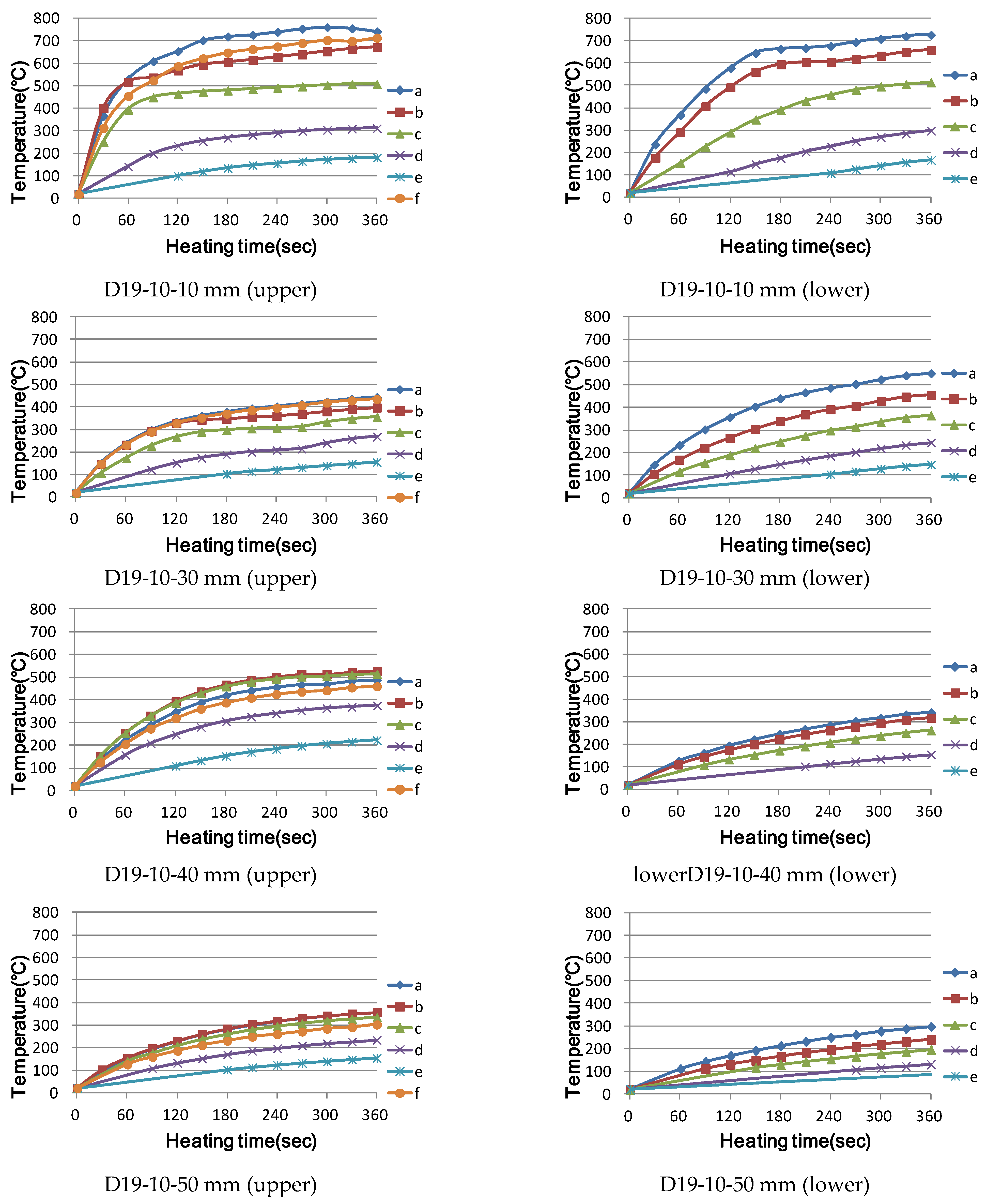

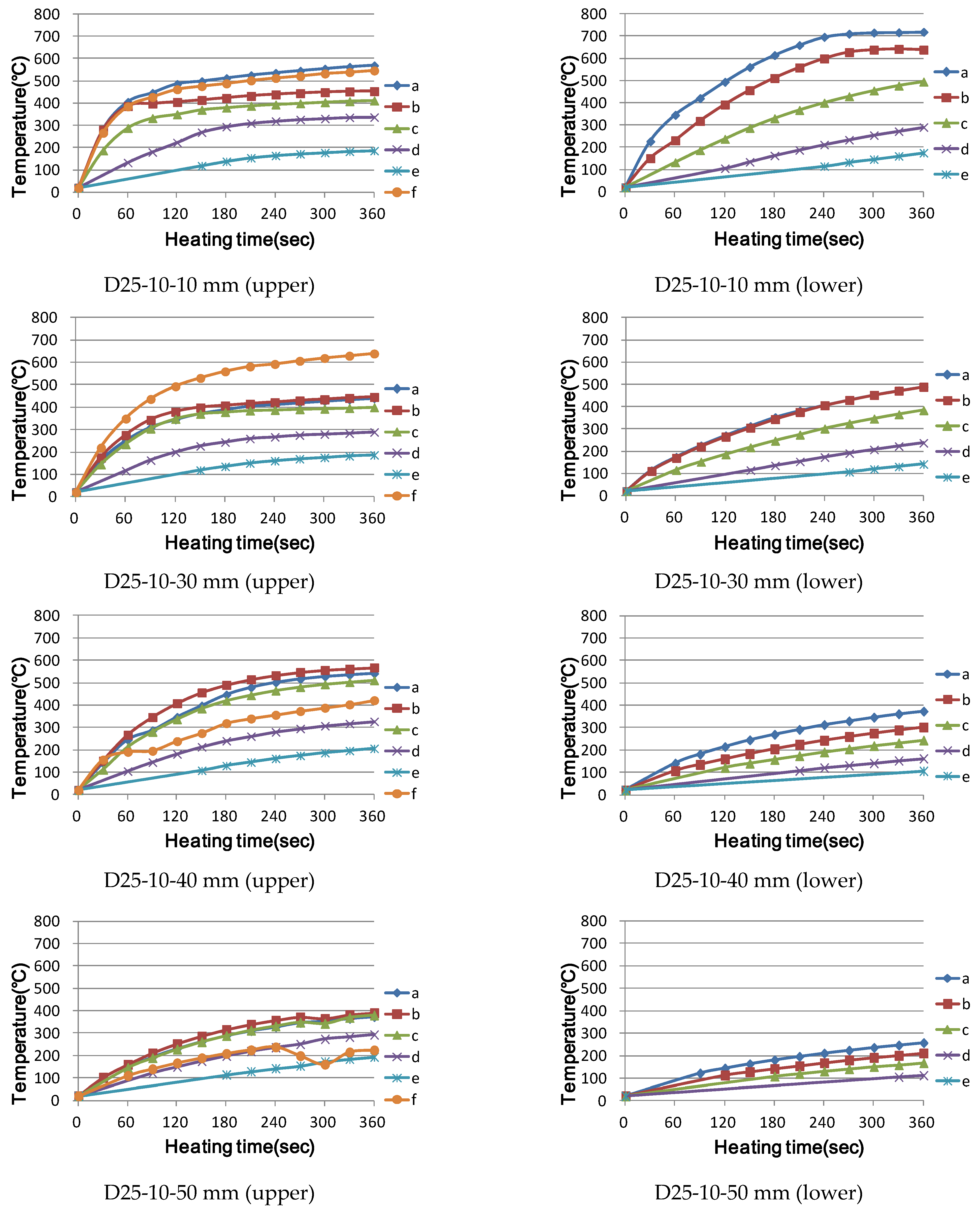

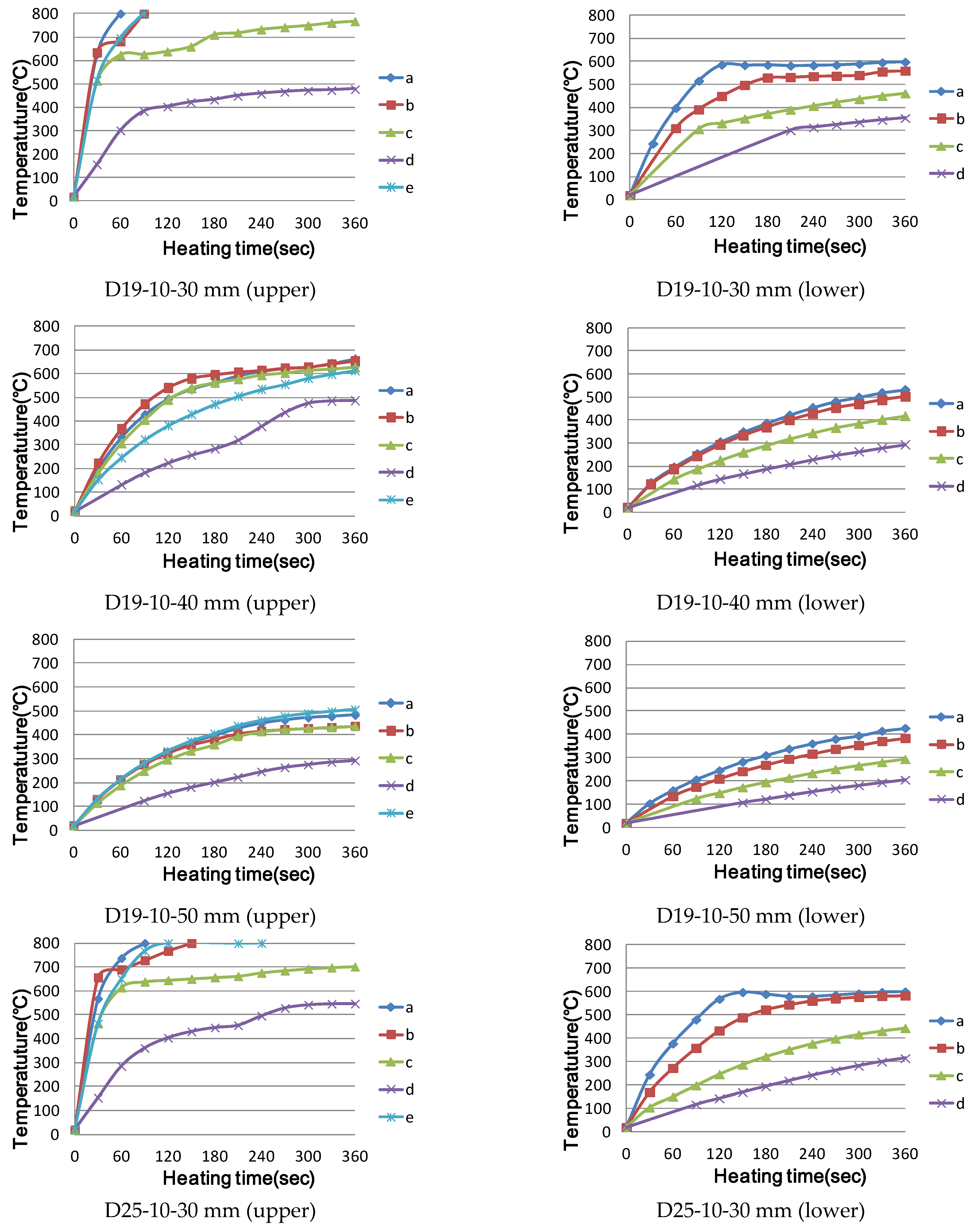

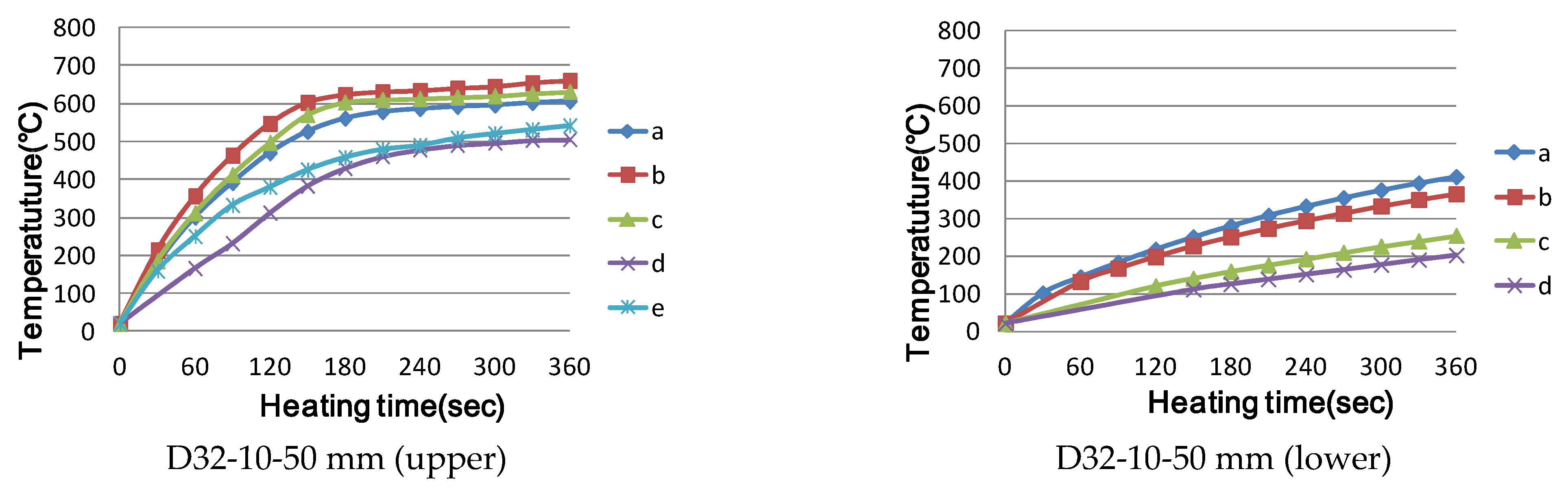

3.2.2. Experimental Results and Investigation

4. Conclusions

- (1)

- When using the high-frequency induction heating system, the difference in temperature characteristics between the maximum output of 5 kW and the maximum output of 6 kW is not large; however, when using the output of 10 kW, the early temperature-rise effect and range of magnetic field formation can be increased.

- (2)

- Small rebar diameters, such as those of D10 or less, at the same power output, show an early rapid temperature rise effect; however, after reaching the Curie point, thermal equilibrium is attained, resulting in power loss. In addition, when the diameter of the reinforcing bar is larger than that of D32, heat is concentrated on the surface owing to the surface heating effect, and the time elapsed to conduct heat to the inside of the reinforcing bar was confirmed.

- (3)

- When all heating conditions were the same, the following were confirmed: there was no significant effect due to the varying length of the reinforcing bar, selective local heating is possible when using the high-frequency induction heating method, and the heating range can be adjusted by changing the output.

- (4)

- When selecting the location of the heating coil, the heating range is found to be larger when there are more steel bars being heated directly inside the heating coil than when it is heated under the same output and distance.

- (5)

- When the heating distance was 30 mm in cross-reinforcing bar heating, even the lower reinforcing bar was included in the magnetic field area, and a resistance heating phenomenon occurred. If the distance is greater than 40 mm, a magnetic field is formed around the upper reinforcing bar, and the lower reinforcing bar is outside the magnetic field area; as the diameter of the lower reinforcing bar increases, the temperature of the lower reinforcing bar increases to the weakened temperature of concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Landau, L.D.; Lifshitz, E.M.; Pitaevskii, L.P. Electrodynamics of Continuous Media; Pergamon Press: Oxford, UK, 1960. [Google Scholar]

- Aguiar, P.M.; Jacquinot, J.F.; Sakellariou, D. Experimental and Numerical Examination of Eddy (Foucault) Currents in Rotating Micro-Coils: Generation of Heat and Its Impact on Sample Temperature. J. Magn. Reson. 2009, 200, 6–14. [Google Scholar] [CrossRef]

- Cheng, J.; Roy, R.; Agrawal, D. Radically Different Effects on Materials by Separated Microwave Electric and Magnetic Fields. Mater. Res. Innov. 2002, 5, 170–177. [Google Scholar] [CrossRef]

- Cherradi, A.; Desgardin, G.; Provost, J.; Raveau, B. Electric & Magnetic Field Contributions to the Microwave Sintering of Ceramics Elelctroceramics IV; Wasner, R., Hoffman, S., Bonnenberg, D., Hoffmann, C., Eds.; RWTN: Aachen, Germany, 1994; Volume 2, pp. 1219–1224. [Google Scholar]

- Cao, Z.; Wang, Z.; Yoshikawa, N.; Taniguchi, S. Microwave Heating Origination and Rapid Crystallization of PZT Thin Films in Separated H Field. J. Phys. D Appl. Phys. 2008, 41, 092003. [Google Scholar] [CrossRef]

- Jin, R.; Chen, Q. Investigation of Concrete Recycling in the U.S. Construction Industry. Procedia Eng. 2015, 118, 894–901. [Google Scholar] [CrossRef]

- McCann, D.M.; Forde, M.C. Review of NDT methods in the assessment of concrete and masonry structures. NDT E Int. 2001, 34, 71–84. [Google Scholar] [CrossRef]

- Pradhan, B.; Bhattacharjee, B. Performance evaluation of rebar in chloride contaminated concrete by corrosion rate. Constr. Build. Mater. 2009, 23, 2346–2356. [Google Scholar] [CrossRef]

- Parthiban, T.; Ravi, R.; Parthiban, G.T. Potential monitoring system for corrosion of steel in concrete. Adv. Eng. Softw. 2006, 37, 375–381. [Google Scholar] [CrossRef]

- Pour-Ghaz, M.; Isgor, O.B.; Ghods, P. Quantitative interpretation of half-cell potential measurements in concrete structures. J. Mater. Civ. Eng. 2009, 21, 467–475. [Google Scholar] [CrossRef]

- Hornbostel, K.; Larsen, K.; Geiker, M.R. Relationship between concrete resistivity and corrosion rate—A literature review. Cem. Concr. Comp. 2013, 39, 60–72. [Google Scholar] [CrossRef]

- Takahashi, Y.; Matsubara, E.; Suzuki, S.; Okamoto, Y.; Komatsu, T.; Konishi, H.; Mizuki, J.; Waseda, Y. In-situ x-ray diffraction of corrosion products formed on iron surfaces. Mater. Trans. 2005, 46, 637–662. [Google Scholar] [CrossRef] [Green Version]

- Yeih, W.; Huang, R. Detection of the corrosion damage in reinforced concrete members by ultrasonic testing. Cem. Concr. Res. 1998, 28, 1071–1083. [Google Scholar] [CrossRef]

- Ahmed, R.; Rifat, A.A.; Yetisen, A.K.; Salem, M.S.; Yun, S.-H.; Butt, H. Optical microring resonator based corrosion sensing. RSC Adv. 2016, 6, 56127–56133. [Google Scholar] [CrossRef]

- Vrana, J.; Goldammer, M.; Bailey, K. Induction and conduction thermography: Optimizing the electromagnetic excitation towards application. Rev. Prog. Quant. Nondestruct. Eval. 2009, 28, 518–525. [Google Scholar]

- Zhang, H.; Liao, L.; Zhao, R.; Zhou, J.; Yang, M.; Zhao, Y. A new judging criterion for corrosion testing of reinforced concrete based on self-magnetic flux leakage. Int. J. Appl. Electromagn. Mech. 2017, 54, 123–130. [Google Scholar] [CrossRef]

- Gonzalez, J.A.; Cobo, A.; Gonzalez, M.N.; Feliu, S. Onsite determination of corrosion rate in reinforced concrete structures by use of galvanostatic pulses. Corros. Sci. 2001, 43, 611–625. [Google Scholar] [CrossRef]

- Abidin, I.Z.; Gui, Y.T.; Wilson, J. Quantitative evaluation of angular defects by pulsed eddy current thermography. NDT E Int. 2010, 43, 537–546. [Google Scholar] [CrossRef]

- Clark, M.R.; McCann, M.R.; Forde, M.C. Application of infrared thermography to the non-destructive testing of concrete and masonry bridges. NDT E Int. 2003, 36, 265–275. [Google Scholar] [CrossRef]

- Clark, M.; McCann, D.M.; Forde, M.C. Infrared thermographic investigation of railway track ballast. NDT E Int. 2002, 35, 83–94. [Google Scholar] [CrossRef]

- Defer, D.; Shen, J.; Lassue, S.; Duthoit, B. Non-destructive testing of a building wall by studying natural thermal signals. Energy Build. 2002, 34, 63–69. [Google Scholar] [CrossRef]

- Engelbert, P.J.; Hotchkiss, R.H.; Kelly, W.E. Integrated remote sensing and geophysical techniques for locating canal seepage in Nebraska. J. Appl. Geophys. 1997, 38, 143–154. [Google Scholar] [CrossRef]

- Sakagami, T.; Kubo, S. Applications of pulse heating thermography and lock-in thermography to quantitative nondestructive evaluations. Infrared Phys. Technol. 2002, 43, 211–218. [Google Scholar] [CrossRef]

- Baek, S.; Xue, W.; Feng, M.Q.; KWon, S. Non-destructive corrosion detection in RC through integrated heat induction and IR thermography. J. Nondestr. Eval. 2012, 31, 181–190. [Google Scholar] [CrossRef]

- Weekes, B.; Almond, D.P.; Cawley, P.; Barden, T. Eddy current induced thermography-probability of detection study of small fatigue cracks in steel, titanium and nickel-based superalloy. NDT E Int. 2012, 49, 47–56. [Google Scholar] [CrossRef]

- He, Y.; Pan, M.; Tian, G.; Chen, D.; Tang, Y.; Zhang, H. Eddy current pulsed phase thermography for subsurface defect quantitatively evaluation. Appl. Phys. Lett. 2013, 103, 144108. [Google Scholar] [CrossRef]

- Liu, L.; Zheng, D.; Zhou, J.T.; He, J.; Xin, J.; Cao, Y. Corrosion detection of bridge reinforced concrete with induction heating and infrared thermography. Int. J. Rob. Autom. 2018, 33, 379–385. [Google Scholar] [CrossRef]

- Harmathy, T.Z. Fire Safety Design and Concrete; Longman Scientific & Technical: New York, NY, USA, 1993. [Google Scholar]

- Schneider, U. Properties of Materials at High Temperatures-Concrete, 2nd ed.; RILEM Report; Gesamthochschule: Kassel, Germany, 1986. [Google Scholar]

- Lim, M. Development of Eco-Friendly Deconstruction Technologies for Recycling Construction Waste. J. Environ. Prot. 2014, 5, 647–661. [Google Scholar] [CrossRef] [Green Version]

- Schneider, U. Behavior of Concrete at High Temperatures; Beuth: Berlin, Germany, 1982. [Google Scholar]

- Bazant, Z.P.; Kapal, M.F. Concrete at High Temperatures: Material Properties and Mathematical Models; Prentice Hall: Hoboken, NJ, USA, 1996. [Google Scholar]

- Arioz, O. Effect of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A. Environmental impact of cement production: Detail of the different processes and cement plant variability evaluation. J. Clean. Prod. 2010, 18, 478–485. [Google Scholar] [CrossRef]

- Rodríguez, G.; Sáez del Bosque, I.F.; Asensio, E.; Sánchez de Rojas, M.I.; Medina, C. Construction and demolition waste applications and maximum daily output in Spanish recycling plants. Waste Manag. Res. 2020, 38, 423–432. [Google Scholar] [CrossRef]

- Li, Y.F. Dielectric Properties and Thermal Properties of Materials during Microwave Heating; Kunming University of Science and Technology: Kunming, China, 2012. [Google Scholar]

- Peng, Z.; Hwang, J.Y.; Park, C.L.; Kim, B.-G.; Onyedika, G. Numerical analysis of heat transfer characteristics in microwave heating of magnetic dielectrics. Metall. Mater. Trans. A 2012, 43, 1070–1078. [Google Scholar] [CrossRef]

- Zhu, J.; Kuznetsov, A.V.; Sandeep, K.P. Mathematical modeling of continuous flow microwave heating of liquids (effects of dielectric properties and design parameters). Int. J. Therm. Sci. 2007, 46, 328–341. [Google Scholar] [CrossRef]

- Catalá-Civera, J.M.; Canós, A.J.; Plaza-González, P.; Gutierrez, J.D.; Garcia-Banos, B.; Penaranda-Foix, F.L. Dynamic measurement of dielectric properties of materials at high temperature during microwave heating in a dual mode cylindrical cavity. IEEE Trans. Microw. Theory Tech. 2015, 63, 2905–2914. [Google Scholar] [CrossRef]

- Szychta, E.; Szychta, L. Comparative analysis of effectiveness of resistance and induction turnout heating. Energies 2020, 13, 5262. [Google Scholar] [CrossRef]

- Eurocode 2: Design of Concrete Structures-Part 1–2: General Rules-Structural Fire Design; BSI: London, UK, 2004; pp. 26–29.

- ASTM C 234, Standard Test Method for Comparing Concrete on the Basis of the Bond Developed with Reinforced Steel; ASTM: Conshohocken, PA, USA, 1991.

- Lie, T.T. Fire and Buildings; Applied Science Publishers Ltd.: London, UK, 1972; p. 276. [Google Scholar]

- Lie, T.T. Structural Fire Protection. In ASCE Manuals and Reports on Engineering Practice; No. 78; ASCE: New York, NY, USA, 1992; 241p. [Google Scholar]

- Lie, T.T.; Lin, T.D.; Allen, D.E.; Abrams, M.S. Fire Resistance of Reinforced Concrete Columns; Technical Paper No. 378; Division of Building Research, National Research Council of Canada: Ottawa, ON, Canada, 1984. [Google Scholar]

- El-Fitiany, S.F.; Youssef, M.A. Assessing the flexural and axial behaviour of reinforced concrete members at elevated temperatures using sectional analysis. Fire Saf. J. 2009, 44, 691–703. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Sultan, M.A. Effect of temperature on thermal properties of high-strength concrete. ASCE J. Mater. Civ. Eng. 2003, 15, 101–107. [Google Scholar] [CrossRef]

- Cosoli, G.; Mobili, A.; Tittarelli, F.; Revel, G.M.; Chiariotti, P. Electrical Resistivity and Electrical Impedance Measurement in Mortar and Concrete Elements: A Systematic Review. Appl. Sci. 2020, 10, 9152. [Google Scholar] [CrossRef]

- Mohapatra, J.; Xing, M.; Liu, J.P. Inductive Thermal Effect of Ferrite Magnetic Nanoparticles. Materials 2019, 12, 3208. [Google Scholar] [CrossRef] [Green Version]

- Yarlagadda, S.; Kim, H.J.; Gillespie, J.W.; Shevchenko, N.B.; Fink, B.K. A Study on the Induction Heating of Conductive Fiber Reinforced Composites. J. Compos. Mater. 2002, 36, 401–421. [Google Scholar] [CrossRef]

- Rudolf, R.; Mitschang, P.; Neitzel, M. Induction Heating of Continuous Carbon-Fibre-Reinforced Thermoplastics. Compos. A 2000, 31, 1191–1202. [Google Scholar] [CrossRef]

- Niknejad, A.M.; Meyer, R.G. Analysis of Eddy-Current Losses Over Conductive Substrates With Applications to Monolithic Inductors and Transformers. IEEE Trans. Microw. Theory Tech. 2001, 49, 166–176. [Google Scholar] [CrossRef]

- Reinert, J.; Brockmeyer, A.; De Doncker, R.W.A.A. Calculation of Losses in Ferro- and Ferrimagnetic Materials Based on the Modified Steinmetz Equation. IEEE Trans. Ind. Appl. 2001, 37, 1055–1061. [Google Scholar] [CrossRef]

- Orihara, H.; Hashimoto, S.; Ishibashi, Y. A Theory of D-E Hysteresis Loop Based on the Avrami Model. J. Phys. Soc. Jpn. 1994, 63, 1031–1035. [Google Scholar] [CrossRef]

- Sadakata, H.; Fujita, A.; Sumiyoshi, S.; Omori, H.; Saha, B.; Ahmed, T.; Nakaoka, M. Latest Practical Developments of Triplex Series Load Resonant Frequency-Operated High Frequency Inverter for Induction-Heated Low Resistivity Metallic Appliances in Consumer Built-In Cooktops. In Proceedings of the 2010 Twenty-Fifth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Palm Springs, CA, USA, 21–25 February 2010; pp. 1825–1832. [Google Scholar]

- Vedalakshmi, R.; Raj, A.S.; Srinivasan, S.; Babu, K.G. Quantification of hydrated cement products of blended cements in kow and medium strength concrete using TG and DTA technique. Thermochim. Acta 2003, 407, 49–60. [Google Scholar] [CrossRef]

- Szczygłowski, J. Influence of eddy currents on magnetic hysteresis loops in soft magnetic materials. J. Magn. Magn. Mater. 2001, 223, 97–102. [Google Scholar] [CrossRef]

| Differential Bar Gauge No. of Bar Steel (JIS G 3112) | Permission of a Clause | The Angle between a Node and an Axis | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Type | Nominal Diameter | Nominal Chieftain | Nominal Cross Section | Unit Weight | Maximum Average Interval for Clause | Knot Height | Maximum Sum of Clause Clearances | ||

| Min | Max | ||||||||

| Unit | mm | cm | cm2 | kg/m | mm | mm | mm | mm | |

| D6 | 6.35 | 2.0 | 0.3167 | 0.2249 | 4.4 | 0.3 | 0.6 | 5.0 | 45° |

| D10 | 9.35 | 3.0 | 0.7133 | 0.560 | 6.7 | 0.4 | 0.8 | 7.5 | |

| D13 | 12.7 | 4.0 | 1.267 | 0.995 | 8.9 | 0.5 | 1.0 | 10.0 | |

| D16 | 15.9 | 5.0 | 1.986 | 1.56 | 11.1 | 0.7 | 1.4 | 12.5 | |

| D19 | 19.1 | 6.0 | 2.865 | 2.25 | 13.4 | 1.0 | 2.0 | 15.0 | |

| D22 | 22.2 | 7.0 | 3.871 | 3.04 | 15.5 | 1.1 | 2.2 | 17.5 | |

| D25 | 25.4 | 8.0 | 5.067 | 3.98 | 17.8 | 1.3 | 2.6 | 20.0 | |

| D29 | 28.6 | 9.0 | 6.424 | 5.04 | 20.0 | 1.4 | 2.8 | 22.5 | |

| D32 | 31.8 | 10.0 | 7.942 | 6.23 | 22.3 | 1.6 | 3.2 | 25.0 | |

| D35 | 34.9 | 11.0 | 9.566 | 7.51 | 24.4 | 1.7 | 3.4 | 27.5 | |

| D38 | 38.1 | 12.0 | 11.40 | 8.95 | 26.7 | 1.9 | 3.8 | 30.0 | |

| D41 | 41.3 | 13.0 | 13.40 | 10.5 | 28.9 | 2.1 | 4.2 | 32.5 | |

| D51 | 50.8 | 14.0 | 20.27 | 15.9 | 35.6 | 2.5 | 5.0 | 40.0 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, M.-k.; Lee, C. Evaluation of Heating Technique of Deformed Reinforcement Using High-Frequency Induction Heating System. Appl. Sci. 2021, 11, 4947. https://doi.org/10.3390/app11114947

Lim M-k, Lee C. Evaluation of Heating Technique of Deformed Reinforcement Using High-Frequency Induction Heating System. Applied Sciences. 2021; 11(11):4947. https://doi.org/10.3390/app11114947

Chicago/Turabian StyleLim, Myung-kwan, and Changhee Lee. 2021. "Evaluation of Heating Technique of Deformed Reinforcement Using High-Frequency Induction Heating System" Applied Sciences 11, no. 11: 4947. https://doi.org/10.3390/app11114947

APA StyleLim, M.-k., & Lee, C. (2021). Evaluation of Heating Technique of Deformed Reinforcement Using High-Frequency Induction Heating System. Applied Sciences, 11(11), 4947. https://doi.org/10.3390/app11114947