Performance of CRTS-II Ballastless Track–Bridge Structural System Rebars under Fatigue Loading Test

Abstract

:1. Introduction

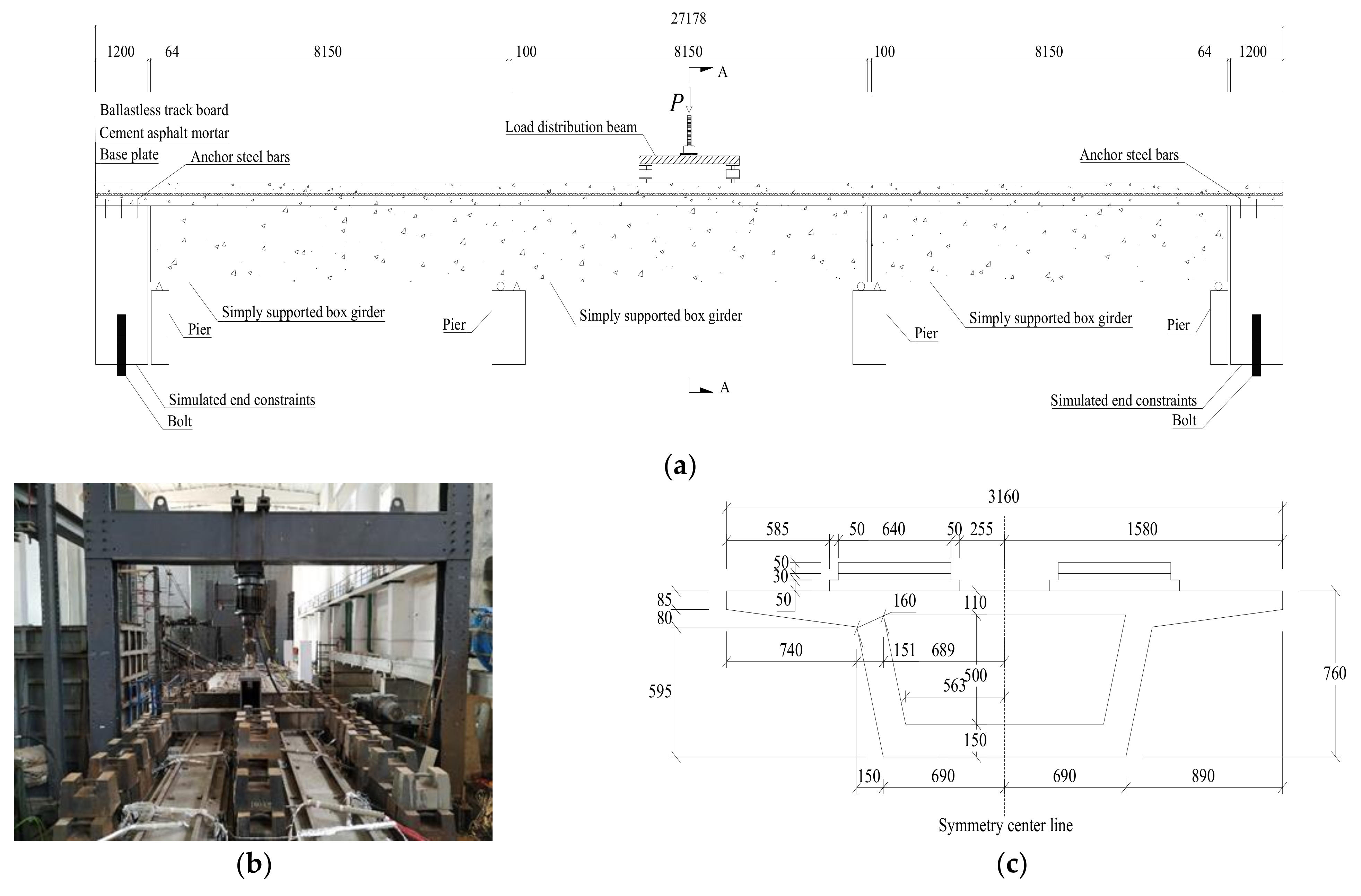

2. Experimental Program

2.1. Design and Construction of the Specimen

2.2. Layout of Data Acquisition Points on Steel Rebars

2.3. Loading Scheme and Testing Device

2.4. Train Load

3. The Result of the Experiment

3.1. Rebar Strain Amplitude under Dynamic Load

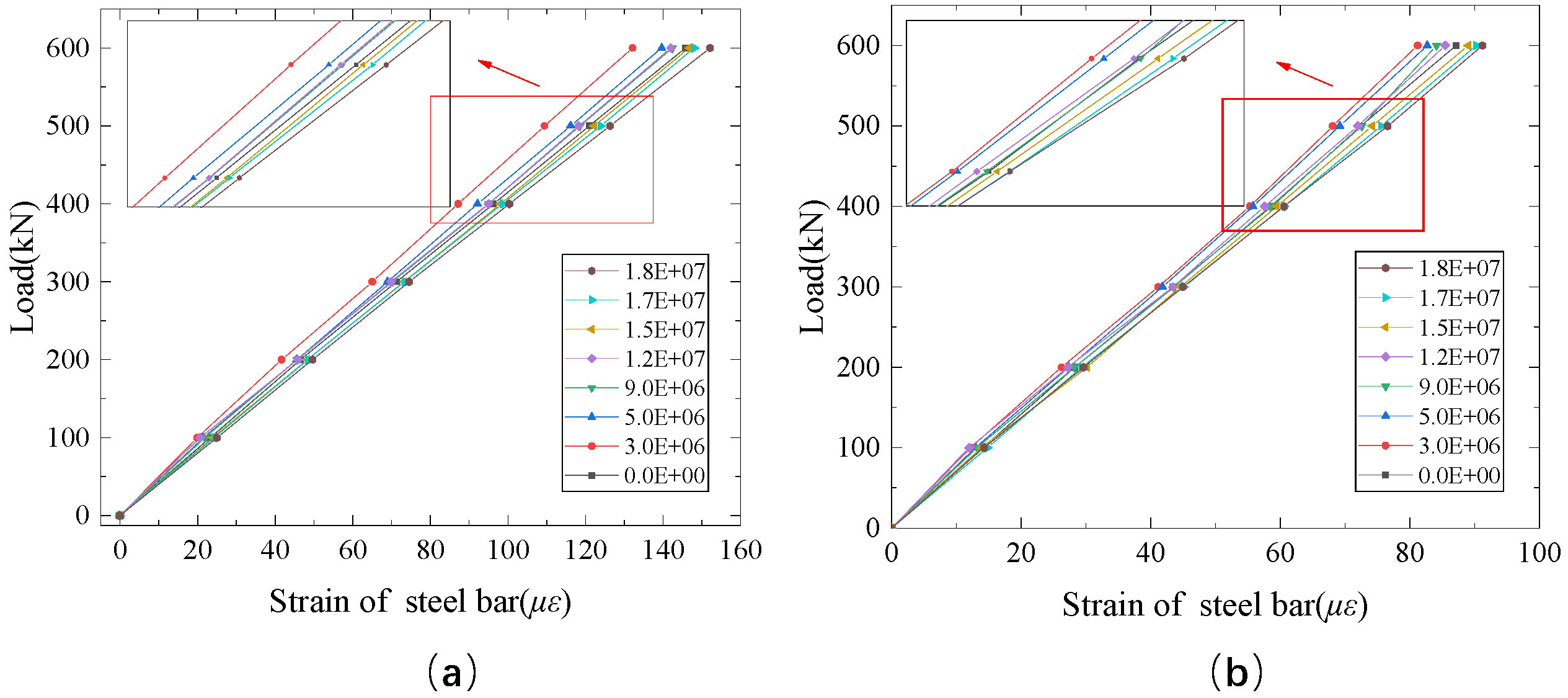

3.2. Rebar Strain Analysis under Static Load

4. Finite Element Analysis Based on Material Fatigue Damage Model

4.1. Constitutive Model of Material

4.1.1. Constitutive Model of Steel Rebar

4.1.2. Concrete Constitutive Model

4.1.3. The Constitutive Model of Cement Asphalt Mortar

4.2. Establishment of Finite Element Mode

4.3. Simplified Calculation Method of Fatigue Damage

4.4. Model Verification

4.5. Analysis and Discussion of Finite Element Results

5. Conclusions

- The strain amplitude of the steel rebar changes proportionally to the fatigue load amplitude, and there is no obvious increase in the strain amplitude under loading stages 1, 2 and 3. Loading stage 4 has the fewest loading cycles, but the highest growth rate (15.40%), which indicates that the greater the fatigue load amplitude, the faster the evolution of the fatigue performance of the steel rebar. During the whole test, the cumulative strain amplitude ratio first decreased and then increased. At the end of the test, the cumulative strain amplitude ratio at L/2 and L/4 sections increased by 5.46% and 5.32%, respectively.

- The load–strain curve of the steel rebars basically maintains the shape of an oblique linear line. Under the first loading stage, the steel rebar load–strain curve “inclines” in the direction of the decreasing strain, while under stages 2, 3 and 4, the curve “inclines” in the direction of the increasing strain. The slope of the load–strain curve is obtained by the least square method and it is found that the slope first increases and then decreases. At the end of the test, the slopes at L/2 and L/4 sections are decreased by 5.15% and 4.81%, respectively.

- Rebars have a fatigue strengthening stage under the first loading stage. The strain amplitude of the rebars gradually decreases from the first to the 3 millionth loading cycle, and the strain amplitudes at L/2 and L/4 sections are reduced by 3.45% and 4.40%, respectively. The slope of the steel rebar load–strain curve gradually increases from the first to the 3 millionth loading cycle, and the slopes at L/2 and L/4 sections are increased by 5.64% and 6.28%, respectively.

- Under the action of the last 15 million loading cycles, steel rebars are in the stage of fatigue damage, and the slopes at L/2 and L/4 sections are reduced by 10.22% and 10.36%, respectively. Based on the fatigue constitutive model of steel bar, concrete and CA mortar, and the multi-stage cumulative damage criterion, the slope change of the fatigue damage stage of the steel rebar is calculated by the finite element method. The numerical simulation results are in good agreement with the experimental data. It is verified that the calculation method proposed in this paper can accurately simulate the evolution process of the mechanical properties of the steel rebars in the ballastless track–bridge structural system.

- This paper only studies the fatigue mechanical properties of the steel bars in the beam, which is a preliminary exploration of the fatigue performance of the ballastless track–bridge structure system under a train load. In the following research, we will further analyze the mechanical fatigue properties of the bridge structure, track structure and ballastless track–bridge structure system and make further reports.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, M.Y.; Shen, L.Z. Impact of high-speed railway network on inter-city connections and its heterogeneity: Taking Nanjing City as the center of network. Prog. Geogr. 2021, 40, 647–659. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, L.Y.; Zou, L.F.; Zhao, L.; Yuan, Y.H. Performance of prestressed reinforcement in fatigue test of simply supported box girder bridge on ballastless track of high-speed railway. J. Cent. South Univ. 2021, 52, 509–518. (In Chinese) [Google Scholar]

- Zhou, L.Y.; Wei, T.Y.; Zhang, G.C.; Zhang, Y.Y.; Akim Djibril Gildas, M. Experimental study of the influence of extremely repeated thermal loading on a ballastless slab track-bridge structure. Appl. Sci. 2020, 10, 461. [Google Scholar] [CrossRef] [Green Version]

- Zhao, G.T. Research and Application of General Construction Technologies for High-Speed Railway in China. J. China Railw. Soc. 2019, 41, 87–100. (In Chinese) [Google Scholar]

- Zhou, L.Y.; Yang, L.Q.; Shan, Z.; Peng, X.S.; Mahunon, A.D. Investigation of the Fatigue Behaviour of a Ballastless Slab Track–Bridge Structural System under Train Load. Appl. Sci. 2019, 9, 3627. [Google Scholar] [CrossRef] [Green Version]

- Pu, Q.H.; Wang, H.Y.; Gou, H.Y.; Bao, Y.; Yan, M. Fatigue Behavior of Prestressed Concrete Beam for Straddle-Type Monorail Tracks. Appl. Sci. 2018, 8, 1136. [Google Scholar] [CrossRef] [Green Version]

- Tong, L.W.; Xiao, S.; He, L.; Zhang, Y.F.; Zhao, X.L. Fatigue behavior of steel reinforced concrete (SRC) beams with different shear span-to-depth ratios. Eng. Struct. 2018, 166, 339–353. [Google Scholar] [CrossRef]

- Tran, N.L. Shear model mSM-c for slender reinforced concrete members without shear reinforcement subjected to fatigue loads. Eng. Struct. 2021, 233, 1–20. [Google Scholar] [CrossRef]

- Zou, R.; Liu, F.; Xiong, Z.; He, S.H.; Li, L.J.; Wei, W. Experimental study on fatigue bond behaviour between basalt fibre-reinforced polymer bars and recycled aggregate concrete. Constr. Build. Mater. 2021, 270, 1–18. [Google Scholar] [CrossRef]

- Yuan, M.; Yan, D.H.; Zhong, H.; Liu, Y.H. Experimental investigation of high-cycle fatigue behavior for prestressedconcrete box-girders. Constr. Build. Mater. 2017, 157, 424–437. [Google Scholar] [CrossRef]

- Han, J.G.; Song, Y.P.; Wang, L.C.; Song, S.D. Residual strain analysis of non-prestressed reinforcement in PPC beams under fatigue loading. Mater. Struct. 2015, 48, 1785–1802. [Google Scholar] [CrossRef]

- Prashanth, M.H.; Singh, P.; Chandra Kishen, J.M. Role of longitudinal reinforcement on the behavior of under reinforced concrete beams subjected to fatigue loading. Int. J. Fatigue 2019, 125, 271–290. [Google Scholar] [CrossRef]

- Li, L.J.; Hou, B.; Lu, Z.Y.; Liu, F. Fatigue behaviour of sea sand concrete beams reinforced with basalt fibre-reinforced polymer bars. Constr. Build. Mater. 2018, 179, 160–171. [Google Scholar] [CrossRef]

- Lu, Z.H.; Ma, Y.F.; Yu, Z.W.; Song, L. The adaptability study on the operation of heavy-Haul trains on existing railway bridges. J. Railw. Sci. Eng. 2016, 13, 1–9. (In Chinese) [Google Scholar]

- Yu, Z.W.; Li, J.Z.; Song, L. Experimental study on fatigue behaviors of heavy-haul railway bridges. China Civ. Eng. J. 2012, 45, 115–126. (In Chinese) [Google Scholar]

- Du, Y.X.; Wei, J.; Yuan, J.; Lai, Y.F.; Sun, D.H. Experimental research on fatigue behavior of prestressed concrete beams under constant-amplitude and variable-amplitude fatigue loading. Constr. Build. Mater. 2020, 259, 1–25. [Google Scholar] [CrossRef]

- Zhao, C.; Dou, Y.M.; Sun, J.S.; Li, Y.F. Study of heavy load traffic effect on fatigue performance of pre-stressed concrete beams. Build. Struct. 2017, 47, 1–5. (In Chinese) [Google Scholar]

- Zhou, L.Y.; Zhao, L.; Mahunon, A.D.; Zhang, Y.Y.; Li, H.Y.; Zou, L.F.; Yuan, Y.H. Experimental study on stiffness degradation of Crts II ballastless track-bridge structural system under fatigue train load. Constr. Build. Mater. 2021, 283, 1–14. [Google Scholar] [CrossRef]

- Yu, Z.W.; Zhou, L.Y.; Zhao, L. Research on Time-Dependent Behavior of High-Speed Railway Ballastless Track-Bridge Structural System: Cooperative Performance Test of High-Speed Railway Ballastless Track-Bridge Structural System; Central South University: Changsha, China, 2018. (In Chinese) [Google Scholar]

- TB10621-2014. Design Code for High Speed Railway; China Railway Publishing House: Beijing, China, 2014; pp. 60–64. [Google Scholar]

- Zhang, J.Q.; Li, P.F.; Mao, Y.; Dong, Z.H. The Mechanical Properties of Reinforced Concrete Plate-Girders when Placed Under Repeated Simulated Vehicle Loads. Materials 2019, 12, 1831. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.P.; Zhou, J.T.; Yan, L. Study of stiffness and bearing capacity degradation of reinforced concrete beams under constant-amplitude fatigue. PLoS ONE 2018, 13, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Hada, H.A.; Nanni, A. Fatigue Behavior of FRCM-Strengthened RC Beams. J. Compos. Constr. 2020, 24, 1–10. [Google Scholar]

- Wu, B.J.; Li, Z.X.; Tang, K.K.; Wang, K. Microscopic Multiple Fatigue Crack Simulation and Macroscopic Damage Evolution of Concrete Beam. Appl. Sci. 2019, 9, 4664. [Google Scholar] [CrossRef] [Green Version]

- Hassanin, A.I.; Fawzy, H.M.; Elsheikh, A.I. Fatigue loading characteristic for the composite steel-concrete beams. Frat. Integrita Strutt. 2021, 55, 110–118. [Google Scholar]

- Hillebrand, M.; Hegger, J. Fatigue Testing of Shear Reinforcement in Prestressed Concrete T-Beams of Bridges. Appl. Sci. 2020, 10, 5560. [Google Scholar] [CrossRef]

- Liang, J.S.; Nie, X.; Masud, M.; Li, J.; Mo, Y.L. A study on the simulation method for fatigue damage behavior of reinforced concrete structures. Eng. Struct. 2017, 150, 25–38. [Google Scholar] [CrossRef]

- Xu, J.J.; Zhu, P.; Ma, J.; Qu, W.J. Fatigue flexural analysis of concrete beams reinforced with hybrid GFRP and steel bar. Eng. Struct. 2019, 199, 1–16. [Google Scholar] [CrossRef]

- Tong, L.W.; Liu, B.; Zhao, X.L. Numerical study of fatigue behaviour of steel reinforced concrete (SRC) beams. Eng. Fract. Mech. 2017, 178, 477–496. [Google Scholar] [CrossRef]

- Zhu, Z.Y.; Zhu, Y.L.; Dai, G.Z.; Wang, Q.Y. Microstructural evolution of strain rate related tensile elastic prestrain on the high-cycle fatigue in medium-carbon steel. Mater. Sci. Eng. A 2019, 764, 1–9. [Google Scholar] [CrossRef]

- Gustavsson, A.; Melander, A. Fatigue of a highly prestrained dual-phase sheet steel. Fatigue Fract. Eng. Mater. Struct. 1995, 18, 201–210. [Google Scholar] [CrossRef]

- Gan, J.; Zhao, K.; Wang, Z.; Wang, X.L.; Wu, W.G. Fatigue damage of designed T-type specimen under different proportion repeating Two-Step variable amplitude loads. Eng. Fract. Mech. 2019, 221, 1–13. [Google Scholar] [CrossRef]

- GB 50010-2010. Code for Design of Concrete Structures; China Architecture & Building Press: Beijing, China, 2015; pp. 19–21. [Google Scholar]

- Sinha, B.P.; Gerstle, K.H.; Tulin, L.G. Stress-strain relations for concrete under cyclic loading. ACI J. 1964, 61, 195–211. [Google Scholar]

- Kachanov, L.M. Time of the rupture process under creep condition. Izv. Akad. Nauk. SSSR Otd. Tek. 1958, 8, 26–31. [Google Scholar]

- Shan, Z. Stochastic Damage Model for Concrete and Its Application. Ph.D. Thesis, Central South University, College of Civil Engineering, Changsha, China, 2017; pp. 125–131. [Google Scholar]

- Yu, Z.W.; Shan, Z.; Ouyang, Z.Y.; Guo, F. A simple damage model for concrete considering irreverible mode-II microcracks. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1419–1432. [Google Scholar] [CrossRef]

- The Concrete Fatigue Task Forces. Research on Failure Reliability Checking Calculation Method of Reinforced Concrete Flexural Components; China Construction Industry Publishing House: Beijing, China, 1994; pp. 26–27. [Google Scholar]

- Yu, Z.W.; Shan, Z.; Li, X. Research on Time-Dependent Behavior of High-Speed Railway Ballastless T Rack-Bridge Structural System: Stochastic Viscoelastic—Damage Constitutive Model of Crts Ii Ca Mortar Layer; Central South University: Changsha, China, 2018. (In Chinese) [Google Scholar]

- Xu, Q.Y.; Lin, Q.T.; Feng, Z.Y.; Lou, P.; Yang, R.; Chen, W.; Zhang, Z. Theoretical study on fatigue stress spectrum of longitudinal connected slab track on bridge. J. Southwest Jiaotong Univ. 2018, 53, 906–912. [Google Scholar]

- Liu, X.Y.; Su, C.G.; Liu, D.; Xiang, F.; Gong, C.; Zhao, P.R. Research on the bond properties between slab and CA mortar layer and the parameters study of cohesive model. J. Railw. Eng. Soc. 2017, 3, 22–28. [Google Scholar]

| Program | Pmin (kN) | Pmax (kN) | ΔP (kN) | Frequency | Fatigue Cycles |

|---|---|---|---|---|---|

| Stage 1 | 300 | 420 | 120 | 3 Hz | 5.0 × 106 |

| Stage 2 | 300 | 540 | 240 | 3 Hz | 7.0 × 106 |

| Stage 3 | 300 | 660 | 360 | 3 Hz | 5.0 × 106 |

| Stage 4 | 300 | 900 | 600 | 3 Hz | 1.0 × 106 |

| Section | Stage 1 | Stage 2 | ||||

|---|---|---|---|---|---|---|

| Initial Ratio | End Ratio | Increasing Rate (%) | Initial Ratio | End Ratio | Increasing Rate (%) | |

| L/2 | 1.00 | 0.98 | −2.10 | 2.09 | 2.14 | 5.32 |

| L/4 | 1.00 | 0.97 | −2.96 | 2.10 | 2.16 | 6.43 |

| Section | Stage 3 | Stage 4 | ||||

| Initial Ratio | End Ratio | Increasing Rate (%) | Initial Ratio | End Ratio | Increasing Rate (%) | |

| L/2 | 3.19 | 3.26 | 7.01 | 5.54 | 5.70 | 15.40 |

| L/4 | 3.31 | 3.39 | 8.61 | 5.67 | 5.82 | 14.85 |

| Section | Initial Ratio | Stage 1 | Stage 2 | ||

|---|---|---|---|---|---|

| Slope Ratio | Degradation Rate (%) | Slope Ratio | Degradation Rate (%) | ||

| L/2 | 1.00 | 1.04 | −4.44 | 1.00 | 4.01 |

| L/4 | 1.00 | 1.05 | −5.02 | 1.00 | 4.33 |

| Section | Stage 3 | Stage 4 | Total Degradation Rate (%) | ||

| Slope Ratio | Degradation Rate (%) | Slope Ratio | Degradation Rate (%) | ||

| L/2 | 0.96 | 3.98 | 0.95 | 1.47 | 5.15 |

| L/4 | 0.97 | 3.93 | 0.95 | 1.40 | 4.81 |

| Loading Stage | Stage 1 | Stage 2 | Stage 3 | Stage 4 | |

|---|---|---|---|---|---|

| Structure | |||||

| Steel rebar | 1.11 × 109 | 1.50 × 108 | 7.77 × 107 | 3.36 × 107 | |

| Support beam | 4.04 × 1012 | 2.52 × 1011 | 4.40 × 1010 | 1.62 × 109 | |

| Track slab | 2.54 × 109 | 7.33 × 108 | 1.95 × 108 | 1.21 × 107 | |

| Track bed | 1.13 × 1010 | 3.80 × 109 | 4.42 × 108 | 2.48 × 107 | |

| Cement asphalt mortar | 1.45 × 109 | 2.11 × 108 | 5.02 × 107 | 8.71 × 106 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Zou, L.; Zhao, L.; Yuan, Y.; Mahunon, A.D.; Gong, Y. Performance of CRTS-II Ballastless Track–Bridge Structural System Rebars under Fatigue Loading Test. Appl. Sci. 2021, 11, 4858. https://doi.org/10.3390/app11114858

Zhou L, Zou L, Zhao L, Yuan Y, Mahunon AD, Gong Y. Performance of CRTS-II Ballastless Track–Bridge Structural System Rebars under Fatigue Loading Test. Applied Sciences. 2021; 11(11):4858. https://doi.org/10.3390/app11114858

Chicago/Turabian StyleZhou, Lingyu, Lifan Zou, Lei Zhao, Yahui Yuan, Akim D. Mahunon, and Yongzhi Gong. 2021. "Performance of CRTS-II Ballastless Track–Bridge Structural System Rebars under Fatigue Loading Test" Applied Sciences 11, no. 11: 4858. https://doi.org/10.3390/app11114858

APA StyleZhou, L., Zou, L., Zhao, L., Yuan, Y., Mahunon, A. D., & Gong, Y. (2021). Performance of CRTS-II Ballastless Track–Bridge Structural System Rebars under Fatigue Loading Test. Applied Sciences, 11(11), 4858. https://doi.org/10.3390/app11114858