A Systematic Study of the Cryogenic Milling of Chrysotile Asbestos

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Characterisation

2.2. Characterisation Techniques

3. Results

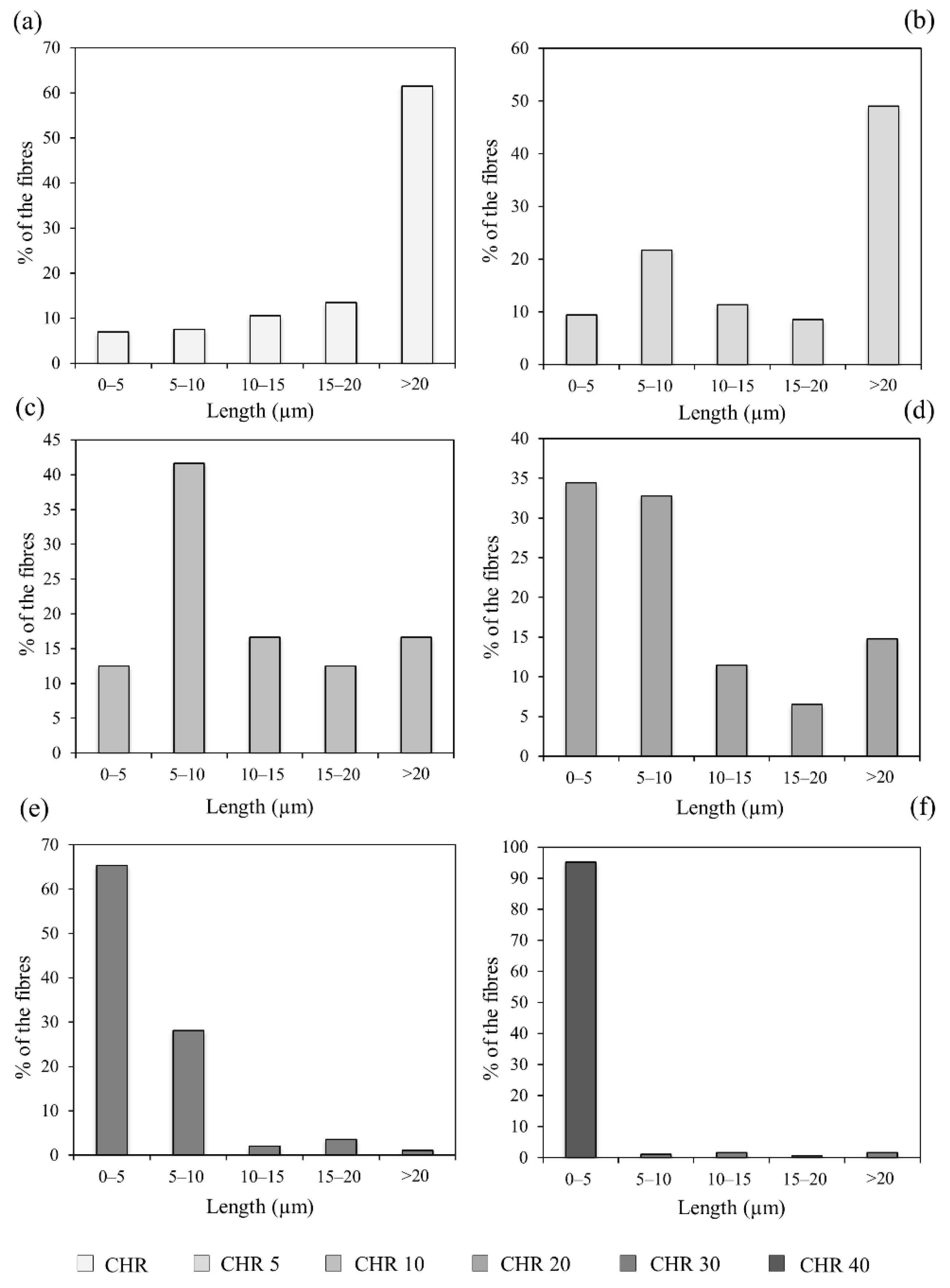

3.1. SEM Characterisation

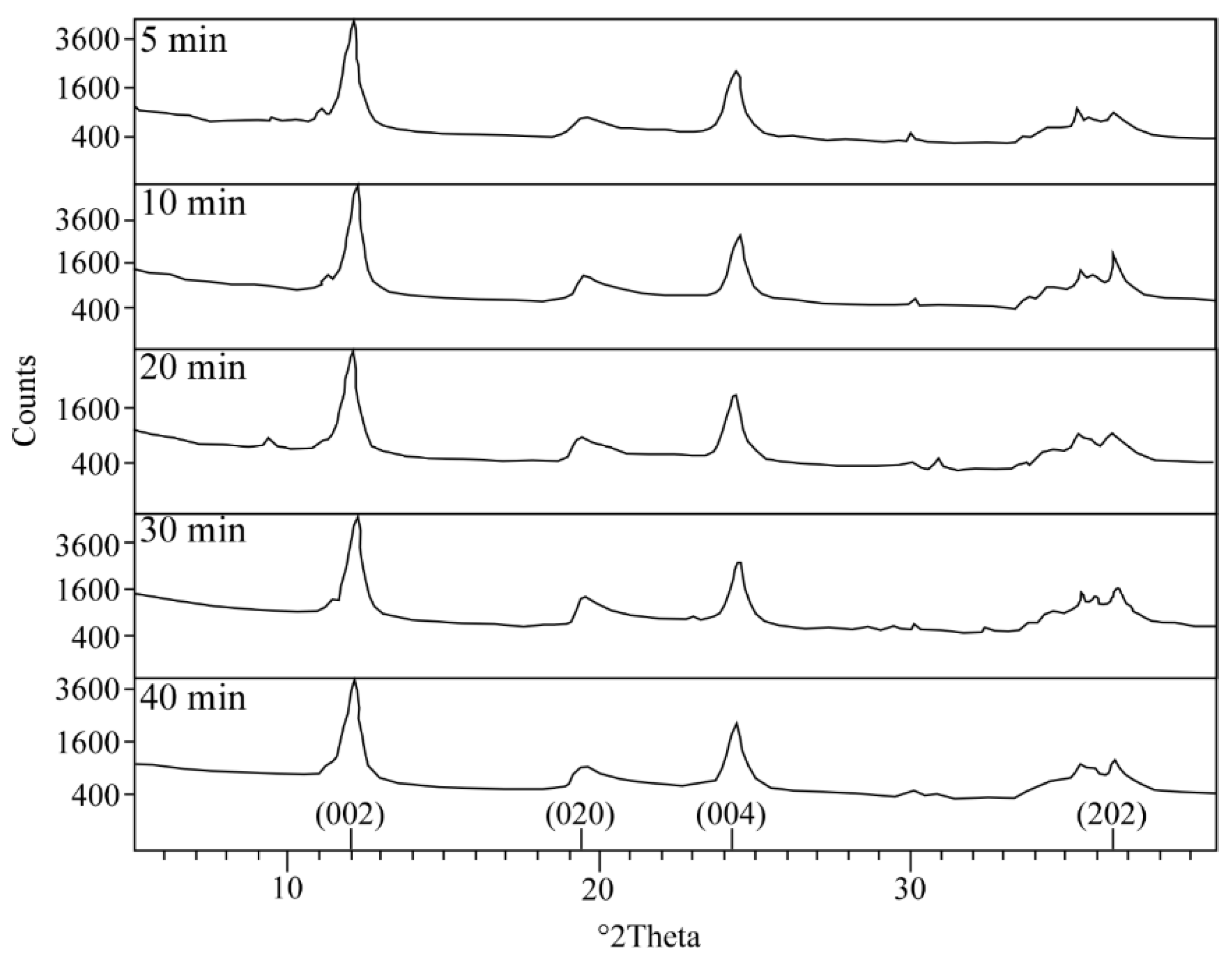

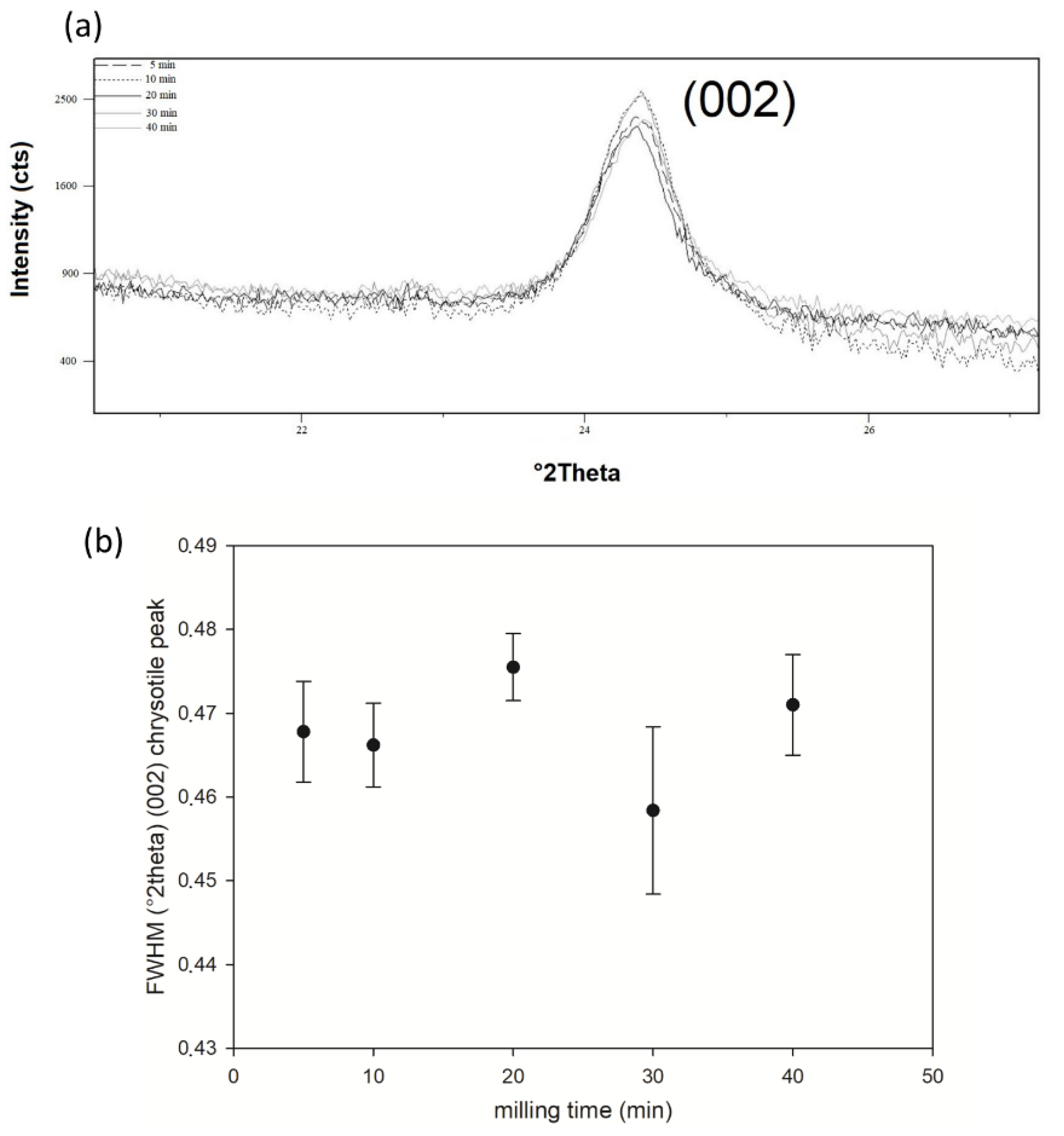

3.2. XRPD Characterisation

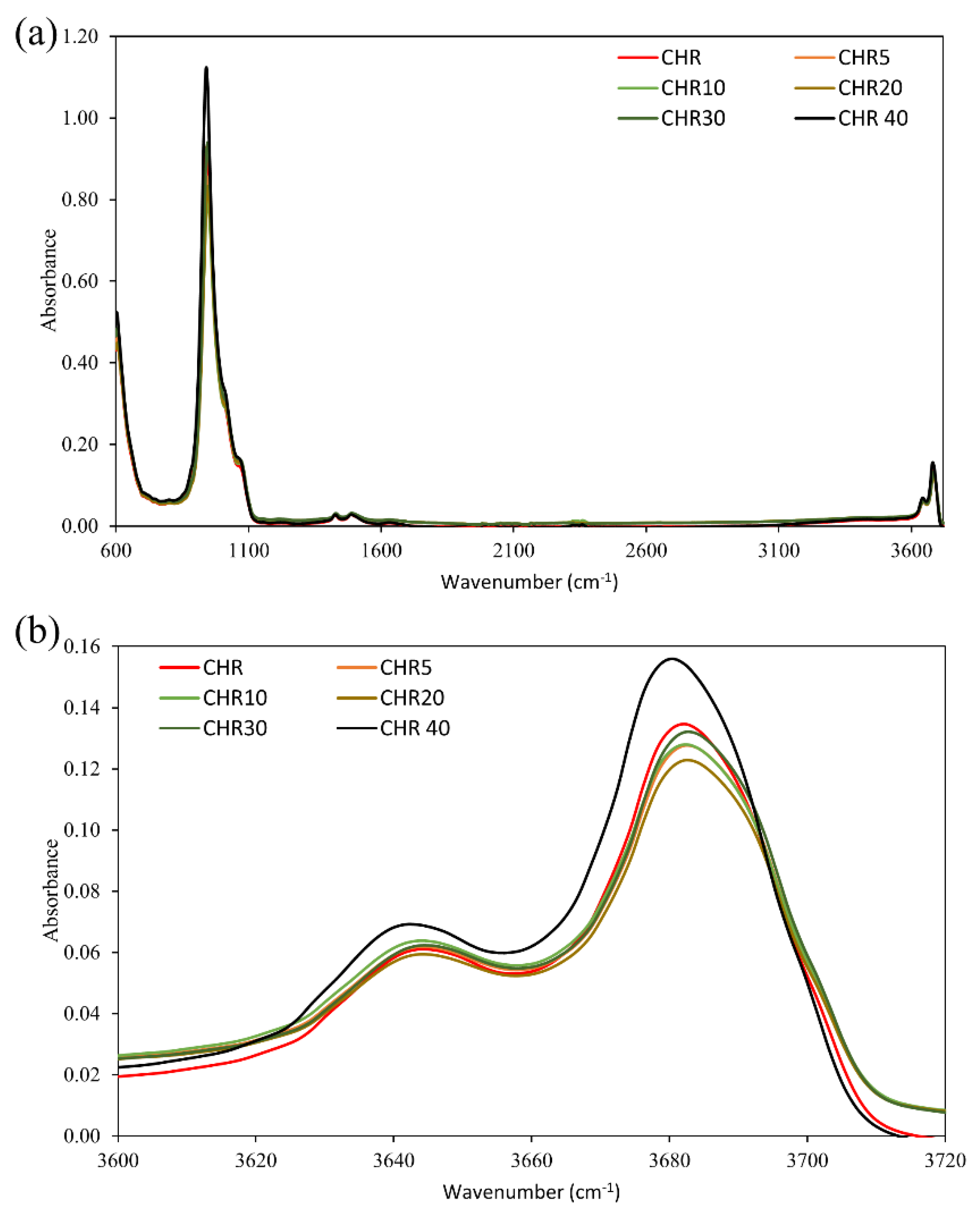

3.3. FTIR Characterisation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ross, M.; Nolan, R.P. History of asbestos discovery and use and asbestos-related disease in context with the occurrence of asbestos within ophiolite complexes. In Ophiolite Concept and the Evolution of Geological Thought; Dilek, Y., Newcomb, S., Eds.; Geological Society of America: Boulder, CO, USA, 2003; pp. 447–470. [Google Scholar]

- NIOSH. Asbestos Fibers and Other Elongate Mineral Particles: State of the Science and Roadmap for Research; National Institute for Occupational Safety and Health: Cincinnati, OH, USA, 2011; pp. 1–153. [Google Scholar]

- IARC. Asbestos (chrysotile, amosite, crocidolite, tremolite, actinolite, and anthophyllite). IARC Monogr. 2012, 100, 219–309. [Google Scholar]

- WHO. Outline for the Development of National Programmes for Elimination of Asbestos-Related Diseases; World Health Organization: Geneva, Switzerland, 2007; pp. 1–20. [Google Scholar]

- Carbone, M.; Adusumilli, P.S.; Alexander, H.R., Jr.; Baas, P.; Bardelli, F.; Bononi, A.; Bueno, R.; Felley-Bosco, E.; Galateu-Salle, F.; Jablons, D.; et al. Mesothelioma: Scientific clues for prevention, diagnosis, and therapy. CA Cancer. J. Clin. 2019, 69, 402–429. [Google Scholar] [CrossRef] [Green Version]

- Cavone, D.; Caputi, A.; De Maria, L.; Cannone, E.S.S.; Mansi, F.; Birtolo, F.; Delfino, C.M.; Vimercati, L. Epidemiology of Mesothelioma. Environments 2019, 6, 76. [Google Scholar] [CrossRef] [Green Version]

- Pass, H.I.; Alimi, M.; Carbone, M.; Yang, H.; Goparaju, C.M. Mesothelioma Biomarkers: Discovery in Search of Validation. Thorac. Surg. Clin. 2020, 30, 395–423. [Google Scholar] [CrossRef] [PubMed]

- Donaldson, K.; Murphy, F.A.; Duffin, R.; Poland, C.A. Asbestos, carbon nanotubes and the pleural mesothelium: A review of the hypothesis regarding the role of long fibre retention in the parietal pleura, inflammation and mesothelioma. Part Fibre Toxicol. 2010, 7, 5. [Google Scholar] [CrossRef] [Green Version]

- Gualtieri, A.F.; Mossman, B.T.; Roggli, V.L. Towards a general model for predicting the toxicity and pathogenicity of minerals fibres. In Mineral Fibres: Crystal Chemistry, Chemical-Physical Properties, Biological Interaction and Toxicity; Gualtieri, A.F., Ed.; European Mineralogical Union: London, UK, 2017; pp. 501–526. [Google Scholar]

- Mossman, B.T.; Gualtieri, A.F. Lung Cancer: Mechanisms of Carcinogenesis by Asbestos. In Occupational Cancers; Anttila, S., Boffetta, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 239–256. [Google Scholar]

- Gualtieri, A.F.; Lusvardi, G.; Zoboli, A.; Di Giuseppe, D.; Lassinantti Gualtieri, M. Biodurability and release of metals during the dissolution of chrysotile, crocidolite and fibrous erionite. Environ. Res. 2019, 171, 550–557. [Google Scholar] [CrossRef] [PubMed]

- Di Giuseppe, D.; Zoboli, A.; Vigliaturo, R.; Gieré, R.; Bonasoni, M.P.; Sala, O.; Gualtieri, A.F. Mineral fibres and asbestos bodies in human lung tissue: A case study. Minerals 2019, 9, 618. [Google Scholar] [CrossRef] [Green Version]

- Giacobbe, C.; Di Giuseppe, D.; Zoboli, A.; Lassinantti Gualtieri, M.; Bonasoni, P.; Moliterni, A.; Corriero, N.; Altomare, A.; Wright, J.; Gualtieri, A.F. Crystal structure determination of a lifelong biopersistent asbestos fibre using single-crystal synchrotron X-ray micro-diffraction. IUCrJ 2021, 8, 76–86. [Google Scholar] [CrossRef] [PubMed]

- Yarborough, C.M. Chrysotile as a cause of mesothelioma: An assessment based on epidemiology. Crit. Rev. Toxicol. 2006, 36, 165–187. [Google Scholar] [CrossRef] [PubMed]

- Pira, E.; Romano, C.; Donato, F.; Pelucchi, C.; La Vecchia, C.; Boffetta, P. Mortality from cancer and other causes among Italian chrysotile asbestos miners. Occup. Environ. Med. 2017, 74, 558–563. [Google Scholar] [CrossRef]

- Kanarek, M.S. Mesothelioma from chrysotile asbestos: Update. Ann. Epidemiol. 2011, 21, 688–697. [Google Scholar] [CrossRef]

- Gilham, C.; Rake, C.; Burdett, G.; Nicholson, A.G.; Davison, L.; Franchini, A.; Carpente, J.; Hodgson, J.; Darnton, A.; Peto, J. Pleural mesothelioma and lung cancer risks in relation to occupational history and asbestos lung burden. Occup. Environ. Med. 2016, 73, 290–299. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yao, S.; Iezzi, G.; Della Ventura, G.; Bellatreccia, F.; Petibois, C.; Marcelli, A.; Nazzari, M.; Lazzarin, F.; Di Gioacchino, M.; Petrarca, C. Mineralogy and textures of riebeckitic asbestos (crocidolite): The role of single versus agglomerated fibres in toxicological experiments. J. Hazard. Mater. 2017, 340, 472–485. [Google Scholar] [CrossRef] [PubMed]

- Current Asbestos Bans. International Ban Asbestos. Secretariat. Available online: http://www.ibasecretariat.org/alpha_ban_list.php (accessed on 13 April 2021).

- Asbestos Statistics and Information. United States Geological Service. Available online: https://pubs.usgs.gov/periodicals/mcs2020/mcs2020-asbestos.pdf (accessed on 6 January 2021).

- Di Giuseppe, D.; Zoboli, A.; Nodari, L.; Pasquali, L.; Sala, O.; Ballirano, P.; Malferrari, D.; Raneri, S.; Hanuskova, M.; Gualtieri, A.F. Characterization and assessment of the potential toxicity/pathogenicity of Russian commercial chrysotile. Am. Min. 2021. [Google Scholar] [CrossRef]

- Ferrante, D.; Mirabelli, D.; Silvestri, S.; Azzolina, D.; Giovannini, A.; Tribaudino, P.; Magnani, C. Mortality and mesothelioma incidence among chrysotile asbestos miners in Balangero, Italy: A cohort study. Am. J. Ind. Med. 2020, 63, 135–145. [Google Scholar] [CrossRef]

- Pollastri, S.; Perchiazzi, N.; Lezzerini, M.; Plaisier, J.R.; Cavallo, A.; Dalconi, M.C.; Bursi Gandolfi, N.; Gualtieri, A.F. The crystal structure of mineral fibres. 1. Chrysotile. Period. Miner. 2016, 85, 249–259. [Google Scholar]

- Spurny, K.R.; Stöber, W.; Opiela, H.; Weiss, G. Size-selective preparation of inorganic fibers for biological experiments. Am. Ind. Hyg. Assoc. J. 1979, 40, 20–38. [Google Scholar] [CrossRef] [PubMed]

- Myojo, T.; Kohyama, N. Separation of Asbestos Fibers by Length–Procedure for Obtaining Different-length Samples for Biological Experiments. J. Soc. Powder Technol. Jpn. 1992, 27, 804–810. [Google Scholar] [CrossRef]

- Vigliaturo, R.; Choi, J.K.; Pérez-Rodríguez, I.; Gieré, R. Dimensional distribution control of elongated mineral particles for their use in biological assays. MethodsX 2020, 28, 100937. [Google Scholar] [CrossRef] [PubMed]

- Jolicoeur, C.; Roberge, P.; Fortier, J.L. Separation of short fibres from bulk chrysotile asbestos fiber materials: Analysis and physico-chemical characterization. Can. J. Chem. 1981, 59, 1140–1148. [Google Scholar] [CrossRef] [Green Version]

- Turci, F.; Tomatis, M.; Pacella, A. Surface and bulk properties of mineral fibres relevant to toxicity. In Mineral Fibres: Crystal Chemistry, Chemical-Physical Properties, Biological Interaction and Toxicity; Gualtieri, A.F., Ed.; European Mineralogical Union: London, UK, 2017; pp. 171–214. [Google Scholar]

- Assuncao, J.; Corn, M. The effects of milling on diameters and lengths of fibrous glass and chrysotile asbestos fibers. Am. Ind. Hyg. Assoc. J. 1975, 36, 811–819. [Google Scholar] [CrossRef] [PubMed]

- Iwaszko, J.; Zawada, A.; Lubas, M. Influence of high-energy milling on structure and microstructure of asbestos-cement materials. J. Mol. Struct. 2018, 1155, 51–57. [Google Scholar] [CrossRef]

- Suquet, H. Effects of dry grinding and leaching on the crystal structure of chrysotile. Clays Clay Miner. 1989, 37, 439–445. [Google Scholar] [CrossRef]

- Occella, E. Analysis of asbestos in bulk materials by X-ray diffraction: Influence of grinding methods on the result. KONA Powder Part. J. 1994, 12, 43–52. [Google Scholar] [CrossRef] [Green Version]

- Spurny, K.R.; Stöber, W.; Opiela, H.; Weiss, G. On the problem of milling and ultrasonic treatment of asbestos and glass fibers in biological and analytical applications. Am. Ind. Hyg. Assoc. J. 1980, 41, 198–203. [Google Scholar] [CrossRef]

- Papirer, E.; Roland, P. Grinding of chrysotile in hydrocarbons, alcohol, and water. Clays Clay Miner. 1981, 29, 161–170. [Google Scholar] [CrossRef]

- Salamatipour, A.; Mohanty, S.K.; Pietrofesa, R.A.; Vann, D.R.; Christofidou-Solomidou, M.; Willenbring, J.K. Asbestos fiber preparation methods affect fiber toxicity. Environ. Sci. Technol. Lett. 2016, 3, 270–274. [Google Scholar] [CrossRef] [Green Version]

- Plescia, P.; Gizzi, D.; Benedetti, S.; Camilucci, L.; Fanizza, C.; De Simone, P.; Paglietti, F. Mechanochemical treatment to recycling asbestos-containing waste. Waste Manag. 2003, 23, 209–218. [Google Scholar] [CrossRef]

- Bloise, A.; Catalano, M.; Gualtieri, A.F. Effect of milling on chrysotile, amosite and crocidolite and implications for thermal treatment. Minerals 2018, 8, 135. [Google Scholar] [CrossRef] [Green Version]

- Turci, F.; Colonna, M.; Tomatis, M.; Mantegna, S.; Cravotto, G.; Gulino, G.; Aldieri, E.; Ghigo, D.; Fubini, B. Surface reactivity and cell responses to chrysotile asbestos nanofibers. Chem. Res. Toxicol. 2012, 25, 884–894. [Google Scholar] [CrossRef]

- Thorne, P.S.; Lightfoot, E.N.; Albrecht, R.M. Physicochemical characterization of cryogenically ground, size separated, fibrogenic particles. Environ. Res. 1985, 36, 89–110. [Google Scholar] [CrossRef]

- Sailors, R.; Corten, H. Relationship between Material Fracture Toughness using Fracture Mechanics and Transition Temperature Tests. In Fracture Toughness, Part II; Corten, H., Ed.; ASTM International: West Conshohocken, PA, USA, 1972; pp. 164–191. [Google Scholar]

- Paul, S.; Chattopadhyay, A.B. The effect of cryogenic cooling on grinding forces. Int. J. Mach. Tool Manuf. 1996, 36, 63–72. [Google Scholar] [CrossRef]

- Kumar, N.; Biswas, K. Cryomilling: An environment friendly approach of preparation large quantity ultrarefined pure aluminium nanoparticles. J. Mater. Res. Technol. 2019, 8, 63–74. [Google Scholar] [CrossRef]

- Zoboli, A.; Di Giuseppe, D.; Baraldi, C.; Gamberini, M.C.; Malferrari, D.; Urso, G.; Lassinantti Gualtieri, M.; Bailey, M.; Gualtieri, A.F. Characterisation of fibrous ferrierite in the rhyolitic tuffs at Lovelock, Nevada, USA. Miner. Mag. 2019, 83, 577–586. [Google Scholar] [CrossRef]

- ImageJ. Available online: https://imagej.nih.gov/ij (accessed on 13 April 2021).

- Degen, T.; Sadki, M.; Bron, E.; König, U.; Nénert, G. The HighScore Suite. Powder Diffr. 2014, 29, 13–18. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, I.C.; Aguiar, E.M.; Silva, A.T.; Santos, L.L.; Cardoso-Sousa, L.; Araújo, T.G.; Santos, D.W.; Goulart, L.R.; Sabino-Silva, R.; Maia, Y.C. Attenuated Total Reflection-Fourier Transform Infrared (ATR-FTIR) Spectroscopy Analysis of Saliva for Breast Cancer Diagnosis. J. Oncol. 2020, 2020, 4343590. [Google Scholar] [CrossRef] [Green Version]

- Di Giuseppe, D.; Perchiazzi, N.; Brunelli, D.; Giovanardi, T.; Nodari, L.; Della Ventura, G.; Malferrari, D.; Maia, M.; Gualtieri, A.F. Occurrence and characterization of tremolite asbestos from the Mid Atlantic Ridge. Sci. Rep. 2021, 11, 6285. [Google Scholar] [CrossRef]

- Della Ventura, G. The analysis of asbestos minerals using vibrational spectroscopies (FTIR, Raman): Crystal-chemistry, identification and environmental applications. In Mineral Fibres: Crystal Chemistry, Chemical-Physical Properties, Biological Interaction and Toxicity; Gualtieri, A.F., Ed.; European Mineralogical Union: London, UK, 2017. [Google Scholar]

- Hofmeister, A.M.; Bowey, J.E. Quantitative infrared spectra of hydrosilicates and related minerals. Mon. Not. R. Astron. Soc. 2006, 367, 577–591. [Google Scholar] [CrossRef]

- Rivero Crespo, M.A.; Pereira Gómez, D.; Villa Garcí, M.V.; Gallardo Amores, J.M.; Sánchez Escribano, V. Characterization of serpentines from different regions by transmission electron microscopy, X-ray diffraction, BET specific surface area and vibrational and electronic spectroscopy. Fibers 2019, 7, 47. [Google Scholar] [CrossRef] [Green Version]

- Giacobbe, C.; Gualtieri, A.F.; Quartieri, S.; Rinaudo, C.; Allegrin, M.; Andreozzi, G.B. Spectroscopic study of the product of thermal transformation of chrysotile-asbestos containing materials (ACM). Eur. J. Miner. 2010, 22, 535–546. [Google Scholar] [CrossRef] [Green Version]

- Sedman, J.; van de Voort, F.R.; Ismail, A.A. Attenuated total reflectance spectroscopy: Principles and applications in Infrared analysis of food. In Spectral Methods in Food Analysis; Mossoba, M.M., Ed.; Marcel Dekker Inc.: New York, NY, USA, 1999; pp. 397–426. [Google Scholar]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Cattaneo, A.; Gualtieri, A.F.; Artioli, G. Kinetic study of the dehydroxylation of chrysotile asbestos with temperature by in situ XRPD. Phys. Chem. Miner. 2003, 30, 177–183. [Google Scholar] [CrossRef]

- Pollastri, S.; Gualtieri, A.F.; Lassinantti Gualtieri, M.; Hanuskova, M.; Cavallo, A.; Gaudino, G. The zeta potential of mineral fibres. J. Hazard. Mater. 2014, 276, 469–479. [Google Scholar] [CrossRef]

| References | Milling Methods | Environmental Conditions | Advantages/ Disadvantages |

|---|---|---|---|

| [23] | Cryogenic vibro-milling with steel balls | −150 °C and wet condition | Preservation of chrysotile crystallinity |

| [32] | Mechanical friction with cylindrical milling elements | Room temperature and wet condition | Reduction in chrysotile crystallinity |

| [32] | Agate mortar | Room temperature and dry condition | Reduction in chrysotile crystallinity |

| [33,35] | Ball milling | Room temperature and dry condition | Reduction in chrysotile crystallinity |

| [34,35] | Ball milling | Room temperature and wet condition | Water-wet conditions preserves the chrysotile crystallinity |

| [36] | Ring mill equipped with a tungsten carbide bowl | Room temperature and dry condition | Reduction in chrysotile crystallinity |

| [37] | Rotary mill | Room temperature and dry condition | Reduction in chrysotile crystallinity |

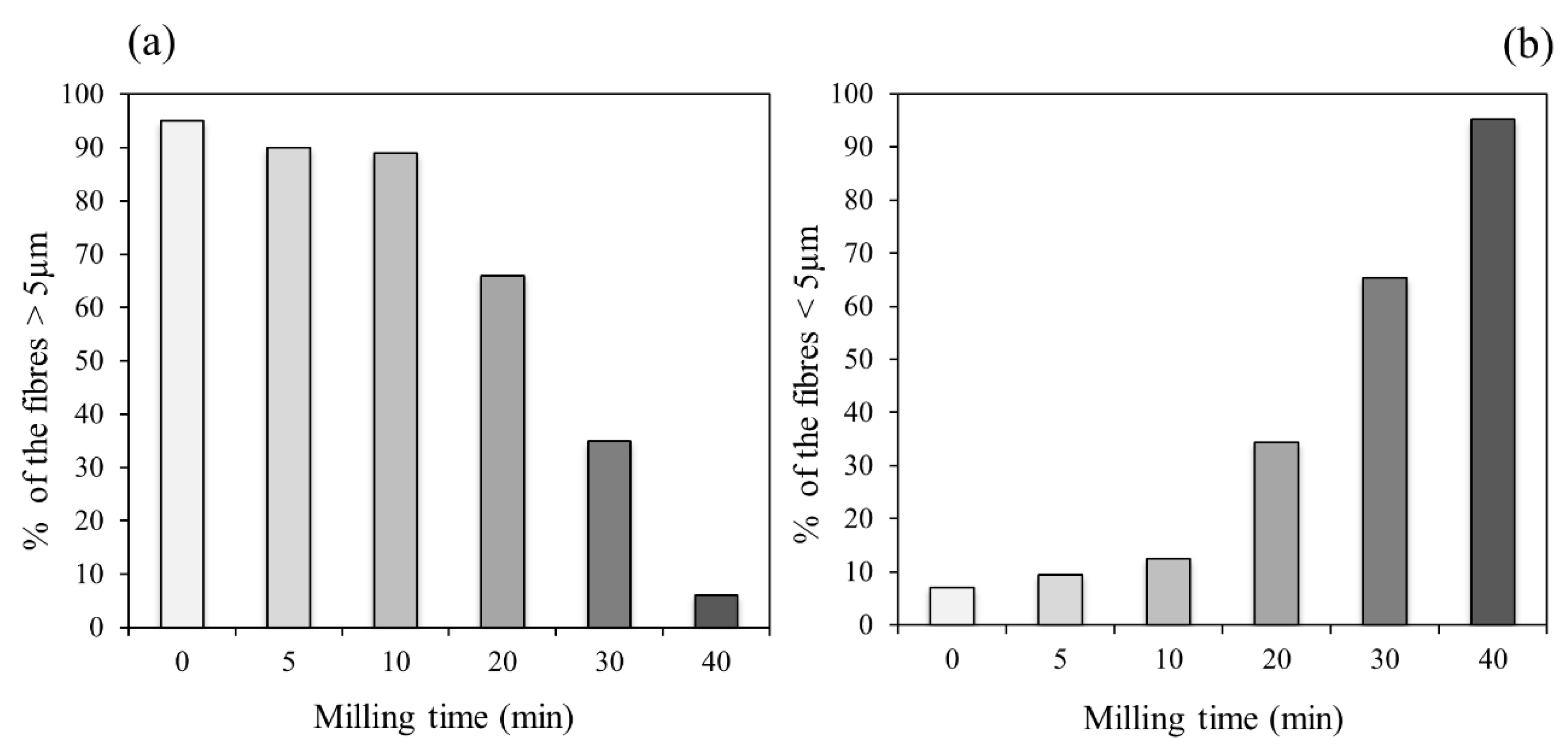

| CHR | CHR5 | CHR10 | CHR20 | CHR30 | CHR40 | |

|---|---|---|---|---|---|---|

| Length classes (µm) | ||||||

| 0–5 | 7.00% | 9.43% | 12.5% | 34.4% | 65.3% | 95.2% |

| 5–10 | 7.50% | 21.7% | 41.7% | 32.8% | 28.1% | 1.08% |

| 10–15 | 10.5% | 11.3% | 16.7% | 11.5% | 2.04% | 1.61% |

| 15–20 | 13.5% | 8.49% | 12.5% | 6.56% | 3.57% | 0.54% |

| >20 | 61.5% | 49.1% | 16.7% | 14.8% | 1.02% | 1.61% |

| Average (µm) | 33.9 | 29.80 | 14.32 | 10.7 | 4.89 | 1.91 |

| Maximum (µm) | 188.1 | 159.8 | 79.9 | 53.6 | 22.1 | 22.1 |

| Minimum (µm) | 1.36 | 1.45 | 2.02 | 1.29 | 0.43 | 0.25 |

| Standard error | 1.99 | 3.08 | 2.08 | 1.34 | 0.27 | 0.21 |

| N | 200 | 100 | 100 | 100 | 200 | 200 |

| Min | Max | Mean | Si/Mg | |

|---|---|---|---|---|

| Raw chrysotile | ||||

| SiO2 | 47.79 | 53.61 | 50.58 (1.2) | 1.05 |

| MgO | 42.15 | 50.84 | 48.27 (2.1) | |

| Chrysotile 40 min | ||||

| SiO2 | 38.74 | 55.39 | 49.46 (0.5) | 1.02 |

| MgO | 40.49 | 61.26 | 48.31 (0.7) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scognamiglio, V.; Di Giuseppe, D.; Lassinantti Gualtieri, M.; Tomassetti, L.; Gualtieri, A.F. A Systematic Study of the Cryogenic Milling of Chrysotile Asbestos. Appl. Sci. 2021, 11, 4826. https://doi.org/10.3390/app11114826

Scognamiglio V, Di Giuseppe D, Lassinantti Gualtieri M, Tomassetti L, Gualtieri AF. A Systematic Study of the Cryogenic Milling of Chrysotile Asbestos. Applied Sciences. 2021; 11(11):4826. https://doi.org/10.3390/app11114826

Chicago/Turabian StyleScognamiglio, Valentina, Dario Di Giuseppe, Magdalena Lassinantti Gualtieri, Laura Tomassetti, and Alessandro F. Gualtieri. 2021. "A Systematic Study of the Cryogenic Milling of Chrysotile Asbestos" Applied Sciences 11, no. 11: 4826. https://doi.org/10.3390/app11114826

APA StyleScognamiglio, V., Di Giuseppe, D., Lassinantti Gualtieri, M., Tomassetti, L., & Gualtieri, A. F. (2021). A Systematic Study of the Cryogenic Milling of Chrysotile Asbestos. Applied Sciences, 11(11), 4826. https://doi.org/10.3390/app11114826