Torsional Behavior Evaluation of Reinforced Concrete Beams Using Artificial Neural Network

Abstract

1. Introduction

2. Current Design Code Approaches for Torsion

2.1. ACI 318-19

2.2. EC2-04

2.3. CSA-14

2.4. JSCE-07

3. Development of ANN Model

3.1. Data Selection for the Training and Validation Set

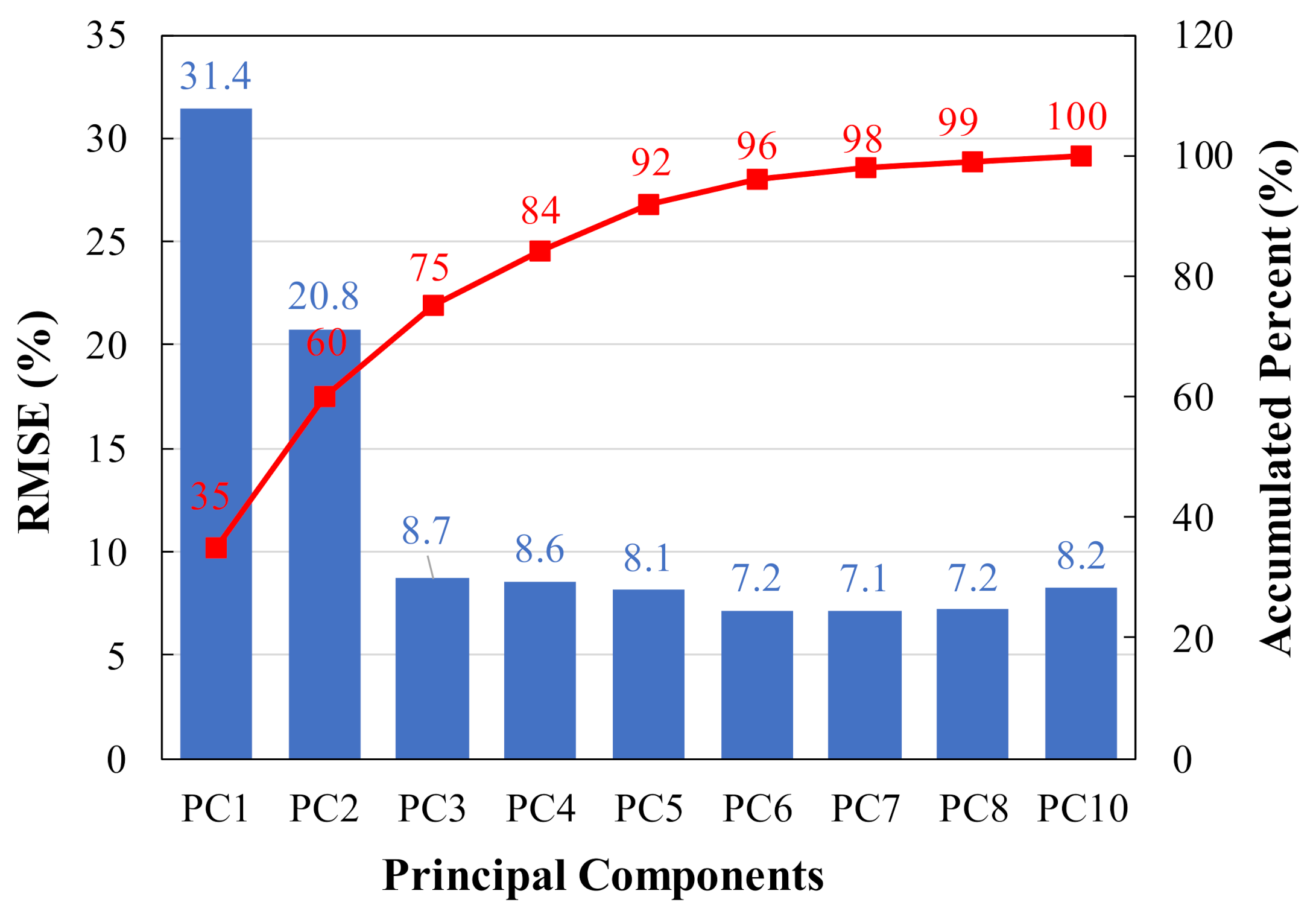

3.2. Principal Component Analysis

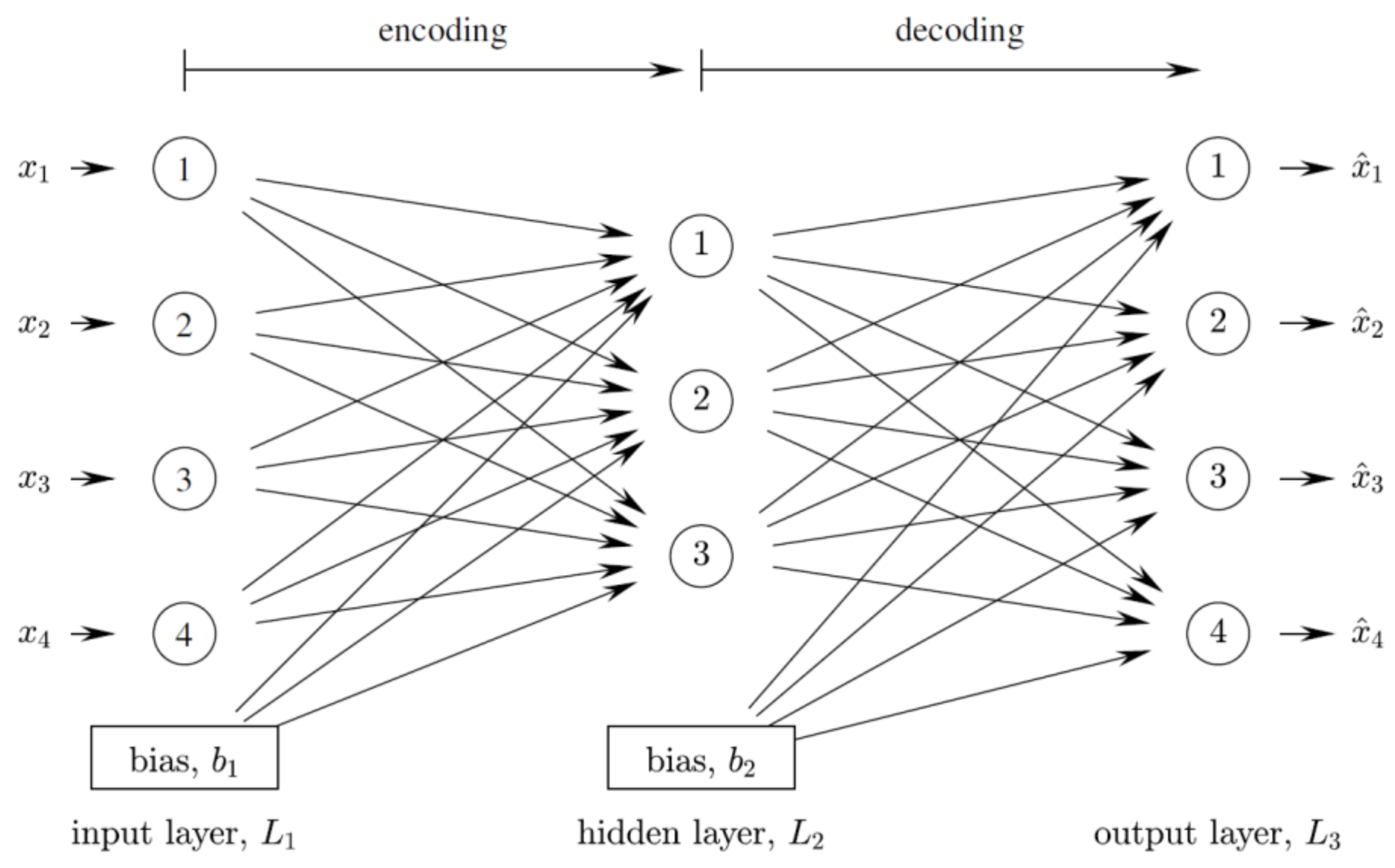

3.3. Autoencoder

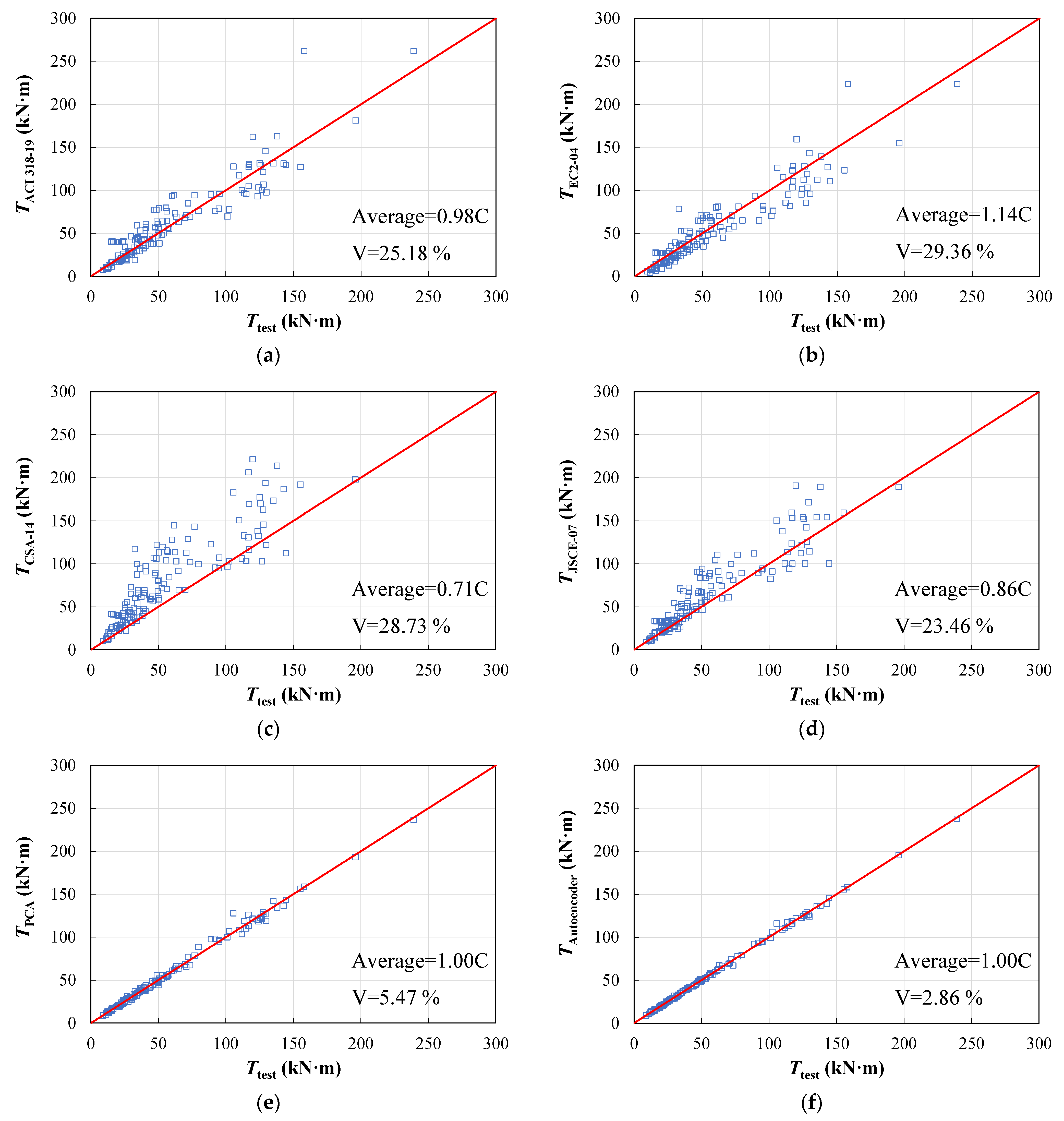

3.4. Results of ANN Analysis

4. Model Validation

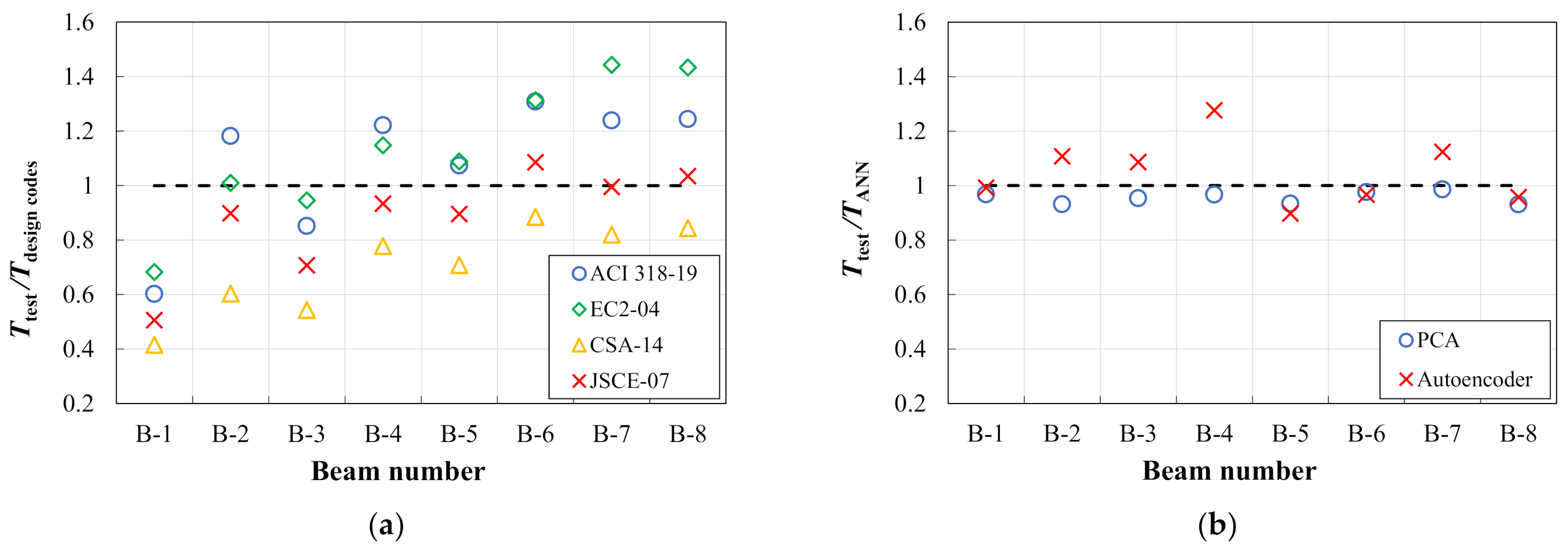

4.1. Validation Data Set

4.2. Validation Data Results

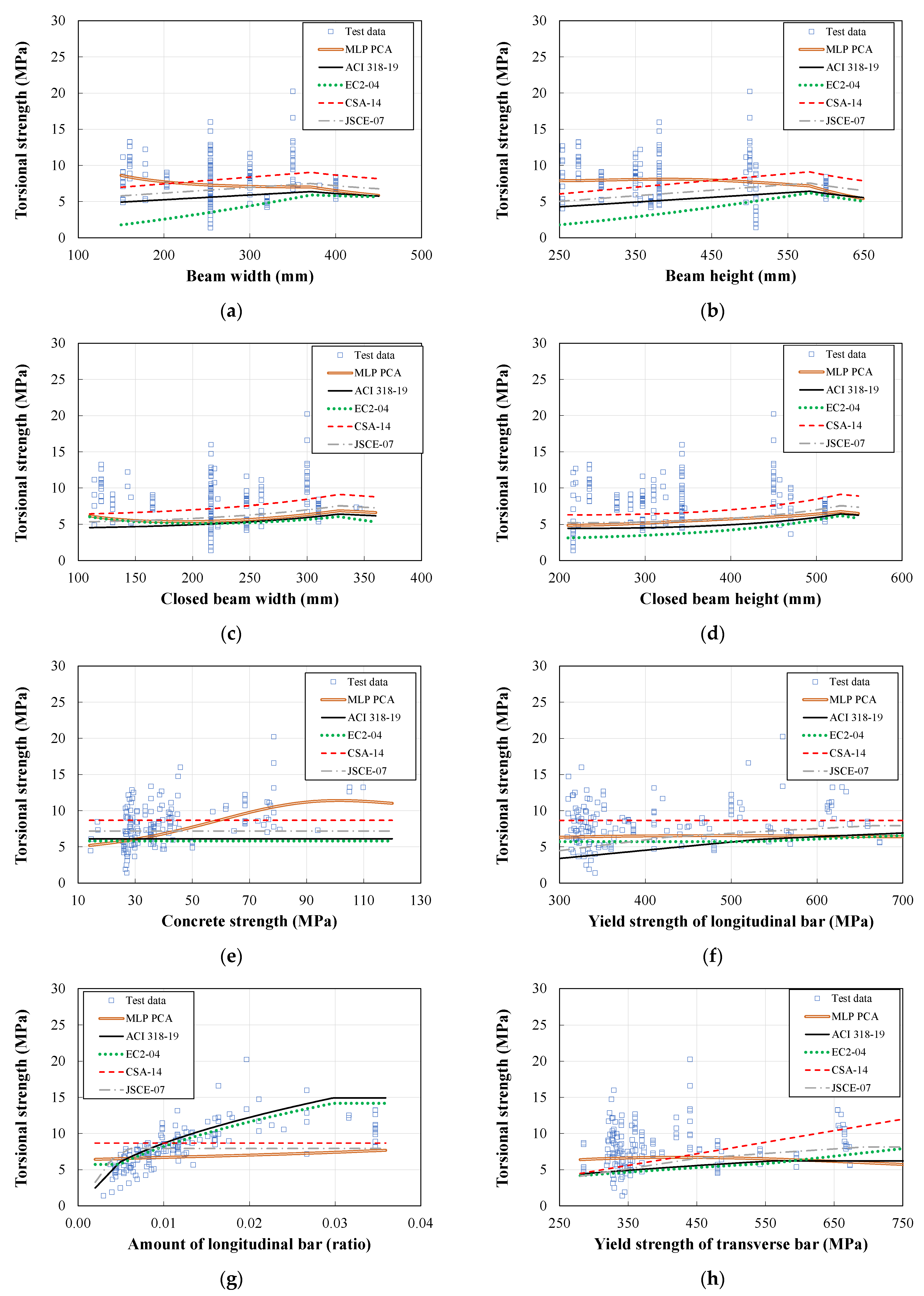

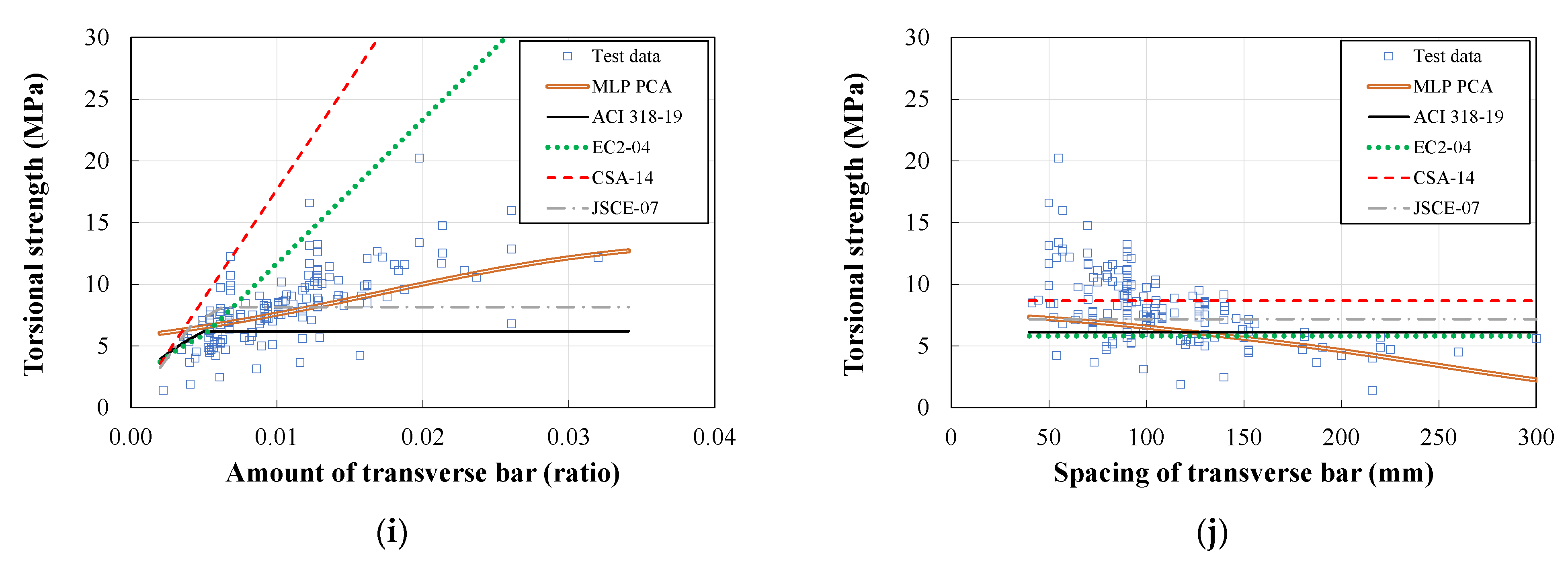

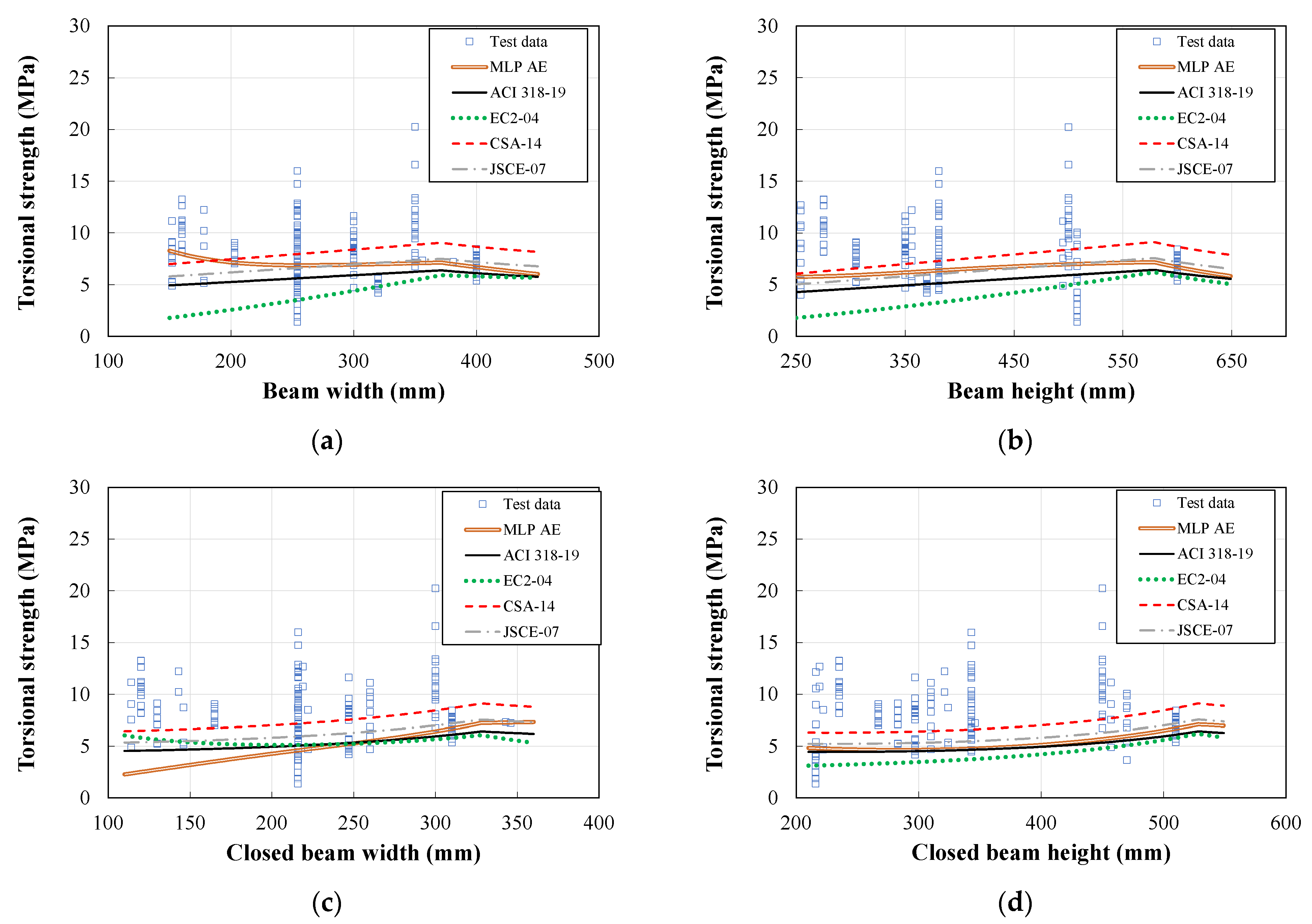

5. Parametric Study

5.1. Size of Concrete Section

5.2. Concrete Strength

5.3. Amount and Yielding Strength of Longitudinal Reinforcement

5.4. Amount and Yielding Strength of Transverse Reinforcement

6. Conclusions

- The data collected to utilize the ANN technique was almost double that of the existing publications.

- In addition to BPNN algorithms, two preconditioners, PCA and an autoencoder, were also used. These were shown to increase the accuracy.

- Predicting the torsional strength of RC beams was straightforward with the trained ANN algorithms.

- The trained ANN could better reflect the effect of input variables for those that were not well reflected by the current design codes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Specimen | Section Details | Concrete | Longitudinal Bar | Transverse Bar | Test Strength | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| b (mm) | h (mm) | b′ (mm) | h′ (mm) | ρl (%) | fyl (MPa) | ρt (%) | fyt (MPa) | s (mm) | Tu (kNm) | ||

| T1-C42S40 | 300 | 350 | 247 | 297 | 42.2 | 1.00 | 317 | 1.01 | 340 | 130 | 44.62 |

| T1-C42S50 | 300 | 350 | 247 | 297 | 42.2 | 1.00 | 469 | 1.01 | 480 | 130 | 50.06 |

| T1-C70S40 | 300 | 350 | 247 | 297 | 68.4 | 1.00 | 317 | 1.01 | 340 | 130 | 50.79 |

| T1-C70S50 | 300 | 350 | 247 | 297 | 68.4 | 1.00 | 469 | 1.01 | 480 | 130 | 50.06 |

| T1-C70S60 | 300 | 350 | 247 | 297 | 68.4 | 1.00 | 659 | 1.01 | 667 | 130 | 50.45 |

| T2-C42S40 | 300 | 350 | 247 | 297 | 42.2 | 1.51 | 310 | 1.88 | 340 | 70 | 56.83 |

| T2-C42S50 | 300 | 350 | 247 | 297 | 42.2 | 1.13 | 466 | 1.46 | 480 | 90 | 53.21 |

| T2-C42S60 | 300 | 350 | 247 | 297 | 42.2 | 1.00 | 659 | 0.94 | 667 | 140 | 46.65 |

| T2-C70S50 | 300 | 350 | 247 | 297 | 68.4 | 1.13 | 466 | 1.46 | 480 | 90 | 48.86 |

| T2-C70S60 | 300 | 350 | 247 | 297 | 68.4 | 1.00 | 659 | 0.94 | 667 | 140 | 48.55 |

| C24SD30-ACI | 320 | 370 | 247 | 297 | 26.0 | 0.67 | 335 | 0.58 | 353 | 200 | 30.16 |

| C24SD30-EC | 320 | 370 | 247 | 297 | 26.0 | 1.34 | 335 | 1.29 | 353 | 90 | 40.60 |

| C24G60-ACI | 320 | 370 | 247 | 297 | 26.0 | 0.43 | 480 | 0.45 | 480 | 260 | 31.58 |

| C24G60-mid | 320 | 370 | 247 | 297 | 26.0 | 0.64 | 480 | 0.65 | 480 | 180 | 32.80 |

| C24G60-EC | 320 | 370 | 247 | 297 | 26.0 | 0.88 | 442 | 0.97 | 480 | 120 | 36.64 |

| C42G60-mid | 320 | 370 | 247 | 297 | 50.0 | 0.64 | 480 | 0.78 | 480 | 150 | 39.70 |

| C42G80-ACI | 320 | 370 | 247 | 297 | 50.0 | 0.43 | 673 | 0.39 | 673 | 300 | 38.96 |

| C42G80-mid | 320 | 370 | 247 | 297 | 50.0 | 0.64 | 673 | 0.53 | 673 | 220 | 39.83 |

| T1-350-65 | 400 | 600 | 310 | 510 | 35.4 | 0.75 | 313 | 0.75 | 334 | 65 | 123.45 |

| T1-480-90 | 400 | 600 | 310 | 510 | 35.4 | 0.55 | 475 | 0.54 | 486 | 90 | 124.11 |

| T1-660-122.5 | 400 | 600 | 310 | 510 | 35.4 | 0.44 | 569 | 0.40 | 595 | 123 | 88.87 |

| T2-480-72.5 | 400 | 600 | 310 | 510 | 35.3 | 0.69 | 468 | 0.67 | 486 | 73 | 105.61 |

| T2-660-100 | 400 | 600 | 310 | 510 | 35.3 | 0.54 | 567 | 0.49 | 595 | 100 | 109.91 |

| T3-350-90 | 400 | 600 | 310 | 510 | 35.4 | 0.55 | 318 | 0.54 | 334 | 90 | 101.10 |

| T3-660-90 | 400 | 600 | 310 | 510 | 35.4 | 0.60 | 570 | 0.54 | 595 | 90 | 117.15 |

| T4-660-72.5 | 400 | 600 | 310 | 510 | 35.3 | 0.75 | 565 | 0.67 | 595 | 73 | 119.83 |

| H1-350-65 | 400 | 600 | 310 | 510 | 36.5 | 0.75 | 365 | 0.75 | 356 | 65 | 127.83 |

| H1-480-90 | 400 | 600 | 310 | 510 | 36.5 | 0.55 | 451 | 0.54 | 454 | 90 | 129.92 |

| H1-540-100 | 400 | 600 | 310 | 510 | 36.5 | 0.50 | 546 | 0.49 | 542 | 100 | 116.80 |

| H2-350-52.5 | 400 | 600 | 310 | 510 | 30.7 | 0.93 | 357 | 0.93 | 360 | 53 | 142.81 |

| H2-480-72.5 | 400 | 600 | 310 | 510 | 36.5 | 0.69 | 449 | 0.67 | 454 | 73 | 127.54 |

| H2-540-80 | 400 | 600 | 310 | 510 | 36.5 | 0.60 | 545 | 0.61 | 542 | 80 | 125.65 |

| H3-350-90 | 400 | 600 | 310 | 510 | 36.5 | 0.55 | 363 | 0.54 | 356 | 90 | 102.48 |

| H3-540-135 | 400 | 600 | 310 | 510 | 36.5 | 0.38 | 544 | 0.36 | 542 | 135 | 94.71 |

| H4-350-72.5 | 400 | 600 | 310 | 510 | 30.7 | 0.69 | 359 | 0.67 | 360 | 73 | 113.65 |

| H4-540-72.5 | 400 | 600 | 310 | 510 | 36.5 | 0.69 | 543 | 0.67 | 542 | 73 | 129.32 |

| B5UR1 | 203 | 305 | 165 | 267 | 39.6 | 0.82 | 386 | 0.92 | 373 | 108 | 19.40 |

| B7UR1 | 203 | 305 | 165 | 267 | 64.6 | 0.82 | 386 | 0.92 | 399 | 108 | 18.90 |

| B9UR1 | 203 | 305 | 165 | 267 | 75.0 | 0.82 | 386 | 0.92 | 373 | 108 | 21.10 |

| B12UR1 | 203 | 305 | 165 | 267 | 80.6 | 0.82 | 386 | 0.92 | 399 | 108 | 19.40 |

| B12UR2 | 203 | 305 | 165 | 267 | 76.2 | 0.82 | 386 | 0.97 | 386 | 102 | 18.40 |

| B12UR3 | 203 | 305 | 165 | 267 | 72.9 | 1.05 | 376 | 1.04 | 386 | 95 | 22.50 |

| B12UR4 | 203 | 305 | 165 | 267 | 75.9 | 1.23 | 373 | 1.10 | 386 | 90 | 23.70 |

| B12UR5 | 203 | 305 | 165 | 267 | 76.7 | 1.28 | 380 | 1.41 | 386 | 70 | 24.00 |

| B1 | 254 | 381 | 216 | 343 | 27.6 | 0.53 | 314 | 0.54 | 341 | 152 | 22.26 |

| B2 | 254 | 381 | 216 | 343 | 28.6 | 0.83 | 316 | 0.82 | 320 | 181 | 29.26 |

| B3 | 254 | 381 | 216 | 343 | 28.1 | 1.17 | 328 | 1.17 | 320 | 127 | 37.51 |

| B4 | 254 | 381 | 216 | 343 | 30.5 | 1.60 | 320 | 1.62 | 323 | 92 | 47.34 |

| B5 | 254 | 381 | 216 | 343 | 29.0 | 2.11 | 332 | 2.13 | 321 | 70 | 56.16 |

| B6 | 254 | 381 | 216 | 343 | 28.8 | 2.67 | 332 | 2.61 | 323 | 57 | 61.69 |

| B7 | 254 | 381 | 216 | 343 | 26.0 | 0.53 | 320 | 1.17 | 319 | 127 | 26.89 |

| B8 | 254 | 381 | 216 | 343 | 26.8 | 0.53 | 322 | 2.61 | 320 | 57 | 32.54 |

| B9 | 254 | 381 | 216 | 343 | 28.8 | 1.17 | 319 | 0.54 | 343 | 152 | 29.83 |

| B10 | 254 | 381 | 216 | 343 | 26.5 | 2.67 | 334 | 0.54 | 342 | 152 | 34.35 |

| D1 | 254 | 381 | 216 | 343 | 26.6 | 0.53 | 333 | 0.54 | 338 | 152 | 22.37 |

| D2 | 254 | 381 | 216 | 343 | 25.6 | 0.83 | 323 | 0.82 | 331 | 181 | 27.68 |

| D3 | 254 | 381 | 216 | 343 | 28.4 | 1.17 | 341 | 1.17 | 333 | 127 | 39.09 |

| D4 | 254 | 381 | 216 | 343 | 30.6 | 1.60 | 330 | 1.62 | 333 | 92 | 47.91 |

| M1 | 254 | 381 | 216 | 343 | 29.9 | 0.83 | 326 | 0.55 | 353 | 149 | 30.39 |

| M2 | 254 | 381 | 216 | 343 | 30.5 | 1.17 | 329 | 0.78 | 357 | 105 | 40.56 |

| M3 | 254 | 381 | 216 | 343 | 26.8 | 1.60 | 322 | 1.07 | 326 | 140 | 43.84 |

| M4 | 254 | 381 | 216 | 343 | 26.5 | 2.11 | 319 | 1.42 | 327 | 105 | 49.60 |

| M5 | 254 | 381 | 216 | 343 | 28.0 | 2.67 | 335 | 1.81 | 331 | 83 | 55.70 |

| M6 | 254 | 381 | 216 | 343 | 29.4 | 3.16 | 318 | 2.13 | 341 | 70 | 60.11 |

| I2 | 254 | 381 | 216 | 343 | 45.2 | 0.83 | 325 | 0.83 | 349 | 98 | 36.04 |

| I3 | 254 | 381 | 216 | 343 | 44.7 | 1.17 | 343 | 1.17 | 334 | 127 | 45.65 |

| I4 | 254 | 381 | 216 | 343 | 45.0 | 1.60 | 315 | 1.62 | 326 | 92 | 58.08 |

| I5 | 254 | 381 | 216 | 343 | 45.0 | 2.11 | 310 | 2.13 | 325 | 70 | 70.73 |

| I6 | 254 | 381 | 216 | 343 | 45.8 | 2.67 | 325 | 2.61 | 329 | 57 | 76.72 |

| G1 | 254 | 508 | 216 | 470 | 29.8 | 0.40 | 322 | 0.40 | 339 | 187 | 26.78 |

| G3 | 254 | 508 | 216 | 470 | 26.8 | 0.88 | 339 | 0.88 | 328 | 156 | 49.60 |

| G4 | 254 | 508 | 216 | 470 | 28.3 | 1.20 | 325 | 1.20 | 321 | 114 | 64.86 |

| G5 | 254 | 508 | 216 | 470 | 26.9 | 1.58 | 331 | 1.60 | 328 | 86 | 71.98 |

| G6 | 254 | 508 | 216 | 470 | 29.9 | 0.60 | 334 | 0.59 | 350 | 127 | 39.09 |

| G7 | 254 | 508 | 216 | 470 | 31.0 | 0.93 | 319 | 0.94 | 323 | 146 | 52.65 |

| G8 | 254 | 508 | 216 | 470 | 28.3 | 1.32 | 322 | 1.31 | 329 | 105 | 73.45 |

| N1 | 152 | 305 | 130 | 283 | 29.5 | 0.61 | 352 | 0.61 | 341 | 92 | 9.09 |

| N1A | 152 | 305 | 130 | 283 | 28.7 | 0.61 | 346 | 0.61 | 345 | 92 | 8.99 |

| N2 | 152 | 305 | 130 | 283 | 30.4 | 1.11 | 331 | 1.11 | 338 | 51 | 14.46 |

| N2A | 152 | 305 | 130 | 283 | 28.4 | 1.11 | 333 | 1.11 | 361 | 114 | 13.22 |

| N3 | 152 | 305 | 130 | 283 | 27.3 | 0.91 | 352 | 0.89 | 352 | 64 | 12.20 |

| N4 | 152 | 305 | 130 | 283 | 27.3 | 1.42 | 340 | 1.42 | 356 | 89 | 15.70 |

| K1 | 152 | 495 | 114 | 457 | 29.9 | 0.56 | 345 | 0.57 | 354 | 191 | 15.36 |

| K2 | 152 | 495 | 114 | 457 | 30.6 | 1.02 | 336 | 1.03 | 338 | 105 | 23.73 |

| K3 | 152 | 495 | 114 | 457 | 29.0 | 1.59 | 316 | 1.58 | 321 | 124 | 28.47 |

| K4 | 152 | 495 | 114 | 457 | 28.6 | 2.26 | 344 | 2.28 | 340 | 86 | 35.03 |

| C1 | 254 | 254 | 216 | 216 | 27.0 | 0.44 | 341 | 0.44 | 341 | 216 | 11.30 |

| C2 | 254 | 254 | 216 | 216 | 26.5 | 0.80 | 334 | 0.81 | 345 | 117 | 15.25 |

| C3 | 254 | 254 | 216 | 216 | 26.9 | 1.24 | 331 | 1.24 | 330 | 140 | 20.00 |

| C4 | 254 | 254 | 216 | 216 | 27.2 | 1.76 | 336 | 1.76 | 328 | 98 | 25.31 |

| C5 | 254 | 254 | 216 | 216 | 27.2 | 2.40 | 328 | 2.37 | 329 | 73 | 29.71 |

| C6 | 254 | 254 | 216 | 216 | 27.6 | 3.16 | 316 | 3.20 | 328 | 54 | 34.23 |

| J1 | 254 | 381 | 216 | 343 | 14.3 | 0.53 | 328 | 0.54 | 346 | 152 | 21.47 |

| J2 | 254 | 381 | 216 | 343 | 14.5 | 0.83 | 320 | 0.83 | 341 | 98 | 29.15 |

| J3 | 254 | 381 | 216 | 343 | 16.9 | 1.17 | 339 | 1.17 | 337 | 127 | 35.25 |

| J4 | 254 | 381 | 216 | 343 | 16.8 | 1.60 | 324 | 1.62 | 332 | 92 | 40.68 |

| PT4 | 381 | 381 | 346 | 346 | 28.6 | 1.10 | 425 | 0.66 | 328 | 102 | 70.00 |

| PT5 | 356 | 356 | 343 | 343 | 33.8 | 1.26 | 373 | 0.75 | 328 | 102 | 65.20 |

| A1 | 254 | 254 | 222 | 222 | 36.9 | 0.44 | 360 | 0.55 | 285 | 79 | 13.10 |

| A1R | 254 | 254 | 222 | 222 | 39.6 | 0.44 | 360 | 0.55 | 285 | 79 | 12.50 |

| A2 | 254 | 254 | 222 | 222 | 38.2 | 0.80 | 380 | 1.06 | 285 | 41 | 22.60 |

| A3 | 254 | 254 | 219 | 219 | 39.4 | 1.24 | 352 | 1.21 | 360 | 79 | 27.80 |

| A4 | 254 | 254 | 219 | 219 | 39.2 | 1.77 | 351 | 1.69 | 360 | 57 | 34.50 |

| B1 | 178 | 356 | 146 | 324 | 36.3 | 0.45 | 360 | 0.57 | 285 | 83 | 12.80 |

| B1R | 178 | 356 | 146 | 324 | 39.9 | 0.45 | 360 | 0.57 | 285 | 83 | 12.30 |

| B2 | 178 | 356 | 146 | 324 | 39.6 | 0.81 | 380 | 1.06 | 285 | 44 | 20.80 |

| B3 | 178 | 356 | 143 | 321 | 38.6 | 1.26 | 352 | 1.26 | 360 | 83 | 25.30 |

| B4 | 178 | 356 | 143 | 321 | 38.5 | 1.80 | 351 | 1.72 | 360 | 60 | 31.80 |

| B30.1 | 160 | 275 | 120 | 235 | 41.7 | 3.47 | 620 | 1.28 | 665 | 90 | 16.62 |

| B30.2 | 160 | 275 | 120 | 235 | 38.2 | 3.47 | 638 | 1.28 | 669 | 90 | 15.29 |

| B30.3 | 160 | 275 | 120 | 235 | 36.3 | 3.47 | 605 | 1.28 | 672 | 90 | 15.25 |

| B50.1 | 160 | 275 | 120 | 235 | 61.8 | 3.47 | 612 | 1.28 | 665 | 90 | 19.95 |

| B50.2 | 160 | 275 | 120 | 235 | 57.1 | 3.47 | 614 | 1.28 | 665 | 90 | 18.46 |

| B50.3 | 160 | 275 | 120 | 235 | 61.7 | 3.47 | 612 | 1.28 | 665 | 90 | 19.13 |

| B70.1 | 160 | 275 | 120 | 235 | 77.3 | 3.47 | 617 | 1.28 | 658 | 90 | 20.06 |

| B70.2 | 160 | 275 | 120 | 235 | 76.9 | 3.47 | 614 | 1.28 | 656 | 90 | 20.74 |

| B70.3 | 160 | 275 | 120 | 235 | 76.2 | 3.47 | 617 | 1.28 | 663 | 90 | 20.96 |

| B110.1 | 160 | 275 | 120 | 235 | 109.8 | 3.47 | 618 | 1.28 | 655 | 90 | 24.72 |

| B110.2 | 160 | 275 | 120 | 235 | 105.0 | 3.47 | 634 | 1.28 | 660 | 90 | 23.62 |

| B110.3 | 160 | 275 | 120 | 235 | 105.1 | 3.47 | 629 | 1.28 | 655 | 90 | 24.77 |

| T1-1 | 300 | 350 | 260 | 310 | 43.2 | 0.48 | 410 | 0.60 | 370 | 130 | 32.86 |

| T1-2 | 300 | 350 | 260 | 310 | 44.0 | 0.72 | 410 | 0.91 | 370 | 85 | 45.89 |

| T1-3 | 300 | 350 | 260 | 310 | 41.7 | 0.97 | 410 | 1.19 | 370 | 65 | 54.05 |

| T1-4 | 300 | 350 | 260 | 310 | 42.6 | 1.13 | 510 | 1.83 | 355 | 75 | 62.41 |

| T2-1 | 300 | 350 | 260 | 310 | 40.1 | 0.48 | 410 | 0.34 | 370 | 225 | 26.05 |

| T2-2 | 300 | 350 | 260 | 310 | 41.7 | 0.76 | 510 | 0.60 | 370 | 130 | 38.11 |

| T2-3 | 300 | 350 | 260 | 310 | 42.7 | 1.13 | 510 | 0.88 | 370 | 88 | 50.16 |

| T2-4 | 300 | 350 | 260 | 310 | 42.6 | 1.33 | 512 | 1.03 | 370 | 75 | 56.39 |

| H-06-06 | 350 | 500 | 300 | 450 | 78.5 | 0.68 | 440 | 0.61 | 440 | 100 | 92.00 |

| H-06-12 | 350 | 500 | 300 | 450 | 78.5 | 1.16 | 410 | 0.61 | 440 | 100 | 115.10 |

| H-12-12 | 350 | 500 | 300 | 450 | 78.5 | 1.16 | 410 | 1.22 | 440 | 50 | 155.30 |

| H-12-16 | 350 | 500 | 300 | 450 | 78.5 | 1.64 | 520 | 1.22 | 440 | 50 | 196.00 |

| H-20-20 | 350 | 500 | 300 | 450 | 78.5 | 1.96 | 560 | 1.97 | 440 | 55 | 239.00 |

| H-07-10 | 350 | 500 | 300 | 450 | 68.4 | 0.98 | 500 | 0.68 | 420 | 90 | 126.70 |

| H-14-10 | 350 | 500 | 300 | 450 | 68.4 | 0.98 | 500 | 1.36 | 360 | 80 | 135.20 |

| H-07-16 | 350 | 500 | 300 | 450 | 68.4 | 1.64 | 500 | 0.68 | 420 | 90 | 144.50 |

| N-06-06 | 350 | 500 | 300 | 450 | 35.5 | 0.68 | 440 | 0.61 | 440 | 100 | 79.70 |

| N-06-12 | 350 | 500 | 300 | 450 | 35.5 | 1.16 | 410 | 0.61 | 440 | 100 | 95.20 |

| N-12-12 | 350 | 500 | 300 | 450 | 35.5 | 1.16 | 410 | 1.22 | 440 | 50 | 116.80 |

| N-12-16 | 350 | 500 | 300 | 450 | 35.5 | 1.64 | 420 | 1.22 | 440 | 50 | 138.00 |

| N-20-20 | 350 | 500 | 300 | 450 | 35.5 | 1.96 | 560 | 1.97 | 440 | 55 | 158.00 |

| N-07-10 | 350 | 500 | 300 | 450 | 33.5 | 0.98 | 500 | 0.68 | 420 | 90 | 111.70 |

| N-14-10 | 350 | 500 | 300 | 450 | 33.5 | 0.98 | 500 | 1.36 | 360 | 80 | 125.00 |

| N-07-16 | 350 | 500 | 300 | 450 | 33.5 | 1.64 | 500 | 0.68 | 420 | 90 | 117.30 |

| HS-33 | 254 | 508 | 215.9 | 469.9 | 28.34 | 1.33 | 321.99 | 1.28 | 328.88 | 104.9 | 63.3 |

| HS-34 | 254 | 508 | 215.9 | 215.9 | 27.03 | 0.30 | 341.29 | 0.22 | 341.29 | 215.9 | 11.3 |

| HS-35 | 254 | 508 | 215.9 | 215.9 | 26.54 | 0.39 | 334.4 | 0.41 | 344.74 | 117.6 | 15.3 |

| HS-36 | 254 | 508 | 215.9 | 215.9 | 26.89 | 0.49 | 330.95 | 0.61 | 329.57 | 139.7 | 20 |

| HS-37 | 254 | 508 | 215.9 | 215.9 | 27.17 | 0.59 | 336.46 | 0.86 | 327.5 | 98.6 | 25.3 |

| HS-38 | 254 | 508 | 215.9 | 215.9 | 27.23 | 0.69 | 328.19 | 1.16 | 328.88 | 73.2 | 29.7 |

| HS-39 | 254 | 508 | 215.9 | 215.9 | 27.58 | 0.79 | 315.78 | 1.57 | 327.5 | 54.1 | 34.2 |

| j | i | Output | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | Bias | ||

| 1 | −0.1545 | 0.1662 | 0.1384 | 0.6391 | 0.4325 | 0.3042 | 0.9473 | 0.7981 |

| 2 | −0.5281 | 1.1510 | 1.2343 | 0.2340 | −0.4649 | −0.6759 | 4.4658 | −1.8626 |

| 3 | −1.4639 | 0.1587 | −0.4870 | −0.0452 | −0.2854 | −0.3282 | −0.7895 | −1.5143 |

| 4 | 0.0019 | 0.0082 | −0.0013 | 0.0156 | 0.0010 | 0.0044 | −0.2514 | 0.0192 |

| 5 | 0.0020 | 0.0064 | −0.0041 | 0.0183 | 0.0021 | 0.0068 | −0.0726 | 0.0215 |

| 6 | 0.0029 | 0.0081 | −0.0045 | 0.0209 | 0.0018 | 0.0083 | −0.0249 | 0.0243 |

| 7 | −0.0013 | 0.0037 | −0.0012 | 0.0026 | 0.0005 | 0.0000 | 0.5251 | 0.0051 |

| 8 | 0.0009 | 0.0031 | −0.0023 | 0.0062 | 0.0008 | 0.0028 | −0.1684 | 0.0080 |

| 9 | 0.0041 | 0.0105 | −0.0044 | 0.0232 | 0.0009 | 0.0087 | −0.0521 | 0.0280 |

| 10 | −0.1247 | 0.1927 | −0.4994 | −0.1091 | −0.5657 | −0.1735 | 0.9192 | 0.6379 |

| 11 | −0.3498 | 0.0057 | 0.0178 | −0.3881 | 0.0938 | −0.9444 | 0.9381 | −0.8587 |

| 12 | −0.1445 | −0.6899 | −0.1118 | −2.1050 | 0.5718 | 0.2138 | 0.9358 | 1.2367 |

| 13 | 0.0008 | 0.0045 | −0.0031 | 0.0067 | 0.0005 | 0.0042 | 0.0629 | 0.0093 |

| 14 | 0.3453 | −0.1055 | 1.0681 | 0.4641 | −0.4305 | 0.3656 | −0.4678 | −0.7170 |

| 15 | 0.0038 | 0.0104 | −0.0094 | 0.0407 | 0.0045 | 0.0165 | 0.1316 | 0.0450 |

| 16 | 0.0028 | 0.0051 | −0.0024 | 0.0145 | 0.0003 | 0.0080 | −0.3654 | 0.0145 |

| 17 | 0.0035 | 0.0091 | −0.0060 | 0.0268 | 0.0027 | 0.0108 | 0.0385 | 0.0311 |

| 18 | −0.0006 | 0.0009 | −0.0011 | −0.0007 | −0.0001 | 0.0006 | 0.0116 | 0.0012 |

| 19 | 0.0003 | 0.0031 | −0.0021 | 0.0049 | 0.0002 | 0.0029 | −0.0442 | 0.0076 |

| 20 | −0.0020 | −0.0016 | 0.0003 | −0.0067 | −0.0010 | −0.0008 | −0.2061 | −0.0061 |

| 21 | 0.1284 | −0.0049 | −0.5827 | 0.6024 | −0.7819 | 0.0078 | 0.0088 | 1.0035 |

| 22 | 1.0685 | 1.0795 | −0.3224 | −1.1641 | 0.0630 | 0.0932 | −0.3027 | −1.7037 |

| 23 | 0.0002 | 0.0020 | −0.0022 | 0.0049 | 0.0003 | 0.0029 | −0.2849 | 0.0053 |

| 24 | 0.0012 | −0.0050 | 0.0057 | −0.0036 | 0.0051 | −0.0082 | −1.1914 | −0.0106 |

| 25 | 0.0033 | 0.0121 | −0.0120 | 0.0516 | 0.0082 | 0.0197 | 0.1696 | 0.0578 |

| 26 | 0.7212 | −0.7731 | −0.2847 | −0.9176 | −0.3761 | −0.7928 | 0.9476 | 1.0558 |

| 27 | −0.0001 | 0.0011 | −0.0021 | 0.0008 | −0.0001 | 0.0016 | 0.1582 | 0.0024 |

| 28 | 0.0002 | 0.0005 | −0.0012 | −0.0025 | −0.0005 | −0.0004 | 0.1512 | 0.0001 |

| 29 | −0.0082 | −0.0771 | 0.0585 | −0.1788 | −0.0213 | −0.0640 | −0.4771 | −0.2064 |

| 30 | 0.0036 | −0.0264 | 0.0254 | −0.0324 | 0.0005 | −0.0274 | −0.3046 | −0.0596 |

| 31 | −0.0009 | 0.0127 | −0.0085 | 0.0164 | 0.0019 | 0.0168 | 0.1461 | 0.0278 |

| 32 | −0.0013 | −0.0016 | 0.0000 | −0.0077 | −0.0009 | −0.0022 | −0.0323 | −0.0067 |

| 33 | −0.0011 | 0.0001 | −0.0017 | −0.0011 | −0.0003 | 0.0003 | 0.0040 | −0.0002 |

| 34 | −0.0021 | −0.0002 | −0.0014 | −0.0059 | −0.0001 | −0.0041 | 0.3393 | −0.0035 |

| 35 | 0.0031 | 0.0085 | −0.0060 | 0.0270 | 0.0036 | 0.0110 | 0.0687 | 0.0312 |

| 36 | 0.0011 | 0.0035 | −0.0034 | 0.0083 | −0.0009 | 0.0038 | −0.1523 | 0.0109 |

| 37 | 0.0005 | 0.0034 | −0.0021 | 0.0157 | 0.0007 | 0.0056 | −0.3042 | 0.0175 |

| 38 | −0.2065 | 0.9972 | −0.3582 | −0.2333 | −0.4763 | 0.3482 | 0.2780 | 1.0032 |

| 39 | 0.0003 | 0.0023 | −0.0023 | 0.0055 | 0.0001 | 0.0024 | −0.0375 | 0.0075 |

| 40 | 0.0035 | 0.0085 | −0.0051 | 0.0199 | 0.0016 | 0.0086 | 0.1094 | 0.0239 |

| 41 | 0.0015 | 0.0050 | −0.0034 | 0.0126 | 0.0011 | 0.0055 | −0.1113 | 0.0147 |

| 42 | −0.0098 | −0.0442 | 0.0361 | −0.1166 | −0.0103 | −0.0444 | −0.4152 | −0.1293 |

| 43 | 0.0003 | 0.0010 | −0.0018 | −0.0005 | −0.0002 | 0.0009 | 0.2403 | 0.0025 |

| 44 | −0.4171 | −0.8559 | 0.4381 | −0.3890 | −0.6355 | −0.0345 | −1.6492 | −1.1249 |

| 45 | −0.0012 | 0.0000 | −0.0008 | −0.0062 | −0.0005 | −0.0015 | 0.2185 | −0.0032 |

| 46 | −0.0005 | −0.0009 | −0.0008 | −0.0066 | −0.0007 | −0.0015 | 0.1369 | −0.0040 |

| 47 | −0.0017 | −0.0124 | −0.0028 | −0.0220 | −0.0022 | 0.0022 | 0.4295 | −0.0091 |

| 48 | 0.0370 | −0.0410 | −0.1221 | 0.0599 | −0.0004 | 0.1190 | −1.7507 | 0.1534 |

| 49 | 0.1348 | 0.0679 | 0.0561 | 0.2256 | 0.0476 | 0.1361 | 0.6825 | 0.2366 |

| 50 | 0.0021 | 0.0057 | −0.0036 | 0.0145 | 0.0007 | 0.0070 | −0.0250 | 0.0174 |

| 51 | 1.3530 | −1.6506 | −1.2656 | −0.6204 | −0.1295 | −0.3793 | −2.6746 | 1.7284 |

| 52 | 0.0011 | 0.0037 | −0.0022 | 0.0072 | 0.0004 | 0.0039 | 0.2319 | 0.0109 |

| i | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| j | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | Bias | Output |

| 1 | 0.479 | 0.091 | 0.116 | −0.027 | −0.123 | 0.203 | 0.203 | 0.092 | −0.194 | −0.275 | −0.128 | 0.309 | −0.191 | −1.096 | 0.062 | −0.183 | 0.303 | 0.170 | −0.236 | −0.148 | −1.762 | −1.164 |

| 2 | 0.203 | −0.587 | −0.370 | −0.223 | −0.211 | −0.076 | 0.282 | −0.009 | −0.108 | −0.008 | −0.043 | −0.197 | 0.391 | 0.324 | −0.061 | 0.418 | 0.349 | −0.137 | −0.095 | 0.066 | 0.331 | −0.737 |

| 3 | −0.007 | 0.010 | 0.017 | −0.014 | −0.014 | 0.019 | 0.010 | −0.007 | −0.034 | −0.007 | −0.001 | −0.010 | 0.022 | 0.006 | −0.002 | 0.016 | 0.009 | −0.002 | 0.012 | 0.002 | −0.559 | 0.061 |

| 4 | 0.013 | −0.018 | −0.037 | 0.024 | 0.028 | −0.035 | −0.022 | 0.016 | 0.066 | 0.016 | 0.005 | 0.017 | −0.043 | −0.015 | 0.006 | −0.026 | −0.019 | 0.004 | −0.025 | 0.000 | 0.648 | −0.119 |

| 5 | 0.000 | 0.009 | −0.006 | −0.011 | −0.010 | 0.007 | 0.005 | −0.004 | −0.001 | 0.002 | 0.011 | 0.000 | −0.007 | −0.009 | 0.003 | −0.007 | 0.005 | 0.008 | −0.005 | −0.006 | 0.118 | 0.014 |

| 6 | 0.005 | −0.006 | −0.010 | 0.008 | 0.010 | −0.012 | −0.008 | 0.004 | 0.023 | 0.004 | −0.001 | 0.008 | −0.015 | 0.000 | 0.000 | −0.010 | −0.007 | 0.002 | −0.007 | −0.003 | 0.186 | −0.043 |

| 7 | −0.237 | 0.032 | −0.110 | −0.051 | 0.215 | 0.305 | −0.321 | −0.083 | 0.010 | −0.151 | −0.166 | −0.186 | 0.224 | 0.646 | −0.117 | 0.564 | −0.085 | 0.141 | 0.480 | −0.178 | −0.922 | 0.949 |

| 8 | 0.004 | −0.005 | −0.011 | 0.009 | 0.009 | −0.012 | −0.008 | 0.005 | 0.023 | 0.004 | −0.001 | 0.008 | −0.015 | −0.001 | 0.000 | −0.010 | −0.007 | 0.002 | −0.007 | −0.003 | 0.210 | −0.044 |

| 9 | 0.000 | −0.004 | 0.002 | 0.004 | 0.006 | −0.003 | 0.000 | 0.003 | 0.002 | −0.002 | −0.003 | 0.002 | 0.004 | 0.005 | −0.005 | 0.000 | 0.000 | −0.002 | 0.002 | −0.002 | 0.293 | −0.001 |

| 10 | −0.077 | −0.023 | 0.148 | −0.024 | −0.164 | 0.122 | 0.083 | −0.054 | −0.196 | −0.124 | 0.000 | −0.011 | 0.151 | 0.158 | −0.131 | 0.028 | 0.119 | 0.024 | 0.075 | −0.150 | −1.517 | 0.484 |

| 11 | −0.005 | 0.006 | 0.009 | −0.008 | −0.009 | 0.011 | 0.006 | −0.005 | −0.021 | −0.004 | 0.000 | −0.007 | 0.014 | 0.002 | −0.001 | 0.010 | 0.006 | −0.001 | 0.008 | 0.002 | −0.448 | 0.036 |

| 12 | 0.005 | −0.006 | −0.012 | 0.006 | 0.007 | −0.005 | −0.004 | −0.001 | 0.011 | −0.002 | 0.006 | 0.001 | −0.002 | −0.008 | 0.004 | −0.001 | −0.002 | −0.004 | −0.005 | −0.001 | 0.603 | −0.024 |

| 13 | 1.183 | 0.053 | 0.276 | −0.822 | 0.604 | 0.694 | 0.044 | −0.155 | 0.124 | −0.072 | −0.005 | 0.319 | 0.463 | 0.277 | −0.996 | −0.213 | 0.141 | 0.456 | −0.241 | −0.073 | −3.233 | 1.624 |

| 14 | 0.045 | −0.179 | 0.543 | 0.259 | −0.603 | 0.120 | 0.236 | −0.131 | −0.704 | −0.315 | 0.105 | 0.066 | 0.279 | 0.098 | −0.495 | −0.071 | 0.136 | 0.156 | 0.423 | −0.393 | −3.889 | 1.460 |

| 15 | −0.064 | −0.019 | −0.085 | −0.032 | −0.029 | −0.194 | −0.183 | 0.079 | 0.285 | 0.103 | −0.094 | 0.094 | −0.228 | 0.508 | 0.121 | −0.159 | −0.120 | −0.071 | 0.026 | −0.005 | −0.927 | −0.682 |

| 16 | −0.005 | −0.017 | −0.020 | 0.024 | 0.024 | −0.027 | −0.015 | 0.013 | 0.058 | 0.006 | 0.017 | 0.034 | −0.034 | −0.020 | −0.035 | −0.016 | −0.014 | 0.011 | −0.024 | −0.012 | 0.475 | −0.093 |

| 17 | 0.000 | 0.000 | 0.000 | 0.001 | 0.000 | −0.001 | 0.000 | 0.000 | 0.001 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | −0.001 | 0.001 | 0.000 | 0.000 | 0.000 | −0.001 | −0.090 | −0.002 |

| 18 | −0.115 | −0.114 | 0.170 | 0.017 | −0.336 | 0.175 | 0.105 | −0.040 | −0.219 | −0.239 | 0.154 | −0.017 | 0.165 | 0.145 | −0.157 | −0.022 | 0.190 | 0.038 | 0.003 | −0.241 | −1.526 | 0.678 |

| 19 | 0.503 | 0.336 | 0.428 | −0.239 | −0.106 | 0.081 | 0.008 | −0.132 | 0.480 | −0.175 | −0.532 | −0.482 | −0.312 | 0.426 | 1.488 | 0.138 | 0.357 | 0.233 | −0.479 | −0.203 | 1.079 | 1.550 |

| 20 | 0.206 | −0.164 | −0.236 | −0.047 | 0.006 | −0.082 | −0.037 | 0.207 | 0.378 | −0.040 | 0.295 | 0.028 | −0.224 | −0.160 | 0.185 | −0.092 | −0.055 | −0.017 | −0.406 | 0.133 | 2.651 | −0.893 |

| 21 | 0.010 | −0.014 | −0.025 | 0.019 | 0.021 | −0.026 | −0.015 | 0.011 | 0.049 | 0.010 | 0.001 | 0.014 | −0.032 | −0.007 | 0.003 | −0.021 | −0.014 | 0.003 | −0.017 | −0.003 | 0.522 | −0.089 |

| 22 | 0.007 | −0.008 | −0.016 | 0.013 | 0.014 | −0.017 | −0.011 | 0.008 | 0.033 | 0.006 | −0.001 | 0.011 | −0.022 | −0.003 | 0.001 | −0.014 | −0.009 | 0.003 | −0.010 | −0.003 | 0.361 | −0.061 |

| 23 | 0.000 | −0.002 | −0.005 | 0.004 | 0.002 | −0.003 | −0.002 | 0.000 | 0.002 | 0.001 | −0.002 | 0.000 | −0.002 | 0.003 | 0.002 | −0.004 | −0.001 | −0.001 | 0.000 | −0.002 | −0.654 | −0.010 |

| 24 | 0.292 | 0.134 | 0.269 | −0.123 | −0.105 | −0.198 | 0.262 | −0.092 | 0.598 | 0.188 | −0.447 | −0.292 | −0.404 | 0.488 | 0.882 | 0.172 | −0.359 | 0.154 | −0.278 | 0.061 | −0.230 | −1.305 |

References

- ACI Committee. Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary; American Concrete Institute: Indianapolis, IN, USA, 2019. [Google Scholar]

- EC2. Eurocode 2: Design of Concrete Structures: Part 1-1: General Rules and Rules for Buildings; British Standards Institution: London, UK, 2004. [Google Scholar]

- CSA A23. 3-14. CSA A23. 3-14: Design of Concrete Structures; Canadian Medical Association Journal: Toronto, ON, Canada, 2014. [Google Scholar]

- JSCE. Standard Specifications for Concrete Structures; Japan Society of Civil Engineers: Shinjuku, Tokyo, 2007. [Google Scholar]

- Rausch, E. Design of Reinforced Concrete in Torsion (Berechnung des Eisenbetons Gegen Verdrehung). Ph.D. Thesis, Technische Hochschule, Berlin, Germany, 1929; p. 53. (In German). [Google Scholar]

- Bredt, R. Kritische Bemerkungen Zur Drehungselastizitat. Zeitschrift des Vereines Dtsch. Ingenieure 1896, 40, 785–790. [Google Scholar]

- Hsu, T.T.C. Shear Flow Zone in Torsion of Reinforced Concrete. J. Struct. Eng. 1990, 116, 3206–3226. [Google Scholar] [CrossRef]

- Jeng, C.H.; Hsu, T.T.C. A Softened Membrane Model for Torsion in Reinforced Concrete Members. Eng. Struct. 2009, 31, 1944–1954. [Google Scholar] [CrossRef]

- Hsu, T.T.C. Torsion of Structural Concrete-Behavior of Reinforced Concrete Rectangular Members. Spec. Publ. 1968, 18, 261–306. [Google Scholar]

- Victor, D.J.; Muthukrishnan, R. Effect of Stirrups on Ultimate Torque of Reinforced Concrete Beams. J. Proc. 1973, 70, 300–306. [Google Scholar]

- McMullen, A.E.; Rangan, B.V. Pure Tension in Rectangular Sections-A Re-Examination. J. Proc. 1978, 75, 511–519. [Google Scholar]

- Collins, M.P.; Mitchell, D. Shear and Torsion Design of Prestressed and Non Prestressed Concrete Beams. Prestress. Concr. Inst. (PCI) J. USA 1980, 25, 32–100. [Google Scholar] [CrossRef]

- Hsu, T.T.C.; Mo, Y.L. Softening of Concrete in Torsional Members-Theroy and Tests. J. Proc. 1985, 82, 290–303. [Google Scholar]

- Koutchoukali, N.-E.; Belarbi, A. Torsion of High-Strength Reinforced Concrete Beams and Minimum Reinforcement Requirement. Struct. J. 2001, 98, 462–469. [Google Scholar]

- Fang, I.-K.; Shiau, J.-K. Torsional Behavior of Normal-and High-Strength Concrete Beams. Struct. J. 2004, 101, 304–313. [Google Scholar]

- Chiu, H.J.; Fang, I.K.; Young, W.T.; Shiau, J.K. Behavior of Reinforced Concrete Beams with Minimum Torsional Reinforcement. Eng. Struct. 2007, 29, 2193–2205. [Google Scholar] [CrossRef]

- Bernardo, L.F.A.; Lopes, S.M.R. Torsion in High-Strength Concrete Hollow Beams: Strength and Ductility Analysis. ACI Struct. J. 2009, 106, 39–48. [Google Scholar]

- Yang, I.H.; Joh, C.; Lee, J.W.; Kim, B.S. Torsional Behavior of Ultra-High Performance Concrete Squared Beams. Eng. Struct. 2013, 56, 372–383. [Google Scholar] [CrossRef]

- Chalioris, C.E. Experimental Study of the Torsion of Reinforced Concrete Members. Struct. Eng. Mech. 2006, 23, 713–737. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Karayannis, C.G. Experimental Investigation of RC Beams with Rectangular Spiral Reinforcement in Torsion. Eng. Struct. 2013, 56, 286–297. [Google Scholar] [CrossRef]

- Hassan, A.; Hafez, L.A. Investigation of Torsional Behaviour of High-Strength Reinforced Concrete Sections. World Appl. Sci. J. 2015, 33, 1–13. [Google Scholar] [CrossRef]

- Lee, J.; Kim, K.; Lee, S.H.; Kim, C.; Kim, M. Maximum Torsional Reinforcement of Reinforced Concrete Beams Subjected to Pure Torsion. ACI Struct. J. 2018, 115, 749–761. [Google Scholar] [CrossRef]

- Sanad, A.; Saka, M.P. Prediction of Ultimate Shear Strength of Reinforced-Concrete Deep Beams Using Neural Networks. J. Struct. Eng. 2001, 127, 818–828. [Google Scholar] [CrossRef]

- Adhikary, B.B.; Mutsuyoshi, H. Artificial Neural Networks for the Prediction of Shear Capacity of Steel Plate Strengthened RC Beams. Constr. Build. Mater. 2004, 18, 409–417. [Google Scholar] [CrossRef]

- Cladera, A.; Marí, A.R. Shear Design Procedure for Reinforced Normal and High-Strength Concrete Beams Using Artificial Neural Networks. Part II: Beams with Stirrups. Eng. Struct. 2004, 26, 927–936. [Google Scholar] [CrossRef]

- Mansour, M.Y.; Dicleli, M.; Lee, J.Y.; Zhang, J. Predicting the Shear Strength of Reinforced Concrete Beams Using Artificial Neural Networks. Eng. Struct. 2004, 26, 781–799. [Google Scholar] [CrossRef]

- Oreta, A.W.C. Simulating Size Effect on Shear Strength of RC Beams without Stirrups Using Neural Networks. Eng. Struct. 2004, 26, 681–691. [Google Scholar] [CrossRef]

- Adhikary, B.B.; Mutsuyoshi, H. Prediction of Shear Strength of Steel Fiber RC Beams Using Neural Networks. Constr. Build. Mater. 2006, 20, 801–811. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Elsanosi, A.; Abdelwahab, A. Modeling and Simulation of Shear Resistance of R/C Beams Using Artificial Neural Network. J. Franklin Inst. 2007, 344, 741–756. [Google Scholar] [CrossRef]

- Yang, K.; Ashour, A.F.; Song, J. Shear Capacity of Reinforced Concrete Beams Using Neural Network. Int. J. Concr. Struct. Mater. 2007, 1, 63–73. [Google Scholar] [CrossRef]

- Perera, R.; Barchín, M.; Arteaga, A.; Diego, A.D. Prediction of the Ultimate Strength of Reinforced Concrete Beams FRP-Strengthened in Shear Using Neural Networks. Compos. Part B Eng. 2010, 41, 287–298. [Google Scholar] [CrossRef]

- Tanarslan, H.M.; Secer, M.; Kumanlioglu, A. An Approach for Estimating the Capacity of RC Beams Strengthened in Shear with FRP Reinforcements Using Artificial Neural Networks. Constr. Build. Mater. 2012, 30, 556–568. [Google Scholar] [CrossRef]

- Tang, C.-W. Using Radial Basis Function Neural Networks to Model Torsional Strength of Reinforced Concrete Beams. Comput. Concr. 2006, 3, 335–355. [Google Scholar] [CrossRef]

- Cevik, A.; Arslan, M.H.; Köroğlu, M.A. Genetic-Programming-Based Modeling of RC Beam Torsional Strength. KSCE J. Civ. Eng. 2010, 14, 371–384. [Google Scholar] [CrossRef]

- Arslan, M.H. Predicting of Torsional Strength of RC Beams by Using Different Artificial Neural Network Algorithms and Building Codes. Adv. Eng. Softw. 2010, 41, 946–955. [Google Scholar] [CrossRef]

- Witten, I.H.; Frank, E.; Hall, M.A.; Pal, C.J. Data Mining: Practical Machine Learning Tools and Techniques; Morgan Kaufmann Publishers: Burlington, MA, USA, 2016. [Google Scholar]

- Kim, C.; Lee, J.-Y.; Kim, M. Prediction of the Dynamic Stiffness of Resilient Materials Using Artificial Neural Network (ANN) Technique. Appl. Sci. 2019, 9, 1088. [Google Scholar] [CrossRef]

- Alwattar, T.A.; Mian, A. Development of an Elastic Material Model for BCC Lattice Cell Structures Using Finite Element Analysis and Neural Networks Approaches. J. Compos. Sci. 2019, 3, 33. [Google Scholar] [CrossRef]

- Al-Wattar, T.A.A. Developing Equivalent Solid Model for Lattice Cell Structure Using Numerical Approaches. Ph.D. Thesis, Wright State University, Dayton, OH, USA, 2020. [Google Scholar]

- Rasmussen, L.J.; Baker, G. Torsion in Reinforced Normal and High-Strength Concrete Beams Part 1: Experimental Test Series. Struct. J. 1995, 92, 56–62. [Google Scholar]

- Rahal, K.N.; Collins, M.P. Simple Model for Predicting Torsional Strength of Reinforced and Pre-Stressed Concrete Sections. ACI Struct. J. 1996, 93, 658–666. [Google Scholar]

- Kim, C.; Kim, S.; Kim, K.; Shin, D.; Haroon, M.; Lee, J. Torsional Behavior of Reinforced Concrete Beams with High-Strength Steel Bars. ACI Struct. J. 2019, 116, 251–263. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Kim, S.-W. Torsional Strength of RC Beams Considering Tension Stiffening Effect. J. Struct. Eng. 2010, 136, 1367–1378. [Google Scholar] [CrossRef]

- Campbell, N.A.; Atchley, W.R. The Geometry of Canonical Variate Analysis. Syst. Biol. 1981, 30, 268–280. [Google Scholar] [CrossRef]

- Freedman, D.; Pisani, R.; Purves, R.; Adhikari, A. Statistics, 2nd ed.; WW Norton: New York, NY, USA, 1991. [Google Scholar]

- Liou, C.-Y.; Cheng, W.-C.; Liou, J.-W.; Liou, D.-R. Autoencoder for Words. Neurocomputing 2014, 139, 84–96. [Google Scholar] [CrossRef]

- Zhang, L.; Ma, W.; Zhang, D. Stacked Sparse Autoencoder in PolSAR Data Classification Using Local Spatial Information. IEEE Geosci. Remote Sens. Lett. 2016, 13, 1359–1363. [Google Scholar] [CrossRef]

- Shao, Z.; Zhang, L.; Wang, L. Stacked Sparse Autoencoder Modeling Using the Synergy of Airborne LiDAR and Satellite Optical and SAR Data to Map Forest Above-Ground Biomass. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2017, 10, 5569–5582. [Google Scholar] [CrossRef]

- Ayinde, B.O.; Zurada, J.M. Deep Learning of Constrained Autoencoders for Enhanced Understanding of Data. IEEE Trans. Neural Networks Learn. Syst. 2017, 29, 3969–3979. [Google Scholar] [CrossRef]

- Poultney, C.; Chopra, S.; Cun, Y.L. Efficient Learning of Sparse Representations with an Energy-Based Model. In Advances in Neural Information Processing Systems; Neural Information Processing Systems Foundation: San Diego, CA, USA, 2007; pp. 1137–1144. [Google Scholar]

| PC1 | PC2 | PC3 | PC4 | PC5 | PC6 | |

|---|---|---|---|---|---|---|

| b (mm) | 0.448 | −0.186 | −0.117 | 0.307 | −0.315 | 0.057 |

| h (mm) | 0.437 | −0.089 | −0.182 | −0.396 | 0.229 | 0.075 |

| (mm) | 0.441 | −0.133 | −0.132 | 0.399 | −0.340 | 0.086 |

| (mm) | 0.407 | −0.101 | −0.246 | −0.440 | 0.271 | 0.230 |

| f′c (MPa) | −0.185 | −0.416 | −0.034 | 0.453 | 0.567 | 0.509 |

| fyl (MPa) | −0.060 | −0.601 | 0.089 | −0.055 | −0.149 | −0.242 |

| ρl (%) | −0.362 | −0.205 | −0.330 | −0.298 | −0.239 | 0.203 |

| fyt (MPa) | −0.101 | −0.585 | 0.119 | −0.223 | −0.145 | −0.185 |

| ρt (%) | −0.256 | 0.099 | −0.557 | −0.008 | −0.370 | 0.364 |

| s (mm) | 0.060 | 0.024 | 0.658 | −0.224 | −0.316 | 0.637 |

| ACI 318-19 | EC2-04 | CSA-14 | JSCE-07 | PCA | Autoencoder | |

|---|---|---|---|---|---|---|

| Correlation Coefficient | 0.9369 | 0.9467 | 0.8924 | 0.9260 | 0.9968 | 0.9993 |

| Root Mean Square Error | 16.1713 | 14.4432 | 36.8951 | 22.8708 | 3.4492 | 1.6022 |

| Relative Absolute Error | 32.1298 | 30.9552 | 76.4643 | 42.4559 | 6.5440 | 2.9346 |

| Root Relative Square Error | 37.6681 | 33.6429 | 85.9407 | 53.2735 | 8.0344 | 3.7321 |

| Error (%) |

| Specimen | Section Details | Concrete | Longitudinal Bar | Transverse Bar | Test Strength | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| b (mm) | h (mm) | b′ (mm) | h′ (mm) | ρl (%) | fyl (MPa) | ρt (%) | fyt (MPa) | s (mm) | Tu (kN·m) | ||

| B-1 | 300 | 350 | 247 | 29 | 42.2 | 1.00 | 659 | 1.01 | 667 | 130 | 47.64 |

| B-2 | 300 | 350 | 247 | 297 | 68.4 | 1.51 | 310 | 1.88 | 340 | 70 | 66.71 |

| B-3 | 320 | 370 | 247 | 297 | 26.0 | 0.86 | 353 | 0.90 | 353 | 130 | 34.91 |

| B-4 | 320 | 370 | 247 | 297 | 50.0 | 0.43 | 480 | 0.53 | 480 | 220 | 34.05 |

| B-5 | 400 | 600 | 310 | 510 | 35.3 | 0.93 | 320 | 0.93 | 334 | 53 | 126.11 |

| B-6 | 400 | 600 | 310 | 510 | 35.3 | 0.69 | 309 | 0.67 | 334 | 73 | 110.14 |

| B-7 | 203 | 305 | 165 | 267 | 93.9 | 0.82 | 386 | 0.92 | 386 | 108 | 21.00 |

| B-8 | 254 | 508 | 216 | 470 | 30.9 | 0.62 | 323 | 0.63 | 334 | 121 | 40.34 |

| ACI 318-19 | EC2-04 | CSA-14 | JSCE-07 | PCA | Autoencoder | |

|---|---|---|---|---|---|---|

| Mean | 1.09 | 1.13 | 0.70 | 0.88 | 0.96 | 1.05 |

| Standard deviation | 0.24 | 0.26 | 0.16 | 0.19 | 0.02 | 0.12 |

| Coefficient of variation | 22.32 | 22.95 | 23.57 | 21.55 | 2.27 | 11.55 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haroon, M.; Koo, S.; Shin, D.; Kim, C. Torsional Behavior Evaluation of Reinforced Concrete Beams Using Artificial Neural Network. Appl. Sci. 2021, 11, 4465. https://doi.org/10.3390/app11104465

Haroon M, Koo S, Shin D, Kim C. Torsional Behavior Evaluation of Reinforced Concrete Beams Using Artificial Neural Network. Applied Sciences. 2021; 11(10):4465. https://doi.org/10.3390/app11104465

Chicago/Turabian StyleHaroon, Muhammad, Seungbum Koo, DongIk Shin, and Changhyuk Kim. 2021. "Torsional Behavior Evaluation of Reinforced Concrete Beams Using Artificial Neural Network" Applied Sciences 11, no. 10: 4465. https://doi.org/10.3390/app11104465

APA StyleHaroon, M., Koo, S., Shin, D., & Kim, C. (2021). Torsional Behavior Evaluation of Reinforced Concrete Beams Using Artificial Neural Network. Applied Sciences, 11(10), 4465. https://doi.org/10.3390/app11104465