Quantitative Inspection of Complex-Shaped Parts Based on Ice-Coupled Ultrasonic Full Waveform Inversion Technology

Abstract

Featured Application

Abstract

1. Introduction

2. Theory of Full Waveform Inversion

2.1. Forward Modelling for Ultrasonic Wave Propagation

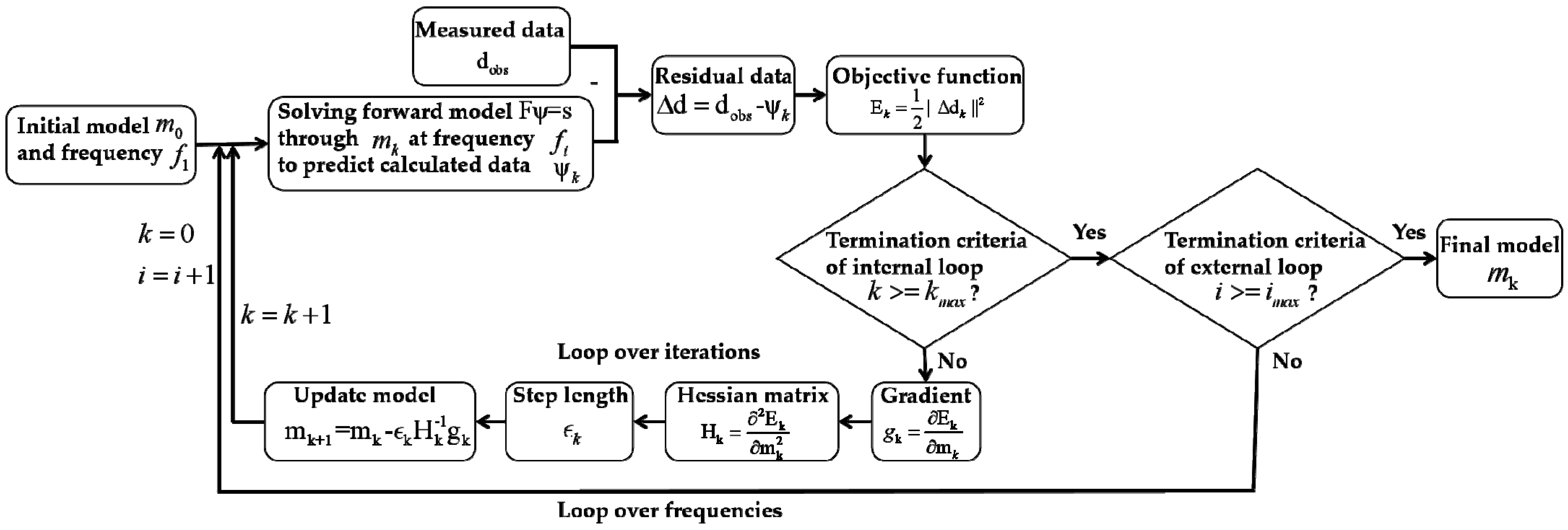

2.2. Full Waveform Inversion

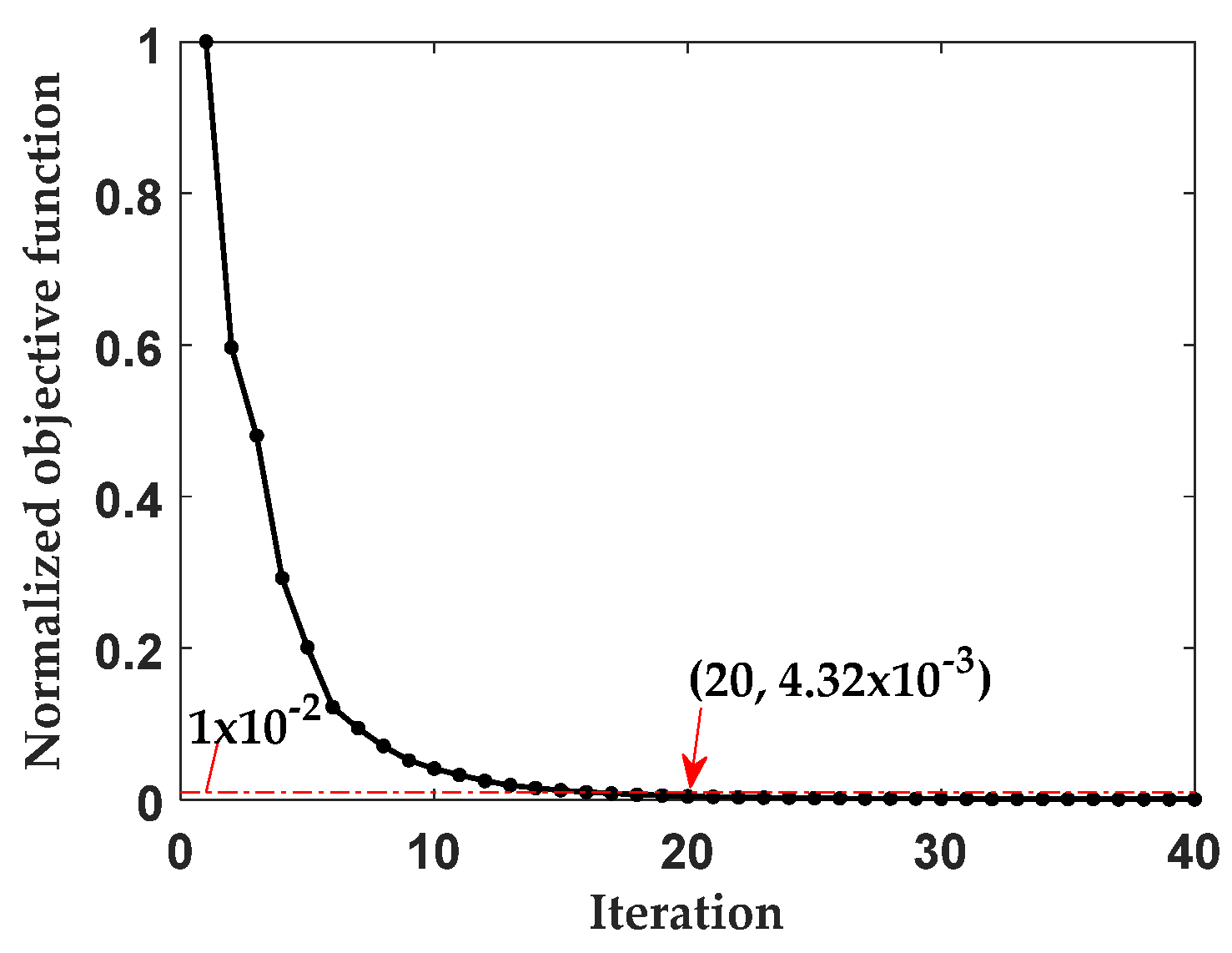

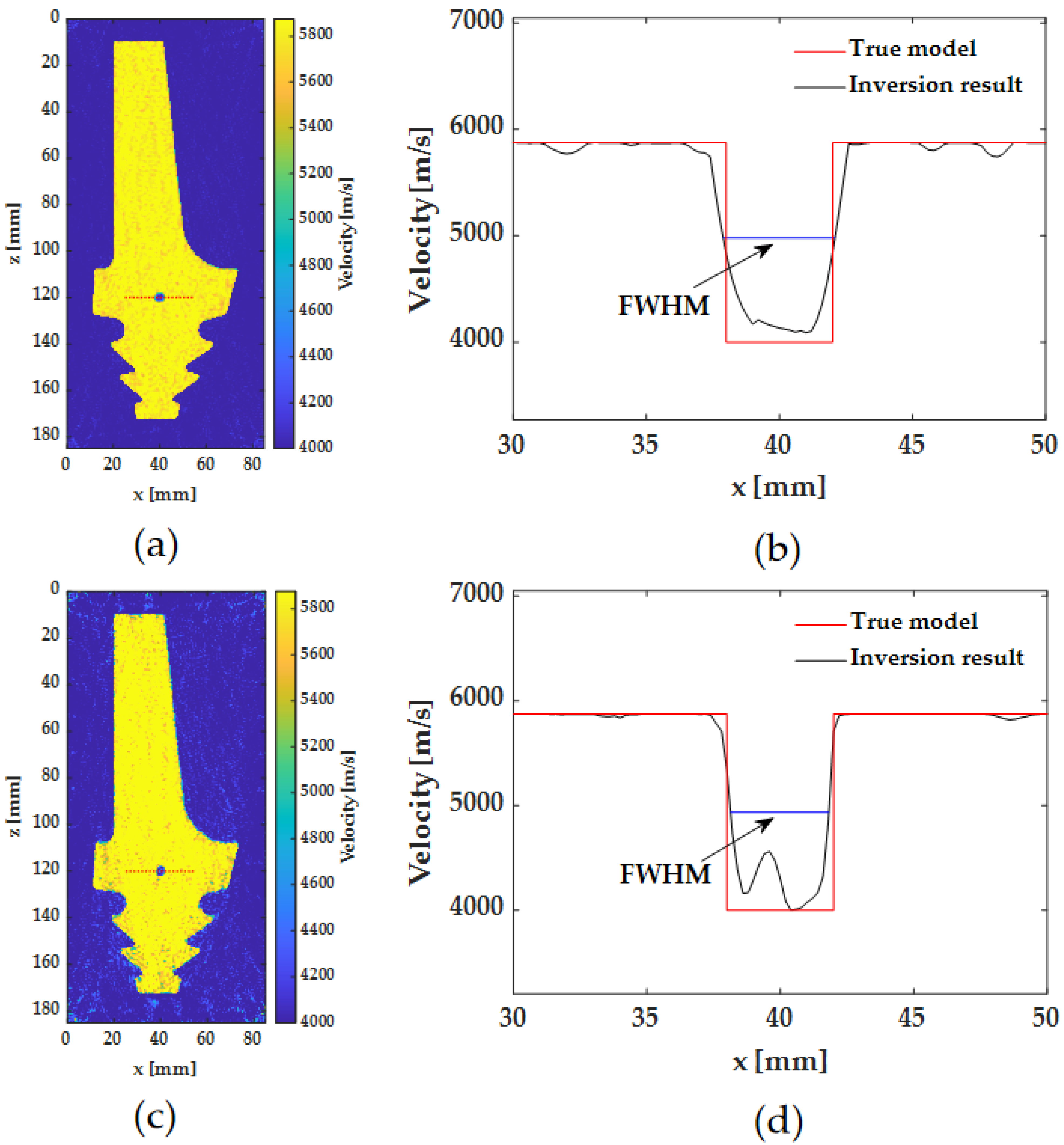

3. Numerical Experiments on a Turbine Blade

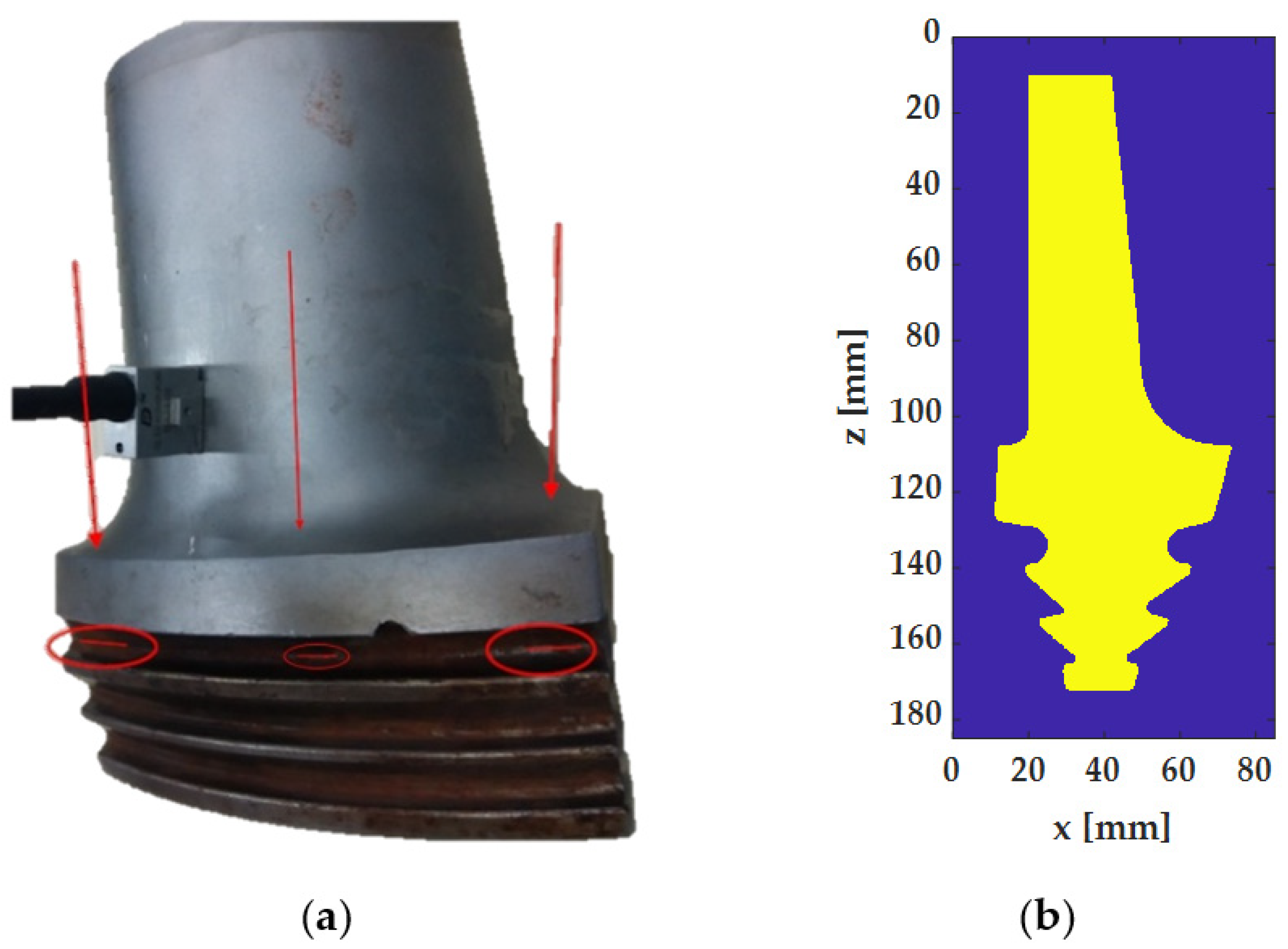

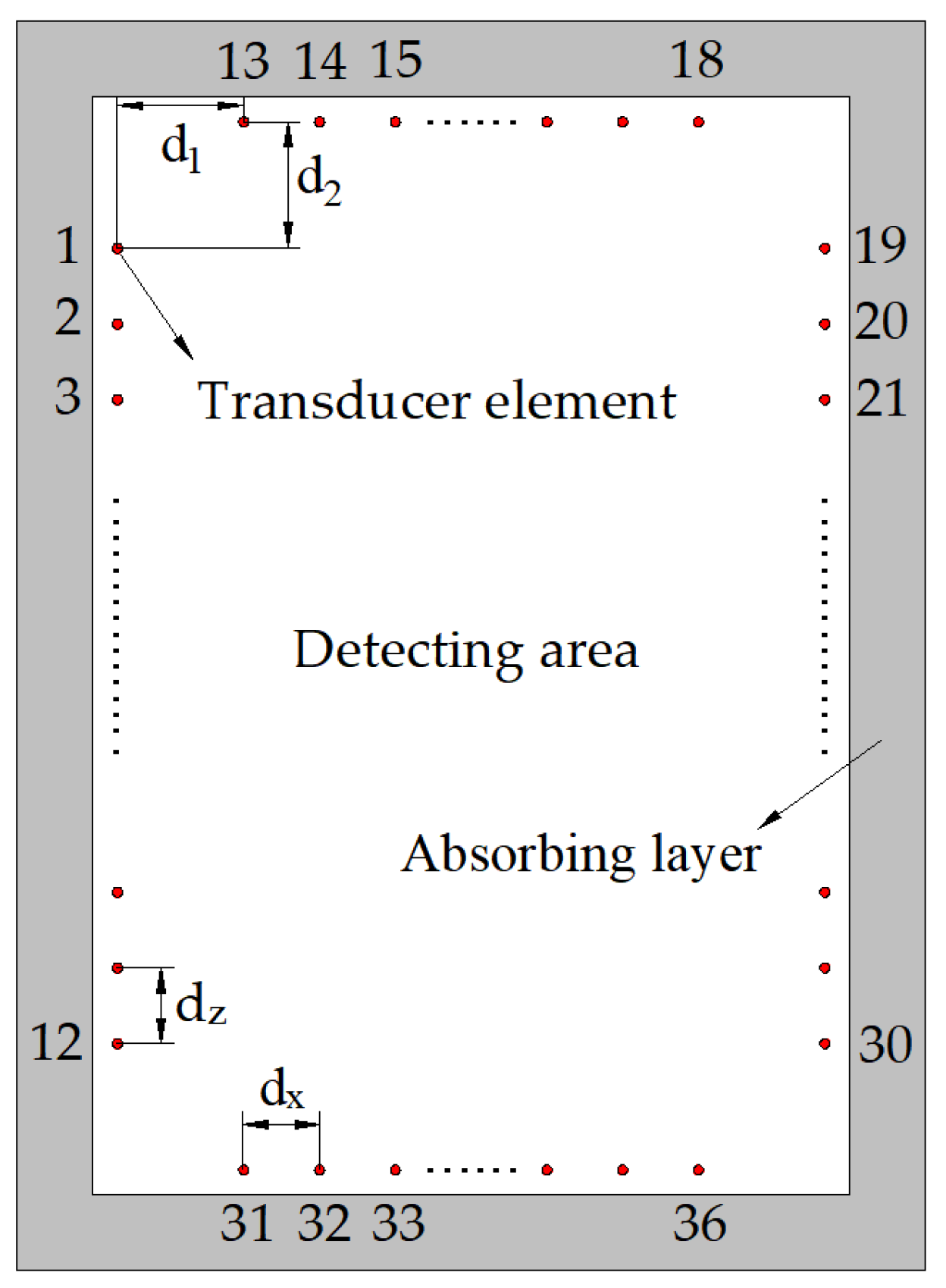

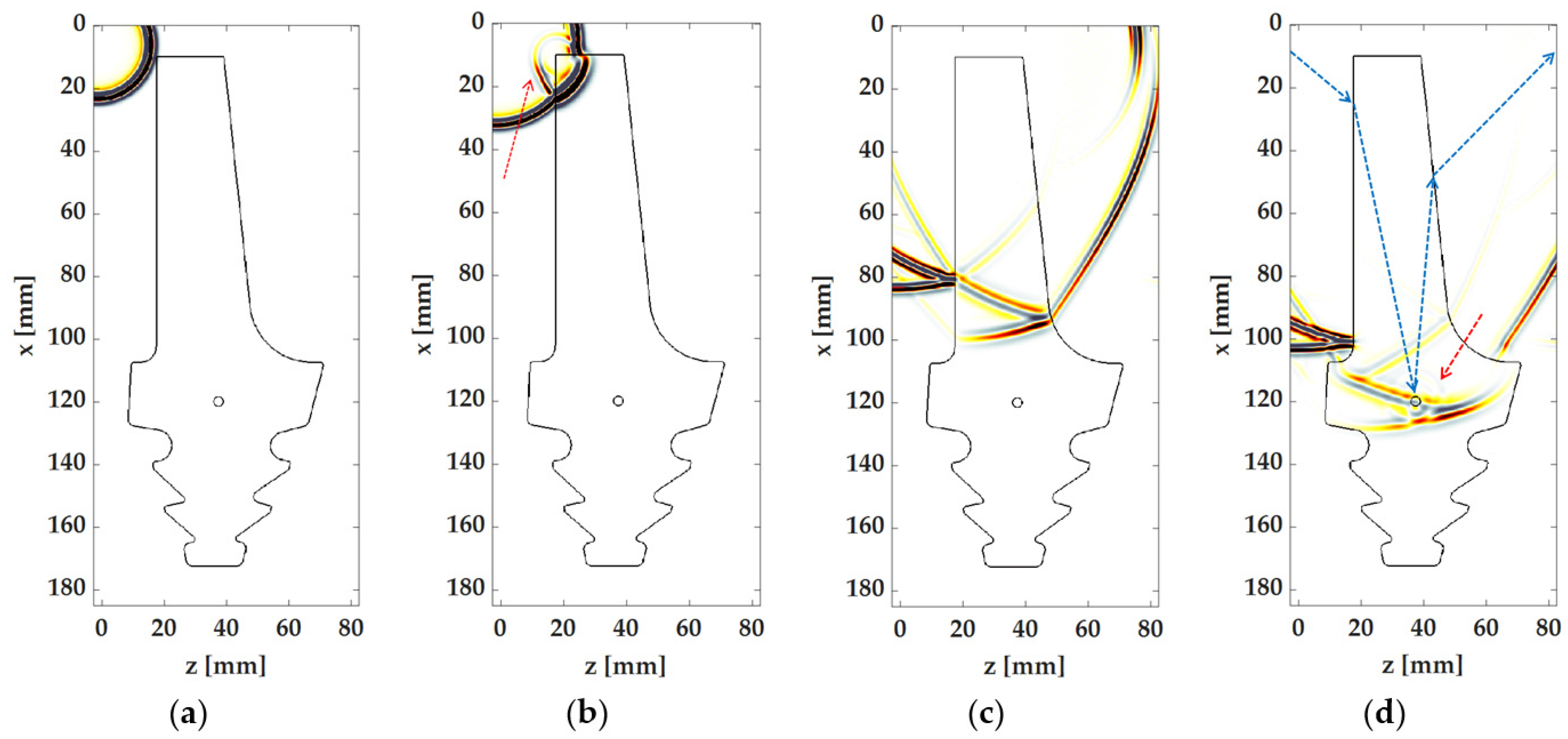

3.1. Simulation of Ice-Coupled Ultrasonic Testing in a Turbine Blade

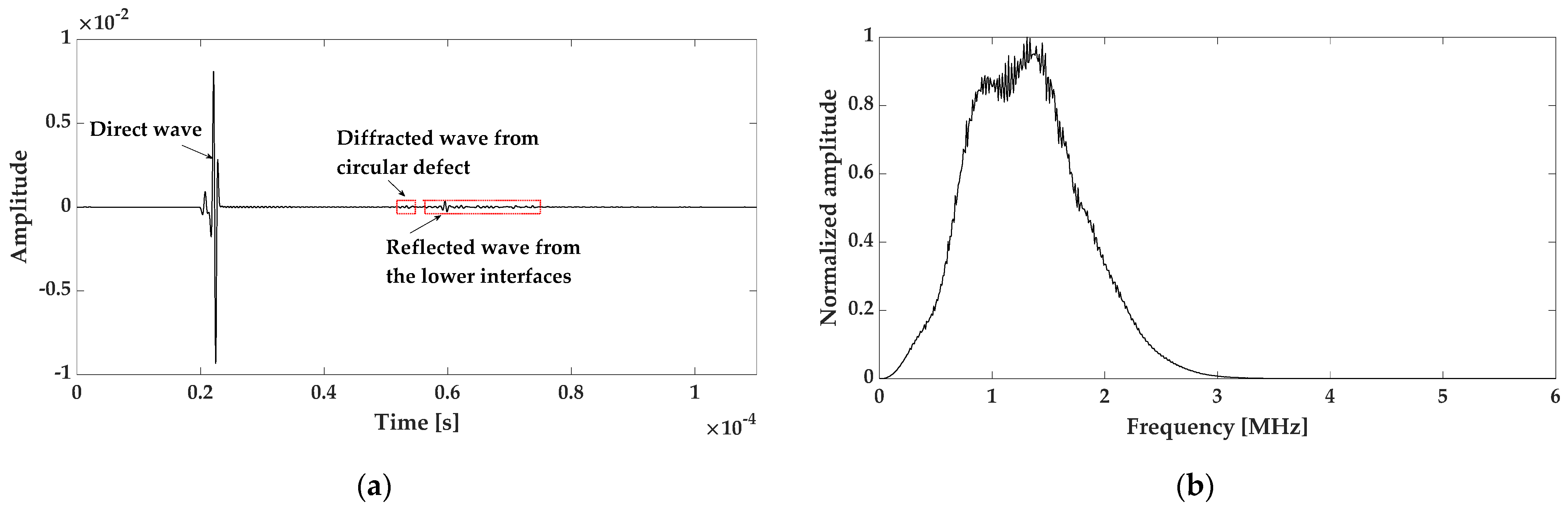

3.2. Data Calibration

4. Results and Discussion

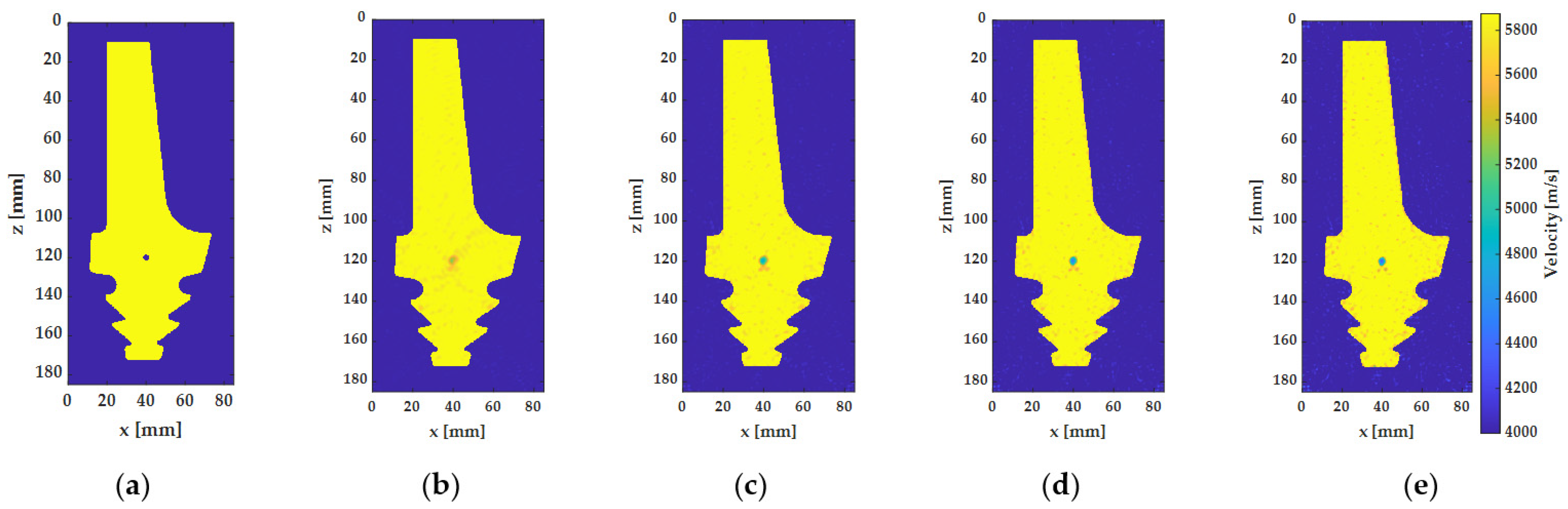

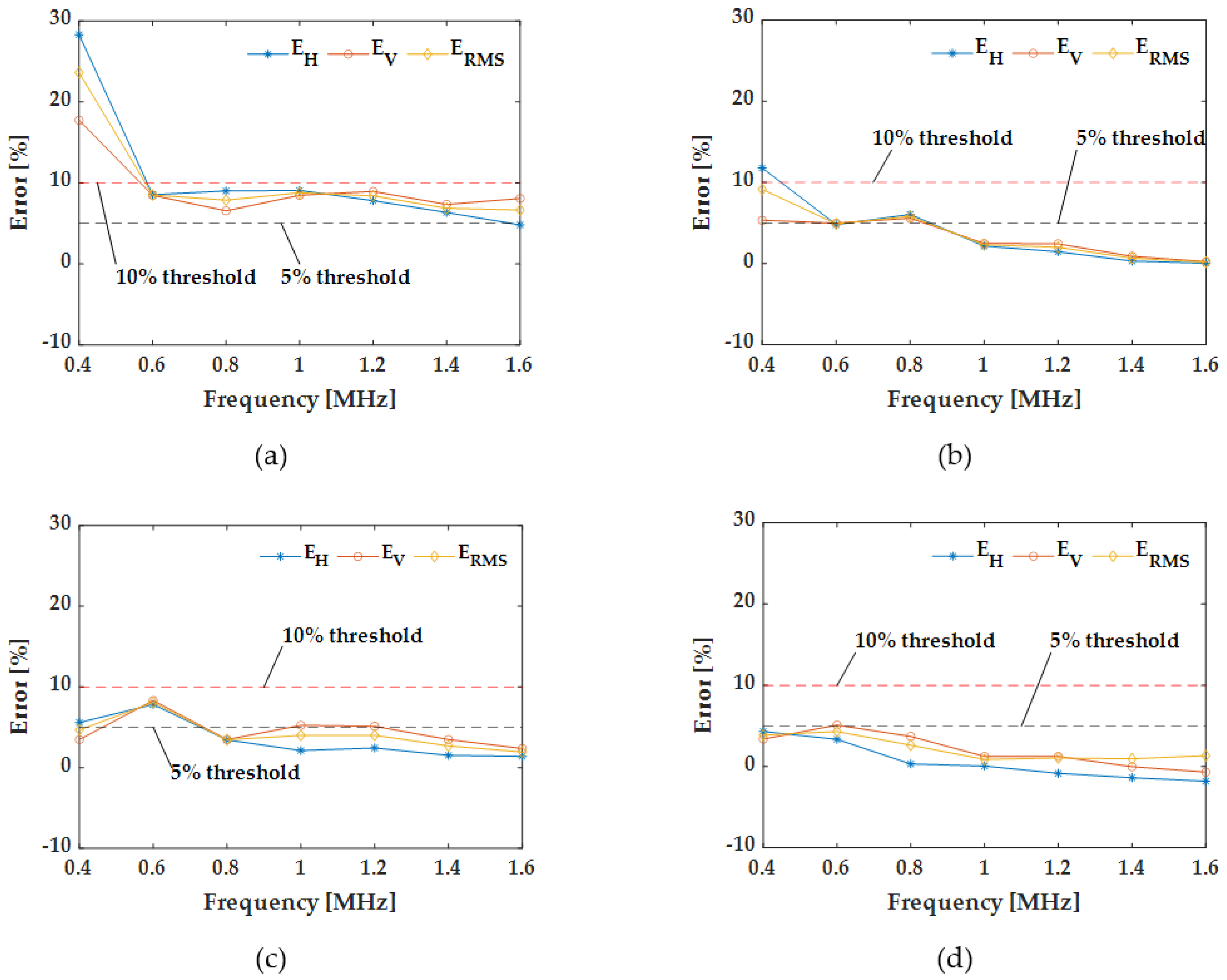

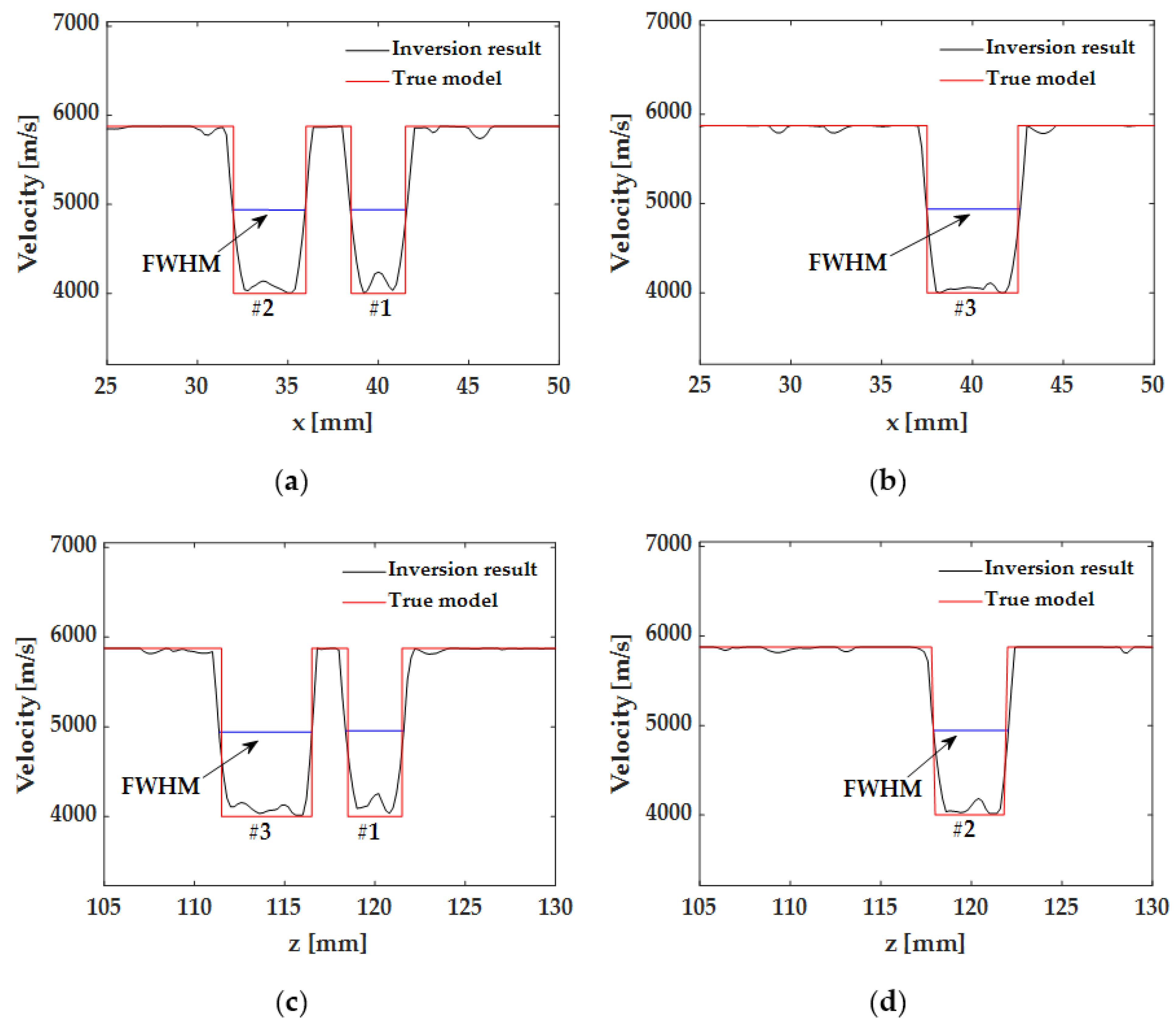

4.1. Single Internal Defect

4.2. Open Notch Crack

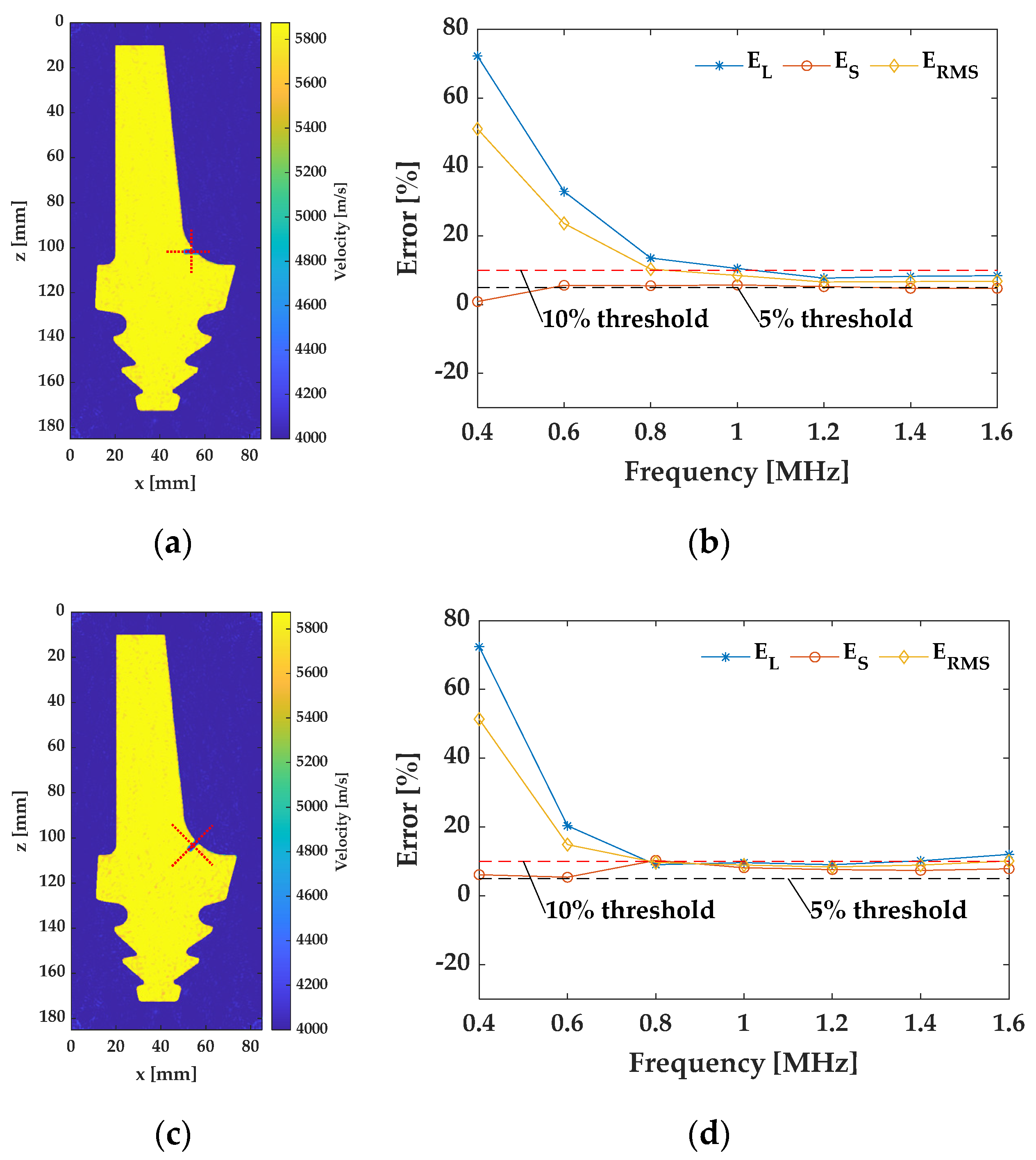

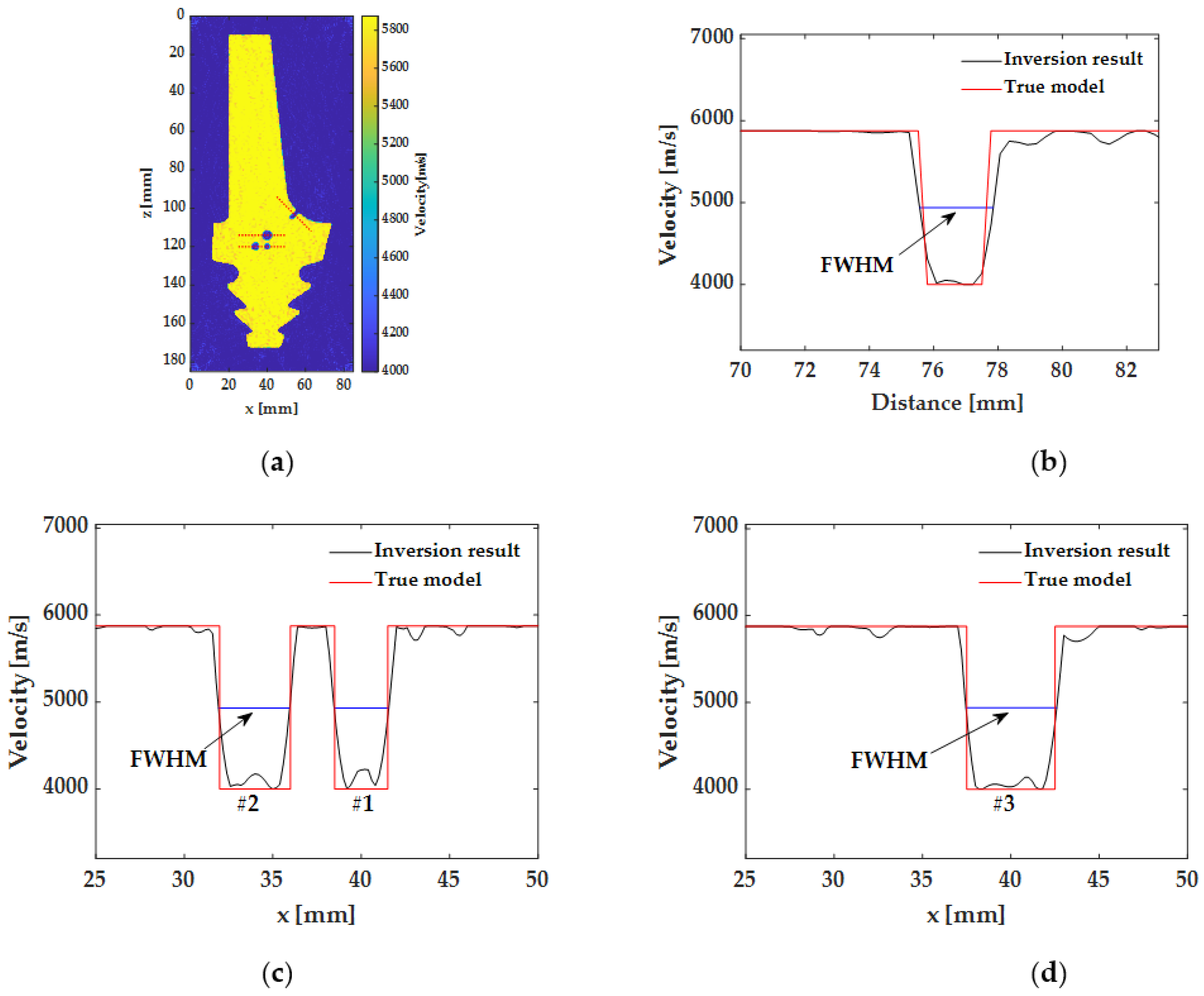

4.3. Multiple Defects

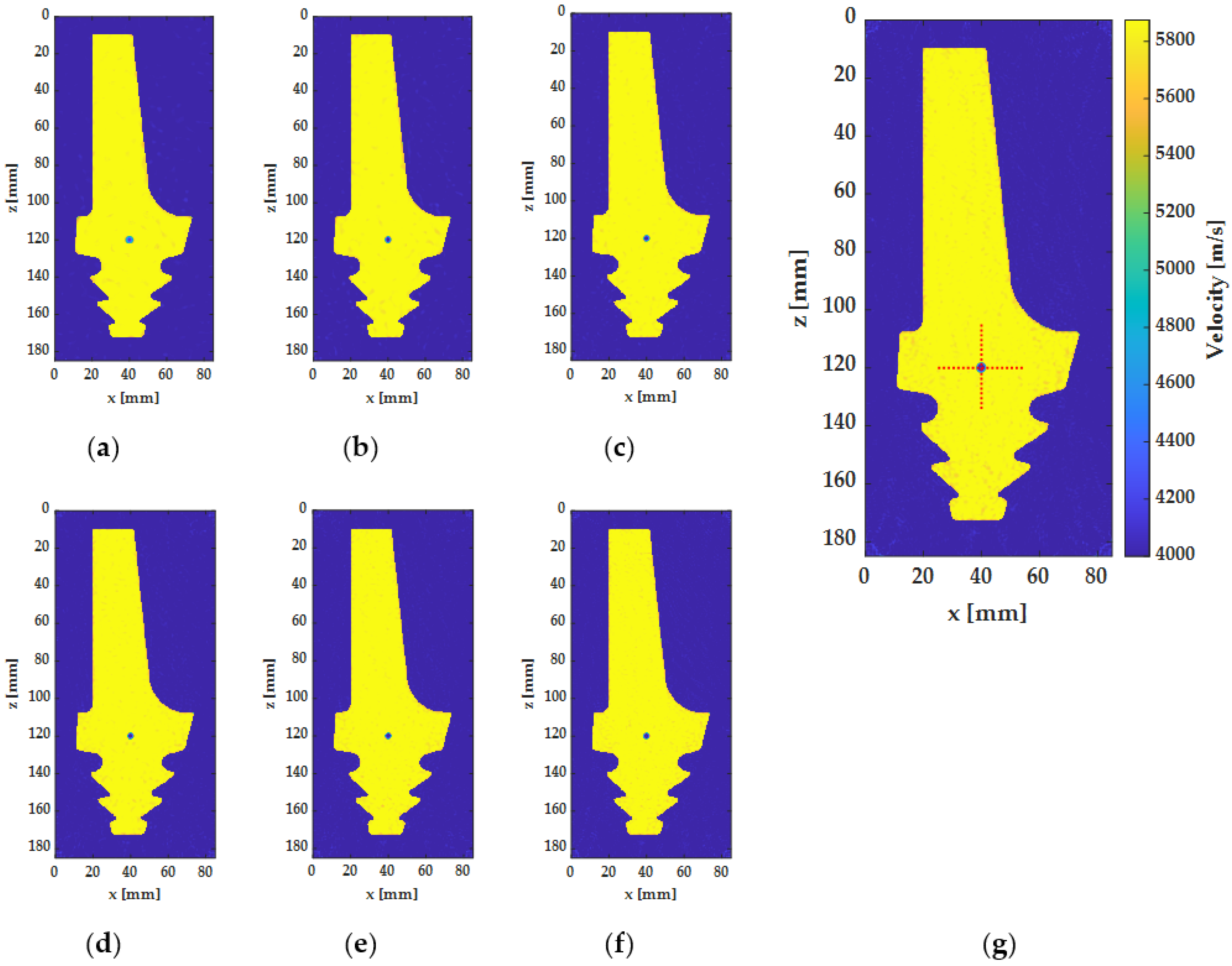

4.4. Uncertainty Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ravi-Kumar, B.V.R. A review on BLISK technology. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 1353–1358. [Google Scholar]

- Pérez, M.; Carou, D.; Rubio, E.M.; Teti, R. Current advances in additive manufacturing. Procedia CIRP 2020, 88, 439–444. [Google Scholar] [CrossRef]

- Brath, A.J.; Simonetti, F. Phased Array Imaging of Complex-Geometry Composite Components. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2017, 64, 1573–1582. [Google Scholar] [CrossRef] [PubMed]

- Fletcher, S.; Lowe, M.J.S.; Ratassepp, M.; Brett, C. Detection of Axial Cracks in Pipes Using Focused Guided Waves. J. Nondestruct. Eval. 2011, 31, 56–64. [Google Scholar] [CrossRef]

- Moreau, L.; Drinkwater, B.W.; Wilcox, P.D. Ultrasonic imaging algorithms with limited transmission cycles for rapid nondestructive evaluation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 1932–1944. [Google Scholar] [CrossRef] [PubMed]

- Holmes, C.; Drinkwater, B.; Wilcox, P. The post-processing of ultrasonic array data using the total focusing method. Insight Non Destr. Test. Cond. Monit. 2004, 46, 677–680. [Google Scholar] [CrossRef]

- Le Jeune, L.; Robert, S.; Villaverde, E.L.; Prada, C. Plane Wave Imaging for ultrasonic non-destructive testing: Generalization to multimodal imaging. Ultrasonics 2016, 64, 128–138. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.; Yuan, M.; Chen, Y. Cloud Ultrasound System with Flexible Ultrasonic Phased-Array Transducer for Critical Component Monitoring. In Proceedings of the International Symposium on Structural Health Monitoring and Nondestructive Testing 2018, Saarbruecken, Germany, 4–5 October 2018. [Google Scholar]

- Jansen, D.; Hutchins, D. Immersion tomography using Rayleigh and Lamb waves. Ultrasonics 1992, 30, 245–254. [Google Scholar] [CrossRef]

- Simonetti, F.; Satow, I.L.; Brath, A.J.; Wells, K.C.; Porter, J.; Hayes, B.; Davis, K. Cryo-Ultrasonic NDE: Ice–Cold Ultrasonic Waves for the Detection of Damage in Complex-Shaped Engineering Components. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2018, 65, 638–647. [Google Scholar] [CrossRef]

- Simonetti, F.; Fox, M. Experimental methods for ultrasonic testing of complex-shaped parts encased in ice. NDT E Int. 2019, 103, 1–11. [Google Scholar] [CrossRef]

- Tarantola, A. A strategy for nonlinear elastic inversion of seismic reflection data. Geophysics 1986, 51, 1893–1903. [Google Scholar] [CrossRef]

- Pratt, R.G.; Worthington, M.H. Inverse theory applied to multi-source cross-hole tomography. Part 1: Acoustic wave-equation method. Geophys. Prospect. 1990, 38, 287–310. [Google Scholar] [CrossRef]

- Pan, G.S.; Phinney, R.A.; Odom, R.I. Full-waveform inversion of plane-wave seismograms in stratified acoustic media: Theory and feasibility. Geophysics 1988, 53, 21–31. [Google Scholar] [CrossRef]

- Pratt, R.G. Seismic waveform inversion in the frequency domain, Part 1: Theory and verification in a physical scale model. Geophysics 1999, 64, 888–901. [Google Scholar] [CrossRef]

- Pérez-Liva, M.; Herraiz, J.L.; Udías, J.M.; Miller, E.; Cox, B.T.; Treeby, B.E. Time domain reconstruction of sound speed and attenuation in ultrasound computed tomography using full wave inversiona. J. Acoust. Soc. Am. 2017, 141, 1595–1604. [Google Scholar] [CrossRef]

- Bernard, S.; Monteiller, V.; Komatitsch, D.; Lasaygues, P.L. Ultrasonic computed tomography based on full-waveform inversion for bone quantitative imaging. Phys. Med. Biol. 2017, 62, 7011–7035. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Tran, K.T.; Gucunski, N. Detection of Bridge-Deck Delamination Using Full Ultrasonic Waveform Tomography. J. Infrastruct. Syst. 2017, 23, 04016027. [Google Scholar] [CrossRef]

- Nguyen, L.T.; Modrak, R.T. Ultrasonic wavefield inversion and migration in complex heterogeneous structures: 2D numerical imaging and nondestructive testing experiments. Ultrasonics 2018, 82, 357–370. [Google Scholar] [CrossRef]

- Rao, J.; Ratassepp, M.; Fan, Z. Limited-view ultrasonic guided wave tomography using an adaptive regularization method. J. Appl. Phys. 2016, 120, 194902. [Google Scholar] [CrossRef]

- Rao, J.; Ratassepp, M.; Fan, Z. Guided Wave Tomography Based on Full Waveform Inversion. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2016, 63, 737–745. [Google Scholar] [CrossRef] [PubMed]

- Brossier, R.; Operto, S.; Virieux, J. Seismic imaging of complex onshore structures by 2D elastic frequency-domain full-waveform inversion. Geophysics 2009, 74, WCC105–WCC118. [Google Scholar] [CrossRef]

- Jo, C.H.; Shin, C.; Suh, J. An optimal 9-point, finite-difference, frequency-space, 2-D Scalar wave extrapolator. Geophysics 1996, 61, 529–537. [Google Scholar] [CrossRef]

- Chen, Z.; Cheng, D.; Feng, W.; Wu, T. An optimal 9-point finite difference scheme for the Helmholtz equation with PML. Int. J. Numer. Anal. Model. 2013, 10, 389–410. [Google Scholar] [CrossRef]

- Pratt, R.G. Frequency-domain elastic wave modeling by finite differences: A tool for crosshole seismic imaging. Geophysics 1990, 55, 626–632. [Google Scholar] [CrossRef]

- Belanger, P.; Cawley, P.; Simonetti, F. Guided wave diffraction tomography within the born approximation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 1405–1418. [Google Scholar] [CrossRef]

- Norton, S.J. Iterative inverse scattering algorithms: Methods of computing Fréchet derivatives. J. Acoust. Soc. Am. 1999, 106, 2653–2660. [Google Scholar] [CrossRef]

- Guitton, A.; Symes, W.W. Robust inversion of seismic data using the Huber norm. Geophysics 2003, 68, 1310–1319. [Google Scholar] [CrossRef]

- Huthwaite, P.; Simonetti, F. High-resolution guided wave tomography. Wave Motion 2013, 50, 979–993. [Google Scholar] [CrossRef]

- Treeby, B.E.; Cox, B.T. K-Wave: MATLAB toolbox for the simulation and reconstruction of photoacoustic wave fields. J. Biomed. Opt. 2010, 15, 021314. [Google Scholar] [CrossRef]

- Lowe, M.J.S.; Alleyne, D.N.; Cawley, P. The Mode Conversion of a Guided Wave by a Part-Circumferential Notch in a Pipe. J. Appl. Mech. 1998, 65, 649–656. [Google Scholar] [CrossRef]

- Leonard, K.R.; Malyarenko, E.V.; Hinders, M.K. Ultrasonic Lamb wave tomography. Inverse Probl. 2002, 18, 1795–1808. [Google Scholar] [CrossRef]

| Mass Density ρ (kg/m3) | Wave Speed c (m/s) | |

|---|---|---|

| Steel | 7800 | 5875 |

| Ice (at −5 °C) | 917 | 4000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Yuan, M.; Xuan, W.; Ji, X.; Chen, Y. Quantitative Inspection of Complex-Shaped Parts Based on Ice-Coupled Ultrasonic Full Waveform Inversion Technology. Appl. Sci. 2021, 11, 4433. https://doi.org/10.3390/app11104433

Xu W, Yuan M, Xuan W, Ji X, Chen Y. Quantitative Inspection of Complex-Shaped Parts Based on Ice-Coupled Ultrasonic Full Waveform Inversion Technology. Applied Sciences. 2021; 11(10):4433. https://doi.org/10.3390/app11104433

Chicago/Turabian StyleXu, Wenjin, Maodan Yuan, Weiming Xuan, Xuanrong Ji, and Yan Chen. 2021. "Quantitative Inspection of Complex-Shaped Parts Based on Ice-Coupled Ultrasonic Full Waveform Inversion Technology" Applied Sciences 11, no. 10: 4433. https://doi.org/10.3390/app11104433

APA StyleXu, W., Yuan, M., Xuan, W., Ji, X., & Chen, Y. (2021). Quantitative Inspection of Complex-Shaped Parts Based on Ice-Coupled Ultrasonic Full Waveform Inversion Technology. Applied Sciences, 11(10), 4433. https://doi.org/10.3390/app11104433