Dynamic Pad Surface Metrology Monitoring by Swing-Arm Chromatic Confocal System

Abstract

:1. Introduction

2. Design and Configuration of DPMS

2.1. System Description

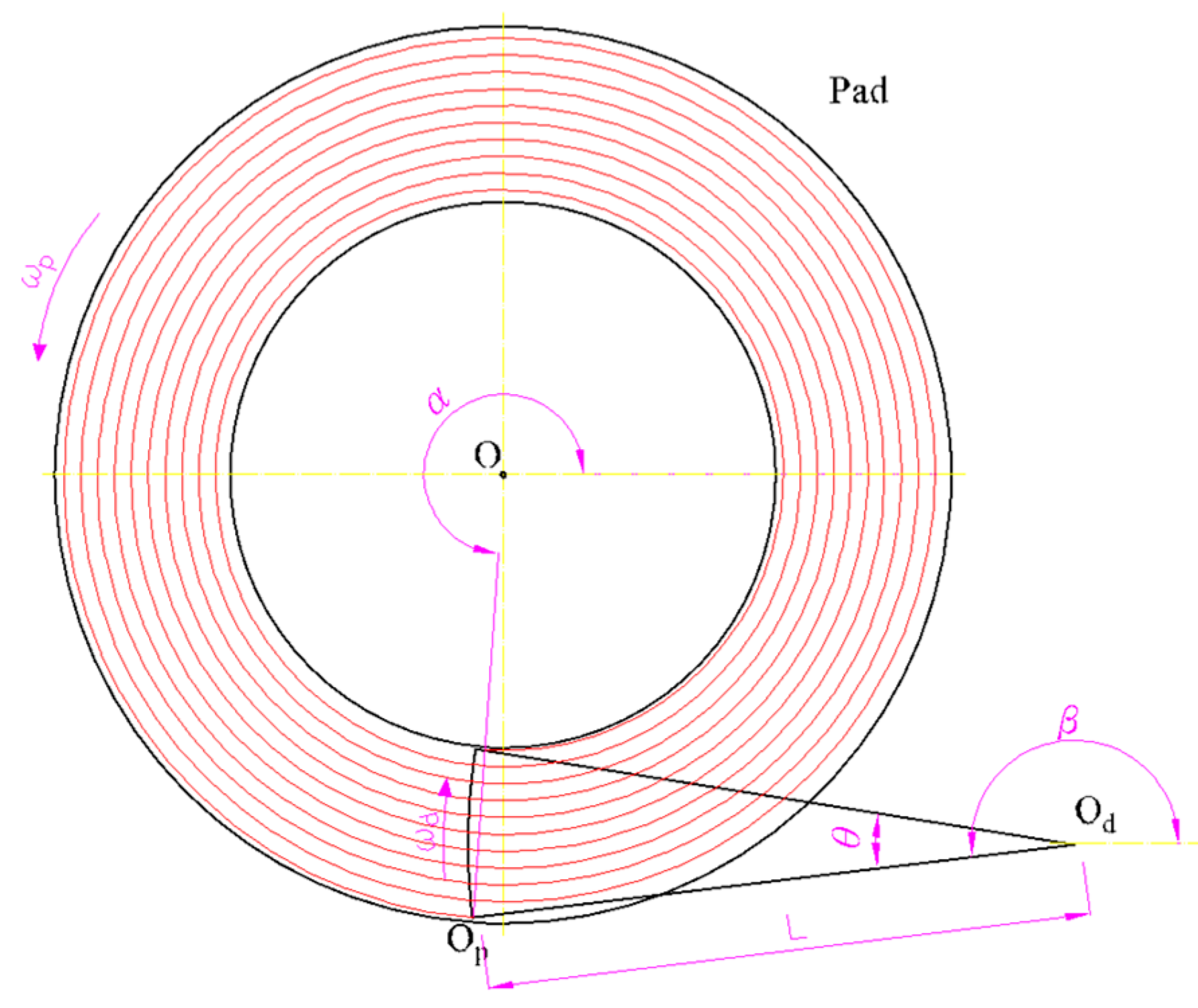

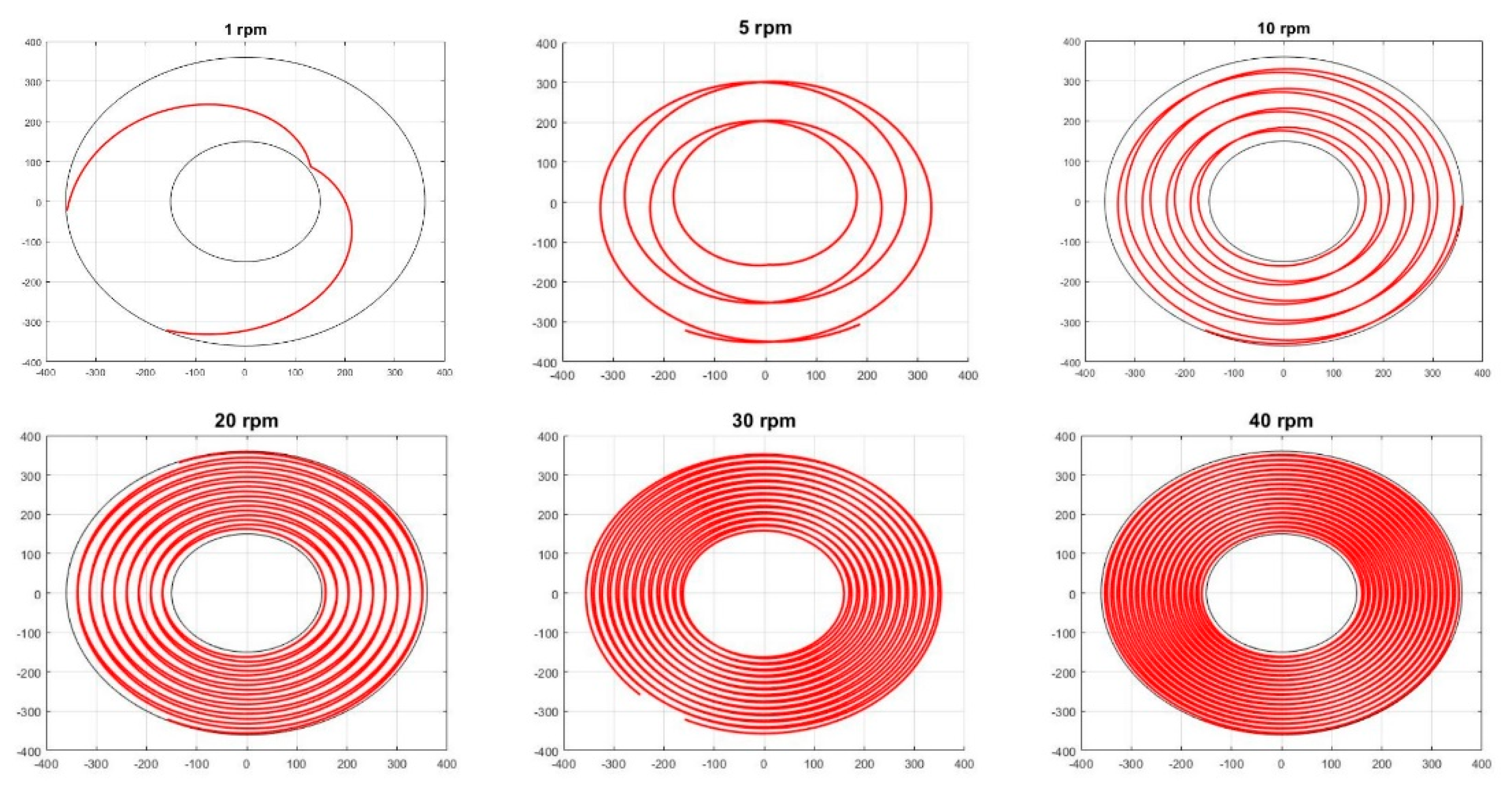

2.2. Mathematical Model of Scanning Locus

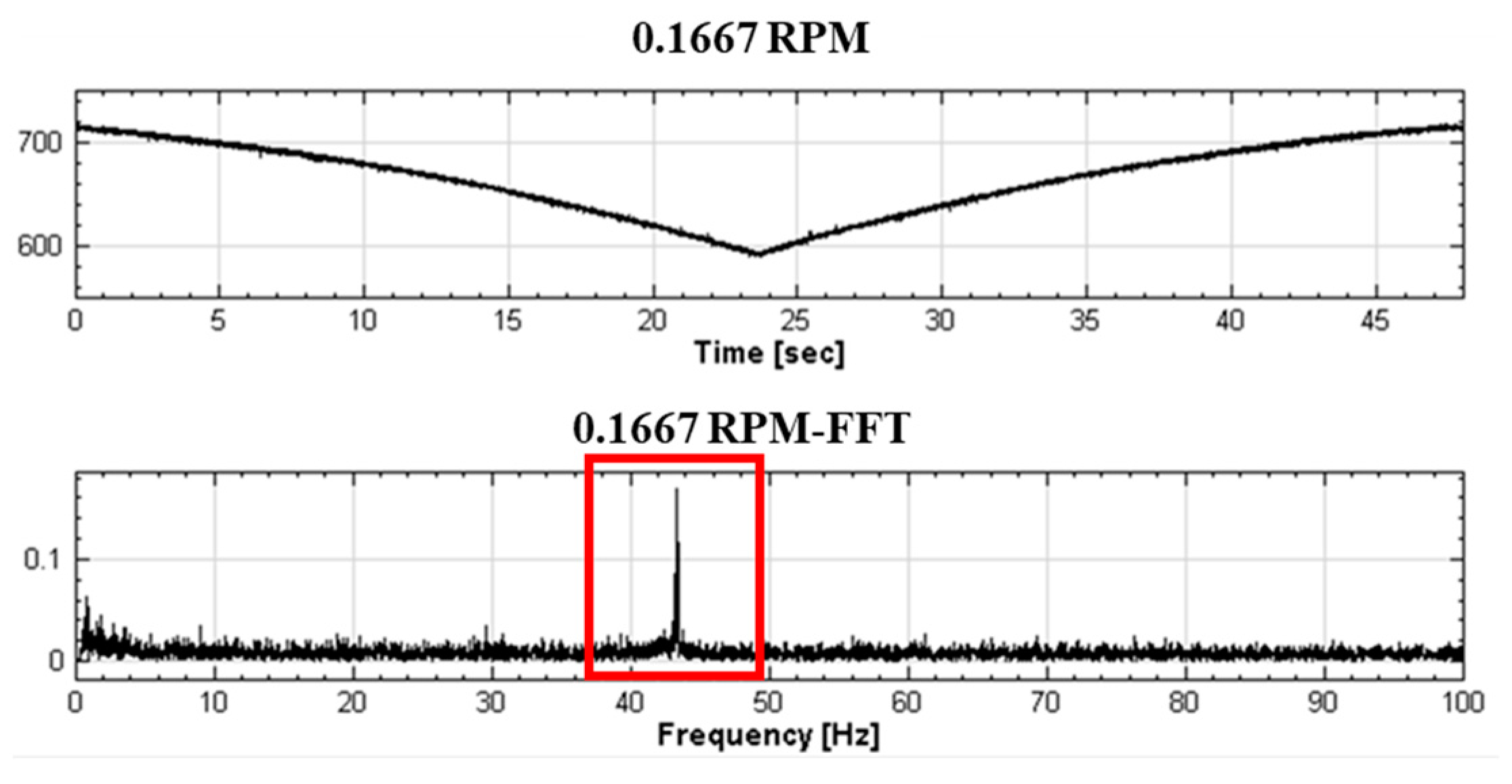

2.3. Signal Processing and Filter Design

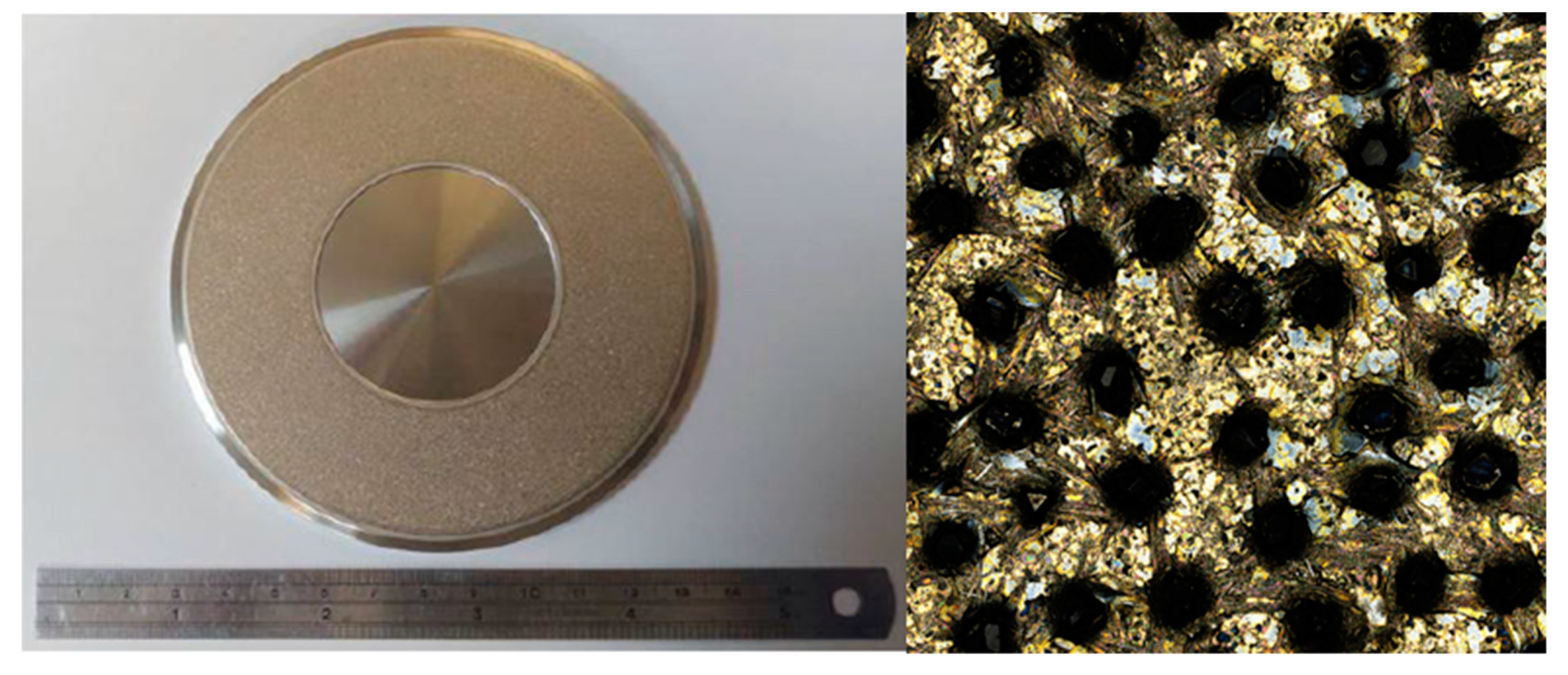

3. Experimental Method and Parameters

4. Results and Discussion

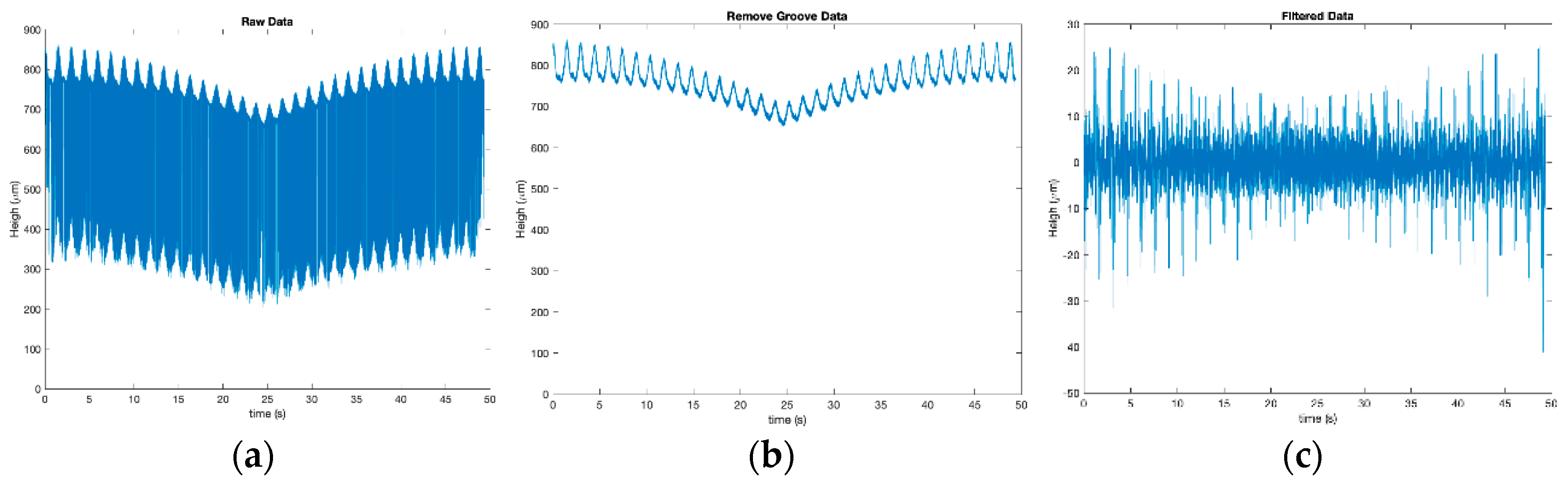

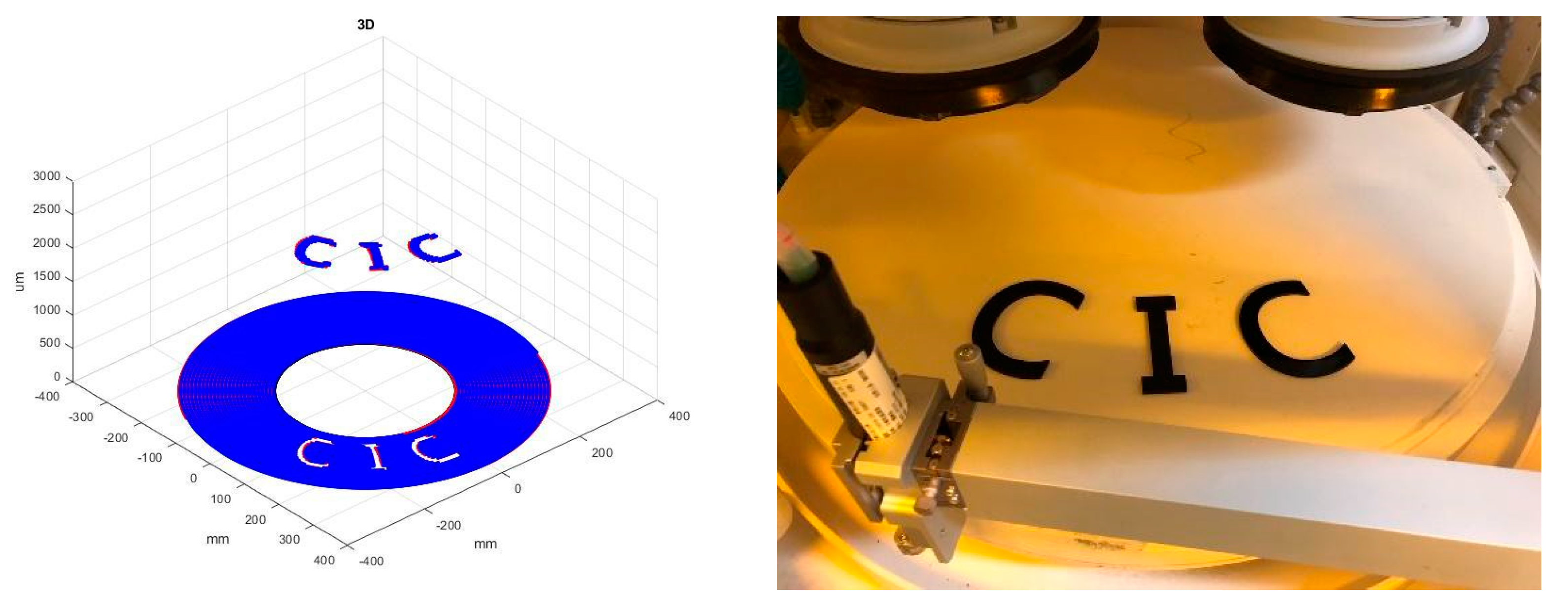

4.1. Measuring Points Allocating and Processing

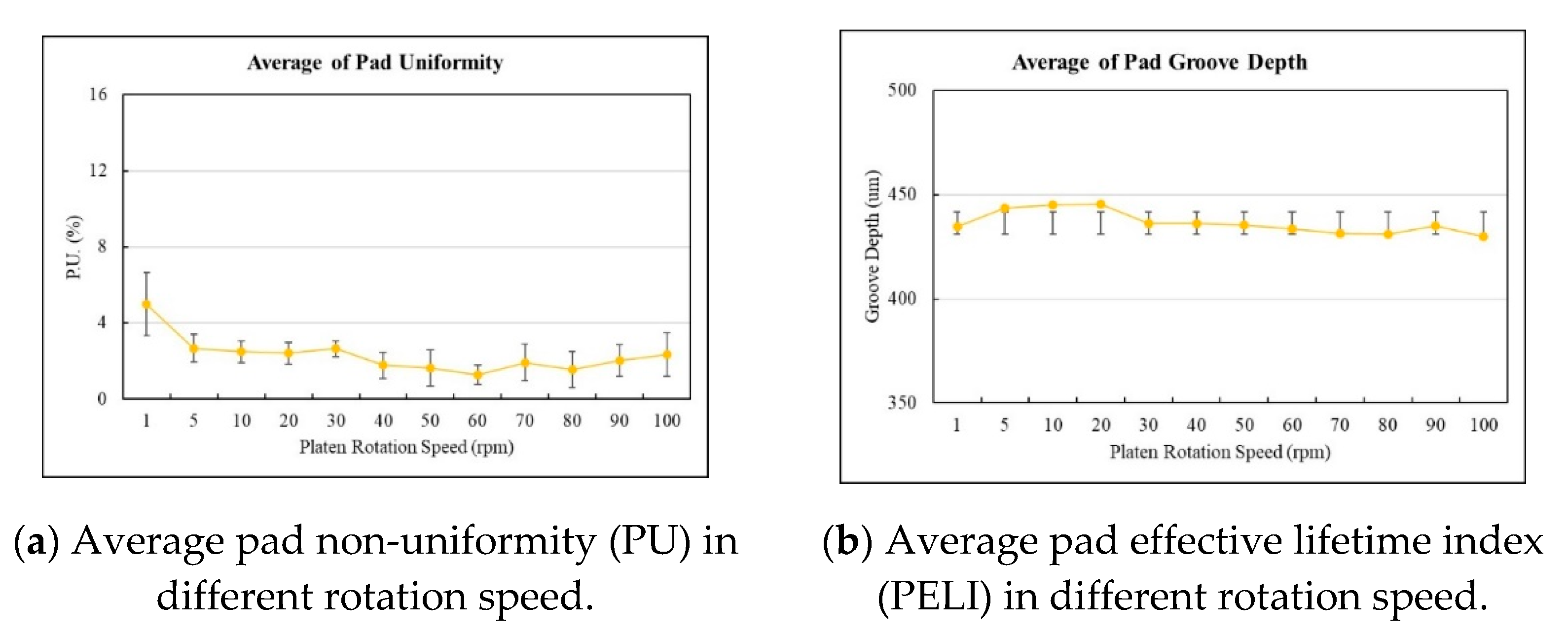

4.2. Metrological Parameters

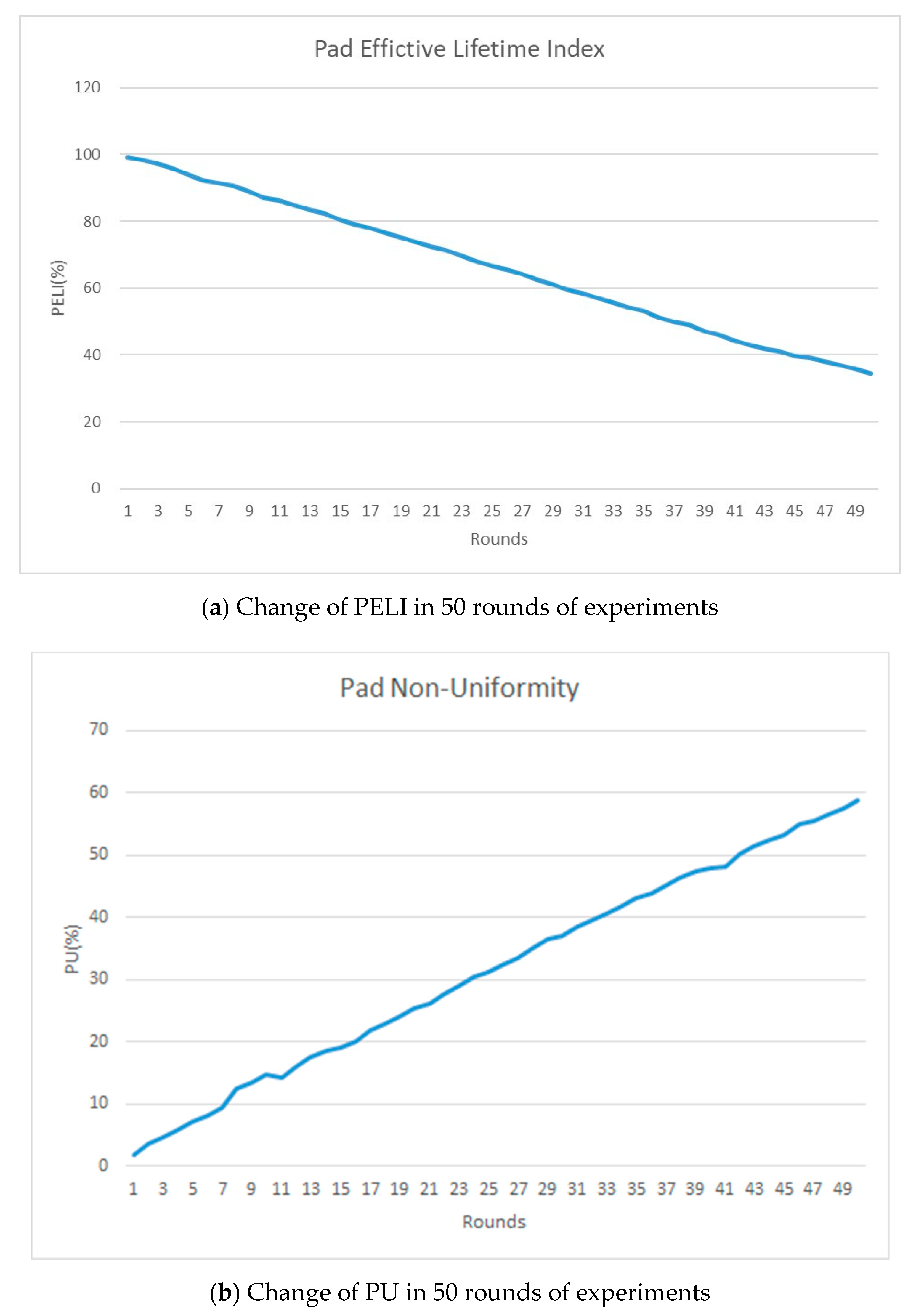

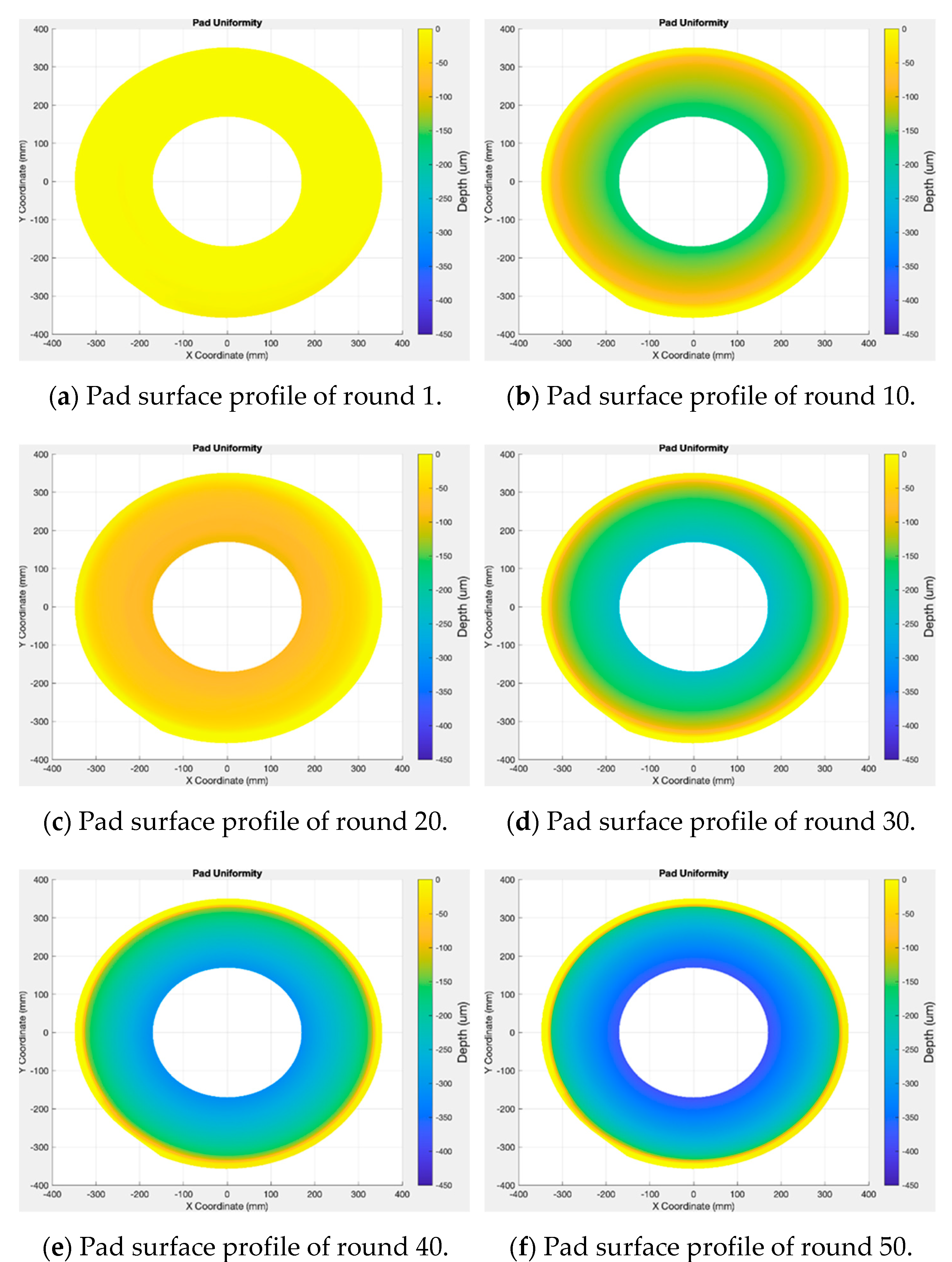

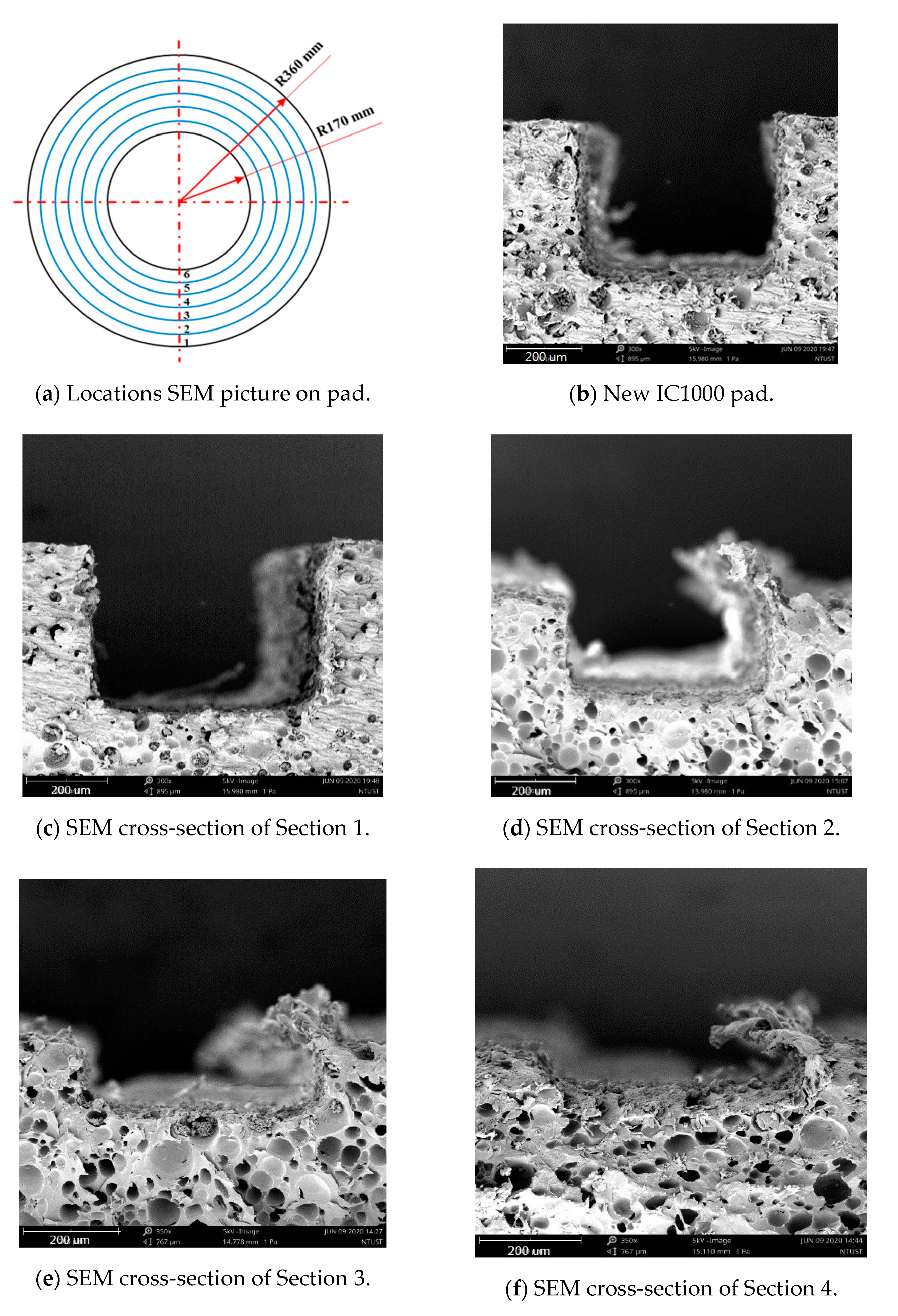

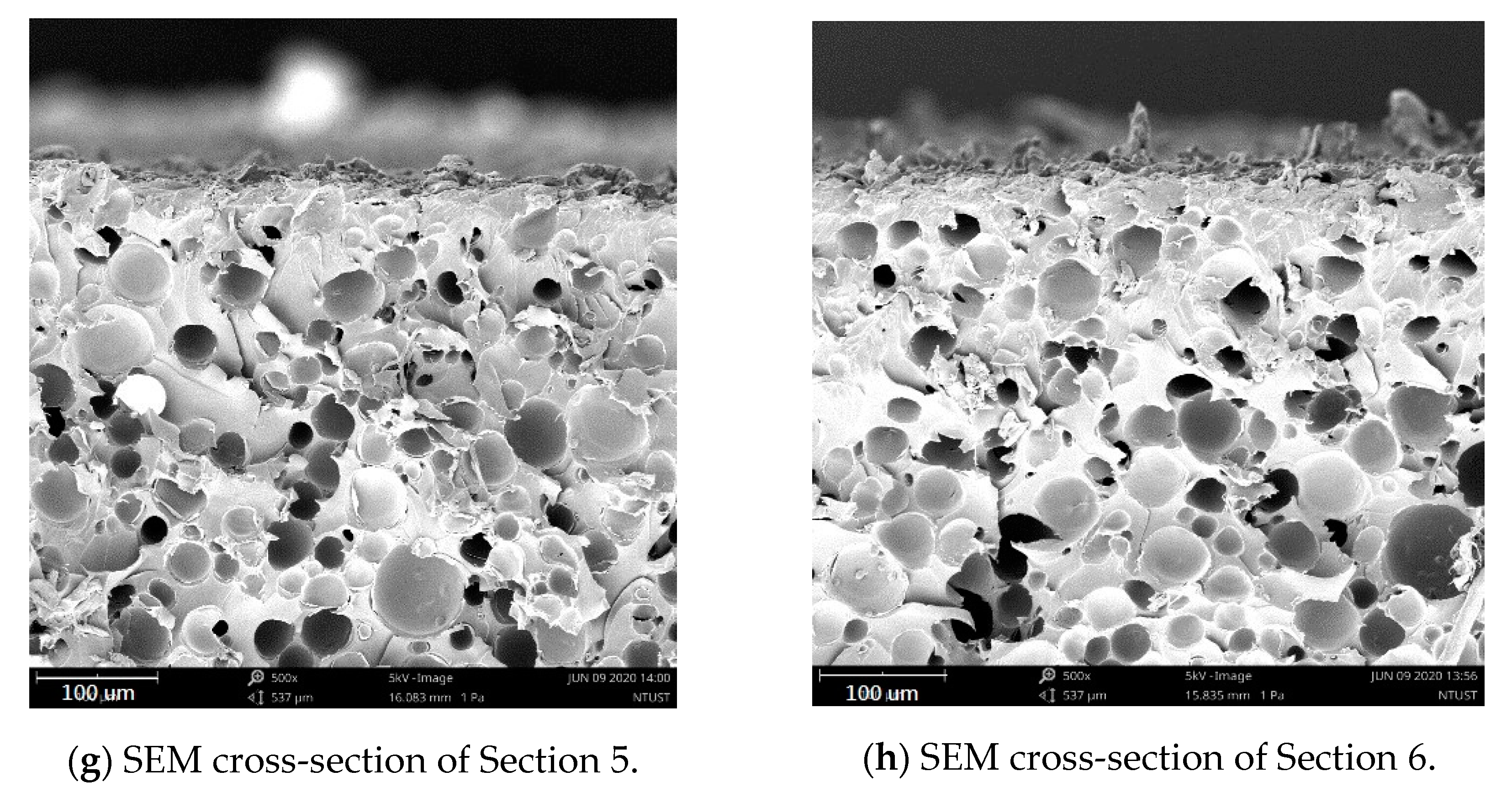

4.3. PU and PELI in CMP Experiments

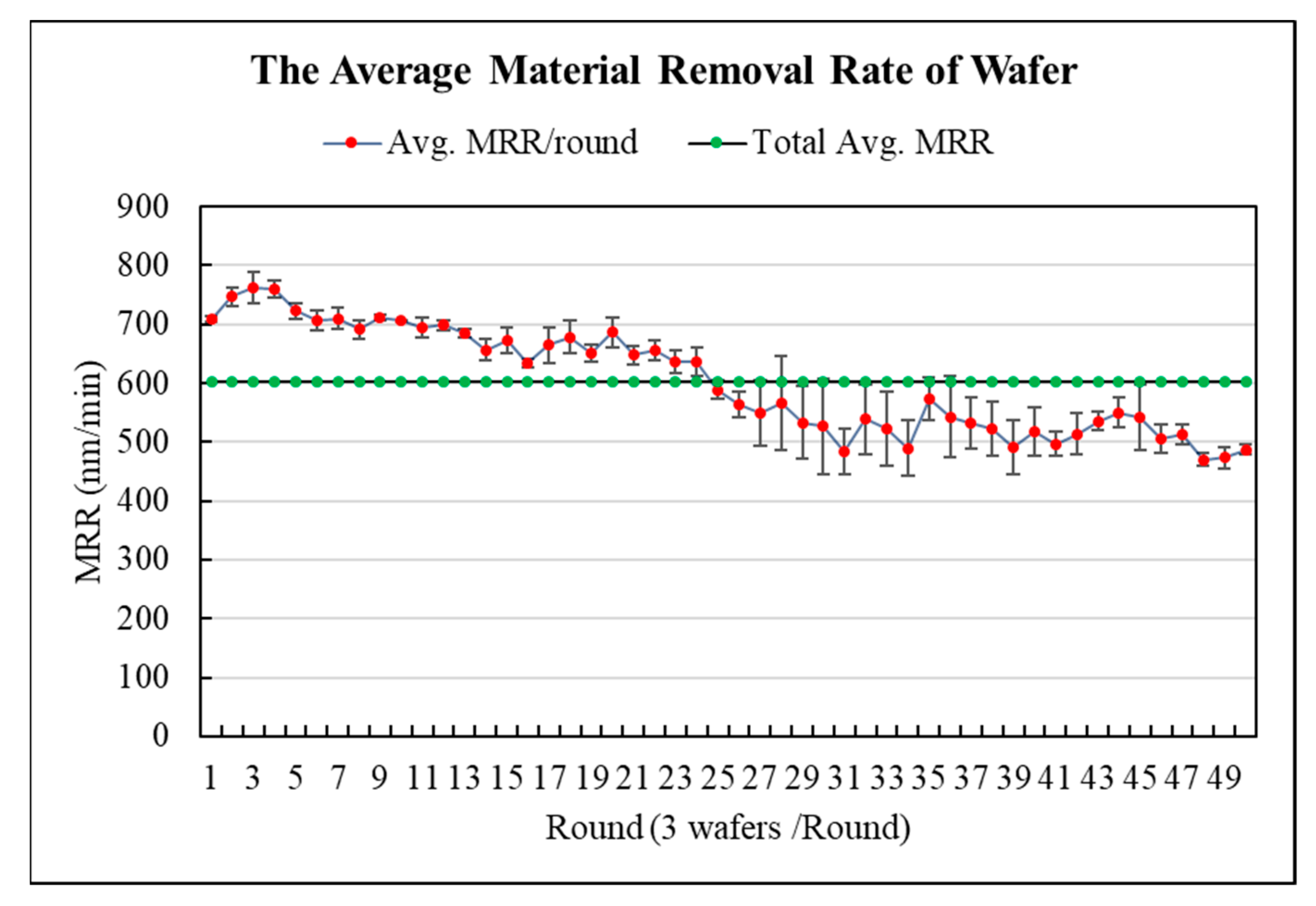

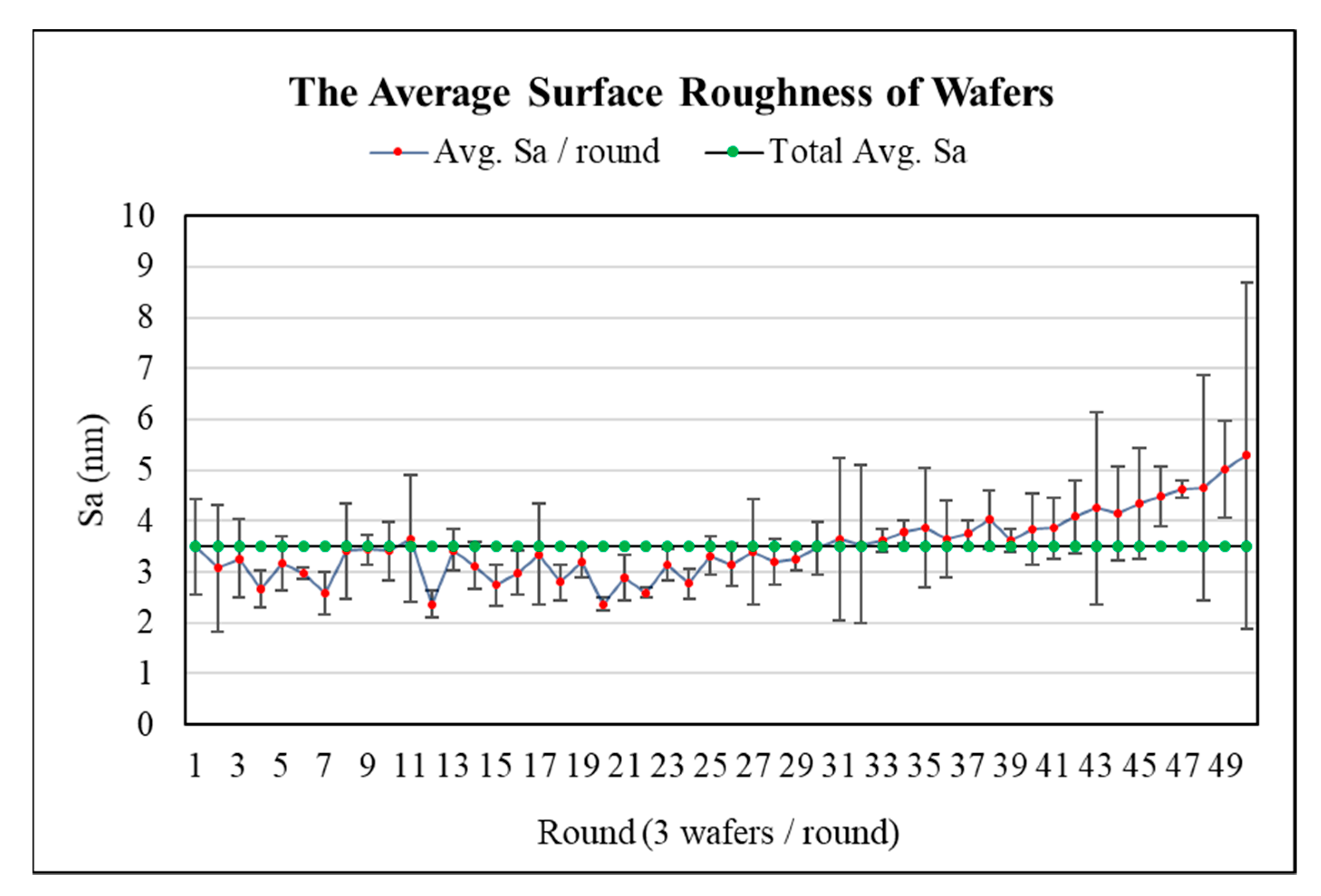

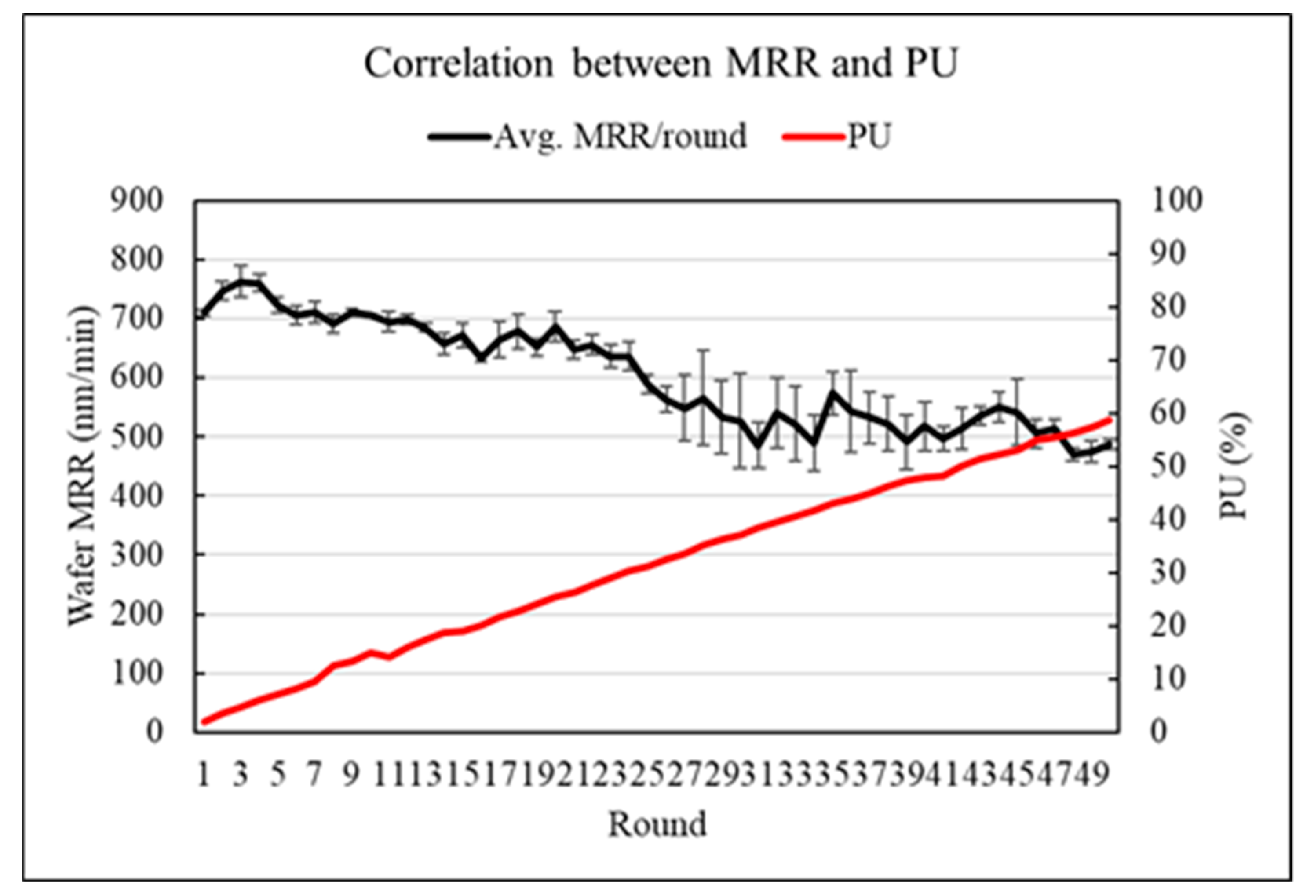

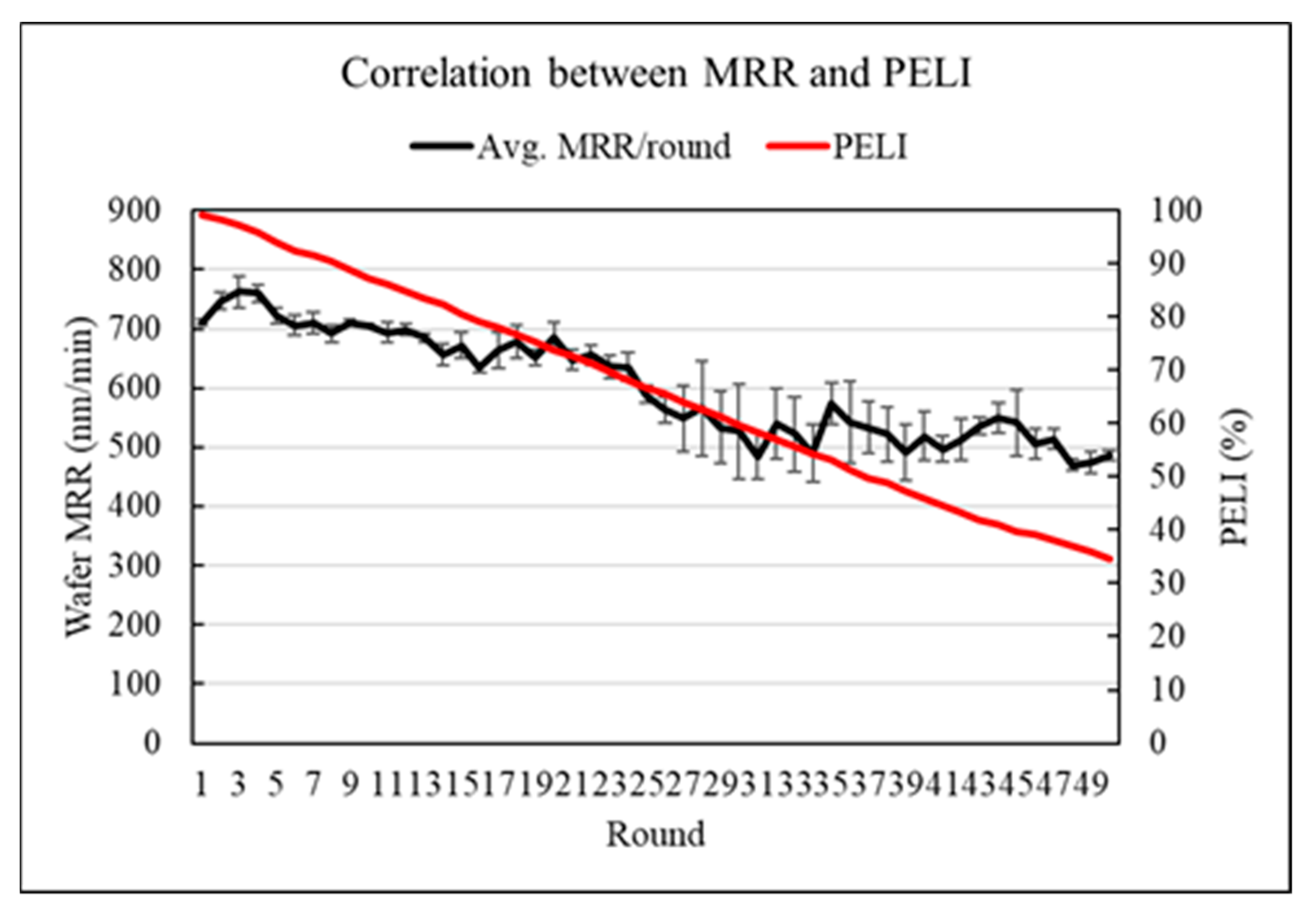

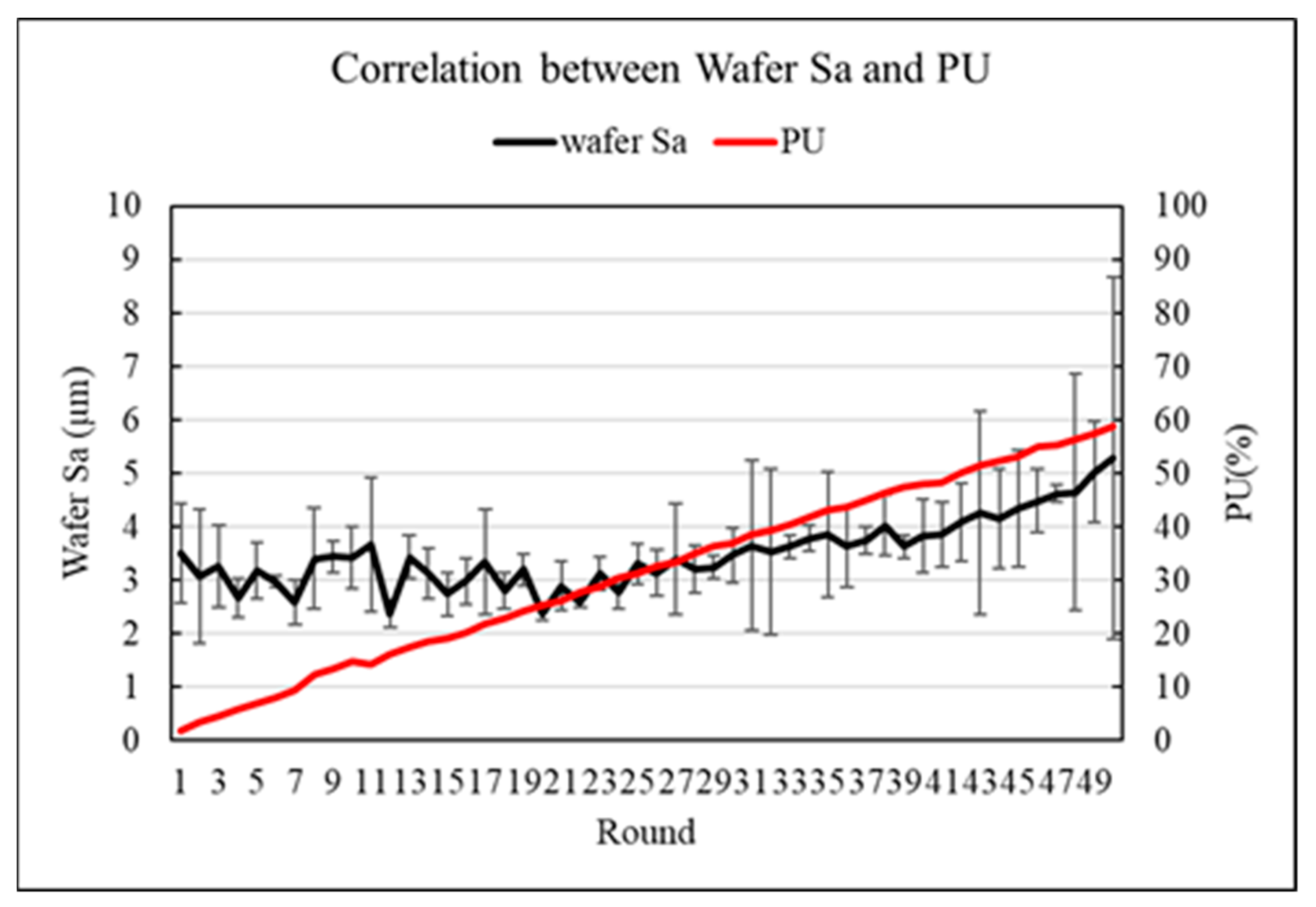

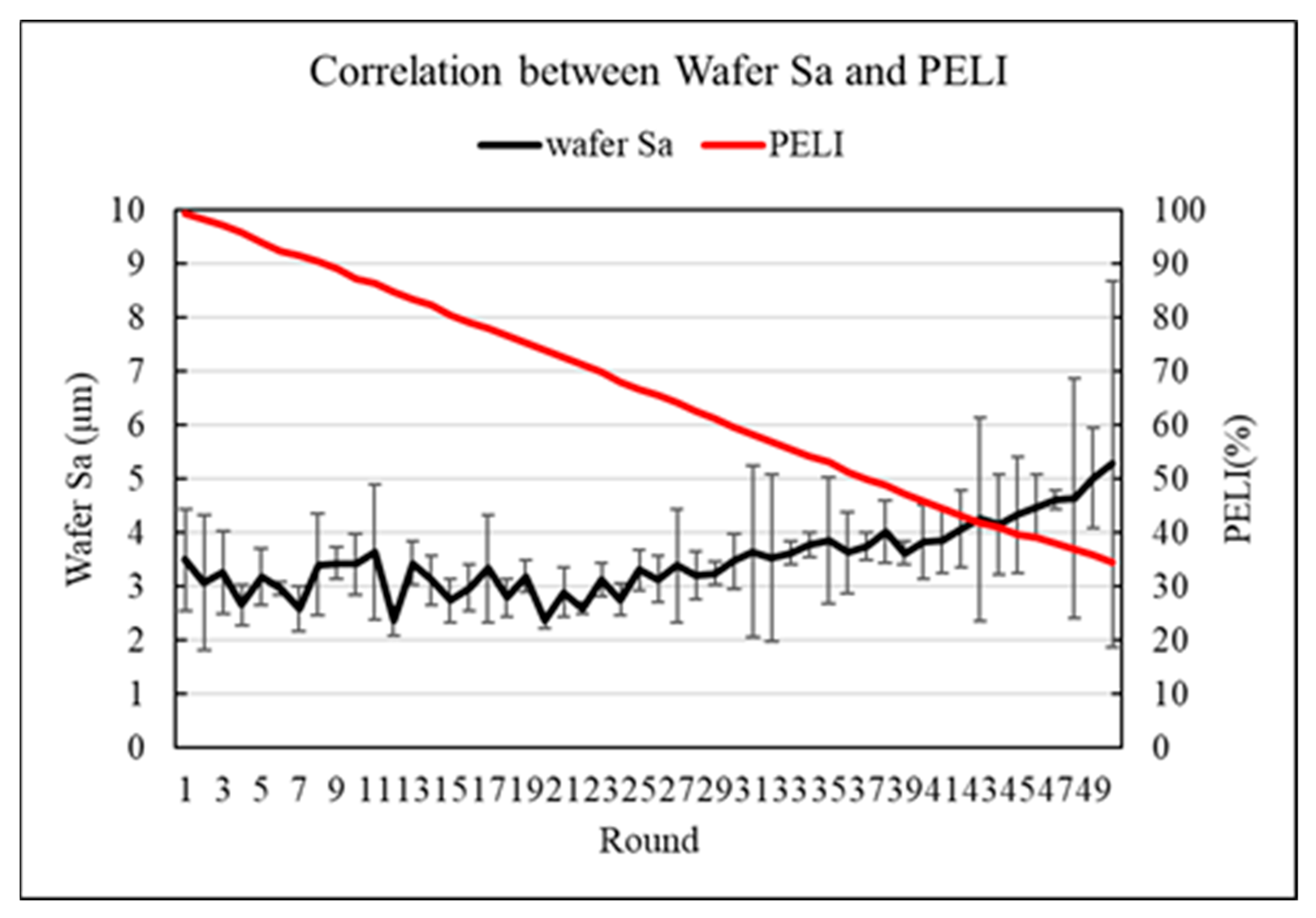

4.4. Correlations of CMP Results with Pad Performance Index

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McGrath, J.; Davis, C. Polishing pad surface characterisation in chemical mechanical planarisation. J. Mater. Process. Technol. 2004, 154, 666–673. [Google Scholar] [CrossRef]

- Lee, E.-S.; Cha, J.-W.; Kim, S.-H. Evaluation of the wafer polishing pad capacity and lifetime in the machining of reliable elevations. Int. J. Mach. Tools Manuf. 2013, 66, 82–94. [Google Scholar] [CrossRef]

- Hooper, B.; Byrne, G.; Galligan, S. Pad conditioning in chemical mechanical polishing. J. Mater. Process. Technol. 2002, 123, 107–113. [Google Scholar] [CrossRef]

- Park, B.; Lee, H.; Park, K.; Kim, H.; Jeong, H. Pad roughness variation and its effect on material removal profile in ceria-based CMP slurry. J. Mater. Process. Technol. 2008, 203, 287–292. [Google Scholar] [CrossRef]

- Choi, W.J.; Jung, S.P.; Shin, J.G.; Yang, D.; Lee, B.-H. Characterization of wet pad surface in chemical mechanical polishing (CMP) process with full-field optical coherence tomography (FF-OCT). Opt. Express 2011, 19, 13343–13350. [Google Scholar] [CrossRef] [PubMed]

- Del Monaco, S.; Calderone, F.; Fritah, M.; Le Tiec, T.; Laurent, A. Chemical Mechanical Planarization (CMP) In-Situ pad groove monitor through Fault Detection and Classification (FDC) system. In Proceedings of the ICPT 2012-International Conference on Planarization/CMP Technology, Grenoble, France, 15–17 October 2012. [Google Scholar]

- Elledge, J.B. In-Situ Chemical-Mechanical Planarization Pad Metrology Using Ultrasonic Imaging. U.S. Patent 7,306,506, 11 December 2007. [Google Scholar]

- Chen, C.-C.A.; Wang, P.-K. Study on Bearing Area Ratio Analysis of CMP Pad Topography Measured by Confocal Laser Scanning System. In Proceedings of the International Conference on Planarization/CMP Technology, Hsinchu, Taiwan, 29 October 2013; pp. 114–117. [Google Scholar]

- Lee, H.; Zhuang, Y.; Sugiyama, M.; Seike, Y.; Takaoka, M.; Miyachi, K.; Nishiguchi, T.; Kojima, H.; Philipossian, A. Pad flattening ratio, coefficient of friction and removal rate analysis during silicon dioxide chemical mechanical planarization. Thin Solid Films 2010, 518, 1994–2000. [Google Scholar] [CrossRef]

- Matsumura, Y.; Hirao, T.; Kinoshita, M. Analysis of Pad Surface Roughness on Copper Chemical Mechanical Planarization. Jpn. J. Appl. Phys. 2008, 47, 2083–2086. [Google Scholar] [CrossRef]

- Khanna, A.J.; Jawali, P.; Redfield, D.; Kakireddy, R.; Chockalingam, A.; Benvegnu, D.; Yang, M.; Rozo, S.; Fung, J.; Cornejo, M.; et al. Methodology for pad conditioning sweep optimization for advanced nodes. Microelectron. Eng. 2019, 216, 111101. [Google Scholar] [CrossRef]

- Lee, H.; Lee, S. Investigation of pad wear in CMP with swing-arm conditioning and uniformity of material removal. Precis. Eng. 2017, 49, 85–91. [Google Scholar] [CrossRef]

- Lee, S.; Kim, H.; Dornfeld, D. Development of a CMP pad with controlled micro features for improved performance. In Proceedings of the ISSM 2005, IEEE International Symposium on Semiconductor Manufacturing, San Jose, CA, USA, 13–15 September 2005; pp. 173–176. [Google Scholar] [CrossRef] [Green Version]

- Huang, B.; Kunoth, A. An optimization based empirical mode decomposition scheme. J. Comput. Appl. Math. 2013, 240, 174–183. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.-C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. A Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Lee, S.; Jeong, S.; Park, K.; Kim, H.; Jeong, H. Kinematical Modeling of Pad Profile Variation during Conditioning in Chemical Mechanical Polishing. Jpn. J. Appl. Phys. 2009, 48, 126502. [Google Scholar] [CrossRef]

- Chen, C.-C.A.; Pham, Q.-P. Study on diamond dressing for non-uniformity of pad surface topography in CMP process. Int. J. Adv. Manuf. Technol. 2017, 91, 3573–3582. [Google Scholar] [CrossRef]

| Pad | IC1000 |

|---|---|

| Thickness (mm) | 1.36 |

| Grid size (mm) | 7.5 |

| Groove width (mm) | 0.5 |

| Groove depth (mm) | 0.436 |

| Hardness (Shore D) | 53 |

| Compressibility (%) | 5% |

| Recovery (%) | 76% |

| Pressure | 6.89 kPa (1 psi) |

|---|---|

| Pad speed | 80 rpm |

| Dresser head speed | 70 rpm |

| Slurry | DIW |

| Slurry feed rate | 200 mL/min |

| Conditioning time | 12 min |

| Pressure | 13.79 kPa (2 psi) |

|---|---|

| Pad speed | 80 rpm |

| Dresser head speed | 70 rpm |

| Slurry | DIW |

| Slurry feed rate | 200 mL/min |

| Conditioning time | 1.5 min |

| Pressure | 20.68 kPa (3 psi) |

|---|---|

| Pad speed | 80 rpm |

| Dresser head speed | 70 rpm |

| Slurry | C8902 |

| Slurry feed rate | 200 mL/min |

| Conditioning time | 1 min |

| Platen Rotation Speed | 1, 5, 10, 20, 30, 40, 50, 60, 70, 80, 90, 100 rpm |

|---|---|

| Swing Arm Rotation Speed | 1°/s |

| Sampling Rate | 1000 Hz |

| Measurement times | 50 times |

| Scan time | 50 s |

| Wafer/Pad Index | MRR(nm/min) | Sa(μm) | Sa(μm) Last 25 rounds |

|---|---|---|---|

| PU(%) | −0.94 | 0.76 | 0.93 |

| PELI(%) | 0.94 | −0.76 | −0.91 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.-C.A.; Li, J.-C.; Liao, W.-C.; Ciou, Y.-J.; Chen, C.-C. Dynamic Pad Surface Metrology Monitoring by Swing-Arm Chromatic Confocal System. Appl. Sci. 2021, 11, 179. https://doi.org/10.3390/app11010179

Chen C-CA, Li J-C, Liao W-C, Ciou Y-J, Chen C-C. Dynamic Pad Surface Metrology Monitoring by Swing-Arm Chromatic Confocal System. Applied Sciences. 2021; 11(1):179. https://doi.org/10.3390/app11010179

Chicago/Turabian StyleChen, Chao-Chang A., Jen-Chieh Li, Wei-Cheng Liao, Yong-Jie Ciou, and Chun-Chen Chen. 2021. "Dynamic Pad Surface Metrology Monitoring by Swing-Arm Chromatic Confocal System" Applied Sciences 11, no. 1: 179. https://doi.org/10.3390/app11010179

APA StyleChen, C.-C. A., Li, J.-C., Liao, W.-C., Ciou, Y.-J., & Chen, C.-C. (2021). Dynamic Pad Surface Metrology Monitoring by Swing-Arm Chromatic Confocal System. Applied Sciences, 11(1), 179. https://doi.org/10.3390/app11010179