Design Optimization and Experimental Verification of Permanent Magnet Synchronous Motor Used in Electric Compressors in Electric Vehicles

Abstract

Featured Application

Abstract

1. Introduction

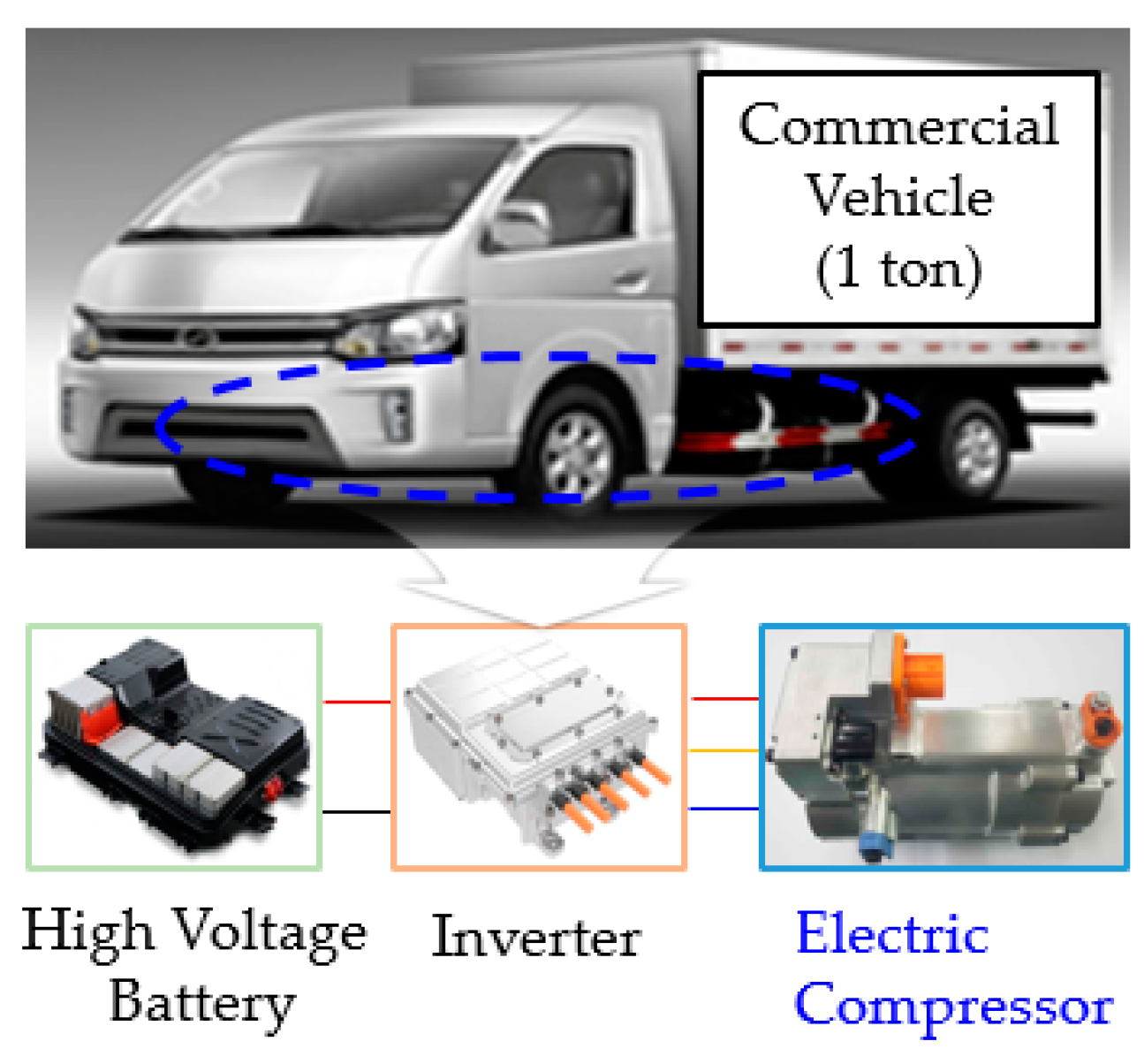

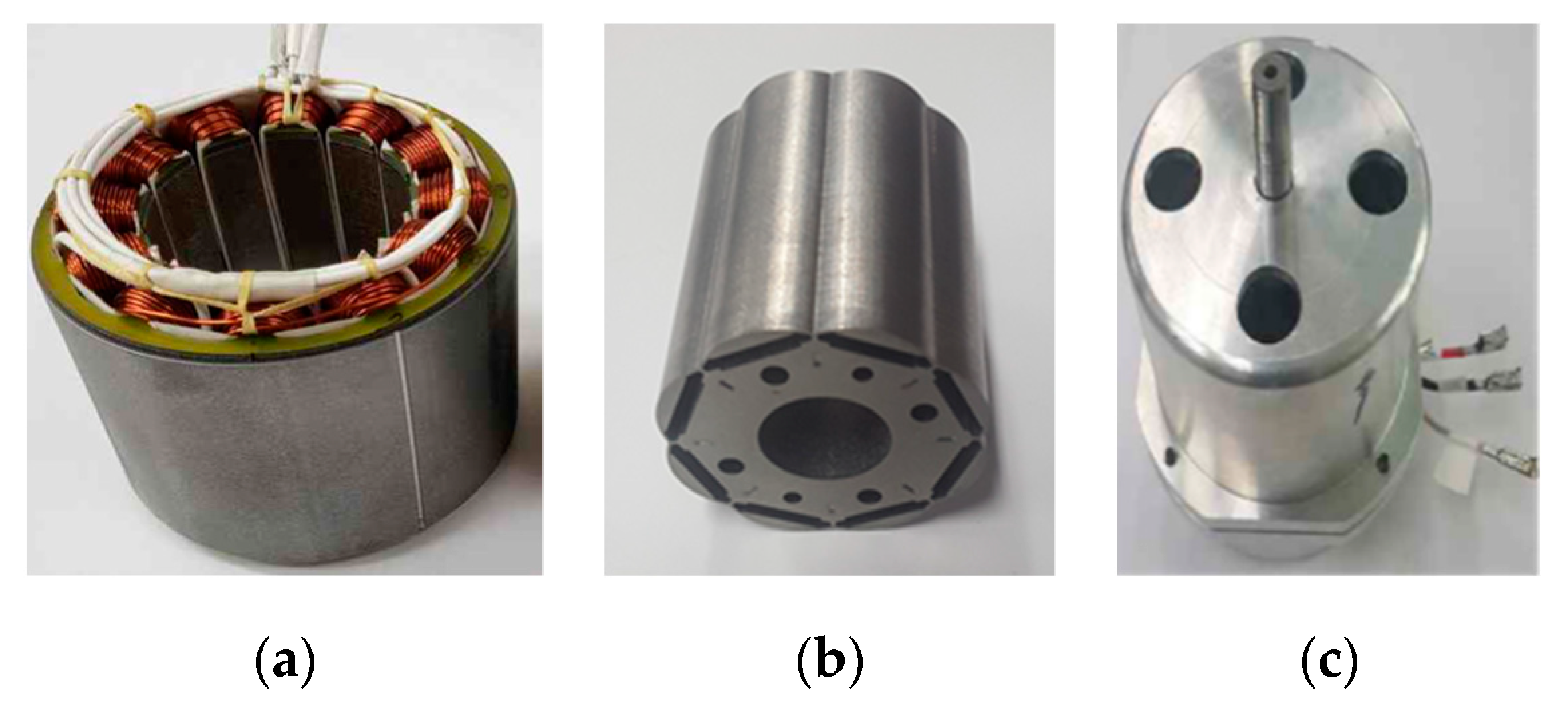

2. PMSM for Electric Compressor

3. Design Optimization

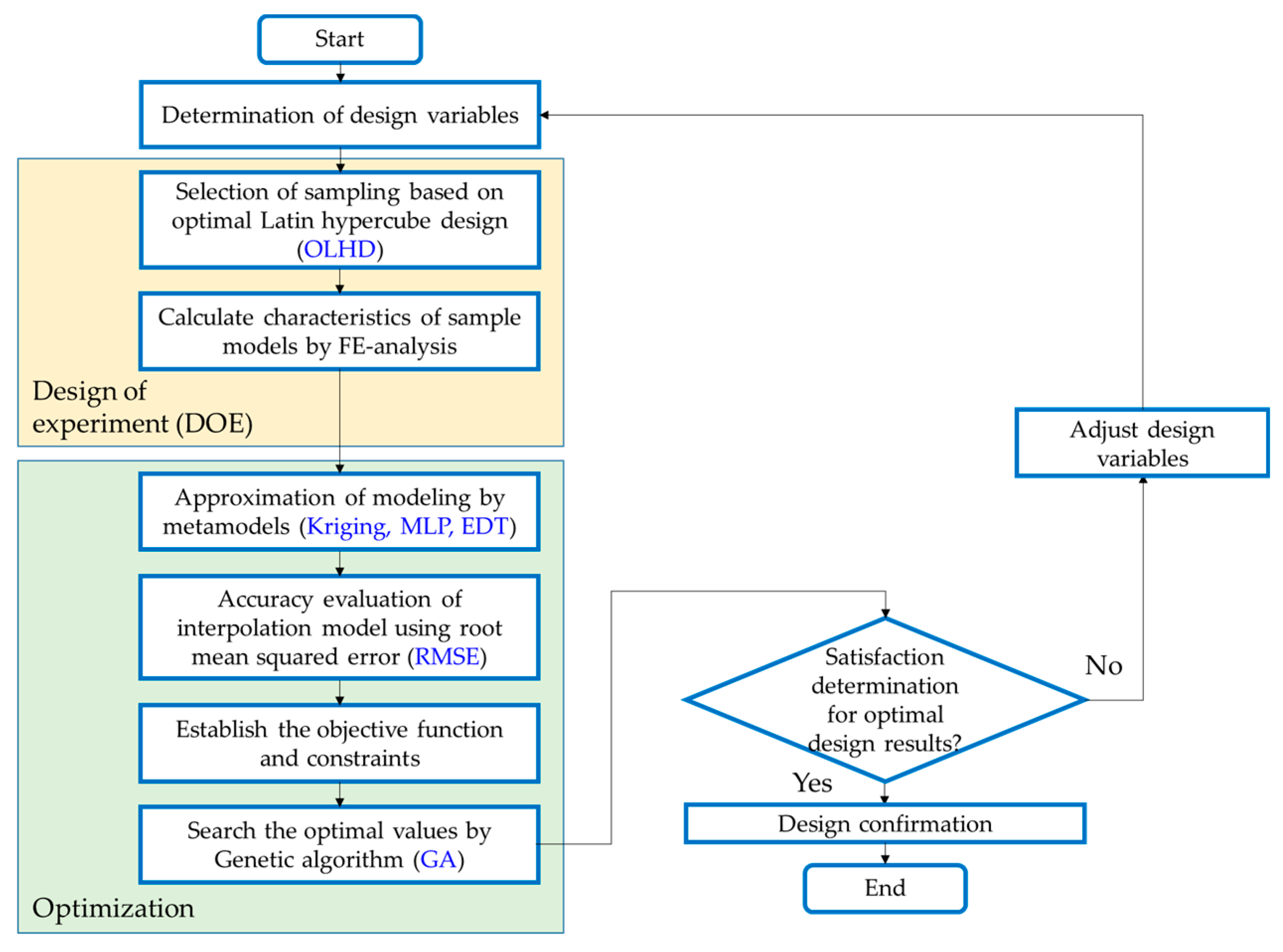

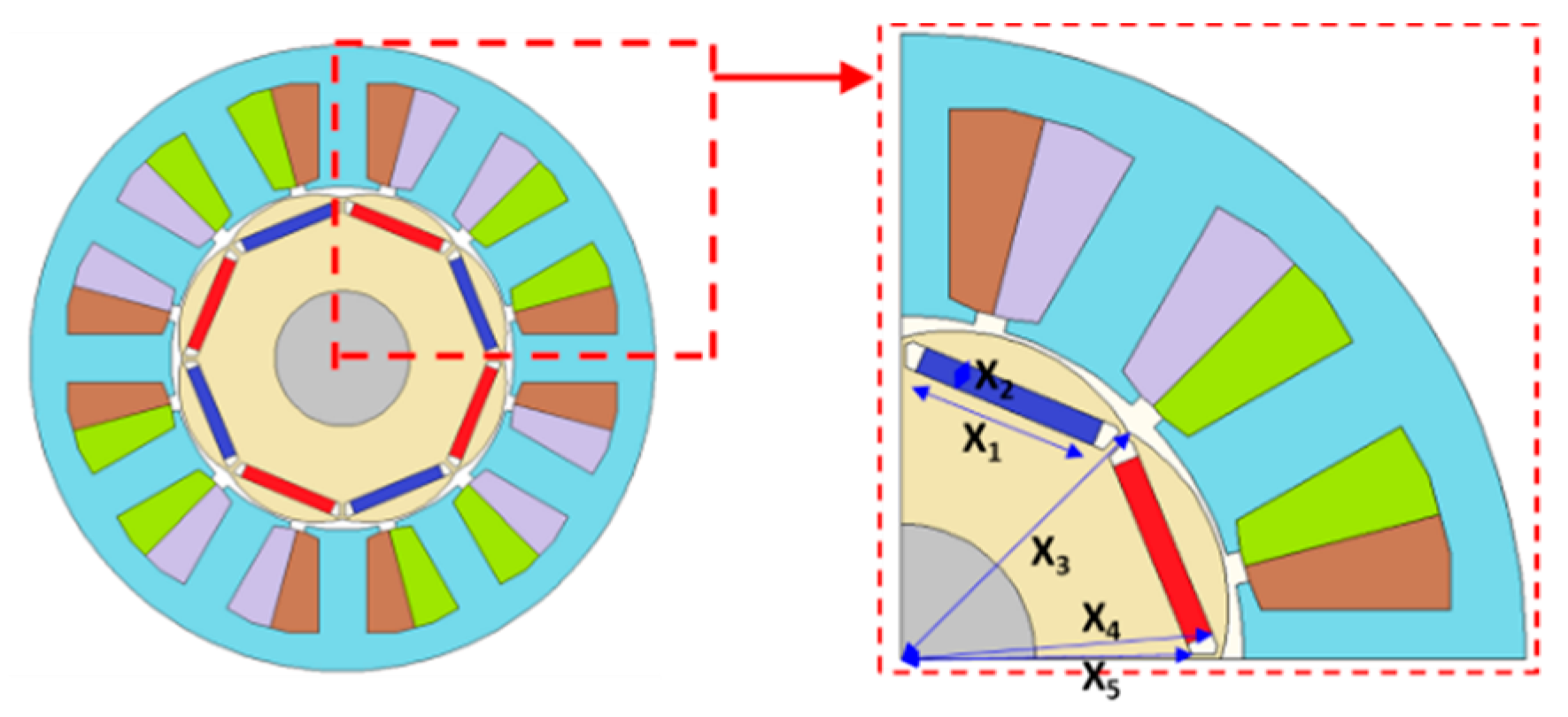

3.1. Rotor Shape Optimization Process

- Objective function:

- Constraints:

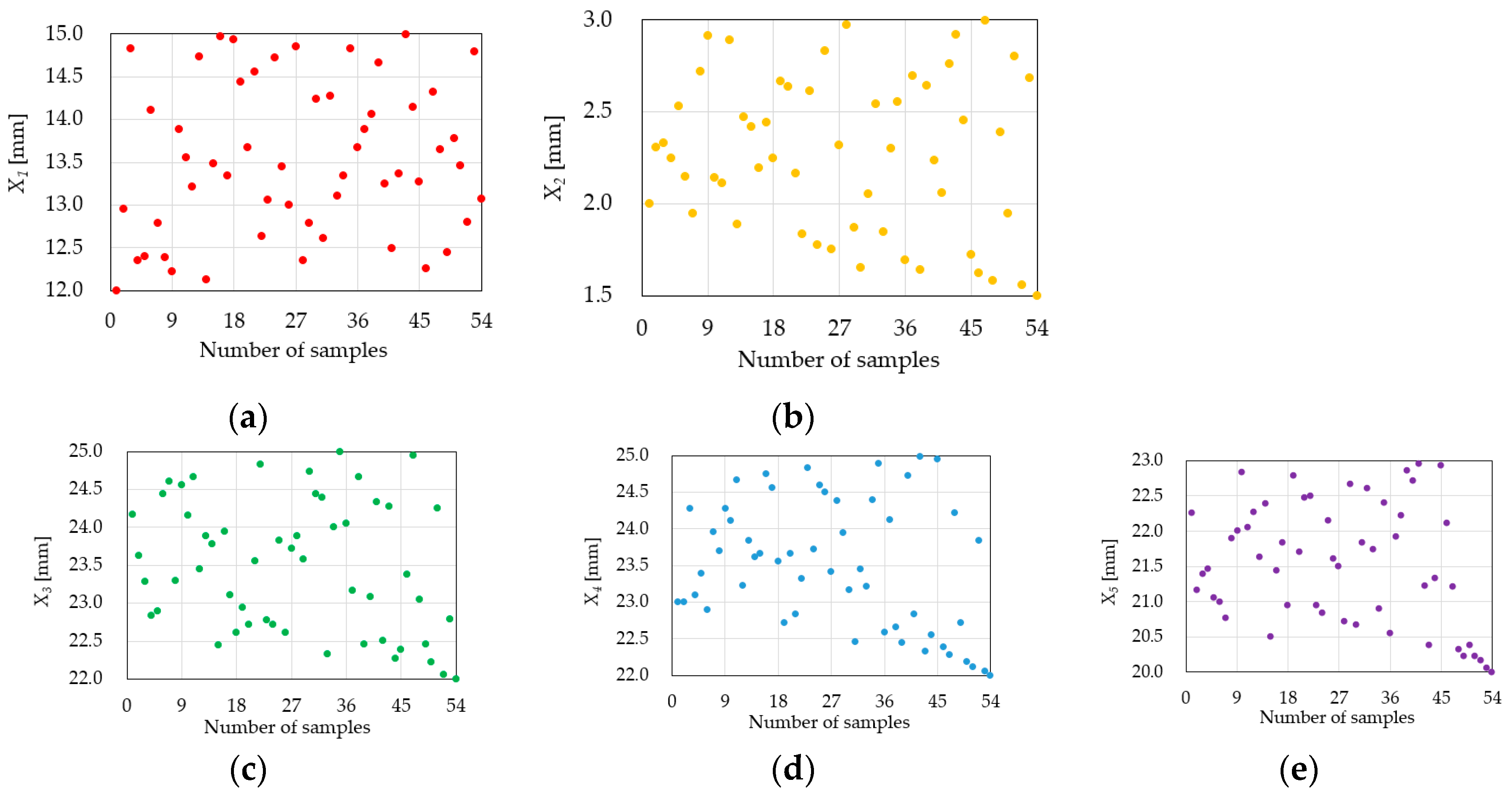

3.2. Design of Experiment

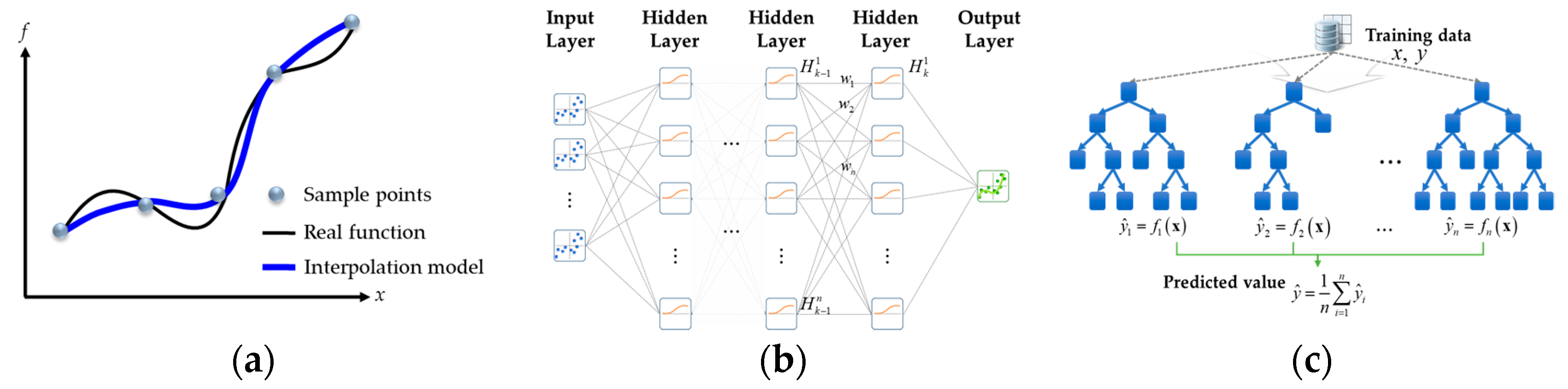

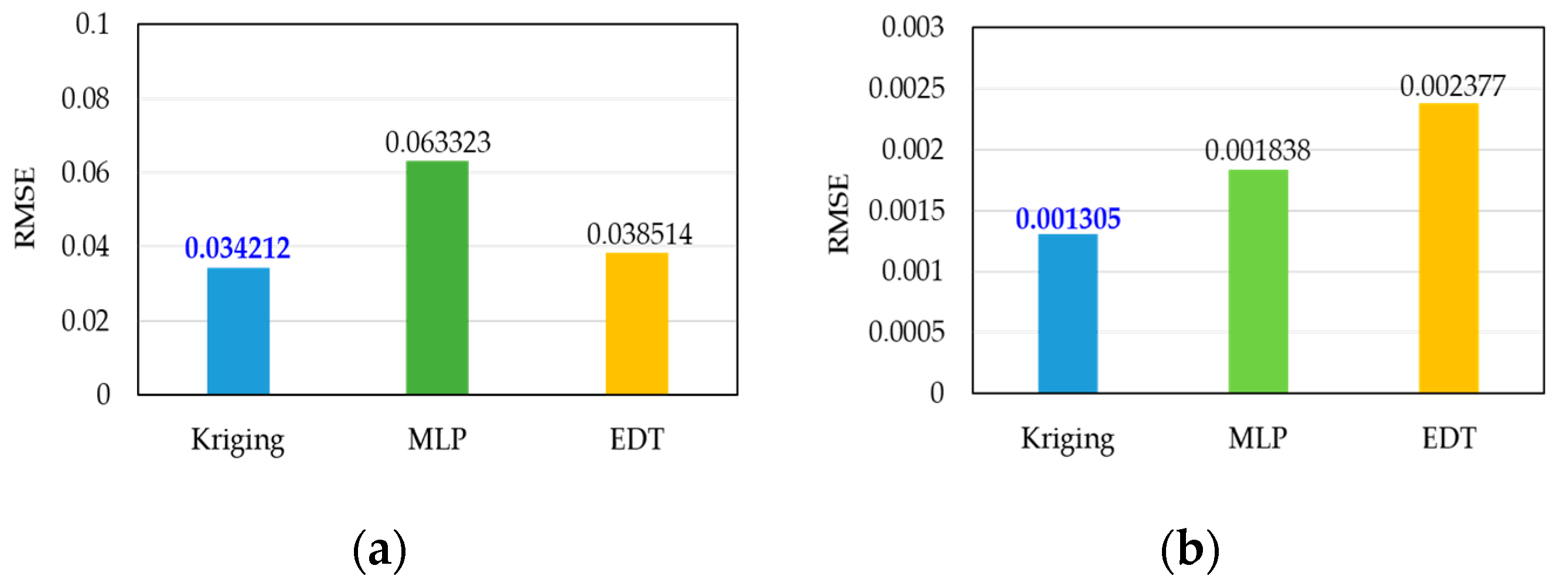

3.3. Metadmodeling

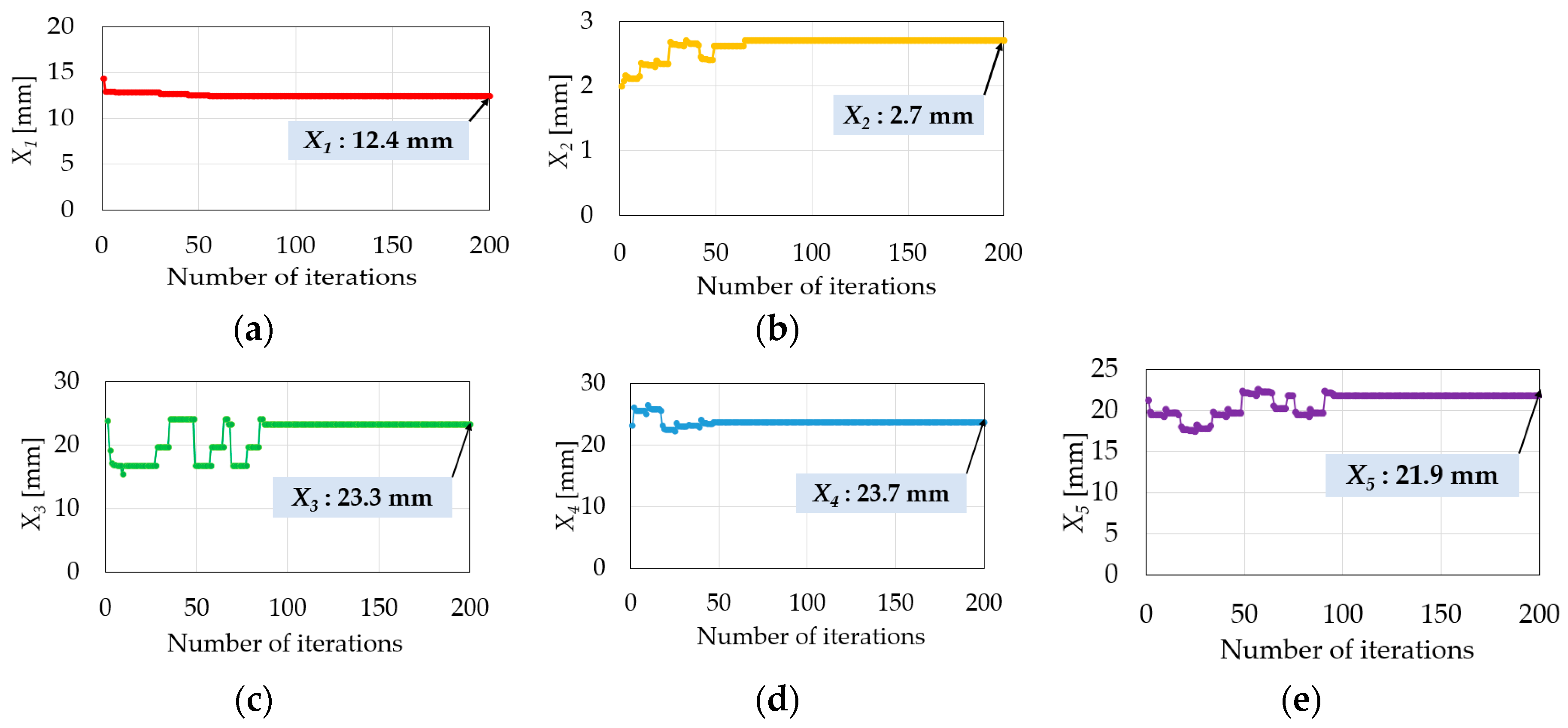

3.4. Global Searching with the GA

4. Verification of Simulations and Experiments

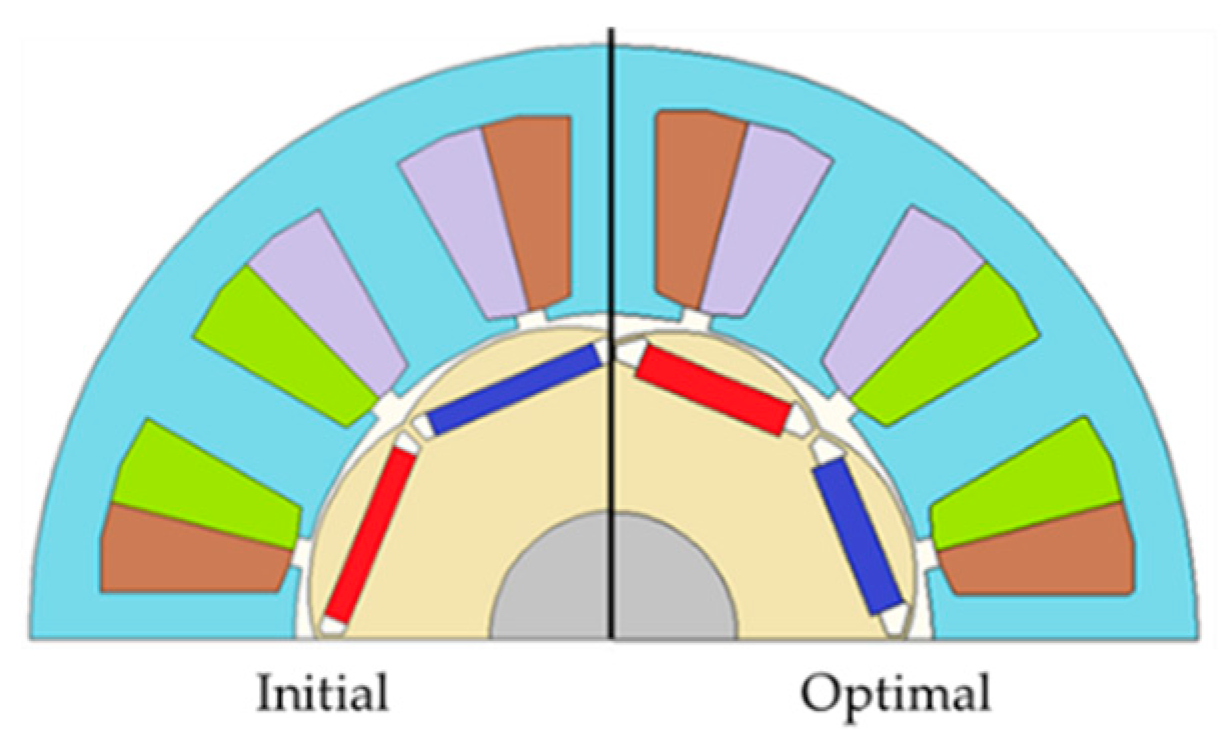

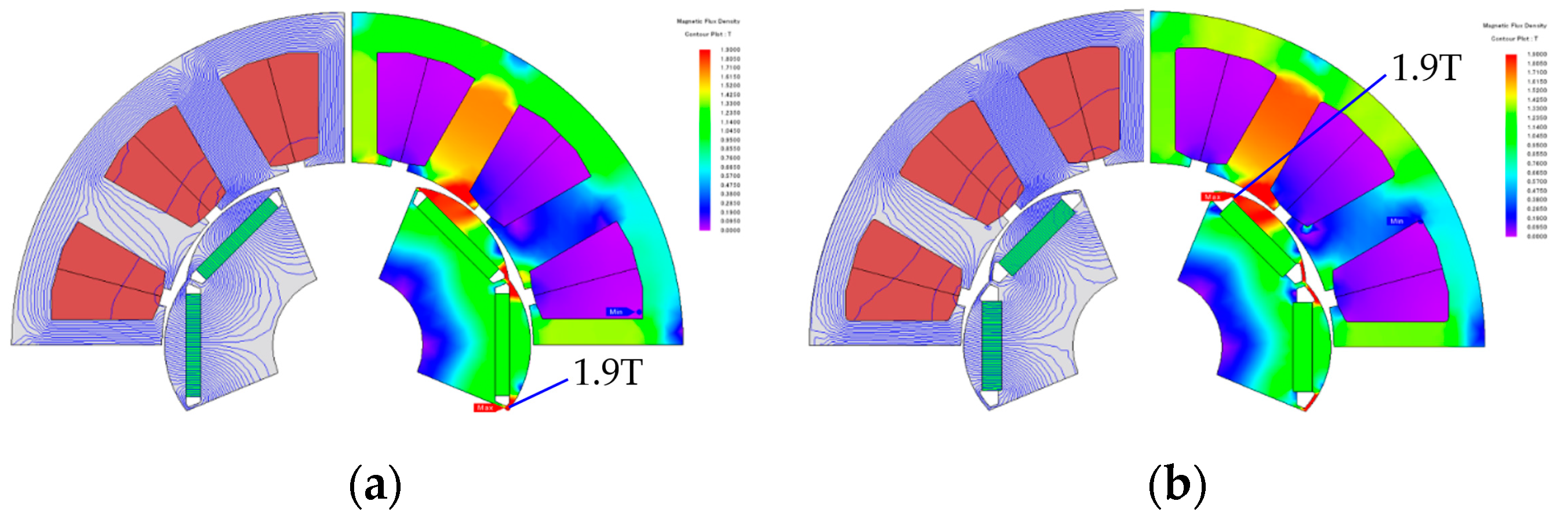

4.1. Simulation Results

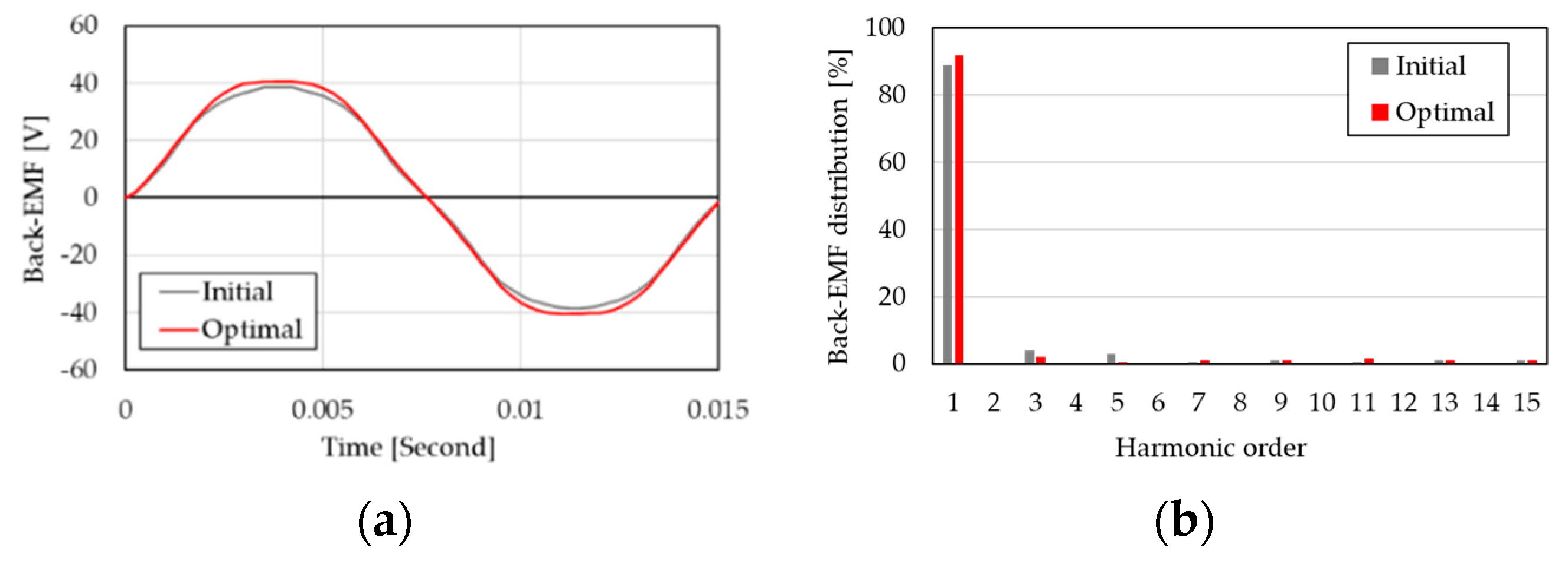

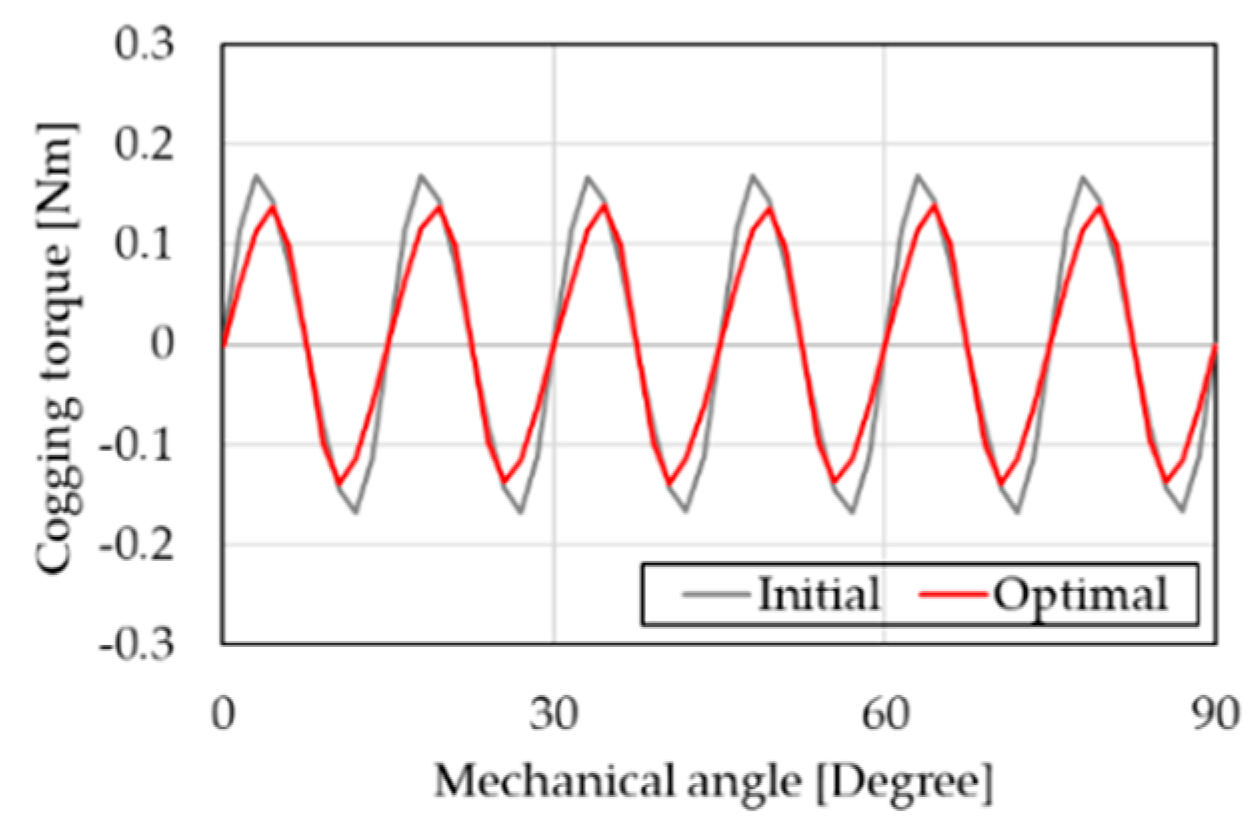

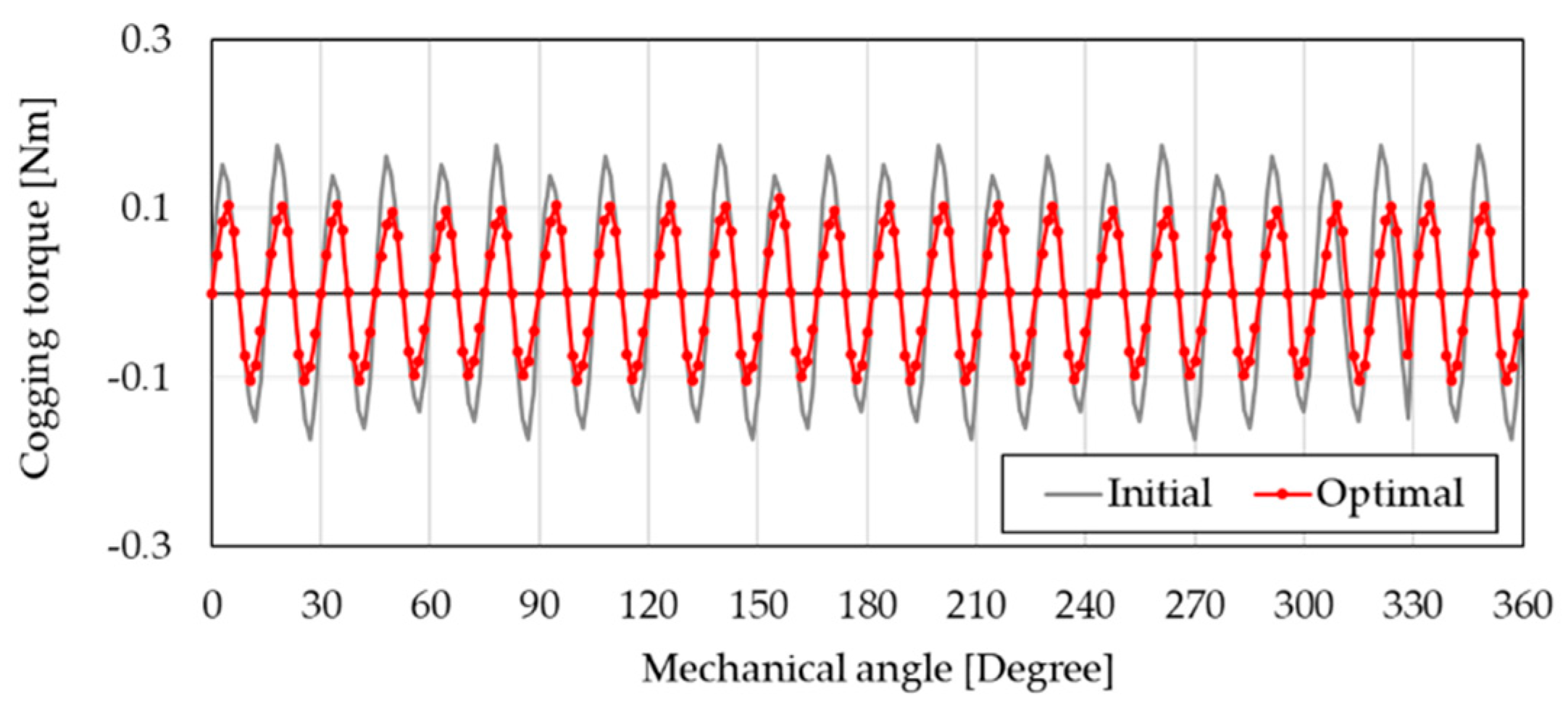

4.1.1. No-Load Analysis

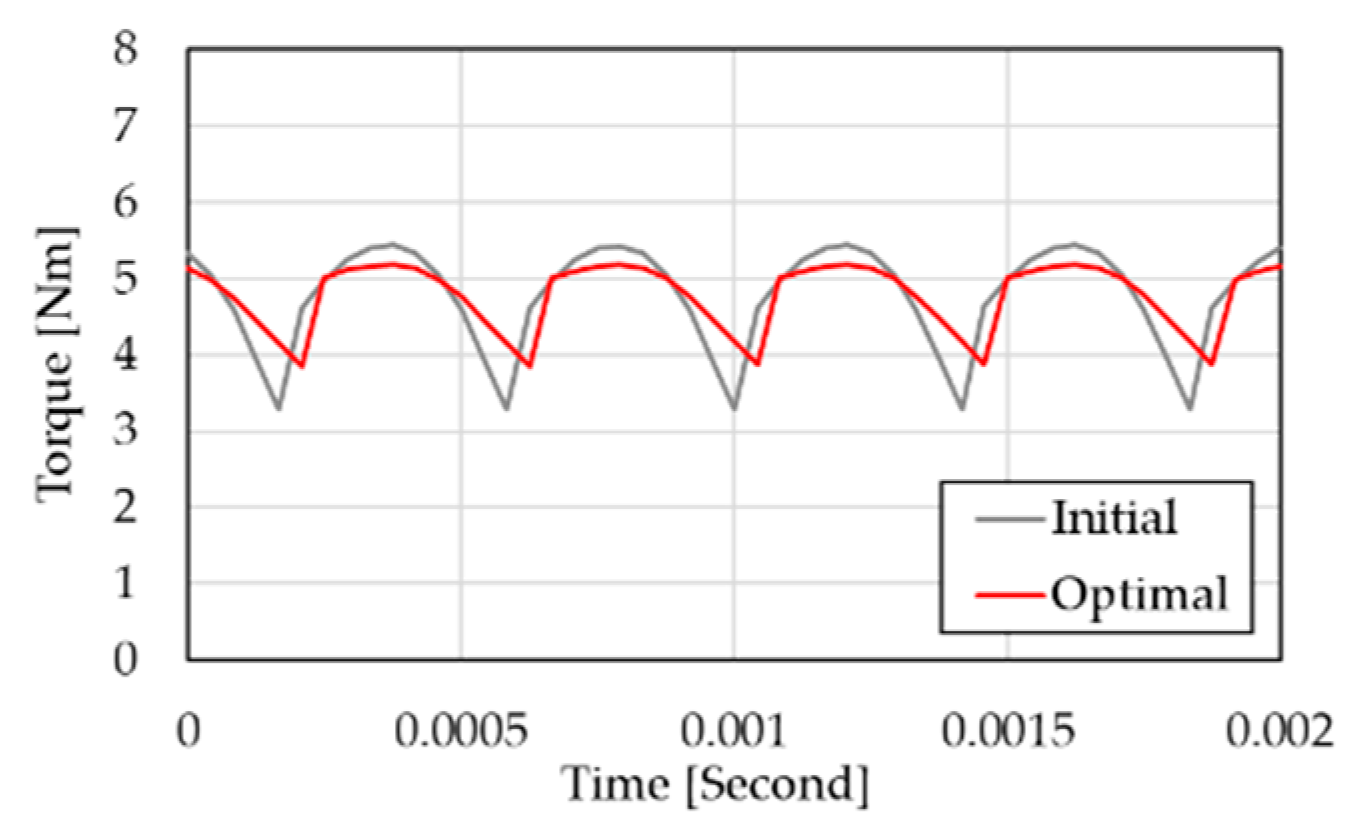

4.1.2. Load Analysis

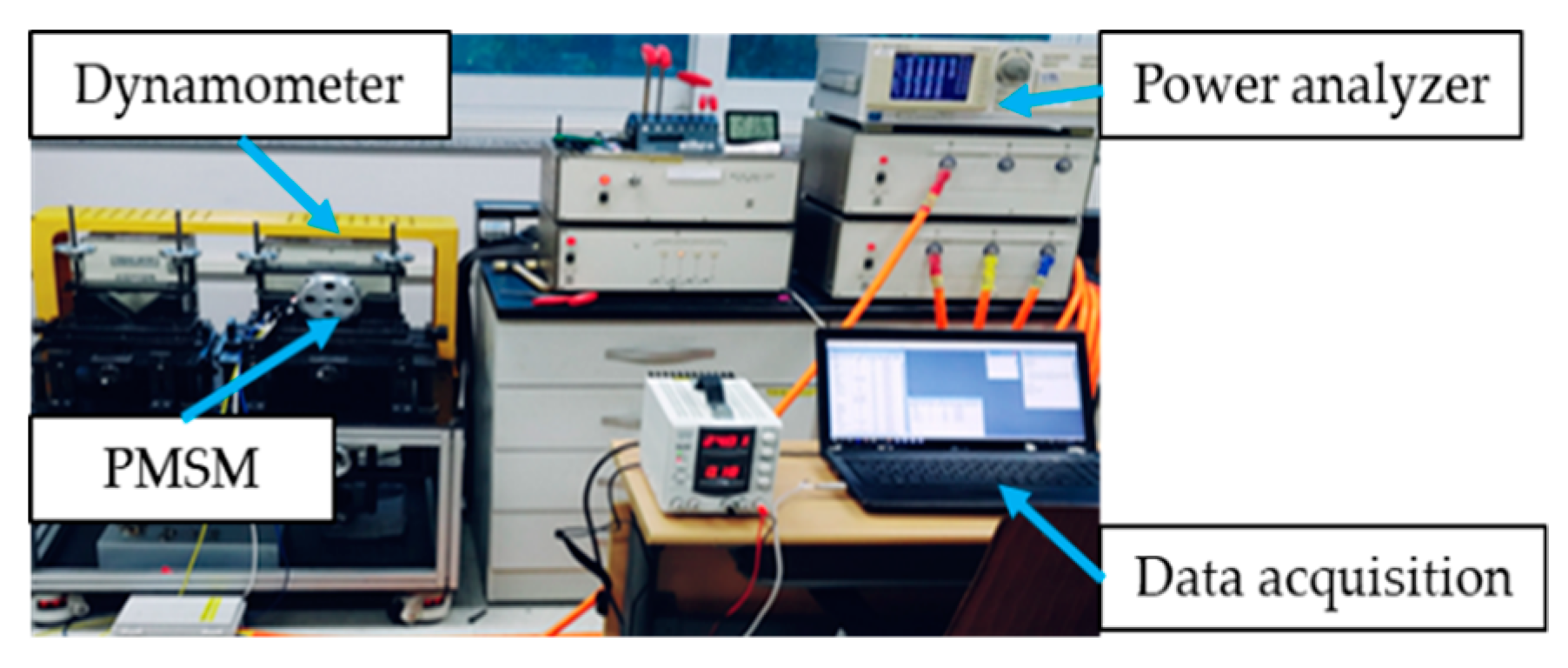

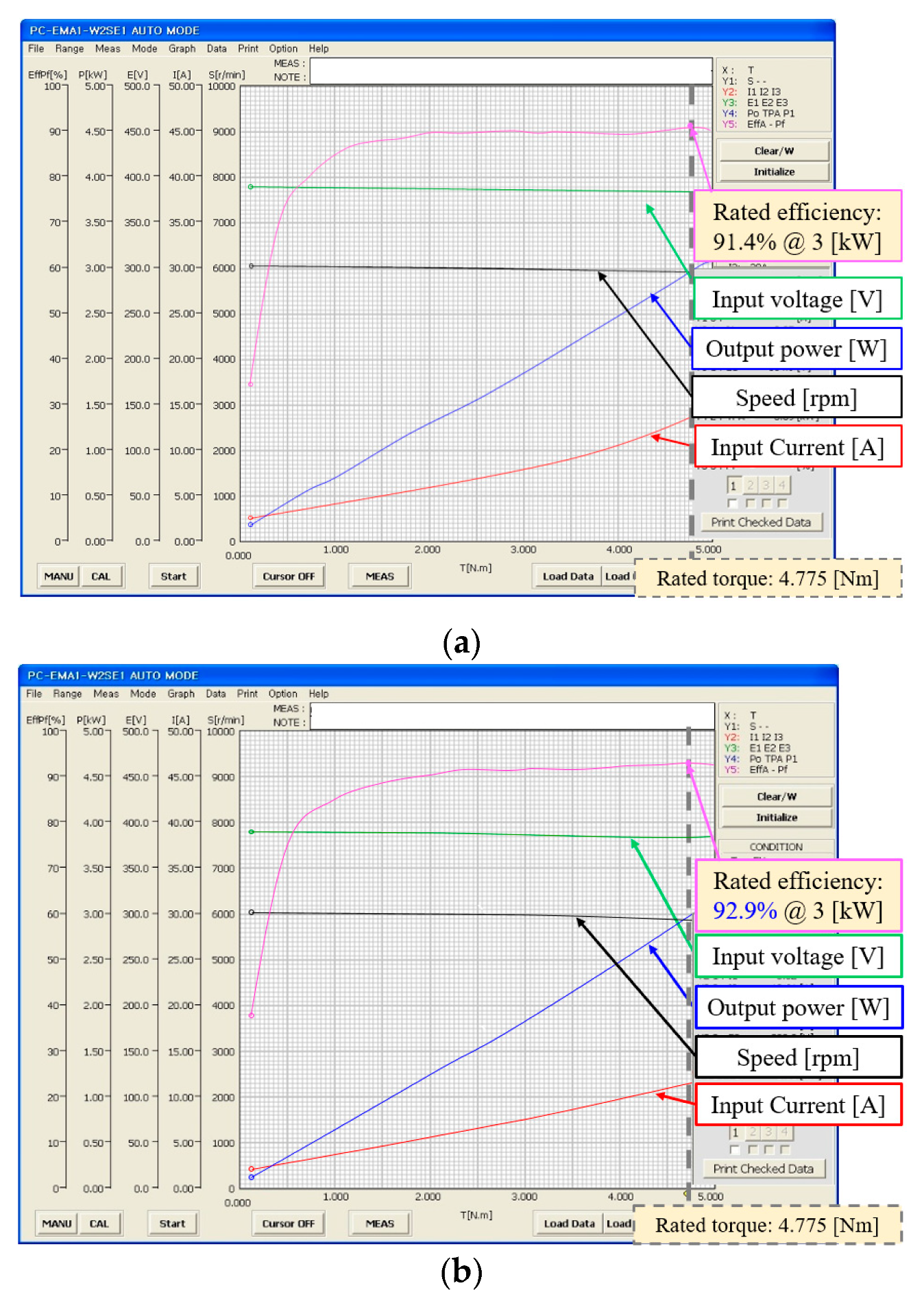

4.2. Experimental Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Number | X1 | X2 | X3 | X4 | X5 | Efficiency (%) | Cogging Torque (Nm) |

|---|---|---|---|---|---|---|---|

| 1 | 12.000 | 2.000 | 24.167 | 22.998 | 22.267 | 91.87 | 0.2746 |

| 2 | 12.956 | 2.306 | 23.625 | 23.000 | 21.166 | 91.91 | 0.2774 |

| 3 | 14.833 | 2.333 | 23.278 | 24.278 | 21.389 | 92.35 | 0.2816 |

| 4 | 12.352 | 2.250 | 22.833 | 23.091 | 21.458 | 92.98 | 0.2939 |

| 5 | 12.400 | 2.528 | 22.889 | 23.389 | 21.056 | 93.21 | 0.2881 |

| 6 | 14.111 | 2.150 | 24.444 | 22.889 | 21.000 | 92.88 | 0.3242 |

| 7 | 12.785 | 1.946 | 24.611 | 23.952 | 20.766 | 92.38 | 0.3438 |

| 8 | 12.380 | 2.720 | 23.300 | 23.700 | 21.900 | 91.55 | 0.2778 |

| 9 | 12.222 | 2.916 | 24.556 | 24.275 | 22.000 | 92.35 | 0.3412 |

| 10 | 13.889 | 2.139 | 24.161 | 24.109 | 22.833 | 91.37 | 0.2751 |

| 11 | 13.558 | 2.111 | 24.670 | 24.662 | 22.056 | 93.06 | 0.2736 |

| 12 | 13.215 | 2.889 | 23.444 | 23.222 | 22.278 | 93.06 | 0.3176 |

| 13 | 14.733 | 1.890 | 23.891 | 23.840 | 21.634 | 91.42 | 0.2765 |

| 14 | 12.122 | 2.472 | 23.778 | 23.611 | 22.389 | 93.44 | 0.3272 |

| 15 | 13.482 | 2.417 | 22.444 | 23.667 | 20.500 | 93.58 | 0.3385 |

| 16 | 14.971 | 2.194 | 23.948 | 24.749 | 21.433 | 93.01 | 0.2761 |

| 17 | 13.347 | 2.444 | 23.111 | 24.555 | 21.833 | 91.11 | 0.2863 |

| 18 | 14.933 | 2.250 | 22.611 | 23.555 | 20.944 | 93.41 | 0.3026 |

| 19 | 14.444 | 2.667 | 22.945 | 22.723 | 22.777 | 92.74 | 0.2855 |

| 20 | 13.668 | 2.639 | 22.722 | 23.667 | 21.704 | 91.51 | 0.2969 |

| 21 | 14.556 | 2.167 | 23.556 | 22.835 | 22.479 | 91.85 | 0.3275 |

| 22 | 12.631 | 1.833 | 24.831 | 23.322 | 22.500 | 93.13 | 0.3438 |

| 23 | 13.055 | 2.611 | 22.778 | 24.833 | 20.947 | 92.96 | 0.2973 |

| 24 | 14.723 | 1.778 | 22.712 | 23.722 | 20.832 | 91.49 | 0.2989 |

| 25 | 13.444 | 2.833 | 23.832 | 24.597 | 22.150 | 91.08 | 0.2779 |

| 26 | 13.000 | 1.750 | 22.608 | 24.500 | 21.611 | 91.12 | 0.3045 |

| 27 | 14.855 | 2.320 | 23.721 | 23.411 | 21.501 | 93.27 | 0.2771 |

| 28 | 12.345 | 2.972 | 23.883 | 24.381 | 20.722 | 91.27 | 0.2774 |

| 29 | 12.784 | 1.872 | 23.575 | 23.942 | 22.667 | 93.41 | 0.2781 |

| 30 | 14.234 | 1.652 | 24.738 | 23.166 | 20.665 | 92.99 | 0.2741 |

| 31 | 12.611 | 2.055 | 24.445 | 22.453 | 21.835 | 92.56 | 0.2737 |

| 32 | 14.278 | 2.540 | 24.388 | 23.444 | 22.611 | 93.34 | 0.2738 |

| 33 | 13.111 | 1.847 | 22.325 | 23.213 | 21.748 | 91.03 | 0.3178 |

| 34 | 13.344 | 2.298 | 24.000 | 24.390 | 20.889 | 93.21 | 0.2965 |

| 35 | 14.834 | 2.556 | 25.000 | 24.885 | 22.407 | 92.97 | 0.2833 |

| 36 | 13.667 | 1.691 | 24.056 | 22.584 | 20.556 | 92.63 | 0.2755 |

| 37 | 13.879 | 2.695 | 23.167 | 24.117 | 21.927 | 93.38 | 0.2829 |

| 38 | 14.056 | 1.639 | 24.666 | 22.662 | 22.216 | 93.67 | 0.2734 |

| 39 | 14.667 | 2.642 | 22.459 | 22.444 | 22.857 | 92.53 | 0.3112 |

| 40 | 13.250 | 2.235 | 23.088 | 24.722 | 22.711 | 93.04 | 0.2836 |

| 41 | 12.489 | 2.057 | 24.331 | 22.832 | 22.958 | 92.83 | 0.2751 |

| 42 | 13.367 | 2.762 | 22.503 | 24.978 | 21.222 | 92.91 | 0.3053 |

| 43 | 14.999 | 2.922 | 24.278 | 22.333 | 20.390 | 92.36 | 0.2941 |

| 44 | 14.145 | 2.452 | 22.271 | 22.553 | 21.333 | 92.61 | 0.2911 |

| 45 | 13.265 | 1.721 | 22.389 | 24.944 | 22.942 | 92.94 | 0.2839 |

| 46 | 12.256 | 1.622 | 23.378 | 22.385 | 22.113 | 92.49 | 0.2781 |

| 47 | 14.325 | 2.996 | 24.944 | 22.278 | 21.218 | 92.33 | 0.2735 |

| 48 | 13.650 | 1.583 | 23.051 | 24.220 | 20.333 | 91.37 | 0.2847 |

| 49 | 12.444 | 2.389 | 22.455 | 22.722 | 20.222 | 92.71 | 0.9267 |

| 50 | 13.777 | 1.944 | 22.222 | 22.192 | 20.389 | 92.21 | 0.3221 |

| 51 | 13.458 | 2.805 | 24.246 | 22.111 | 20.221 | 92.19 | 0.3333 |

| 52 | 12.798 | 1.558 | 22.060 | 23.833 | 20.167 | 93.45 | 0.3445 |

| 53 | 14.795 | 2.685 | 22.794 | 22.056 | 20.056 | 92.15 | 0.2736 |

| 54 | 13.075 | 1.500 | 22.001 | 22.001 | 20.001 | 92.11 | 0.3511 |

References

- Yilmaz, M.; Krein, P.T. Review of battery charger topologies, charging power levels, and infrastructure for plug-in electric and hybrid vehicles. IEEE Trans. Power Electron. 2013, 28, 2151–2169. [Google Scholar] [CrossRef]

- Chukwu, U.C.; Mahajan, S.M. Real-time management of power systems with V2G facility for smart-grid applications. IEEE Trans. Sustain. Energy 2014, 5, 558–566. [Google Scholar] [CrossRef]

- Babin, A.; Rizoug, N.; Mesbahi, T.; Boscher, D.; Hamdoun, Z.; Larouci, C. Total cost of ownership improvement of commercial electric vehicles using battery sizing and intelligent charge method. IEEE Trans. Ind. Appl. 2018, 54, 1691–1700. [Google Scholar] [CrossRef]

- Loiselle-Lapointe, A.; Whittal, I.; Christenson, M. Electric Vehicles: Impacts of Mileage Accumulation and Fast Charging. World Electr. Veh. J. 2016, 8, 249–262. [Google Scholar] [CrossRef]

- De Almeida, A.T.; Ferreira, F.J.; Baoming, G. Beyond Induction Motors—Technology Trends to Move Up Efficiency. IEEE Trans. Ind. Appl. 2013, 50, 2103–2114. [Google Scholar] [CrossRef]

- Yang, Z.; Shang, F.; Brown, I.P.; Krishnamurthy, M. Comparative study of interior permanent magnet, induction, and switched reluctance motor drives for EV and HEV applications. IEEE Trans. Transp. Electrif. 2015, 1, 245–254. [Google Scholar] [CrossRef]

- Lu, C.; Ferrari, S.; Pellegrino, G. Two Design Procedures for PM Synchronous Machines for Electric Powertrains. IEEE Trans. Transp. Electrif. 2017, 4, 98–107. [Google Scholar] [CrossRef]

- Jung, T.-U. Development of Hybrid Electric Compressor Motor Drive System for Hybrid Electrical Vehicles. J. Power Electron. 2009, 9, 960–968. [Google Scholar]

- Jolly, L.; Jabbar, M.A.; Qinghua, L. Design optimization of permanent magnet motors using response surface methodology and genetic algorithms. IEEE Trans. Magn. 2005, 41, 3928–3930. [Google Scholar] [CrossRef]

- Hwang, C.-C.; Cho, Y.H. Effects of leakage flux on magnetic fields of interior permanent magnet synchronous motors. IEEE Trans. Magn. 2001, 37, 3021–3024. [Google Scholar] [CrossRef]

- Ilka, R.; Alinejad-Beromi, Y.; Yaghobi, H. Techno-economic Design Optimisation of an Interior Permanent-Magnet Synchronous Motor by the Multi-Objective Approach. IET Electr. Power Appl. 2018, 12, 972–978. [Google Scholar] [CrossRef]

- Hong, G.; Wei, T.; Ding, X. Multi-objective Optimal Design of Permanent Magnet Synchronous Motor for High Effciency and High Dynamic Performance. IEEE Access 2018, 6, 23568–23581. [Google Scholar] [CrossRef]

- Cho, S.; Jung, K.; Choi, J. Design Optimization of Interior Permanent Magnet Synchronous Motor for Electric Compressors of Air-Conditioning Systems Mounted on EVs and HEVs. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Baek, S. Optimum shape design of a BLDC motor for electric continuous variable valve timing system considering efficiency and torque characteristics. Microsyst. Technol. 2018, 24, 4441–4452. [Google Scholar] [CrossRef]

- Lee, S.; Baek, S. A study on the improvement of the cam phase control performance of an electric continuous variable valve timing system using a cycloid reducer and BLDC motor. Microsyst. Technol. 2020, 26, 59–70. [Google Scholar] [CrossRef]

- Ortega, A.J.P.; Paul, S.; Islam, R.; Xu, L. Analytical model for predicting effects of manufacturing variations on cogging torque in surface-mounted permanent magnet motors. IEEE Trans. Magn. 2016, 52, 3050–3061. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, H.; Meng, G.; Zhou, S.; Cao, Q. Analytical calculation of magnetic field and cogging torque in surface-mounted permanent-magnet machines accounting for any eccentric rotor shape. IEEE Trans. Ind. Electron. 2015, 62, 3438–3447. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, J.W.; Song, J.Y.; Kim, Y.J.; Jung, S.Y. A Novel Memetic Algorithm Using Modified Particle Swarm Optimization and Mesh Adaptive Direct Search for PMSM Design. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Edhah, S.O.; Alsawalhi, J.Y.; Al-Durra, A.A. Multi-Objective Optimization Design of Fractional Slot Concentrated Winding Permanent Magnet Synchronous Machines. IEEE Access 2019, 7, 162874–162882. [Google Scholar] [CrossRef]

- Chung, S.U.; Kim, J.W.; Chun, Y.D.; Woo, B.C.; Hong, D.K. Fractional Slot Concentrated Winding PMSM with Consequent Pole Rotor for a Low-Speed Direct Drive Reduction of Rare Earth Permanent Magnet. IEEE Trans. Energy Convers. 2015, 30, 103–109. [Google Scholar] [CrossRef]

- Kwon, J.W.; Lee, J.H.; Zhao, W.L.; Kwon, B.I. Flux-Switching Permanent Magnet Machine with Phase-Group Concentrated-Coil Windings and Cogging Torque Reduction Technique. Energies 2018, 11, 2758. [Google Scholar] [CrossRef]

- Yoon, K.-Y.; Baek, S.-W. Robust design optimization with penalty function for electric oil pumps with BLDC motors. Energies 2019, 12, 153. [Google Scholar] [CrossRef]

- Guo, H.; He, H.; Sun, F. A combined cooperative braking model with a predictive control strategy in an electric vehicle. Energies 2013, 6, 6455–6475. [Google Scholar] [CrossRef]

- Ma, P.; Zhou, Y.; Shang, X.; Yang, M. Firing accuracy evaluation of electromagnetic railgun based on multicriteria optimal Latin hypercube design. IEEE Trans. Plasma Sci. 2017, 45, 1503–1511. [Google Scholar] [CrossRef]

- Shin, P.S.; Woo, S.H.; Koh, C.S. An optimal design of large scale permanent magnet pole shape using adaptive response surface method with Latin hypercube sampling strategy. IEEE Trans. Magn. 2009, 45, 1214–1217. [Google Scholar] [CrossRef]

- Zhang, B.S.; Song, B.W.; Mao, Z.Y.; Tian, W.L.; Li, B.Y.; Li, B. Novel parametric modeling method and optimal design for savonius wind turbines. Energies 2017, 10, 301. [Google Scholar] [CrossRef]

- Li, Y.K.; Song, B.W.; Mao, Z.Y.; Tian, W.L. Analysis and optimization of the electromagnetic performance of a novel stator modular ring drive thruster motor. Energies 2018, 11, 1598. [Google Scholar] [CrossRef]

- Gong, J.; Gillon, F.; Canh, J.T.; Xu, Y. Proposal of a Kriging output space mapping technique for electromagnetic design optimization. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Zhang, L.; Tian, F. Performance study of multilayer perceptrons in a low-cost electronic nose. IEEE Trans. Instrum. Meas. 2014, 36, 1670–1679. [Google Scholar] [CrossRef]

- Franzese, G.; Visintin, M. Probabilistic ensemble of deep Information networks. Entropy 2020, 22, 100. [Google Scholar] [CrossRef]

- Baek, S.; Kwon, B. Optimum design of a single-phase line-start PM motor considering efficiency, maximum torque, and starting torque. IEEE Trans. Magn. 2012, 48, 4850–4859. [Google Scholar] [CrossRef]

- Yan, C.; Zhu, J.; Shen, X.; Fan, J.; Mi, D.; Qian, Z. Ensemble of regression-type and interpolation-type metamodels. Energies 2020, 13, 654. [Google Scholar] [CrossRef]

| Items | Unit | Value | |

|---|---|---|---|

| Required specification | Input voltage | V | 380 |

| Rated speed | rpm | 6000 | |

| Rated output power | W | 3000 | |

| Operation frequency | Hz | 400 | |

| Mechanical dimension | Stator’s outer diameter | mm | 93 |

| Stator’s inner diameter | mm | 51 | |

| Rotor’s outer diameter | mm | 50.2 | |

| Shaft diameter | mm | 20 | |

| Air gap length | mm | 0.4 | |

| Stack length | mm | 60 | |

| Electrical dimension | Coil turns | mm | 40 |

| Coil thickness | 0.9 | ||

| Material | Electrical steel | - | 35PN230 |

| Permanent magnet | N42UH | ||

| Characteristics | Back-EMF(@1000rpm) | Vrms | 27.8 |

| Cogging torque(peak to peak) | Nm | 0.3479 | |

| Torque(@rated speed) | Nm | 4.775 | |

| Input current(@rated speed) | Arms | 12.85 | |

| Efficiency(@rated speed) | % | 91.40 | |

| Parameters | Lower (XL) | Upper (XU) | Unit | Remark |

|---|---|---|---|---|

| X1 | 12 | 15 | mm | Magnet length |

| X2 | 1.5 | 3.0 | mm | Magnet width |

| X3 | 22 | 25 | mm | Distance between the center and the inner diameter of rotor |

| X4 | 22 | 25 | mm | Distance between the center and the magnet |

| X5 | 20 | 23 | mm | Distance between the center and the barrier |

| Parameters | Initial | Optimal | Unit |

|---|---|---|---|

| X1 | 14.3 | 12.4 | mm |

| X2 | 2 | 2.7 | mm |

| X3 | 23.8 | 23.3 | mm |

| X4 | 23.2 | 23.7 | mm |

| X5 | 21.3 | 21.9 | mm |

| Items | Initial | Optimal | Unit | |

|---|---|---|---|---|

| Simulation | Rated efficiency | 92.0 | 93.5 | % |

| Cogging torque | 0.3479 | 0.2778 | Nm | |

| Experiment | Rated efficiency | 91.4 | 92.9 | % |

| Cogging torque | 0.2778 | 0.2153 | Nm | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, S.-W.; Lee, S.W. Design Optimization and Experimental Verification of Permanent Magnet Synchronous Motor Used in Electric Compressors in Electric Vehicles. Appl. Sci. 2020, 10, 3235. https://doi.org/10.3390/app10093235

Baek S-W, Lee SW. Design Optimization and Experimental Verification of Permanent Magnet Synchronous Motor Used in Electric Compressors in Electric Vehicles. Applied Sciences. 2020; 10(9):3235. https://doi.org/10.3390/app10093235

Chicago/Turabian StyleBaek, Soo-Whang, and Sang Wook Lee. 2020. "Design Optimization and Experimental Verification of Permanent Magnet Synchronous Motor Used in Electric Compressors in Electric Vehicles" Applied Sciences 10, no. 9: 3235. https://doi.org/10.3390/app10093235

APA StyleBaek, S.-W., & Lee, S. W. (2020). Design Optimization and Experimental Verification of Permanent Magnet Synchronous Motor Used in Electric Compressors in Electric Vehicles. Applied Sciences, 10(9), 3235. https://doi.org/10.3390/app10093235