Novel Utility-Scale Photovoltaic Plant Electroluminescence Maintenance Technique by Means of Bidirectional Power Inverter Controller

Abstract

Featured Application

Abstract

1. Introduction

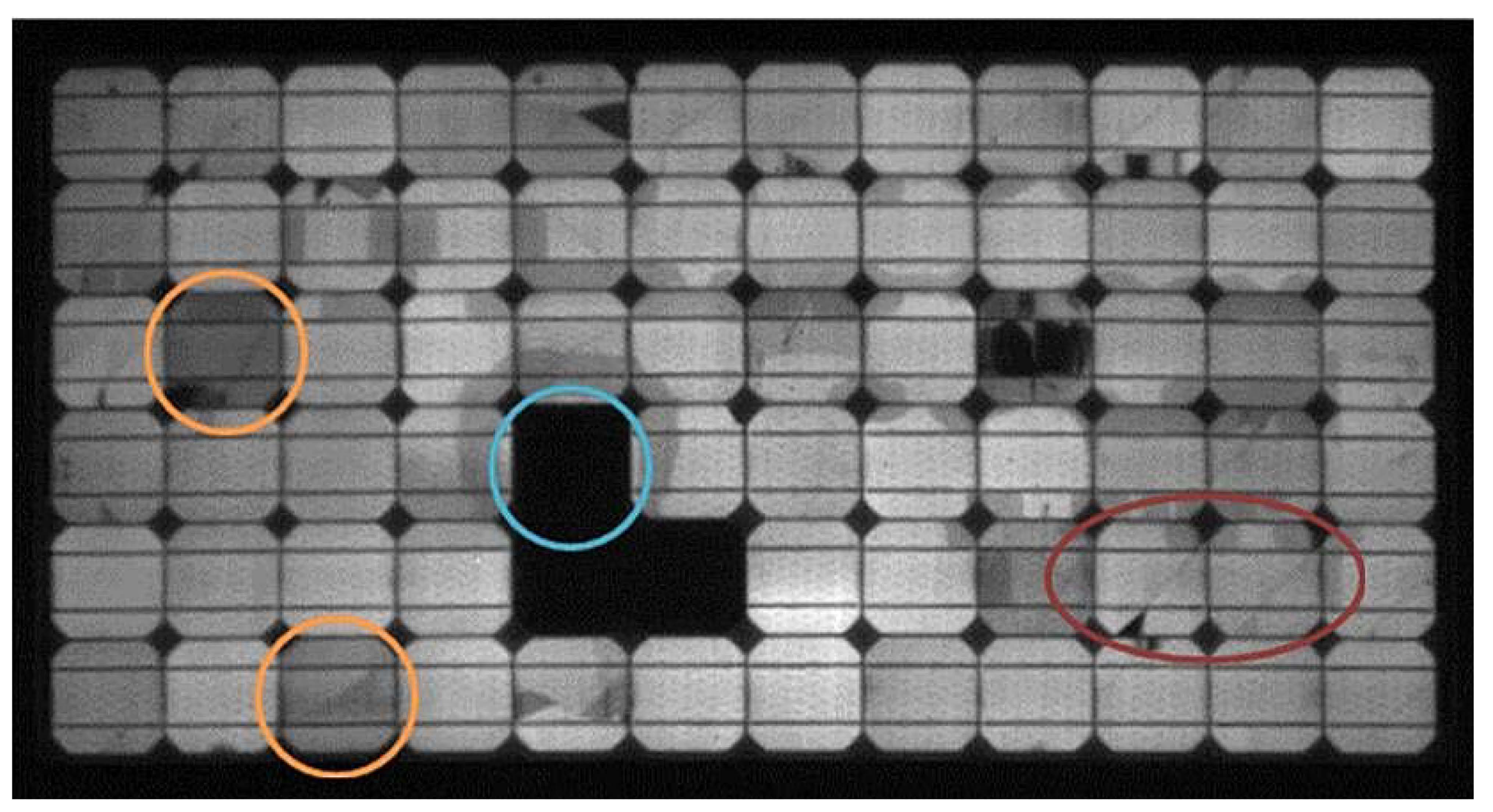

2. Electroluminescence Technique

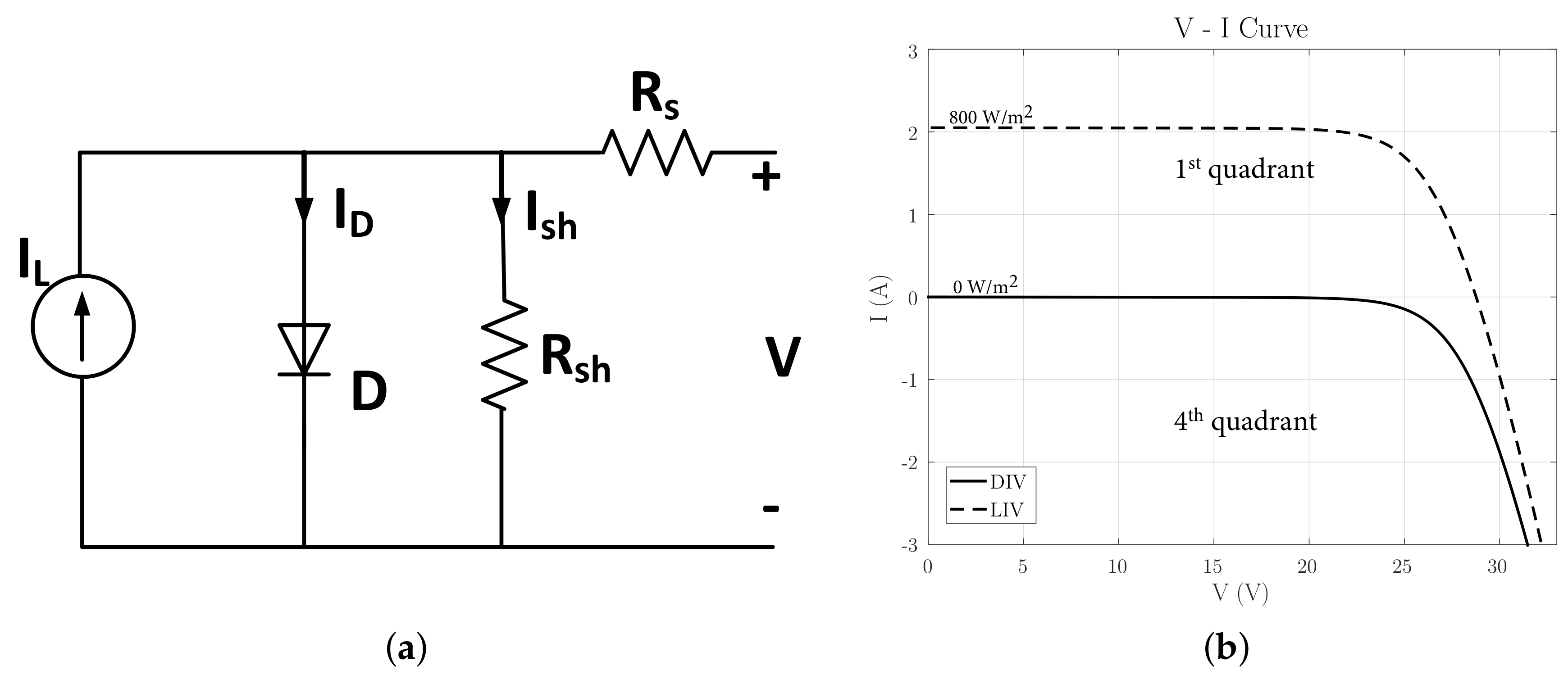

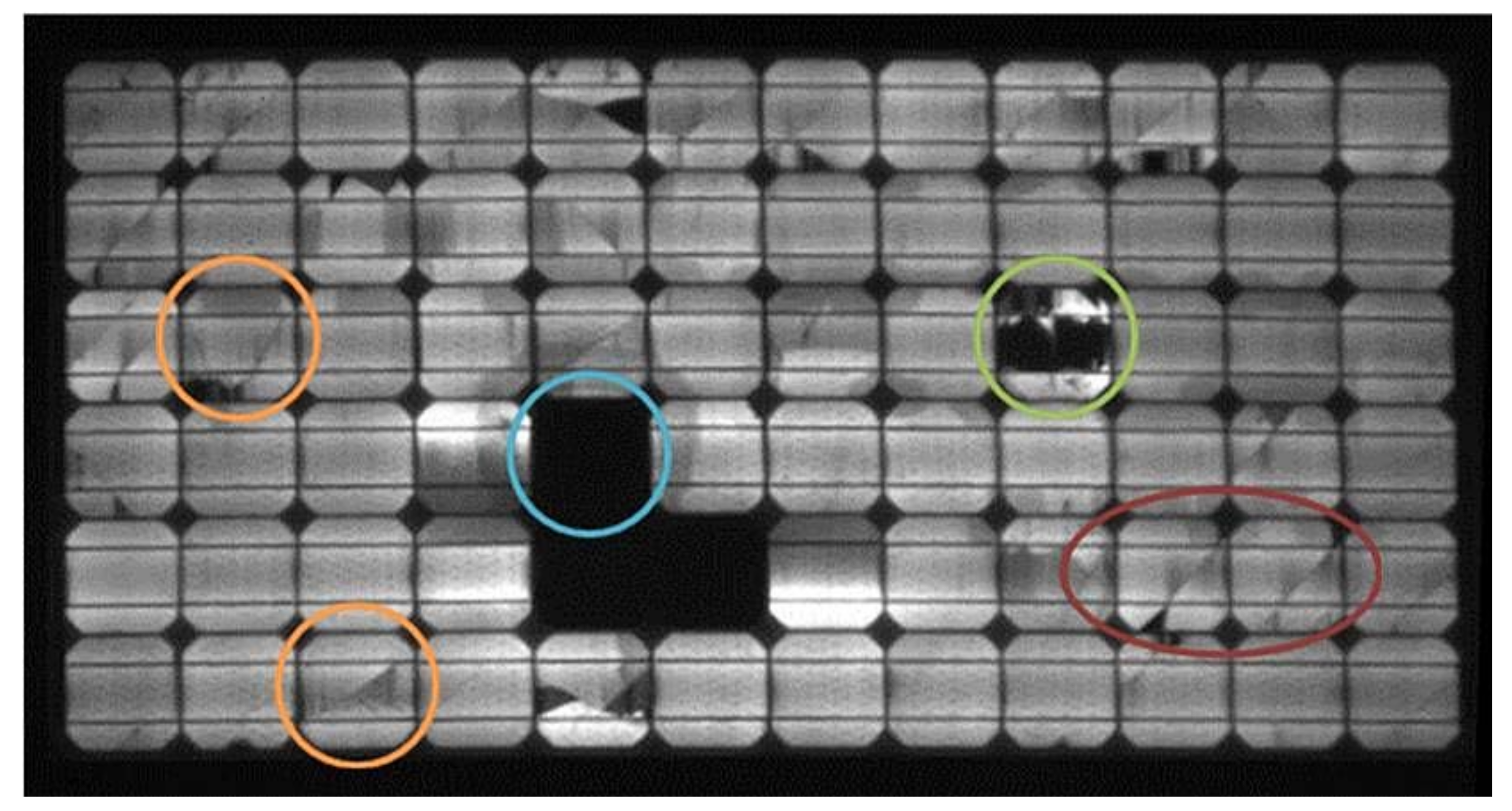

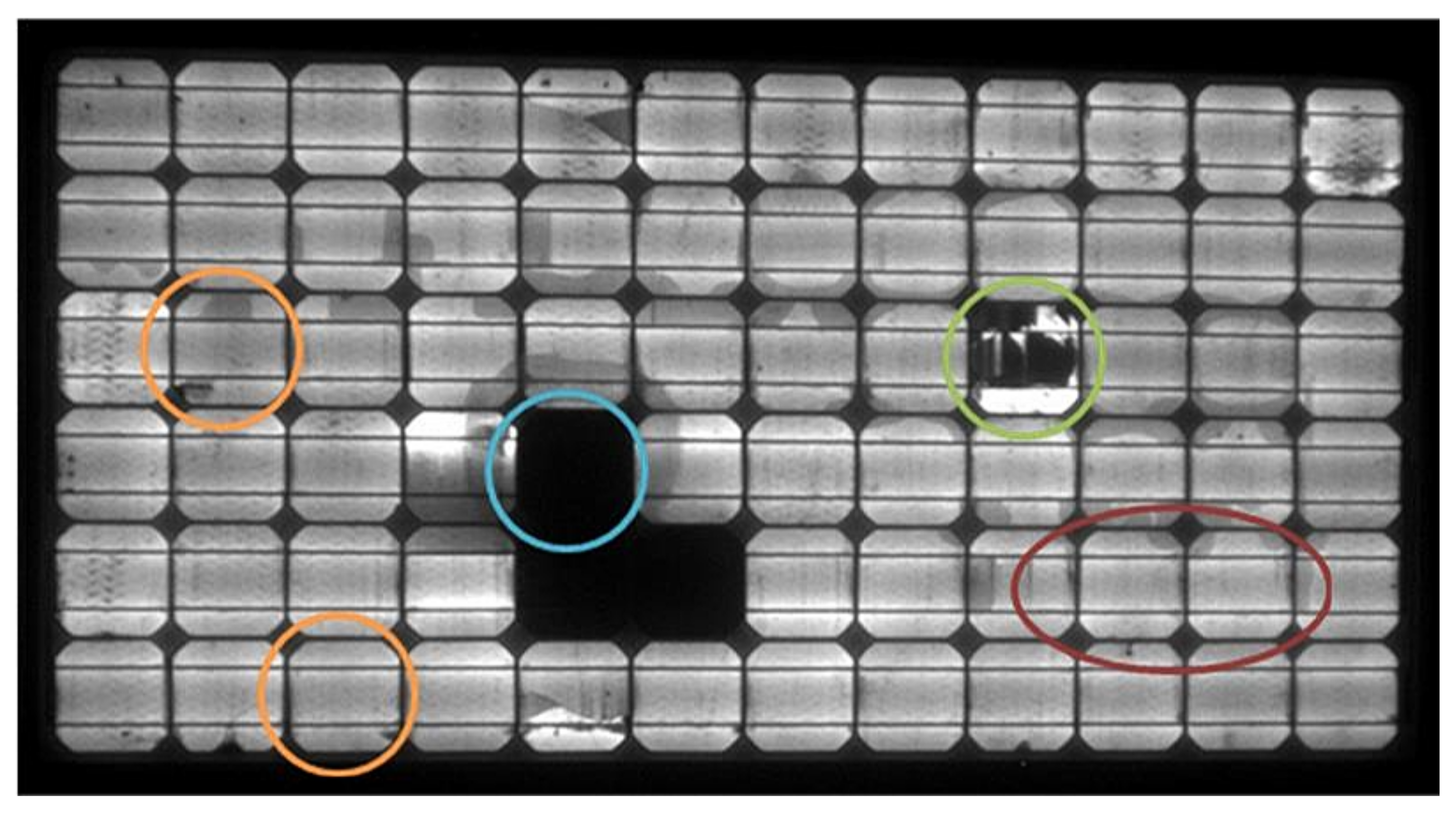

2.1. EL Principles Applied to PV Panels

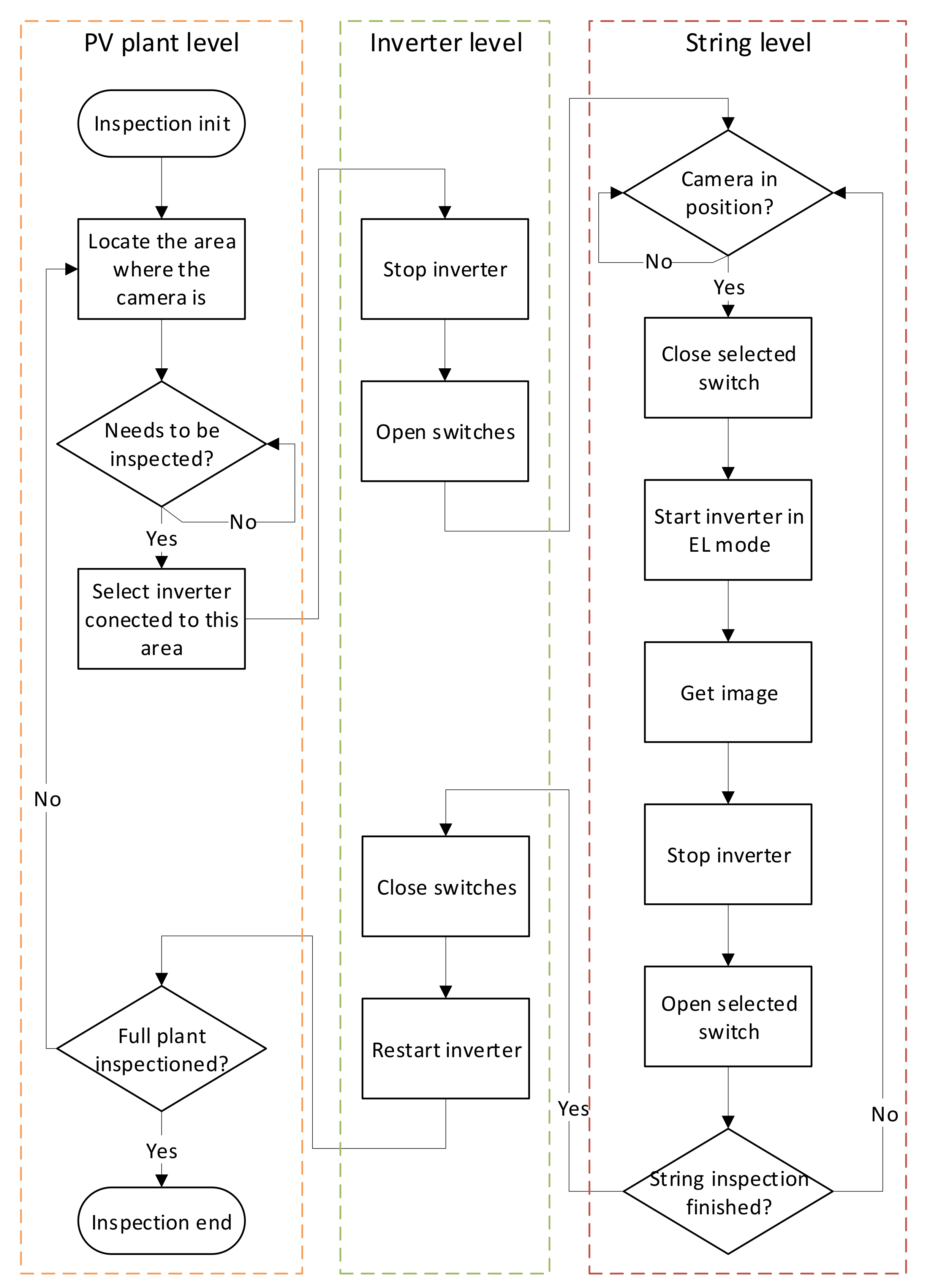

2.2. EL Analysis Procedure

2.3. IRT Versus EL Inspections

3. USPVPs Power Inverters

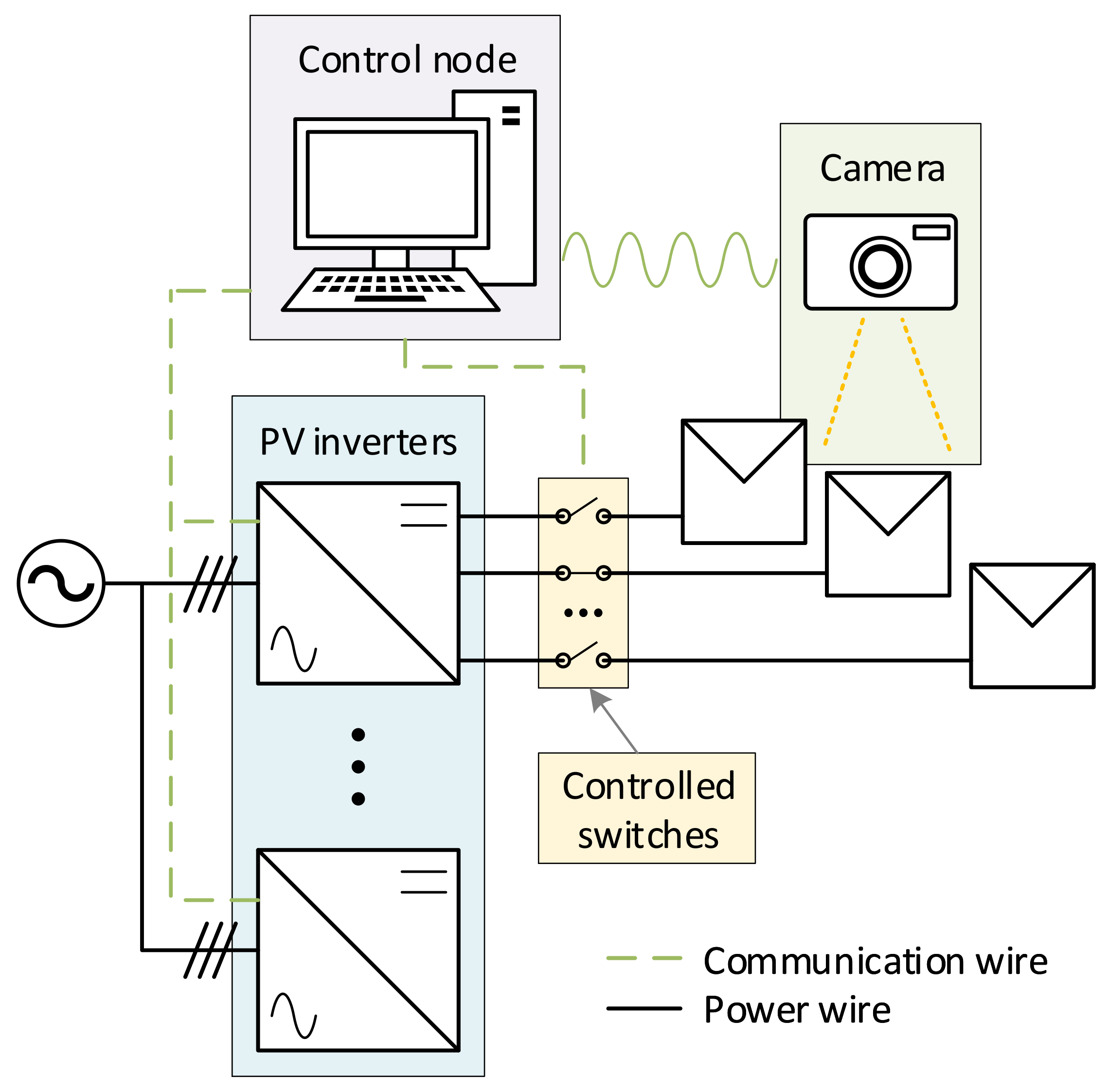

3.1. USPVPs Retrofit Requirements to Apply EL on-Site

- Working-mode as a current source: the inverter must be able to work as a power supply with the capability of producing the PV panel string at a voltage near the PV panel open-circuit value, . Therefore, the inverter must have a completely bidirectional feature.

- Starting-up without irradiation: in order to avoid parasitic light irradiance and PV plant power losses, all tests must be carried out during sunrise, sunset or at night. Therefore, the DC-Link precharge of the inverter must be done from the alternating current (AC) grid side, instead of doing it in the usual way, from the PV panels. Consequently, the PV inverter must include a precharge mechanism from its grid side.

- PV string sequencing: especially in the cases of large solar inverters, the number of PV string arrays in parallel can be considerable, covering a large ground area. Thus, it is desirable to apply direct polarisation to a single fraction of all panels connected to the inverter, limiting the action area, and therefore minimising the power needed to carry out the EL inspection. Therefore, it is recommended to replace isolators with several lower power automatic switches connected to one or a few strings.

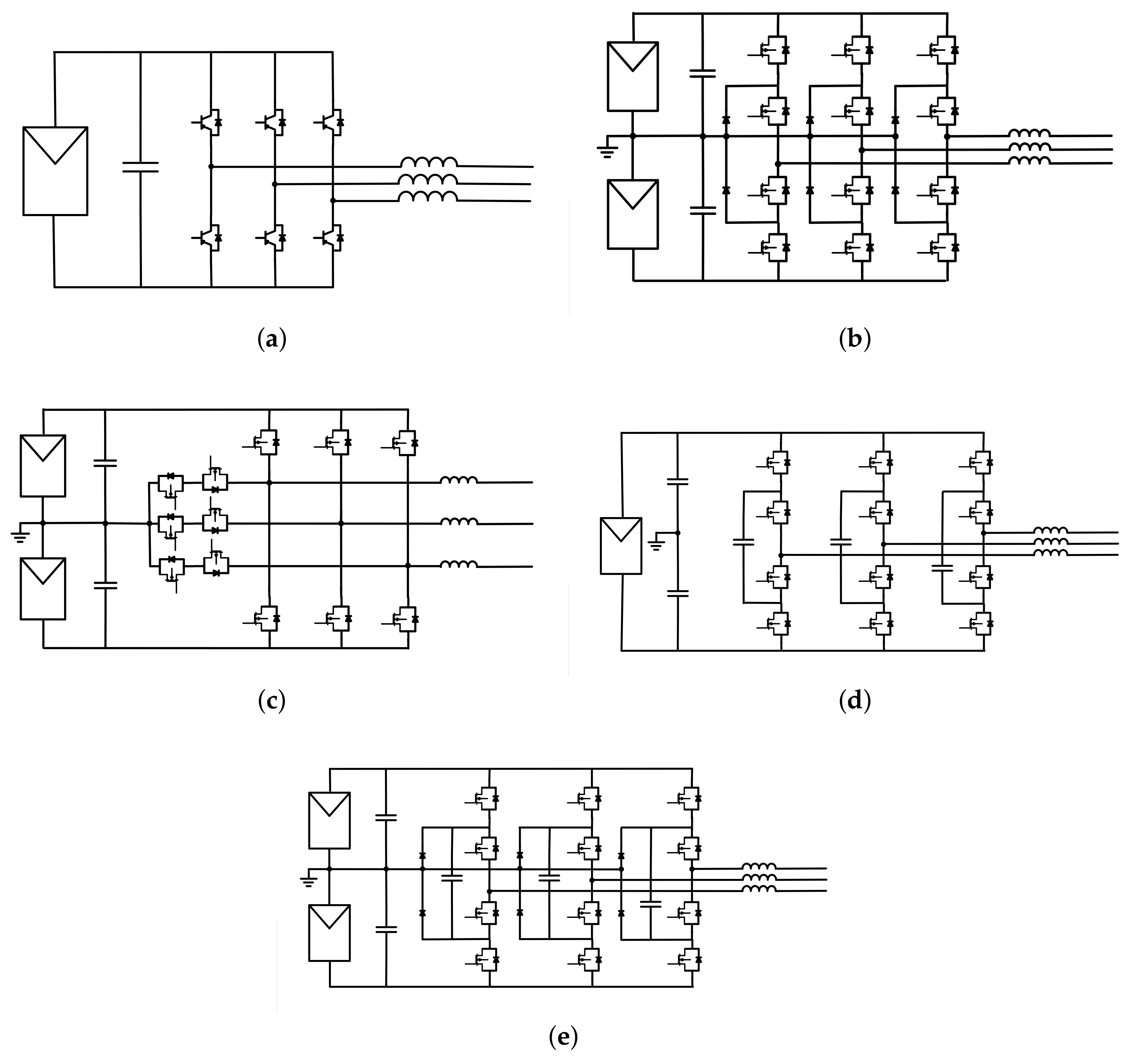

3.2. USPVPs Power Inverters Topologies

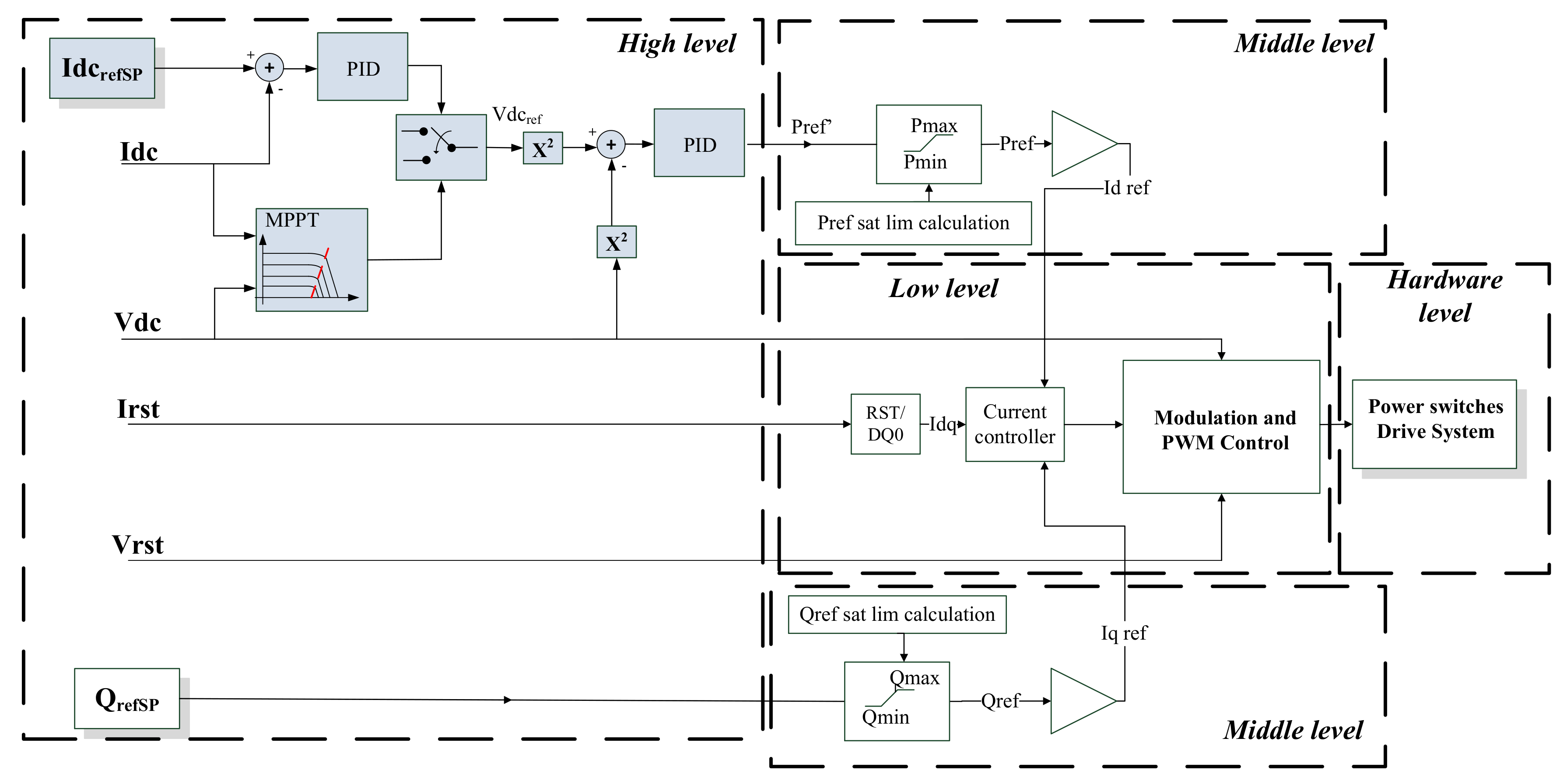

4. USPVPs Control for Applying EL Technique

4.1. Power Inverter Controller Structure

- High level controller: The highest level control is responsible for providing the right active and reactive power set-points to the lower level controllers. Its objective is to maximise the active power generation and to help the utility grid with the reactive power injection.

- Middle level controller: The middle level controller is tasked to follow the higher level control references. Besides, it is in charge of checking the power inverter limitations due to restrictions (such as temperature and over voltages), and setting up priorities whenever necessary.

- Low level controller: The low level controller includes both the instantaneous current controller based on a proportional-integrative-derivative (PID) controller, a direct-quadrature-zero (DQ0) transformation and the modulation control technique, which provides the switching pulse width modulation (PWM) signal to the power converter semiconductors.

- Hardware level: Finally, the hardware level is in charge of translating the control signals to the physical pulses of the converter in order to produce the expected voltage signal behaviour by the power converter.

4.2. Complete System Control Architecture

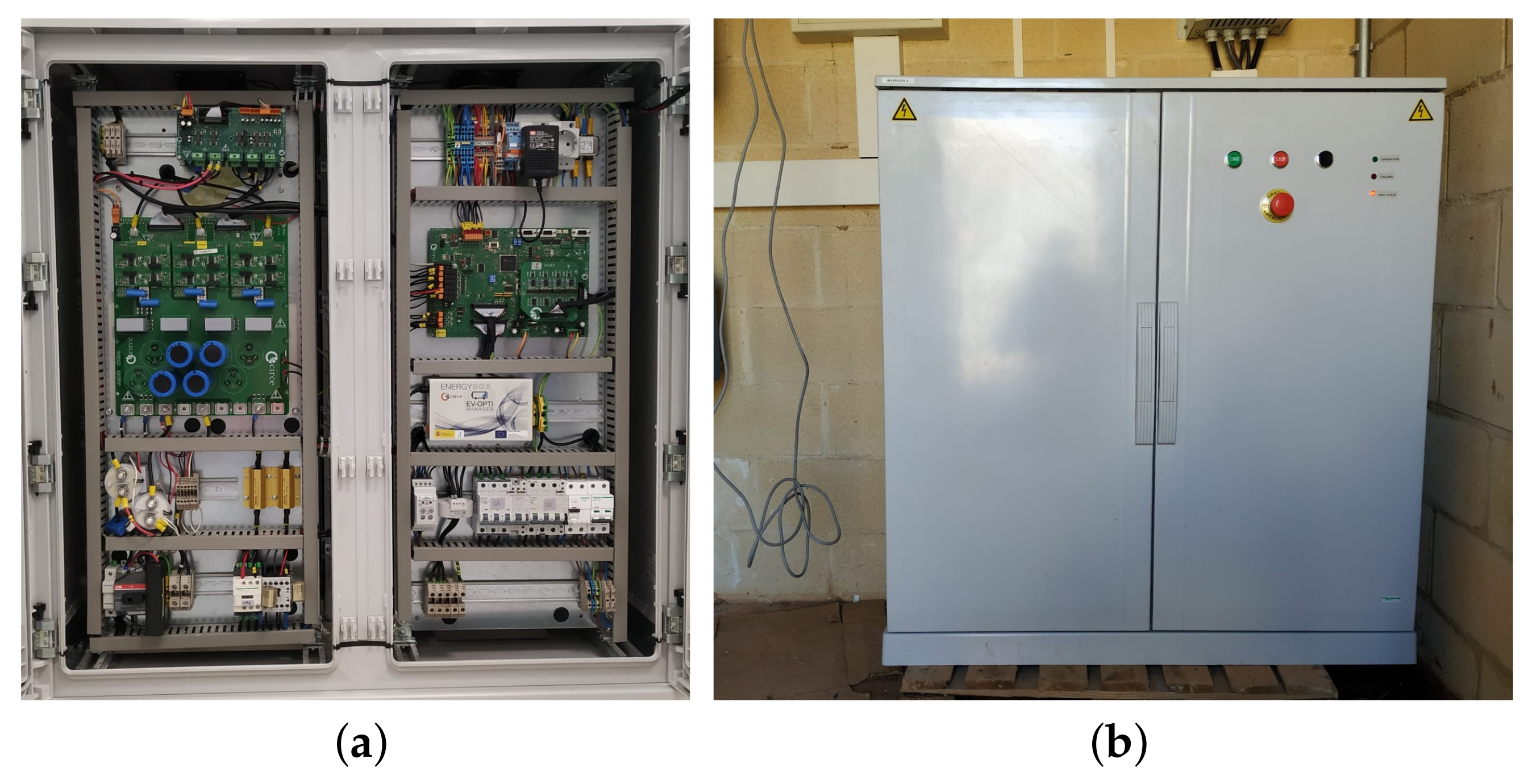

5. Prototype Design and Installation on the Demo Site

6. Simulation and Experimental Results

6.1. Simulation

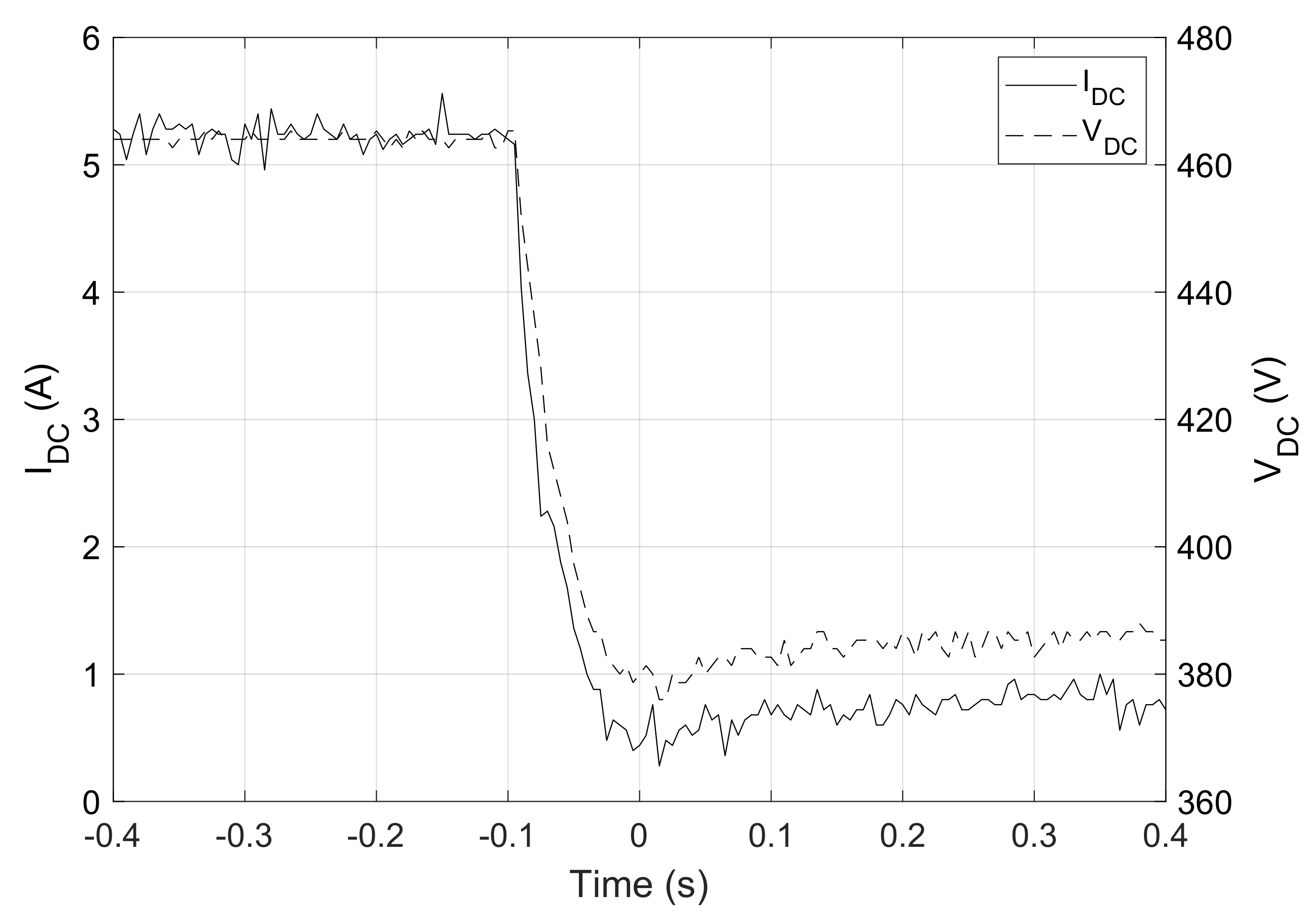

6.2. Field Test

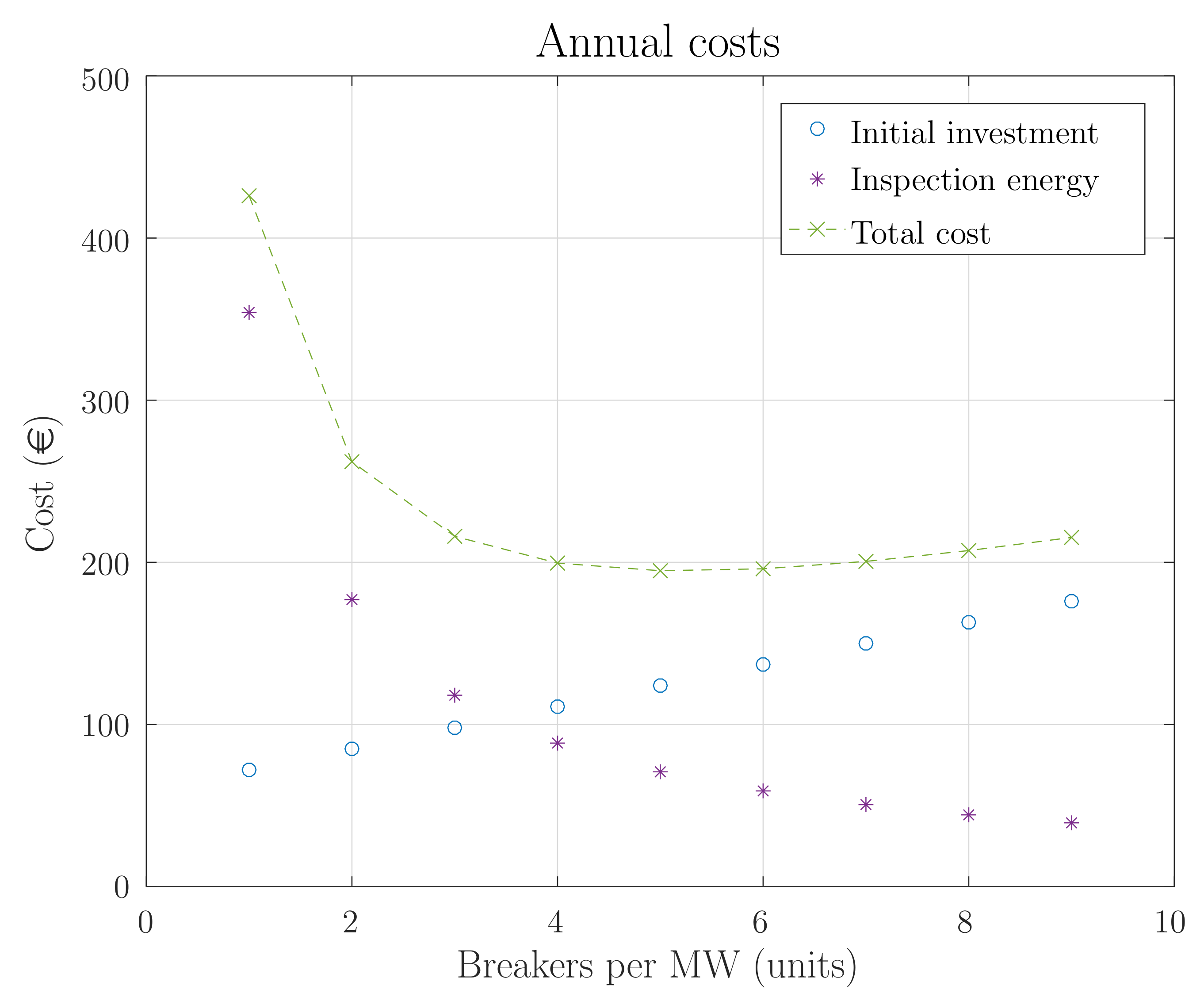

7. Economic Analysis of Solution Cost

7.1. Solution Cost

7.2. Economic Optimisation of the Solution

8. Discussion

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- European Commission. Europe leads the global clean energy transition: commission welcomes ambitious agreement on further renewable energy development in the EU. Int. Energy Agency 2018, 1, 718. [Google Scholar] [CrossRef]

- European Parliament. U targets: More Renewables, Better Energy Efficiency (Video). 2018. Available online: https://www.europarl.europa.eu/news/en/headlines/economy/20181031STO18175/eu-targets-more-renewables-better-energy-efficiency-video (accessed on 19 February 2020).

- Agora Energiewende and Sandbag. The European Power Sector in 2017. State of Affairs and Review of Current Developments; 128/02-A-2018/EN; Agora Energiewende and Sandbag: Berlin, Germany, 2018. [Google Scholar]

- U.S. Energy Information Administration. Energy Information Administration. Choice Rev. Online 2007, 44, 44–3624. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2018; International Renewable Energy Agency: Abu Dhabi, UAE, 2019; ISBN 978-92-9260-126-3. [Google Scholar]

- InterSolarEurope. Global Market Outlook for Solar Power 2018-2022; InterSolarEurope: Brussels, Belgium, 2018; ISBN 978-908-271-431-9. [Google Scholar]

- Rakhshani, E.; Rouzbehi, K.; Adolfo, J.S.; Tobar, A.C. Integration of Large Scale PV-Based Generation into Power Systems: A Survey. Energies 2019, 12, 1425. [Google Scholar] [CrossRef]

- SolarInsure. Larges Solar Power Plants of the World; SolarInsure: Costa Mesa, CA, USA, 2019. [Google Scholar]

- Wikipedia. Direct and Indirect Band Gaps. Available online: https://en.wikipedia.org/wiki/Direct_and_indirect_band_gaps (accessed on 5 July 2019).

- Glavaš, H.; Vukobratović, M.; Primorac, M.; Muštran, D. Infrared thermography in inspection of photovoltaic panels. In Proceedings of the International Conference on Smart Systems and Technologies 2017, Osijek, Croatia, 19 October 2017; pp. 63–68. [Google Scholar] [CrossRef]

- Frazão, M.; Silva, J.A.; Lobato, K.; Serra, J.M. Electroluminescence of silicon solar cells using a consumer grade digital camera. Meas. J. Int. Meas. Confed. 2017, 99, 7–12. [Google Scholar] [CrossRef]

- Rodriguez, P.; Sera, D.; Teodorescu, R.; Rodriguez, P. PV Panel Model Based on Datasheet Values PV. In Proceedings of the 2007 IEEE International Symposium on Industrial Electronics, Vigo, Spain, 4–7 June 2007; pp. 2392–2396. [Google Scholar] [CrossRef]

- PV Performance Modeling Collaborative. Single Diode Equivalent Circuit Models. Available online: https://pvpmc.sandia.gov/modeling-steps/2-dc-module-iv/diode-equivalent-circuit-models/ (accessed on 20 February 2020).

- Liu, S.; Dougal, R.A. Dynamic Multi-Physics Model for Solar Array. IEEE Power Eng. Rev. 2002, 22, 66. [Google Scholar] [CrossRef]

- Wu, F.; Lin, H.; Yang, Z.; Liao, M.; Wang, Z.; Li, Z.; Gao, P.; Ye, J.; Shen, W. Suppression of surface and auger recombination by formation and control of radial junction in silicon microwire solar cells. Nano Energy 2019, 58, 817–824. [Google Scholar] [CrossRef]

- IEA International Energy Agency. Review on Infrared and Electroluminescence Imaging for PV Field Applications; Technical Report IEA-PVPS T13-10:2018, IEA-PVPS Task 13; IEA International Energy Agency: Paris, France, 2018. [Google Scholar]

- Waqar Akram, M.; Li, G.; Jin, Y.; Chen, X.; Zhu, C.; Zhao, X.; Aleem, M.; Ahmad, A. Improved outdoor thermography and processing of infrared images for defect detection in PV modules. Solar Energy 2019, 190, 549–560. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Maria Carlomagno, G. Nondestructive Testing With Infrared Thermography. In Infrared Thermography in the Evaluation of Aerospace Composite Materials; Elsevier: Cambridge, MA, USA, 2017; pp. 85–125. [Google Scholar] [CrossRef]

- Botsaris, P.N.; Tsanakas, J.A. Infrared Thermography as an Estimator Technique of a Photovoltaic Module Performance Via Operating Temperature Measurements. In Proceedings of the 10th ECNDT, Moscow, Russia, 7–11 June 2010; pp. 199–202. [Google Scholar]

- Ebner, R.; Kubicek, B.; Ujvari, G.; Novalin, S.; Rennhofer, M.; Halwachs, M. Optical characterization of different thin film module technologies. Int. J. Photoenergy 2015, 2015. [Google Scholar] [CrossRef]

- Berardone, I.; Lopez Garcia, J.; Paggi, M. Quantitative analysis of electroluminescence and infrared thermal images for aged monocrystalline silicon photovoltaic modules. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 402–407. [Google Scholar] [CrossRef]

- Gallardo-Saavedra, S.; Hernández-Callejo, L.; Alonso-García, M.d.C.; Santos, J.; Morales-Aragonés, J.I.; Alonso-Gómez, V. Failure diagnosis on photovoltaic modules using thermography, electroluminescence, RGB and I-V techniques. In Proceedings of the 36th European Photovoltaic Solar Energy Conference and Exhibition, Marseille, France, 9 September 2019; pp. 1171–1175. [Google Scholar]

- Tsanakas, J.A.; Ha, L.; Buerhop, C. Faults and infrared thermographic diagnosis in operating c-Si photovoltaic modules: A review of research and future challenges. Renew. Sustain. Energy Rev. 2016, 62, 695–709. [Google Scholar] [CrossRef]

- Salazar, A.M.; Macabebe, E.Q.B. Hotspots Detection in Photovoltaic Modules Using Infrared Thermography. MATEC Web Conf. 2016, 70, 10015. [Google Scholar] [CrossRef]

- Jaffery, Z.A.; Dubey, A.K.; Irshad; Haque, A. Scheme for predictive fault diagnosis in photo-voltaic modules using thermal imaging. Infrared Phys. Technol. 2017, 83, 182–187. [Google Scholar] [CrossRef]

- Köntges, M.; Kurtz, S.; Packard, C.; Jahn, U.; Berger, K.A.; Kato, K.; Friesen, T.; Liu, H.; Van Iseghem, M. IEA-PVPS T13-01 2014 Review of Failures of Photovoltaic Modules Final; Technical Report IEA-PVPS T13-01:2014, IEA-PVPS Task 13; IEA International Energy Agency: Paris, France, 2014. [Google Scholar]

- Deitsch, S.; Christlein, V.; Berger, S.; Buerhop-Lutz, C.; Maier, A.; Gallwitz, F.; Riess, C. Automatic classification of defective photovoltaic module cells in electroluminescence images. Sol. Energy 2019, 185, 455–468. [Google Scholar] [CrossRef]

- Ebner, R.; Zamini, S.; Újvári, G. Defect analysis in different photovoltaic modules using electroluminescence (EL) and infrared (IR)-thermography. In Proceedings of the 25th European Photovoltaic Solar Energy Conference and Exhibition/5th World Conference on Photovoltaic Energy Conversion, Valencia, Spain, 6–10 September 2010. [Google Scholar] [CrossRef]

- Gallardo-Saavedra, S.; Hernández-Callejo, L.; Alonso-García, M.D.C.; Santos, J.; Morales-Aragonés, J.I.; Alonso-Gómez, V. Nondestructive characterization of solar PV cells defects by means of electroluminescence, infrared thermography, I-V curves and visual tests: experimental study and comparison. Energies 2020. (pending publication). [Google Scholar]

- Seth, N.; Goel, V.; Kulkami, R.D. Three phase innovative multilevel inverter topologies for research and industrial applications: A review. In Proceedings of the 2017 International Conference on Nascent Technologies in Engineering, Navi Mumbai, India, 27 January 2017. [Google Scholar] [CrossRef]

- Cabrera-Tobar, A.; Bullich-Massagué, E.; Aragüés-Peñalba, M.; Gomis-Bellmunt, O. Topologies for large scale photovoltaic power plants. Renew. Sustain. Energy Rev. 2016, 59, 309–319. [Google Scholar] [CrossRef]

- Kjaer, S.; Pedersen, J.; Blaabjerg, F. Power inverter topologies for photovoltaic modules-a review. In Proceedings of the Conference Record of the 2002 IEEE Industry Applications Conference. 37th IAS Annual Meeting (Cat. No.02CH37344), Pittsburgh, PA, USA, 13–18 October 2002; Volume 3, pp. 782–788. [Google Scholar] [CrossRef]

- Dogga, R.; Pathak, M.K. Recent trends in solar PV inverter topologies. Sol. Energy 2019, 183, 57–73. [Google Scholar] [CrossRef]

- Deshpande, S.; Bhasme, N.R. A review of topologies of inverter for grid connected PV systems. Innov. Power Adv. Comput. Technol. 2018, 2017, 1–6. [Google Scholar] [CrossRef]

- Smyth, D. What Is the Best Grid Connected PV Inverter Topology and Why? Technical Report; AC Solar Warehouse. 2016. Available online: www.acsolarwarehouse.com (accessed on 15 February 2020).

- Zhao, T.; Bhavaraju, V.; Nirantare, P.; Xu, J. Evaluation of commercial scale transformerless solar inverter technology. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition, ECCE 2015, Montreal, QC, Canada, 20–24 September 2015; pp. 5342–5348. [Google Scholar] [CrossRef]

- Shehadeh, S.H.; Aly, H.H.; El-Hawary, M.E. An overview of topologies for photovoltaic electrical energy. In Proceedings of the IEEE Electrical Power and Energy Conference, Halifax, NS, Canada, 21–23 August 2013; pp. 1–8. [Google Scholar]

- SMA Solar Technology, AG. Sunny Central 1000CP Xt. Technical report. Available online: www.SMA.de (accessed on 20 February 2020).

- Schneider Electric Solar. 1500V Context SmartGen. Available online: https://solar.schneider-electric.com/product/conext-smartgen/ (accessed on 20 February 2020).

- Ingeteam. INGECON SUN Power (1000V/1500V). Available online: https://www.ingeteam.com/us/en-us/sectors/photovoltaic-energy/p15_24_36/ingecon-sun-power-1000v-1500v.aspx (accessed on 20 February 2020).

- ABB Central Inverters, PVS980, 1818 to 2091 kVA—Data Sheet. Available online: http://search.abb.com/library/Download.aspx?DocumentID=3AXD50000027473&LanguageCode=en&DocumentPartId=&Action=Launch (accessed on 20 February 2020).

- GPTech. SmartPV. Available online: http://www.greenpower.es/en/gptech-solutions/products/smartpv/#!tab1 (accessed on 20 February 2020).

- FreesunHEM | Power Electronics. Available online: https://power-electronics.com/productos/solar-products/freesun-hem/ (accessed on 27 February 2020).

- Tayab, U.B.; Bashir, M.A. Multilevel inverter topologies for photovoltaic power system: A review. ARPN J. Eng. Appl. Sci. 2017, 12, 3537–3549. [Google Scholar]

- Prabaharan, N.; Palanisamy, K. A comprehensive review on reduced switch multilevel inverter topologies, modulation techniques and applications. Renew. Sustain. Energy Rev. 2017, 76, 1248–1282. [Google Scholar] [CrossRef]

- Busquets-Monge, S.; Rocabert, J.; Rodriguez, P.; Alepuz, S.; Bordonau, J. Multilevel Diode-Clamped Converter for Photovoltaic Generators with Independent Voltage Control of Each Solar Array. IEEE Trans. Ind. Electron. 2008, 55, 2713–2723. [Google Scholar] [CrossRef]

- Ma, L.; Kerekes, T.; Teodorescu, R.; Jin, X.; Floricau, D.; Liserre, M. The high efficiency transformer-less PV inverter topologies derived from NPC topology. In Proceedings of the 2009 13th European Conference on Power Electronics and Applications, Barcelona, Spain, 8–10 September 2009; pp. 1–10. [Google Scholar]

- Burkart, R.; Kolar, J.W.; Griepentrog, G. Comprehensive comparative evaluation of single- and multi-stage three-phase power converters for photovoltaic applications. In Proceedings of the IEEE 34th International Telecommunications Energy Conference (INTELEC), Scottsdale, AZ, USA, 30 September–4 October 2012; pp. 1–8. [Google Scholar]

- Tahir, S.; Wang, J.; Baloch, M.H.; Kaloi, G.S. Digital control techniques based on voltage source inverters in renewable energy applications: A review. Electronics 2018, 7, 18. [Google Scholar] [CrossRef]

- Muñoz-Cruzado-Alba, J.; Villegas-Núñez, J.; Vite-Frías, J.A.; Carrasco-Solís, J.M.; Galván-Díez, E. New Low-Distortion Q-f Droop Plus Correlation Anti-Islanding Detection Method for Power Converters in Distributed Generation Systems. IEEE Trans. Ind. Electron. 2015, 62, 5072–5081. [Google Scholar] [CrossRef]

- Muñoz-Cruzado-Alba, J.; Villegas-Núñez, J.; Vite-Frías, J.A.; Solís, J.M.C. A new fast peak current controller for transient voltage faults for power converters. Energies 2016, 9, 1. [Google Scholar] [CrossRef]

- Kalogerakis, C.; Koutroulis, E.; Lagoudakis, M.G. Global MPPT Based on Machine-Learning for PV Arrays Operating under Partial Shading Conditions. Appl. Sci. 2020, 10, 700. [Google Scholar] [CrossRef]

- Basha, C.H.; Rani, C. Different conventional and soft computing MPPT techniques for solar PV systems with high step-up boost converters: A comprehensive analysis. Energies 2020, 13, 371. [Google Scholar] [CrossRef]

- Costanzo, L.; Vitelli, M. A Novel MPPT technique for single stage grid-connected PV systems: T4S. Energies 2019, 12, 4501. [Google Scholar] [CrossRef]

- Tobón, A.; Peláez-restrepo, J.; Montano, J.; Durango, M. MPPT of a Photovoltaic Panels Array with Partial Shading Using the IPSM with Implementation Both in Simulation as in Hardware. Energies 2020, 13, 815. [Google Scholar] [CrossRef]

- What is a Combiner Box? Available online: https://power-electronics.com/productos/solar-products/freesun-hem/ (accessed on 27 February 2020).

- Solar String Combiner Boxes—ABB Enclosures. Available online: https://new.abb.com/low-voltage/products/enclosures/solar-combiners (accessed on 29 February 2020).

- Niccolai, A.; Gandelli, A.; Grimaccia, F.; Zich, R.; Leva, S. Overview on photovoltaic inspections procedure by means of unmanned aerial vehicles. In Proceedings of the 2019 IEEE Milan PowerTech, PowerTech 2019, Milan, Italy, 23–27 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Luo, X.; Li, X.; Yang, Q.; Wu, F.; Zhang, D.; Yan, W.; Xi, Z. Optimal path planning for UAV based inspection system of large-scale photovoltaic farm. In Proceedings of the 2017 Chinese Automation Congress, CAC 2017, Jinan, China, 20–22 October 2017; pp. 4495–4500. [Google Scholar] [CrossRef]

- Sizkouhi, A.M.M.; Esmailifar, S.M.; Aghaei, M.; Vidal de Oliveira, A.K.; Rüther, R. Autonomous Path Planning by Unmanned Aerial Vehicle (UAV) for Precise Monitoring of Large-Scale PV plants. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; Volume 2, pp. 1398–1402. [Google Scholar]

- Cabrera-Tobar, A.; Bullich-Massagué, E.; Aragüés-Peñalba, M.; Gomis-Bellmunt, O. Active and reactive power control of a PV generator for grid code compliance. Energies 2019, 12, 3872. [Google Scholar] [CrossRef]

- Marinopoulos, A.; Papandrea, F.; Reza, M.; Norrga, S.; Spertino, F.; Napoli, R. Grid integration aspects of large solar PV installations: LVRT capability and reactive power/voltage support requirements. In Proceedings of the 2011 IEEE PES Trondheim PowerTech: The Power of Technology for a Sustainable Society, POWERTECH 2011, Trondheim, Norway, 19–23 June 2011; pp. 1–8. [Google Scholar] [CrossRef]

- Cagnano, A.; De Tuglie, E.; Dicorato, M.; Forte, G.; Trovato, M. PV plants for voltage regulation in distribution networks. In Proceedings of the Universities Power Engineering Conference, London, UK, 4–7 September 2012; pp. 1–5. [Google Scholar] [CrossRef]

- IEC International Electrotechnical Commission. IEC TS 60904-13 Photovoltaic Devices-Part 13: Electroluminescence of Photovoltaic Modules; IEC International Electrotechnical Commission: Geneva, Switzerland, 2018. [Google Scholar]

- ST 500/69/23 | Transformadores para Panel de Control Block, 230V ac, 500VA, 1 salida | RS Components. Available online: https://es.rs-online.com/web/p/transformadores-de-montaje-en-panel-y-carril-din/7315208/ (accessed on 18 April 2020).

- LC1D09BL | Contactor 9 A, 3 NA, Bobina 24 V dc, TeSys D | RS Components. Available online: https://es.rs-online.com/web/p/contactores/4001899/ (accessed on 17 April 2020).

- HS200 68R J | Arcol | Resistencias Fijas para Montaje en Panel | RS. Available online: https://es.rs-online.com/web/p/resistencias-fijas-para-montaje-en-panel/6150583/ (accessed on 17 April 2020).

- Disyuntor 100A NZMB1-A100 | Eaton | NZMB1-A100 | 259079 | Interruptor potencia protección transfo. eibabo.es. Available online: https://www.eibabo.es/eaton/disyuntor-100a-nzmb1-a100-eb10784156 (accessed on 17 April 2020).

- Disyuntor 160A XT2N 160 R160 | ABB | XT2N 160 R160 | 1SDA067058R0001 | Interruptor potencia protección transfo. eibabo.es. Available online: https://www.eibabo.es/abb/disyuntor-160a-xt2n-160-r160-eb17803409 (accessed on 17 April 2020).

- Disyuntor 250A XT4N 250 EKIP LS/I | ABB | XT4N 250 EKIP LS/I | 1SDA068147R0001 | Interruptor potencia protección transfo. eibabo.es. Available online: https://www.eibabo.es/abb/disyuntor-250a-xt4n-250-ekip-ls-i-eb12102121?fs=4278333618 (accessed on 17 April 2020).

- Disyuntor 400A T5N000040E02403 | ABB | T5N000040E02403 | 1SDA054317R0001 | Interruptor potencia protección transfo. eibabo.es. Available online: https://www.eibabo.es/abb/disyuntor-400a-t5n000040e02403-eb12102118 (accessed on 17 April 2020).

- Disyuntor 400A NZMN3-AE400 | Eaton | NZMN3-AE400 | 259114 | Interruptor potencia protección transfo. eibabo.es. Available online: https://www.eibabo.es/eaton/disyuntor-400a-nzmn3-ae400-eb10703722?fs=2659164480 (accessed on 17 April 2020).

- Disyuntor 1000A 33241 | Schneider Electric | 33241 | Interruptor potencia protección transfo. eibabo.es. Available online: https://www.eibabo.es/schneider-electric/disyuntor-1000a-33241-eb15803670 (accessed on 17 April 2020).

- Disyuntor 1000A IZMX16N3-V10F-1 | Eaton | IZMX16N3-V10F-1 | 183333 | Interruptor potencia protección transfo. eibabo.es. Available online: https://www.eibabo.es/eaton/disyuntor-1000a-izmx16n3-v10f-1-eb17403569 (accessed on 17 April 2020).

- Fu, R.; Feldman, D.; Margolis, R. U.S. Solar Photovoltaic System Cost Benchmark: Q1 2018; NREL: Golden, CO, USA, 2018; pp. 1–47. [Google Scholar] [CrossRef]

- EIA. Cost and Performance Characteristics of New Generating Technologies. In Annual Energy Outlook 2019; EIA: Washington, DC, USA, 2019; Volume 2019, pp. 1–3. [Google Scholar]

| Irradiance | Daytime | Nighttime | ||||||

|---|---|---|---|---|---|---|---|---|

| Current (A) | 0.5 | 1 | 2.5 | 5 | 0.5 | 1 | 2.5 | 5 |

| Voltage (V) | 461 | 464 | 475 | 490 | 401 | 418 | 446 | 472 |

| Avg. power (W) | 231 | 465 | 1186 | 2445 | 200 | 419 | 1114 | 2359 |

| Irradiance | Daytime | Nighttime | ||||||

|---|---|---|---|---|---|---|---|---|

| Current (A) | 0.5 | 1 | 2.5 | 5 | 0.5 | 1 | 2.5 | 5 |

| Voltage (V) | 462 | 468 | 486 | 512 | 439 | 460 | 498 | 528 |

| Power (W) | 231 | 468 | 1215 | 2560 | 220 | 460 | 1245 | 2640 |

| Technology | Illuminated IRT | Dark IRT | Off-site EL | On-site EL | |

|---|---|---|---|---|---|

| Feature | |||||

| Implementation test cost | + | + | ++++ | + | |

| Plant production losses | - | - | +++ | - | |

| Results accuracy | ++ | + | +++ | +++ | |

| Time per test | + | + | +++ | ++ | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ballestín-Fuertes, J.; Muñoz-Cruzado-Alba, J.; Sanz-Osorio, J.F.; Hernández-Callejo, L.; Alonso-Gómez, V.; Morales-Aragones, J.I.; Gallardo-Saavedra, S.; Martínez-Sacristan, O.; Moretón-Fernández, Á. Novel Utility-Scale Photovoltaic Plant Electroluminescence Maintenance Technique by Means of Bidirectional Power Inverter Controller. Appl. Sci. 2020, 10, 3084. https://doi.org/10.3390/app10093084

Ballestín-Fuertes J, Muñoz-Cruzado-Alba J, Sanz-Osorio JF, Hernández-Callejo L, Alonso-Gómez V, Morales-Aragones JI, Gallardo-Saavedra S, Martínez-Sacristan O, Moretón-Fernández Á. Novel Utility-Scale Photovoltaic Plant Electroluminescence Maintenance Technique by Means of Bidirectional Power Inverter Controller. Applied Sciences. 2020; 10(9):3084. https://doi.org/10.3390/app10093084

Chicago/Turabian StyleBallestín-Fuertes, Javier, Jesús Muñoz-Cruzado-Alba, José F. Sanz-Osorio, Luis Hernández-Callejo, Victor Alonso-Gómez, José Ignacio Morales-Aragones, Sara Gallardo-Saavedra, Oscar Martínez-Sacristan, and Ángel Moretón-Fernández. 2020. "Novel Utility-Scale Photovoltaic Plant Electroluminescence Maintenance Technique by Means of Bidirectional Power Inverter Controller" Applied Sciences 10, no. 9: 3084. https://doi.org/10.3390/app10093084

APA StyleBallestín-Fuertes, J., Muñoz-Cruzado-Alba, J., Sanz-Osorio, J. F., Hernández-Callejo, L., Alonso-Gómez, V., Morales-Aragones, J. I., Gallardo-Saavedra, S., Martínez-Sacristan, O., & Moretón-Fernández, Á. (2020). Novel Utility-Scale Photovoltaic Plant Electroluminescence Maintenance Technique by Means of Bidirectional Power Inverter Controller. Applied Sciences, 10(9), 3084. https://doi.org/10.3390/app10093084