Porosity Structure Offering Improved Biomechanical Stress Distribution and Enhanced Pain-Relieving Potential

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Preparation

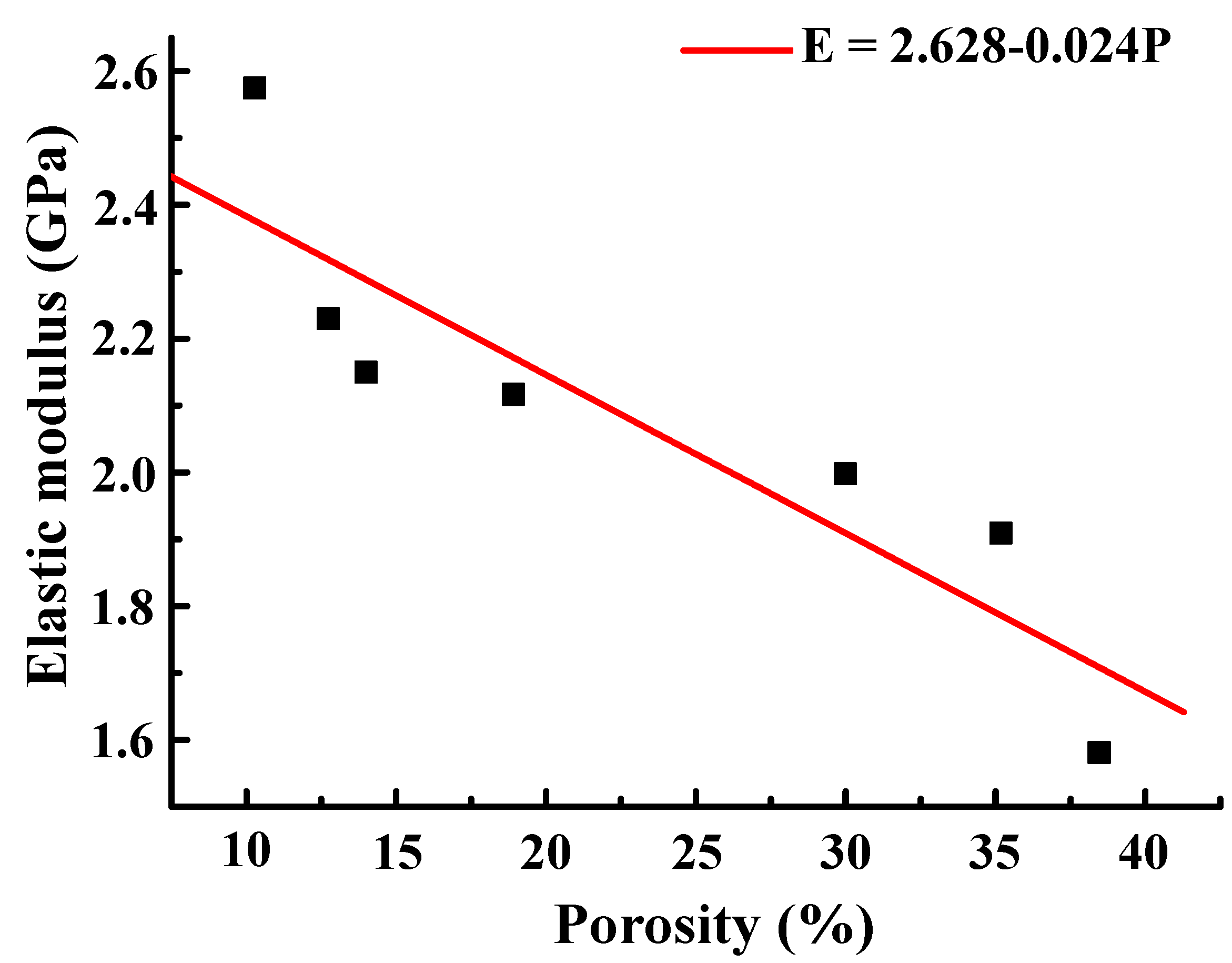

2.2. Fabrics Elastic Modulus Measurement

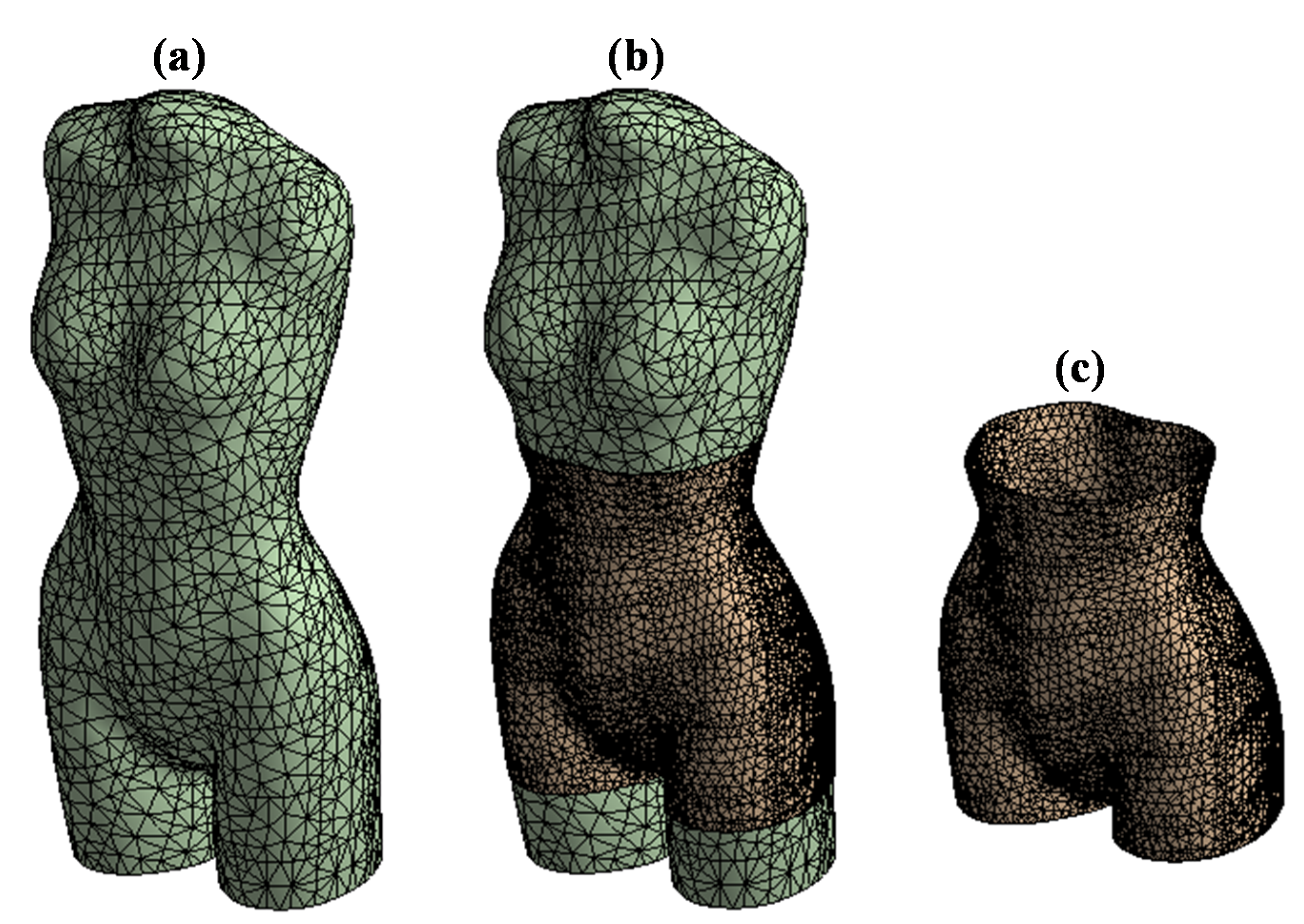

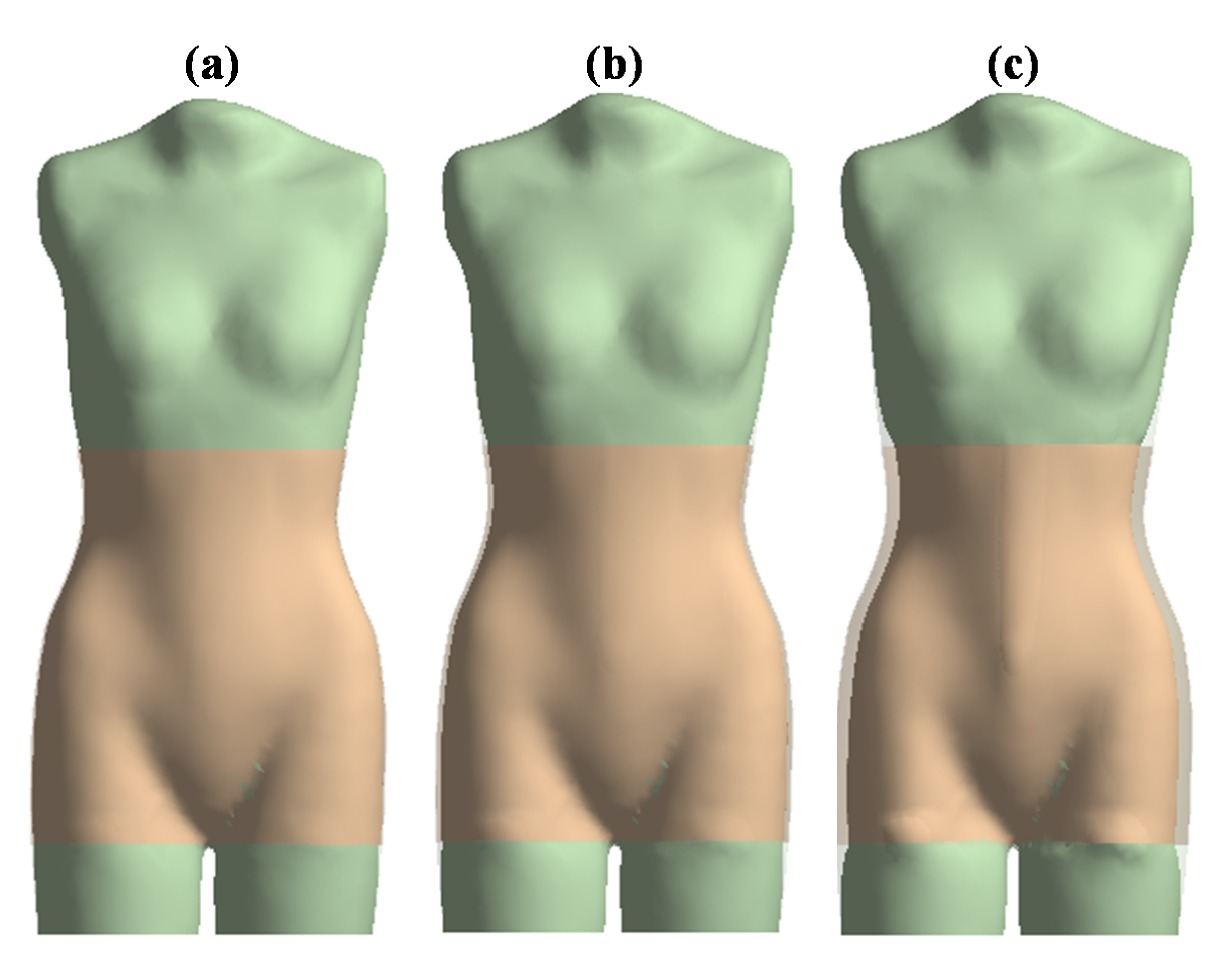

2.3. FEA Simulation

2.4. Statistical Analysis

3. Results and Discussion

3.1. Knitted Structure of the Nylon Fabric

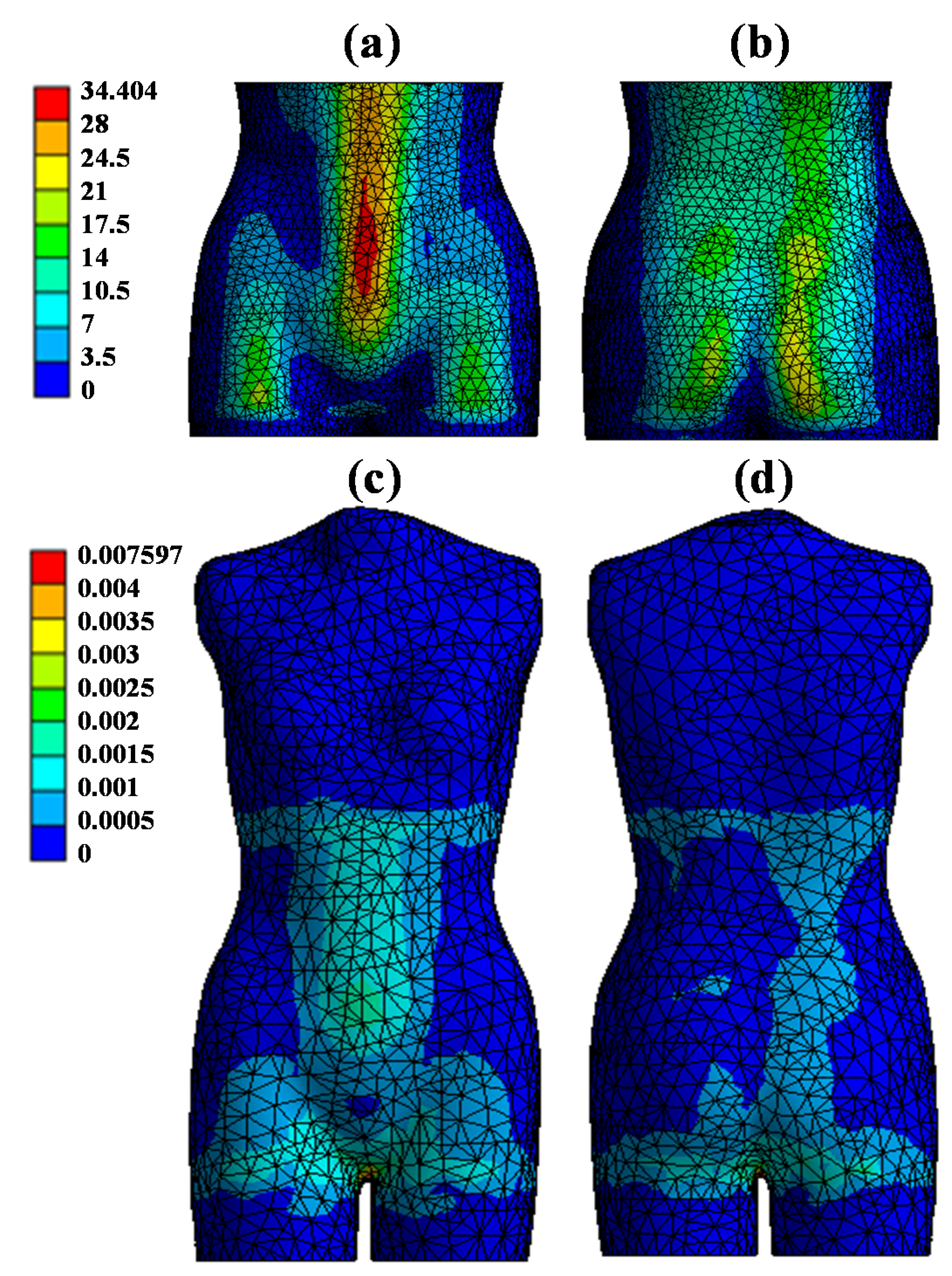

3.2. Stress Transfer Behaviors

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Czajka, R. Development of medical textile market. Fibres Text. East. Eur. 2005, 13, 13–15. [Google Scholar]

- Goswami, B.C.; Martindale, J.G.; Scardino, F. Textile Yarns: Technology, Stracture, and Applications; Wiley India Pvt Ltd.: Noida, India, 1977. [Google Scholar]

- Dattilo, P.P., Jr.; King, M.W.; Cassill, N.L.; Leung, J.C. Medical textiles: Application of an absorbable barbed bi-directional surgical suture. J. Text. Appar. Technol. Manag. 2002, 2, 1–5. [Google Scholar]

- King, M.W. Overview of opportunities in medical textiles. Can. Text. J. 2001, 118, 34–36. [Google Scholar]

- Cooper, J.A.; Lu, H.H.; Ko, F.K.; Freeman, J.W.; Laurencin, C.T. Fiber-based tissue-engineered scaffold for ligament replacement: Design considerations and in vitro evaluation. Biomaterials 2005, 26, 1523–1532. [Google Scholar] [CrossRef] [PubMed]

- Illouz, Y.-G. Clinical Evaluation of Pressure Therapy in Conjunction with Aesthetic and Reconstructive Surgery. 1989. Available online: https://www.medicalz.com/media/uploads/filemanager/plasticstudy.pdf (accessed on 12 January 2020).

- Liu, R.; Kwok, Y.-L.; Li, Y.; Lao, T.-T. Fabric mechanical-surface properties of compression hosiery and their effects on skin pressure magnitudes when worn. Fibres Text. East. Eur. 2010, 18, 79. [Google Scholar]

- Blattler, W.; Kreis, N.; Lun, B.; Winiger, J.; Amsler, F. Leg symptoms of healthy people and their treatment with compression hosiery. Phlebology 2008, 23, 214–221. [Google Scholar] [CrossRef]

- Campbell, P.E.; Smith, G.S.; Smith, J.M. Retrospective clinical evaluation of gauze-based negative pressure wound therapy. Int. Wound J. 2008, 5, 280–286. [Google Scholar] [CrossRef]

- Yang, C.; Li, L. The Application Wearable Thermal Textile Technology in Thermal-Protection Applications. Trends Text. Fash Des. 2018, 1, 22–30. [Google Scholar]

- Yang, K.; Meadmore, K.; Freeman, C.; Grabham, N.; Hughes, A.M.; Wei, Y.; Torah, R.; Glanc-Gostkiewicz, M.; Beeby, S.; Tudor, J. Development of User-Friendly Wearable Electronic Textiles for Healthcare Applications. Sensors 2018, 18, 2410. [Google Scholar] [CrossRef]

- Yang, K.; Isaia, B.; Brown, L.J.E.; Beeby, S. E-Textiles for Healthy Ageing. Sensors 2019, 19, 4463. [Google Scholar] [CrossRef]

- Kojima, A.U.Y.; Masaya, K.; Akane, O.; Yoshiaki, F.; Toshio, K.; Osami, K. Mechanical properties of nylon 6-clay hybrid. J. Mater. Res. 1993, 8, 5. [Google Scholar] [CrossRef]

- Wong, A.S.W.; Li, Y.; Zhang, X. Influence of fabric mechanical property on clothing dynamic pressure distribution and pressure comfort on tight-fit sportswear. Sen-I Gakkaishi 2004, 60, 293–299. [Google Scholar] [CrossRef][Green Version]

- Zhang, X.; Yeung, K.W.; Li, Y. Numerical simulation of 3D dynamic garment pressure. Text Res. J. 2002, 72, 245–252. [Google Scholar] [CrossRef]

- Kang, T.J.; Kim, S.M. Optimized garment pattern generation based on three-dimensional anthropometric measurement. Int. J. Cloth. Sci. Technol. 2000, 12, 15. [Google Scholar]

- Makabe, H.; Momota, H.; Mitsuno, T. A study of clothing pressure developed by the girdle. J. Jpn. Res. Assoc. Text. End Uses 1991, 32, 15. [Google Scholar]

- Ohura, T.; Takahashi, M.; Ohura, N., Jr. Influence of external forces (pressure and shear force) on superficial layer and subcutis of porcine skin and effects of dressing materials: Are dressing materials beneficial for reducing pressure and shear force in tissues? Wound Repair Regen 2008, 16, 102–107. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Yeung, K.W. A 3D biomechanical model for numerical simulation of dynamic mechanical interactions of bra and breast during wear. Sen-I Gakkaishi 2003, 59, 12–21. [Google Scholar] [CrossRef]

- House, D.; Breen, D. Cloth Modeling and Animation; A K Peters/CRC Press: Natick, MA, USA, 2000. [Google Scholar]

- Matsuda, R.; Imaoka, H. A graphic method to simulate garment fitting on a human body model in various posture. Sen’i Gakkaishi 1995, 51, 9. [Google Scholar] [CrossRef][Green Version]

- Pourdeyhimi, B. Porosity of surgical mesh fabrics: New technology. J. Biomed. Mater. Res. 1989, 23, 145–152. [Google Scholar] [CrossRef]

- Rodel, H. Relationship between knitting parameters, computer aided pattern design and fit of knitting underwear. Int. J. Cloth. Sci. Technol. 1999, 11, 2. [Google Scholar]

- Chu, C.C.; Welch, L. Characterization of morphologic and mechanical properties of surgical mesh fabrics. J. Biomed. Mater. Res. 1985, 19, 903–916. [Google Scholar] [CrossRef] [PubMed]

- Hiatt, J.H. The Principles of Knitting: Methods and Techniques of Hand Knitting; Simon & Schuster: New York, NY, USA, 1989. [Google Scholar]

- Xie, S.T. Characterization of Interyarn Pore Size and its Distribution in Plain Woven Fabrics. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2002. [Google Scholar]

- Karaguzel, B. Characterization and Role of Porosity in Knitted Fabrics. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2004. [Google Scholar]

- Silvain, A.H. Form-Fitting Seamless Garment and Method. U.S. Patent 3,479,844, 25 November 1969. [Google Scholar]

- VanDolah, H.J.; Bauer, B.A.; Mauck, K.F. Clinicians’ Guide to Cannabidiol and Hemp Oils. Mayo. Clin. Proc. 2019, 94, 1840–1851. [Google Scholar] [CrossRef] [PubMed]

- Baron, E.P. Comprehensive Review of Medicinal Marijuana, Cannabinoids, and Therapeutic Implications in Medicine and Headache: What a Long Strange Trip It‘s Been. Headache 2015, 55, 885–916. [Google Scholar] [CrossRef] [PubMed]

| Samples | BSC-1 | BSC-2 | BSC-3 | BSC-4 | BSC-5 | BSC-6 | BSC-7 |

|---|---|---|---|---|---|---|---|

| Porosity (%) | 10.28 | 12.73 | 14.00 | 18.91 | 29.98 | 35.18 | 38.46 |

| Materials | Elastic Modulus (MPa) | Poisson’s Ratio |

|---|---|---|

| Human body | 8.8 × 10−2 | 0.22 |

| Nylon | Determined by the tensile test | 0.35 |

| Porosity (%) | Elastic Modulus (GPa) | Stress of the BSC (MPa) | Stress of the Human Body (kPa) | Abdomen Circumference Decreasing (cm) |

|---|---|---|---|---|

| BSC-7 (38.46) | 1.58 | 207.30 | 6.742 | 10 |

| BSC-6 (35.18) | 1.91 | 249.98 | 6.783 | 10 |

| BSC-5 (29.98) | 2.00 | 267.13 | 6.910 | 10 |

| BSC-4 (18.91) | 2.12 | 282.20 | 7.365 | 10 |

| BSC-3 (14.00) | 2.15 | 287.28 | 7.523 | 10 |

| BSC-2 (12.73) | 2.23 | 289.04 | 7.588 | 10 |

| BSC-1 (10.28) | 2.57 | 337.79 | 7.645 | 10 |

| BSC-1 (10.28) | 2.57 | 506.53 | 11.464 | 15 |

| BSC-1 (10.28) | 2.57 | 675.60 | 15.283 | 20 |

| BSC-1 (10.28) | 2.57 | 845.12 | 19.109 | 25 |

| BSC-1 (10.28) | 2.57 | 1032.48 | 22.825 | 30 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.-C.; Wu, C.-Y.; Huang, M.-S.; Huang, B.-H.; Chou, H.-H.; Ou, K.-L.; Liu, C.-M.; Pai, F.-T.; Huang, H.-W.; Peng, P.-W. Porosity Structure Offering Improved Biomechanical Stress Distribution and Enhanced Pain-Relieving Potential. Appl. Sci. 2020, 10, 3026. https://doi.org/10.3390/app10093026

Lin C-C, Wu C-Y, Huang M-S, Huang B-H, Chou H-H, Ou K-L, Liu C-M, Pai F-T, Huang H-W, Peng P-W. Porosity Structure Offering Improved Biomechanical Stress Distribution and Enhanced Pain-Relieving Potential. Applied Sciences. 2020; 10(9):3026. https://doi.org/10.3390/app10093026

Chicago/Turabian StyleLin, Chia-Cheng, Chia-Yu Wu, Mao-Suan Huang, Bai-Hung Huang, Hsin-Hua Chou, Keng-Liang Ou, Chung-Ming Liu, Fang-Tzu Pai, Han-Wei Huang, and Pei-Wen Peng. 2020. "Porosity Structure Offering Improved Biomechanical Stress Distribution and Enhanced Pain-Relieving Potential" Applied Sciences 10, no. 9: 3026. https://doi.org/10.3390/app10093026

APA StyleLin, C.-C., Wu, C.-Y., Huang, M.-S., Huang, B.-H., Chou, H.-H., Ou, K.-L., Liu, C.-M., Pai, F.-T., Huang, H.-W., & Peng, P.-W. (2020). Porosity Structure Offering Improved Biomechanical Stress Distribution and Enhanced Pain-Relieving Potential. Applied Sciences, 10(9), 3026. https://doi.org/10.3390/app10093026