Evaluation of Pressure Distribution against Root Canal Walls of NiTi Rotary Instruments by Finite Element Analysis

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Geometrical Model

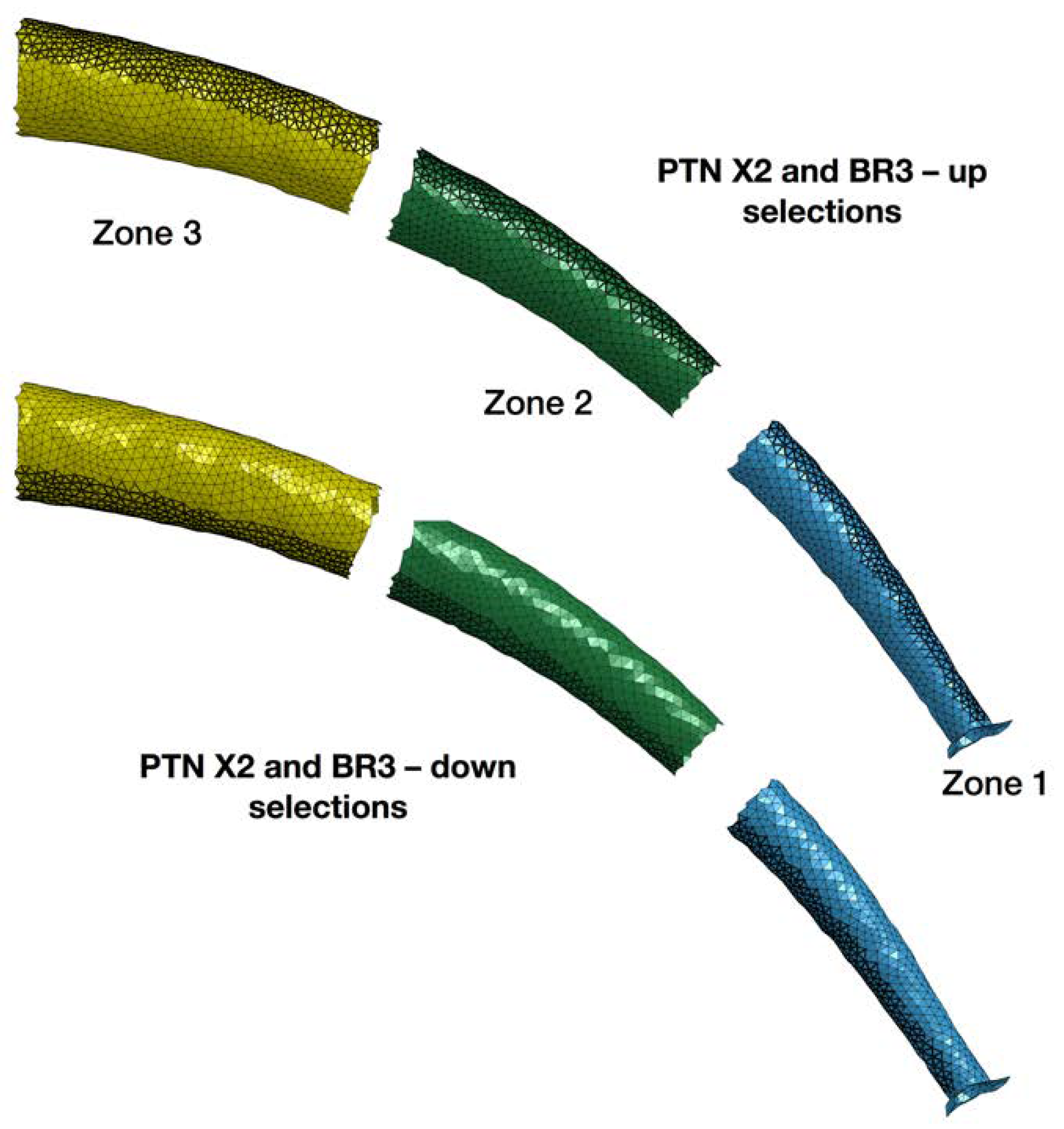

2.2. Meshing Procedure

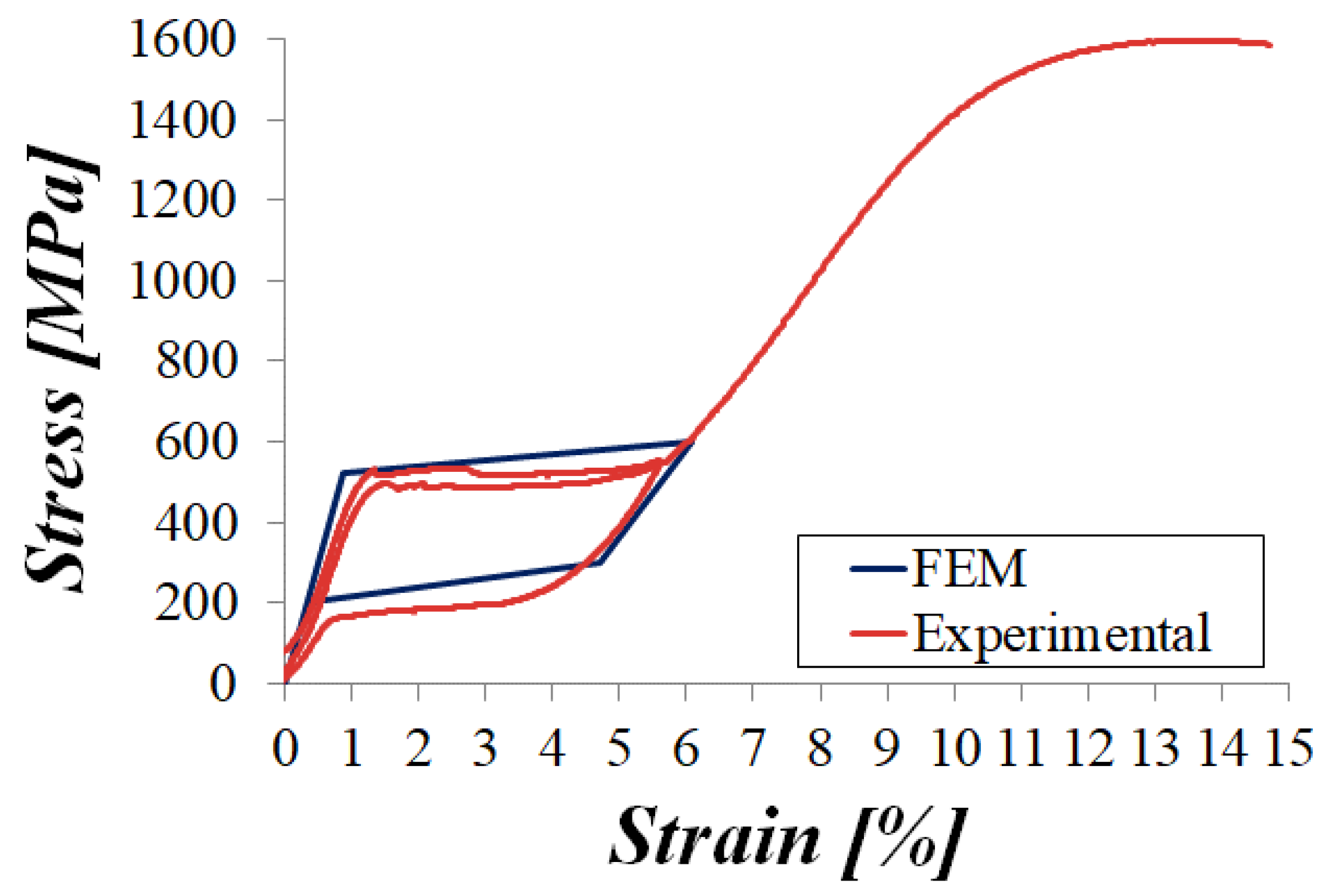

2.3. Material Model

2.4. Boundary Conditions

3. Results

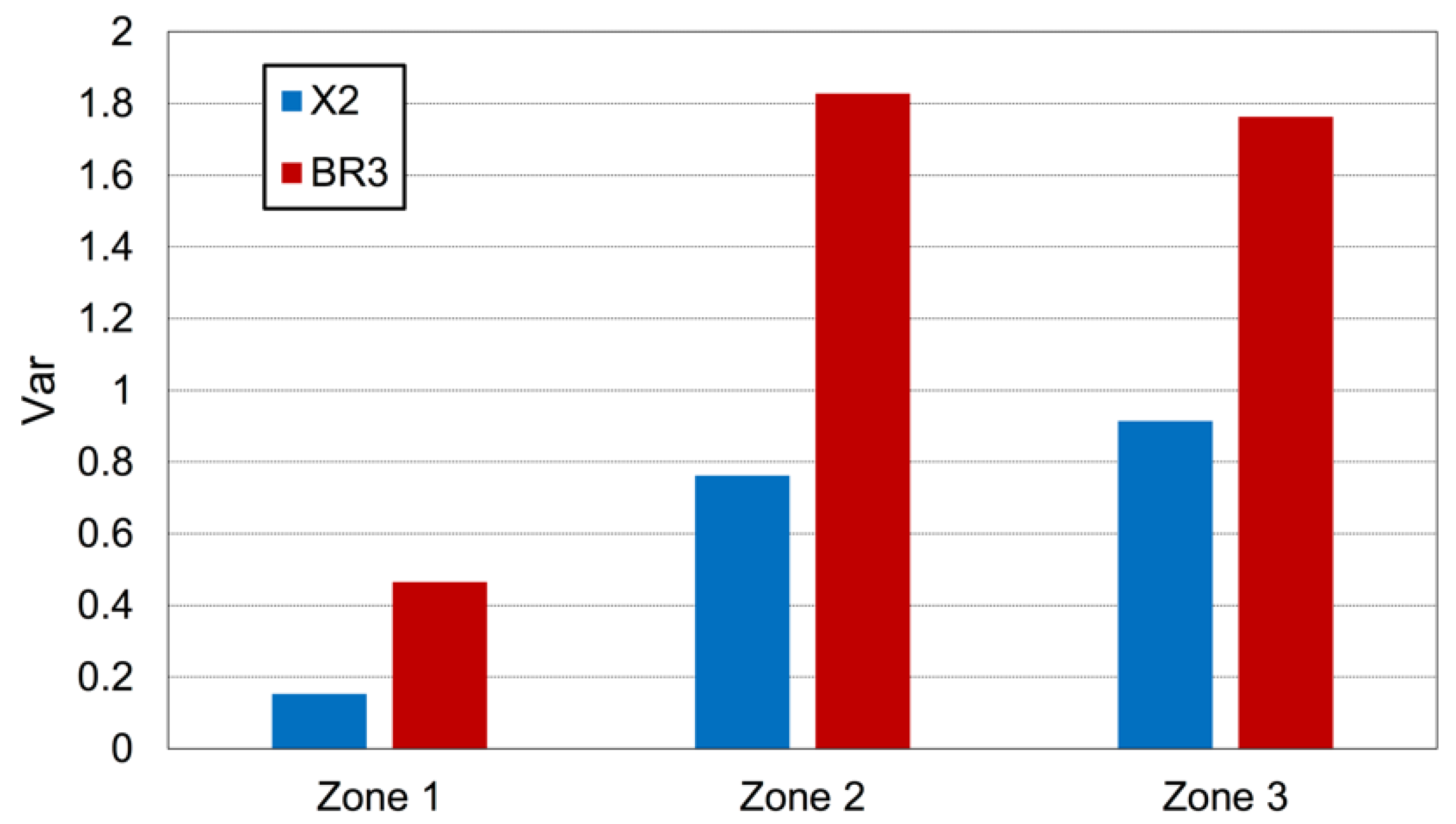

Evaluation of FEA Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Metzger, Z.; Solomonov, M.; Kfir, A. The role of mechanical instrumentation in the cleaning of root canals. Endod. Top. 2013, 29, 87–109. [Google Scholar] [CrossRef]

- Peters, O.A. Current challenges and concepts in the preparation of root canal systems: A review. J. Endod. 2004, 30, 559–567. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schilder, H. Cleaning and shaping the root canal. Dent. Clin. North Am. Apr. 1974, 18, 269–296. [Google Scholar]

- Burklein, S.; Schafer, E. Critical evaluation of root canal transportation by instrumentation. Endod. Top. 2013, 29, 110–124. [Google Scholar] [CrossRef]

- Bergmans, L.; Van Cleynenbreugel, J.; Wevers, M.; Lambrechts, P. Mechanical root canal preparation with NiTi rotary instruments: Rationale, performance and safety: Status report for the American Journal of Dentistry. Am. J. Dent. 2001, 14, 324–333. [Google Scholar]

- Jafarzadeh, H.; Abbott, P.V. Ledge formation: Review of a great challenge in endodontics. J. Endod. 2007, 33, 1155–1162. [Google Scholar] [CrossRef]

- Bier, C.A.; Shemesh, H.; Tanomaru-Filho, M.; Wesselink, P.R.; Wu, M.K. The ability of different nickel-titanium rotary instruments to induce dentinal damage during canal preparation. J. Endod. 2009, 35, 236–238. [Google Scholar] [CrossRef]

- Tamse, A.; Fuss, Z.; Lustig, J.; Kaplavi, J. An evaluation of endodontically treated vertically fractured teeth. J. Endod. 1999, 25, 506–508. [Google Scholar] [CrossRef]

- Gambill, J.M.; Alder, M.; del Rio, C.E. Comparison of nickel-titanium and stainless steel hand-file instrumentation using computed tomography. J. Endod. 1996, 22, 369–375. [Google Scholar] [CrossRef]

- Gergi, R.; Rjeily, J.A.; Sader, J.; Naaman, A. Comparison of canal transportation and centering ability of twisted files, Pathfile-ProTaper system, and stainless steel hand K-files by using computed tomography. J. Endod. 2010, 36, 904–907. [Google Scholar] [CrossRef]

- Çapar, I.D.; Arslan, H. A review of instrumentation kinematics of engine-driven nickel-titanium instruments. Int. Endod. J. 2016, 49, 119–135. [Google Scholar] [CrossRef] [PubMed]

- Haapasalo, M.; Shen, Y. Evolution of nickel-titanium instruments: From past to future. Endod. Top. 2013, 29, 3–17. [Google Scholar] [CrossRef]

- Al-Sudani, D.; Al-Shahrani, S. A comparison of the canal centering ability of ProFile, K3, and RaCe Nickel Titanium rotary systems. J. Endod. 2006, 32, 1198–1201. [Google Scholar] [CrossRef]

- Zanesco, C.; Só, M.V.; Schmidt, S.; Fontanella, V.R.; Grazziotin-Soares, R.; Barletta, F.B. Apical transportation, centering ratio, and volume increase after manual, rotary, and reciprocating instrumentation in curved root canals: Analysis by micro-computed tomographic and digital subtraction radiography. J. Endod. 2017, 43, 486–490. [Google Scholar] [CrossRef]

- Berutti, E.; Chiandussi, G.; Gaviglio, I.; Ibba, A. Comparative analysis of torsional and bending stresses in two mathematical models of nickel-titanium rotary instruments: ProTaper versus ProFile. J. Endod. 2003, 29, 15–19. [Google Scholar] [CrossRef] [PubMed]

- Bonessio, N.; Pereira, E.S.; Lomiento, G.; Arias, A.; Bahia, M.G.; Buono, V.T.; Peters, O.A. Validated finite element analyses of WaveOne Endodontic Instruments: A comparison between M-Wire and NiTi alloys. Int. Endod. J. 2015, 48, 441–450. [Google Scholar] [CrossRef]

- Kim, H.C.; Kim, H.J.; Lee, C.J.; Kim, B.M.; Park, J.K.; Versluis, A. Mechanical response of nickel-titanium instruments with different cross-sectional designs during shaping of simulated curved canals. Int. Endod. J. 2009, 42, 593–602. [Google Scholar] [CrossRef]

- Kim, T.O.; Cheung, G.S.; Lee, J.M.; Kim, B.M.; Hur, B.; Kim, H.C. Stress distribution of three NiTi rotary files under bending and torsional conditions using a mathematic analysis. Int. Endod. J. 2009, 42, 14–21. [Google Scholar] [CrossRef]

- Lee, M.H.; Versluis, A.; Kim, B.M.; Lee, C.J.; Hur, B.; Kim, H.C. Correlation between experimental cyclic fatigue resistance and numerical stress analysis for nickel-titanium rotary files. J. Endod. 2011, 37, 1152–1157. [Google Scholar] [CrossRef]

- Scattina, A.; Alovisi, M.; Paolino, D.S.; Pasqualini, D.; Scotti, N.; Chiandussi, G.; Berutti, E. Prediction of Cyclic Fatigue Life of Nickel-Titanium Rotary Files by Virtual Modeling and Finite Elements Analysis. J. Endod. 2015, 41, 1867–1870. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Eng, M.; Zheng, Y.; Eng, D. Comparative study of torsional and bending properties for six models of nickel-titanium root canal instruments with different cross-sections. J. Endod. 2006, 32, 372–375. [Google Scholar] [CrossRef]

- Lazari, P.C.; Oliveira, R.C.; Anchieta, R.B.; Almeida, E.O.; Freitas Junior, A.C.; Kina, S.; Rocha, E.P. Stress distribution on dentin-cement-post interface varying root canal and glass fiber post diameters. A three- dimensional finite element analysis based on micro-CT data. J. Appl. Oral Sci. 2013, 21, 511–517. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Auricchio, F.; Taylor, R.L.; Lubliner, J. Shape-memory alloys: Macromodelling and numerical simulations of the superelastic behavior. Comput. Methods Appl. Mech. Engrg. 1997, 146, 281–312. [Google Scholar] [CrossRef]

- Hartmann, M.S.; Barletta, F.B.; Camargo Fontanella, V.R.; Vanni, J.R. Canal transportation after root canal instrumentation: A comparative study with computed tomography. J. Endod. 2007, 33, 962–965. [Google Scholar] [CrossRef] [PubMed]

- Capar, I.D.; Ertas, H.; Ok, E.; Arslan, H.; Ertas, E.T. Comparative study of different novel nickel-titanium rotary systems for root canal preparation in severely curved root canals. J. Endod. 2014, 40, 852–856. [Google Scholar] [CrossRef] [PubMed]

- Gundappa, M.; Bansal, R.; Khoriya, S.; Mohan, R. Root canal centering ability of rotary cutting nickel titanium instruments: A meta-analysis. J. Conserv. Dent. 2014, 17, 504–509. [Google Scholar] [CrossRef]

- Elnaghy, A.M.; Elsaka, S.E. Evaluation of root canal transportation, centering ratio, and remaining dentin thickness associated with ProTaper Next instruments with and without glide path. J. Endod. 2014, 40, 2053–2056. [Google Scholar] [CrossRef]

- Stern, S.; Patel, S.; Foschi, F.; Sherriff, M.; Mannocci, F. Changes in centering and shaping ability using three nickel–titanium instrumentation techniques analyzed by micro-computed tomography (μCT). Int. Endod. J. 2012, 45, 514–523. [Google Scholar] [CrossRef]

- Ha, J.H.; Cheung, G.S.; Versluis, A.; Lee, C.J.; Kwak, S.W.; Kim, H.C. ‘Screw-in’ tendency of rotary nickel- titanium files due to design geometry. Int. Endod. J. 2015, 48, 666–672. [Google Scholar] [CrossRef]

- Kim, H.C.; Cheung, G.S.; Lee, C.J.; Kim, B.M.; Park, J.K.; Kang, S.I. Comparison of forces generated during root canal shaping and residual stresses of three nickel-titanium rotary files by using a three-dimensional finite-element analysis. J. Endod. 2008, 34, 743–747. [Google Scholar] [CrossRef]

- Arbab-Chirani, R.; Chevalier, V.; Arbab-Chirani, S.; Calloch, S. Comparative analysis of torsional and bending behavior through finite-element models of 5 Ni-Ti endodontic instruments. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2011, 111, 115–121. [Google Scholar] [CrossRef] [PubMed]

- Tsao, C.C.; Liou, J.U.; Wen, P.H.; Peng, C.C.; Liu, T.S. Study on bending behavior of nickel-titanium rotary endodontic instruments by analytical and numerical analyses. Int. Endod. J. 2013, 46, 379–388. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adorno, C.G.; Yoshioka, T.; Suda, H. Crack initiation on the apical root surface caused by three different nickel-titanium rotary files at different working lengths. J. Endod. 2011, 37, 522–525. [Google Scholar] [CrossRef]

- Liu, R.; Kaiwar, A.; Shemesh, H.; Wesselink, P.R.; Hou, B.; Wu, M.K. Incidence of apical root cracks and apical dentinal detachments after canal preparation with hand and rotary files at different instrumentation lengths. J. Endod. 2013, 39, 129–132. [Google Scholar] [CrossRef] [PubMed]

- Peters, O.A.; Schönenberger, K.; Laib, A. Effects of four Ni-Ti preparation techniques on root canal geometry assessed by micro computed tomography. Int. Endod. J. 2001, 34, 221–230. [Google Scholar] [CrossRef]

- Berutti, E.; Cantatore, G.; Castellucci, A.; Chiandussi, G.; Pera, F.; Migliaretti, G.; Pasqualini, D. Use of nick- el-titanium rotary PathFile to create the glide path: Comparison with manual preflaring in simulated root canals. J. Endod. 2009, 35, 408–412. [Google Scholar] [CrossRef]

- Pasqualini, D.; Alovisi, M.; Cemenasco, A.; Mancini, L.; Paolino, D.S.; Bianchi, C.C.; Roggia, A.; Scotti, N.; Berutti, E. Micro-Computed Tomography Evaluation of ProTaper Next and BioRace Shaping Outcomes in Maxillary First Molar Curved Canals. J. Endod. 2015, 41, 1706–1710. [Google Scholar] [CrossRef]

- Yoshimine, Y.; Ono, M.; Akamine, A. The shaping effects of three nickel-titanium rotary instruments in simulated S-shaped canals. J. Endod. 2005, 31, 373–375. [Google Scholar] [CrossRef]

| Material Parameter | Values |

|---|---|

| E (Young’s modulus) | 60,000 |

| σASS (austenite-martensite, starting stress) | 520 |

| σASF (austenite-martensite, final stress) | 600 |

| σSAS (martensite-austenite, starting stress) | 300 |

| σSAF (martensite-austenite, final stress) | 200 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carpegna, G.; Alovisi, M.; Paolino, D.S.; Marchetti, A.; Gibello, U.; Scotti, N.; Pasqualini, D.; Scattina, A.; Chiandussi, G.; Berutti, E. Evaluation of Pressure Distribution against Root Canal Walls of NiTi Rotary Instruments by Finite Element Analysis. Appl. Sci. 2020, 10, 2981. https://doi.org/10.3390/app10082981

Carpegna G, Alovisi M, Paolino DS, Marchetti A, Gibello U, Scotti N, Pasqualini D, Scattina A, Chiandussi G, Berutti E. Evaluation of Pressure Distribution against Root Canal Walls of NiTi Rotary Instruments by Finite Element Analysis. Applied Sciences. 2020; 10(8):2981. https://doi.org/10.3390/app10082981

Chicago/Turabian StyleCarpegna, Giorgia, Mario Alovisi, Davide Salvatore Paolino, Andrea Marchetti, Umberto Gibello, Nicola Scotti, Damiano Pasqualini, Alessandro Scattina, Giorgio Chiandussi, and Elio Berutti. 2020. "Evaluation of Pressure Distribution against Root Canal Walls of NiTi Rotary Instruments by Finite Element Analysis" Applied Sciences 10, no. 8: 2981. https://doi.org/10.3390/app10082981

APA StyleCarpegna, G., Alovisi, M., Paolino, D. S., Marchetti, A., Gibello, U., Scotti, N., Pasqualini, D., Scattina, A., Chiandussi, G., & Berutti, E. (2020). Evaluation of Pressure Distribution against Root Canal Walls of NiTi Rotary Instruments by Finite Element Analysis. Applied Sciences, 10(8), 2981. https://doi.org/10.3390/app10082981