Adaptive Robust Force Position Control for Flexible Active Prosthetic Knee Using Gait Trajectory

Abstract

Featured Application

Abstract

1. Introduction

- A novel APK with a variable stiffness actuator (VSA), which can provide the ability to adjust joint stiffness depending on the different gaits, is proposed.

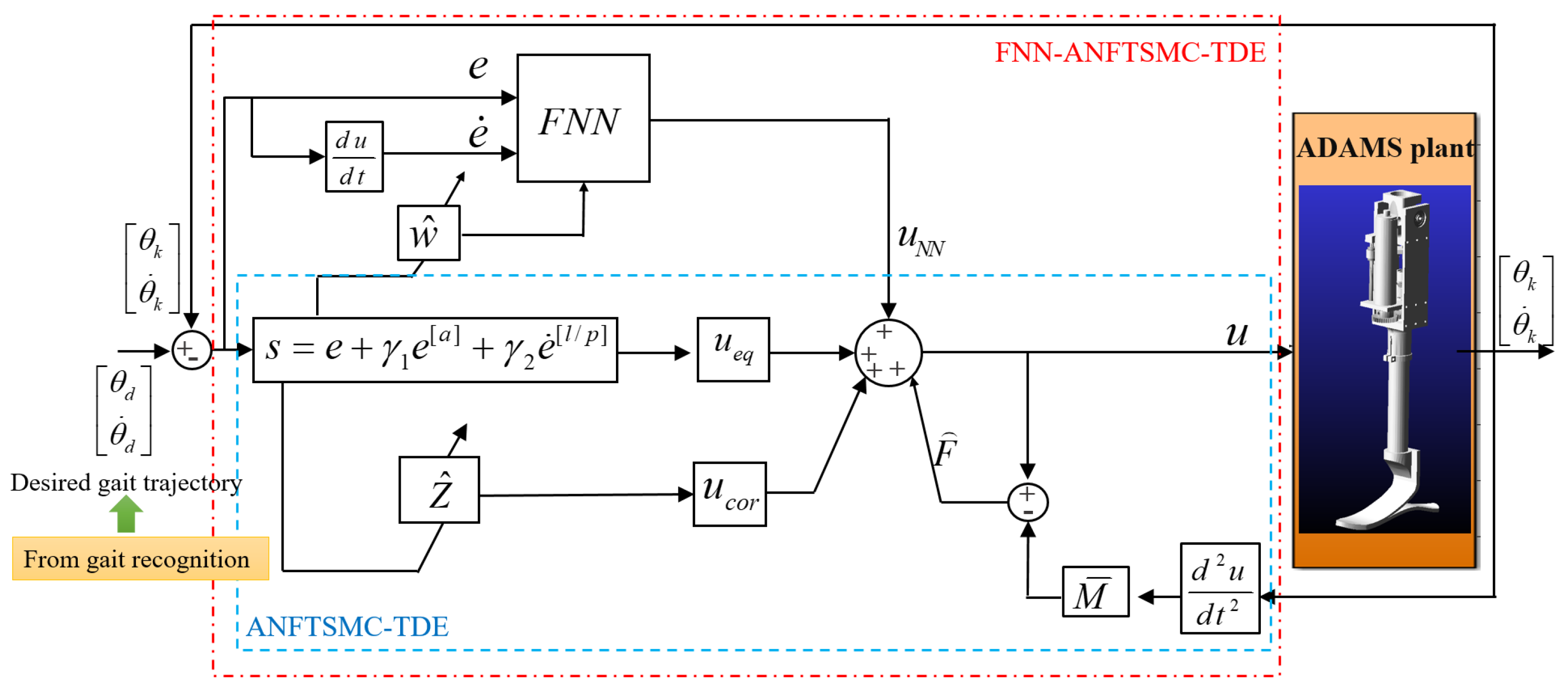

- An adaptive robust force/position controller for flexible APK by using the TDE technique combined with adaptive nonsingular fast terminal sliding mode control and fuzzy neural network is proposed.

- The stability analysis of the control system by Lyapunov stability theory is carried out, and some demonstrations using the virtual prototype illustrate the effectiveness of the proposed algorithm.

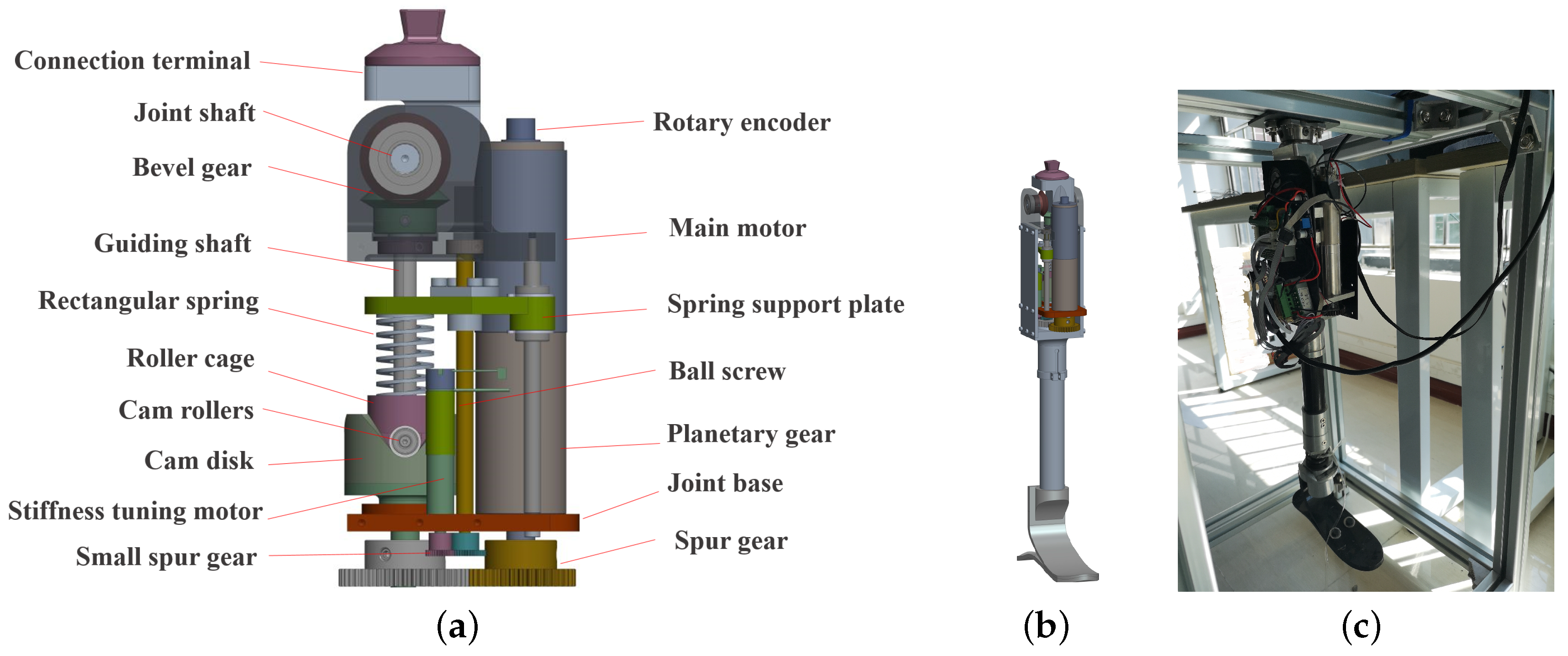

2. Design of APK with VSA

3. Dynamics Model of the APK Joint with VSA

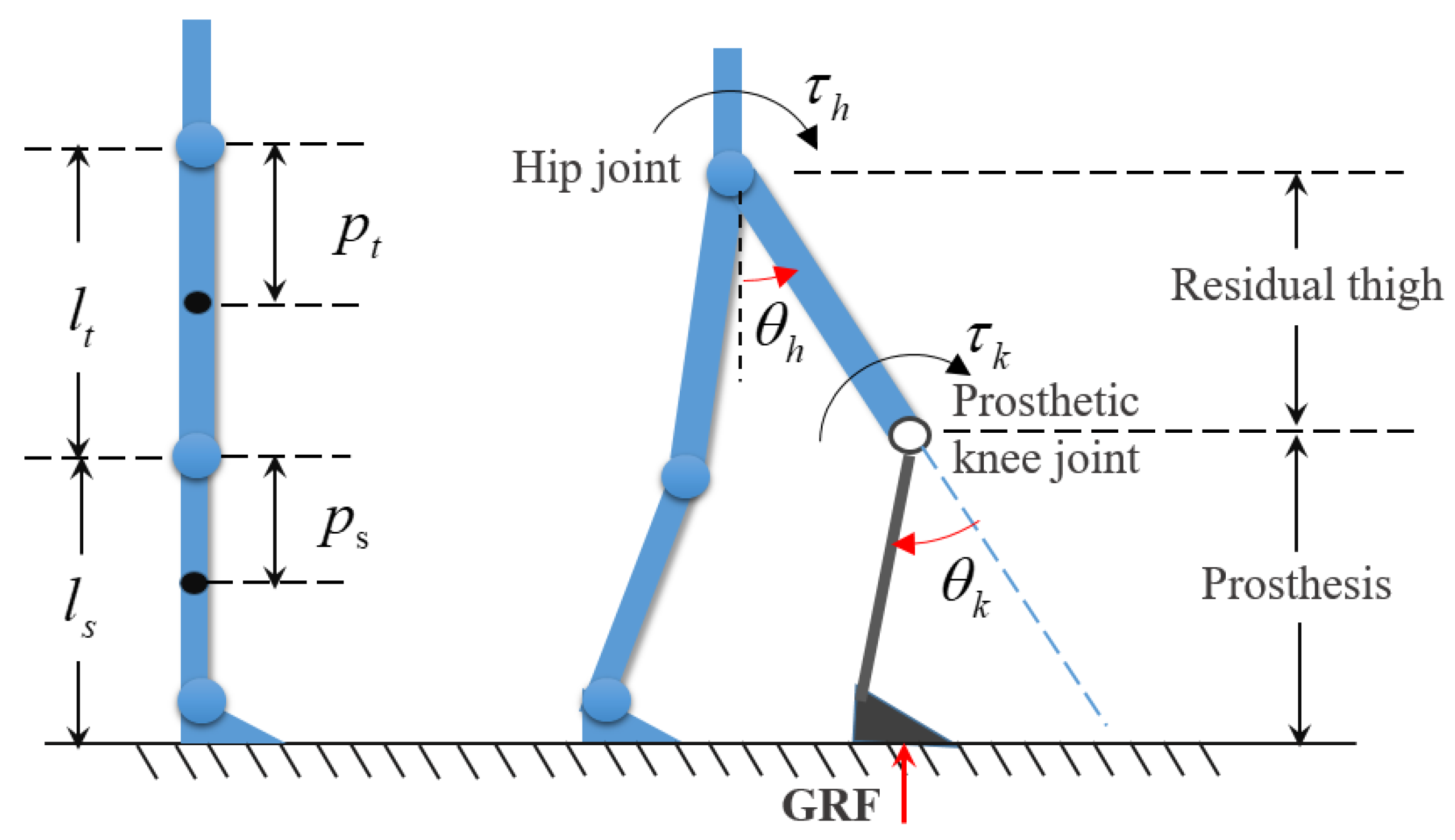

3.1. Dynamic Model of Human–Machine Hybrid System

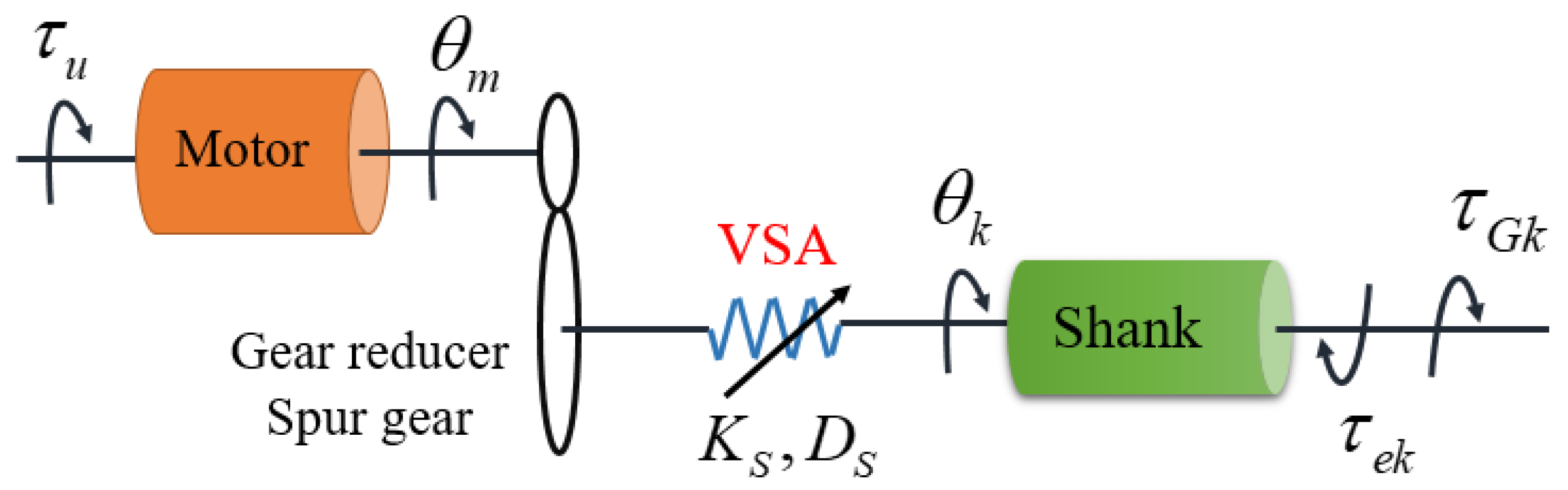

3.2. Dynamic Model of the APK Joint

4. Adaptive Robust Model Free Control

4.1. System Problem Description

4.2. Design of Control Based on ANFTSMC

4.3. Adaptive Fuzzy Neural Network Compensator

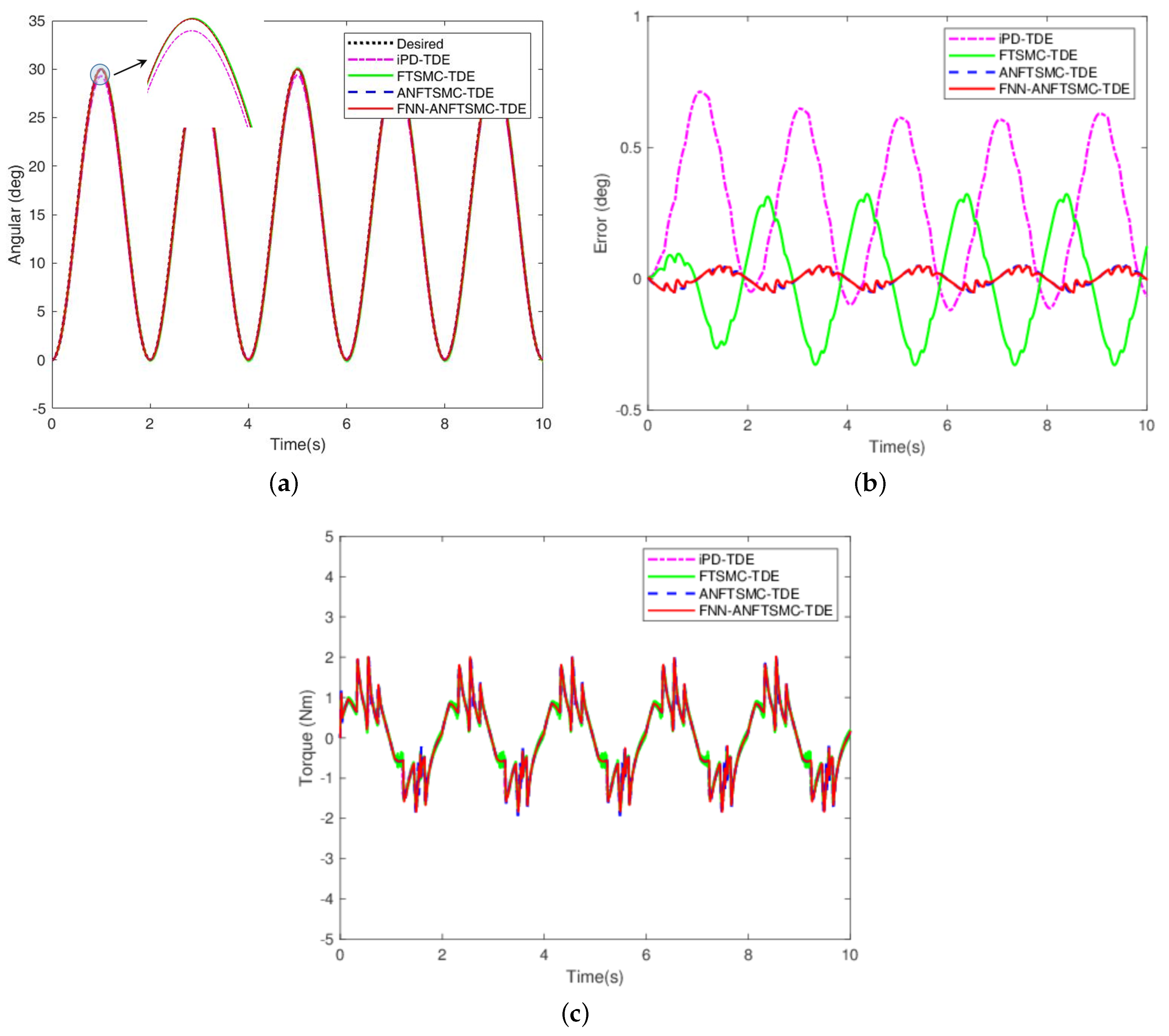

4.4. Simulation Setup

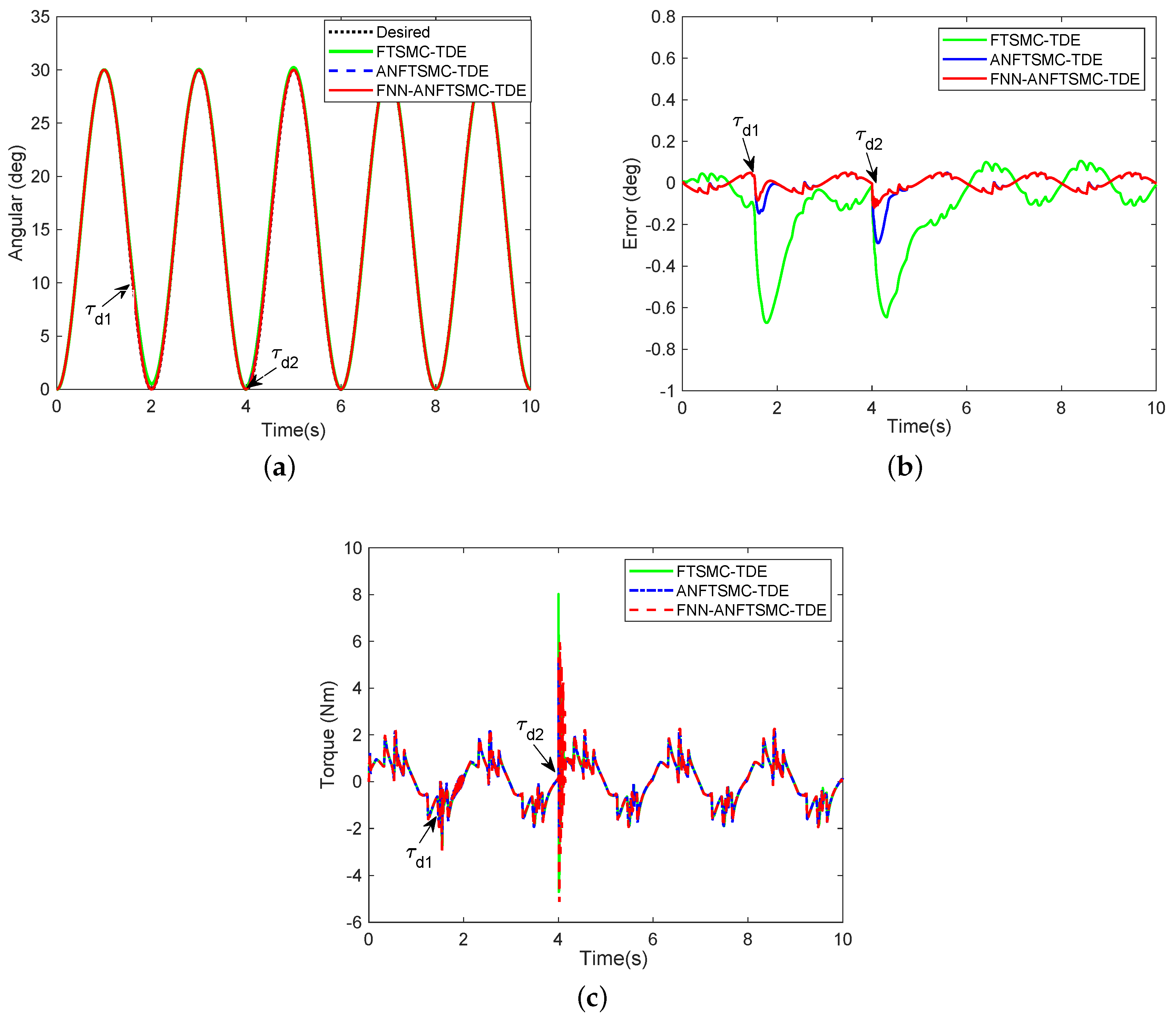

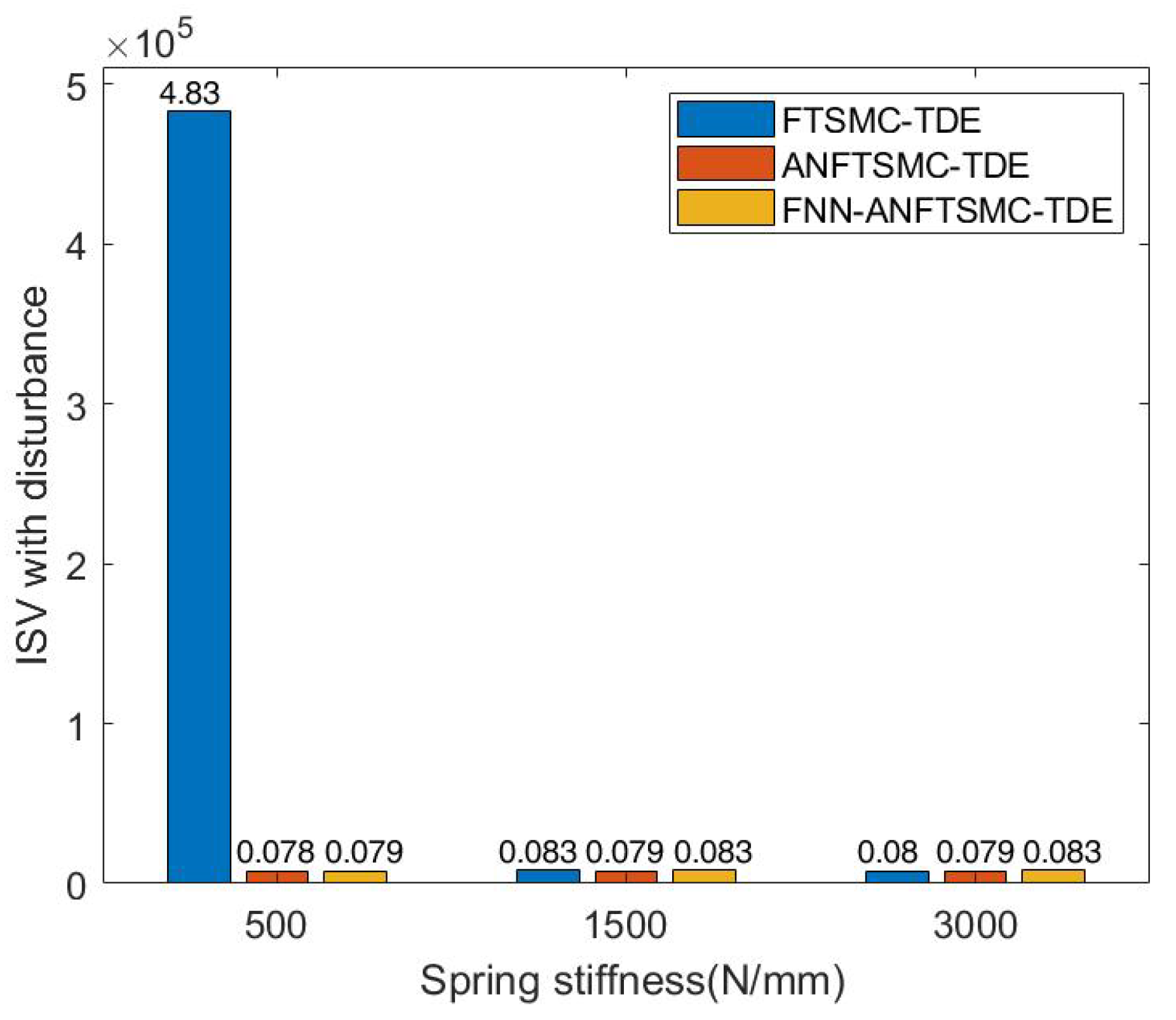

4.5. Robustness Verification

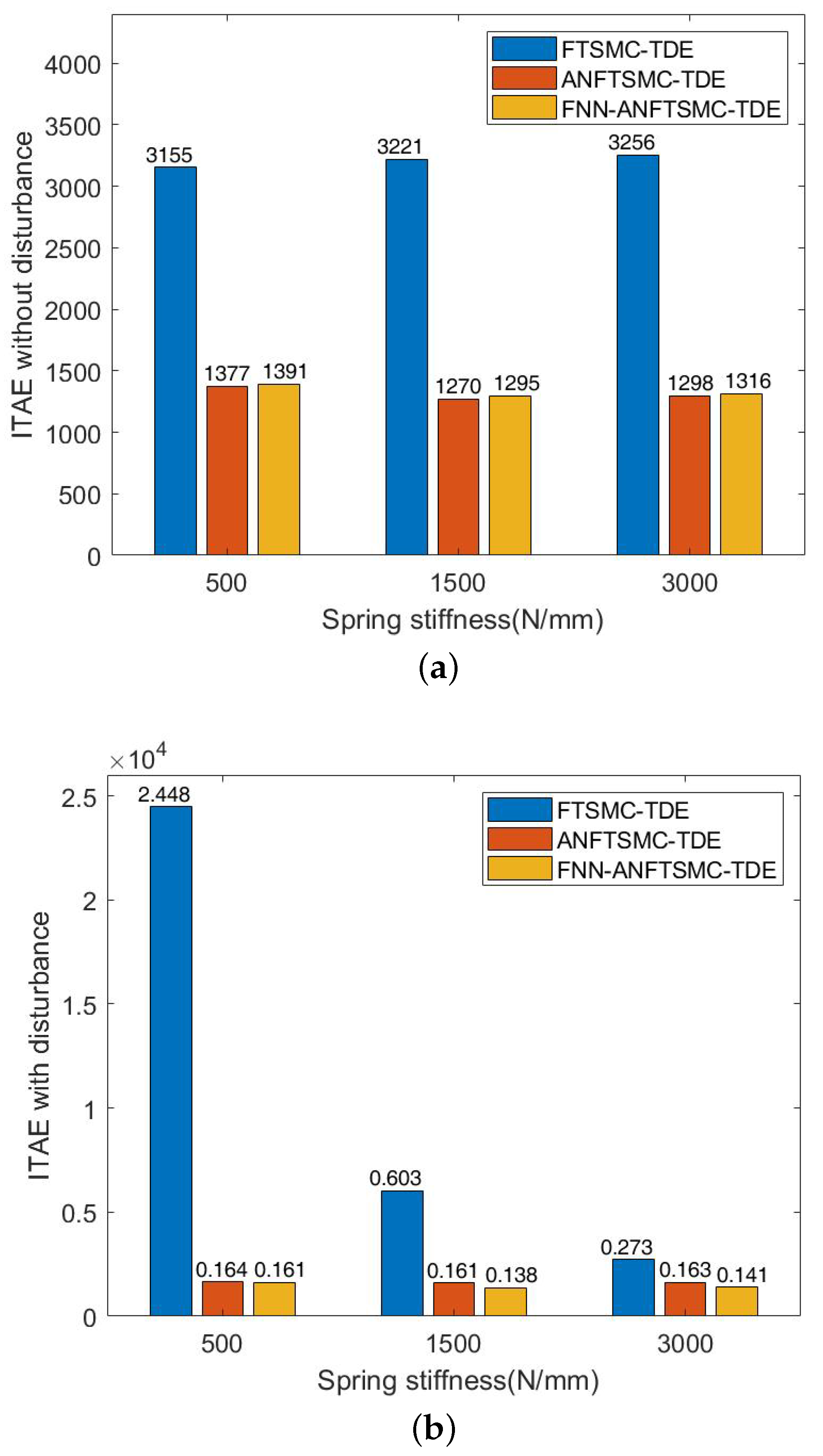

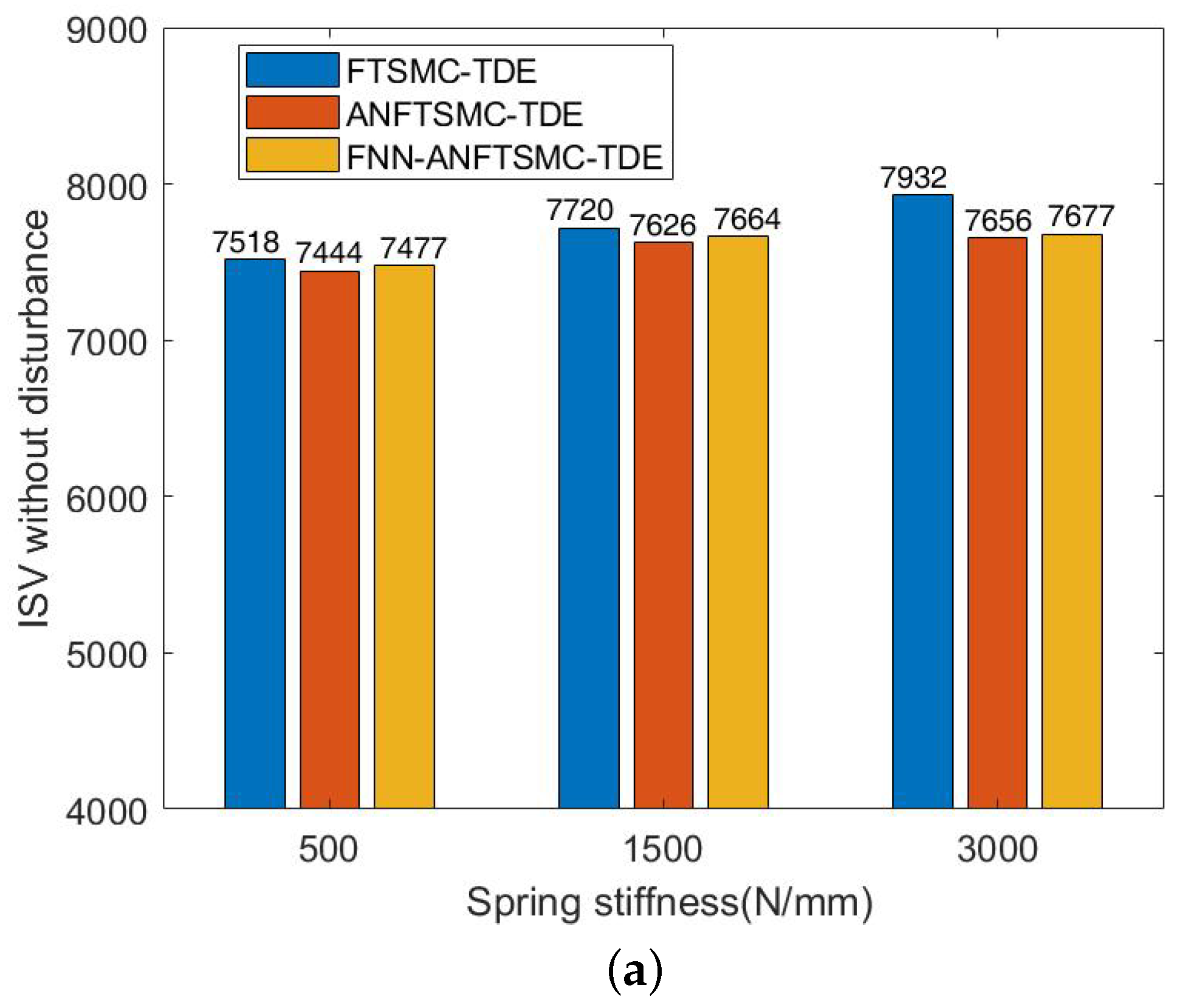

4.6. Performance Analysis

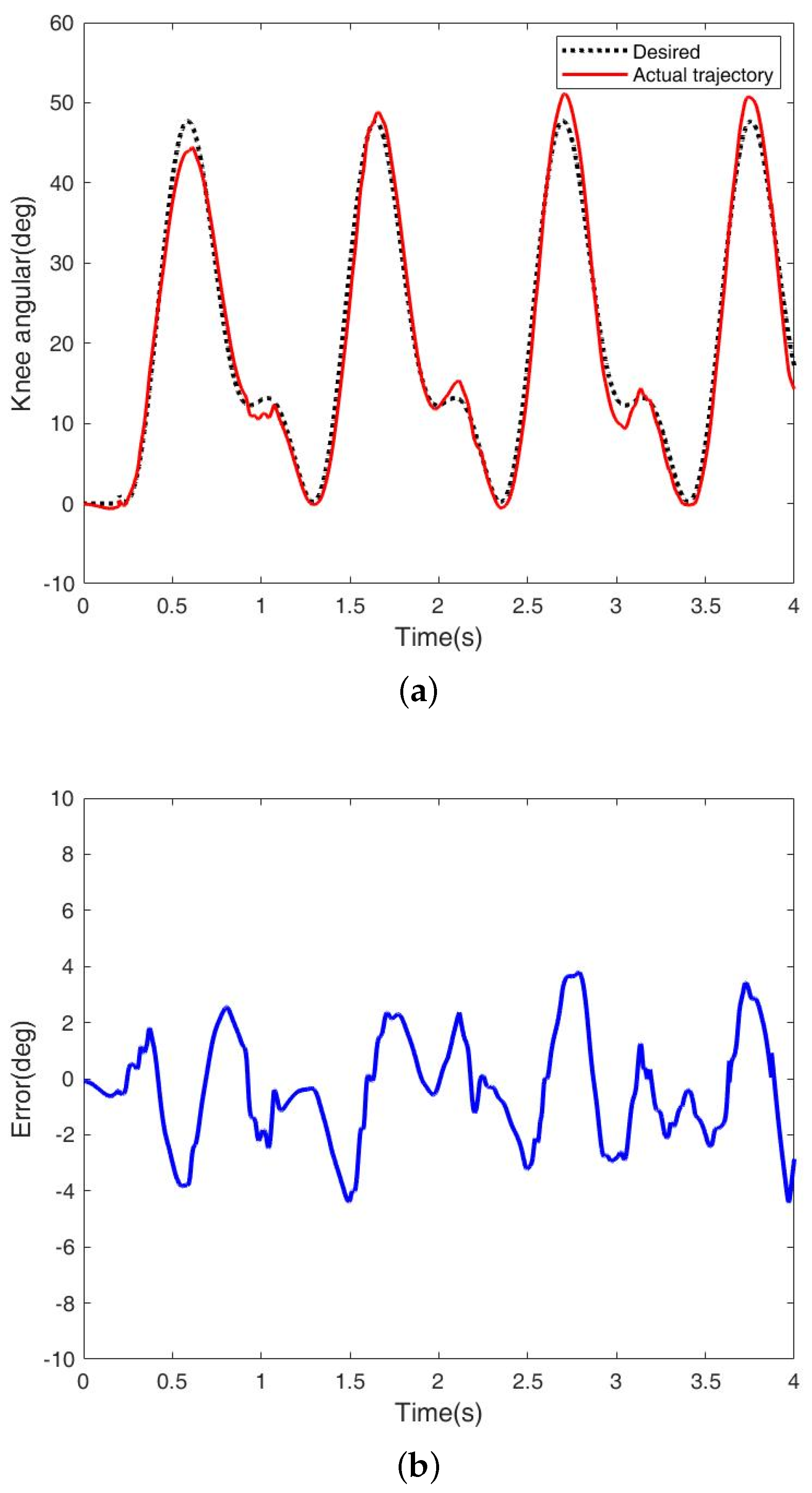

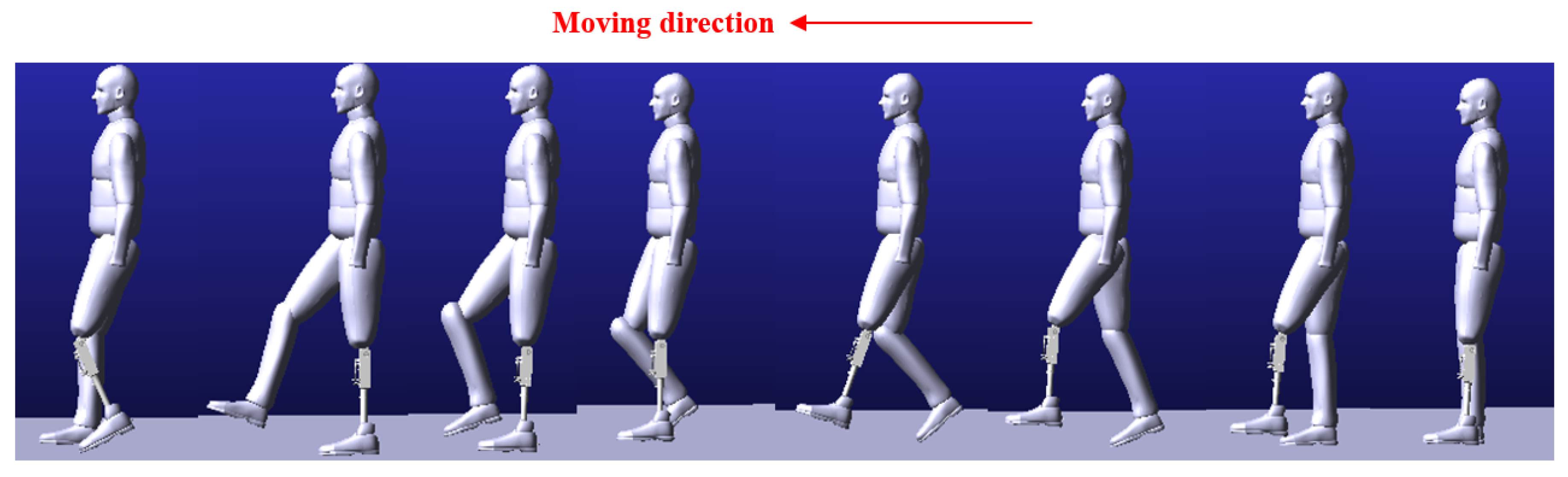

4.7. Human–Machine Hybrid Simulation

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zhang, X.; Li, J.; Hu, Z.; Qi, W.; Zhang, L.; Hu, Y.; Su, H.; Ferrigno, G.; Momi, E.D. Novel Design and Lateral Stability Tracking Control of a Four-Wheeled Rollator. Appl. Sci. 2019, 9, 2327. [Google Scholar] [CrossRef]

- Tucker, M.R.; Olivier, J.; Pagel, A.; Bleuler, H.; Bouri, M.; Lambercy, O.; Millán, J.d.R.; Riener, R.; Vallery, H.; Gassert, R. Control strategies for active lower extremity prosthetics and orthotics: A review. J. NeuroEng. Rehabil. 2015, 12, 1. [Google Scholar] [CrossRef]

- Li, Z.; Huang, B.; Ajoudani, A.; Yang, C.; Su, C.Y.; Bicchi, A. Asymmetric bimanual control of dual-arm exoskeletons for human-cooperative manipulations. IEEE Trans. Robot. 2017, 34, 264–271. [Google Scholar] [CrossRef]

- Azimi, V.; Abolfazl Fakoorian, S.; Tien Nguyen, T.; Simon, D. Robust Adaptive Impedance Control With Application to a Transfemoral Prosthesis and Test Robot. J. Dyn. Syst. Meas. Control 2018, 140, 121002. [Google Scholar] [CrossRef]

- Li, Z.; Huang, B.; Ye, Z.; Deng, M.; Yang, C. Physical Human–Robot Interaction of a Robotic Exoskeleton by Admittance Control. IEEE Trans. Ind. Electron. 2018, 65, 9614–9624. [Google Scholar] [CrossRef]

- Li, Z.; Yuan, Y.; Luo, L.; Su, W.; Zhao, K.; Xu, C.; Huang, J.; Pi, M. Hybrid brain/muscle signals powered wearable walking exoskeleton enhancing motor ability in climbing stairs activity. IEEE Trans. Med Robot. Bionics 2019, 1, 218–227. [Google Scholar] [CrossRef]

- Hoover, C.D.; Fulk, G.D.; Fite, K.B. The Design and Initial Experimental Validation of an Active Myoelectric Transfemoral Prosthesis. J. Med. Devices 2012, 6, 011005. [Google Scholar] [CrossRef]

- Gregg, R.D.; Lenzi, T.; Hargrove, L.J.; Sensinger, J.W. Virtual Constraint Control of a Powered Prosthetic Leg: From Simulation to Experiments With Transfemoral Amputees. IEEE Trans. Robot. 2014, 30, 1455–1471. [Google Scholar] [CrossRef]

- Li, Z.; Su, C.Y.; Li, G.; Su, H. Fuzzy approximation-based adaptive backstepping control of an exoskeleton for human upper limbs. IEEE Trans. Fuzzy Syst. 2014, 23, 555–566. [Google Scholar] [CrossRef]

- Sup, F.; Bohara, A.; Goldfarb, M. Design and Control of a Powered Transfemoral Prosthesis. Int. J. Robot. Res. 2008, 27, 263–273. [Google Scholar] [CrossRef]

- Lawson, B.E.; Mitchell, J.; Truex, D.; Shultz, A.; Ledoux, E.; Goldfarb, M. A Robotic Leg Prosthesis: Design, Control, and Implementation. IEEE Robot. Autom. Mag. 2014, 21, 70–81. [Google Scholar] [CrossRef]

- Ahn, H.J.; Lee, K.H.; Lee, C.H. Design optimization of a knee joint for an active transfemoral prosthesis for weight reduction. J. Mech. Sci. Technol. 2017, 31, 5905–5913. [Google Scholar] [CrossRef]

- Martinez-Villalpando, E.C.; Hugh, H. Agonist-antagonist active knee prosthesis: A preliminary study in level-ground walking. J. Rehabil. Res. Dev. 2009, 46, 361–373. [Google Scholar] [CrossRef]

- Rouse, E.J.; Mooney, L.M.; Herr, H.M. Clutchable series-elastic actuator: Implications for prosthetic knee design. Int. J. Robot. Res. 2014, 33, 1611–1625. [Google Scholar] [CrossRef]

- Geeroms, J.; Flynn, L.; Jimenez-Fabian, R.; Vanderborght, B.; Lefeber, D. Design and energetic evaluation of a prosthetic knee joint actuator with a lockable parallel spring. Bioinspir. Biomimetics 2017, 12, 026002. [Google Scholar] [CrossRef]

- Zhang, X.; Li, J.; Fan, K.; Chen, Z.; Hu, Z.; Yu, Y. Neural Approximation Enhanced Predictive Tracking Control of a Novel Designed Four-Wheeled Rollator. Appl. Sci. 2020, 10, 125. [Google Scholar] [CrossRef]

- Su, H.; Yang, C.; Mdeihly, H.; Rizzo, A.; Ferrigno, G.; De Momi, E. Neural Network Enhanced Robot Tool Identification and Calibration for Bilateral Teleoperation. IEEE Access 2019, 7, 122041–122051. [Google Scholar] [CrossRef]

- Zhang, X.; Li, J.; Ovur, S.E.; Chen, Z.; Li, X.; Hu, Z.; Hu, Y. Novel Design and Adaptive Fuzzy Control of a Lower-Limb Elderly Rehabilitation. Electronics 2020, 9, 343. [Google Scholar] [CrossRef]

- Stoeffler, C.; Kumar, S.; Peters, H.; Brüls, O.; Müller, A.; Kirchner, F. Conceptual Design of a Variable Stiffness Mechanism in a Humanoid Ankle using Parallel Redundant Actuation. In Proceedings of the 2018 IEEE-RAS 18th International Conference on Humanoid Robots (Humanoids), Beijing, China, 6–9 November 2018; pp. 462–468. [Google Scholar]

- Wang, B.; Wang, J.; Wang, S.; Li, J. Parallel Structure of Six Wheel-legged Robot Model Predictive Tracking Control based on Dynamic Model. In Proceedings of the 2019 Chinese Automation Congress (CAC), Hangzhou, China, 22–24 November 2019; pp. 5143–5148. [Google Scholar]

- Liu, Z.; Lin, W.; Geng, Y.; Yang, P. Intent pattern recognition of lower-limb motion based on mechanical sensors. IEEE/CAA J. Autom. Sin. 2017, 4, 651–660. [Google Scholar] [CrossRef]

- Peng, F.; Peng, W.; Zhang, C.; Zhong, D. IoT Assisted Kernel Linear Discriminant Analysis Based Gait Phase Detection Algorithm for Walking with Cognitive Tasks. IEEE Access 2019, 7, 68240–68249. [Google Scholar] [CrossRef]

- Qi, W.; Su, H.; Yang, C.; Ferrigno, G.; De Momi, E.; Aliverti, A. A Fast and Robust Deep Convolutional Neural Networks for Complex Human Activity Recognition Using Smartphone. Sensors 2019, 19, 3731. [Google Scholar] [CrossRef]

- Su, H.; Qi, W.; Hu, Y.; Sandoval, J.; Zhang, L.; Schmirander, Y.; Chen, G.; Aliverti, A.; Knoll, A.; Ferrigno, G.; et al. Towards Model-Free Tool Dynamic Identification and Calibration Using Multi-Layer Neural Network. Sensors 2019, 19, 3636. [Google Scholar] [CrossRef]

- Youcef-Toumi, K.; Ito, O. A Time Delay Controller for Systems with Unknown Dynamics. In Proceedings of the 1988 American Control Conference, Atlanta, GA, USA, 15–17 June 1988; pp. 904–913. [Google Scholar]

- Jin, M.; Lee, J.; Tsagarakis, N.G. Model-Free Robust Adaptive Control of Humanoid Robots with Flexible Joints. IEEE Trans. Ind. Electron. 2017, 64, 1706–1715. [Google Scholar] [CrossRef]

- Li, Z.; Li, J.; Zhao, S.; Yuan, Y.; Kang, Y.; Chen, C.P. Adaptive neural control of a kinematically redundant exoskeleton robot using brain-machine interfaces. IEEE Trans. Neural Networks Learn. Syst. 2018, 30, 3558–3571. [Google Scholar] [CrossRef]

- Jin, M.; Lee, J.; Chang, P.H.; Choi, C. Practical Nonsingular Terminal Sliding-Mode Control of Robot Manipulators for High-Accuracy Tracking Control. IEEE Trans. Ind. Electron. 2009, 56, 3593–3601. [Google Scholar]

- Van, M.; Ge, S.S.; Ren, H. Finite Time Fault Tolerant Control for Robot Manipulators Using Time Delay Estimation and Continuous Nonsingular Fast Terminal Sliding Mode Control. IEEE Trans. Cybern. 2017, 47, 1681–1693. [Google Scholar] [CrossRef]

- Su, H.; Qi, W.; Yang, C.; Aliverti, A.; Ferrigno, G.; De Momi, E. Deep Neural Network approach in Human-Like Redundancy Optimization for Anthropomorphic Manipulators. IEEE Access 2019, 7, 124207–124216. [Google Scholar] [CrossRef]

- Su, H.; Ovur, S.E.; Zhou, X.; Qi, W.; Ferrigno, G.; De Momi, E. Depth vision guided hand gesture recognition using electromyographic signals. Adv. Robot. 2020, 1–13. [Google Scholar] [CrossRef]

- Chang, J.L. Sliding mode control design for mismatched uncertain systems using output feedback. Int. J. Control. Autom. Syst. 2016, 14, 579–586. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, J.; Zhu, K.; Chen, B.; Wu, H. Time-Delay Control of Cable-Driven Robots with Adaptive Fractional-Order Nonsingular Terminal Sliding Mode. IEEE Access 2018, 6, 54086–54096. [Google Scholar] [CrossRef]

- Ham, R.V.; Sugar, T.G.; Vanderborght, B.; Hollander, K.W.; Lefeber, D. Compliant actuator designs. IEEE Robot. Autom. Mag. 2009, 16, 81–94. [Google Scholar] [CrossRef]

- Li, X.; Pan, Y.; Chen, G.; Yu, H. Multi-modal control scheme for rehabilitation robotic exoskeletons. Int. J. Robot. Res. 2017, 36, 759–777. [Google Scholar] [CrossRef]

- Liang, P.; Yang, C.; Wang, N.; Li, Z.; Li, R.; Burdet, E. Implementation and Test of Human-Operated and Human-Like Adaptive Impedance Controls on Baxter Robot; Advances in Autonomous Robotics Systems; Springer International Publishing: Cham, Switzerland, 2014; pp. 109–119. [Google Scholar]

- Veneman, J.F.; Ekkelenkamp, R.; Kruidhof, R.; van der Helm, F.C.; van der Kooij, H. A Series Elastic- and Bowden-Cable-Based Actuation System for Use as Torque Actuator in Exoskeleton-Type Robots. Int. J. Robot. Res. 2006, 25, 261–281. [Google Scholar] [CrossRef]

- Wolf, S.; Hirzinger, G. A new variable stiffness design: Matching requirements of the next robot generation. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 1741–1746. [Google Scholar]

- Li, Z.; Xu, C.; Wei, Q.; Shi, C.; Su, C.Y. Human-Inspired Control of Dual-Arm Exoskeleton Robots with Force and Impedance Adaptation. IEEE Trans. Syst. Man Cybern. Syst. 2018. [Google Scholar] [CrossRef]

- Precup, R.E.; Radac, M.B.; Roman, R.C.; Petriu, E.M. Model-free sliding mode control of nonlinear systems: Algorithms and experiments. Inf. Sci. 2017, 381, 176–192. [Google Scholar] [CrossRef]

- Yang, L.; Yang, J. Nonsingular fast terminal sliding-mode control for nonlinear dynamical systems. Int. J. Robust Nonlinear Control 2011, 21, 1865–1879. [Google Scholar] [CrossRef]

- Lee, J.; Chang, P.H.; Jin, M. Adaptive Integral Sliding Mode Control With Time-Delay Estimation for Robot Manipulators. IEEE Trans. Ind. Electron. 2017, 64, 6796–6804. [Google Scholar] [CrossRef]

- Rouhani, E.; Erfanian, A. A Finite-time Adaptive Fuzzy Terminal Sliding Mode Control for Uncertain Nonlinear Systems. Int. J. Control. Autom. Syst. 2018, 16, 1938–1950. [Google Scholar] [CrossRef]

- Fliess, M.; Join, C. Model-free control. Int. J. Control 2013, 86, 2228–2252. [Google Scholar] [CrossRef]

- Jin, M.; Lee, J.; Ahn, K.K. Continuous Nonsingular Terminal Sliding-Mode Control of Shape Memory Alloy Actuators Using Time Delay Estimation. IEEE/ASME Trans. Mechatronics 2015, 20, 899–909. [Google Scholar] [CrossRef]

- Viveiros, C.; Melicio, R.; Igreja, J.; Mendes, V. Performance Assessment of a Wind Turbine Using Benchmark Model: Fuzzy Controllers and Discrete Adaptive LQG. Procedia Technol. 2014, 17, 487–494. [Google Scholar] [CrossRef][Green Version]

| Parameter | Value |

|---|---|

| Maximum knee torque | 87 Nm |

| Range of motion | ∼ |

| Range of length | 48∼52 cm |

| Total mass | ≤2.3 kg |

| Parameter (Equation) | iPD-TDE | FTSMC -TDE | ANFTSMC -TDE | FNN- ANFTSMC -TDE |

|---|---|---|---|---|

| Equation (39) | ||||

| Equation (39) | ||||

| Equation (40) | ||||

| m Equations (12) and (40) | 5 | 5 | 5 | |

| n Equations (12) and (40) | 3 | 3 | 3 | |

| Equation (12) | 10 | 1 | 1 | |

| Equation (12) | 1 | |||

| a Equation (12) | 2 | 2 | ||

| Equation (17) | 20 | 20 | ||

| Equation (25) | ||||

| c Equation (28) | [ 0 1 3; 0 1 3] | |||

| b Equation (28) | ||||

| Equation (34) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, F.; Wen, H.; Zhang, C.; Xu, B.; Li, J.; Su, H. Adaptive Robust Force Position Control for Flexible Active Prosthetic Knee Using Gait Trajectory. Appl. Sci. 2020, 10, 2755. https://doi.org/10.3390/app10082755

Peng F, Wen H, Zhang C, Xu B, Li J, Su H. Adaptive Robust Force Position Control for Flexible Active Prosthetic Knee Using Gait Trajectory. Applied Sciences. 2020; 10(8):2755. https://doi.org/10.3390/app10082755

Chicago/Turabian StylePeng, Fang, Haiyang Wen, Cheng Zhang, Bugong Xu, Jiehao Li, and Hang Su. 2020. "Adaptive Robust Force Position Control for Flexible Active Prosthetic Knee Using Gait Trajectory" Applied Sciences 10, no. 8: 2755. https://doi.org/10.3390/app10082755

APA StylePeng, F., Wen, H., Zhang, C., Xu, B., Li, J., & Su, H. (2020). Adaptive Robust Force Position Control for Flexible Active Prosthetic Knee Using Gait Trajectory. Applied Sciences, 10(8), 2755. https://doi.org/10.3390/app10082755