Kinematic and Dynamic Response of a Novel Engine Mechanism Design Driven by an Oscillation Arm

Abstract

1. Introduction

1.1. Background

1.2. Objective

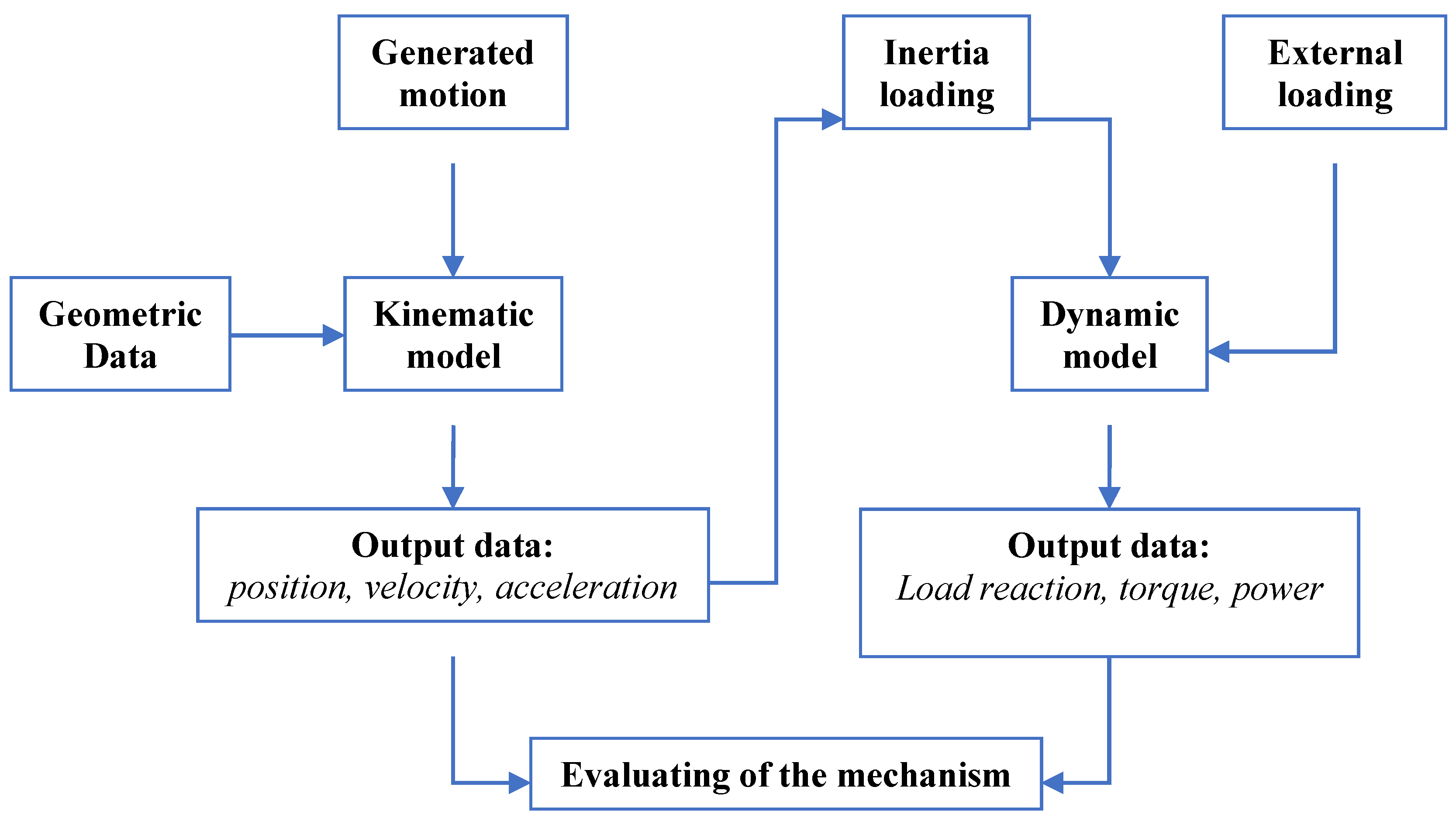

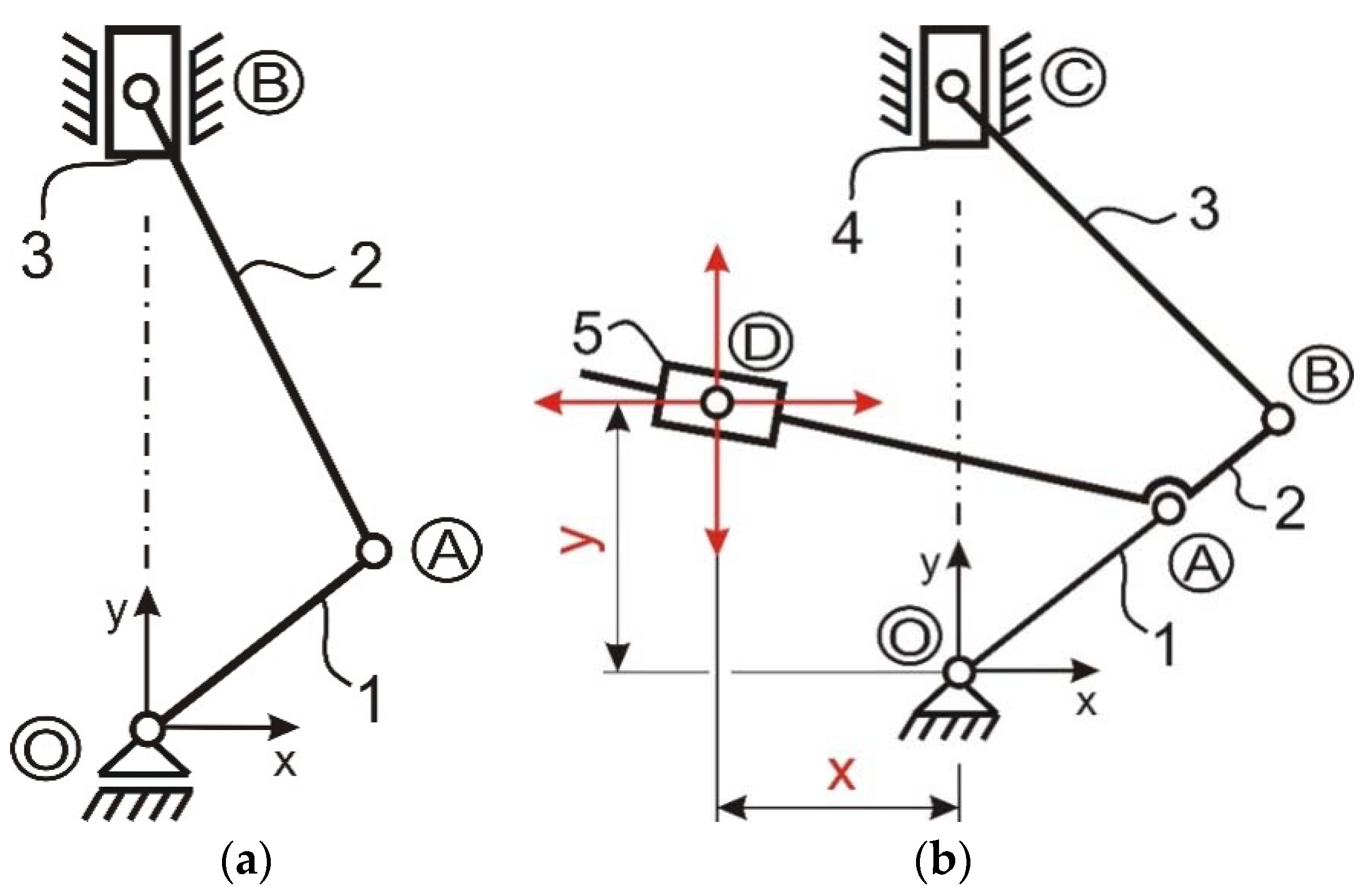

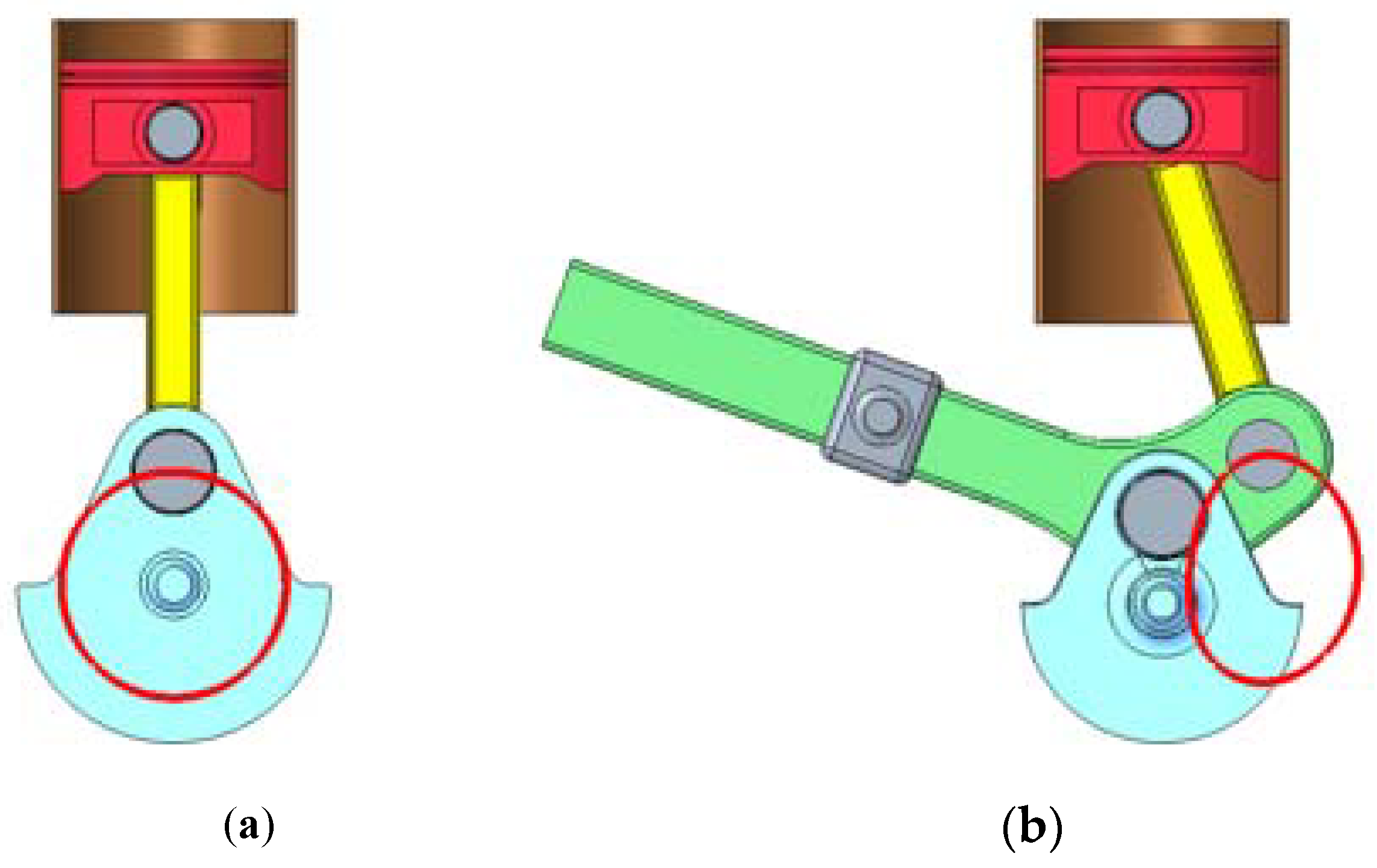

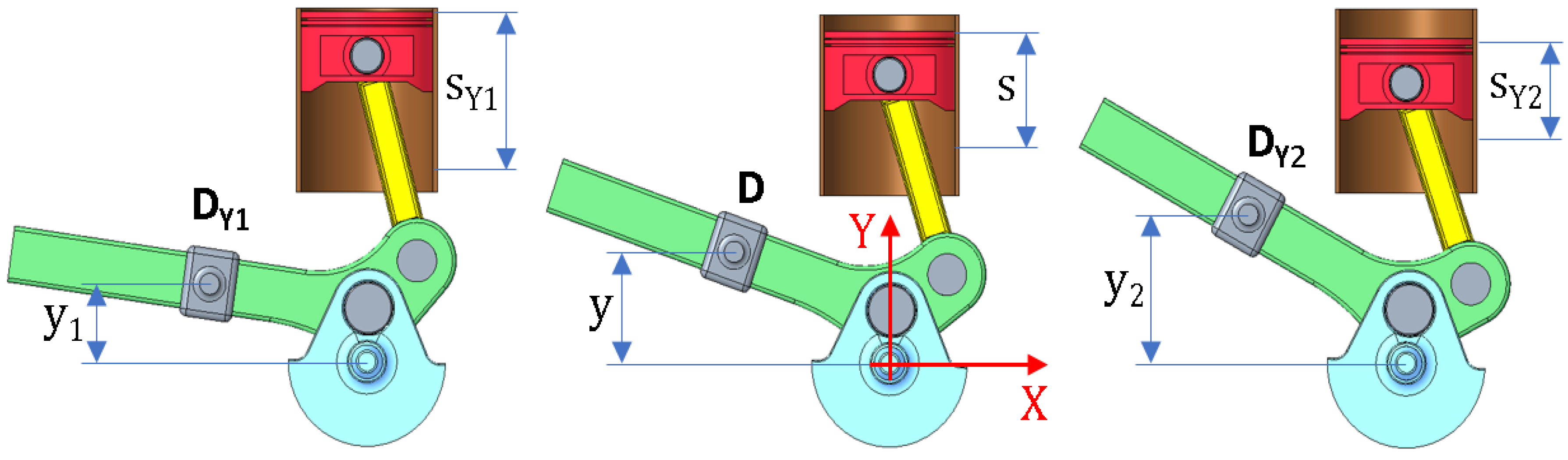

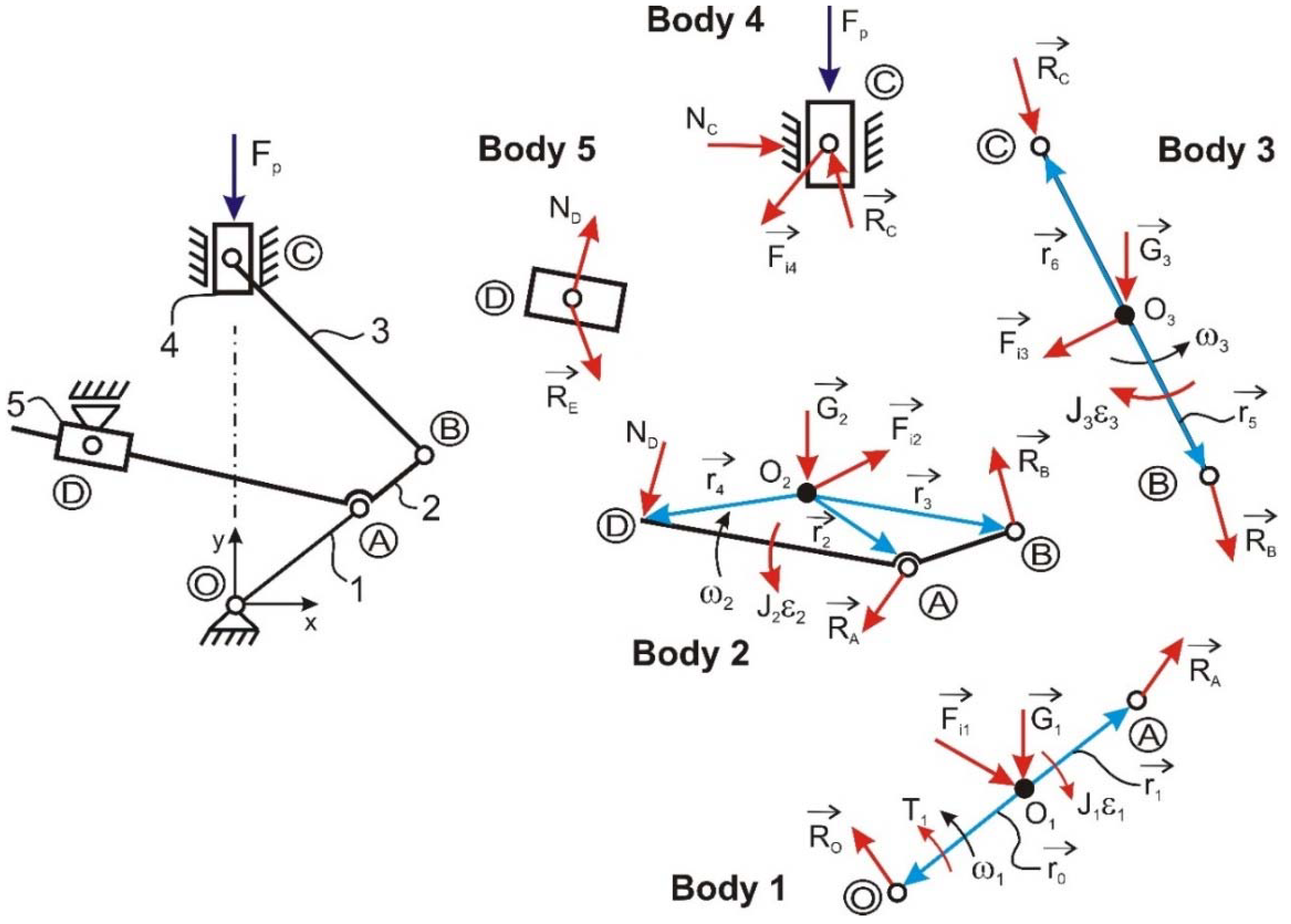

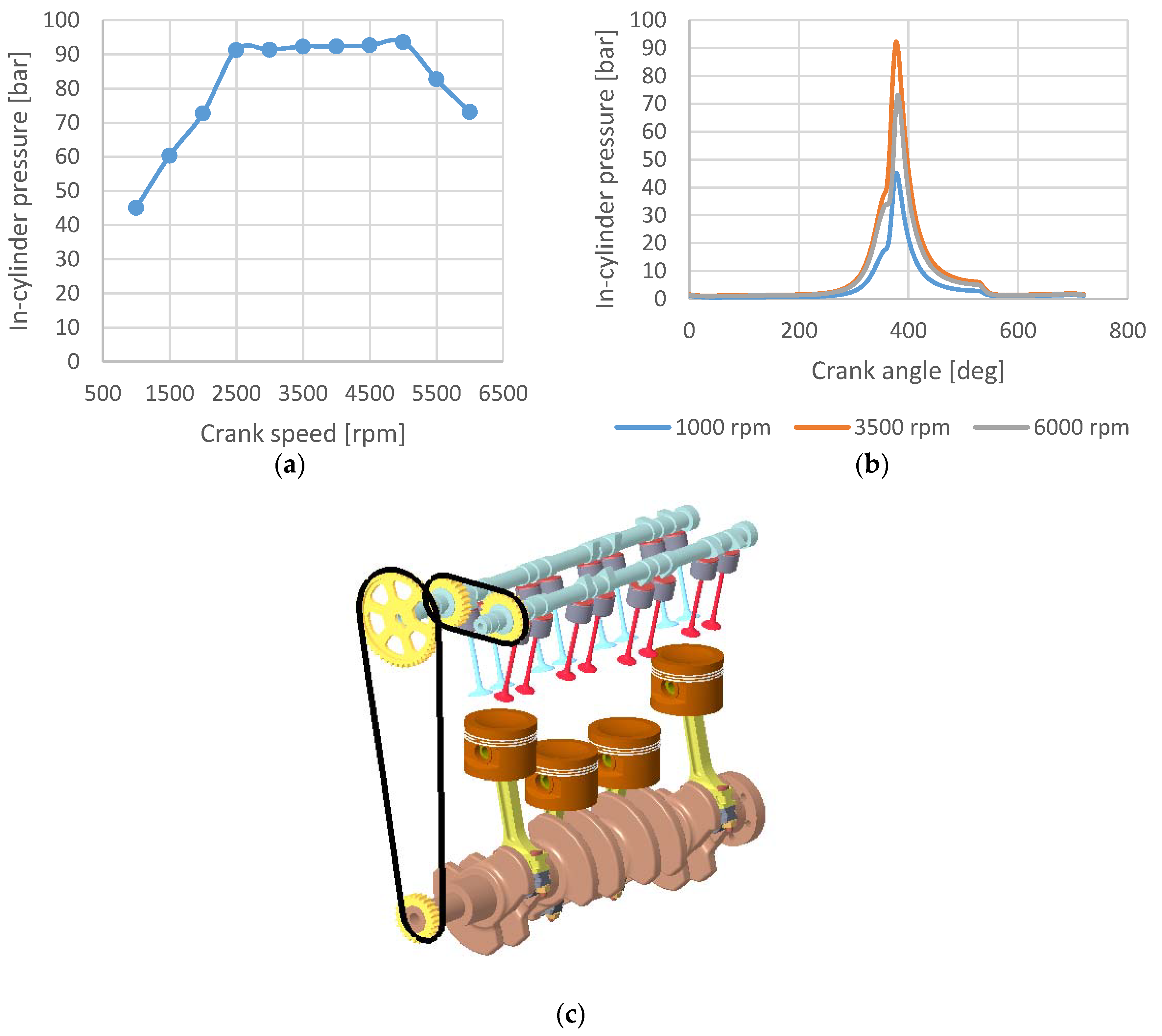

2. Simulation Method

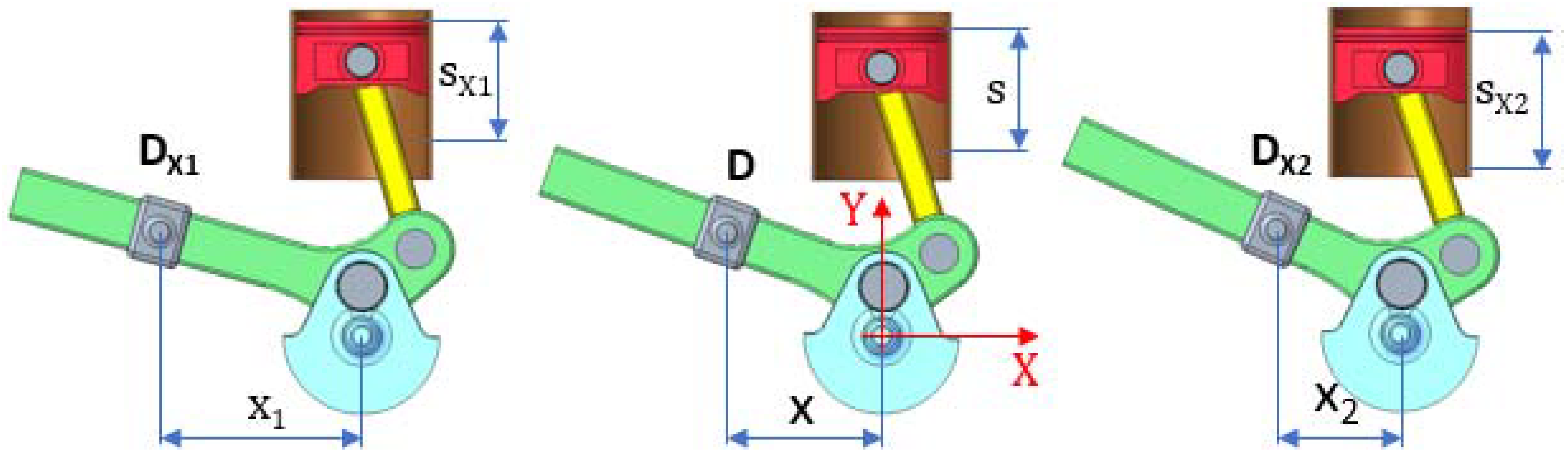

- Ff the bearing joint is moved in the opposite direction with respect to GCS axes, the number “1” is used as a secondary subscript of the letter D; the first subscript indicates the axis direction of the movement takes place;

- In a similar manner, a subscript number “2” will be used if the bearing joint is moved in the positive direction of the GCS axes. In the kinematic analysis, the movable range of pivot point has been considered as +/−40 mm on the horizontal direction and +/−25 mm on the vertical direction.

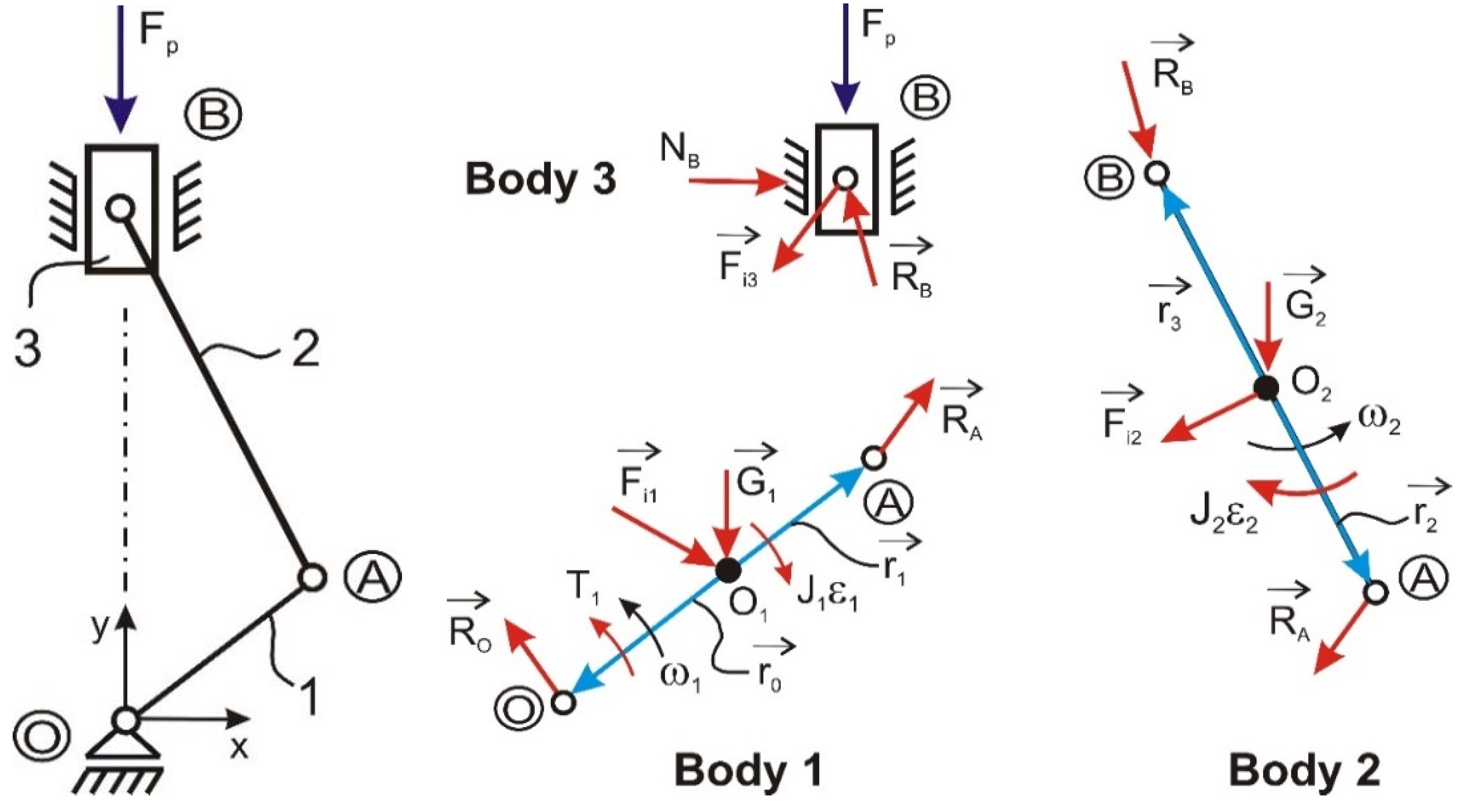

- for translational motion: ;

- for rotational motion: .

3. Conclusions

- ○

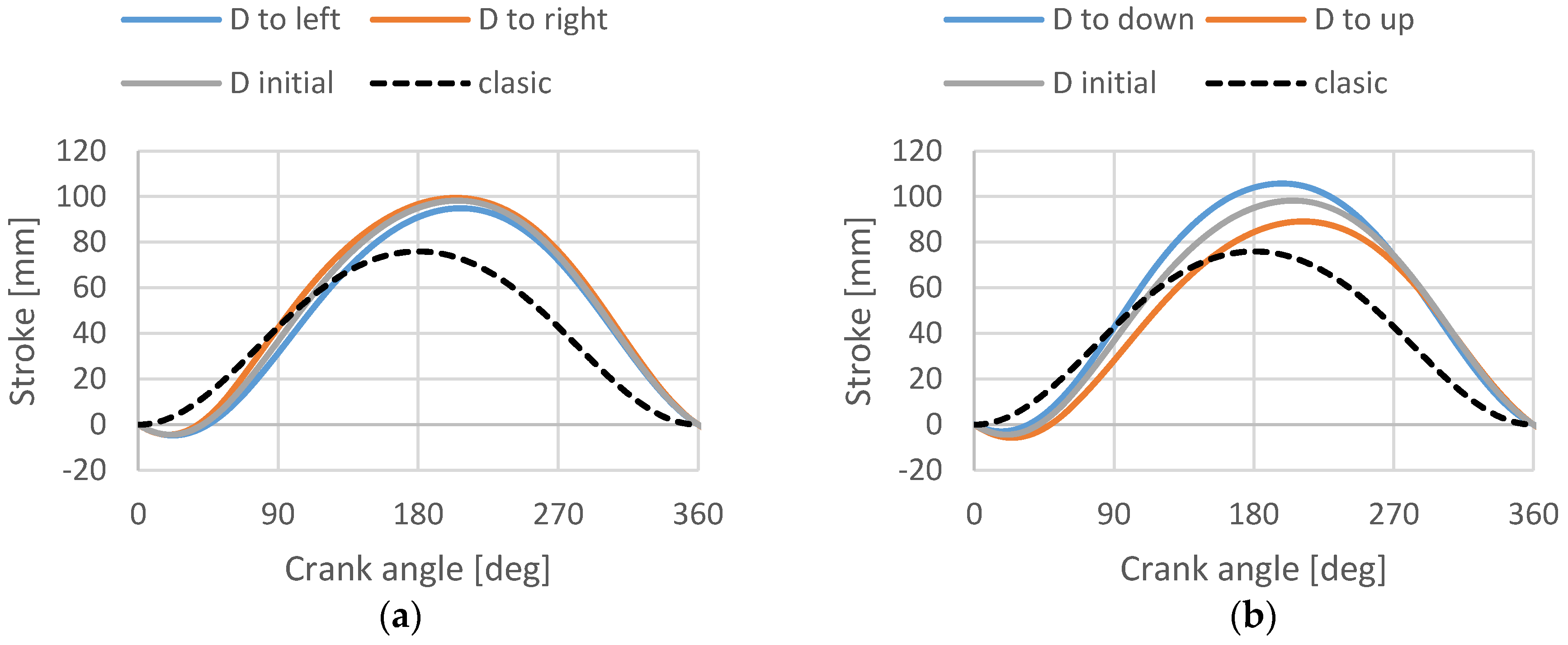

- From a kinematic point of view, an increase of 25% was obtained for piston stroke on the novelty design mechanism compared to the classical one. This increase is due to the oscillating arm included in the configuration of the mechanism between the crankshaft and con-rod.

- ○

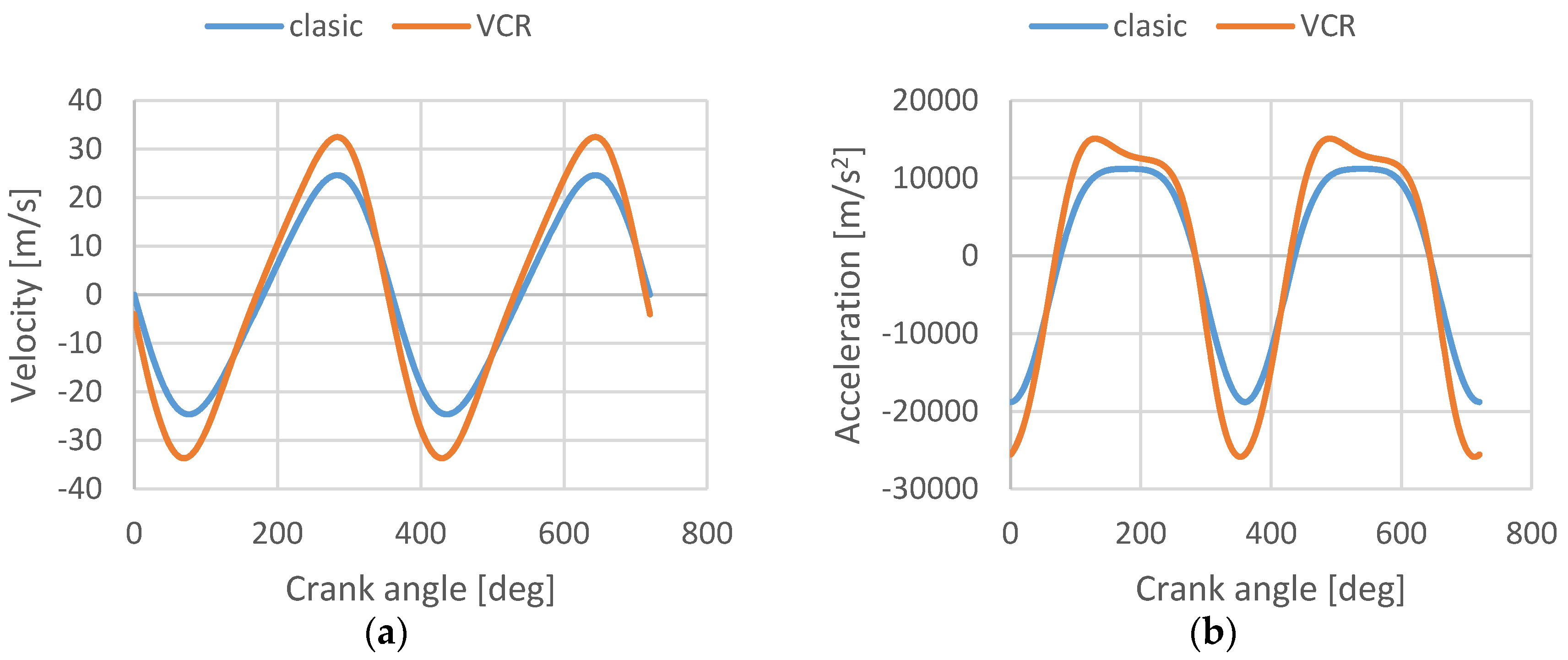

- Furthermore, the velocity and acceleration of the piston for the novelty mechanism have a similar percent of increase with respect to the piston stroke obtained with a classic mechanism.

- ○

- The percentage increase of the kinematic parameters also led to the increase of the internal dynamic loads in the mechanism. For example, in the novel mechanism, on the big end of a con-rod, a maximum value of the resulting dynamic load greater than 8% compared to the classical mechanism was obtained.

- ○

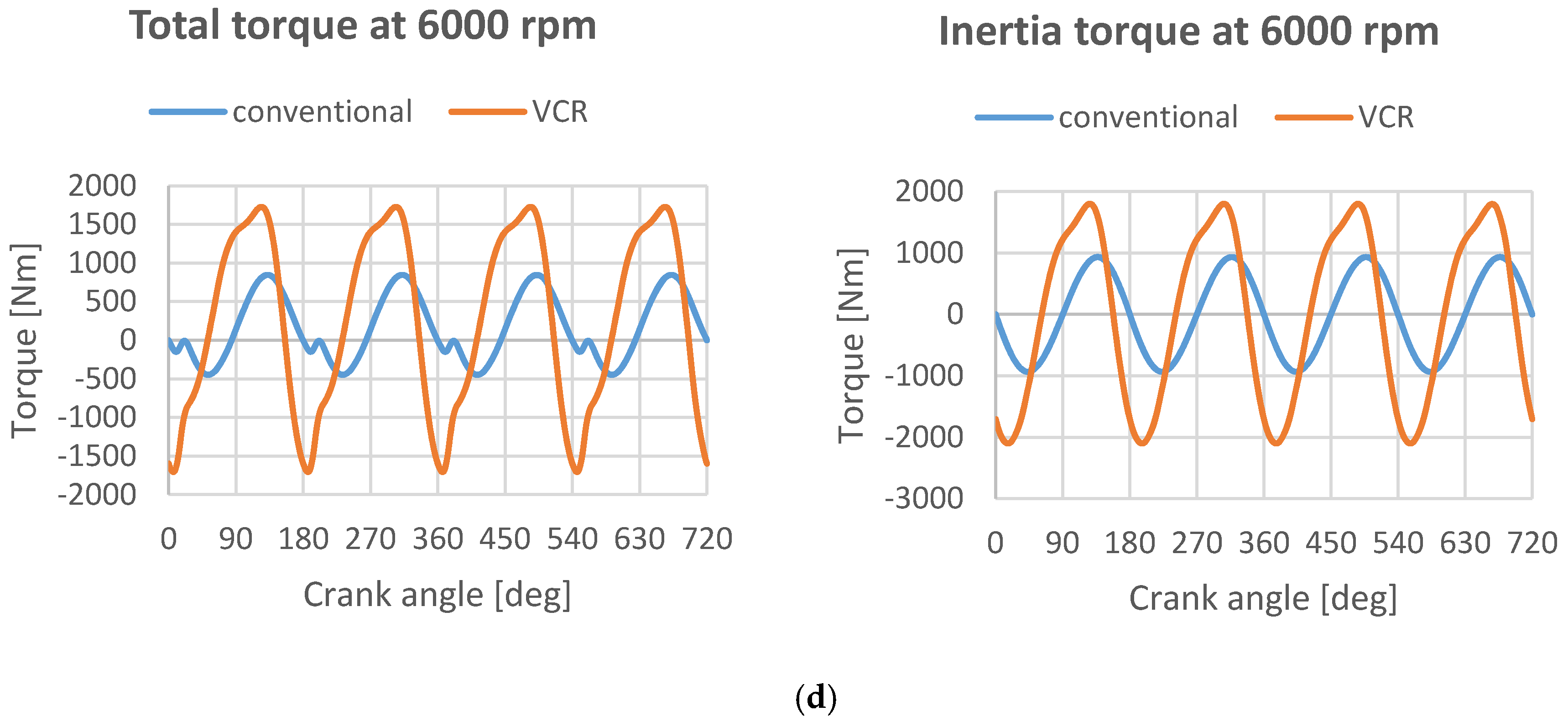

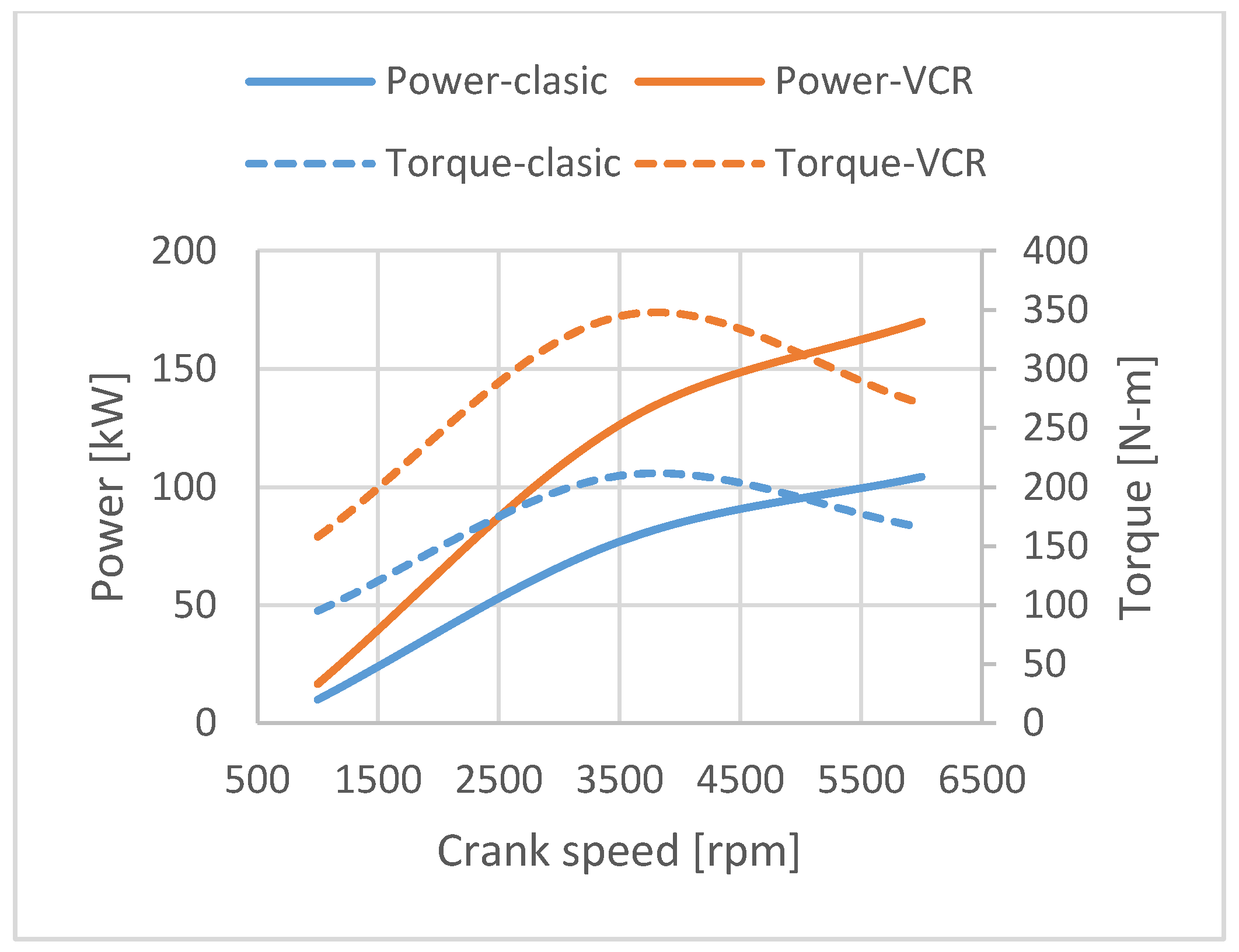

- The dynamic loading reduced to the lever of crankshaft will induce an increase of the torque and also an increase of power. According to the simulations, a major percent of 40% is obtained for the novel mechanism compared to the classic one.

- ○

- Finally, the lithic power calculated in terms of kinematic and dynamic parameters has a 20% increasing obtain for the novel mechanism comparison to the classic one.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kushwaha, M.; Gupta, S.; Kelly, P.; Rahnejat, H. Elasto-multi-body dynamics of a multicylinder internal combustion engine. Proc. Inst. Mech. Eng. Part K J. Multibody Dyn. 2002, 216, 281–293. [Google Scholar] [CrossRef]

- Louvigny, Y.; Duysinx, P. Advanced engine dynamics using MBS: Application to twin-cylinder boxer engines. In Proceedings of the 1st Joint International Conference on Multibody System Dynamics, Lappeenranta, Finland, 25–27 May 2010. [Google Scholar]

- Joshi, M.P.; Aparna, V.K. Variable Compression Ratio (VCR) Engine—A review of future power plant for automobile. IJMERD 2012, 2, 1159–1168. [Google Scholar]

- Nakamura, H. A Low Vibration Engine with Unique Counter-Balance Shafts. SAE Trans. 1976, 85, 397–412. [Google Scholar]

- Thomson, W. Fundamentals of Automotive Balance; Mechanical Engineering Publications Ltd.: London, UK, 1978; 96p. [Google Scholar]

- Schedel, R. A Breakthrough in Technology? Auto Technol. 2001, 1, 26–27. [Google Scholar]

- Webb, A. A Piston Revolution. Eng. Manag. J. 2002, 17, 25–30. [Google Scholar]

- Wharton, A.J. Diesel Engines, 3rd ed.; Elsevier: Butterworth-Heinemann, UK, 2013; 144p. [Google Scholar]

- Kojima, S.; Kiga, S.; Moteki, K.; Takahashi, E.; Matsuoka, K. Development of a New 2L Gasoline VC-Turbo Engine with the World’s First Variable Compression Ratio Technology. SAE Tech. Pap. 2018. [Google Scholar] [CrossRef]

- Shaik, A.; Moorthi, N.S.V.; Rudramoorthy, R. Variable compression ratio engine: A future power plant for automobiles—An overview. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2007, 221, 1159–1168. [Google Scholar] [CrossRef]

- Pesic, R.; Milojevic, S. Efficiency and ecological characteristics of a VCR diesel engine. Int. J. Automot. Technol. 2013, 14, 675–681. [Google Scholar] [CrossRef]

- Milojević, S.; Pešić, R. Determination of Combustion Process Model Parameters in Diesel Engine with Variable Compression Ratio. J. Combust. 2018, 8, 212–218. [Google Scholar] [CrossRef]

- Hosamani, B.R.; Kattib, V.V. Experimental analysis of combustion characteristics of CI DI VCR engine using mixture of two biodiesel blend with diesel. Eng. Sci. Technol. Int. J. 2018, 21, 769–777. [Google Scholar] [CrossRef]

- Mishra, R.K.; Soota, T.; Singh, R. Effect of Variable Compression Ratio on Performance of a Diesel Engine Fueled with Karanja Biodiesel and its Blends. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 012064. [Google Scholar] [CrossRef]

- Nayyar, A.; Sharma, D.; Soni, S.L.; Mathur, A. Experimental investigation of performance and emissions of a VCR diesel engine fuelled with n-butanol diesel blends under varying engine parameters. Environ. Sci. Pollut. Res. Int. 2017, 24, 20315–20329. [Google Scholar] [CrossRef] [PubMed]

- Vairavel, M.; Chandrasekaran, M.; Vivek, P.; Kumar, V. Empirical performance analysis of VCR engine fuelled with karanja oil and various additives using ANOVA technique. Int. J. Ambient Energy 2020, 41, 369–373. [Google Scholar] [CrossRef]

- Drangel, H.; Reinmann, R.; Olofsson, E. The Variable Compression (Svc) and the Combustion Control (Scc)—Two Ways to Improve Fuel Economy and Still Comply with World-Wide Emission Requirements; SAE Technical Paper 2002-01-0996; SAE Int.: Warrendale, PA, USA, 2002. [Google Scholar] [CrossRef]

- Duchemin, M.; Collee, V. Profile optimization of the teeth of the double rack-and-pinion gear mechanism in the MCE-5 VCRi engine. SAE Int. J. Engines 2016, 9, 1786–1794. [Google Scholar] [CrossRef][Green Version]

- Vlase, S.; Teodorescu, P.P.; Itu, C.; Scutaru, M.L. Elasto-Dynamics of a Solid with a General “Rigid” Motion using FEM Model. Theoretical Approach. Rom. J. Phys. 2013, 58, 882–892. [Google Scholar]

- Vlase, S. Dynamical Response of a Multibody System with Flexible Elements with a General Three-Dimensional Motion. Rom. J. Phys. 2012, 57, 676–693. [Google Scholar]

- Vlase, S. Elimination of Lagrangian-Multipliers. Mech. Res. Commun. 1987, 14, 17–22. [Google Scholar] [CrossRef]

- Rahnejat, H.; Rothberg, S. Multi-Body Dynamics: Monitoring and Simulation Techniques—III; Professional Engineering Publications: London, UK, 2004; 544p. [Google Scholar]

- Yogesh, M. VCR Technology in Si Engine with LPG: Emission Norms; Lap Lambert Academic Publishing: Saarbrücken, Germany, 2012. [Google Scholar]

- DeGooijer, L.H. A Reciprocating Piston Mechanism and a Method of Increasing Internal egr in an Internal Combustion Engine. U.S. Patent No. WO2009100759A1, 20 August 2009. [Google Scholar]

- DeGooijer, L.H. A Reciprocating Piston Mechanism. U.S. Patent No. WO2011006537A1, 20 January 2011. [Google Scholar]

- Pischinger, S.; Wittek, K.; Tiemann, C. Two-stage Variable Compression Ratio with Eccentric Piston Pin MTZ worldwide. Springer Automot. Media 2009, 70, 20–27. [Google Scholar]

- Kleeberg, H.; Tomazic, D.; Dohmen, J.; Wittek, K.; Balazs, A. Increasing Efficiency in Gasoline Powertrains with a Two-Stage Variable Compression Ratio (VCR) System. SAE 2013 World Congress & Exhibition, RWTH Aachen University; SAE Technical Paper, Article 2013-01-0288; SAE Int.: Warrendale, PA, USA; Aachen, Germany, 2013. [Google Scholar]

- Tomazic, D.; Kleeberg, H.; Bowyer, S.; Dohmen, J.; Wittek, K.; Haake, B. Two-Stage Variable Compression Ratio (VCR) System to Increase Efficiency in Gasoline Powertrains. In Proceedings of the DEER Conference, Dearborn, MI, USA, 16 October 2012; pp. 267–276. [Google Scholar]

- Rao, V.D.N.; German, D.J.; Vrsek, G.A.; Chottiner, J.E.; Madin, M.M. Variable Compression Ratio Pistons and Connecting Rods. U.S. Patent 6,568,357 B1, 18 October 2000. [Google Scholar]

- Schiehlen, W. Research trends in multibody system dynamics. Multibody Syst. Dyn. 2007, 18, 3–13. [Google Scholar] [CrossRef]

- Setright, L.J.K. Some Unusual Engines. In The Institute of Mechanic Engineering; Mechanical Engineering Publications Ltd.: London, UK, 1975. [Google Scholar]

- Twigg, P. Science for Motor Vehicle Engineers, 1st ed.; Elsevier: Butterworth-Heinemann, UK, 2012; 304p. [Google Scholar]

- SIMDRIVE 3D Documentation. Available online: http://www.contecs-engineering.de (accessed on 15 March 2020).

- Taylor, C.F. The Internal Combustion Engine. In Theory and Practice; MIT Press: Cambrige, MA, USA, 1966; Volume 1, 584p. [Google Scholar]

- Vlase, S.; Danasel, C.; Scutaru, M.L.; Mihalcica, M. Finite Element Analysis of a Two-Dimensional Linear Elastic Systems with a Plane “Rigid Motion”. Rom. J. Phys. 2014, 59, 476–487. [Google Scholar]

- Styron, J. Variable Compression Ratio Internal Combustion Engine Using Field-Sensitive Fluid. U.S. Patent No. 6394048 B1, 16 January 2001. [Google Scholar]

- RazaKhan, I.R.; Kailas, T.M. Study of Variable Compression Ratio Engine (VCR) and Different Innovations to Achieve VCR. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 7, 344–349. [Google Scholar]

- Witteka, K. Experimental Investigation of a Variable Compression Ratio System Applied to a Gasoline Passenger Car Engine, Energy Conversion and Management; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; Volume 183, pp. 753–763. [Google Scholar]

- Tomar, S.K.; Mishra, R.K.; Bisht, S.; Kumar, S.; Saxena, G. Design of Variable Length Connecting rod for VCR Engine. Int. J. Eng. Res. Appl. 2014, 6, 280–285. [Google Scholar]

- Joshi, M.P. Variable compression ratio (vcr) engine—A review of future power plant for automobile. Int. J. Mech. Eng. Res. Dev. IJMERD 2012, 2, 2–3. [Google Scholar]

- Kitayama, S.; Saikyo, M.; Nishio, Y.; Tsutsumi, K. Torque control strategy and optimization for fuel consumption and emission reduction in parallel hybrid electric vehicles. Struct. Multidisc. Optim. 2015, 52, 595. [Google Scholar] [CrossRef]

- Available online: http://www.altair.com (accessed on 15 March 2020).

- Available online: http://www.simulia.com (accessed on 15 March 2020).

- Available online: http://www.mscsoftware.com (accessed on 15 March 2020).

- Available online: http://www.ansys.com (accessed on 15 March 2020).

- Gomecsys Homepage. Available online: https://gomecsys.com/our-product/gomecsys-vcr-technology (accessed on 15 March 2020).

- Aoyama, S. Study of a Variable Compression Ratio System, Nissan. AutoTechnology 2007, 2, 65–68. [Google Scholar]

- Ryosuke, H. Variable Compression Ratio Internalcombustion Engine. U.S. Patent 8,881,695 B2, 3 April 2013. [Google Scholar]

- Chiodi, M.; Kaechele, A.; Bargende, M.; Wichelhaus, D.; Poetsch, C. Development of an innovative combustion process: Spark-assisted compression ignition. SAE Int. J. Engines 2017, 10, 5. [Google Scholar] [CrossRef]

- Nakata, K.; Nogawa, S.; Takahashi, D.; Kumagai, A.; Suzuki, T. Engine technologies for achieving 45% thermal efficiency of S.I. engine. SAE Int. J. Engines 2016, 9, 1. [Google Scholar] [CrossRef]

| Initial Position of Joints Considering in Mechanism [mm] | ||||

|---|---|---|---|---|

| Joint | Classic | VCR | ||

| x | y | x | y | |

| O | 0 | 0 | 0 | 0 |

| A | 0 | 38 | 0 | 38 |

| B | 0 | 165 | 43.15 | 63.5 |

| C | 0 | 207.2 | ||

| D | − | − | −120 | 80 |

| D Point ExtremePosition | Clearance [mm] | Stroke [mm] | Bore Diameter [mm] | Total Volume [L] | Clearance Volume [L] | Compression Ratio (CR) |

|---|---|---|---|---|---|---|

| initial | 13.78 | 98.21 | 82 | 0.59 | 0.07 | 8.13 |

| Left | 9.80 | 94.88 ↘ | 82 | 0.55 | 0.05 | 10.68 ↗ |

| Right | 21.35 | 99.42 ↗ | 82 | 0.64 | 0.11 | 5.66 ↘ |

| Down | 6.18 | 105.7 ↗ | 82 | 0.59 | 0.03 | 18.1 ↗ |

| Up | 21.20 | 89.1 ↘ | 82 | 0.58 | 0.11 | 5.2 ↘ |

| Element | Classic | VCR | ||

|---|---|---|---|---|

| Mass [kg] | Inertia Moment [kg∙mm2] | Mass [kg] | Inertia Moment [kg∙mm2] | |

| 1—crank | 16.5 | 24,560 | 16.5 | 24,560 |

| 2—con-rod | 0.3 | 1185 | 0.3 | 1185 |

| 3—piston | 0.354 | 387.5 | 0.354 | 387.5 |

| 4—oscillation arm | − | − | 1.55 | 13,400 |

| 5—pivot | − | − | 0.275 | 100 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Itu, C.; Scutaru, M.-L.; Pruncu, C.I.; Muntean, R. Kinematic and Dynamic Response of a Novel Engine Mechanism Design Driven by an Oscillation Arm. Appl. Sci. 2020, 10, 2733. https://doi.org/10.3390/app10082733

Itu C, Scutaru M-L, Pruncu CI, Muntean R. Kinematic and Dynamic Response of a Novel Engine Mechanism Design Driven by an Oscillation Arm. Applied Sciences. 2020; 10(8):2733. https://doi.org/10.3390/app10082733

Chicago/Turabian StyleItu, Călin, Maria-Luminiţa Scutaru, Cătălin Iulian Pruncu, and Radu Muntean. 2020. "Kinematic and Dynamic Response of a Novel Engine Mechanism Design Driven by an Oscillation Arm" Applied Sciences 10, no. 8: 2733. https://doi.org/10.3390/app10082733

APA StyleItu, C., Scutaru, M.-L., Pruncu, C. I., & Muntean, R. (2020). Kinematic and Dynamic Response of a Novel Engine Mechanism Design Driven by an Oscillation Arm. Applied Sciences, 10(8), 2733. https://doi.org/10.3390/app10082733