Evaluation of the Hydraulic, Physical, and Mechanical Properties of Pervious Concrete Using Iron Tailings as Coarse Aggregates

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design

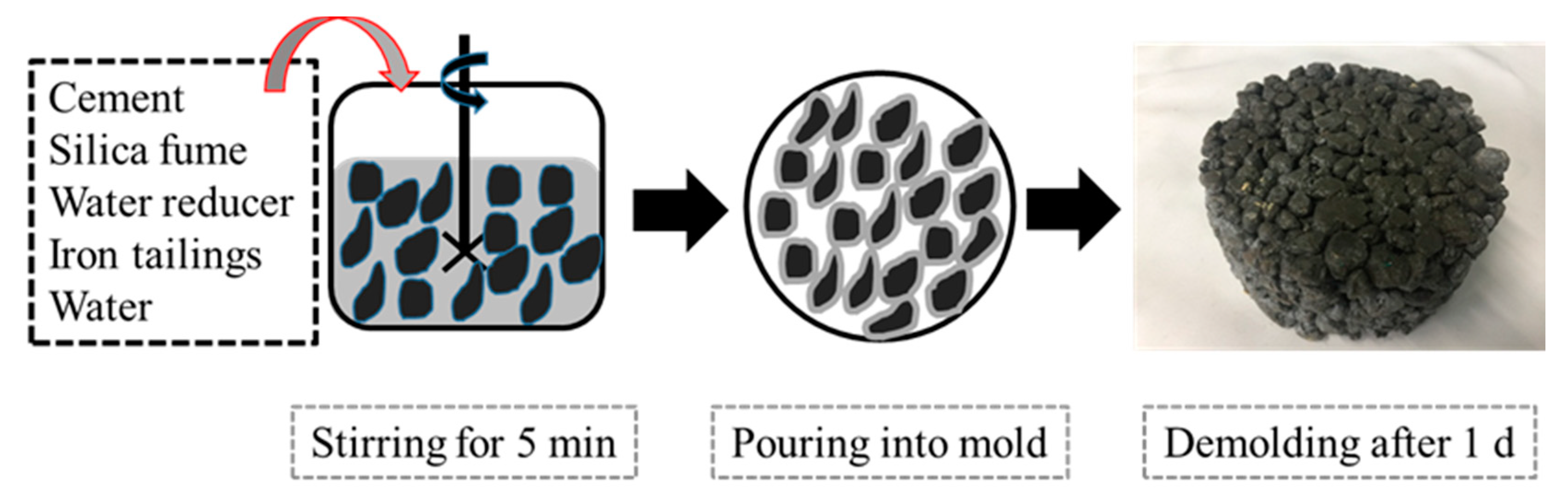

2.3. Sample Preparation

2.4. Methodology

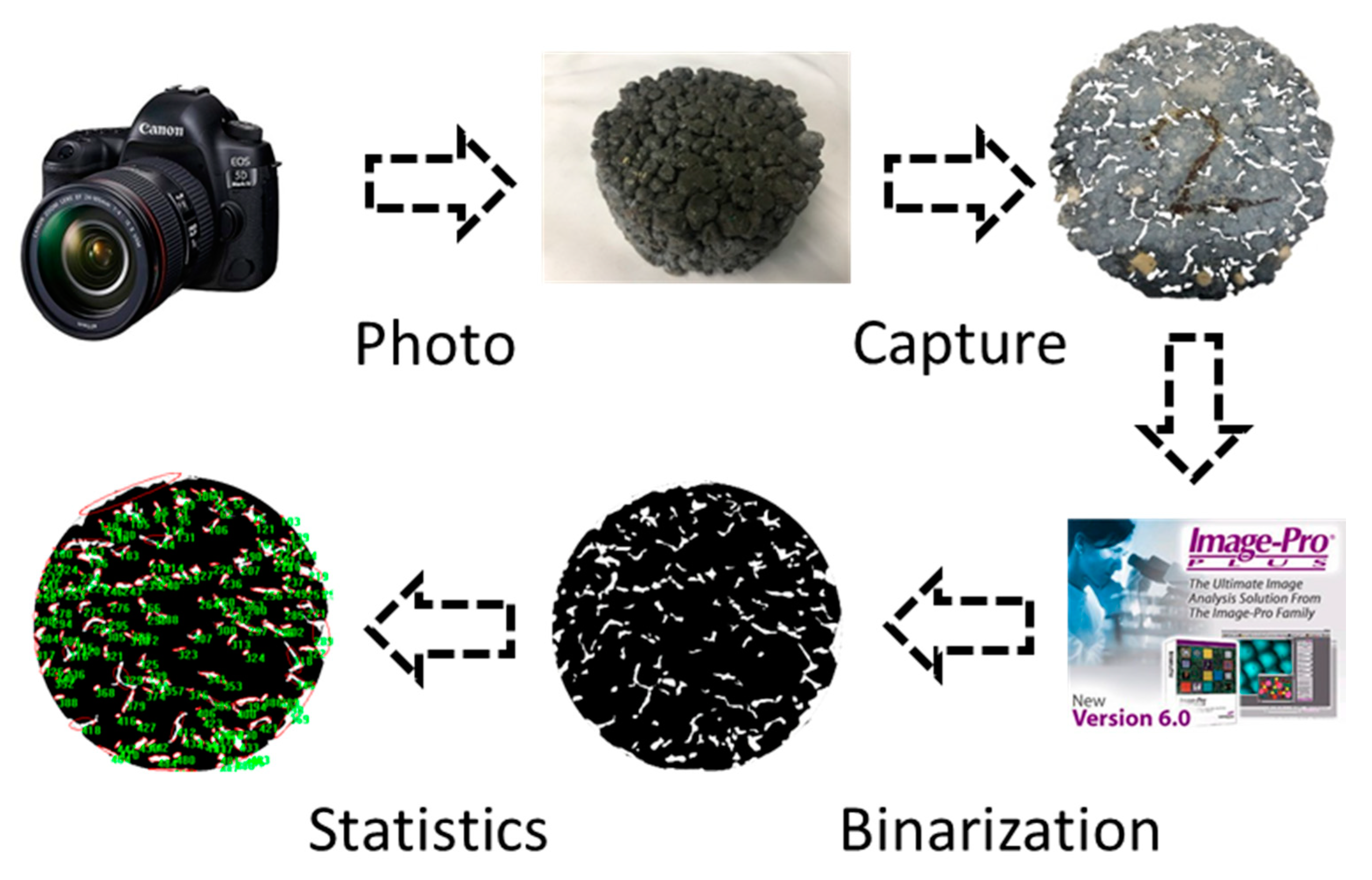

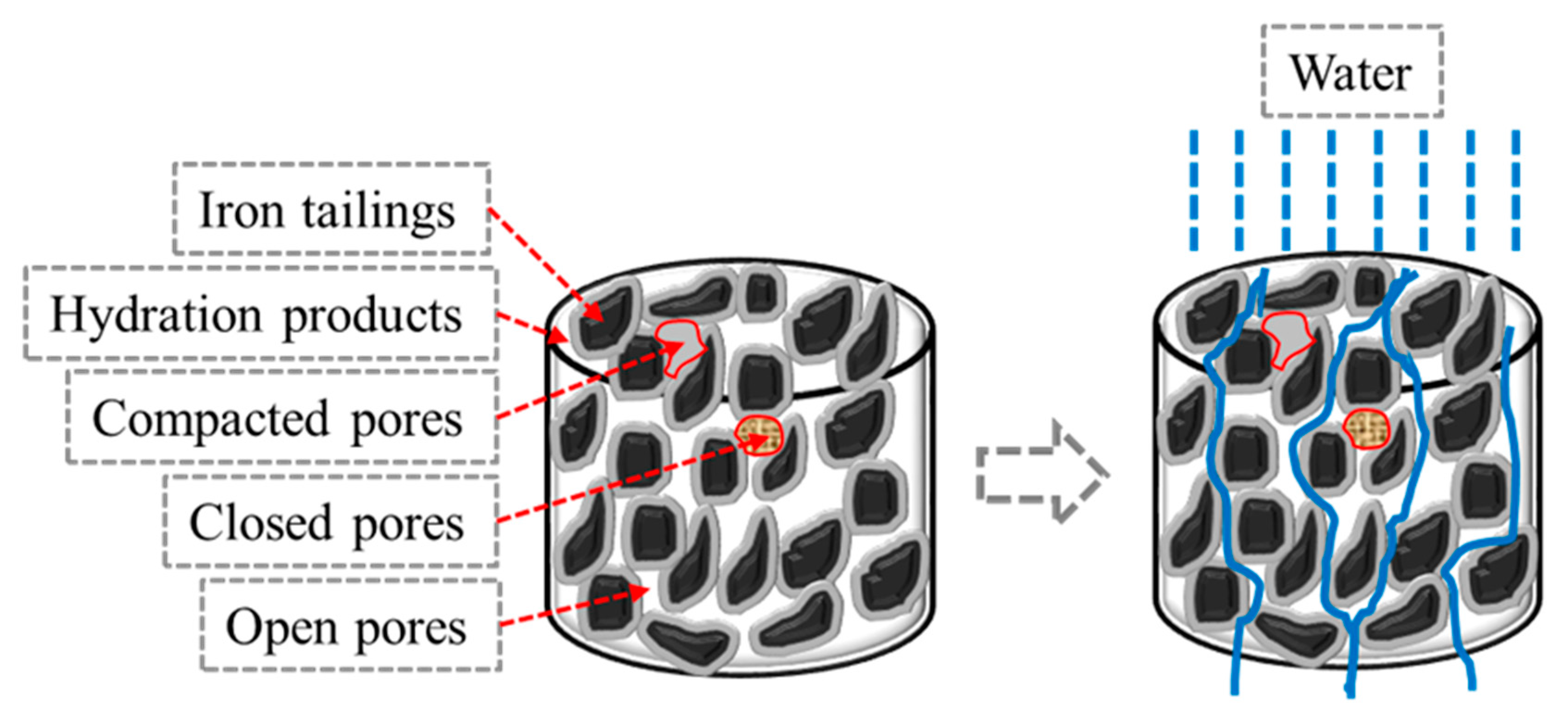

2.4.1. Effective Porosity and Measured Porosity

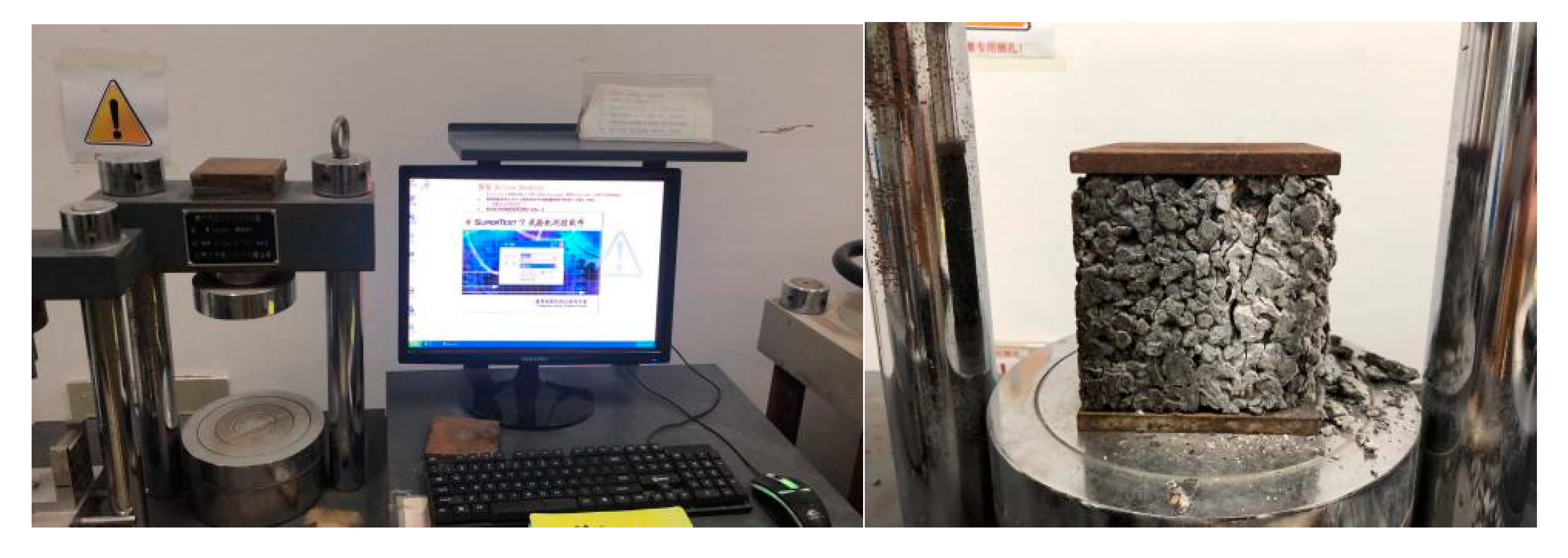

2.4.2. Bulk Density and Compressive Strength

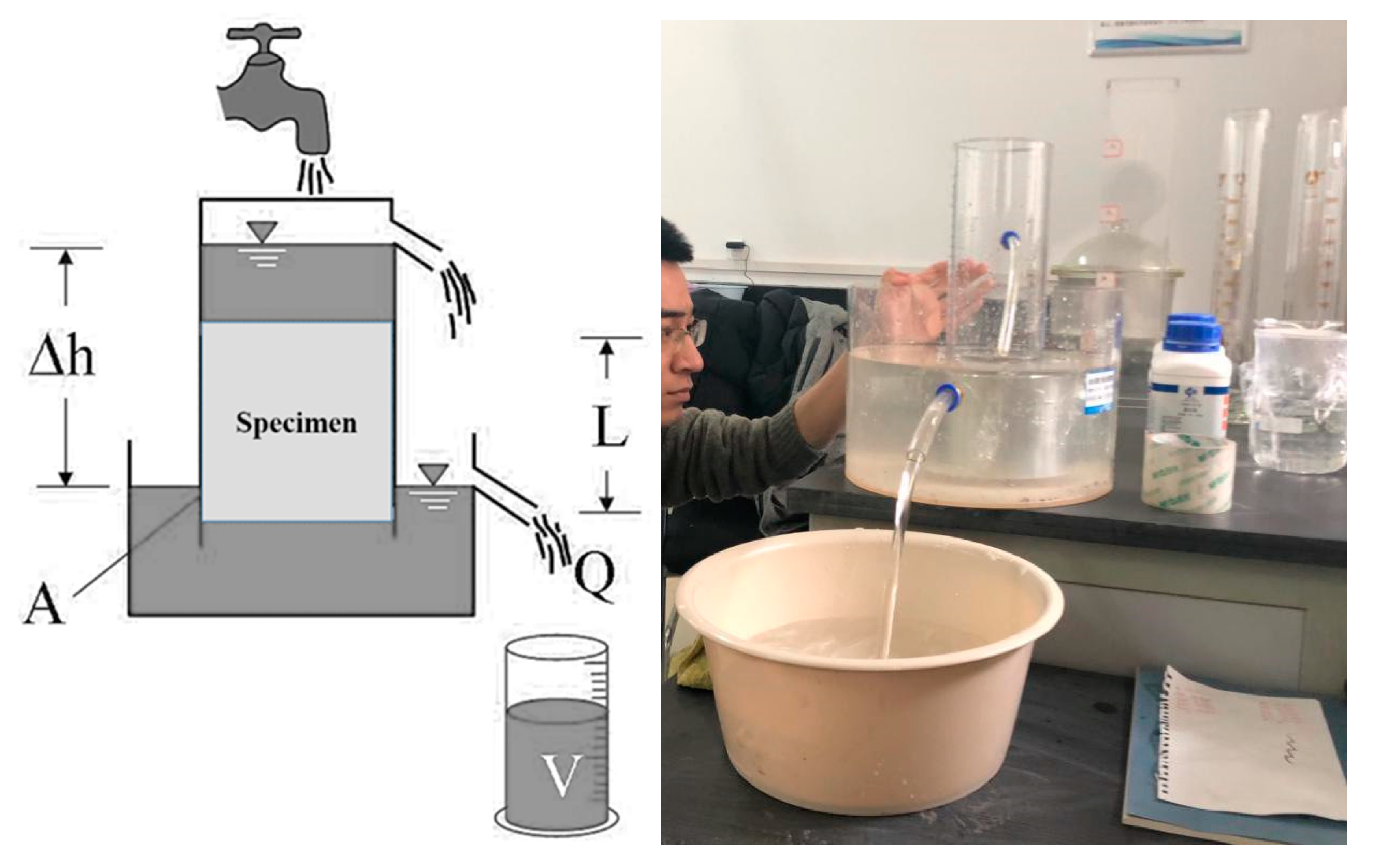

2.4.3. Permeability Coefficient

3. Results and Discussions

3.1. Measured Porosity and Effective Porosity of Pervious Concrete

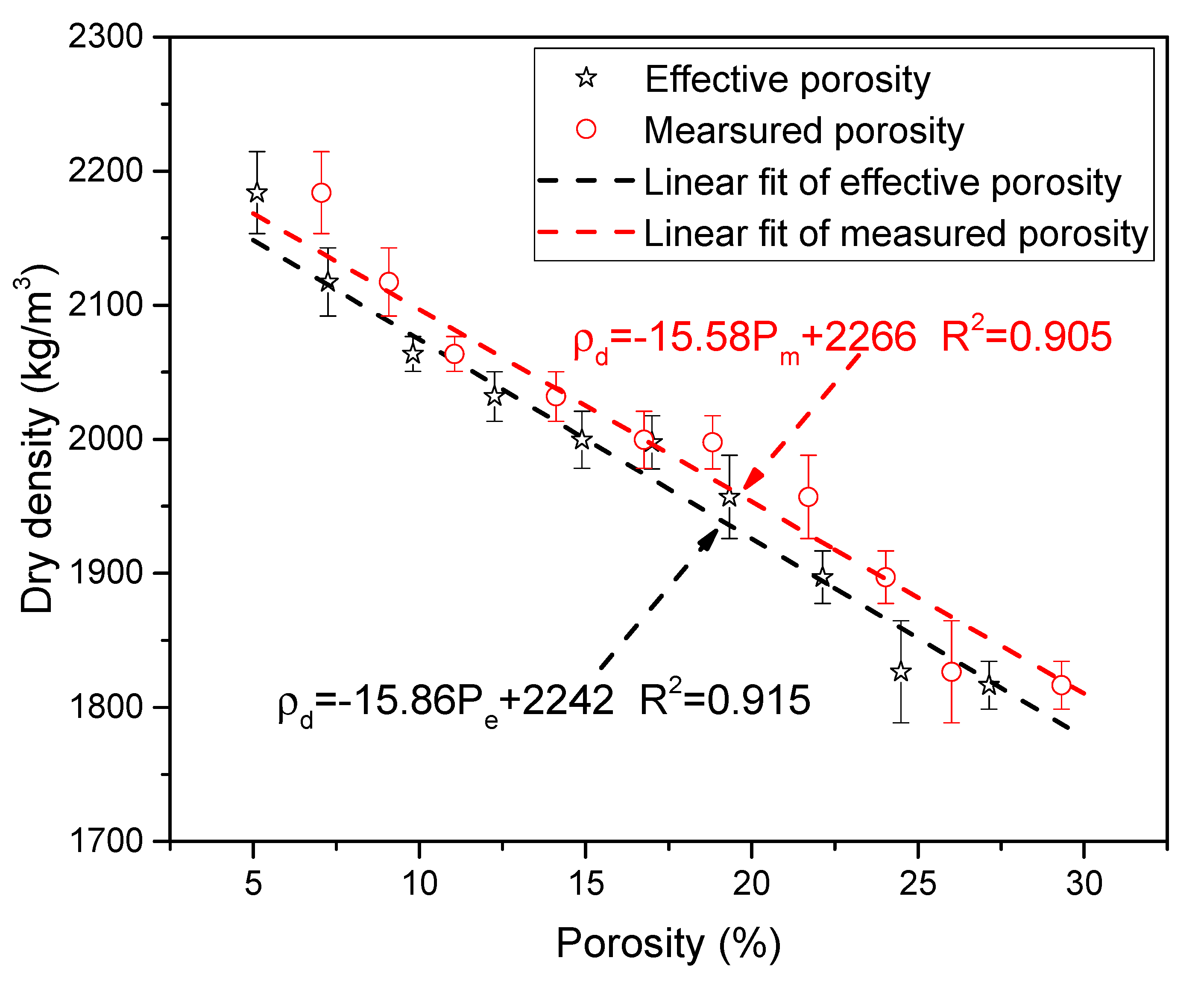

3.2. Dry Density of Pervious Concrete

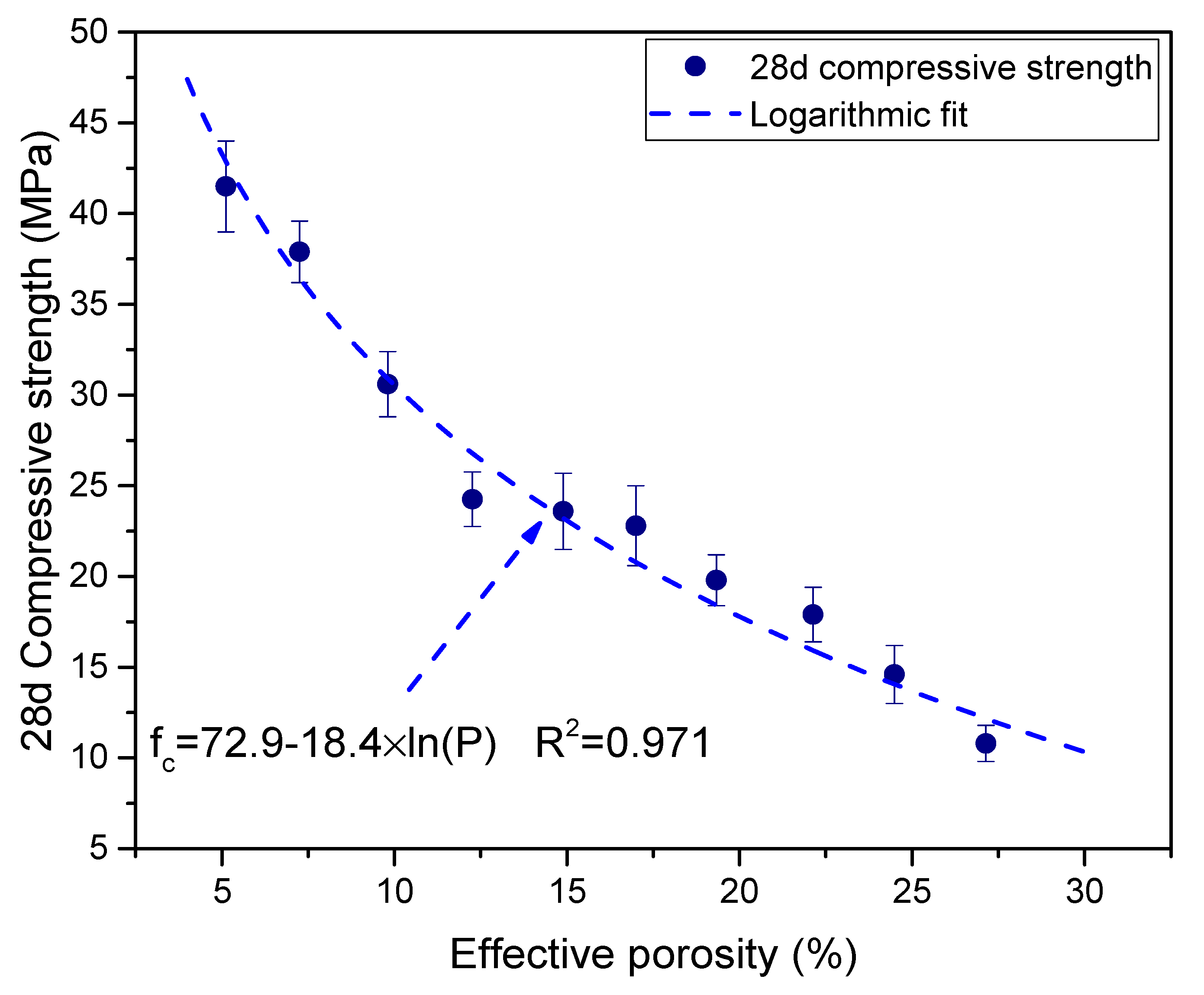

3.3. Compressive Strength of Pervious Concrete

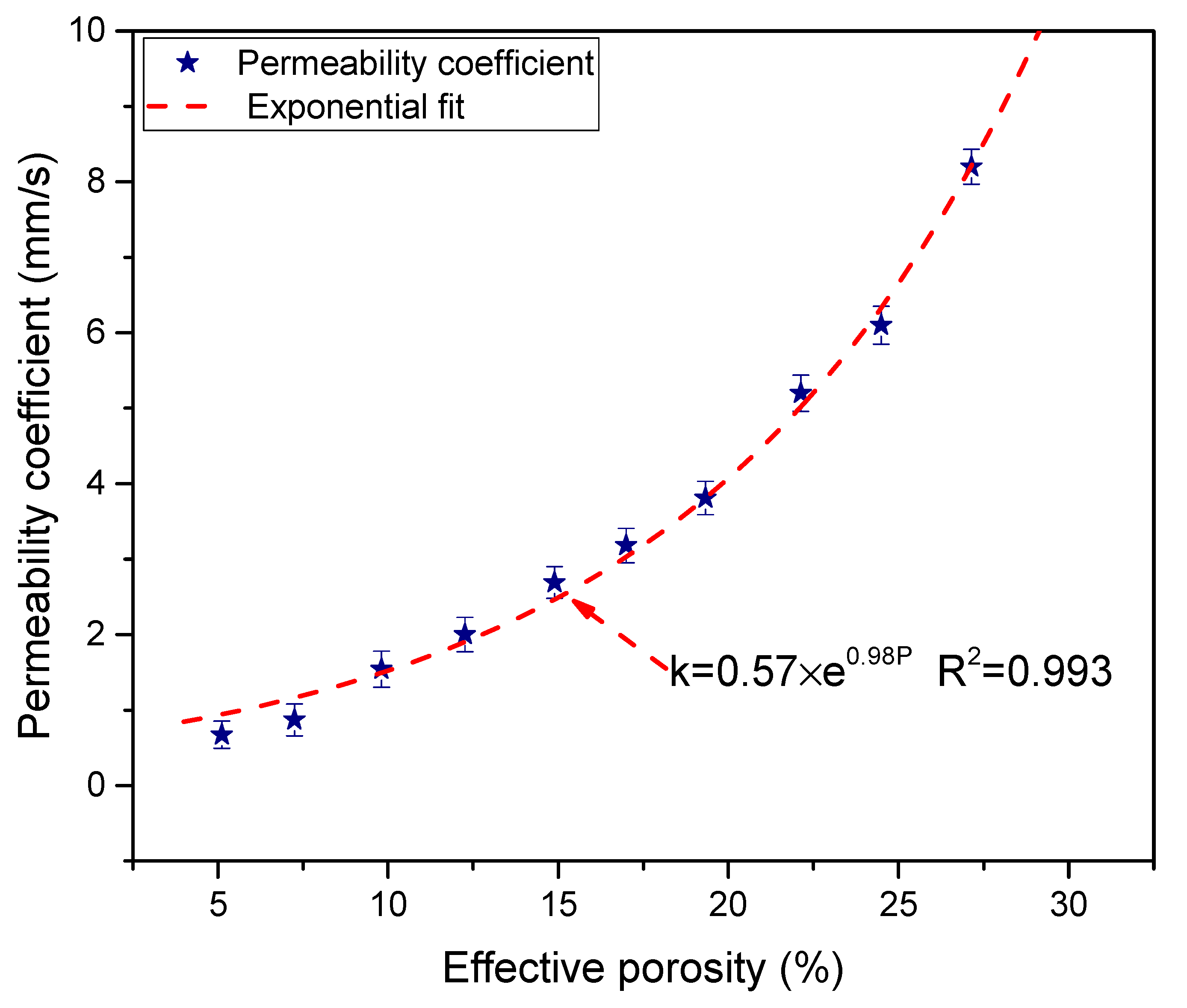

3.4. Permeability Coefficient of Pervious Concrete

3.5. Equilibrium Point of the Permeability and Strength of Pervious Concrete

3.6. Comparisons of the Permeability Coefficient and Compressive Strength of Pervious with Different Types of Aggregates

4. Conclusions

- (1)

- According to a mix design procedure, when the target porosity of pervious concrete was designed from 8% to 30%, the measured porosity of the pervious concrete ranged from 7.05% to 29.32%, while the effective porosity ranged from 5.12% to 27.14%. It is relatively accurate to utilize the mix design procedure for pervious concrete using iron tailing as coarse aggregates.

- (2)

- The dry density of the pervious concrete, ranging from 2240 to 1798 kg/m3, was linearly distributed with both the measured porosity and effective porosity. The 28 d compressive strength of the pervious concrete decreased from 42 to 11 MPa as the effective porosity increased from 5.2% to 27.2%. The relationship between the dry density and effective porosity can be expressed as ρd = 15.86 × Pe + 2242, while the relationship between the compressive strength and effective porosity can be expressed as fc = 72.9 − 18.4 × ln(P).

- (3)

- The limitation and conditions for the compressive strength and permeability coefficient functions can be summarized as following: (1) P.O. 42.5 grade Portland cement is used as cementitious materials, (2) the water to cement mass ratio is about 0.23, (3) the compaction method is a compact effort of five drops of Proctor hammer per layer for two layers in the molds, and (4) the aggregate size is 4.75–9.5 mm.

- (4)

- The permeability coefficient of pervious concrete, ranging from 0.67 to 8.2 mm/s can be predicted by as a function of the effective porosity, as displayed k = 0.57 × e0.98P. The effective porosity of the equilibrium point of the compressive strength and permeability coefficient of pervious concrete was approximately 16%, where the compressive strength was 21.5 MPa and the water permeability was 3.2 mm/s. The products prepared here can be used in parks, gardens, open parking lots, sidewalks, and some riverbanks.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Data Availability

References

- Herrmann, H.; Bucksch, H. Pervious Concrete, 1st ed.; Dictionary Geotechnical Engineering, Wörterbuch GeoTechnik; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–100. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Nanjegowda, V.H. Pervious concrete as a sustainable pavement material—Research findings and future prospects: A state-of-the-art review. Constr. Build. Mater. 2016, 111, 262–274. [Google Scholar] [CrossRef]

- Scholz, M.; Grabowiecki, P. Review of permeable pavement systems. Build. Environ. 2007, 42, 3830–3836. [Google Scholar] [CrossRef]

- Kayhanian, M.; Anderson, D.; Harvey, J.T. Permeability measurement and scan imaging to assess clogging of pervious concrete pavements in parking lots. J. Environ. Manag. 2012, 95, 114–123. [Google Scholar] [CrossRef] [PubMed]

- Deo, O.; Neithalath, N. Compressive behavior of pervious concretes and a quantification of the influence of random pore structure features. Mater. Sci. Eng. A 2010, 528, 402–412. [Google Scholar] [CrossRef]

- Neithalath, N.; Sumanasooriya, M.S.; Deo, O. Characterizing pore volume, sizes, and connectivity in pervious concretes for permeability prediction. Mater. Charact. 2010, 61, 802–813. [Google Scholar] [CrossRef]

- Nguyen, D.; Sebaib, N.; Boutouil, M. A modified method for the design of pervious concrete mix. Constr. Build. Mater. 2014, 73, 271–282. [Google Scholar] [CrossRef]

- Chinese Standard CJJ/T135, Technical Specifications for Permeable Concrete Pavement; Standards Press of China: Beijing, China, 2009.

- Yang, Y. Practical problems and Countermeasures in the development and utilization of mineral resources in China. Sci. Tech. Manag. Land Resour. 2005, 4, 66–70. (In Chinese) [Google Scholar] [CrossRef]

- Osinubi, K.J.; Yohanna, P.; Eberemu, A.O. Cement modification of tropical black clay using iron ore tailings as admixture. Transp. Geotech. 2015, 5, 35–49. [Google Scholar] [CrossRef]

- Zhang, S.; Xue, X.; Liu, X. Current situation and comprehensive utilization of iron ore tailing resources. J. Min. Sci. 2006, 42, 403–408. [Google Scholar] [CrossRef]

- Han, F.; Li, L.; Song, S. Early-age hydration characteristics of composite binder containing iron tailing powder. Powder Tech. 2017, 315, 322–331. [Google Scholar] [CrossRef]

- Sirkeci, A.A.; Gül, A.; Bulut, G. Recovery of Co, Ni, and Cu from the tailings of divrigi iron ore concentrator. Miner. Process. Extr. Metall. Rev. 2006, 27, 131–141. [Google Scholar] [CrossRef]

- Yang, C.; Cui, C.; Qin, J. Characteristics of the fired bricks with low-silicon iron tailings. Constr. Build. Mater. 2014, 70, 36–42. [Google Scholar] [CrossRef]

- Das, S.K.; Kumar, S.; Ramachandrarao, P. Explotation of iron ore tailing for the development of ceramic tiles. Waste Manag. 2000, 20, 725–729. [Google Scholar] [CrossRef]

- Zhao, S.; Fan, J.; Sun, W. Utilization of iron ore tailings as fine aggregate in ultra-high performance concrete. Constr. Build. Mater. 2014, 50, 540–548. [Google Scholar] [CrossRef]

- Cai, L.; Ma, B.; Li, X.; Lv, Y.; Liu, Z.; Jian, S. Mechanical and hydration characteristics of autoclaved aerated concrete (AAC) containing iron-tailings: Effect of content and fineness. Constr. Build. Mater. 2016, 128, 361–372. [Google Scholar] [CrossRef]

- Ma, B.G.; Cai, L.X.; Li, X.G. Utilization of iron tailings as substitute in autoclaved aerated concrete: Physico-mechanical and microstructure of hydration products. J. Clean. Prod. 2016, 127, 162–171. [Google Scholar] [CrossRef]

- Chinese Standard GB/T 5085.3, Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity; Standards Press of China: Beijing, China, 2007.

- Da, S.F.L.; Araújo, F.G.S.; Teixeira, M.P. Study of the recovery and recycling of tailings from the concentration of iron ore for the production of ceramic. Ceram. Int. 2014, 40, 16085–16089. [Google Scholar] [CrossRef]

- Debnath, B.; Sarkar, P. Permeability prediction and pore structure feature of pervious concrete using brick as aggregate. Constr. Build. Mater. 2019, 213, 643–651. [Google Scholar] [CrossRef]

- El-Hassan, H.; Kianmehr, P.; Zouaoui, S. Properties of pervious concrete incorporating recycled concrete aggregates and slag. Constr. Build. Mater. 2019, 212, 164–175. [Google Scholar] [CrossRef]

- Yu, F.; Sun, D.; Wang, J. Influence of aggregate size on compressive strength of pervious concrete. Constr. Build. Mater. 2019, 209, 463–475. [Google Scholar] [CrossRef]

- Sun, Z.; Lin, X.; Vollpracht, A. Pervious concrete made of alkali activated slag and geopolymers. Constr. Build. Mater. 2018, 189, 797–803. [Google Scholar] [CrossRef]

- Lori, A.; Hassani, A.; Sedghi, R. Investigating the mechanical and hydraulic characteristics of pervious concrete containing copper slag as coarse aggregate. Constr. Build. Mater. 2019, 197, 130–142. [Google Scholar] [CrossRef]

- Lang, L.; Duan, H.; Chen, B. Properties of pervious concrete made from steel slag and magnesium phosphate cement. Constr. Build. Mater. 2019, 209, 95–104. [Google Scholar] [CrossRef]

- Yeih, W.; Chang, J. The influences of cement type and curing condition on properties of pervious concrete made with electric arc furnace slag as aggregates. Constr. Build. Mater. 2019, 197, 813–820. [Google Scholar] [CrossRef]

- Saboo, N.; Shivhare, S.; Kori, K. Effect of fly ash and metakaolin on pervious concrete properties. Constr. Build. Mater. 2019, 223, 322–328. [Google Scholar] [CrossRef]

- Chinese Standard GB/T 175, Common Portland Cement; Standards Press of China: Beijing, China, 2007.

- Yu, F.; Sun, D.; Hu, M. Study on the pores characteristics and permeability simulation of pervious concrete based on 2D/3D CT images. Constr. Build. Mater. 2019, 200, 687–702. [Google Scholar] [CrossRef]

- Liu, H.; Luo, G.; Wang, L. Laboratory Evaluation of Eco-Friendly Pervious Concrete Pavement Material Containing Silica Fume. Appl. Sci. 2019, 9, 73. [Google Scholar] [CrossRef]

- O’Farrell, M.; Wild, S.; Sabir, B.B. Pore Size Distribution and Compressive Strength of Waste Clay Brick Mortars. Cem. Concr. Compos. 2001, 23, 81–91. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Meininger, R.C. No-fines pervious concrete for paving. Concr. Int. 1988, 10, 20–27. Available online: https://www.mendeley.com/catalogue/a37dbe1b-942f-3a0e-af35-1b8a5f0eee01/ (accessed on 2 April 2020).

- Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious geopolymer concrete using recycled aggregates. Constr. Build. Mater. 2013, 42, 33–39. [Google Scholar] [CrossRef]

- Zhong, R.; Wille, K. Material design and characterization of high performance pervious concrete. Constr. Build. Mater. 2015, 98, 51–60. [Google Scholar] [CrossRef]

- Kevern, J.T.; Wang, K.; Suleiman, M.T. Pervious concrete mixture proportions for improved freeze-thaw durability. J. ASTM Int. 2008, 5, 101320–101331. [Google Scholar] [CrossRef]

- Yahia, A.; Kabagire, K.D. New approach to proportion pervious concrete. Constr. Build. Mater. 2014, 62, 38–46. [Google Scholar] [CrossRef]

| Cementitious Materials | Aggregate Types | Variables | Porosity (%) | Permeability (mm/s) | Compressive Strength (MPa) | Reference |

|---|---|---|---|---|---|---|

| 43-grade Ordinary Portland 44-cement | Over burnt brick | aggregate size | 8~31 | 7~19 | 7~30 | [21] a |

| ordinary Portland cement (OPC) | Natural aggregates and recycled concrete aggregates (RCA) | RCA replacement | 18~22 | 8~20 | 3~17 | [22] b |

| Ordinary Portland Cement | basalt aggregates | aggregate size | 20.50~21.16 | -- | 19.86~32.00 | [23] |

| alkali activated materials based on slag and/or metakaolin | natural gravel | aggregate size and binder type | 17.7~34.5 | 3.2~16.2 | 11.3~36.2 | [24] |

| type I Portland cement | dolomite aggregate and copper slag | Copper slag replacement | 20.44~22.77 | 3.05~3.53 | 17.93~23.45 | [25] |

| magnesium phosphate cement | waste steel slag | aggregate size | 25~26 | 6.8~7.1 | 34~38 | [26] c |

| type I cement, type II cement, sulphoaluminate cement and calcium aluminate cement | electric arc furnace slag | cement type and curing condition | 8.45~21.31 | 4.52~7.62 | 10.02~24.72 | [27] d |

| 53-grade Ordinary Portland Cement, class-F type fly-ash | limestone aggregates | fly ash content | 18~35 | 6.1~9.8 | 5.0~10.8 | [28] e |

| Category | Particle Size (mm) | Specific Gravity (kg·m−3) | Bulk Density (kg·m−3) | Void Ratio (%) |

|---|---|---|---|---|

| Iron tailing | 4.75–9.5 | 2750 | 1500 | 45 |

| Target Porosity % | Cement kg·m−3 | Aggregate kg·m−3 | Silica Fume kg·m−3 | Superplasticizer kg·m−3 | Water kg·m−3 |

|---|---|---|---|---|---|

| 8.0 | 666.8 | 1470 | 29.2 | 1.39 | 160 |

| 10.0 | 631.8 | 1470 | 27.6 | 1.32 | 152 |

| 12.5 | 588.0 | 1470 | 25.7 | 1.23 | 141 |

| 15.0 | 544.3 | 1470 | 23.8 | 1.14 | 131 |

| 17.5 | 500.5 | 1470 | 21.9 | 1.04 | 120 |

| 20.0 | 456.8 | 1470 | 20.0 | 0.95 | 110 |

| 22.5 | 413.0 | 1470 | 18.1 | 0.86 | 99 |

| 25.0 | 369.3 | 1470 | 16.2 | 0.77 | 89 |

| 27.5 | 325.5 | 1470 | 14.2 | 0.68 | 78 |

| 30.0 | 281.8 | 1470 | 12.3 | 0.59 | 68 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Y.; Zhu, Y.; Xiao, H. Evaluation of the Hydraulic, Physical, and Mechanical Properties of Pervious Concrete Using Iron Tailings as Coarse Aggregates. Appl. Sci. 2020, 10, 2691. https://doi.org/10.3390/app10082691

Tan Y, Zhu Y, Xiao H. Evaluation of the Hydraulic, Physical, and Mechanical Properties of Pervious Concrete Using Iron Tailings as Coarse Aggregates. Applied Sciences. 2020; 10(8):2691. https://doi.org/10.3390/app10082691

Chicago/Turabian StyleTan, Yan, Yuntao Zhu, and Henglin Xiao. 2020. "Evaluation of the Hydraulic, Physical, and Mechanical Properties of Pervious Concrete Using Iron Tailings as Coarse Aggregates" Applied Sciences 10, no. 8: 2691. https://doi.org/10.3390/app10082691

APA StyleTan, Y., Zhu, Y., & Xiao, H. (2020). Evaluation of the Hydraulic, Physical, and Mechanical Properties of Pervious Concrete Using Iron Tailings as Coarse Aggregates. Applied Sciences, 10(8), 2691. https://doi.org/10.3390/app10082691