Non-Destructive Tests for Damage Evaluation of Stone Columns: The Case Study of Sacro Monte in Ghiffa (Italy)

Abstract

1. Introduction

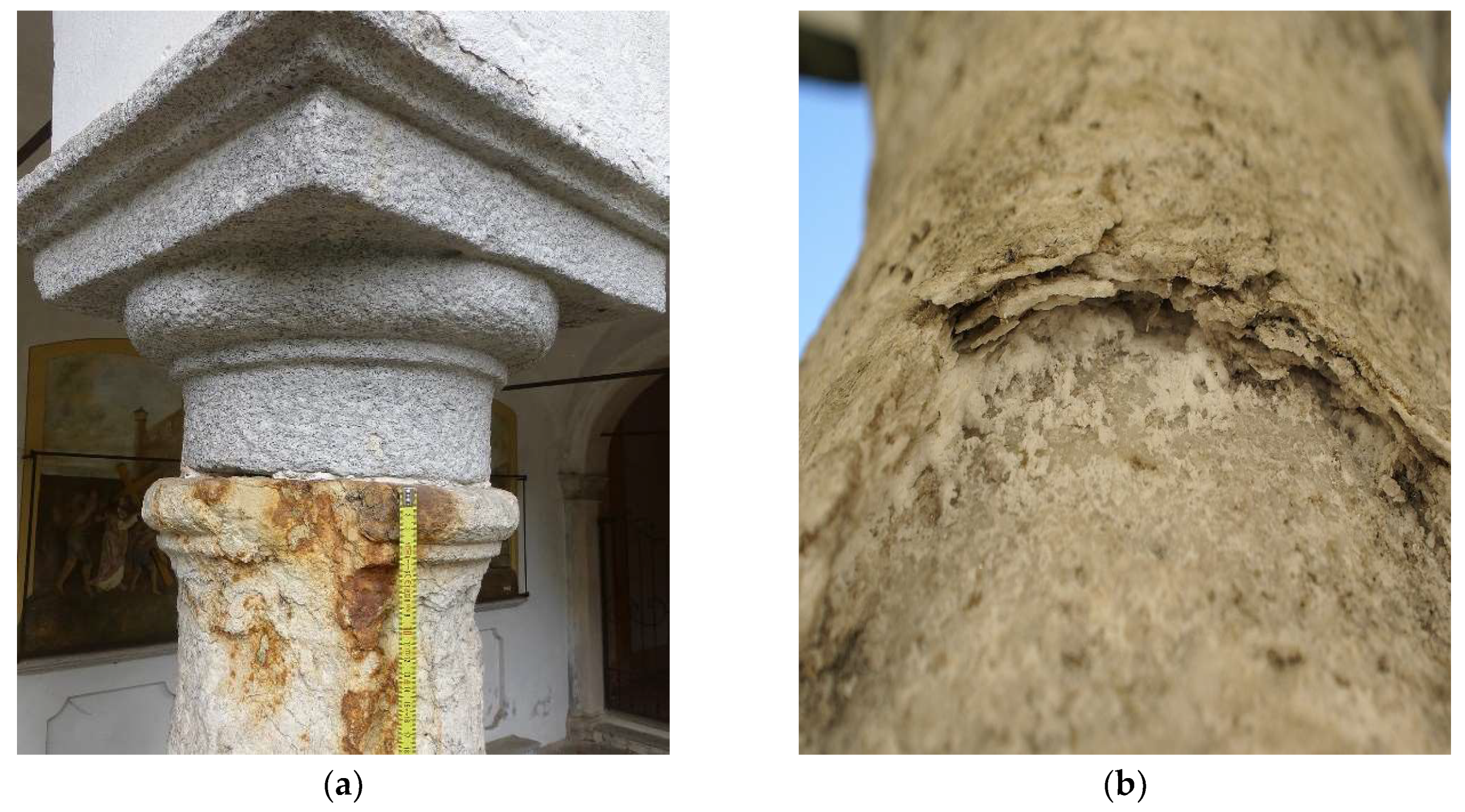

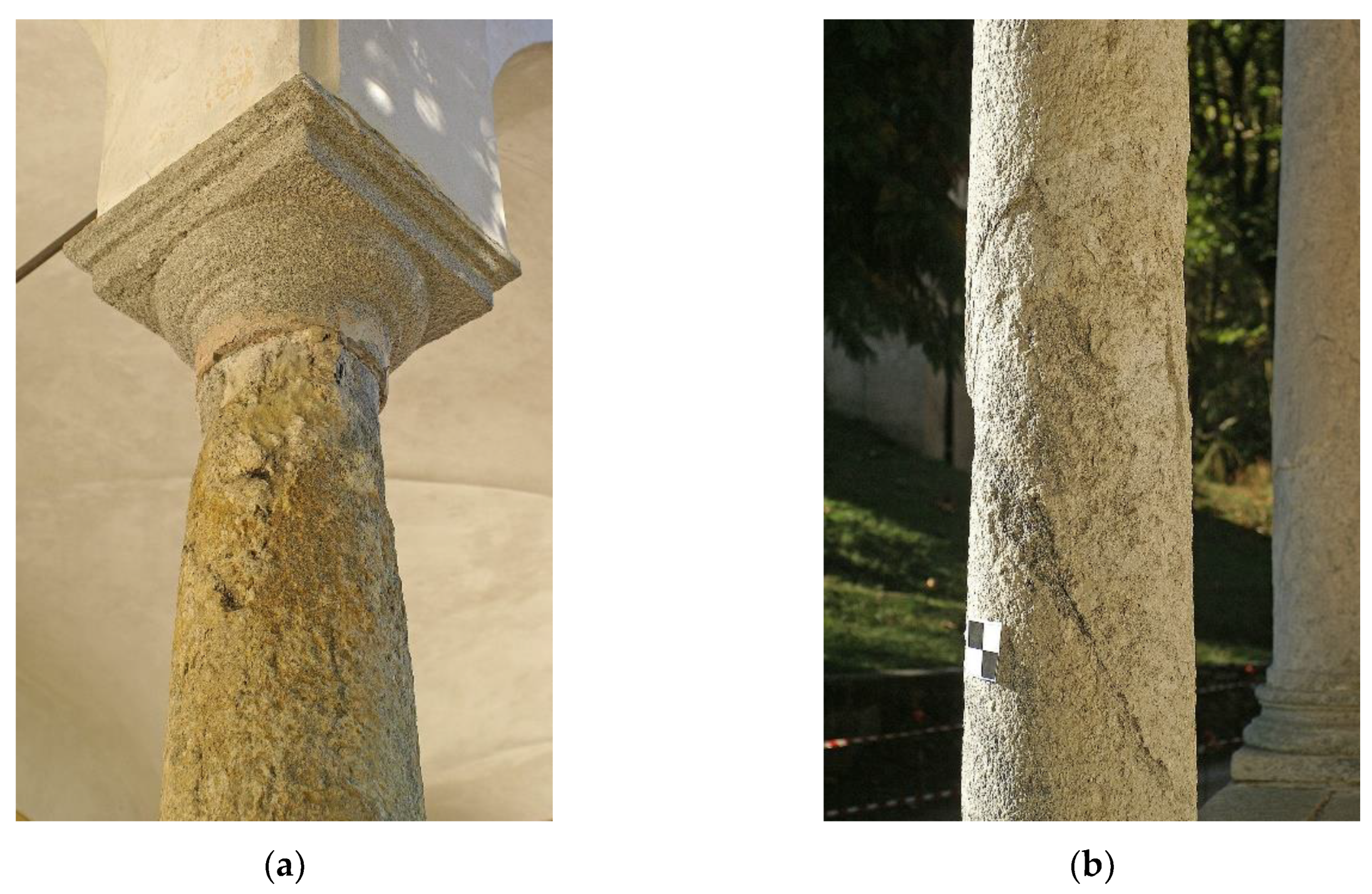

2. Materials and Methods

2.1. Ultrasonic Test

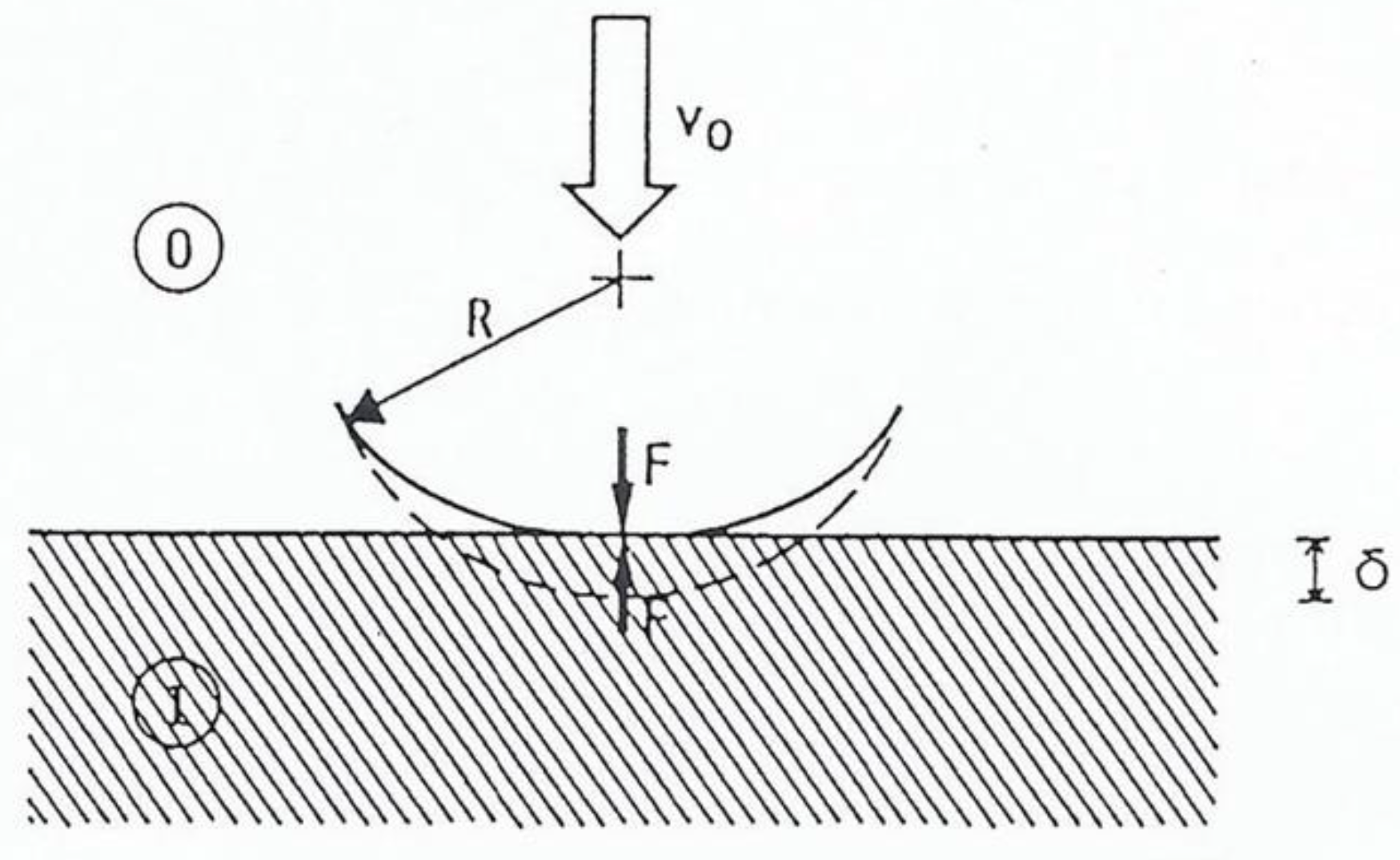

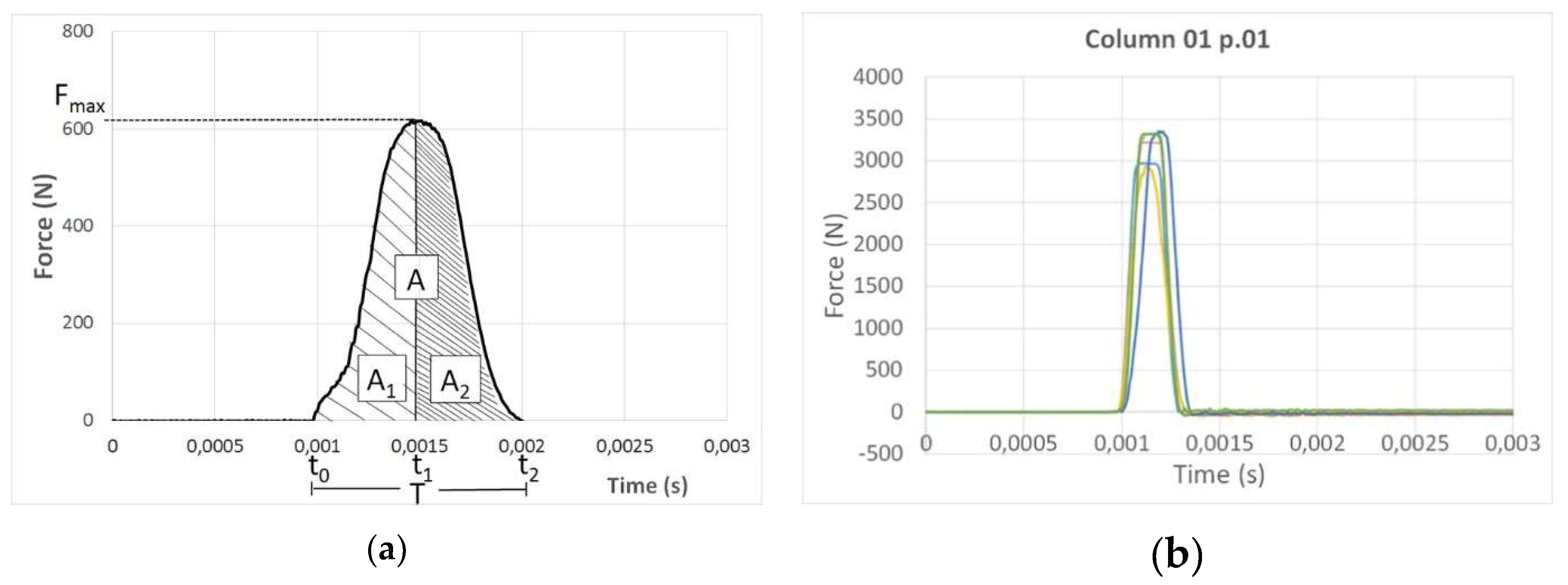

2.2. Impact Test

3. Results

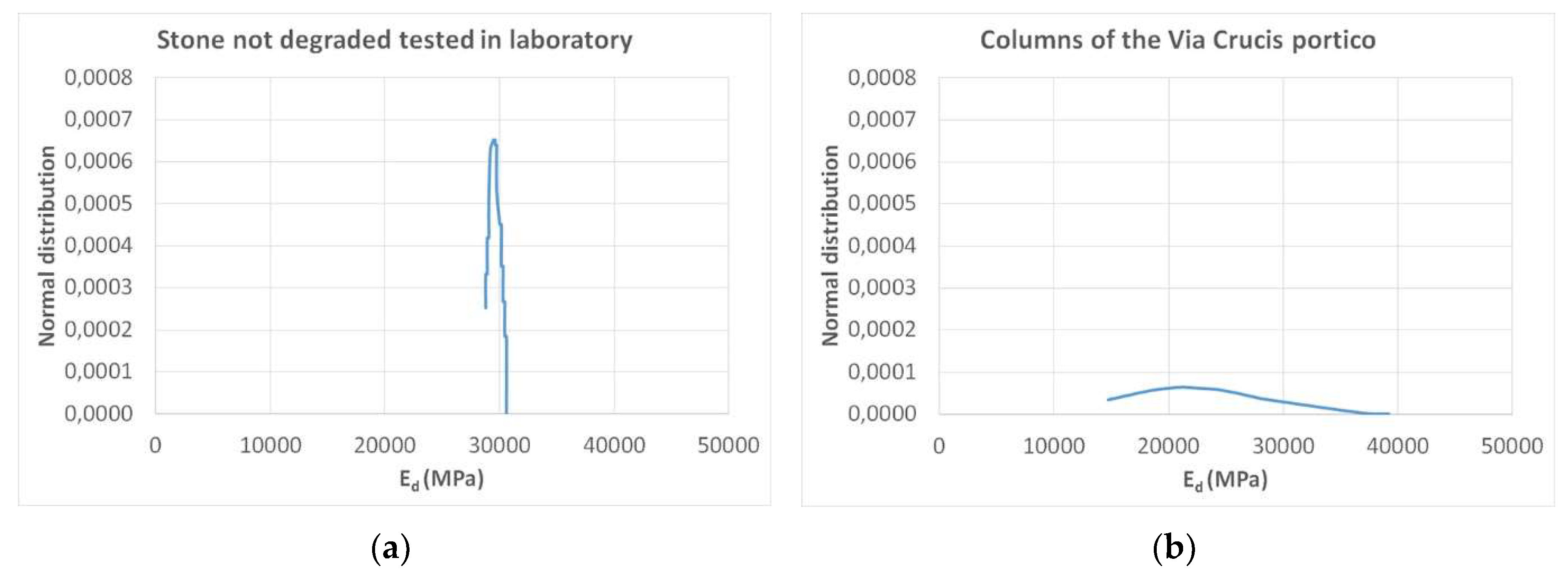

3.1. Ultrasonic Tests

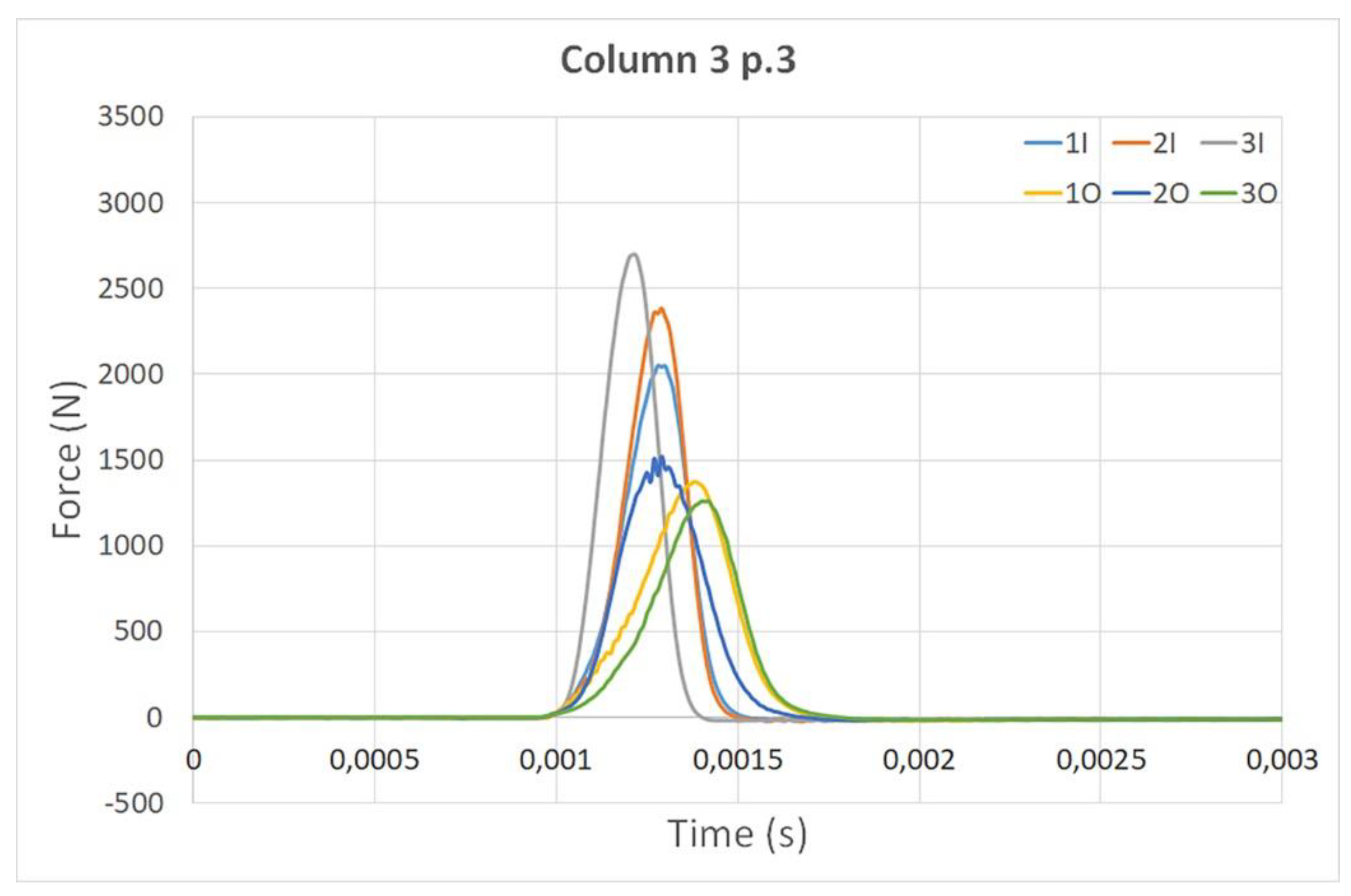

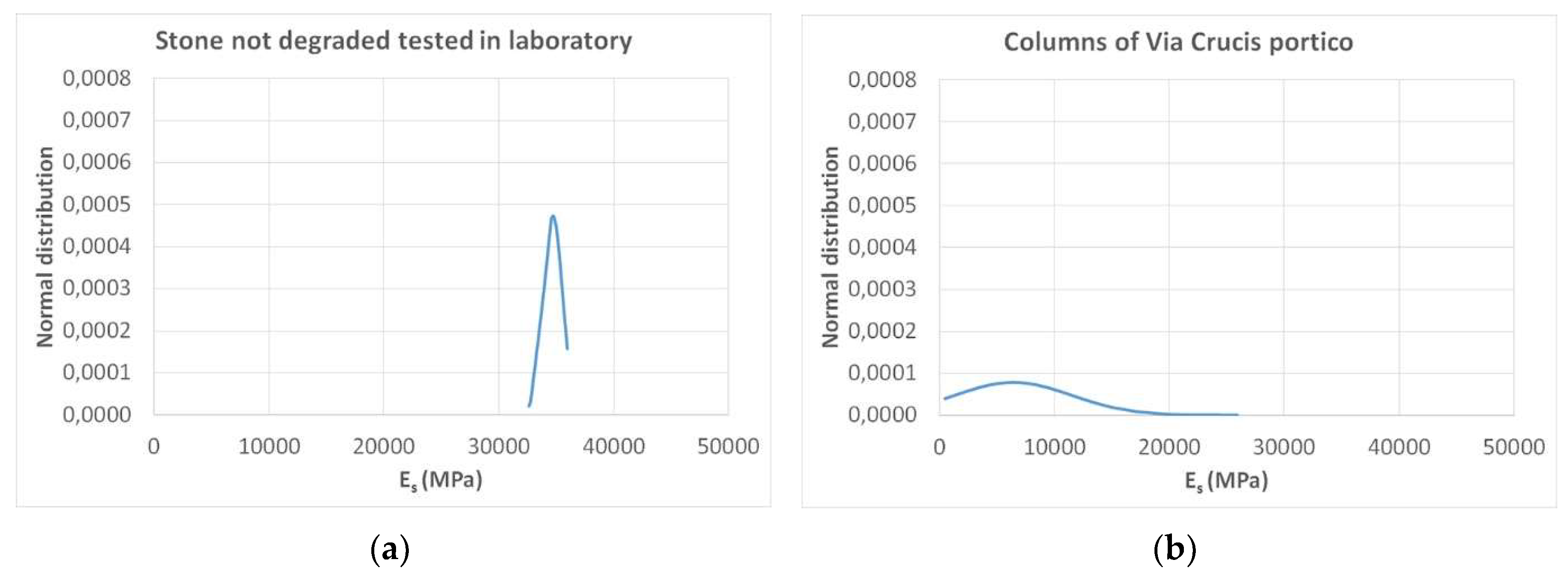

3.2. Impact Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Formia, A.; Serra, C.L.; Zerbinatti, M.; Tulliani, J.M. The plasters of the Sacro Monte of Varallo Sesia. From the characterization to the proposition of a restorative mix. Case Stud. Constr. Mater. 2014, 1, 46–52. [Google Scholar] [CrossRef][Green Version]

- Cizer, Ö.; Schueremans, L.; Serre, G.; Janssens, E.; Van Balen, K. Assessment of the compatibility of repair mortars in restoration projects. Adv. Mater. Res. 2010, 133–134, 1071–1076. [Google Scholar] [CrossRef]

- Wiggins, D.E.; Klemm, A.J. Compatible repairs to stone built structures. Proc. Inst. Civ. Eng. Eng. Hist. Herit. 2014, 167, 196–207. [Google Scholar] [CrossRef]

- Grazzini, A.; Zerbinatti, M.; Fasana, S. Mechanical characterization of mortars used in the restoration of historical buildings: An operative atlas for maintenance and conservation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 629, 1–7. [Google Scholar] [CrossRef]

- Isebaert, A.; Van Parys, L.; Cnudde, V. Composition and compatibility requirements of mineral repair mortars for stone—A review. Const. Build. Mater. 2014, 59, 39–50. [Google Scholar] [CrossRef]

- Binda, L.; Gambarotta, L.; Lagomarsino, S.; Modena, C. A multilevel approach to the damage assessment and the seismic improvement of masonry buildings in Italy. In Seismic Damage to Masonry Buildings; Bernardini, A., Ed.; Balkema: Rotterdam, Holland, 1999; pp. 179–194. [Google Scholar]

- Binda, L.; Cantini, L.; Tedeschi, C. Diagnosis of Historic Masonry Structures Using Non-Destructive Techniques. In Nondestructive Testing of Materials and Structures; Buyukozturk, O., Tasdemir, M.A., Gunes, O., Akkaya, Y., Eds.; Springer Netherlands: Heidelberg, Germany, 2013; pp. 1089–1102. [Google Scholar] [CrossRef]

- Grazzini, A. The important role of diagnostics for the structural recovery of historic buildings. Int. J. Arch. Eng. Technol. 2019, 6, 7–16. [Google Scholar] [CrossRef]

- Invernizzi, S.; Lacidogna, G.; Carpinteri, A. Structural monitoring and assessment of an ancient masonry tower. Eng. Fract. Mech. 2019, 210, 429–443. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G. Damage monitoring of an historical masonry building by the acoustic emission technique. Mater. Struct. 2006, 39, 161–167. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Pugno, N. Structural damage diagnosis and life-time assessment by acoustic emission monitoring. Eng. Fract. Mech. 2007, 74, 273–289. [Google Scholar] [CrossRef]

- Carpinteri, A.; Invernizzi, S.; Lacidogna, G. Historical brick-masonry subjected to double flat-jack test: Acoustic emissions and scale effects on cracking density. Constr. Build. Mater. 2009, 23, 2813–2820. [Google Scholar] [CrossRef]

- Cantini, L.; Bonavita, A.; Parisi, M.A.; Tardini, C. Historical analysis and diagnostic investigations in the knowledge acquisition path for architectural heritage. In Proceedings of the Congress in Structural Analysis of Historical Constructions—Anamnesis, Diagnosis, Therapy, Controls, Leuven, Belgium, 13–15 September 2016; Van Balen, V., Ed.; Taylor & Francis Group: London, UK, 2016. [Google Scholar]

- Grazzini, A. Sonic and Impact Test for Structural Assessment of Historical Masonry. Appl. Sci. 2019, 9, 5148. [Google Scholar] [CrossRef]

- Chastre, C.; Ludovico-Marques, M. Nondestructive testing methodology to assess the conservation of historic stone buildings and monuments. In Handbook of Materials Failure Analysis with Case Studies from the Construction Industries; Hamdy Makhlouf, A.S., Aliofkhazraei, M., Eds.; Elsevier: New York, NY, USA, 2018; pp. 255–294. ISBN 978-0-08-101928-3. [Google Scholar] [CrossRef]

- Vasconcelos, G.; Lourenço, P.B.; Alves, C.S.A.; Pamplona, G. Prediction of the mechanical properties of granites by ultrasonic pulse velocity and Schmidt hammer hardness. In Proceedings of the 10th North American Masonry Conference, St. Louis, MO, USA, 3–6 June 2007; Myers, B., Ed.; Masonry Society: Longmont, CO, USA, 2007. [Google Scholar]

- Grazzini, A. In Situ Analysis of Plaster Detachment by Impact Tests. Appl. Sci. 2019, 9, 258. [Google Scholar] [CrossRef]

- The Sacred Mounts of Piedmont and of Lombardy. Available online: www.sacrimonti.net (accessed on 10 February 2020).

- Gonçalves, T.D.; Pel, L.; Delgado Rodrigues, J. Influence of paints on drying and salt distribution processes in porous building materials. Constr. Build. Mater. 2009, 23, 1751–1759. [Google Scholar] [CrossRef]

- Bocca, P.; Grazzini, A.; Masera, D.; Alberto, A.; Valente, S. Mechanical interaction between historical brick and repair mortar: Experimental and numerical tests. J. Phys. Conf. Ser. 2011, 305, 1–10. [Google Scholar] [CrossRef]

- Bocca, P.; Valente, S.; Grazzini, A.; Alberto, A. Detachment analysis of dehumidified repair mortars applied to historical masonry walls. Int. J. Arch. Herit. 2014, 8, 336–348. [Google Scholar] [CrossRef]

- Grazzini, A.; Lacidogna, G.; Accornero, F. Delamination of plasters applied to historical masonry walls: Analysis by acoustic emission technique and numerical model. IPO Conf. Ser. Mater. Sci. Eng. 2018, 372, 1–7. [Google Scholar] [CrossRef]

- Accornero, F.; Invernizzi, S.; Lacidogna, G.; Carpinteri, A. The Sacred Mountain of Varallo renaissance complex in Italy: Damage analysis of decorated surfaces and structural supports. In Acoustic, Electromagnetic, Neutron Emissions from Fracture and Earthquakes, 1st ed.; Carpinteri, A., Lacidogna, G., Manuello, A., Eds.; Springer: Heidelberg, Germany, 2015; pp. 249–264. [Google Scholar] [CrossRef]

- Delgado Rodrigues, J. Conservation of stone monuments. From diagnostic to practice. In Proceedings of the MINBAR AL JAMIAA n°7—RIPAM 2005, Mekés, Maroc, 26–28 September 2005; pp. 287–295. [Google Scholar]

- Delgado Rodrigues, J.; Ferreira Pinto, A.; Rodrigues da Costa, D. Tracing of decay profiles and evaluation of stone treatments by means of microdrilling techniques. J. Cult. Herit. 2002, 3, 117–125. [Google Scholar] [CrossRef]

- ASTM D2845 1995. Standard Test Method for Laboratory Determination of Pulse Velocities and Ultrasonic Elastic Constants of Rock; American Society for Testing Materials: West Conshohocken, PA, USA, 1995. [Google Scholar]

- UNI EN 12504-4: 2005. Prove sul Calcestruzzo nelle Strutture—Parte 4: Determinazione della Velocità di Propagazione Degli Impulsi Ultrasonici (in Italian); Ente Nazionale Italiano di Unificazione: Milan, Italy, 2005. [Google Scholar]

- Domede, N.; Parent, T.; Sellier, A. Mechanical behaviour of granite: A compilation, analysis and correlation of data from around the world. Eur. J. Environ. Civ. Eng. 2019, 23, 193–211. [Google Scholar] [CrossRef]

- Bocca, P.; Scavia, C. The impulse method for the evaluation of concrete elastic characteristics. In Proceedings of the 9th International Conference on Experimental Mechanics, Copenhagen, Denmark, 20–24 August 1990. [Google Scholar]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Deresiewicz, H. A note on Hertz Impact. Acta Mech. 1968, 6, 110–112. [Google Scholar] [CrossRef]

- Dhawan, K.R.; Muralidhar, B. Relationship between static and two types of dynamic moduli for different rocks. Ind. Getech. J. 2015, 45, 341–348. [Google Scholar] [CrossRef]

- Bocca, P.; Carpinteri, A.; Valente, S. On the applicability of fracture mechanics to masonry. In Proceedings of the 8th International Brick/Block Masonry Conference, Dublin, Ireland, 19–21 September 1988. [Google Scholar]

| Column | Test Point | Height (cm) | v (m/s) | Ed (MPa) | fc (MPa) 2 |

|---|---|---|---|---|---|

| 1 | 1 | 57 | 3269 | 25,878 | 97 |

| 2 | 98 | 2503 | 15,170 | 66 | |

| 3 | 230 | 2805 | 19064 | 78 | |

| 2 | 1 | 65 | 3411 | 28,183 | 103 |

| 2 | 123 | 2466 | 14,728 | 64 | |

| 3 | 223 | 2494 | 15,067 | 65 | |

| 3 | 1 | 70 | 2910 | 20,506 | 82 |

| 2 | 230 | 2939 | 25,406 | 96 | |

| 4 | 1 | 60 | 4024 | 39,219 | 127 |

| 2 | 232 | 3908 | 36,985 | 123 | |

| 5 | 1 | 68 | 2724 | 17,972 | 75 |

| 2 | 228 | 2738 | 18,156 | 75 | |

| 6 | 1 | 55 | 2766 | 18,525 | 76 |

| 7 | 1 | 86 | 3402 | 28,033 | 102 |

| 2 | 206 | 2948 | 21,046 | 84 | |

| 8 | 1 | 86 | 2774 | 18,644 | 77 |

| 2 | 229 | 3223 | 25,158 | 95 | |

| 9 | 1 | 146 | 2495 | 15,080 | 65 |

| 10 | 1 | 100 | 2522 | 15,406 | 66 |

| 2 | 228 | 2756 | 18,402 | 76 | |

| 11 | 1 | 101 | 2698 | 17,627 | 73 |

| 2 | 204 | 2773 | 18,629 | 77 | |

| 12 | 1 | 90 | 2965 | 21,300 | 84 |

| 2 | 190 | 3178 | 24,468 | 93 | |

| 13 | 1 | 35 | 4638 | 52,111 1 | 152 1 |

| 2 | 130 | 2840 | 19,532 | 79 | |

| 3 | 224 | 3149 | 24,024 | 92 |

| Stone | Es average (MPa) | σ (MPa) |

|---|---|---|

| New stone in the laboratory | 34,711 | 843 |

| Old stone of the columns | 6394 | 5100 |

| Stone | Vaverage (m/s) | Ed average (MPa) | σ (MPa) |

|---|---|---|---|

| New stone in the laboratory | 3498 | 29,640 | 611 |

| Old stone of the columns | 2961 | 21,623 | 6183 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grazzini, A.; Fasana, S.; Zerbinatti, M.; Lacidogna, G. Non-Destructive Tests for Damage Evaluation of Stone Columns: The Case Study of Sacro Monte in Ghiffa (Italy). Appl. Sci. 2020, 10, 2673. https://doi.org/10.3390/app10082673

Grazzini A, Fasana S, Zerbinatti M, Lacidogna G. Non-Destructive Tests for Damage Evaluation of Stone Columns: The Case Study of Sacro Monte in Ghiffa (Italy). Applied Sciences. 2020; 10(8):2673. https://doi.org/10.3390/app10082673

Chicago/Turabian StyleGrazzini, Alessandro, Sara Fasana, Marco Zerbinatti, and Giuseppe Lacidogna. 2020. "Non-Destructive Tests for Damage Evaluation of Stone Columns: The Case Study of Sacro Monte in Ghiffa (Italy)" Applied Sciences 10, no. 8: 2673. https://doi.org/10.3390/app10082673

APA StyleGrazzini, A., Fasana, S., Zerbinatti, M., & Lacidogna, G. (2020). Non-Destructive Tests for Damage Evaluation of Stone Columns: The Case Study of Sacro Monte in Ghiffa (Italy). Applied Sciences, 10(8), 2673. https://doi.org/10.3390/app10082673