NURBS-Enhanced Meshfree Method with an Integration Subtraction Technique for Complex Topology

Abstract

1. Introduction

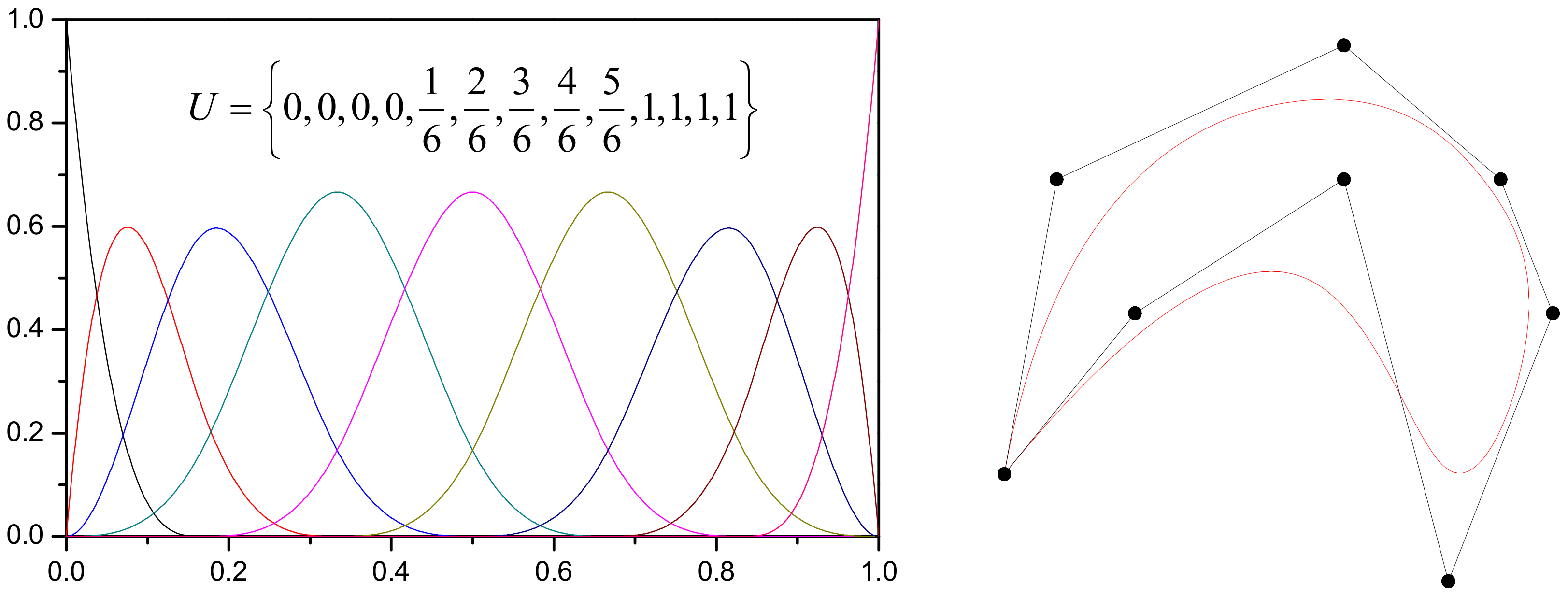

2. Basic Theory for the NURBS and RPIM Meshfree Methods

2.1. NURBS

- 1.

- Nonnegativity:

- 2.

- Partition of unity:

- 3.

- Local support: if u is outside the interval given by

- 4.

- Differentiability: is at least p-k times continuously differentiable at the knot of multiplicity k

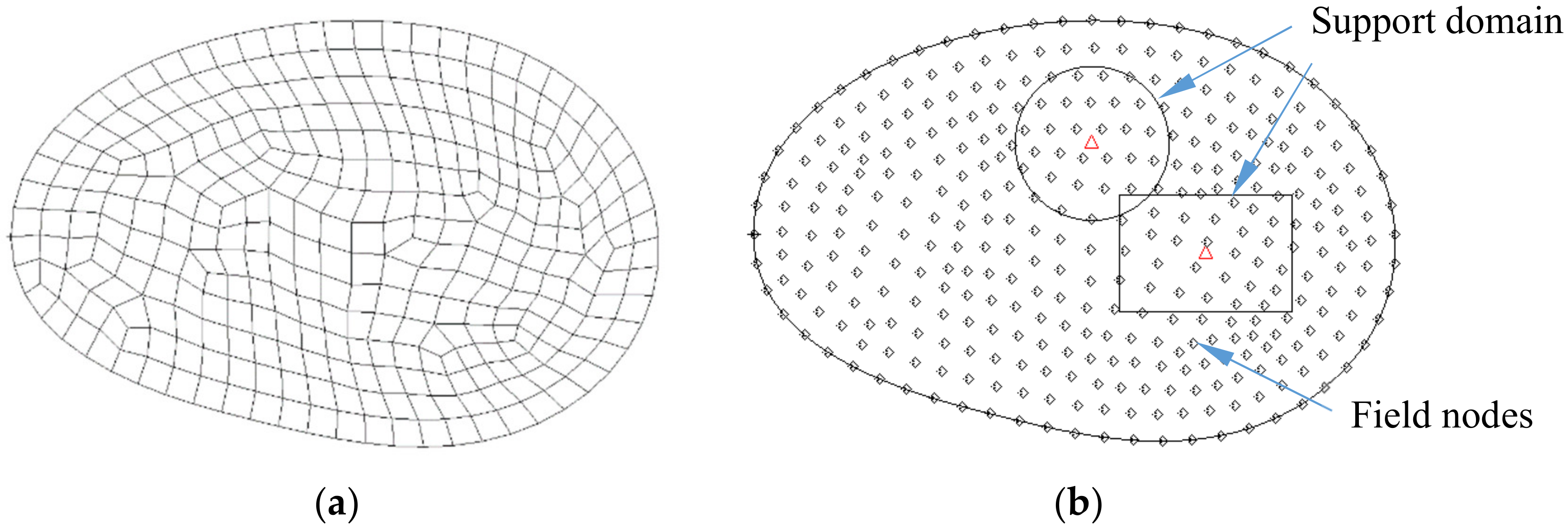

2.2. RPIM Meshfree Method

- 1.

- It is time consuming to generate a quality mesh in an arbitrary geometry with the desired accuracy.

- 2.

- It is difficult to construct approximations with an arbitrary order of continuity, making PDEs with higher-order differentiation or problems with discontinuities difficult to solve.

- 3.

- Performing h- or p-adaptive refinement is tedious.

- 4.

- The finite element method is ineffective in dealing with mesh entanglement-related difficulties (such as those in large deformation and fragment-impact problems).

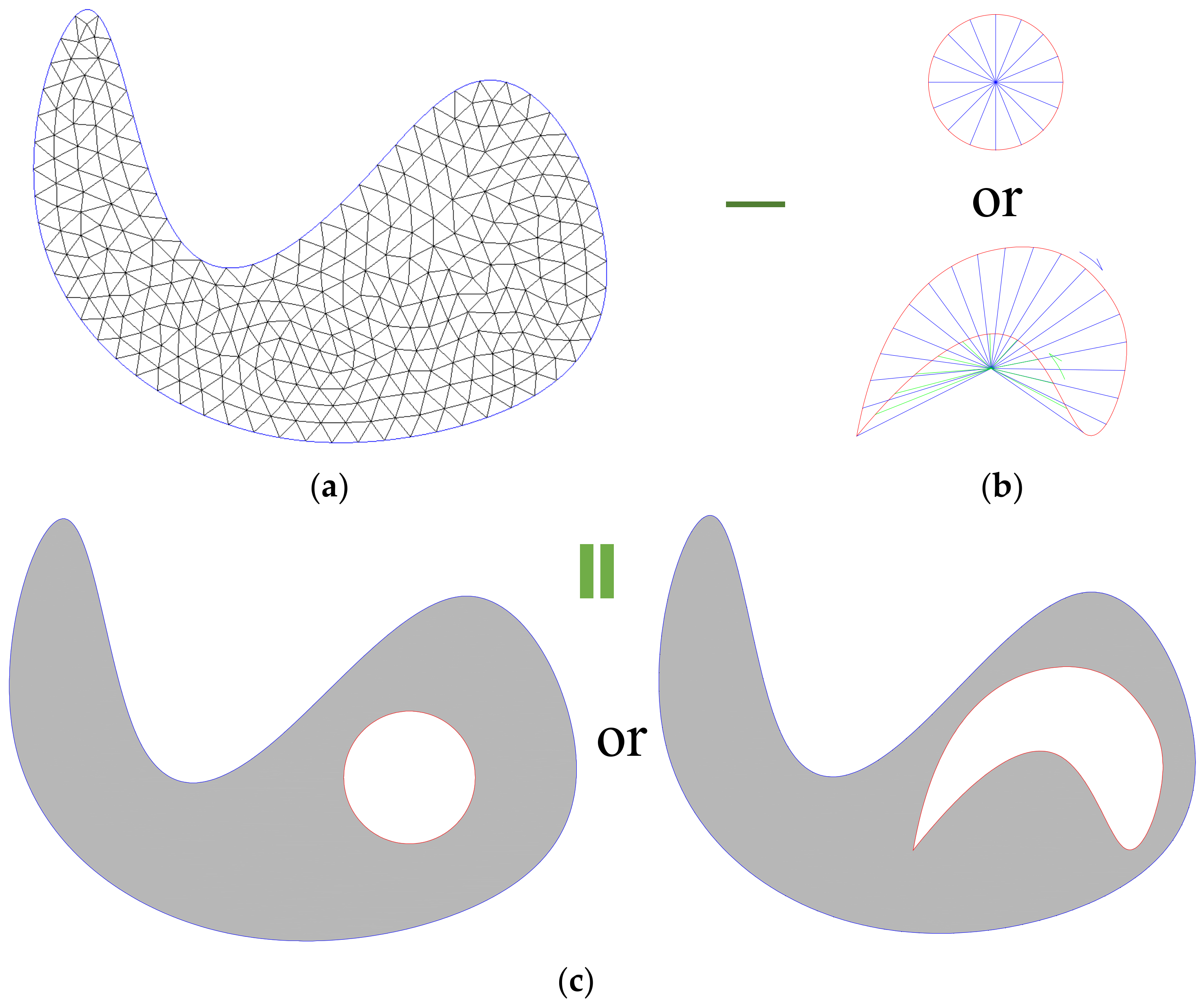

3. NURBS-Enhanced Meshfree Method with the Integration Subtraction Technique

3.1. NURBS-Enhanced Meshfree Method

3.2. Integration Subtraction Technique

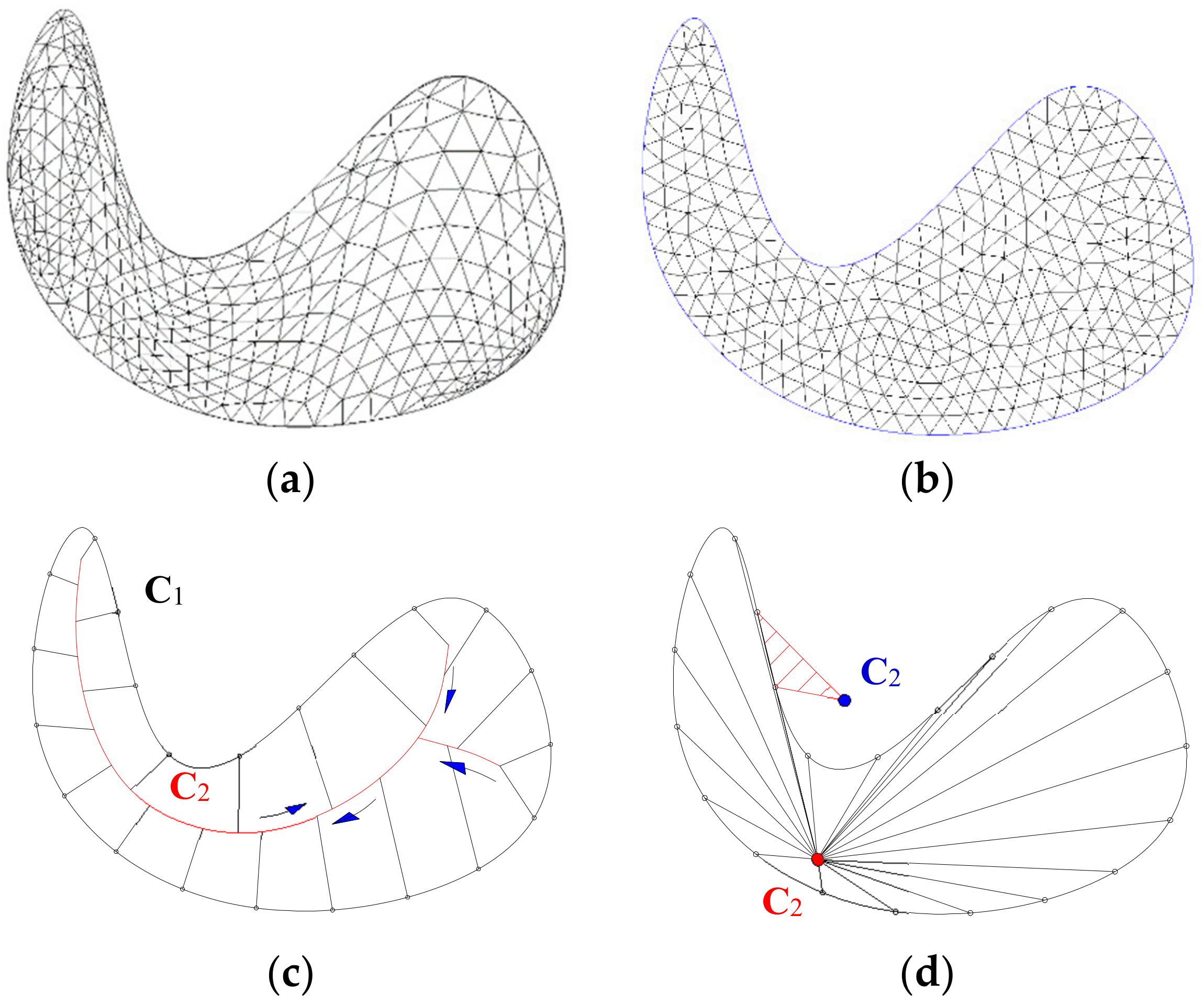

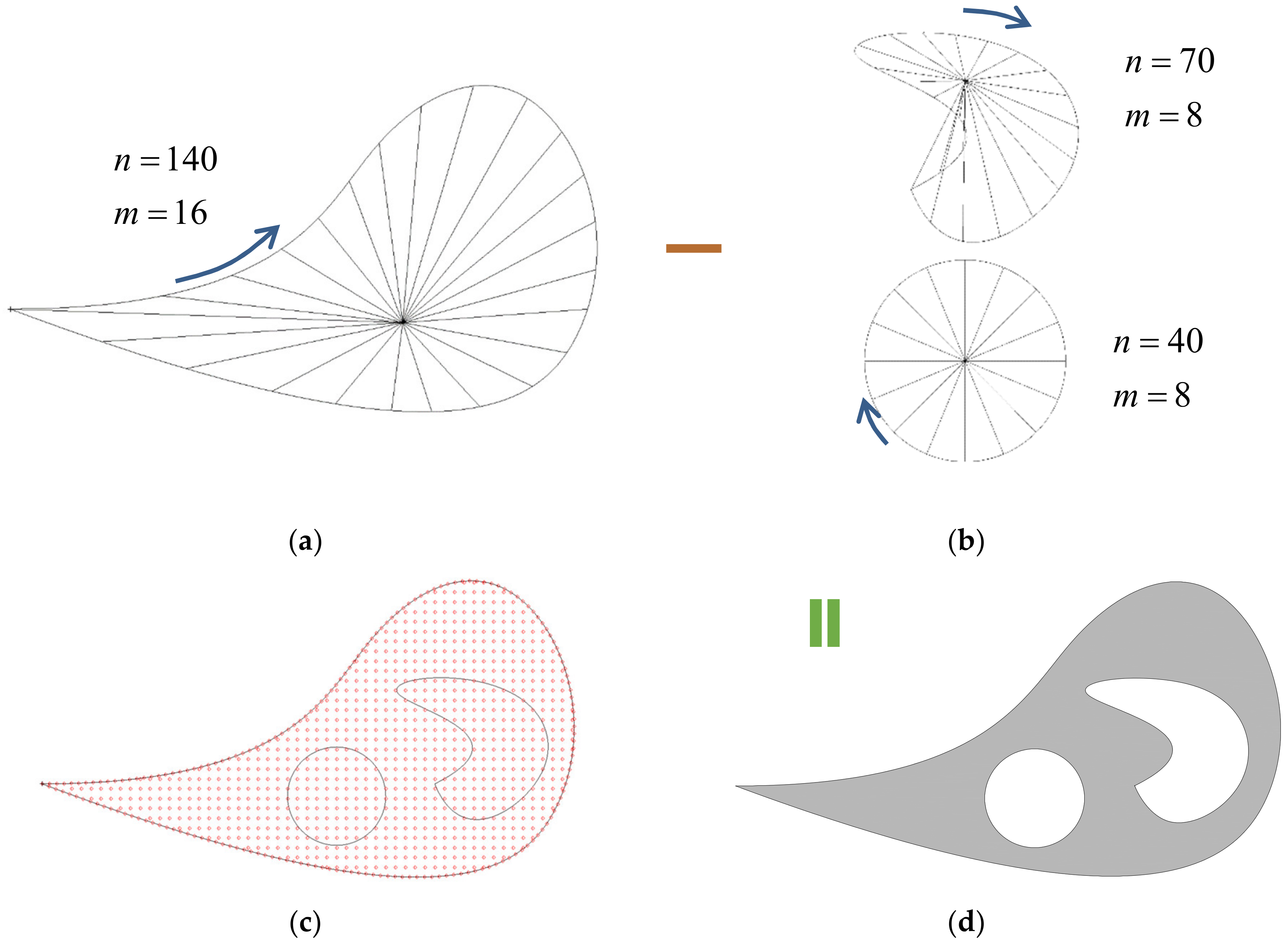

3.2.1. Meshing for a Predesigned Simply Connected Domain

3.2.2. Deploying the Field Nodes

3.2.3. Meshing Homotopically for the Holes

3.2.4. Numerical Integration and Normal Subtraction Technique

3.2.5. Moving Subtraction Technique for a Varying Hole

4. Numerical Examples

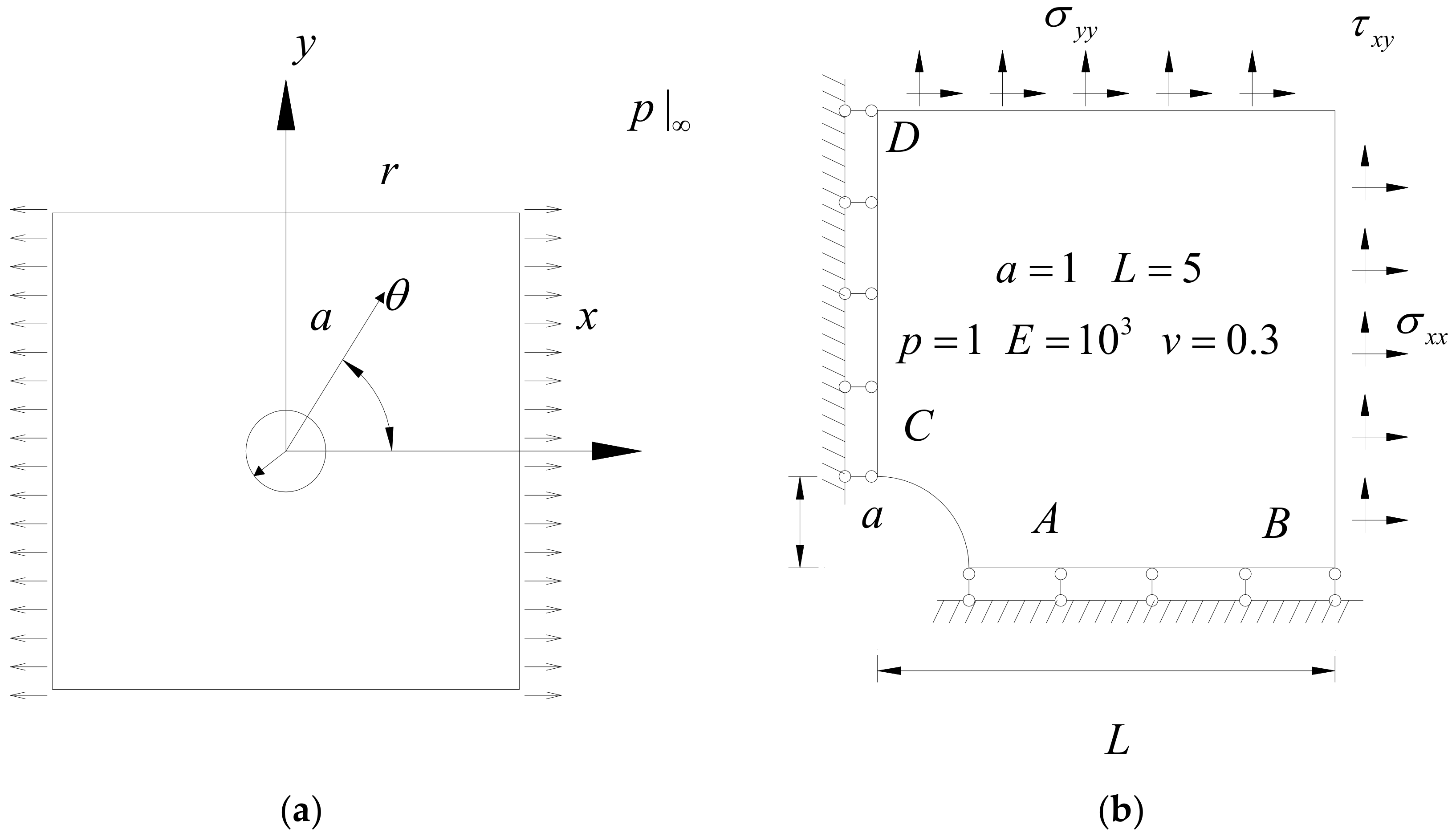

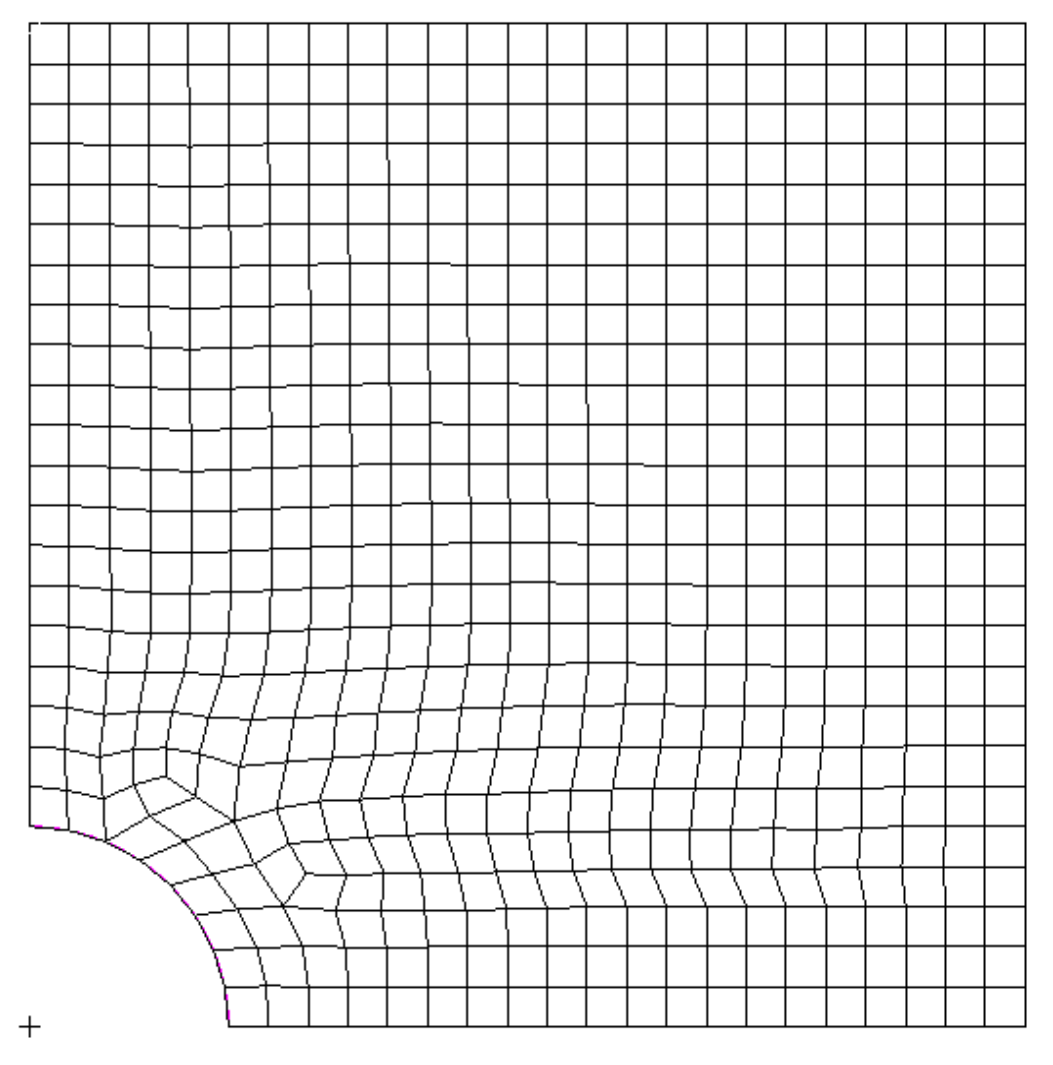

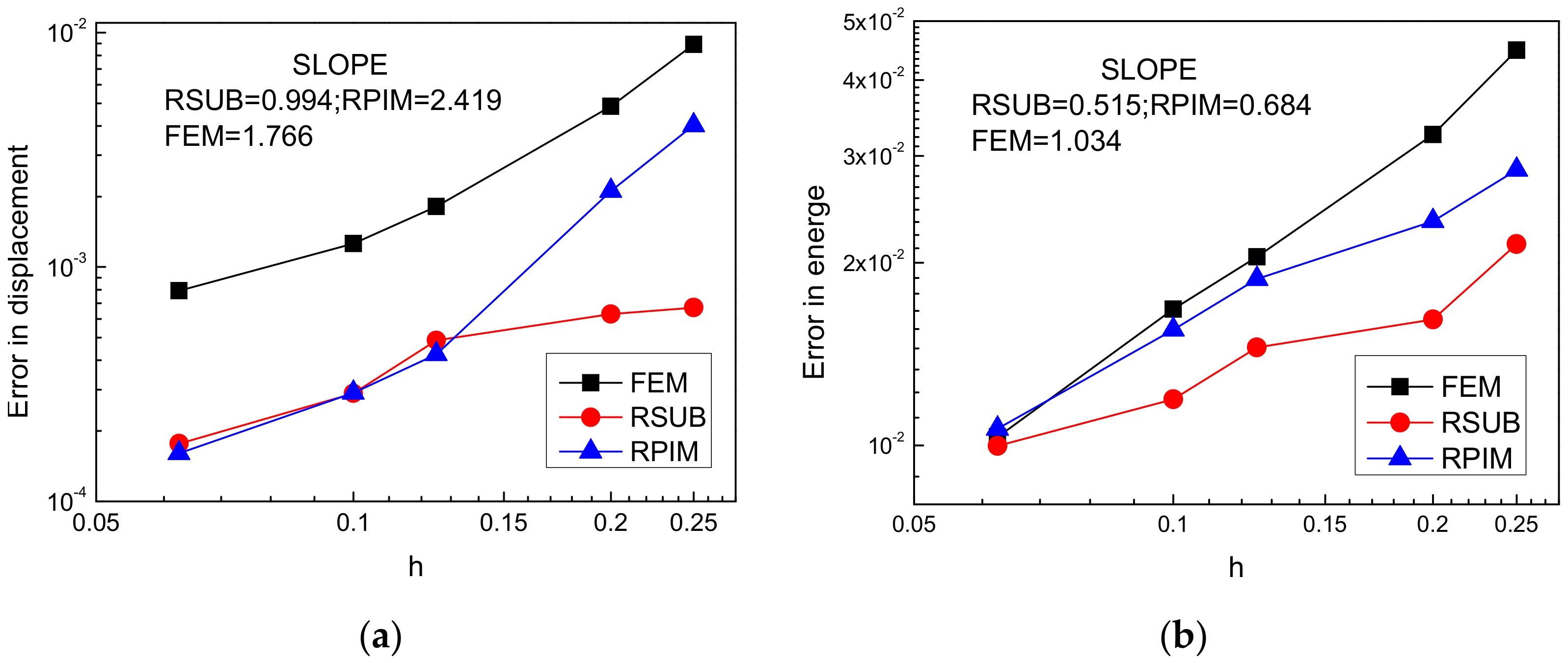

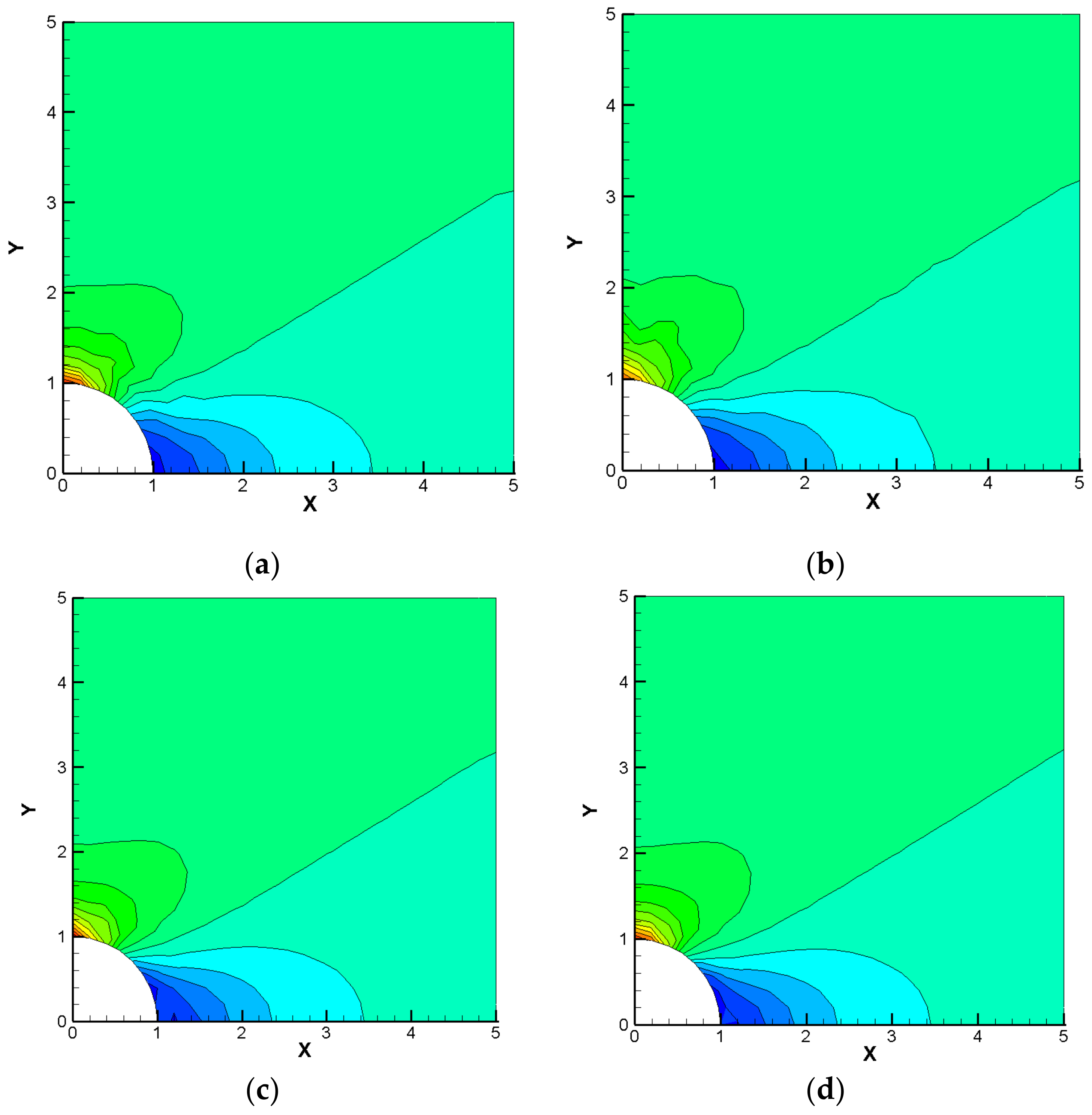

4.1. Infinite Plate with a Circular Hole

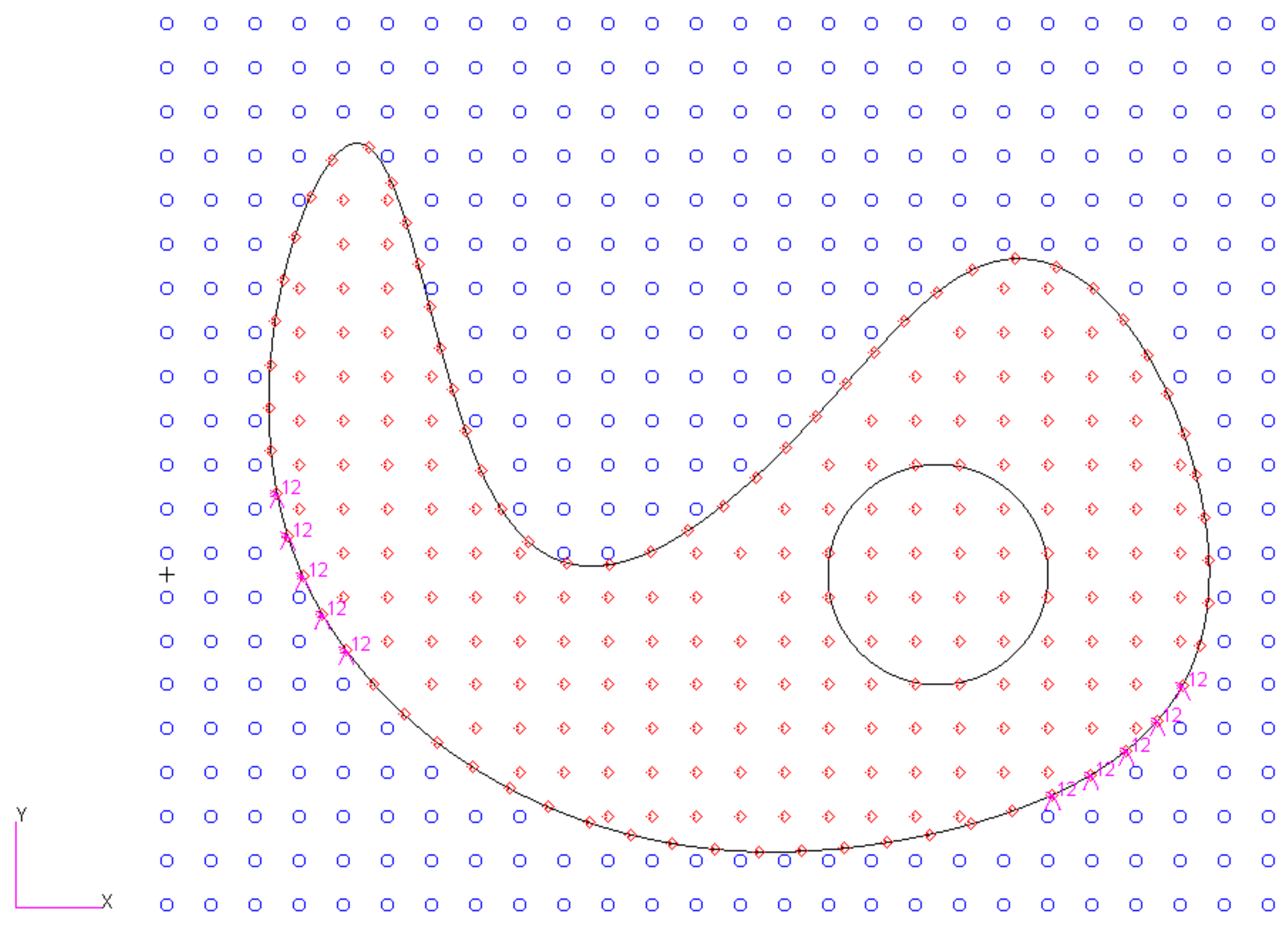

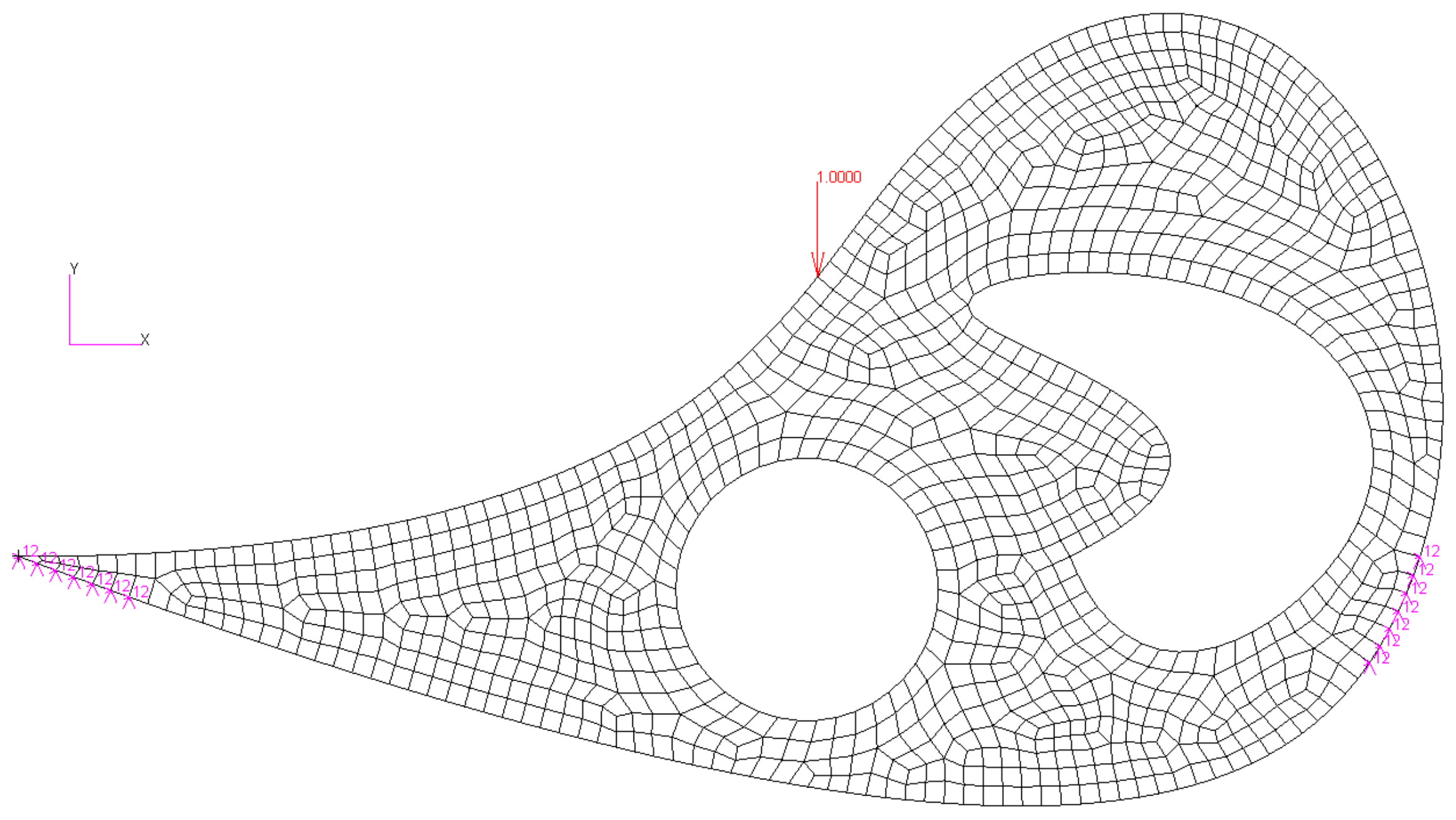

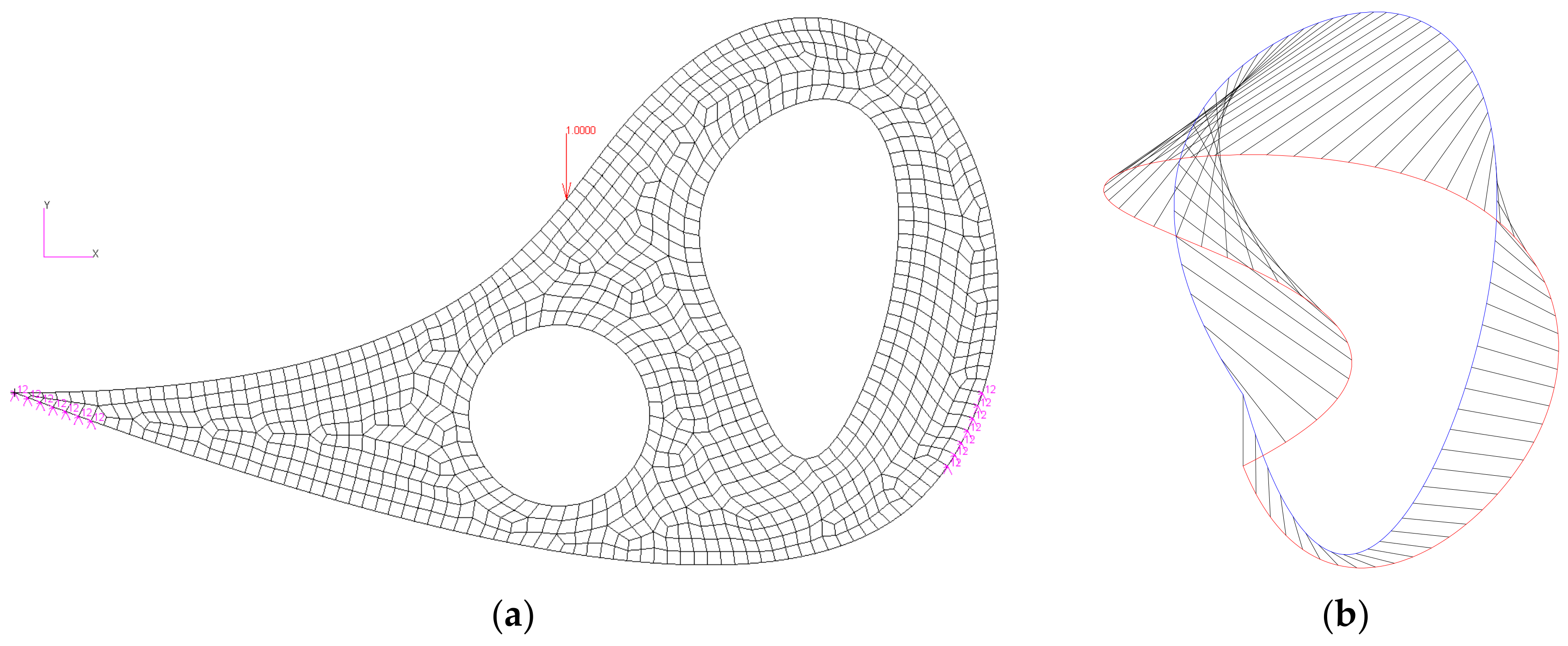

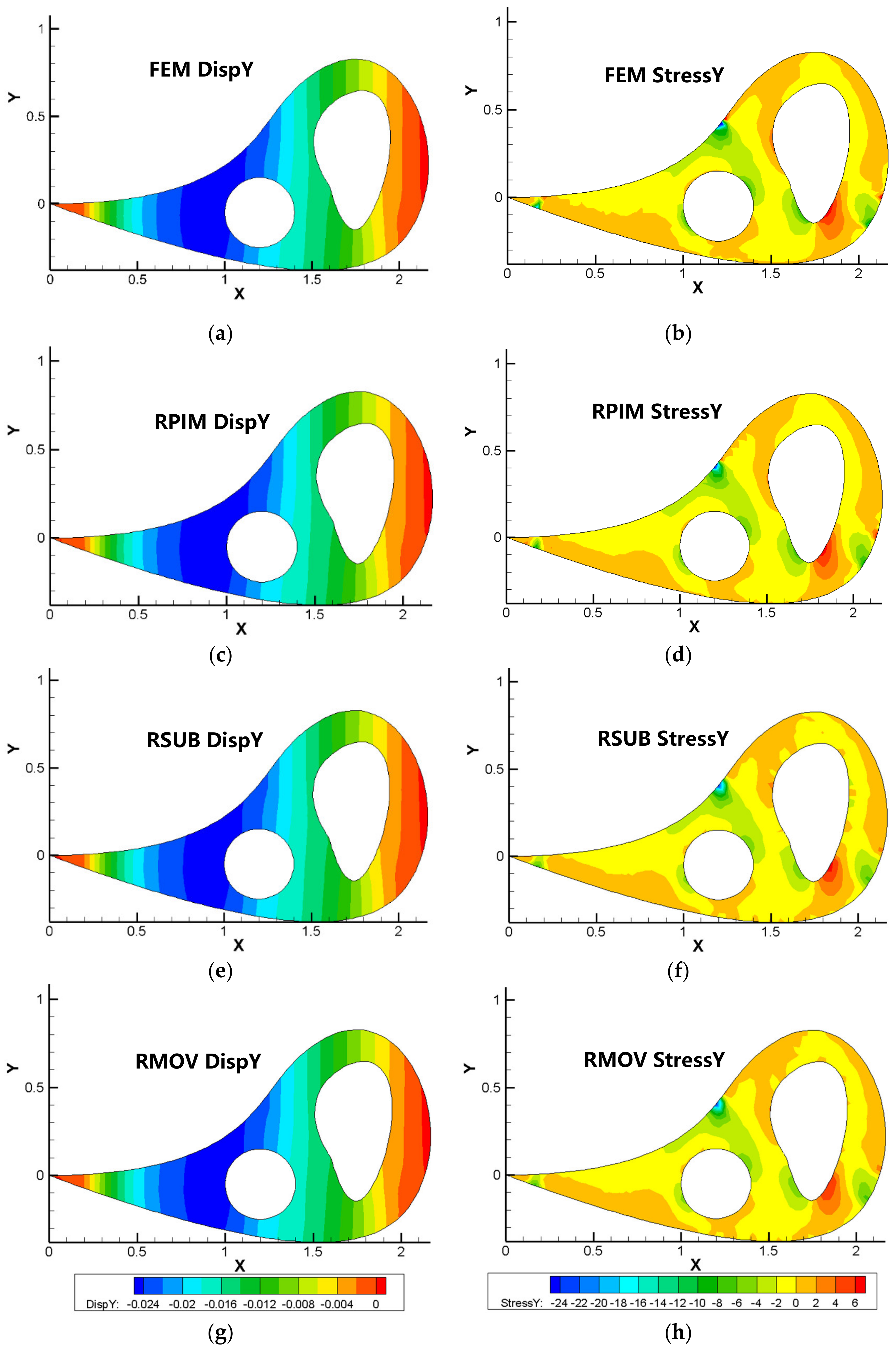

4.2. Bubble with Arbitrary Holes

4.3. Bubble with Varied Holes

5. Conclusions

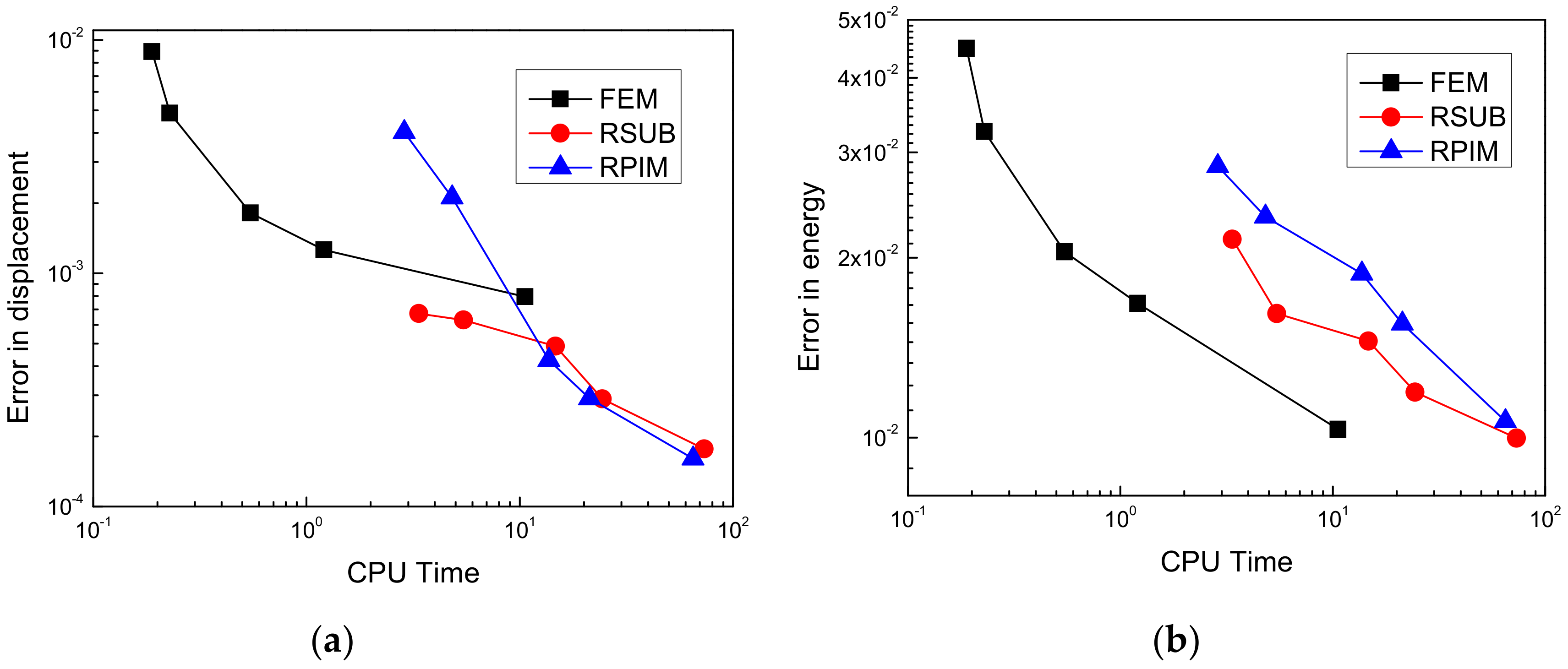

- 1.

- Both RPIM and RSUB are more accurate than FEM and show higher convergence in displacement but do not have good enough energy convergence.

- 2.

- The proposed RSUB method achieves superior accuracy on a coarse mesh and a smoother stress result with a regular hole.

- 3.

- The duplicated integration of holes for subtraction yields improvements in precision, making RSUB more efficient than the original RPIM.

- 4.

- The results of both the proposed RSUB method and RMOV in displacement and stress are in good agreement with those of FEM and RPIM but cause little oscillation in the stress field near the boundary of the irregular hole, with RMOV causing less than RSUB.

Author Contributions

Funding

Conflicts of Interest

References

- Nguyen, V.P.; Anitescu, C.; Bordas, S.P.A.; Rabczuk, T. Isogeometric analysis: An overview and computer implementation aspects. Math. Comput. Simul. 2015, 117, 89–116. [Google Scholar] [CrossRef]

- Hughes, T.J.R.; Cottrell, J.A.; Bazilevs, Y. Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput. Methods Appl. Mech. Eng. 2005, 194, 4135–4195. [Google Scholar] [CrossRef]

- Cottrell, J.A.; Hughes, T.J.R.; Reali, A. Studies of refinement and continuity in isogeometric structural analysis. Comput. Methods Appl. Mech. Eng. 2007, 196, 4160–4183. [Google Scholar] [CrossRef]

- Bazilevs, Y.; Calo, V.M.; Cottrell, J.A.; Hughes, T.J.R.; Reali, A.; Scovazzi, G. Variational multiscale residual-based turbulence modeling for large eddy simulation of incompressible flows. Comput. Methods Appl. Mech. Eng. 2007, 197, 173–201. [Google Scholar] [CrossRef]

- Bazilevs, Y.; Calo, V.M.; Zhang, Y.; Hughes, T.J.R. Isogeometric fluid–structure interaction analysis with applications to arterial blood flow. Comput. Mech. 2006, 38, 310–322. [Google Scholar] [CrossRef]

- Lipton, S.; Evans, J.A.; Bazilevs, Y.; Elguedj, T.; Hughes, T.J.R. Robustness of isogeometric structural discretizations under severe mesh distortion. Comput. Methods Appl. Mech. Eng. 2010, 199, 357–373. [Google Scholar] [CrossRef]

- Hughes, T.J.R.; Reali, A.; Sangalli, G. Efficient quadrature for NURBS-based isogeometric analysis. Comput. Methods Appl. Mech. Eng. 2010, 199, 301–313. [Google Scholar] [CrossRef]

- Kim, H.-J.; Seo, Y.-D.; Youn, S.-K. Isogeometric analysis with trimming technique for problems of arbitrary complex topology. Comput. Methods Appl. Mech. Eng. 2010, 199, 2796–2812. [Google Scholar] [CrossRef]

- Kim, H.-J.; Seo, Y.-D.; Youn, S.-K. Isogeometric analysis for trimmed CAD surfaces. Comput. Methods Appl. Mech. Eng. 2009, 198, 2982–2995. [Google Scholar] [CrossRef]

- Xu, J.; Chen, F.; Deng, J. Two-dimensional domain decomposition based on skeleton computation for parameterization and isogeometric analysis. Comput. Methods Appl. Mech. Eng. 2015, 284, 541–555. [Google Scholar] [CrossRef]

- Xu, G.; Li, M.; Mourrain, B.; Rabczuk, T.; Xua, J.; Bordas, S.P.A. Constructing IGA-suitable planar parameterization from complex CAD boundary by domain partition and global/local optimization. Comput. Methods Appl. Mech. Eng. 2018, 328, 175–200. [Google Scholar] [CrossRef]

- Hamrani, A.; Habib, S.H.; Belaidi, I. CS-IGA: A new cell-based smoothed isogeometric analysis for 2D computational mechanics problems. Comput. Methods Appl. Mech. Eng. 2017, 315, 671–690. [Google Scholar] [CrossRef]

- Sevilla, R.; Fernández-Méndez, S.; Huerta, A. NURBS-enhanced finite flement method (NEFEM). Arch. Comput. Methods Eng. 2008, 76, 56–83. [Google Scholar] [CrossRef]

- Bazilevs, Y.; Calo, V.M.; Cottrell, J.A.; Evans, J.A.; Hughes, T.J.R.; Lipton, S.; Scott, M.A.; Sederberg, T.W. Isogeometric analysis using T-splines. Comput. Methods Appl. Mech. Eng. 2010, 199, 229–263. [Google Scholar] [CrossRef]

- Dörfel, M.R.; Jüttler, B.; Simeon, B. Adaptive isogeometric analysis by local h-refinement with T-splines. Comput. Methods Appl. Mech. Eng. 2010, 199, 264–275. [Google Scholar] [CrossRef]

- Javier, V.; Felipe, C.; Hoang, X.; Nguyen, E.A. Application of PHT-splines in bending and vibration analysis of cracked Kirchhoff–Love plates. Comput. Methods Appl. Mech. Eng. 2020, 361, 112754. [Google Scholar] [CrossRef]

- Valizadeh, N.; Bazilevs, Y.; Chen, J.S.; Rabczuk, T. A coupled IGA–meshfree discretization of arbitrary order of accuracy and without global geometry parameterization. Comput. Methods Appl. Mech. Eng. 2015, 293, 20–37. [Google Scholar] [CrossRef]

- Thai, C.H.; Nguyen, T.N.; Rabczuk, T.; Nguyen-Xuan, H. An improved moving kriging meshfree method for plate analysis using a refined plate theory. Comput Struct. 2016, 176, 34–49. [Google Scholar] [CrossRef]

- Greco, F.; Coox, L.; Maurin, F.; Desmet, W. NURBS-enhanced maximum-entropy schemes. Comput. Methods Appl. Mech. Eng. 2017, 317, 580–597. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, D. An isogeometric enriched quasi-convex meshfree formulation with application to material interface modeling. Eng. Anal. Bound. Elem. 2015, 60, 37–50. [Google Scholar] [CrossRef]

- Gingold, R.A.; Monaghan, J.J. Smoothed Particle Hydrodynamics—Theory and Application to Non-Spherical Stars. Mon. Not. R. Astron. Soc. 1977, 181, 375–389. [Google Scholar] [CrossRef]

- Lucy, L.B. A numerical approach to the testing of the fission hypothesis. Astron. J. 1977, 82, 1013–1024. [Google Scholar] [CrossRef]

- Liu, M.B.L.G.R. Smoothed Particle Hydrodyndmics a Mesh Free Particle Method; World Scientific Publishing Co., Pte. Ltd.: Singapore, 2003. [Google Scholar]

- Belytschko, T.; Lu, Y.Y.; Gu, L. Element-free Galerkin methods. Int. J. Numer. Meth. Eng. 1994, 37, 229–256. [Google Scholar] [CrossRef]

- Kansa, E.J. Multiquadrics—A scattered data approximation scheme with applications to computational fluid-dynamics-I surface approximations and partial derivative estimates. Comput. Math. Appl. 1990, 19, 127–145. [Google Scholar] [CrossRef]

- Liu, G.R. Meshfree Methods: Moving Beyond the Finite Element Method; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Simpson, R.N.; Bordas, S.P.A.; Trevelyan, J.; Rabczuk, T. A two-dimensional isogeometric boundary element method for elastostatic analysis. Comput. Methods Appl. Mech. Eng. 2012, 209–212, 87–100. [Google Scholar] [CrossRef]

- Natarajana, S.; Wang, J.; Song, C.; Birk, C. Isogeometric analysis enhanced by the scaled boundary finite element method. Comput. Struct. 2015, 283, 733–762. [Google Scholar] [CrossRef]

- Katsikadelis, J.T. Boundary Elements: Theory and Applications; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Song, C.; Wolf, J.P. The scaled boundary finite-element method—Alias consistent infinitesimal finite-element cell method—For elastodynamics. Comput. Methods Appl. Mech. Eng. 1997, 147, 329–355. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Li, P.; Lin, G.; Xu, T.; Chen, L. New application of the isogeometric boundary representations methodology with SBFEM to seepage problems in complex domains. Comput. Fluids 2018, 174, 241–255. [Google Scholar] [CrossRef]

- Chasapi, M.; Klinkel, S. A scaled boundary isogeometric formulation for the elasto-plastic analysis of solids in boundary representation. Comput. Methods Appl. Mech. Eng. 2018, 333, 475–496. [Google Scholar] [CrossRef]

- Gu, J.; Zhang, J.; Li, G. Isogeometric analysis in BIE for 3-D potential problem. Eng. Anal. Bound. Elem. 2012, 36, 858–865. [Google Scholar] [CrossRef]

- Heltai, L.; Arroyo, M.; DeSimone, A. Nonsingular isogeometric boundary element method for Stokes flows in 3D. Comput. Methods Appl. Mech. Eng. 2014, 268, 514–539. [Google Scholar] [CrossRef]

- Heltai, L.; Arroyo, M.; DeSimone, A. A review of the scaled boundary finite element method for two-dimensional linear elastic fracture mechanics. Eng. Fract. Mech. 2018, 187, 45–73. [Google Scholar] [CrossRef]

- Farin, G.; Hoschek, J.; Kim, M.-S. Handbook of Computer Aided Geometric Design; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Piegl, L.; Tiller, W. The NURBS Book; Springer: Berlin/Heidelberg, Germany, 1997. [Google Scholar]

- Chen, J.-S.; Hillman, M.; Chi, S.-W. Meshfree methods: Progress made after 20 Years. J. Eng. Mech. 2007, 143, 04017001. [Google Scholar] [CrossRef]

- Golberg, M.A.; Chen, C.S.; Bowman, H. Some recent results and proposals for the use of radial basis functions in the BEM. Eng. Anal. Bound. Elem. 1999, 23, 285–296. [Google Scholar] [CrossRef]

- Liu, G.R.; Gu, Y.T. A meshfree method: Meshfree weak–strong (MWS) form method for 2-D solids. Comput. Mech. 2003, 33, 2–14. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Wan, Z.; Yang, C.; Wang, X. NURBS-Enhanced Meshfree Method with an Integration Subtraction Technique for Complex Topology. Appl. Sci. 2020, 10, 2587. https://doi.org/10.3390/app10072587

Liu Y, Wan Z, Yang C, Wang X. NURBS-Enhanced Meshfree Method with an Integration Subtraction Technique for Complex Topology. Applied Sciences. 2020; 10(7):2587. https://doi.org/10.3390/app10072587

Chicago/Turabian StyleLiu, Yunzhen, Zhiqiang Wan, Chao Yang, and Xiaozhe Wang. 2020. "NURBS-Enhanced Meshfree Method with an Integration Subtraction Technique for Complex Topology" Applied Sciences 10, no. 7: 2587. https://doi.org/10.3390/app10072587

APA StyleLiu, Y., Wan, Z., Yang, C., & Wang, X. (2020). NURBS-Enhanced Meshfree Method with an Integration Subtraction Technique for Complex Topology. Applied Sciences, 10(7), 2587. https://doi.org/10.3390/app10072587