Status of BIPV and BAPV System for Less Energy-Hungry Building in India—A Review

Abstract

1. Introduction

2. PV Technologies for BIPV/BAPV

3. Building Integrated and Applied Photovoltaic (BIPV/BAPV) Technologies

4. Potential of BIPV/BAPV in India

5. Perspective and Discussion

Future Pathway of BIPV/BAPV in India

6. Conclusions

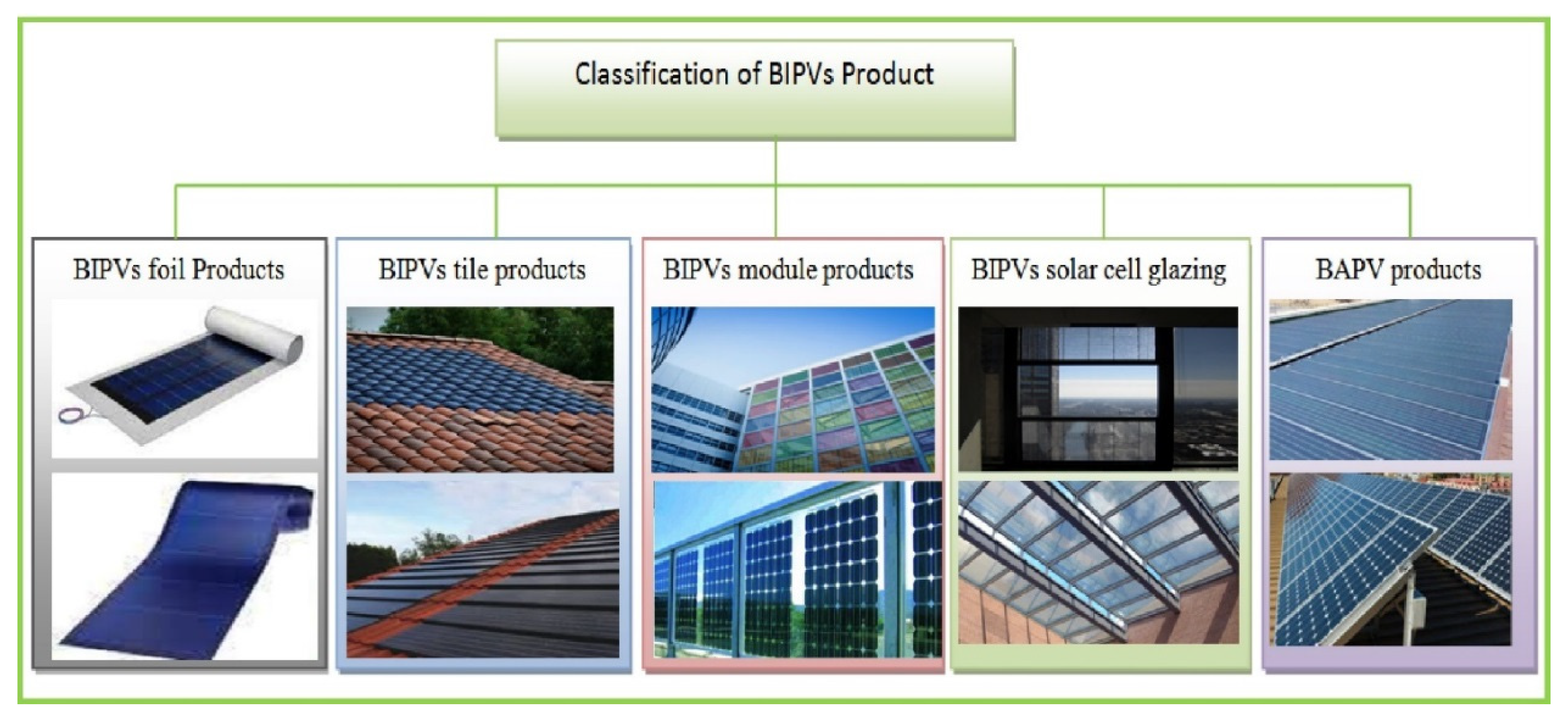

- Building integrated photovoltaic (BIPV) replaces traditional building envelop, such as window, wall, roof and most often they are thin film, or third-generation based transparent or semi-transparent in nature.

- Building attached/applied photovoltaic (BAPV) indicates when PV systems are attached to a building without replacing its traditional envelops.

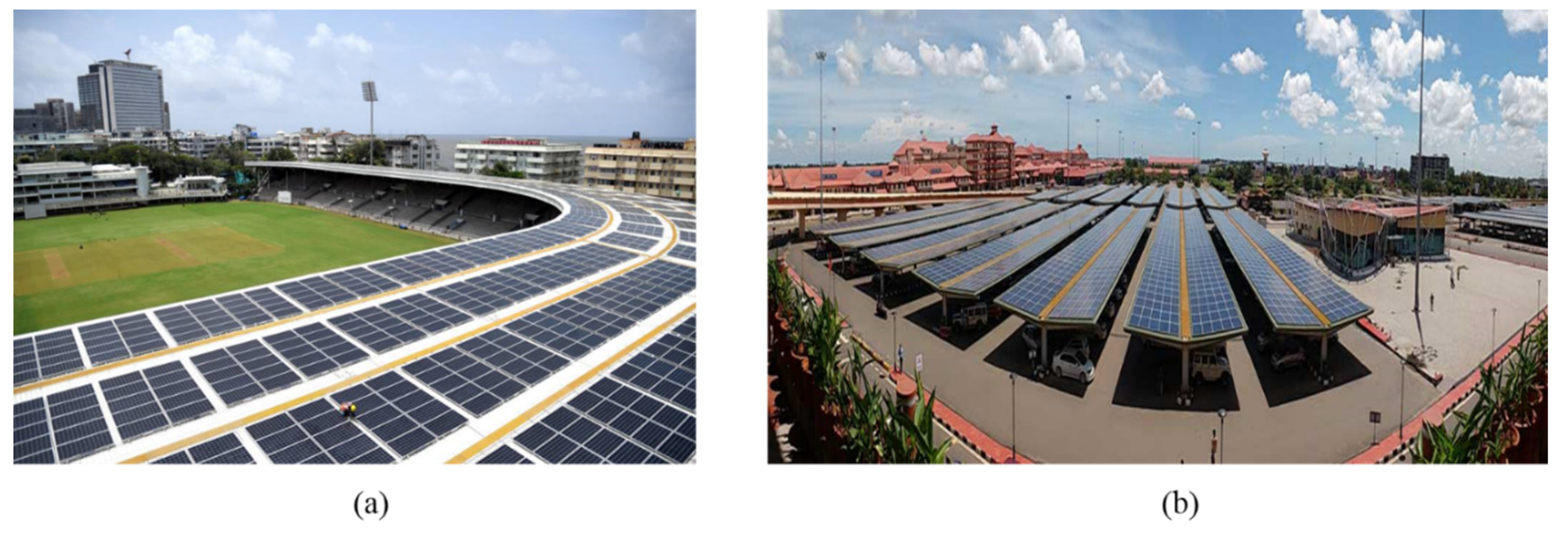

- India’s solar mission which geared up from 2015, accelerated the rooftop PV integration. For building, the rooftop application’s majority are BAPV types and capacity higher than kW level. India’s total installed solar capacity reached only 33.8 GW by the end of September 2019, which is way behind to achieve India’s 40 GW rooftop PV power generation by 2022.

- New technologies, such as PV tiles, foil and windows, as part of BIPV or BPAV, are not popular in India.

- Indian electricity market needs a complete reform to allow smooth penetration of BIPV/BAPV in building. Also, due to rapid urbanization and development of zero and sustainable building industry, BIPV will keep pace in India soon.

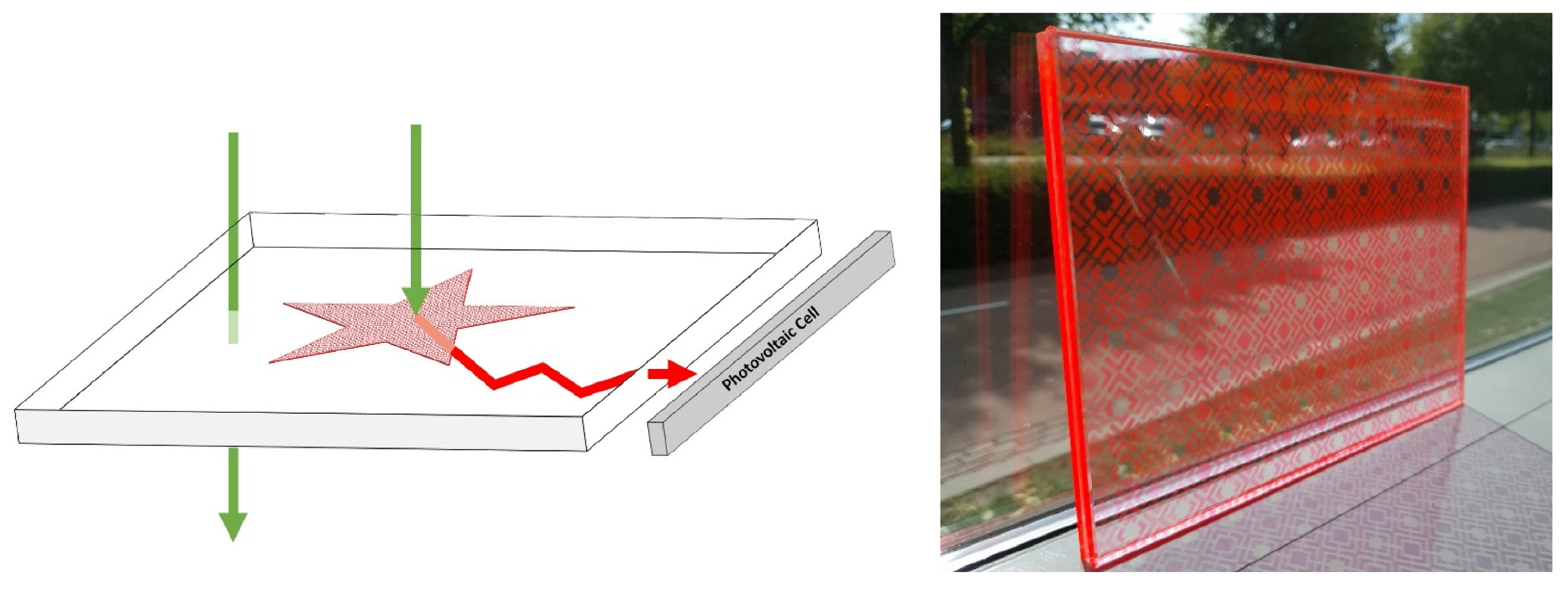

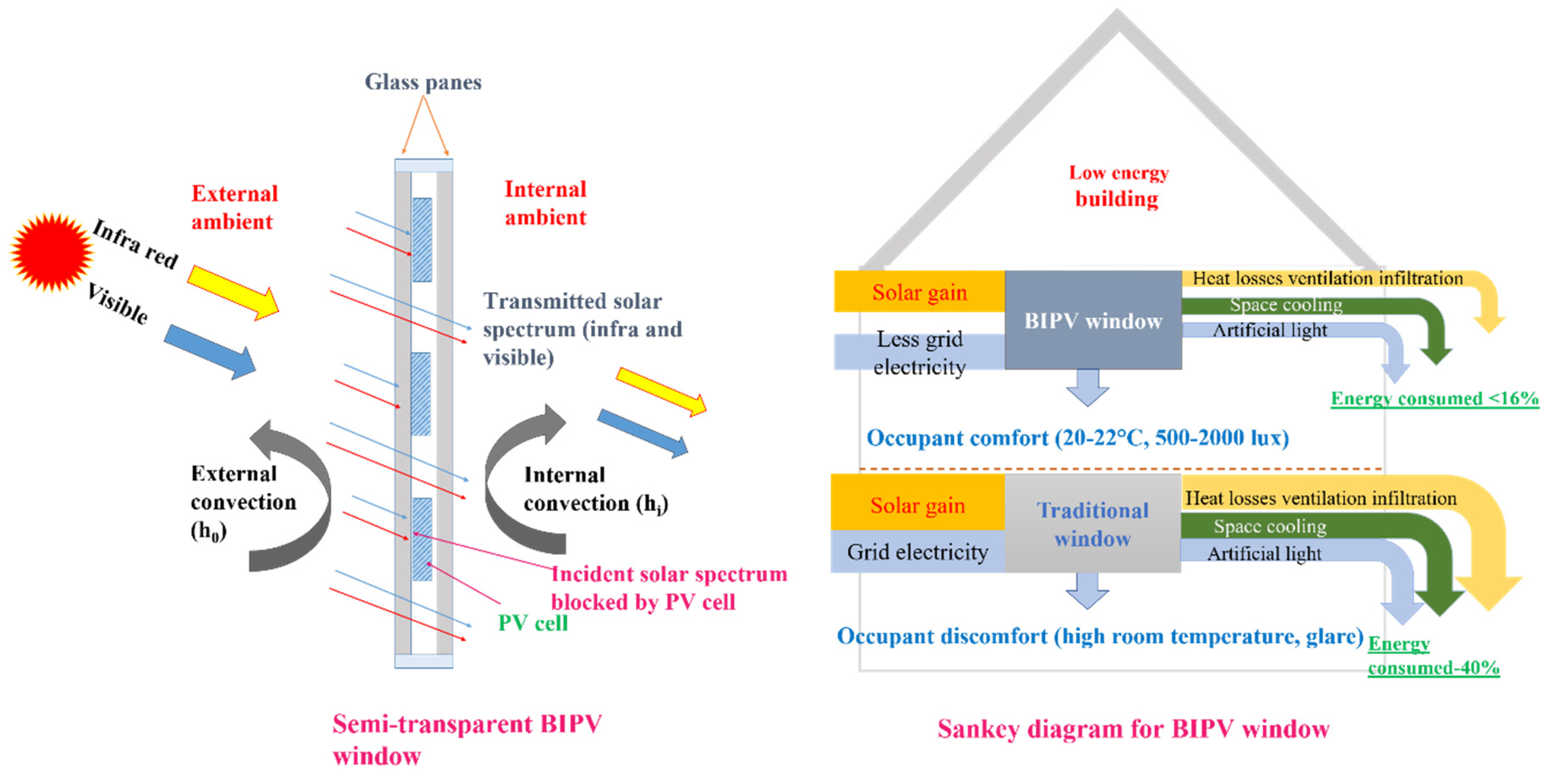

- Single and double glass BIPV window systems have been identified as one of the most potential candidates for India.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kumar Sahu, B. A study on global solar PV energy developments and policies with special focus on the top ten solar PV power producing countries. Renew. Sustain. Energy Rev. 2015, 43, 621–634. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. A comprehensive review on design of building integrated photovoltaic system. Energy Build. 2016, 128, 99–110. [Google Scholar] [CrossRef]

- Gupta, D.; Ghersi, F.; Vishwanathan, S.S.; Garg, A. Achieving sustainable development in India along low carbon pathways: Macroeconomic assessment. World Dev. 2019, 123, 104623. [Google Scholar] [CrossRef]

- Muniyoor, K. Is there a trade-off between energy consumption and employment: Evidence from India. J. Clean. Prod. 2020, 255, 120262. [Google Scholar] [CrossRef]

- Tang, X.; McLellan, B.C.; Zhang, B.; Snowden, S.; Höök, M. Trade-Off analysis between embodied energy exports and employment creation in China. J. Clean. Prod. 2016, 134, 310–319. [Google Scholar] [CrossRef]

- Bano, F.; Kamal, M.A. Examining the role of building envelope for energy efficiency in office buildings in India. Archit. Res. 2016, 6, 107–115. [Google Scholar] [CrossRef]

- Bhatt, M.S.; Rajkumar, N.; Jothibasu, S.; Sudirkumar, R.; Pandian, G.; Nair, K.R.C. Commercial and residential building energy labeling. J. Sci. Ind. Res. (India) 2005, 64, 30–34. [Google Scholar]

- Manu, S.; Brager, G.; Rawal, R.; Geronazzo, A.; Kumar, D. Performance evaluation of climate responsive buildings in India—Case studies from cooling dominated climate zones. Build. Environ. 2019, 148, 136–156. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Pathak, C.R.; Dentinho, T.P. Urbanization and Regional Sustainability in South Asia; Springer Open Ltd.: Cham, Switzerland, 2020; ISBN 978-3-030-23795-0. [Google Scholar]

- Zhang, S.; He, Y. Analysis on the development and policy of solar PV power in China. Renew. Sustain. Energy Rev. 2013, 21, 393–401. [Google Scholar] [CrossRef]

- Thapar, S.; Sharma, S. Factors impacting wind and solar power sectors in India: A survey-based analysis. Sustain. Prod. Consum. 2020, 21, 204–215. [Google Scholar] [CrossRef]

- Righini, G.C.; Enrichi, F. Solar Cells’ Evolution and Perspectives: A Short Review; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; ISBN 9780081027622. [Google Scholar]

- Røyset, A.; Kolås, T.; Jelle, B.P. Coloured building integrated photovoltaics: Influence on energy efficiency. Energy Build. 2020, 208. [Google Scholar] [CrossRef]

- Peharz, G.; Ulm, A. Quantifying the influence of colors on the performance of c-Si photovoltaic devices. Renew. Energy 2018, 129, 299–308. [Google Scholar] [CrossRef]

- Saga, T. Advances in crystalline silicon solar cell technology for industrial mass production. NPG Asia Mater. 2010, 2, 96–102. [Google Scholar] [CrossRef]

- Liu, Z.; Sofia, S.E.; Laine, H.S.; Woodhouse, M.; Wieghold, S.; Peters, I.M.; Buonassisi, T. Revisiting thin silicon for photovoltaics: A technoeconomic perspective. arXiv 2019, arXiv:1906.06770. [Google Scholar] [CrossRef]

- Battaglia, C.; Cuevas, A.; De Wolf, S. High-Efficiency crystalline silicon solar cells: Status and perspectives. Energy Environ. Sci. 2016, 9, 1552–1576. [Google Scholar] [CrossRef]

- Chen, Y.; Altermatt, P.P.; Chen, D.; Zhang, X.; Xu, G.; Yang, Y.; Wang, Y.; Feng, Z.; Shen, H.; Verlinden, P.J. From laboratory to production: Learning models of efficiency and manufacturing cost of industrial crystalline silicon and thin-film photovoltaic technologies. IEEE J. Photovolt. 2018, 8, 1531–1538. [Google Scholar] [CrossRef]

- Ardente, F.; Latunussa, C.F.L.; Blengini, G.A. Resource efficient recovery of critical and precious metals from waste silicon PV panel recycling. Waste Manag. 2019, 91, 156–167. [Google Scholar] [CrossRef]

- Hughes, L.; Bristow, N.; Korochkina, T.; Sanchez, P.; Gomez, D.; Kettle, J.; Gethin, D. Assessing the potential of steel as a substrate for building integrated photovoltaic applications. Appl. Energy 2018, 229, 209–223. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, W.; Xie, L.; Ni, Z.; Wei, Q.; Wang, W.; Tian, H. Experimental and numerical evaluation of the crystalline silicon PV window under the climatic conditions in southwest China. Energy 2019, 183, 584–598. [Google Scholar] [CrossRef]

- Akhsassi, M.; El Fathi, A.; Erraissi, N.; Aarich, N.; Bennouna, A.; Raoufi, M.; Outzourhit, A. Experimental investigation and modeling of the thermal behavior of a solar PV module. Sol. Energy Mater. Sol. Cells 2018, 180, 271–279. [Google Scholar] [CrossRef]

- Gottschalg, R.; Betts, T.R.; Eeles, A.; Williams, S.R.; Zhu, J. Influences on the energy delivery of thin film photovoltaic modules. Sol. Energy Mater. Sol. Cells 2013, 119, 169–180. [Google Scholar] [CrossRef]

- Taraba, M.; Adamec, J.; Danko, M.; Drgona, P.; Urica, T. Properties measurement of the thin film solar panels under adverse weather conditions. Transp. Res. Procedia 2019, 40, 535–540. [Google Scholar] [CrossRef]

- Shah, A.V.; Schade, H.; Vanecek, M.; Meier, J.; Vallat-Sauvain, E.; Wyrsch, N.; Kroll, U.; Droz, C.; Bailat, J. Thin-Film silicon solar cell technology. Photovolt. Res. Appl. 2004, 12, 113–142. [Google Scholar] [CrossRef]

- Sebastian, P.J.; Sivaramakrishnan, V. Electrical conduction and transmission electron microscopy studies of CdSe0.8Te0.2 thin films. Thin Solid Films 1991, 202, 1–9. [Google Scholar] [CrossRef]

- Lee, T.D.; Ebong, A.U. A review of thin film solar cell technologies and challenges. Renew. Sustain. Energy Rev. 2017, 70, 1286–1297. [Google Scholar] [CrossRef]

- Matsui, T.; Sai, H.; Bidiville, A.; Hsu, H.J.; Matsubara, K. Progress and limitations of thin-film silicon solar cells. Sol. Energy 2018, 170, 486–498. [Google Scholar] [CrossRef]

- Stuckelberger, M.; Biron, R.; Wyrsch, N.; Haug, F.-J.; Ballif, C. Review: Progress in solar cells from hydrogenated amorphous silicon. Renew. Sustain. Energy Rev. 2017, 76, 1–27. [Google Scholar] [CrossRef]

- Myong, S.Y.; Jeon, S.W. Efficient outdoor performance of esthetic bifacial a-Si: H semi-transparent PV modules. Appl. Energy 2016, 164, 312–320. [Google Scholar] [CrossRef]

- Kichou, S.; Silvestre, S.; Nofuentes, G.; Torres-Ramírez, M.; Chouder, A.; Guasch, D. Characterization of degradation and evaluation of model parameters of amorphous silicon photovoltaic modules under outdoor long term exposure. Energy 2016, 96, 231–241. [Google Scholar] [CrossRef]

- Sabri, L.; Benzirar, M. Effect of ambient conditions on thermal properties of photovoltaic cells: Crystalline and amorphous silicon. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 17815–17821. [Google Scholar] [CrossRef]

- Staebler, D.L.; Wronski, C.R. Reversible conductivity changes in discharged-produced amorphous Si. Appl. Phys. Lett. 1977, 31, 274–292. [Google Scholar] [CrossRef]

- Feurer, T.; Carron, R.; Torres Sevilla, G.; Fu, F.; Pisoni, S.; Romanyuk, Y.E.; Buecheler, S.; Tiwari, A.N. Efficiency improvement of near-stoichiometric CuInSe2 solar cells for application in tandem devices. Adv. Energy Mater. 2019, 9, 2–7. [Google Scholar] [CrossRef]

- Kazmerski, L.L.; White, F.R.; Morgan, G.K. Thin-Film CuInSe2/CdS heterojunction solar cells. Appl. Phys. Lett. 1976, 29, 268–270. [Google Scholar] [CrossRef]

- Stoichkov, V.; Sweet, T.K.N.; Jenkins, N.; Kettle, J. Studying the outdoor performance of organic building-integrated photovoltaics laminated to the cladding of a building prototype. Sol. Energy Mater. Sol. Cells 2019, 191, 356–364. [Google Scholar] [CrossRef]

- Sato, R.; Chiba, Y.; Chikamatsu, M.; Yoshida, Y.; Taima, T.; Kasu, M.; Masuda, A. Investigation of the power generation of organic photovoltaic modules connected to the power grid for more than three years. Jpn. J. Appl. Phys. 2019, 58, 52001. [Google Scholar] [CrossRef]

- Chemisana, D.; Moreno, A.; Polo, M.; Aranda, C.; Riverola, A.; Ortega, E.; Lamnatou, C.; Domènech, A.; Blanco, G.; Cot, A. Performance and stability of semitransparent OPVs for building integration: A benchmarking analysis. Renew. Energy 2019, 137, 177–188. [Google Scholar] [CrossRef]

- O’Regan, B.; Gratzel, M. A low-cost, high efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 1991, 353, 737–740. [Google Scholar] [CrossRef]

- Sharma, S.; Siwach, B.; Ghoshal, S.K.; Mohan, D. Dye sensitized solar cells: From genesis to recent drifts. Renew. Sustain. Energy Rev. 2017, 70, 529–537. [Google Scholar] [CrossRef]

- Kumara, N.T.R.N.; Lim, A.; Lim, C.M.; Petra, M.I.; Ekanayake, P. Recent progress and utilization of natural pigments in dye sensitized solar cells: A review. Renew. Sustain. Energy Rev. 2017, 78, 301–317. [Google Scholar] [CrossRef]

- Ghosh, A.; Selvaraj, P.; Sundaram, S.; Mallick, T.K. The colour rendering index and correlated colour temperature of dye-sensitized solar cell for adaptive glazing application. Sol. Energy 2018, 163, 537–544. [Google Scholar] [CrossRef]

- Cornaro, C.; Renzi, L.; Pierro, M.; Di Carlo, A.; Guglielmotti, A. Thermal and electrical characterization of a semi-transparent dye-sensitized photovoltaic module under real operating conditions. Energies 2018, 11, 155. [Google Scholar] [CrossRef]

- Ghosh, A.; Bhandari, S.; Sundaram, S.; Mallick, T.K. Carbon counter electrode mesoscopic ambient processed & characterised perovskite for adaptive BIPV fenestration. Renew. Energy 2020, 145, 2151–2158. [Google Scholar] [CrossRef]

- Bhandari, S.; Roy, A.; Ghosh, A.; Mallick, T.K.; Sundaram, S. Performance of WO3—Incorporated carbon electrodes for ambient mesoscopic perovskite solar cells. ACS Omega 2019, 5, 422–429. [Google Scholar] [CrossRef] [PubMed]

- Cannavale, A.; Ierardi, L.; Hörantner, M.; Eperon, G.E.; Snaith, H.J.; Ayr, U.; Martellotta, F. Improving energy and visual performance in offices using building integrated perovskite-based solar cells: A case study in Southern Italy. Appl. Energy 2017, 205, 834–846. [Google Scholar] [CrossRef]

- Cannavale, A.; Hörantner, M.; Eperon, G.E.; Snaith, H.J.; Fiorito, F.; Ayr, U.; Martellotta, F. Building integration of semitransparent perovskite-based solar cells: Energy performance and visual comfort assessment. Appl. Energy 2017, 194, 94–107. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, D.; Liu, C.; Wang, Z.; Zou, Y.; He, Y.; Wang, Y.; Yuan, L.; Gong, J.; Lin, W.; et al. Mass production of industrial tunnel oxide passivated contacts (i-TOPCon) silicon solar cells with average efficiency over 23% and modules over 345 W. Prog. Photovolt. Res. Appl. 2019, 1–8. [Google Scholar] [CrossRef]

- Glunz, S.W.; Preu, R.; Biro, D. Crystalline Silicon Solar Cells: State-of-the-Art and Future Developments; Elsevier Ltd.: Amsterdam, The Netherlands, 2012; Volume 1, ISBN 9780080878737. [Google Scholar]

- Zhang, T.; Wang, M.; Yang, H. A review of the energy performance and life-cycle assessment of building-integrated photovoltaic (BIPV) systems. Energies 2018, 11, 3157. [Google Scholar] [CrossRef]

- Haegel, N.M.; Atwater, H.; Barnes, T.; Breyer, C.; Burrell, A.; Chiang, Y.-M.; De Wolf, S.; Dimmler, B.; Feldman, D.; Glunz, S.; et al. Terawatt-Scale photovoltaics: Transform global energy. Science 2019, 364, 836–838. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H. Review on life cycle assessment of energy payback and greenhouse gas emission of solar photovoltaic systems. Renew. Sustain. Energy Rev. 2013, 19, 255–274. [Google Scholar] [CrossRef]

- Tsai, C.Y.; Tsai, C.Y. See-through, light-through, and color modules for large-area tandem amorphous/microcrystalline silicon thin-film solar modules: Technology development and practical considerations for building-integrated photovoltaic applications. Renew. Energy 2020, 145, 2637–2646. [Google Scholar] [CrossRef]

- Minemoto, T.; Fukushige, S.; Takakura, H. Difference in the outdoor performance of bulk and thin-film silicon-based photovoltaic modules. Sol. Energy Mater. Sol. Cells 2009, 93, 1062–1065. [Google Scholar] [CrossRef]

- Han, J.; Lu, L.; Yang, H. Numerical evaluation of the mixed convective heat transfer in a double-pane window integrated with see-through a-Si PV cells with low-e coatings. Appl. Energy 2010, 87, 3431–3437. [Google Scholar] [CrossRef]

- Zidane, T.E.K.; Adzman, M.R.B.; Tajuddin, M.F.N.; Mat Zali, S.; Durusu, A. Optimal configuration of photovoltaic power plant using grey wolf optimizer: A comparative analysis considering CdTe and c-Si PV modules. Sol. Energy 2019, 188, 247–257. [Google Scholar] [CrossRef]

- Kumar, N.M.; Sudhakar, K.; Samykano, M. Performance evaluation of CdTe BIPV roof and façades in tropical weather conditions. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 1–15. [Google Scholar] [CrossRef]

- Bosio, A.; Rosa, G.; Romeo, N. Past, present and future of the thin film CdTe/CdS solar cells. Sol. Energy 2018, 31–43. [Google Scholar] [CrossRef]

- Rawat, R.; Kaushik, S.C.; Sastry, O.S.; Bora, B.; Singh, Y.K. Long-Term performance analysis of CdTe PV module in real operating conditions. Mater. Today Proc. 2018, 5, 23210–23217. [Google Scholar] [CrossRef]

- Barman, S.; Chowdhury, A.; Mathur, S.; Mathur, J. Assessment of the efficiency of window integrated CdTe based semi-transparent photovoltaic module. Sustain. Cities Soc. 2018, 37, 250–262. [Google Scholar] [CrossRef]

- Ozden, T.; Akinoglu, B.G.; Turan, R. Long term outdoor performances of three different on-grid PV arrays in central Anatolia—An extended analysis. Renew. Energy 2017, 101, 182–195. [Google Scholar] [CrossRef]

- Powalla, M.; Dimmler, B. Development of large-area CIGS modules. Sol. Energy Mater. Sol. Cells 2003, 75, 27–34. [Google Scholar] [CrossRef]

- Dhere, N.G. Scale-Up issues of CIGS thin film PV modules. Sol. Energy Mater. Sol. Cells 2011, 95, 277–280. [Google Scholar] [CrossRef]

- Yalçin, L.; Öztürk, R. Performance comparison of c-Si, mc-Si and a-Si thin film PV by PVsyst simulation. J. Optoelectron. Adv. Mater. 2013, 15, 326–334. [Google Scholar] [CrossRef]

- De Wild-Scholten, M.J. Energy payback time and carbon footprint of commercial photovoltaic systems. Sol. Energy Mater. Sol. Cells 2013, 119, 296–305. [Google Scholar] [CrossRef]

- Theelen, M.; Foster, C.; Steijvers, H.; Barreau, N.; Vroon, Z.; Zeman, M. The impact of atmospheric species on the degradation of CIGS solar cells. Sol. Energy Mater. Sol. Cells 2015, 141, 49–56. [Google Scholar] [CrossRef]

- Theelen, M.; Daume, F. Stability of Cu(In,Ga)Se2 solar cells: A literature review. Sol. Energy 2016, 133, 586–627. [Google Scholar] [CrossRef]

- Rudra, S.; Sarker, S.; Kim, D.M. Review on simulation of current-voltage characteristics of dye-sensitized solar cells. J. Ind. Eng. Chem. 2019, 80, 516–526. [Google Scholar] [CrossRef]

- Gong, J.; Sumathy, K.; Qiao, Q.; Zhou, Z. Review on dye-sensitized solar cells (DSSCs): Advanced techniques and research trends. Renew. Sustain. Energy Rev. 2017, 68, 234–246. [Google Scholar] [CrossRef]

- Mehmood, U.; Al-Ahmed, A.; Al-Sulaiman, F.A.; Malik, M.I.; Shehzad, F.; Khan, A.U.H. Effect of temperature on the photovoltaic performance and stability of solid-state dye-sensitized solar cells: A review. Renew. Sustain. Energy Rev. 2017, 79, 946–959. [Google Scholar] [CrossRef]

- Howard, I.A.; Abzieher, T.; Hossain, I.M.; Eggers, H.; Schackmar, F.; Ternes, S.; Richards, B.S.; Lemmer, U.; Paetzold, U.W. Coated and printed perovskites for photovoltaic applications. Adv. Mater. 2019, 31, 1806702. [Google Scholar] [CrossRef]

- Iqbal, T.; Shabbir, U.; Sultan, M.; Tahir, M.B.; Farooq, M.; Mansha, M.S.; Ijaz, M.; Maraj, M. All ambient environment-based perovskite film fabrication for photovoltaic applications. Int. J. Energy Res. 2019, 43, 806–813. [Google Scholar] [CrossRef]

- Agresti, A.; Pescetelli, S.; Palma, A.L.; Martín-García, B.; Najafi, L.; Bellani, S.; Moreels, I.; Prato, M.; Bonaccorso, F.; Di Carlo, A. Two-Dimensional material interface engineering for efficient perovskite large-area modules. ACS Energy Lett. 2019, 1862–1871. [Google Scholar] [CrossRef]

- Ballif, C.; Perret-Aebi, L.E.; Lufkin, S.; Rey, E. Integrated thinking for photovoltaics in buildings. Nat. Energy 2018, 3, 438–442. [Google Scholar] [CrossRef]

- Peng, C.; Huang, Y.; Wu, Z. Building-Integrated photovoltaics (BIPV) in architectural design in China. Energy Build. 2011, 43, 3592–3598. [Google Scholar] [CrossRef]

- Jelle, B.P.; Breivik, C.; Røkenes, H.D. Building integrated photovoltaic products: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 100, 69–96. [Google Scholar] [CrossRef]

- Jelle, B.P. Building integrated photovoltaics: A concise description of the current state of the art and possible research pathways. Energies 2016, 9, 21. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Exergetic assessment of BIPV module using parametric and photonic energy methods: A review. Energy Build. 2016, 119, 62–73. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Recent advancement in BIPV product technologies: A review. Energy Build. 2017, 140, 188–195. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P.; Mamat, R. BIPV in Southeast Asian countries—Opportunities and challenges. Renew. Energy Focus 2017, 21, 25–32. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P.; Mamat, R. BIPV based sustainable building in South Asian countries. Sol. Energy 2018, 170, 1162–1170. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P.; Mamat, R. Solar PV and BIPV system: Barrier, challenges and policy recommendation in India. Renew. Sustain. Energy Rev. 2018, 82, 3314–3322. [Google Scholar] [CrossRef]

- Ghosh, A.; Sundaram, S.; Mallick, T.K. Investigation of thermal and electrical performances of a combined semi-transparent PV-vacuum glazing. Appl. Energy 2018, 228, 1591–1600. [Google Scholar] [CrossRef]

- Ghosh, A.; Sundaram, S.; Mallick, T.K. Colour properties and glazing factors evaluation of multicrystalline based semi-transparent Photovoltaic-vacuum glazing for BIPV application. Renew. Energy 2019, 131, 730–736. [Google Scholar] [CrossRef]

- Wang, M.; Peng, J.; Li, N.; Yang, H.; Wang, C.; Li, X.; Lu, T. Comparison of energy performance between PV double skin facades and PV insulating glass units. Appl. Energy 2017, 194, 148–160. [Google Scholar] [CrossRef]

- Peng, J.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.; Zhang, W. Numerical investigation of the energy saving potential of a semi-transparent photovoltaic double-skin facade in a cool-summer Mediterranean climate. Appl. Energy 2016, 165, 345–356. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, L.; Peng, J.; Song, A. Comparison of the overall energy performance of semi-transparent photovoltaic windows and common energy-efficient windows in Hong Kong. Energy Build. 2016, 128, 511–518. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H.; Ma, T. Comparative study of the thermal and power performances of a semi-transparent photovoltaic façade under different ventilation modes. Appl. Energy 2015, 138, 572–583. [Google Scholar] [CrossRef]

- Alrashidi, H.; Ghosh, A.; Issa, W.; Sellami, N.; Mallick, T.K.; Sundaram, S. Evaluation of solar factor using spectral analysis for CdTe photovoltaic glazing. Mater. Lett. 2019, 237, 332–335. [Google Scholar] [CrossRef]

- Alrashidi, H.; Ghosh, A.; Issa, W.; Sellami, N.; Mallick, T.K.; Sundaram, S. Thermal performance of semitransparent CdTe BIPV window at temperate climate. Sol. Energy 2020, 195, 536–543. [Google Scholar] [CrossRef]

- Selvaraj, P.; Ghosh, A.; Mallick, T.K.; Sundaram, S. Investigation of semi-transparent dye-sensitized solar cells for fenestration integration. Renew. Energy 2019, 141, 516–525. [Google Scholar] [CrossRef]

- Roy, A.; Ghosh, A.; Bhandari, S.; Selvaraj, P.; Sundaram, S.; Mallick, T.K. Color comfort evaluation of dye-sensitized solar cell (DSSC) based building-integrated photovoltaic (BIPV) glazing after 2 years of ambient exposure. J. Phys. Chem. C 2019, 123, 23834–23837. [Google Scholar] [CrossRef]

- Sun, Y.; Shanks, K.; Baig, H.; Zhang, W.; Hao, X.; Li, Y.; He, B.; Wilson, R.; Liu, H.; Sundaram, S.; et al. Integrated semi-transparent cadmium telluride photovoltaic glazing into windows: Energy and daylight performance for different architecture designs. Appl. Energy 2018, 231, 972–984. [Google Scholar] [CrossRef]

- Li, G.; Xuan, Q.; Akram, M.W.; Golizadeh Akhlaghi, Y.; Liu, H.; Shittu, S. Building integrated solar concentrating systems: A review. Appl. Energy 2020, 260, 114288. [Google Scholar] [CrossRef]

- Rafiee, M.; Chandra, S.; Ahmed, H.; McCormack, S.J. An overview of various configurations of luminescent solar concentrators for photovoltaic applications. Opt. Mater. 2019, 91, 212–227. [Google Scholar] [CrossRef]

- Baig, H.; Sellami, N.; Mallick, T.K. Performance modeling and testing of a building integrated concentrating photovoltaic (BICPV) system. Sol. Energy Mater. Sol. Cells 2015, 134, 29–44. [Google Scholar] [CrossRef]

- Tian, M.; Su, Y.; Zheng, H.; Pei, G.; Li, G.; Riffat, S. A review on the recent research progress in the compound parabolic concentrator (CPC) for solar energy applications. Renew. Sustain. Energy Rev. 2018, 82, 1272–1296. [Google Scholar] [CrossRef]

- Shanks, K.; Senthilarasu, S.; Mallick, T.K. Optics for concentrating photovoltaics: Trends, limits and opportunities for materials and design. Renew. Sustain. Energy Rev. 2016, 60, 394–407. [Google Scholar] [CrossRef]

- Baig, H.; Heasman, K.C.; Mallick, T.K. Non-Uniform illumination in concentrating solar cells. Renew. Sustain. Energy Rev. 2012, 16, 5890–5909. [Google Scholar] [CrossRef]

- Sarmah, N.; Mallick, T.K. Design, fabrication and outdoor performance analysis of a low concentrating photovoltaic system. Sol. Energy 2015, 112, 361–372. [Google Scholar] [CrossRef]

- Sellami, N.; Mallick, T.K. Optical characterisation and optimisation of a static window integrated concentrating photovoltaic system. Sol. Energy 2013, 91, 273–282. [Google Scholar] [CrossRef]

- Mallick, T.K.; Eames, P.C.; Hyde, T.J.; Norton, B. The design and experimental characterisation of an asymmetric compound parabolic photovoltaic concentrator for building façade integration in the UK. Sol. Energy 2004, 77, 319–327. [Google Scholar] [CrossRef]

- Muhammad-Sukki, F.; Abu-Bakar, S.H.; Ramirez-Iniguez, R.; McMeekin, S.G.; Stewart, B.G.; Sarmah, N.; Mallick, T.K.; Munir, A.B.; Mohd Yasin, S.H.; Abdul Rahim, R. Mirror symmetrical dielectric totally internally reflecting concentrator for building integrated photovoltaic systems. Appl. Energy 2014, 113, 32–40. [Google Scholar] [CrossRef]

- Selvaraj, P.; Baig, H.; Mallick, T.K.; Siviter, J.; Montecucco, A.; Li, W.; Paul, M.; Sweet, T.; Gao, M.; Knox, A.R.; et al. Enhancing the efficiency of transparent dye-sensitized solar cells using concentrated light. Sol. Energy Mater. Sol. Cells 2018, 175, 29–34. [Google Scholar] [CrossRef]

- Baig, H.; Kanda, H.; Asiri, A.M.; Nazeeruddin, M.K.; Mallick, T. Increasing efficiency of perovskite solar cells using low concentrating photovoltaic systems. Sustain. Energy Fuels 2020, 1–10. [Google Scholar] [CrossRef]

- Chandra, S.; Doran, J.; McCormack, S.J.; Kennedy, M.; Chatten, A.J. Enhanced quantum dot emission for luminescent solar concentrators using plasmonic interaction. Sol. Energy Mater. Sol. Cells 2012, 98, 385–390. [Google Scholar] [CrossRef]

- Chandra, S.; Doran, J.; McCormack, S.J. Two step continuous method to synthesize colloidal spheroid gold nanorods. J. Colloid Interface Sci. 2015, 459, 218–223. [Google Scholar] [CrossRef] [PubMed]

- Chandra, S.; McCormack, S.J.; Kennedy, M.; Doran, J. Quantum dot solar concentrator: Optical transportation and doping concentration optimization. Sol. Energy 2015, 115, 552–561. [Google Scholar] [CrossRef]

- Ter Schiphorst, J.; Cheng, M.L.M.K.H.Y.K.; van der Heijden, M.; Hageman, R.L.; Bugg, E.L.; Wagenaar, T.J.L.; Debije, M.G. Printed luminescent solar concentrators: Artistic renewable energy. Energy Build. 2020, 207, 27–30. [Google Scholar] [CrossRef]

- Sethi, A.; Rafiee, M.; Chandra, S.; Ahmedj, H.; McCormack, S. A unified methodology for fabrication and quantification of gold nanorods, gold core silver shell nanocuboids and their polymer Nanocomposites. Langmuir 2019, 35. [Google Scholar] [CrossRef]

- Aste, N.; Tagliabue, L.C.; Palladino, P.; Testa, D. Integration of a luminescent solar concentrator: Effects on daylight, correlated color temperature, illuminance level and color rendering index. Sol. Energy 2015, 114, 174–182. [Google Scholar] [CrossRef]

- Aste, N.; Del Pero, C.; Tagliabue, L.C.; Leonforte, F.; Testa, D.; Fusco, R. Performance monitoring and building integration assessment of innovative LSC components. In Proceedings of the 5th International Conference on Clean Electrical Power: Renewable Energy Resources Impact, ICCEP 2015, Taormina, Italy, 16–18 June 2015; pp. 129–133. [Google Scholar] [CrossRef]

- Fathi, M.; Abderrezek, M.; Djahli, F. Experimentations on luminescent glazing for solar electricity generation in buildings. Opt. Int. J. Light Electron. Opt. 2017, 148, 14–27. [Google Scholar] [CrossRef]

- Vossen, F.M.; Aarts, M.P.J.; Debije, M.G. Visual performance of red luminescent solar concentrating windows in an office environment. Energy Build. 2016, 113, 123–132. [Google Scholar] [CrossRef]

- Ahmed, H.; McCormack, S.J.; Doran, J. External quantum efficiency improvement with luminescent downshifting layers: Experimental and modelling. Int. J. Spectrosc. 2016, 2016, 1–7. [Google Scholar] [CrossRef]

- Lamnatou, C.; Chemisana, D. Photovoltaic/Thermal (PVT) systems: A review with emphasis on environmental issues. Renew. Energy 2017, 105, 270–287. [Google Scholar] [CrossRef]

- Shukla, A.; Kant, K.; Sharma, A.; Biwole, P.H. Cooling methodologies of photovoltaic module for enhancing electrical efficiency: A review. Sol. Energy Mater. Sol. Cells 2017, 160, 275–286. [Google Scholar] [CrossRef]

- Phiraphat, S.; Prommas, R.; Puangsombut, W. Experimental study of natural convection in PV roof solar collector. Int. Commun. Heat Mass Transf. 2017, 89, 31–38. [Google Scholar] [CrossRef]

- Hasanuzzaman, M.; Malek, A.B.M.A.; Islam, M.M.; Pandey, A.K.; Rahim, N.A. Global advancement of cooling technologies for PV systems: A review. Sol. Energy 2016, 137, 25–45. [Google Scholar] [CrossRef]

- Kumar, A.; Baredar, P.; Qureshi, U. Historical and recent development of photovoltaic thermal (PVT) technologies. Renew. Sustain. Energy Rev. 2015, 42, 1428–1436. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; Dentice d’Accadia, M.; Vicidomini, M. Dynamic simulation, energy and economic comparison between BIPV and BIPVT collectors coupled with micro-wind turbines. Energy 2020, 191, 116439. [Google Scholar] [CrossRef]

- Xu, L.; Luo, K.; Ji, J.; Yu, B.; Li, Z.; Huang, S. Study of a hybrid BIPV/T solar wall system. Energy 2020, 193, 116578. [Google Scholar] [CrossRef]

- Debbarma, M.; Sudhakar, K.; Baredar, P. Comparison of BIPV and BIPVT: A review. Resour. Technol. 2016, 3, 263–271. [Google Scholar] [CrossRef]

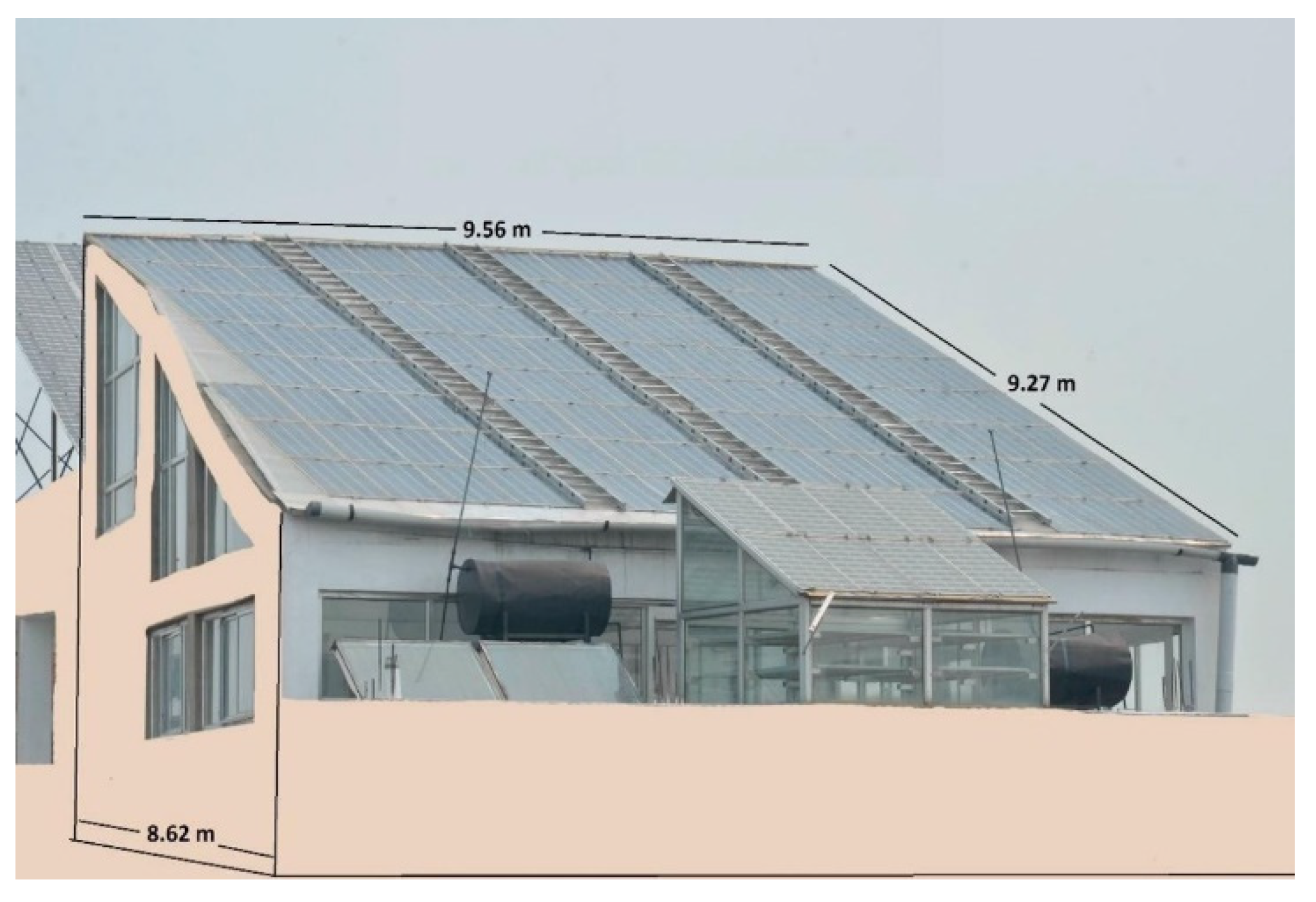

- Vats, K.; Tiwari, G.N. Performance evaluation of a building integrated semitransparent photovoltaic thermal system for roof and faade. Energy Build. 2012, 45, 211–218. [Google Scholar] [CrossRef]

- Kamthania, D.; Nayak, S.; Tiwari, G.N. Performance evaluation of a hybrid photovoltaic thermal double pass facade for space heating. Energy Build. 2011, 43, 2274–2281. [Google Scholar] [CrossRef]

- Agrawal, B.; Tiwari, G.N. Optimizing the energy and exergy of building integrated photovoltaic thermal (BIPVT) systems under cold climatic conditions. Appl. Energy 2010, 87, 417–426. [Google Scholar] [CrossRef]

- Agathokleous, R.A.; Kalogirou, S.A. Double skin facades (DSF) and building integrated photovoltaics (BIPV): A review of configurations and heat transfer characteristics. Renew. Energy 2016, 89, 743–756. [Google Scholar] [CrossRef]

- Yang, T.; Athienitis, A.K. A study of design options for a building integrated photovoltaic/thermal (BIPV/T) system with glazed air collector and multiple inlets. Sol. Energy 2014, 104, 82–92. [Google Scholar] [CrossRef]

- Rajoria, C.S.; Agrawal, S.; Chandra, S.; Tiwari, G.N.; Chauhan, D.S. A Novel investigation of building integrated photovoltaic thermal (BiPVT) system: A comparative study. Sol. Energy 2016, 131, 107–118. [Google Scholar] [CrossRef]

- Kim, J.H.; Park, S.H.; Kang, J.G.; Kim, J.T. Experimental performance of heating system with buildingintegrated PVT (BIPVT) collector. Energy Procedia 2014, 48, 1374–1384. [Google Scholar] [CrossRef]

- Browne, M.C.; Norton, B.; McCormack, S.J. Phase change materials for photovoltaic thermal management. Renew. Sustain. Energy Rev. 2015, 47, 762–782. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Phase change materials for building applications: A state-of-the-art review. Energy Build. 2010, 42, 1361–1368. [Google Scholar] [CrossRef]

- Chandel, S.S.; Agarwal, T. Review of cooling techniques using phase change materials for enhancing efficiency of photovoltaic power systems. Renew. Sustain. Energy Rev. 2017, 73, 1342–1351. [Google Scholar] [CrossRef]

- Deo, A.; Mishra, G.K.; Tiwari, G.N. A thermal periodic theory and experimental validation of building integrated semi-transparent photovoltaic thermal (BiSPVT) system. Sol. Energy 2017, 155, 1021–1032. [Google Scholar] [CrossRef]

- Tewari, P.; Mathur, S.; Mathur, J.; Kumar, S.; Loftness, V. Field study on indoor thermal comfort of office buildings using evaporative cooling in the composite climate of India. Energy Build. 2019, 199, 145–163. [Google Scholar] [CrossRef]

- Ali, M.; Jamil, B.; Fakhruddin. Estimating diffuse solar radiation in India: Performance characterization of generalized single-input empirical models. Urban Clim. 2019, 27, 314–350. [Google Scholar] [CrossRef]

- Makade, R.G.; Chakrabarti, S.; Jamil, B.; Sakhale, C.N. Estimation of global solar radiation for the tropical wet climatic region of India: A theory of experimentation approach. Renew. Energy 2020, 146, 2044–2059. [Google Scholar] [CrossRef]

- Lam, N.L.; Smith, K.R.; Gauthier, A.; Bates, M.N. Kerosene: A review of household uses and their hazards in low-and middle-income countries. J. Toxicol. Environ. Health Part B Crit. Rev. 2012, 15, 396–432. [Google Scholar] [CrossRef]

- Singh, Y.; Pal, N. Obstacles and comparative analysis in the advancement of photovoltaic power stations in India. Sustain. Comput. Inform. Syst. 2020, 25, 100372. [Google Scholar] [CrossRef]

- Behuria, P. The politics of late late development in renewable energy sectors: Dependency and contradictory tensions in India’s National Solar Mission. World Dev. 2020, 126, 104726. [Google Scholar] [CrossRef]

- Kapoor, K.; Pandey, K.K.; Jain, A.K.; Nandan, A. Evolution of solar energy in India: A review. Renew. Sustain. Energy Rev. 2014, 40, 475–487. [Google Scholar] [CrossRef]

- Raina, G.; Sinha, S. Outlook on the Indian scenario of solar energy strategies: Policies and challenges. Energy Strateg. Rev. 2019, 24, 331–341. [Google Scholar] [CrossRef]

- Goel, M. Solar rooftop in India: Policies, challenges and outlook. Green Energy Environ. 2016, 1, 129–137. [Google Scholar] [CrossRef]

- Yadav, S.K.; Bajpai, U. Energy, economic and environmental performance of a solar rooftop photovoltaic system in India. Int. J. Sustain. Energy 2020, 39, 51–66. [Google Scholar] [CrossRef]

- Tarai, R.K.; Kale, P. Solar PV policy framework of Indian States: Overview, pitfalls, challenges, and improvements. Renew. Energy Focus 2018, 26, 46–57. [Google Scholar] [CrossRef]

- Sethi, M. Climate change and urban areas. Clim. Chang. Urban Settl. 2018, 86, 1–44. [Google Scholar] [CrossRef]

- Gupta, A.; Dalei, N.N. Energy, Environment and Globalization: An Interface; Springer: Singapore, 2020; ISBN 9789811393099. [Google Scholar]

- Tulsyan, A.; Dhaka, S.; Mathur, J.; Yadav, J.V. Potential of energy savings through implementation of energy conservation building code in Jaipur city, India. Energy Build. 2013, 58, 123–130. [Google Scholar] [CrossRef]

- Yu, S.; Tan, Q.; Evans, M.; Kyle, P.; Vu, L.; Patel, P.L. Improving building energy efficiency in India: State-Level analysis of building energy efficiency policies. Energy Policy 2017, 110, 331–341. [Google Scholar] [CrossRef]

- Sharma, M. Development of a ‘green building sustainability model’ for green buildings in India. J. Clean. Prod. 2018, 190, 538–551. [Google Scholar] [CrossRef]

- Chandel, S.S.; Sharma, A.; Marwaha, B.M. Review of energy efficiency initiatives and regulations for residential buildings in India. Renew. Sustain. Energy Rev. 2016, 54, 1443–1458. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B. Advances in switchable and highly insulating autonomous (self-powered) glazing systems for adaptive low energy buildings. Renew. Energy 2018, 126, 1003–1031. [Google Scholar] [CrossRef]

- Ghosh, A.; Sarmah, N.; Sundaram, S.; Mallick, T.K. Numerical studies of thermal comfort for semi-transparent building integrated photovoltaic (BIPV)-vacuum glazing system. Sol. Energy 2019, 190, 608–616. [Google Scholar] [CrossRef]

- Ravikumar, D.; Malghan, D. Material constraints for indigenous production of CdTe PV: Evidence from a Monte Carlo experiment using India’s national solar mission benchmarks. Renew. Sustain. Energy Rev. 2013, 25, 393–403. [Google Scholar] [CrossRef]

- Hairat, M.K.; Ghosh, S. 100 GW solar power in India by 2022—A critical review. Renew. Sustain. Energy Rev. 2017, 73, 1041–1050. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Rathore, S.; Pratap Singh, R.; Agnihotri, S. Solar power utility sector in india: Challenges and opportunities. Renew. Sustain. Energy Rev. 2018, 81, 2703–2713. [Google Scholar] [CrossRef]

- Tomar, V.; Tiwari, G.N. Techno-Economic evaluation of grid connected PV system for households with feed in tariff and time of day tariff regulation in New Delhi—A sustainable approach. Renew. Sustain. Energy Rev. 2017, 70, 822–835. [Google Scholar] [CrossRef]

- Rohankar, N.; Jain, A.K.; Nangia, O.P.; Dwivedi, P. A study of existing solar power policy framework in India for viability of the solar projects perspective. Renew. Sustain. Energy Rev. 2016, 56, 510–518. [Google Scholar] [CrossRef]

- Jain, S.; Jain, N.K. Cost of electricity banking under open-access arrangement: A case of solar electricity in India. Renew. Energy 2020, 146, 776–788. [Google Scholar] [CrossRef]

- Heeter, J.; Vora, R.; Mathur, S.; Madrigal, P.; Chatterjee, S.K.; Shah, R. Wheeling and Banking Strategies for Optimal Renewable Energy Deployment: International Experiences; A Clean Energy Regulators Initiative Report NREL/TP-6A20-65660; United States Department of Energy (DOE): Washington, DC, USA, 2016; Volume 1, pp. 1–56.

- Rathore, P.K.S.; Chauhan, D.S.; Singh, R.P. Decentralized solar rooftop photovoltaic in India: On the path of sustainable energy security. Renew. Energy 2019, 131, 297–307. [Google Scholar] [CrossRef]

- Satsangi, K.P.; Das, D.B.; Babu, G.S.S.; Saxena, A.K. Real time performance of solar photovoltaic microgrid in India focusing on self-consumption in institutional buildings. Energy Sustain. Dev. 2019, 52, 40–51. [Google Scholar] [CrossRef]

- Nundy, S.; Ghosh, A.; Mallick, T.K. Hydrophilic and superhydrophilic self-cleaning coatings by morphologically varying ZnO microstructures for photovoltaic and glazing applications. ACS Omega 2020, 5, 1033–1039. [Google Scholar] [CrossRef]

- Chanchangi, Y.N.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Dust and PV performance in Nigeria: A review. Renew. Sustain. Energy Rev. 2020, 121, 109704. [Google Scholar] [CrossRef]

- Smestad, G.P.; Germer, T.A.; Alrashidi, H.; Fernández, E.F.; Dey, S.; Brahma, H.; Sarmah, N.; Ghosh, A.; Sellami, N. Modelling photovoltaic soiling losses through optical characterization. Sci. Rep. 2020, 1–13. [Google Scholar] [CrossRef]

- Kumar, A.; Prakash, O.; Dube, A. A review on progress of concentrated solar power in India. Renew. Sustain. Energy Rev. 2017, 79, 304–307. [Google Scholar] [CrossRef]

- Bano, F.; Sehgal, V. Evaluation of energy-efficient design strategies: Comparison of the thermal performance of energy-efficient office buildings in composite climate, India. Sol. Energy 2018, 176, 506–519. [Google Scholar] [CrossRef]

- Agrawal, B.; Tiwari, G.N. Life cycle cost assessment of building integrated photovoltaic thermal (BIPVT) systems. Energy Build. 2010, 42, 1472–1481. [Google Scholar] [CrossRef]

- Gaur, A.; Tiwari, G.N.; Ménézo, C.; Al-Helal, I.M. Numerical and experimental studies on a building integrated semi-transparent photovoltaic thermal (BiSPVT) system: Model validation with a prototype test setup. Energy Convers. Manag. 2016, 129, 329–343. [Google Scholar] [CrossRef]

- Karthick, A.; Kalidasa Murugavel, K.; Ghosh, A.; Sudhakar, K.; Ramanan, P. Investigation of a binary eutectic mixture of phase change material for building integrated photovoltaic (BIPV) system. Sol. Energy Mater. Sol. Cells 2020, 207, 110360. [Google Scholar] [CrossRef]

- Karthick, A.; Murugavel, K.K.; Ramanan, P. Performance enhancement of a building-integrated photovoltaic module using phase change material. Energy 2018, 142, 803–812. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B. Optimization of PV powered SPD switchable glazing to minimise probability of loss of power supply. Renew. Energy 2019, 131, 993–1001. [Google Scholar] [CrossRef]

- Nundy, S.; Ghosh, A. Thermal and visual comfort analysis of adaptive vacuum integrated switchable suspended particle device window for temperate climate. Renew. Energy 2019, in press. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Mallick, T.K. Influence of atmospheric clearness on PDLC switchable glazing transmission. Energy Build. 2018, 172, 257–264. [Google Scholar] [CrossRef]

- Ghosh, A.; Mallick, T.K. Evaluation of colour properties due to switching behaviour of a PDLC glazing for adaptive building integration. Renew. Energy 2018, 120, 126–133. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Mallick, T.K. Daylight characteristics of a polymer dispersed liquid crystal switchable glazing. Sol. Energy Mater. Sol. Cells 2018, 174, 572–576. [Google Scholar] [CrossRef]

- Feng, Y.; Duan, Q.; Wang, J.; Baur, S. Approximation of building window properties using in situ measurements. Build. Environ. 2020, 160, 106590. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B. Interior colour rendering of daylight transmitted through a suspended particle device switchable glazing. Sol. Energy Mater. Sol. Cells 2017, 163, 218–223. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Effect of atmospheric transmittance on performance of adaptive SPD-vacuum switchable glazing. Sol. Energy Mater. Sol. Cells 2017, 161, 424–431. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Effect of sky clearness index on transmission of evacuated (vacuum) glazing. Renew. Energy 2017, 105, 160–166. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Effect of sky conditions on light transmission through a suspended particle device switchable glazing. Sol. Energy Mater. Sol. Cells 2017, 160, 134–140. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B. Durability of switching behaviour after outdoor exposure for a suspended particle device switchable glazing. Sol. Energy Mater. Sol. Cells 2017, 163, 178–184. [Google Scholar] [CrossRef]

- Ghosh, A.; Mallick, T.K. Evaluation of optical properties and protection factors of a PDLC switchable glazing for low energy building integration. Sol. Energy Mater. Sol. Cells 2017, 176, 391–396. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. First outdoor characterisation of a PV powered suspended particle device switchable glazing. Sol. Energy Mater. Sol. Cells 2016, 157, 1–9. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Daylighting performance and glare calculation of a suspended particle device switchable glazing. Sol. Energy 2016, 132, 114–128. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Measured overall heat transfer coefficient of a suspended particle device switchable glazing. Appl. Energy 2015, 159, 362–369. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Measured thermal & daylight performance of an evacuated glazing using an outdoor test cell. Appl. Energy 2016, 177, 196–203. [Google Scholar] [CrossRef]

- Ghosh, A.; Norton, B.; Duffy, A. Measured thermal performance of a combined suspended particle switchable device evacuated glazing. Appl. Energy 2016, 169, 469–480. [Google Scholar] [CrossRef]

- Hemaida, A.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Evaluation of thermal performance for a smart switchable adaptive polymer dispersed liquid crystal ( PDLC ) glazing. Sol. Energy 2020, 195, 185–193. [Google Scholar] [CrossRef]

- Michaux, G.; Greffet, R.; Salagnac, P.; Ridoret, J.B. Modelling of an airflow window and numerical investigation of its thermal performances by comparison to conventional double and triple-glazed windows. Appl. Energy 2019, 242, 27–45. [Google Scholar] [CrossRef]

- Cuce, E. Accurate and reliable U-value assessment of argon-filled double glazed windows: A numerical and experimental investigation. Energy Build. 2018, 171, 100–106. [Google Scholar] [CrossRef]

- Aguilar, J.O.; Xamán, J.; Olazo, Y.; Hernández-López, I.; Becerra, G.; Jaramillo, O.A. Thermal performance of a room with a double glazing window using glazing available in Mexican market. Appl. Therm. Eng. 2017, 119, 505–515. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.W.; Zheng, Y.M.; Liu, C.Y.; Lu, L.B. Optical performance of single and double glazing units in the wavelength 337–900 nm. Sol. Energy 2015, 122, 1091–1099. [Google Scholar] [CrossRef]

- Wong, P.W.; Shimoda, Y.; Nonaka, M.; Inoue, M.; Mizuno, M. Semi-Transparent PV: Thermal performance, power generation, daylight modelling and energy saving potential in a residential application. Renew. Energy 2008, 33, 1024–1036. [Google Scholar] [CrossRef]

- Lu, L.; Law, K.M. Overall energy performance of semi-transparent single-glazed photovoltaic (PV) window for a typical office in Hong Kong. Renew. Energy 2013, 49, 250–254. [Google Scholar] [CrossRef]

- Ng, P.K.; Mithraratne, N.; Kua, H.W. Energy analysis of semi-transparent BIPV in Singapore buildings. Energy Build. 2013, 66, 274–281. [Google Scholar] [CrossRef]

- Miyazaki, T.; Akisawa, A.; Kashiwagi, T. Energy savings of office buildings by the use of semi-transparent solar cells for windows. Renew. Energy 2005, 30, 281–304. [Google Scholar] [CrossRef]

- Chow, T.T.; Pei, G.; Chan, L.S.; Lin, Z.; Fong, K.F. A comparative study of PV glazing performance in warm climate. Indoor Built Environ. 2009, 18, 32–40. [Google Scholar] [CrossRef]

- Kiran Kumar, G.; Saboor, S.; Ashok Babu, T.P. Investigation of various wall and window glass material buildings in different climatic zones of India for energy efficient building construction. Mater. Today Proc. 2018, 5, 23224–23234. [Google Scholar] [CrossRef]

- Gorantla, K.; Shaik, S.; Setty, A.B.T.P. Effect of different double glazing window combinations on heat gain in buildings for passive cooling in various climatic regions of India. Mater. Today Proc. 2017, 4, 1910–1916. [Google Scholar] [CrossRef]

- Skandalos, N.; Karamanis, D. PV glazing technologies. Renew. Sustain. Energy Rev. 2015, 49, 306–322. [Google Scholar] [CrossRef]

- Saifullah, M.; Gwak, J.; Yun, J.H. Comprehensive review on material requirements, present status, and future prospects for building-integrated semitransparent photovoltaics (BISTPV). J. Mater. Chem. A 2016, 4, 8512–8540. [Google Scholar] [CrossRef]

| Solar cell | Advantages | Disadvantages |

|---|---|---|

| Monocrystalline silicon solar cells [17,48,49] |

|

|

| Polycrystalline silicon solar cells [50,51,52] |

|

|

| Amorphous silicon solar cells [53,54,55] |

|

|

| CdTe solar cells [56,57,58,59,60,61] |

|

|

| CIGS solar cells [35,52,62,63,64,65,66,67] |

|

|

| Organic solar cells [36,37,38] |

|

|

| DSSC [68,69,70] |

|

|

| Perovskite solar cells [71,72,73] |

|

|

| Product | Type of Cell | Particular Purpose |

|---|---|---|

| BIPV window |

|

|

| BIPV foil/tiles |

|

|

| Spaced type concentrating BIPV |

|

|

| BAPV/T |

| Suitable for rooftop application |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reddy, P.; Gupta, M.V.N.S.; Nundy, S.; Karthick, A.; Ghosh, A. Status of BIPV and BAPV System for Less Energy-Hungry Building in India—A Review. Appl. Sci. 2020, 10, 2337. https://doi.org/10.3390/app10072337

Reddy P, Gupta MVNS, Nundy S, Karthick A, Ghosh A. Status of BIPV and BAPV System for Less Energy-Hungry Building in India—A Review. Applied Sciences. 2020; 10(7):2337. https://doi.org/10.3390/app10072337

Chicago/Turabian StyleReddy, Pranavamshu, M. V. N. Surendra Gupta, Srijita Nundy, A. Karthick, and Aritra Ghosh. 2020. "Status of BIPV and BAPV System for Less Energy-Hungry Building in India—A Review" Applied Sciences 10, no. 7: 2337. https://doi.org/10.3390/app10072337

APA StyleReddy, P., Gupta, M. V. N. S., Nundy, S., Karthick, A., & Ghosh, A. (2020). Status of BIPV and BAPV System for Less Energy-Hungry Building in India—A Review. Applied Sciences, 10(7), 2337. https://doi.org/10.3390/app10072337