Optimizing Food Waste Composting Parameters and Evaluating Heat Generation

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

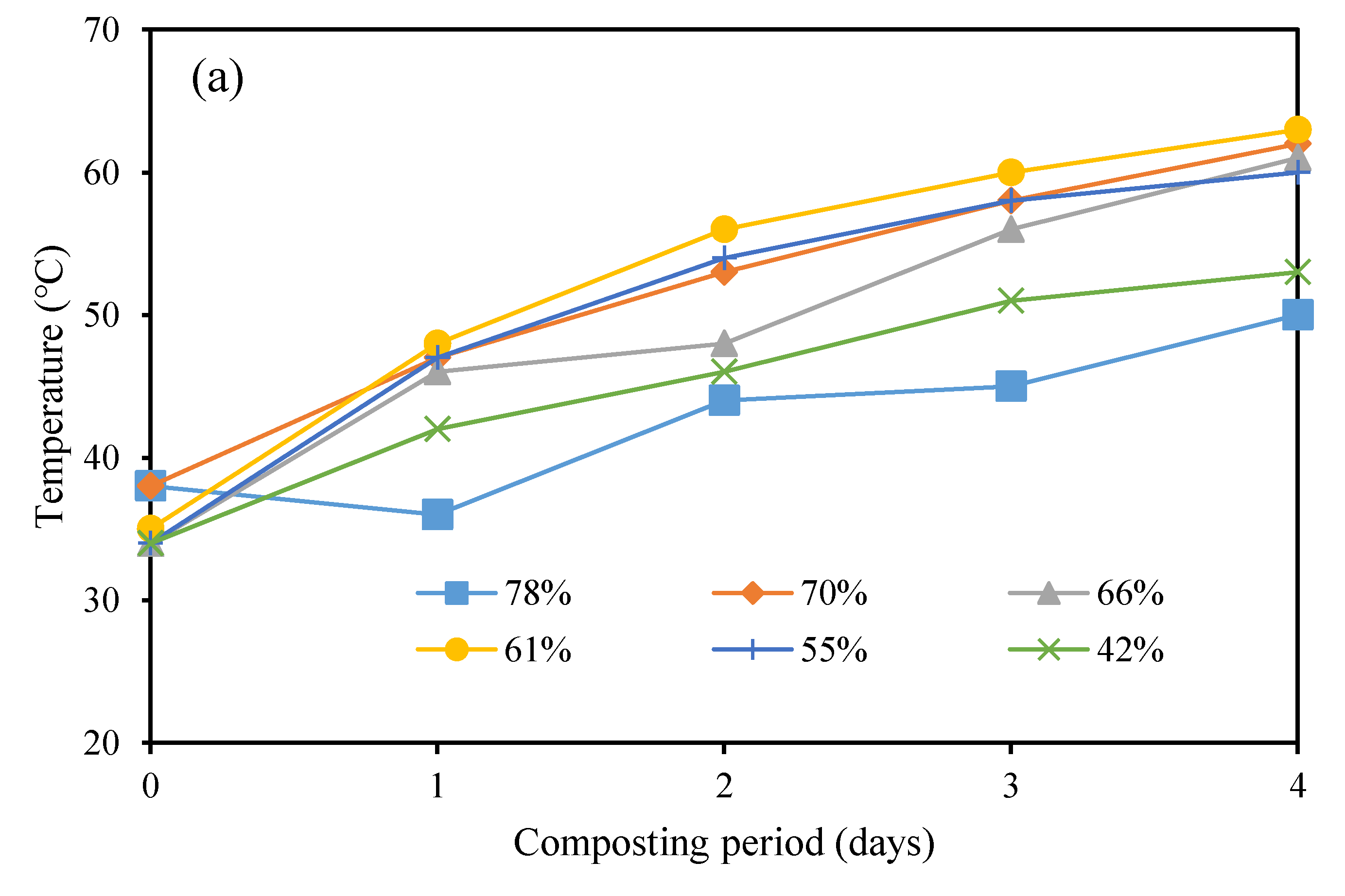

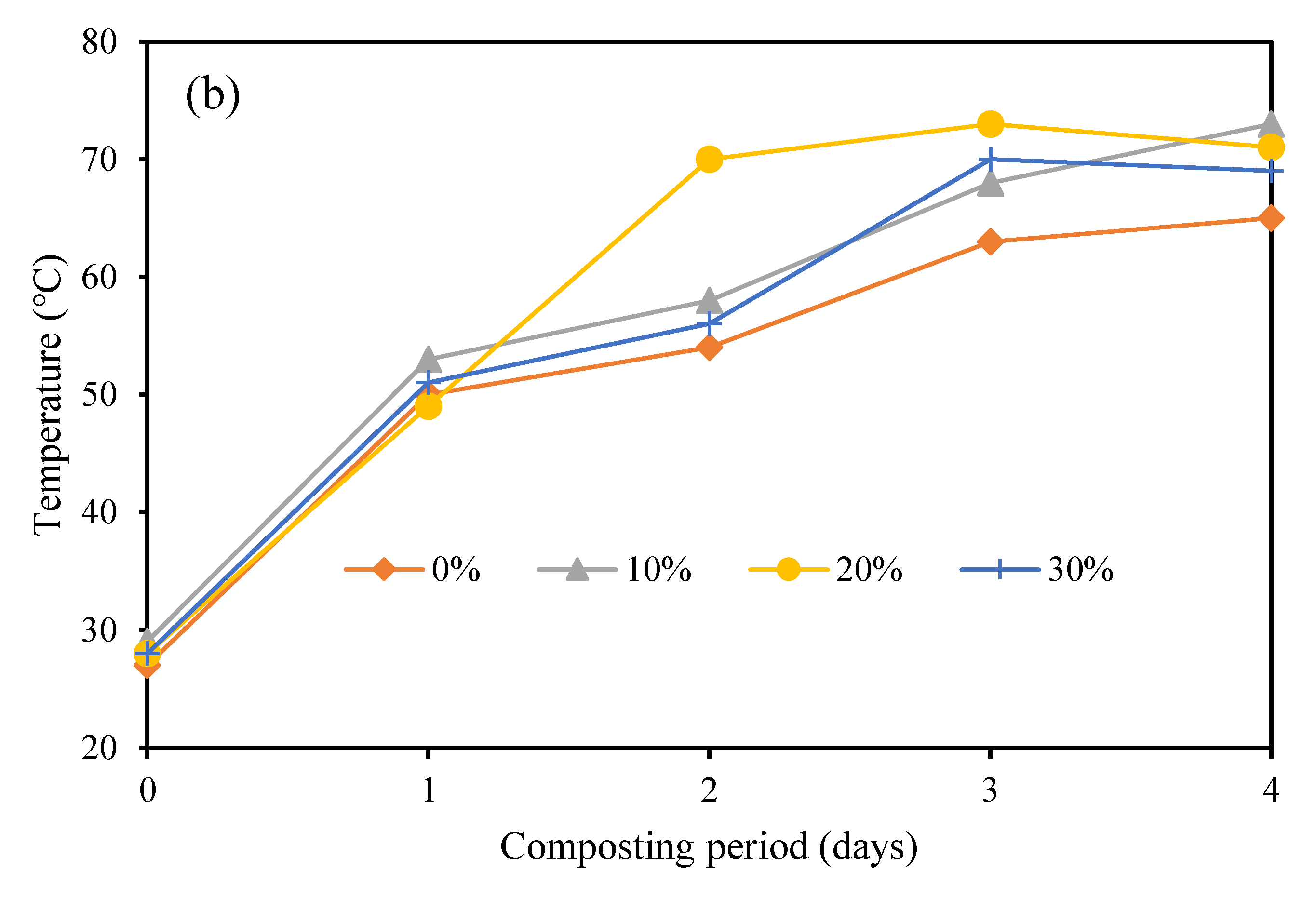

3.1. Optimal Moisture Content and Mature Compost Seeding Amount for Effective Composting

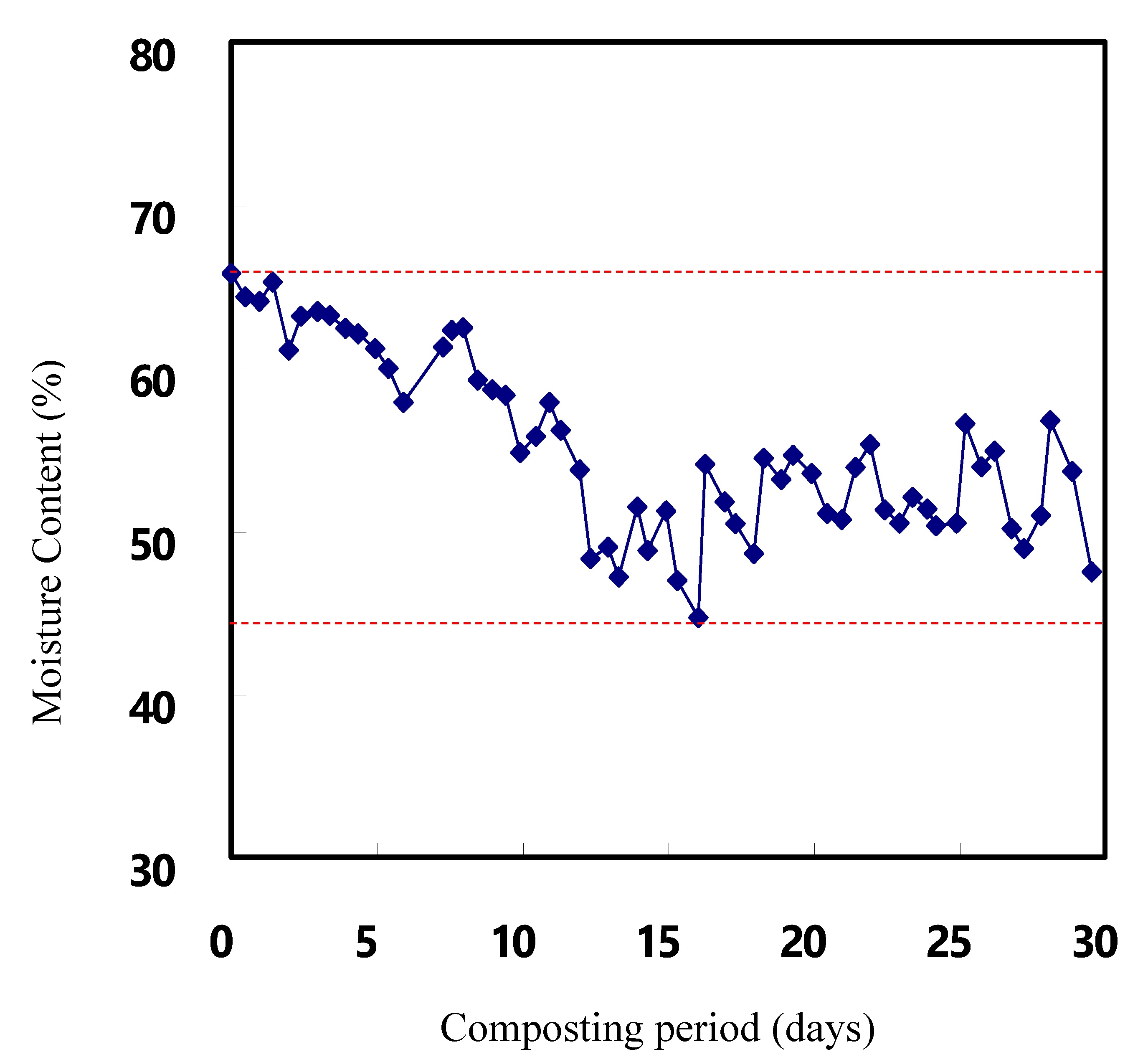

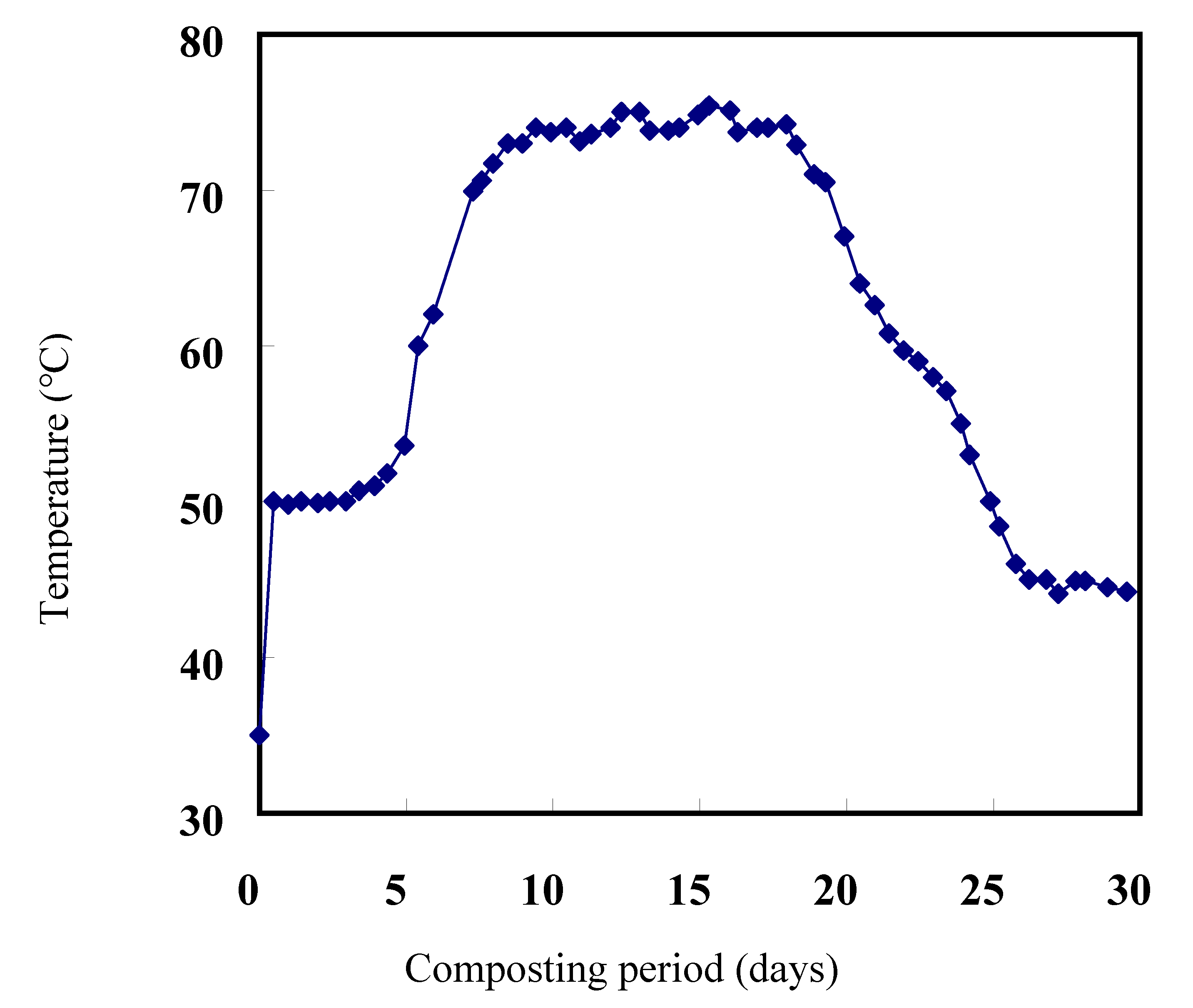

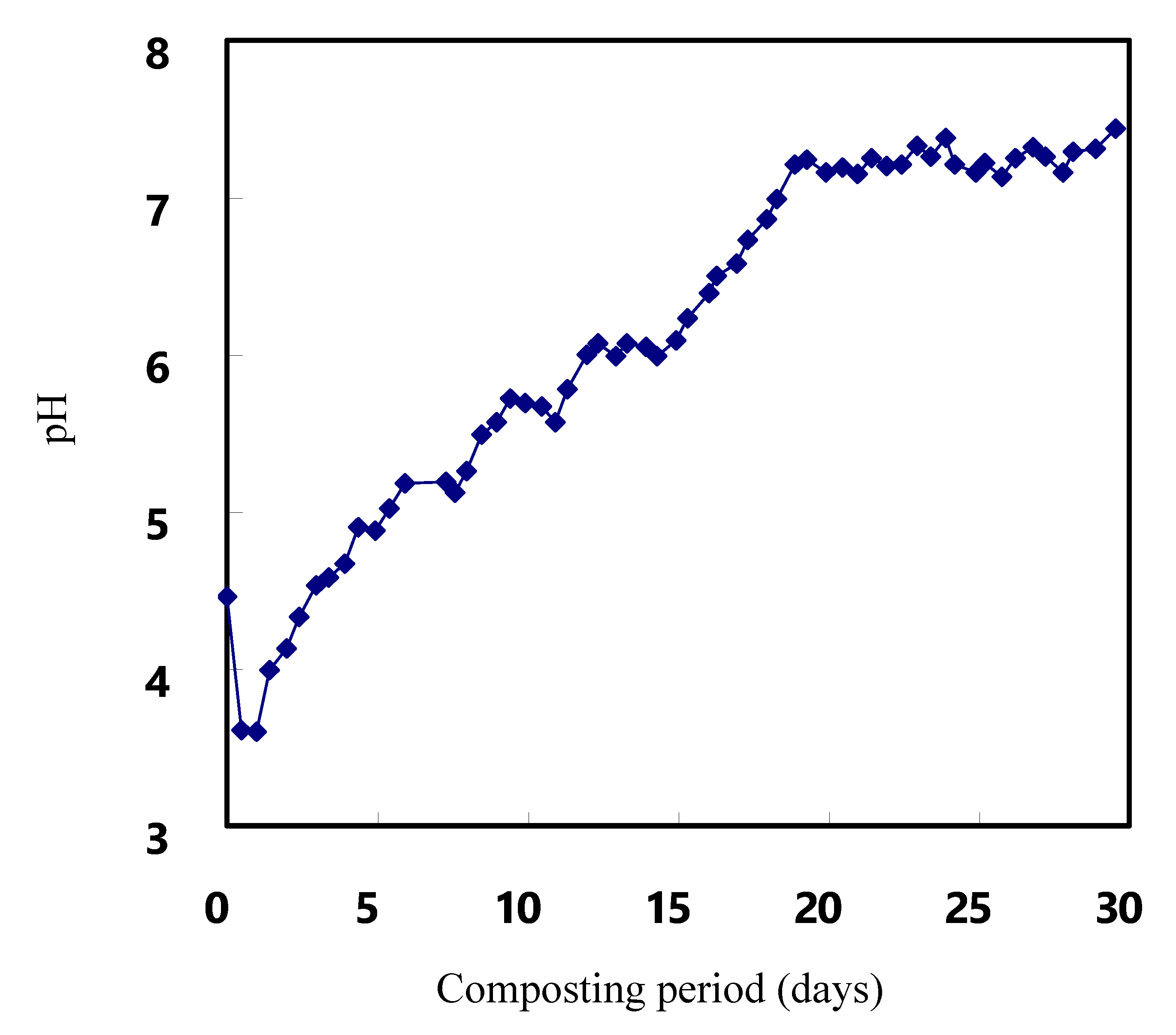

3.2. Moisture Content, Temperature, and pH Variation during a 30-Day Composting Period

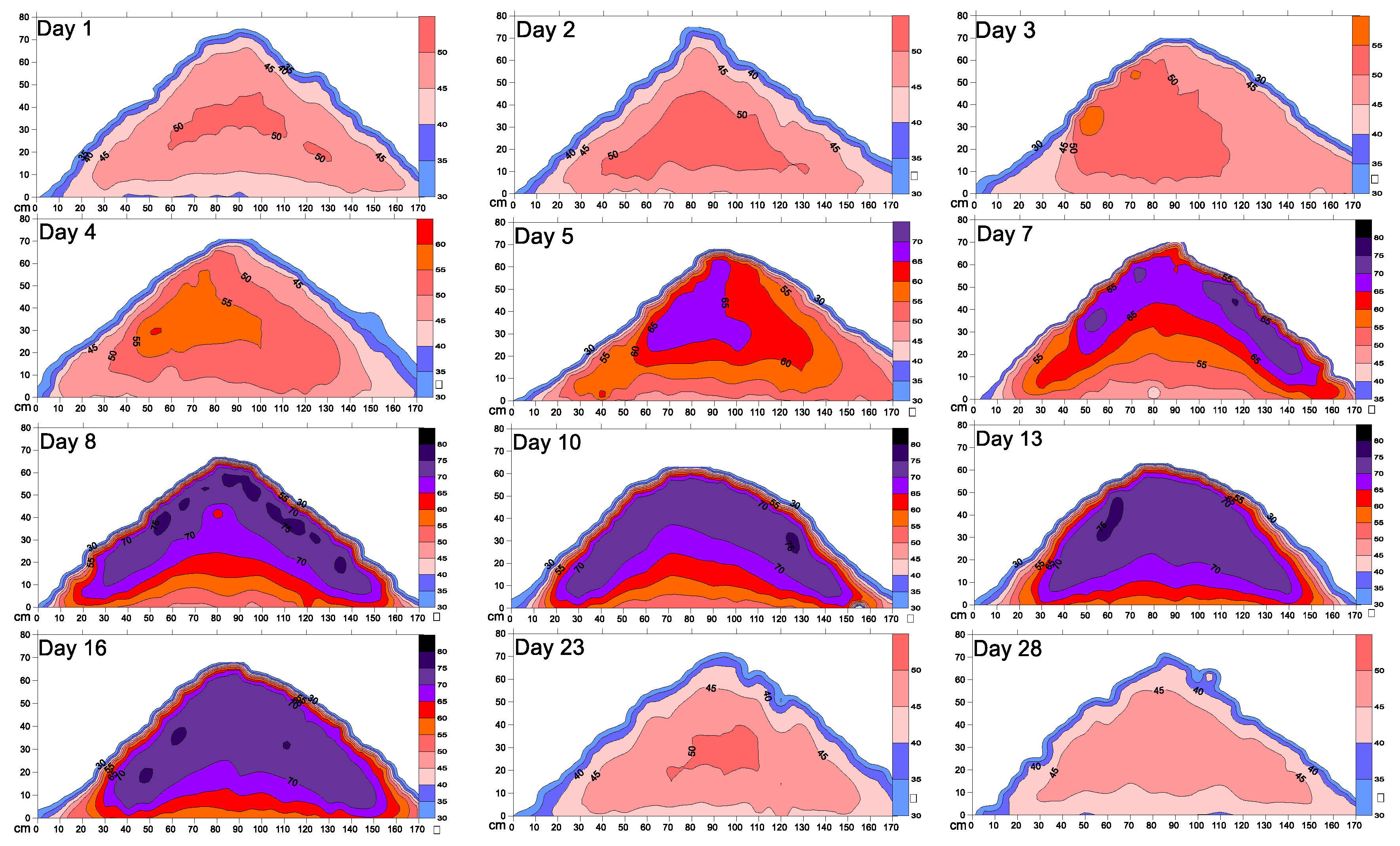

3.3. Evolution and Spatial Distribution of Temperature during the Composting Period

3.4. Estimation of Heat Produced during the Composting Process

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. B 2010, 365, 3065–3081. [Google Scholar] [CrossRef] [PubMed]

- Van Zanten, H.H.; Mollenhorst, H.; Oonincx, D.G.; Bikker, P.; Meerburg, B.G.; de Boer, I.J. From environmental nuisance to environmental opportunity: Housefly larvae convert waste to livestock feed. J. Clean. Prod. 2015, 102, 362–369. [Google Scholar] [CrossRef]

- Zhang, C.; Su, H.; Baeyens, J.; Tan, T. Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sust. Energ. Rev. 2014, 38, 383–392. [Google Scholar] [CrossRef]

- Sanchez-Vazquez, S.; Hailes, H.; Evans, J. Hydrophobic polymers from food waste: Resources and synthesis. Polym. Rev. 2013, 53, 627–694. [Google Scholar] [CrossRef]

- Park, S.Y.; Lee, H.U.; Park, E.S.; Lee, S.C.; Lee, J.W.; Jeong, S.W.; Kim, C.H.; Lee, Y.C.; Huh, Y.S.; Lee, J. Photoluminescent green carbon nanodots from food-waste-derived sources: Large-scale synthesis, properties, and biomedical applications. ACS Appl. Mater. 2014, 6, 3365–3370. [Google Scholar] [CrossRef]

- Maitan-Alfenas, G.P.; Visser, E.M.; Guimarães, V.M. Enzymatic hydrolysis of lignocellulosic biomass: Converting food waste in valuable products. Curr. Opin. Food Sci. 2015, 1, 44–49. [Google Scholar] [CrossRef]

- Li, Z.; Lu, H.; Ren, L.; He, L. Experimental and modeling approaches for food waste composting: A review. Chemosphere 2013, 93, 1247–1257. [Google Scholar] [CrossRef]

- Lin, C. A negative-pressure aeration system for composting food wastes. Bioresour. Technol. 2008, 99, 7651–7656. [Google Scholar] [CrossRef]

- Nakakubo, T.; Tokai, A.; Ohno, K. Comparative assessment of technological systems for recycling sludge and food waste aimed at greenhouse gas emissions reduction and phosphorus recovery. J. Clean. Prod. 2012, 32, 157–172. [Google Scholar] [CrossRef]

- Mao, I.F.; Tsai, C.J.; Shen, S.H.; Lin, T.F.; Chen, W.K.; Chen, M.L. Critical components of odors in evaluating the performance of food waste composting plants. Sci. Total Environ. 2006, 370, 323–329. [Google Scholar] [CrossRef]

- Cerda, A.; Artola, A.; Font, X.; Barrena, R.; Gea, T.; Sánchez, A. Composting of food wastes: Status and challenges. Bioresour. Technol. 2018, 248, 57–67. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.; Wu, E.M.Y.; Lee, C.N.; Kuo, S.L. Multivariate statistical factor and cluster analyses for selecting food waste optimal recycling methods. Environ. Eng. Sci. 2011, 28, 349–356. [Google Scholar] [CrossRef]

- Wong, J.; Ma, K.; Fang, K.; Cheung, C. Utilization of a manure compost for organic farming in Hong Kong. Bioresour. Technol. 1999, 67, 43–46. [Google Scholar] [CrossRef]

- Lovell, S.T. Multifunctional urban agriculture for sustainable land use planning in the United States. Sustainability 2010, 2, 2499–2522. [Google Scholar] [CrossRef]

- Tran, H.T.; Vu, C.T.; Lin, C.; Bui, X.T.; Huang, W.Y.; Hoang, H.G.; Liu, W.Y. Remediation of highly fuel oil-contaminated soil by food waste composting and its volatile organic compound (VOC) emission. Bioresour. Technol. Rep. 2018, 4, 145–152. [Google Scholar] [CrossRef]

- Chang, J.I.; Chen, Y.J. Effects of bulking agents on food waste composting. Bioresour. Technol. 2010, 101, 5917–5924. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, B.K.; Barrington, S.; Martinez, J.; King, S. Effectiveness of three bulking agents for food waste composting. Waste Manag. 2009, 29, 197–203. [Google Scholar] [CrossRef]

- Pan, I.; Dam, B.; Sen, S. Composting of common organic wastes using microbial inoculants. 3 Biotech 2012, 2, 127–134. [Google Scholar] [CrossRef]

- Karnchanawong, S.; Nissaikla, S. Effects of microbial inoculation on composting of household organic waste using passive aeration bin. Int. J. Recy. Org. Waste Agric. 2014, 3, 113–119. [Google Scholar] [CrossRef]

- Guo, R.; Li, G.; Jiang, T.; Schuchardt, F.; Chen, T.; Zhao, Y.; Shen, Y. Effect of aeration rate, C/N ratio and moisture content on the stability and maturity of compost. Bioresour. Technol. 2012, 112, 171–178. [Google Scholar] [CrossRef]

- Pace, M.G.; Miller, B.E.; Farrell-Poe, K.L. The Composting Process; Utah State University: Logan, UT, USA, 1995. [Google Scholar]

- Ahn, H.; Richard, T.; Choi, H. Mass and thermal balance during composting of a poultry manure—Wood shavings mixture at different aeration rates. Process Biochem. 2007, 42, 215–223. [Google Scholar] [CrossRef]

- Lin, C.; Sheu, D.S.; Lin, T.C.; Kao, C.M.; Grasso, D. Thermophilic biodegradation of diesel oil in food waste composting processes without bioaugmentation. Environ. Eng. Sci. 2012, 29, 117–123. [Google Scholar] [CrossRef]

- Sobel, A.; Muck, R. Energy in animal manures. Eng. Agric. 1983, 2, 161–176. [Google Scholar] [CrossRef]

- Smith, M.M.; Aber, J.D.; Rynk, R. Heat recovery from composting: A comprehensive review of system design, recovery rate, and utilization. Compost. Sci. Util. 2017, 25, S11–S22. [Google Scholar] [CrossRef]

- Smith, M.M. Creating an Economically Viable, Closed-System, Energy-Independent Dairy Farm through the On-Farm Production of Animal Bedding and Heat Capture from an Aerated Static Pile Heat Recovery Composting Operation. Ph.D. Thesis, University of New Hampshire, Durham, NH, USA, 2016. [Google Scholar]

- Kumar, M.; Ou, Y.L.; Lin, J.G. Co-composting of green waste and food waste at low C/N ratio. Waste Manag. 2010, 30, 602–609. [Google Scholar] [CrossRef]

- Liu, L.; Wang, S.; Guo, X.; Zhao, T.; Zhang, B. Succession and diversity of microorganisms and their association with physicochemical properties during green waste thermophilic composting. Waste Manag. 2018, 73, 101–112. [Google Scholar] [CrossRef]

- Jiang, T.; Schuchardt, F.; Li, G.; Guo, R.; Zhao, Y. Effect of C/N ratio, aeration rate and moisture content on ammonia and greenhouse gas emission during the composting. J. Environ. Sci. 2011, 23, 1754–1760. [Google Scholar] [CrossRef]

- Liang, C.; Das, K.C.; McClendon, R.W. The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Bioresour. Technol. 2003, 86, 131–137. [Google Scholar] [CrossRef]

- Mihial, D.J.; Viraraghavan, T.; Jin, Y.C. Bioremediation of petroleum-contaminated soil using composting. J. Hazard. Toxic Radioact. Waste 2006, 10, 108–115. [Google Scholar] [CrossRef][Green Version]

- Wang, X.; Pan, S.; Zhang, Z.; Lin, X.; Zhang, Y.; Chen, S. Effects of the feeding ratio of food waste on fed-batch aerobic composting and its microbial community. Bioresour. Technol. 2017, 224, 397–404. [Google Scholar] [CrossRef]

- Yu, H.; Zeng, G.; Huang, H.; Xi, X.; Wang, R.; Huang, D.; Huang, G.; Li, J.J.B. Microbial community succession and lignocellulose degradation during agricultural waste composting. Biodegradation 2007, 18, 793–802. [Google Scholar] [CrossRef] [PubMed]

- Mbah, B.N.; Odili, P.N. Changes in moisture retention properties of five waste materials during short-term mesophilic composting. Compost Sci. Util. 1998, 6, 67–73. [Google Scholar] [CrossRef]

- Sundberg, C.; Jönsson, H.J.B. Process inhibition due to organic acids in fed-batch composting of food waste–influence of starting culture. Biodegradation 2005, 16, 205–213. [Google Scholar] [CrossRef] [PubMed]

- Beck-Friis, B.; Smårs, S.; Jönsson, H.; Eklind, Y.; Kirchmann, H. Composting of source-separated household organics at different oxygen levels: Gaining an understanding of the emission dynamics. Compost Sci. Util. 2003, 11, 41–50. [Google Scholar] [CrossRef]

- Cheung, H.; Huang, G.; Yu, H. Microbial-growth inhibition during composting of food waste: Effects of organic acids. Bioresour. Technol. 2010, 101, 5925–5934. [Google Scholar] [CrossRef] [PubMed]

- Irvine, G.; Lamont, E.; Antizar-Ladislao, B. Energy from waste: Reuse of compost heat as a source of renewable energy. Int. J. Chem. Eng. 2010, 2010. [Google Scholar] [CrossRef]

- Ahn, H.; Sauer, T.; Richard, T.L.; Glanville, T.D. Determination of thermal properties of composting bulking materials. Bioresour. Technol. 2009, 100, 3974–3981. [Google Scholar] [CrossRef]

- Harper, E.; Miller, F.; Macauley, B. Physical management and interpretation of an environmentally controlled composting ecosystem. Aust. J. Exp. Agric. 1992, 32, 657–667. [Google Scholar] [CrossRef]

- Klejment, E.; Rosiński, M. Testing of thermal properties of compost from municipal waste with a view to using it as a renewable, low temperature heat source. Bioresour. Technol. 2008, 99, 8850–8855. [Google Scholar] [CrossRef]

- Vemmelund, N.; Berthelsen, L. A note on heat recovery from mechanically aerated farm-yard manure. Agric. Wastes 1979, 1, 157–160. [Google Scholar] [CrossRef]

- Jaccard, L.; Lehmann, P.; Civilini, M.; Bertoldi, M.d. Yard waste composting with heat recovery. Compos. Sci. Util. 1993, 1, 10–14. [Google Scholar] [CrossRef]

- Alwell, A. Innovative system uses composting process to heat high tunnel. Org. Broadcast. 2014, 22, 5. [Google Scholar]

- Thostrup, P. Heat Recovery from Composting Solid Manure. In Proceedings of the Bioenergy 84, Göteborg, Sweden, 15–21 June 1984; pp. 217–225. [Google Scholar]

- Tucker, M.F. Extracting thermal energy from composting. BioCycle 2006, 47, 38. [Google Scholar]

| Component | Weight (kg) | pH | C/N Ratio | Moisture Content (%) |

|---|---|---|---|---|

| 1. Food waste (comprised of 80 kg vegetable and fruit peel, 70 kg meat and animal skin and 110 kg cooked food) | 260 | 4.3 | 11 | 80 |

| 2. Sawdust | 60 | 6.8 | 519 | 15 |

| 3. Mature compost | 80 | 6.5 | 29 | 20 |

| Initial compost mixture | 400 | 4.5 | 22 | 65 |

| Material | Amount Present (%) | s (kJ/kg °C) | Overall s |

|---|---|---|---|

| Water | 65 | 4.184 | 3.1336 |

| Sawdust | 15 | 1.4 b | |

| Mature compost | 20 | 1.02 a,b |

| Compost Material | Thermophilic Temp (°C) | Period (Days) | Heat Production (MJ/ kg) | Reference |

|---|---|---|---|---|

| Food waste | 70 | 30 | 2.99 | This study |

| Mushroom waste | 55–63 | – | 1.23 | [40] |

| Municipal waste | ~60 | 16 | 1.14 | [41] |

| Poultry manure and wood shavings | >60 | – | 16.83–19.70 | [22] |

| Compost Scale | Compost Material | Period (Days) | Heat Production Rate (kJ/hr) | References |

|---|---|---|---|---|

| Small-scale (0.6 m3) | Food waste | 30 | 1659 | This study |

| Small-scale (1 m3) | Farmyard manure | – | 2304 | [42] |

| Pilot-scale (1 m3) | Yard waste | 5 | 1948 | [43] |

| Pilot-scale (5 m3) | Agricultural wastes | 5 | 4023 | [44] |

| Pilot-scale (5 m3) | Pig manure | 21 | 16,925 | [45] |

| Large-scale (142 m3) | Agricultural wastes | – | 211,011 | [46] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeh, C.K.; Lin, C.; Shen, H.C.; Cheruiyot, N.K.; Camarillo, M.E.; Wang, C.L. Optimizing Food Waste Composting Parameters and Evaluating Heat Generation. Appl. Sci. 2020, 10, 2284. https://doi.org/10.3390/app10072284

Yeh CK, Lin C, Shen HC, Cheruiyot NK, Camarillo ME, Wang CL. Optimizing Food Waste Composting Parameters and Evaluating Heat Generation. Applied Sciences. 2020; 10(7):2284. https://doi.org/10.3390/app10072284

Chicago/Turabian StyleYeh, Chin Ko, Chitsan Lin, Hsueh Chen Shen, Nicholas Kiprotich Cheruiyot, Mary Ellen Camarillo, and Chung Lung Wang. 2020. "Optimizing Food Waste Composting Parameters and Evaluating Heat Generation" Applied Sciences 10, no. 7: 2284. https://doi.org/10.3390/app10072284

APA StyleYeh, C. K., Lin, C., Shen, H. C., Cheruiyot, N. K., Camarillo, M. E., & Wang, C. L. (2020). Optimizing Food Waste Composting Parameters and Evaluating Heat Generation. Applied Sciences, 10(7), 2284. https://doi.org/10.3390/app10072284