Improvement of Marine Clay Soil Using Lime and Alkaline Activation Stabilized with Inclusion of Treated Coir Fibre

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Marine Clay

2.1.2. Coir Fibre

2.1.3. Additive

Lime

Fly Ash

Activator

2.2. Method

2.2.1. Sample Preparation

2.2.2. Geotechnical Testing

Unconfined Compression Strength Test

Flexural Test (Three Point Bending)

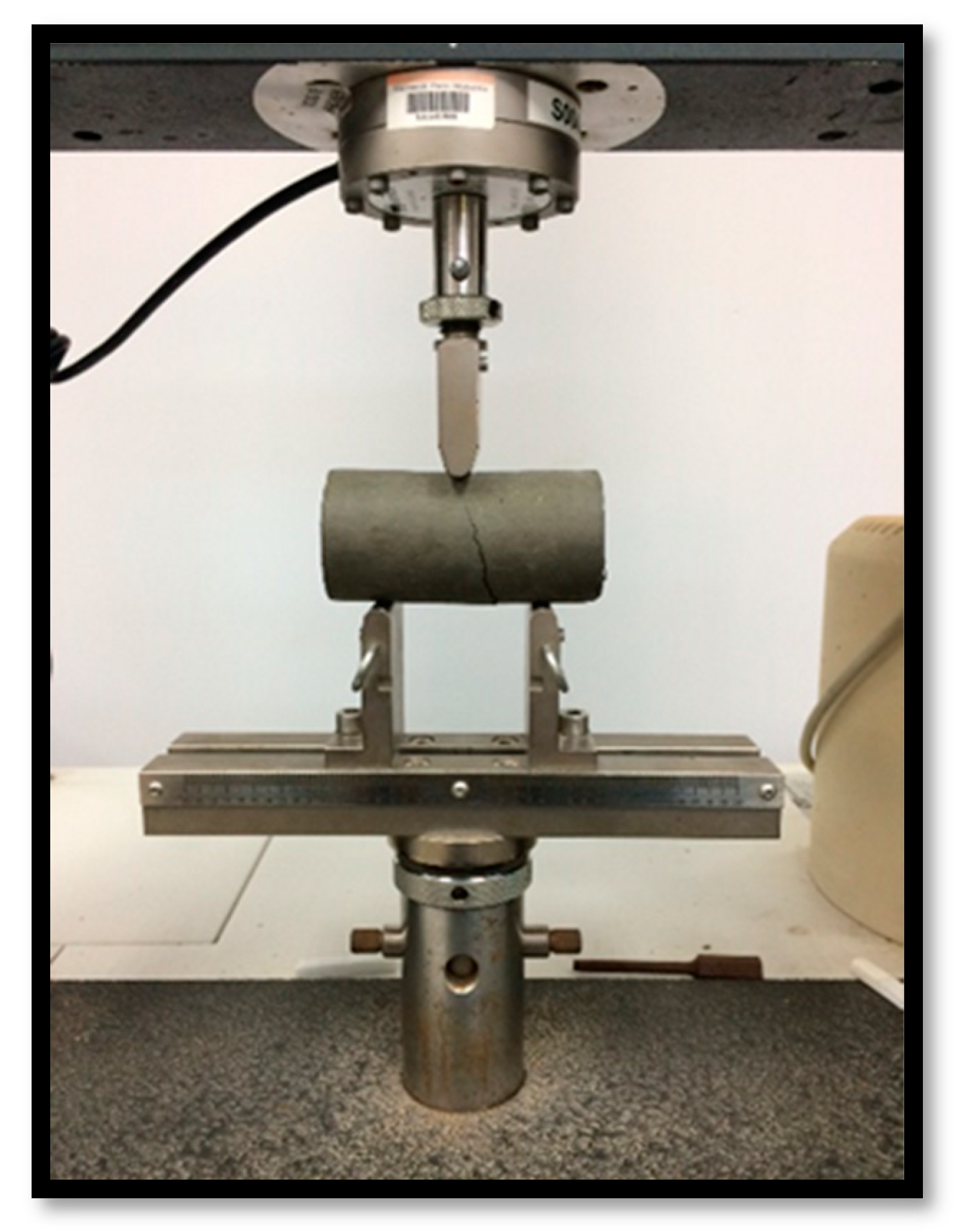

Indirect Tensile Strength Test

2.2.3. Microstructural Analysis

3. Results and Discussion

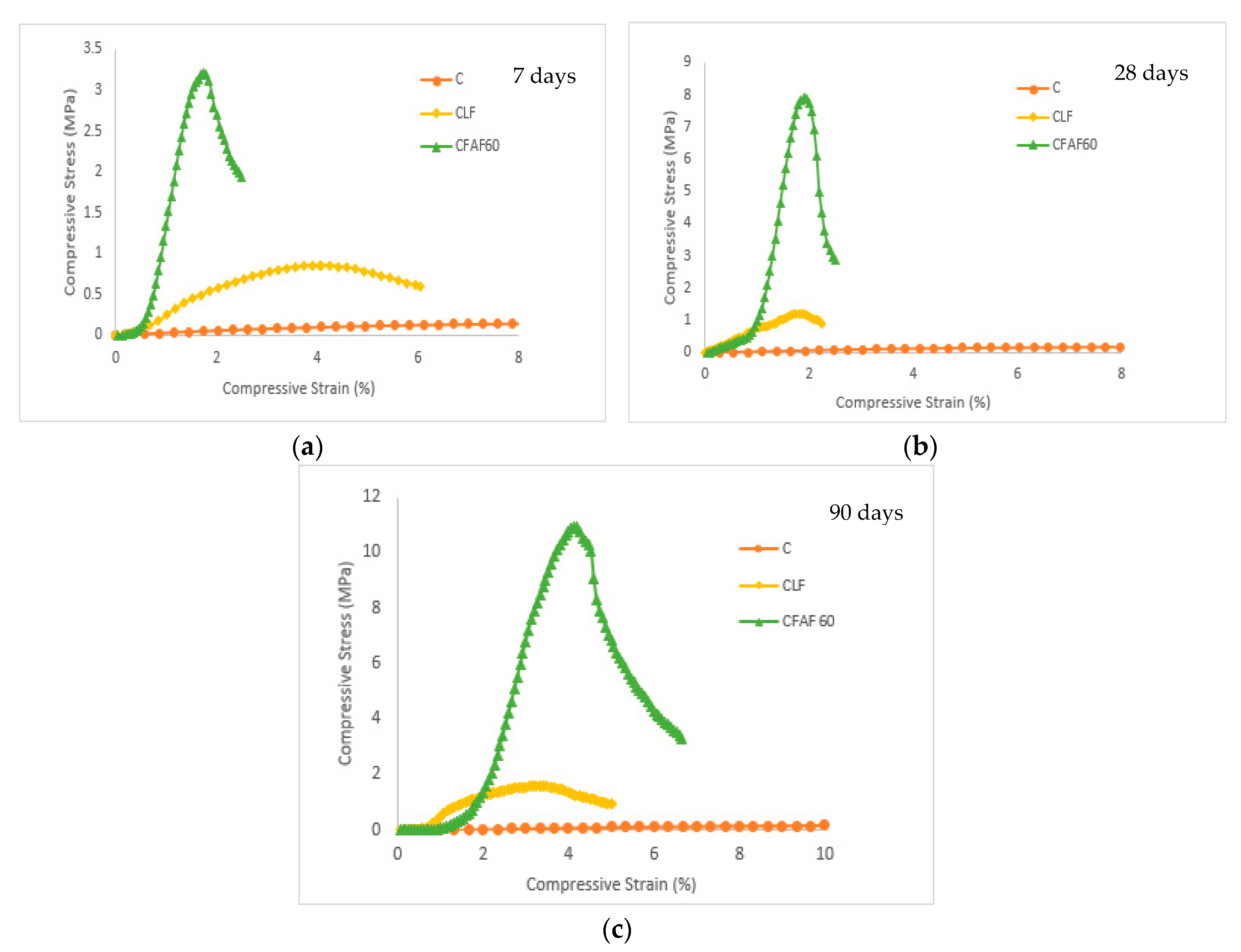

3.1. Unconfined Compressive Strength

Secant Modulus (Es) and Deformability Index (ID)

3.2. Flexural Strength Test

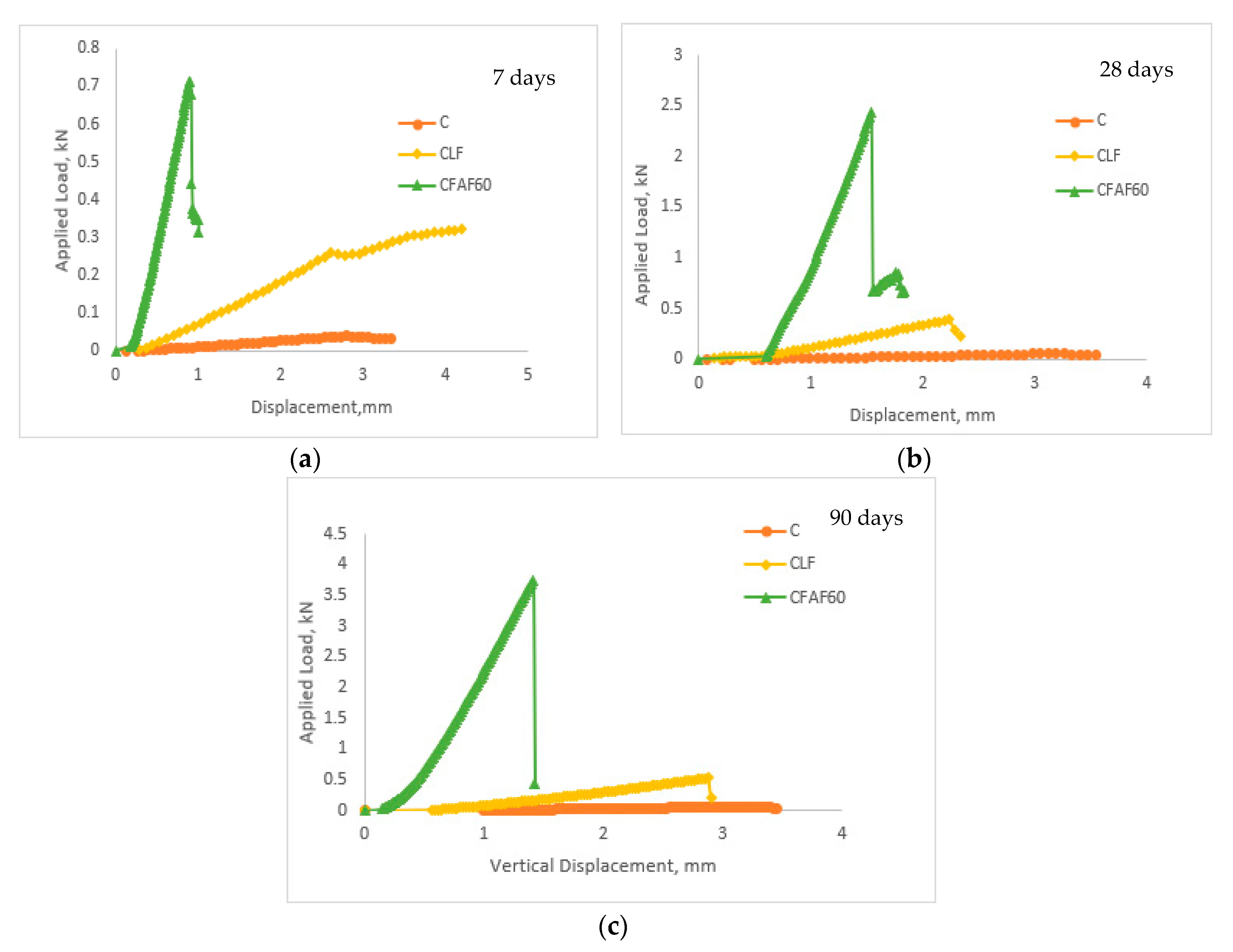

3.3. Indirect Tensile Strength Test

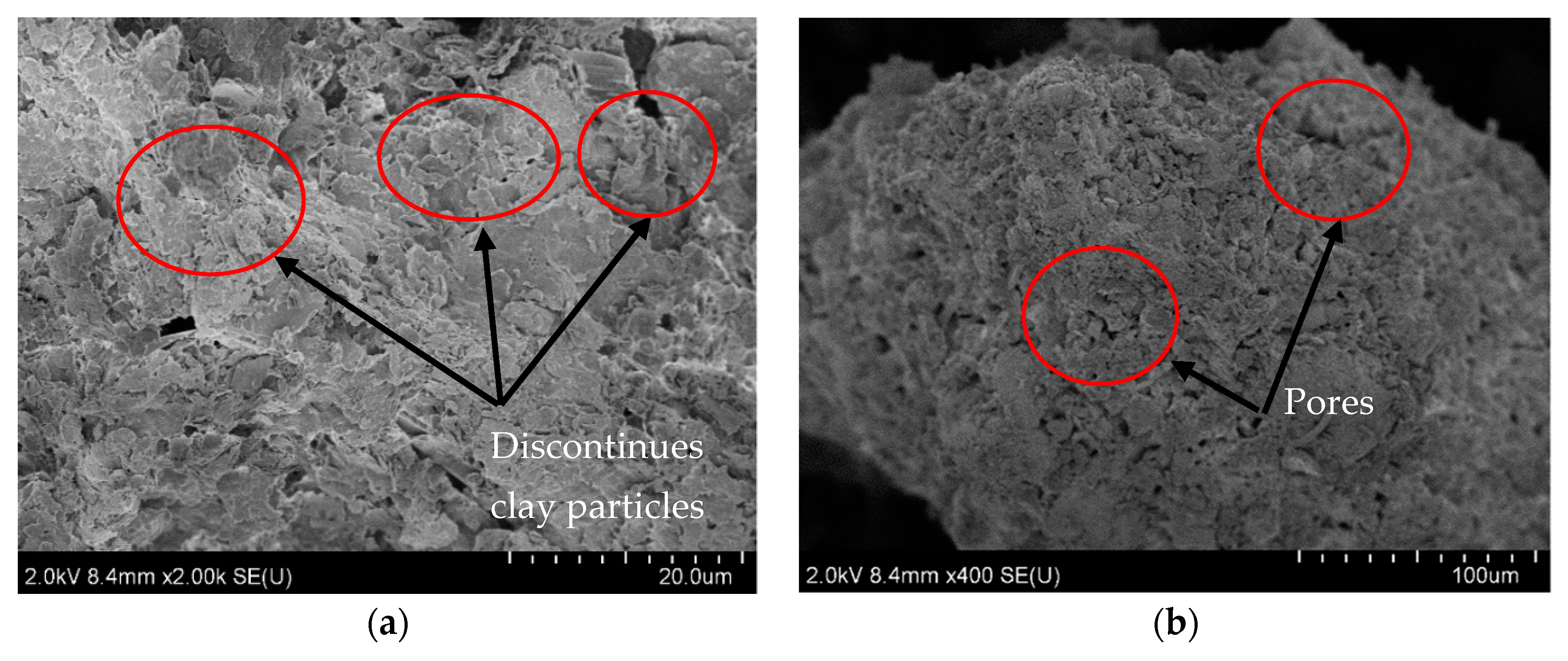

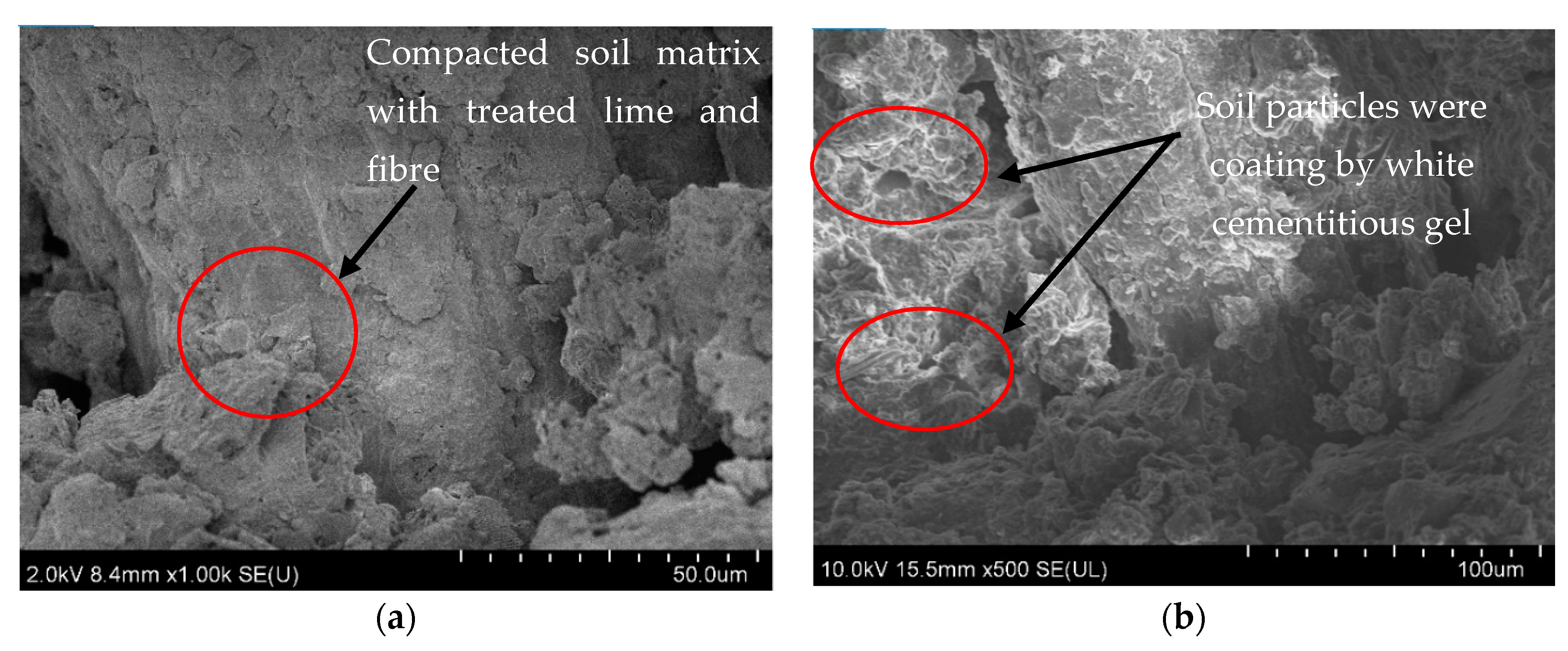

3.4. Microstructural Analysis

4. Conclusions

- Inclusion of fibre in treated soil for lime and alkaline stabilized soil increases the compressive strength, tensile strength and indirect tensile strength test for both chemical agents.

- The inclusion of fibre in the treated soil enhances the post-peak behaviour at the different curing period of 7, 28 and 90 days.

- There is an important pozzolanic reaction that occurred after 28 days curing period for treated soil with lime and alkaline activation compared to the untreated clay soil.

- Stabilization on soil using reinforce alkali activation shows higher strength compared the utilization by lime for all curing periods. The noticeable is clearly seen after 90 days of curing periods. The interfacial interlocking of treated soil and fibre shows a good bonding compared to the untreated soil.

- Analysis of FESEM and EDX shows that, reaction occurs between the treated soil with lime and alkaline activation contributes to denser soil. The reaction also seems to bind the soil particles around and strengthen the soil.

- Cementitious reaction products of calcium- silicate hydrate (C-S-H) and calcium aluminium silicate hydrate (C-A-S-H) for lime and formation of SI-O-Al and Si-O-Si bonds for alkaline activator shows that interaction between fibre and treated soil contribute in enhance the behaviour of reinforced mixtures.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zainuddin, N.; Yunus, N.Z.M.; Al-Bared, M.A.M.; Marto, A.; Harahap, I.S.H.; Rashid, A.S.A. Measuring the engineering properties of marine clay treated with disposed granite waste. Measurement 2019, 131, 50–60. [Google Scholar] [CrossRef]

- Phetchuay, C.; Horpibulsuk, S.; Arulrajah, A.; Suksiripattanapong, C.; Udomchai, A. Strength development in soft marine clay stabilized by fly ash and calcium carbide residue based polymer. Appl. Clay Sci. 2016, 127, 134–142. [Google Scholar] [CrossRef]

- Ahmad, N.R.; Harahap, I.S. The compression behaviour of marine clays in Malaysia. In Proceedings of the ASME 35th International Conference on Ocean, Offshore and Artic Engineering, Busan, Korea, 1–6 June 2016. [Google Scholar]

- Jiang, N.J.; Du, Y.J.; Liu, S.Y.; Wei, M.L.; Horpibulsuk, S.; Arulrajah, A. Multi-scale laboratory evaluation of the physical, mechanical and microstructural properties of soft highway subgrade soil stabilized with calcium carbide residue. Can. Geotech. J. 2015, 53, 373–383. [Google Scholar] [CrossRef]

- Pourakbar, S.; Huat, B.B.K. A review of alternatives traditional cementitious binders for engineering improvement of soils. Int. J. Geotech. Eng. 2016, 11, 206–216. [Google Scholar] [CrossRef]

- Rajasekaran, G.; Narasimha Rao, S. Compressibility behaviour of lime-treated marine clay. Ocean Eng. 2002, 29, 545–559. [Google Scholar] [CrossRef]

- Balasubramaniam, A.S.; Bergado, D.T.; Buensucoso, B.R., Jr.; Yan, W.C. Strength and deformation characteristic of lime treated soft clay. J. Geotech. Eng. 1989, 20, 49–65. [Google Scholar]

- Locat, J.; Berube, M.A.; Choquette, M. Laboratory investigation on the lime stabilization of sensitive clays: Shear strength development. Can. Geotech. J. 1990, 27, 294–304. [Google Scholar] [CrossRef]

- Anggraini, V.; Asadi, A.; Farzadnia, N.; Jahangirian, H.; Huat, B.B.K. Effect of coir fibres modified Ca(OH)2 and Mg (OH)2 nanoparticles on mechanical properties of lime-treated marine clay. Geosynth. Int. 2016, 23, 206–218. [Google Scholar] [CrossRef]

- Reddy, S.S.; Prasad, A.C.S.V.; Krishna, V. Lime-stabilized black cotton soil and brick powder mixture as subbase material. Adv. Civ. Eng. 2018, 2018, 1–5. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Horpibulsuk, S.; Boongrasan, S.; Udomchai, A.; Chinkulkijniwat, A.; Arulrajah, A. Unit weight, strength and microstructure of a water treatment sludge-fly ash lightweight cellular geopolymer. Constr. Build. Mater. 2015, 94, 807–816. [Google Scholar] [CrossRef]

- Weng, L.; Sagoe-Crentsil, K. Dissolution processes, hydrolysis and condensation reactions during geopolymer synthesis: Part I—Low Si/Al ratio systems. J. Mater. Sci. 2007, 42, 2997–3006. [Google Scholar] [CrossRef]

- Yunsheng, Z.; Wei, S.; Zongjin, L.; Xiangming, Z.; Chungkong, C. Impact properties of geopolymer based extrudates incorporated with fly ash and PVA short fiber. Constr. Build. Mater. 2008, 22, 370–383. [Google Scholar] [CrossRef]

- Sargent, P.; Hughes, P.N.; Rouainia, M.; White, M.L. The use of alkali activated waste binders in enhancing the mechanical properties and durability of soft alluvial soils. Eng. Geol. 2013, 152, 96–108. [Google Scholar] [CrossRef]

- Pourakbar, S.; Asadi, A.; Huat, B.B.K.; Fasihnikoutalab, M.H. Soil stabilization with alkali-activated agro-waste. Environ. Geotech. 2015, 2, 359–370. [Google Scholar] [CrossRef]

- Cristelo, N.; Miranda, T.; Oliveira, D.V.; Rosa, I.; Soares, E.; Ceolho, P.; Fernandes, L. Assessing the production of jet mix columns using alkali activated waste based on mechanical and financial performance of CO2 (eq) emissions. J. Clean. Prod. 2015, 102, 447–460. [Google Scholar] [CrossRef]

- Kamaruddin, F.A.; Huat, B.B.K.; Anggraini, V.; Nahazanan, H. Modified natural fiber on soil stabilization with lime and alkaline activation treated marine clay. Int. J. 2019, 16, 69–75. [Google Scholar] [CrossRef]

- Teing, T.T.; Huat, B.B.K.; Anggraini, V.; Shukla, S.K.; Nahazanan, H. Strength behaviour of fly ash-tabilized soil reinforced with coir fibers in alkaline environment. J. Nat. Fibers 2019, 1–14. [Google Scholar] [CrossRef]

- Singh, H.P.; Bagra, M. Improvement in CBR value of soil reinforced with jute fiber. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 3447–3452. [Google Scholar]

- Sarbaz, H.; Ghiassian, H.; Heshmati, A.A. CBR strength of reinforced soil with natural fibres and considering environmental conditions. Int. J. Pavement Eng. 2014, 15, 577–583. [Google Scholar] [CrossRef]

- Ishak, M.R.; Leman, Z.; Sapuan, S.M.; Edeerozey, A.M.M.; Othman, I.S. Mechanical properties of kenaf bast and core fibre reinforced unsaturated polyester composites. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2010; Volume 11, p. 012006. [Google Scholar]

- Joy, N.J.; Thomas, C.T. Effect of sisal fibre on shear strength characteristics of Kuttanad Clay. Int. Res. J. Eng. Technol. 2017, 4, 973–976. [Google Scholar]

- Himanshu, B.; Jauhari, N.; Varshney, H. Performance and analysis of coir fibre reinforcement. IJRASET 2017, 5, 2321–9653. [Google Scholar]

- Anggraini, V. Reinforcement Effects of Nano-Modified Coir Fibres on Lime-Treated Marine Clay. Ph.D. Thesis, Universiti Putra Malaysia (UPM), Selangor, Malaysia, 2015. [Google Scholar]

- Ramesh, H.; Krishna, K.M.; Mamatha, H. Compaction and strength behaviour of lime-coir fiber treated black cotton soil. Geome. Eng. 2010, 2, 19–28. [Google Scholar] [CrossRef]

- Sivakumar Babu, G.L.; Vasudevan, A.K.; Sayida, M.K. Use of coir fibers for improving the engineering properties of expansive soils. J. Nat. Fibers 2008, 5, 61–75. [Google Scholar] [CrossRef]

- ASTM C618 (American Standard Test Method)-17a. Standard Specification for Coal Fly Ash and Raw or ASTM D 2487(American Standard Test Method). Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 1998. [Google Scholar]

- Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2005.

- Petry, T.M.; Little, D.N. Review of stabilization of clays and expansive soils in pavements and lightly loaded structures—History, practice, and future. J. Mater. Civil Eng. 2002, 14, 447–460. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Dash, S.K.; Hussain, M. Lime stabilization of soils: Reappraisal. J. Mater. Civ. Eng. 2011, 24, 707–714. [Google Scholar] [CrossRef]

- Sivakumar Babu, G.L.; Vasudevan, A.K. Evaluation of strength and stiffness response of coir fiber reinforced soil. J. Ground Improv. 2007, 11, 111–116. [Google Scholar] [CrossRef]

- Cristelo, N.; Glendinning, S.; Pinto, A.T. Deep soft soil improvement by alkaline activation. Proc. ICE-Gr. Improv. 2011, 164, 1–10. [Google Scholar] [CrossRef]

- ASTM D 2166 (American Standard Test Method). Standard Test Method for Unconfined Compressive Strength of Cohesive Soil; ASTM International: West Conshohocken, PA, USA,, 2016. [Google Scholar]

- ASTM D 1635 (American Standard Test Method). Standard Test Method for Flexural Strength of Soil-Cement Using Simple Beam with Third-Point Loading; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM D4123-82 (American Standard Test Method). Standard Test Method for Indirect Tension Test for Resilient Modulus of Bituminous Mixtures (Withdrawn 2003); ASTM International: West Conshohocken, PA, USA, 1995. [Google Scholar]

- Dexter, A.; Kroesbergen, B. Methodology for determination of tensile strength of soil aggregates. J. Agric. Eng. Res. 1985, 31, 139–147. [Google Scholar] [CrossRef]

- Bandyopadhyay, K.; Bhattacharjee, S. Indirect tensile strength test of stabilized fly ash. In Proceedings of the Indian Geotechnical Conference, Mumbai, India, 16–18 December 2010; Volume 1, pp. 279–282. [Google Scholar]

- Pourakbar, S.; Asadi, A.; Huat, B.B.K. Application of alkali-activated agro-waste reinforced with wollastonite fibers in soil stabilization. ASCE 2016, 29, 04016206. [Google Scholar] [CrossRef]

- Teing, T.T.; Anggraini, V.; Shukla, S.K.; Huat, B.B.K. Improving the engineering behaviour of residual soil with fly ash and treated coir fibres in alkaline condition. Int. J. Geotech. Eng. 2019, 1–14. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Zhao, L.Z. Interfacial shear strength of fiber reinforced soil. Geotext. Geomembr. 2010, 28, 54–62. [Google Scholar] [CrossRef]

- Anggraini, V.; Asadi, A.; Farzadnia, N.; Jahangirian, H.; Huat, B.B.K. Reinforcement benefits of nanomodified coir fibre in lime-treated marine clay. Measurement 2016, 111, 206–218. [Google Scholar]

- Rahgozar, M.A.; Saberian, M. Geotechnical properties of peat soil stabilised with shredded waste tyre chips. Mires Peat 2016, 18, 1–12. [Google Scholar]

- Saberian, M.; Jahandari, S.; Li, J.; Zivari, F. Effect of curing, capillary action and groundwater level increment on geotechnical properties of lime concrete: Experimental and prediction studies. J. Rock Mech. Geotech. Eng. 2017, 9, 638–647. [Google Scholar] [CrossRef]

- Teing, T.T. Stabilization of Residual Soil with Alkali-Activated Fly Ash and Inclusion of Treated Coir Fibre. Master Thesis, Universiti Putra Malaysia (UPM), Selangor, Malaysia, 2019. [Google Scholar]

- Park, S.S. Unconfined compressive strength and ductility of fiber-reinforced cemented sand. Constr. Build. Mater. 2011, 25, 1134–1138. [Google Scholar] [CrossRef]

- Moghal, A.; Obaid, A.; Al-Refeai, T. Effect of accelerated loading on the compressibility characteristics of lime treated semiarid soils. J. Mater. Civ. Eng. 2014, 26, 1009–1016. [Google Scholar] [CrossRef]

- Figueiredo, D.T.R.; Correia, A.A.S.; Hunkeler, D.; Rasteiro, M.G.B.V. Surfactants for dispersion of carbon nanotubes applied in soil stabilization. Colloids Surfaces a Physicochem. Eng. Asp. 2015, 480, 405–412. [Google Scholar] [CrossRef]

- Ayeldeen, M.; Kitazume, M. Using fiber and liquid polymer to improve the behaviour of cement-stabilized soft clay. Geotext. Geomembr. 2017, 45, 592–602. [Google Scholar] [CrossRef]

- Sakai, E.; Sugita, J. Composite mechanism of polymer modified cement. Cem. Concr. Res. 1995, 25, 127–135. [Google Scholar] [CrossRef]

- Anggraini, V.; Asadi, A.; Huat, B.B.K.; Nahazanan, H. Effects of coir fibers on tensile and compressive strength of lime treated soft soil. Measurement 2015, 59, 372–381. [Google Scholar] [CrossRef]

- Jha, A.K.; Sivapullaiah, P.V. Mechanism of improvement in the strength and volume change behavior of lime stabilized soil. J. Eng. Geol. 2015, 198, 53–64. [Google Scholar] [CrossRef]

- Ghosh, A.; Subbarao, C. Microstructural development in fly ash modified with lime and gypsum. J. Mater. Civ. Eng. ASCE 2001, 13, 65–70. [Google Scholar] [CrossRef]

- Al-Swaidani, A.; Hammoud, I.; Meziab, A. Effect of adding natural pozzolana on geotectnical properties of lime-stabilized clayey soil. J. Rock Mech. Geotech. Eng. 2016, 8, 714–725. [Google Scholar] [CrossRef]

| Parameter | Values | Method Standard |

|---|---|---|

| Moisture Content | 72% | BS 1377-2-1990 |

| Specific Gravity | 2.59 | BS 1377-2-1990 |

| Particle Size | Clay—31% | BS 1377-2-1990 |

| Distribution | Silt—67% | |

| Sand—2% | ||

| Plastic Limit | 32%–40% | BS 1377-2-1990 |

| Liquid Limit | 57%–72% | BS 1377-2-1990 |

| Plasticity Index | 25%–37% | BS 1377-2-1990 |

| pH | 7.5 | BS 1377-3-1990 |

| Organic Content | 6.88% | BS 1377-3-1990 |

| Compound Oxides | (%) by Weight |

|---|---|

| SiO2 | 75.84 |

| Al2O3 | 12.09 |

| Fe2O3 | 3.47 |

| K2O | 1.51 |

| MgO | 1.33 |

| Na2O | 1.13 |

| CaO | 0.72 |

| TiO2 | 0.68 |

| P2O5 | 0.092 |

| LOI | 3.14 |

| Basic Properties | Value |

|---|---|

| Chemical Analysis | |

| Ash | 2 |

| Cellulose (%) | 44 |

| Lignin (%) | 48 |

| Water Soluble (%) | 6 |

| Physical Properties | |

| Diameter (mm) | 0.15–0.40 |

| Unit Weight (kN/m3) | 14 |

| Breaking elongation (%) | 30 |

| Length (mm) | 50–200 |

| Tensile Strength (MPa) | 50–118 |

| Major Oxides | (%) by Weight |

|---|---|

| SiO2 | 57.471 |

| Al2O3 | 15.365 |

| Fe2O3 | 4.707 |

| CaO | 3.317 |

| Group Series | Test Number | Samples | Optimum Moisture Content (OMC) (%) | UCS/ITS/ FS Curing Days |

|---|---|---|---|---|

| C | C | Natural Soil | 31 | 7, 28 & 90 |

| CLF | CL | Clay + Lime + | 30.5 | 7, 28 & 90 |

| CLF | Clay + Lime + Fiber | 35 | 7, 28 & 90 | |

| CFA | CFA | Clay + FA(60) + 10 KOH | 23 | 7, 28 & 90 |

| CFAF | Clay + FA(60) + 10 KOH + Fiber | 22.4 | 7, 28 & 90 |

| Mixture | Curing Period (Days) | Failure Strain (%) | Secant Modulus (Es) MPa | Deformability Index (ID) |

|---|---|---|---|---|

| Clay | 7 | 11.96 | 0.013 | - |

| 28 | 10.98 | 0.018 | - | |

| 90 | 23.00 | 0.0091 | - | |

| CLF | 7 | 4.05 | 0.21 | 0.34 |

| 28 | 1.75 | 0.68 | 0.16 | |

| 90 | 3.25 | 0.48 | 0.14 | |

| CFAF | 7 | 1.75 | 1.83 | 0.15 |

| 28 | 1.90 | 4.16 | 0.17 | |

| 90 | 4.19 | 2.16 | 0.18 |

| Element | Si | Al | Ca | Si/Al | Ca/Si | Al/Si |

|---|---|---|---|---|---|---|

| Clay | 21.49 | 7.86 | 0.99 | 2.73 | 0.05 | 0.37 |

| CLF | 19.87 | 3.85 | 4.73 | 2.88 | 0.72 | 0.35 |

| CFAF | 24.36 | 6.19 | 3.33 | 3.3 | 0.31 | 0.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamaruddin, F.A.; Nahazanan, H.; Kim Huat, B.; Anggraini, V. Improvement of Marine Clay Soil Using Lime and Alkaline Activation Stabilized with Inclusion of Treated Coir Fibre. Appl. Sci. 2020, 10, 2129. https://doi.org/10.3390/app10062129

Kamaruddin FA, Nahazanan H, Kim Huat B, Anggraini V. Improvement of Marine Clay Soil Using Lime and Alkaline Activation Stabilized with Inclusion of Treated Coir Fibre. Applied Sciences. 2020; 10(6):2129. https://doi.org/10.3390/app10062129

Chicago/Turabian StyleKamaruddin, Fatin Amirah, Haslinda Nahazanan, Bujang Kim Huat, and Vivi Anggraini. 2020. "Improvement of Marine Clay Soil Using Lime and Alkaline Activation Stabilized with Inclusion of Treated Coir Fibre" Applied Sciences 10, no. 6: 2129. https://doi.org/10.3390/app10062129

APA StyleKamaruddin, F. A., Nahazanan, H., Kim Huat, B., & Anggraini, V. (2020). Improvement of Marine Clay Soil Using Lime and Alkaline Activation Stabilized with Inclusion of Treated Coir Fibre. Applied Sciences, 10(6), 2129. https://doi.org/10.3390/app10062129