A Novel Dense Full-Field Displacement Monitoring Method Based on Image Sequences and Optical Flow Algorithm

Abstract

Featured Application

Abstract

1. Introduction

2. Purpose and Concept

3. Test Overview

3.1. Intelligent NRS System

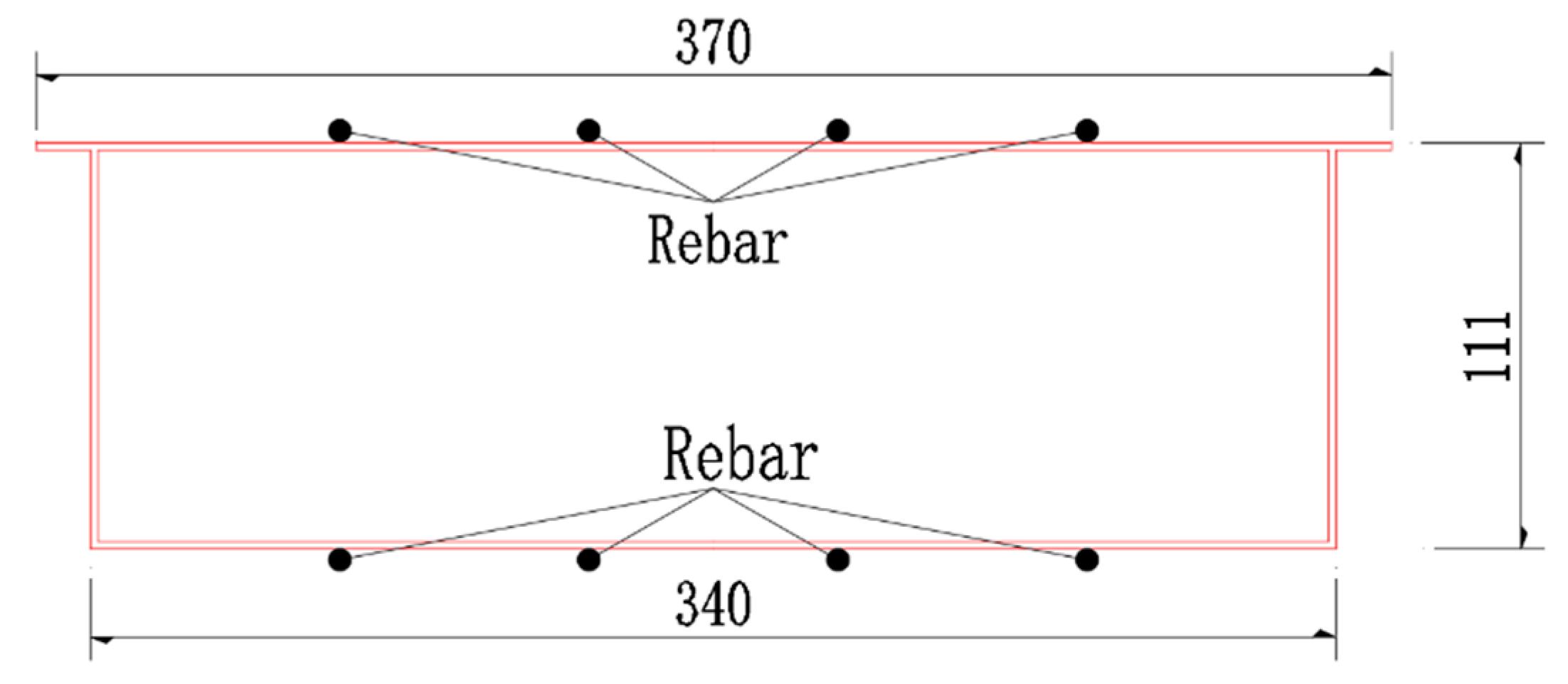

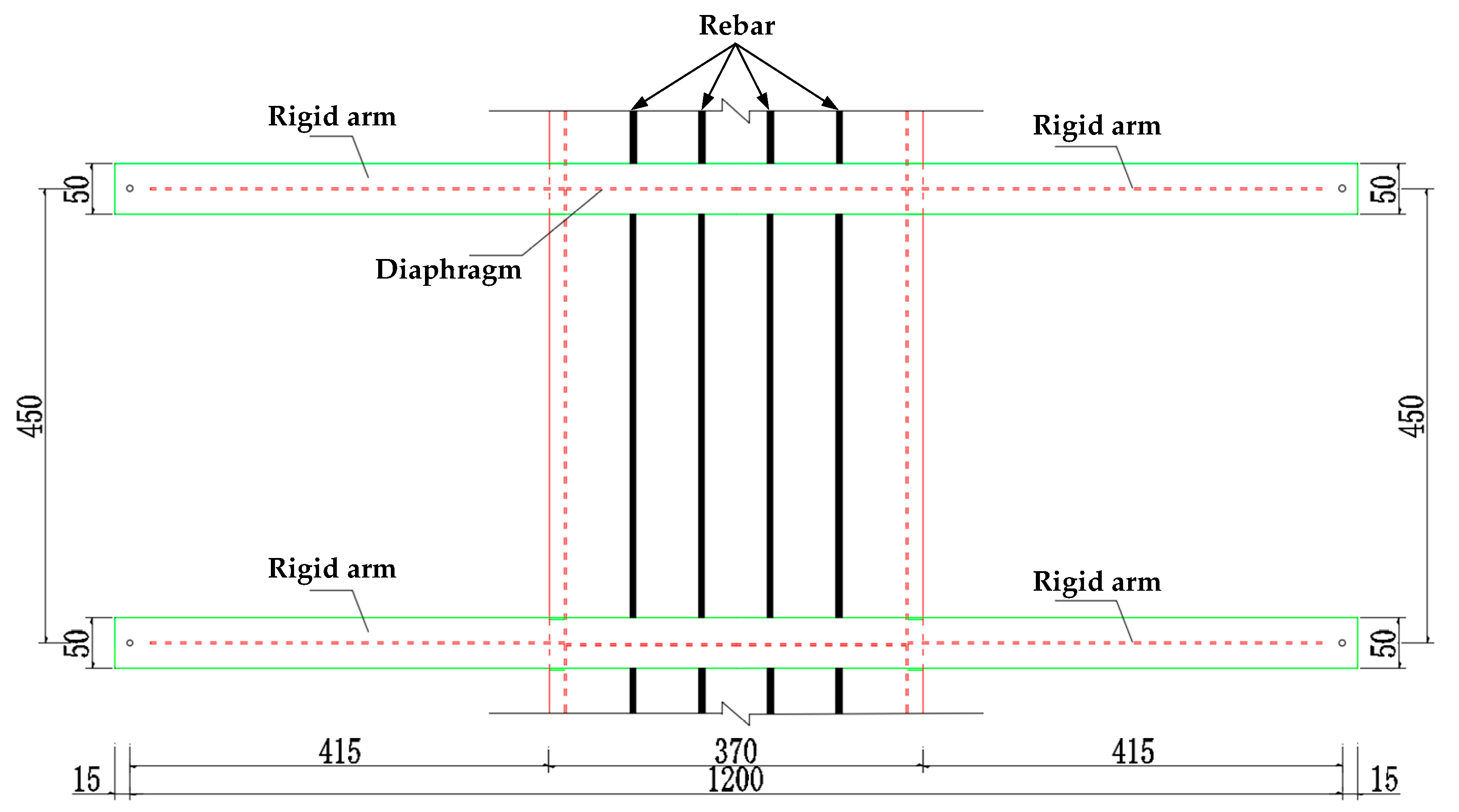

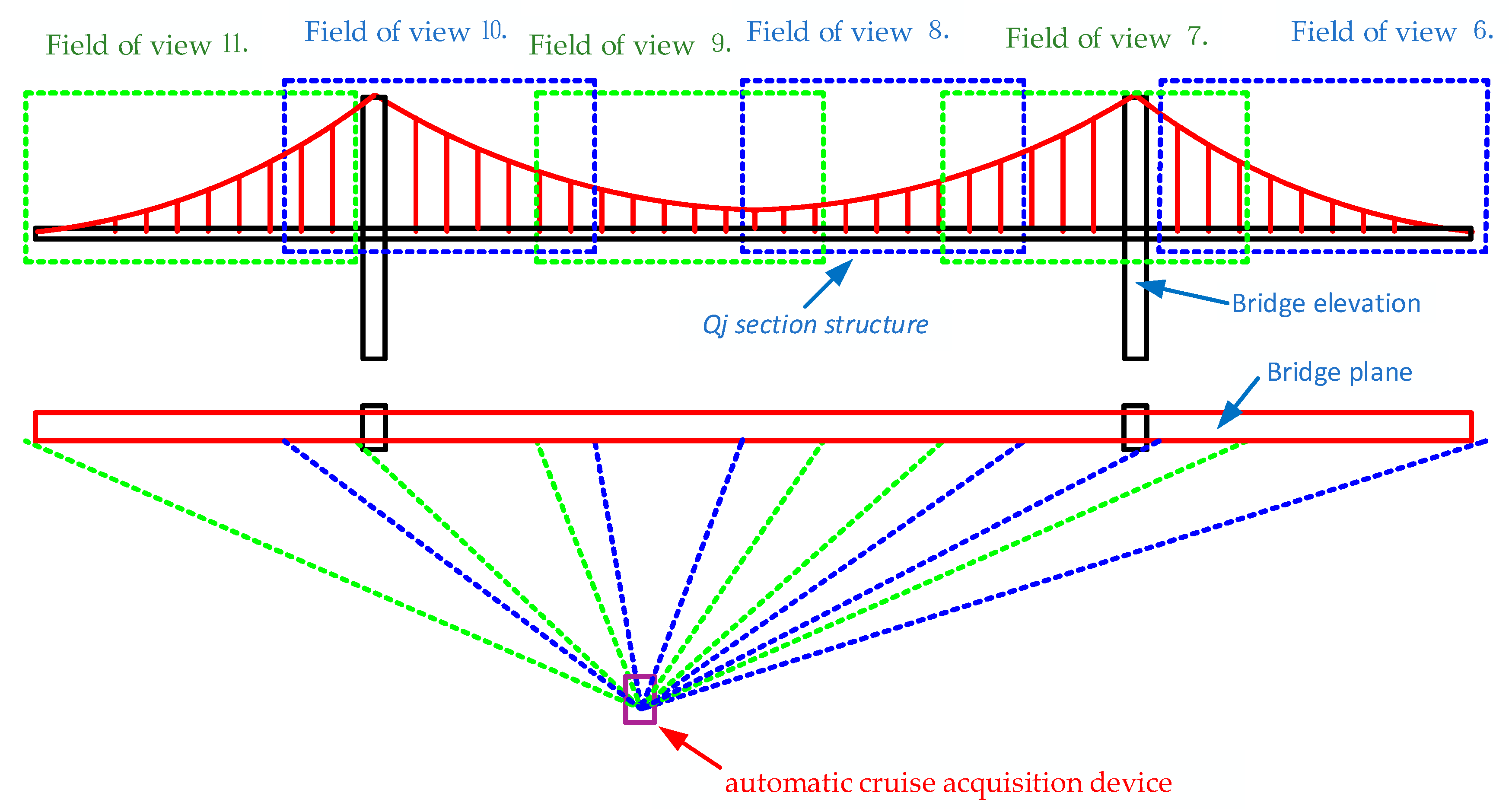

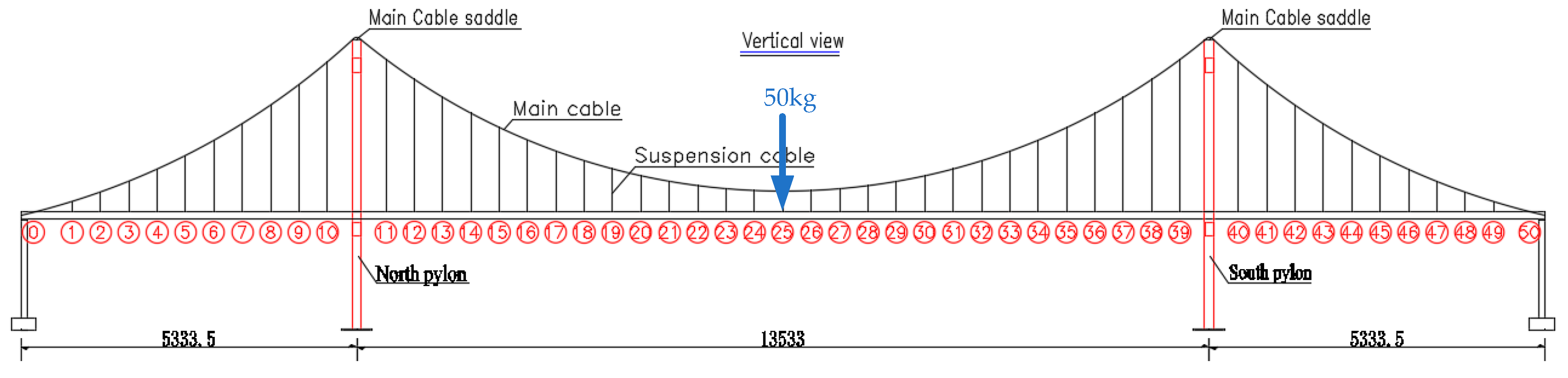

3.2. Object and data Collection

3.3. Test Contents

3.4. Finite Element Model

4. Design of Multipoint Displacement Monitoring Algorithm for Bridge Structure

4.1. Location and Extraction Method of Bridge Structure Contour

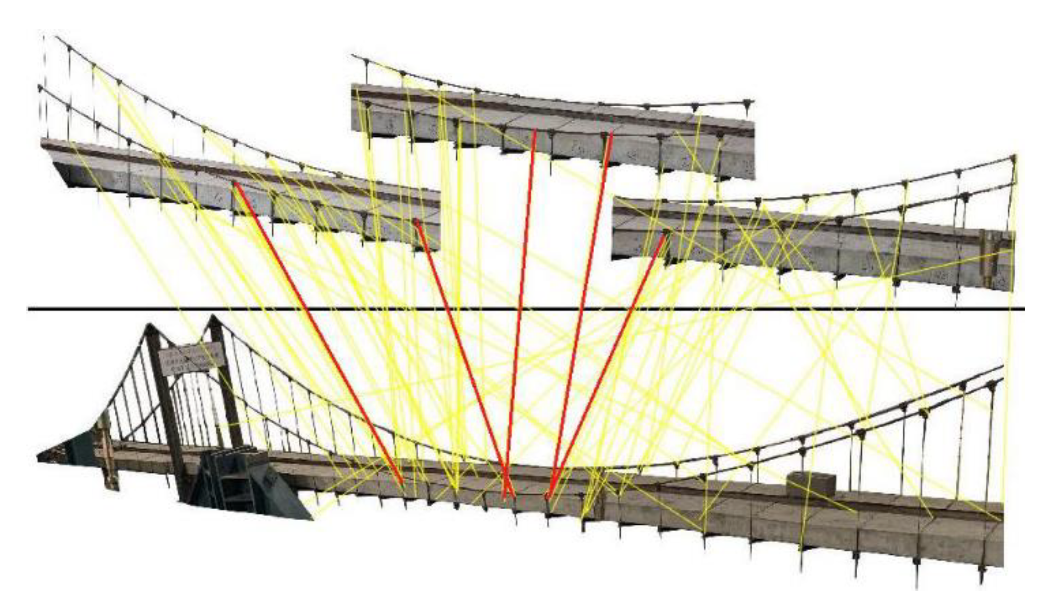

4.2. The Method of Establishing the Space-Time Relationship of Image Sequence Data

4.2.1. Dataset Construction Based on Spatiotemporal Static Image Sequences

4.2.2. Target Tracking and Displacement Calculation

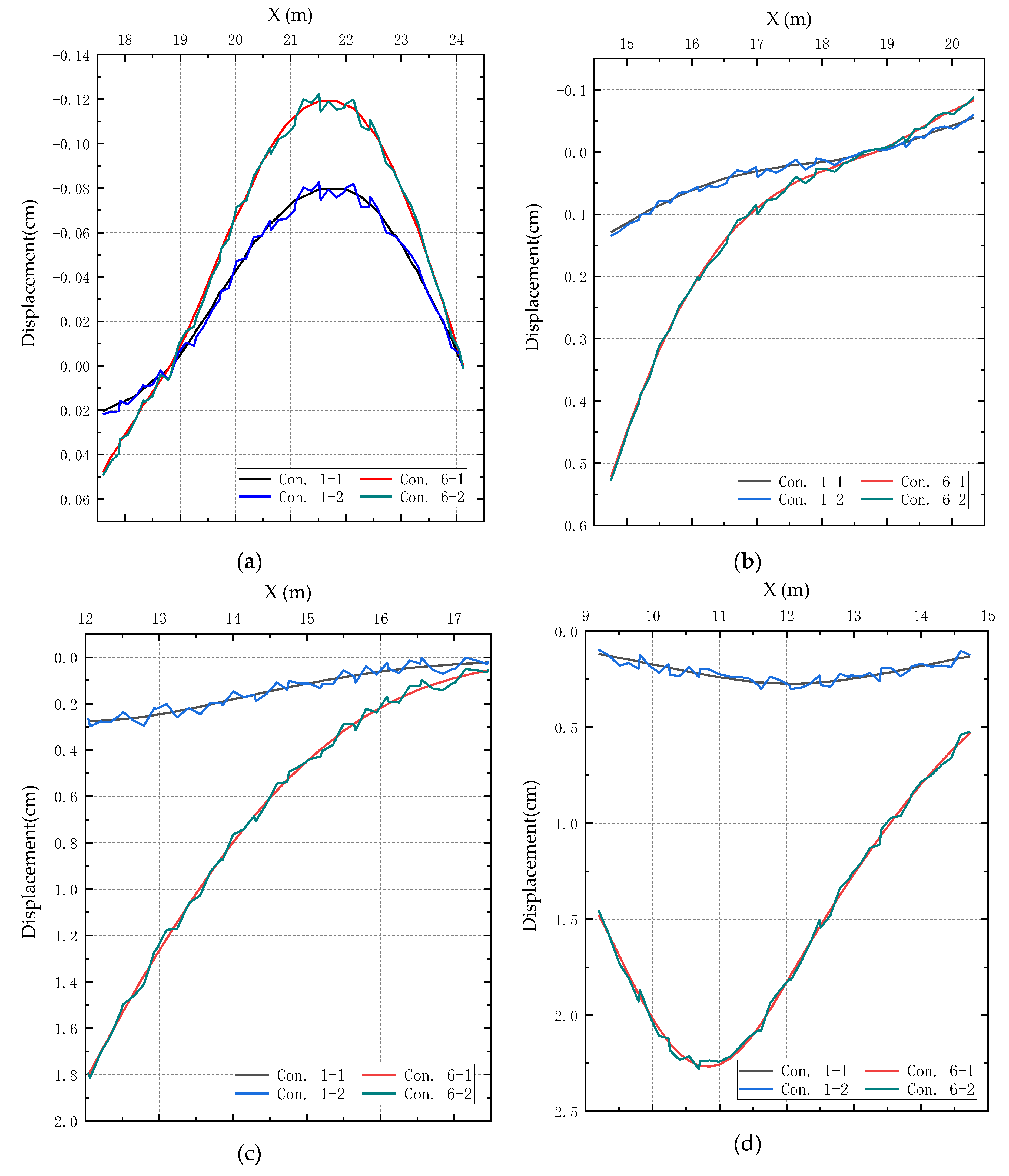

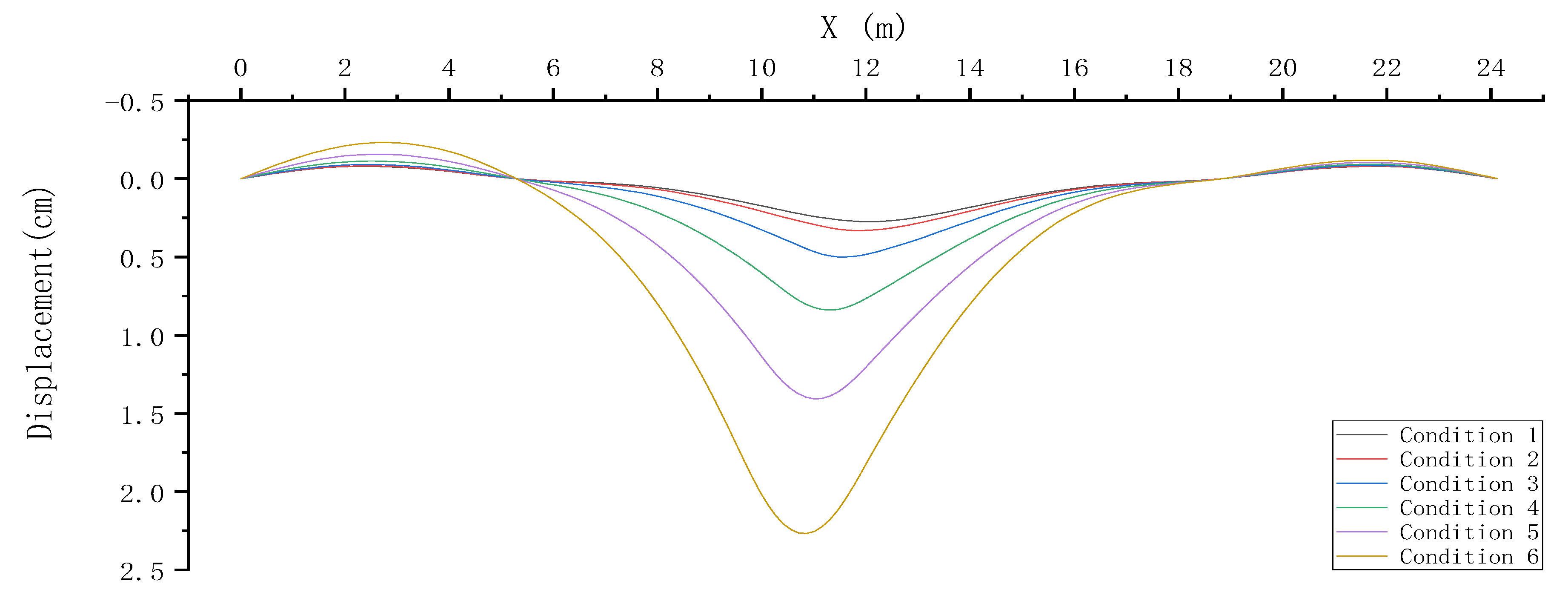

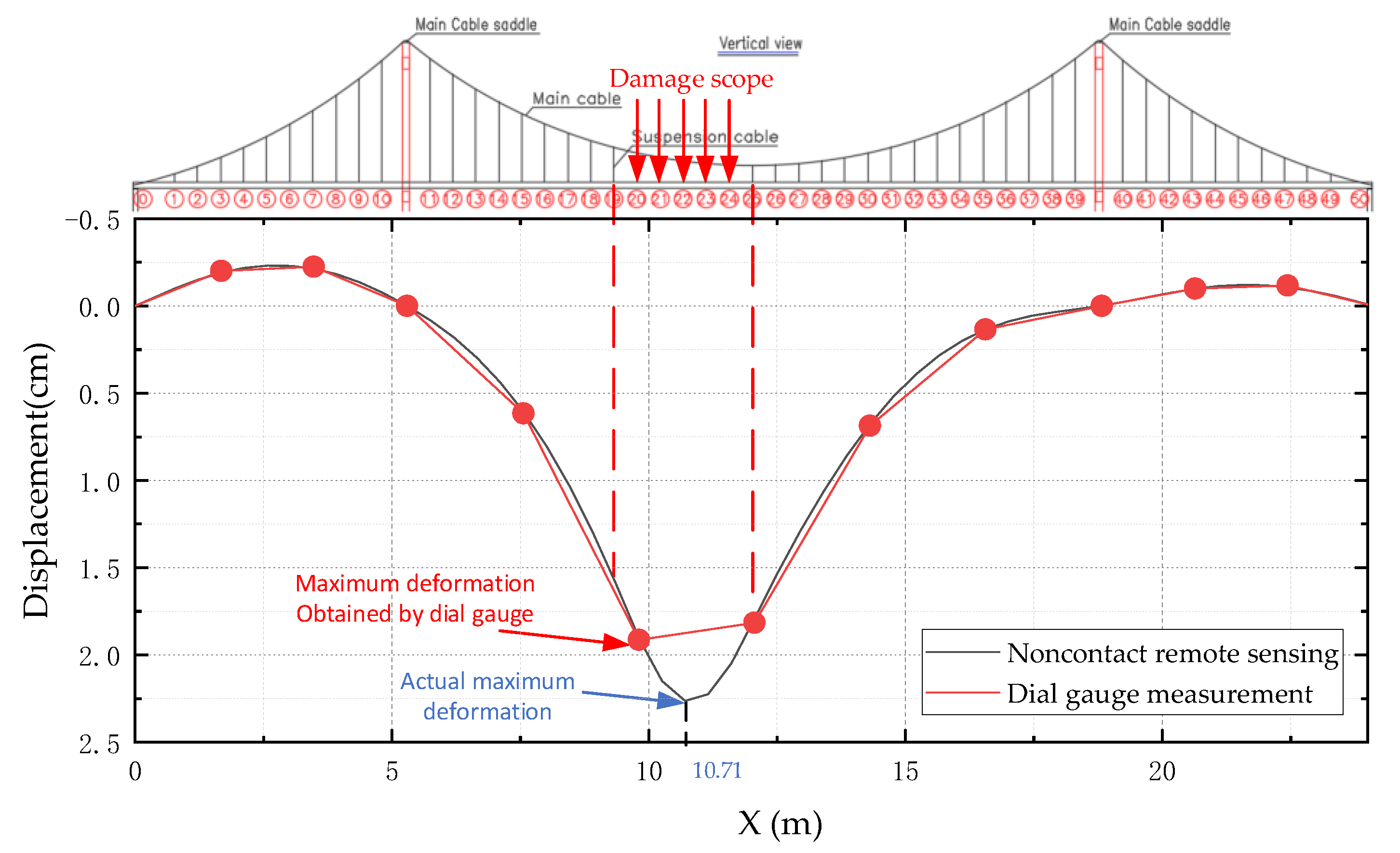

5. Extraction Deformation and Discussion

6. Conclusions

- (1)

- A fixed point uniaxial automatic cruise acquisition device was designed to collect the static images of the bridge façade under different damage conditions. Then, the spatiotemporal sequences of static images were processed by the edge detection method, the edge pixel virtual marker point, the SIFT algorithm and the optical flow algorithm to obtain a dense full-field displacement of the whole test bridge girder, which can be used as the data base to make the structural health monitoring technology more economical, efficient and direct. Compared with other monitoring methods, the girder dense points displacement information provides a data-base for more accurate model updating and damage identification. Meanwhile, the technology proposed in this paper is low-cost and can be used as a long-term regular monitoring method to accumulate massive real structural displacement information and provide big data set for the subsequent study of machine learning for damage identification.

- (2)

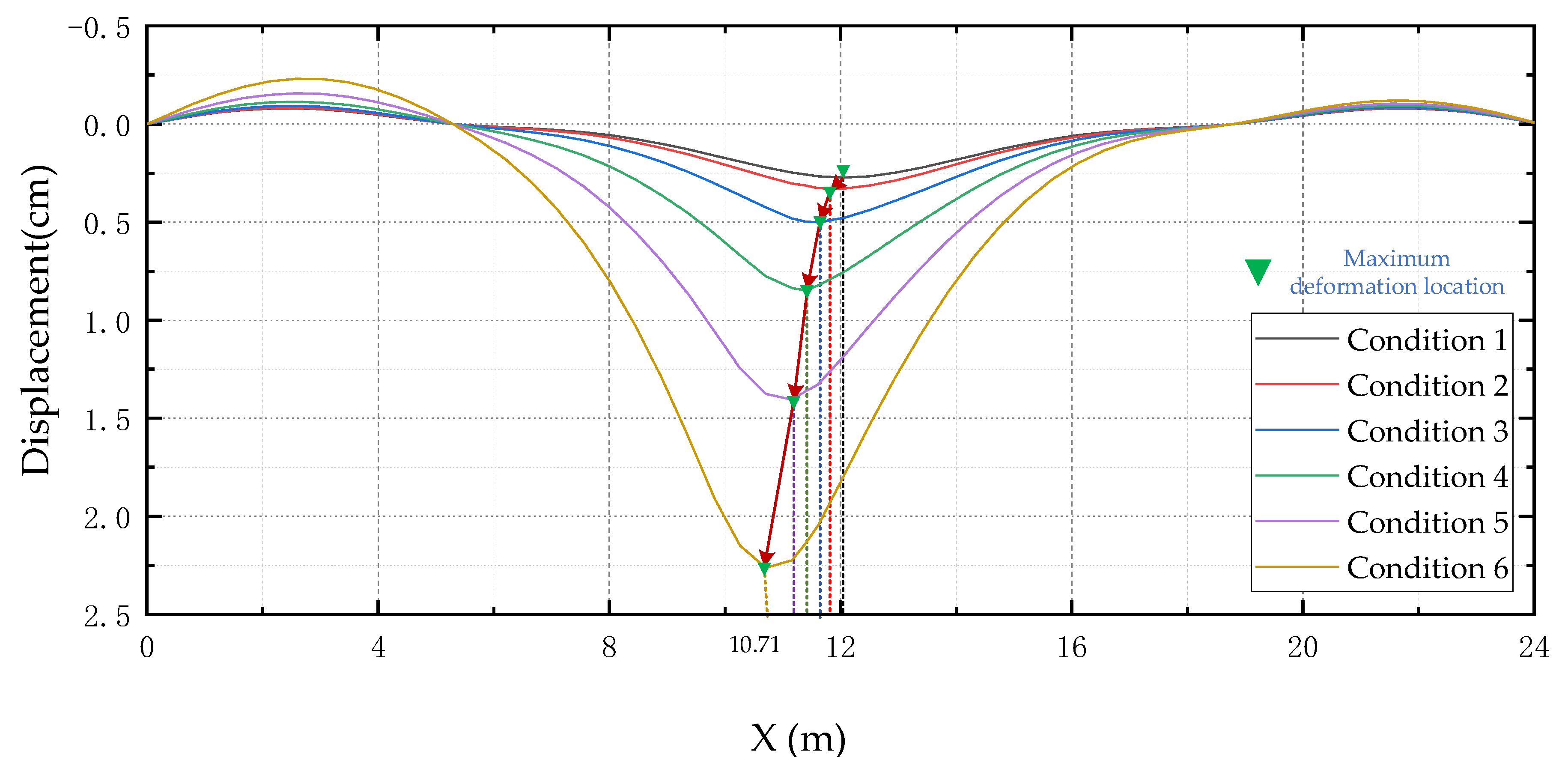

- The optical flow algorithm, which is widely used in video analysis, was used in the static image data set to track the target and calculate the displacement, overcoming the shortcomings of many manual interventions in the early stage of research group. Meanwhile, the number of monitoring points remains the same (i.e. the displacement of each pixel of the lower edge contour line of the girder). The output data are basically consistent with the finite-element prediction and dial gauge measurement. The global holographic deformation curves of the test bridge exhibit similar trends under different damage conditions, with an error of less than 12%. This means that the proposed method in this paper satisfies the engineering requirement on measurement accuracy.

- (3)

- A new method of making a virtual target was used. The coordinates of the required lower edge contour of the girder were extracted and then used it to make the pixels of the initial image of the lower edge of the girder as a virtual target back, and then track and calculate the displacement information of all pixels of the contour through the optical flow algorithm. Although this method needs a certain amount of manual intervention in the early stage, it can locate accurately and obtain more measuring point displacement simultaneously.

- (4)

- The information obtained from the combination of several points does not really reflect the structural deformation characteristics of the bridge under different damage conditions, and the abnormal local deformation information caused by the damage will be lost. Thus, the dense full-field displacement information is more sensitive to the structural stiffness change.

- (5)

- The characteristics of the linear change of the test bridge under different damage conditions indicate a strong correlation between the damage location and degree and the linear change. The relationship between the three can be established, and the method of amplifying the damage and deformation characteristics and carrying out the quantification requires further study.

- (6)

- This work is only the first exploration of the dense full-field displacement monitoring of the whole bridge girder using NRS. It involves less in the optimization of parameters in the experiment, less in the improvement of the algorithm and the accuracy of the algorithm, which needs to be further studied in the future. Meanwhile, it only shows that the dense full-field displacement is more sensitive to the damage identification, but the damage identification is not involved.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Editorial Department of China Journal of Highway and Transport. Review on China’s Bridge Engineering Research: 2014. China J. Highw. Transp. 2014, 27, 1–96. [Google Scholar]

- He, S.-H.; Zhao, X.-M.; Ma, J.; Zhao, Y.; Song, H.-S.; Song, H.-X.; Cheng, L.; Yuan, Z.-Y.; Huang, F.-W.; Zhang, J.; et al. Review of Highway Bridge Inspection and Condition Assessment. China J. Highw. Transp. 2017, 30, 63–80. [Google Scholar]

- Nhat-Duc, H. Detection of Surface Crack in Building Structures Using Image Processing Technique with an Improved Otsu Method for Image Thresholding. Adv. Civ. Eng. 2018, 2018, 3924120. [Google Scholar]

- Li, H.; Bao, Y.-Q.; Li, S.-L. Data Science and Engineering Structural Health Monitoring. J. Eng. Mech. 2015, 32, 1–7. [Google Scholar]

- Bao, Y.-Q.; James, L.B.; Li, H. Compressive Sampling for Accelerometer Signals in Structural Health Monitoring. Struct. Health Monit. 2011, 10, 235–246. [Google Scholar]

- Gul, M.; Dumlupinar, T.; Hattori, H.; Catbas, N. Structural monitoring of movable bridge mechanical components for maintenance decision-making. Struct. Monit. Maint. 2014, 1, 249–271. [Google Scholar] [CrossRef]

- Gul, M.; Catbas, F.N.; Hattori, H. Image-based monitoring of open gears of movable bridges for condition assessment and maintenance decision making. J. Comput. Civ. Eng. 2015, 29, 04014034. [Google Scholar] [CrossRef]

- Garcia-Palencia, A.; Santini-Bell, E.; Gul, M.; Çatbaş, N. A FRF-based algorithm for damage detection using experimentally collected data. Struct. Monit. Maint. 2015, 24, 399–418. [Google Scholar] [CrossRef][Green Version]

- Spencer, B.F., Jr.; Hoskere, V.; Narazaki, Y. Advances in computer vision-based civil infrastructure inspection and monitoring. Engineering 2019, 5, 199–222. [Google Scholar] [CrossRef]

- Yang, Y.; Jung, H.K.; Dorn, C.; Park, G.; Farrar, C.; Mascareñas, D. Estimation of full-field dynamic strains from digital video measurements of output-only beam structures by video motion processing and modal superposition. Struct. Control Health Monit. 2019, 26, e2408. [Google Scholar] [CrossRef]

- Kim, H.; Shin, S. Reliability verification of a vision-based dynamic displacement measurement for system identification. J. Wind Eng. Ind. Aerod. 2019, 191, 22–31. [Google Scholar] [CrossRef]

- Ojio, T.; Carey, C.H.; Obrien, E.J.; Doherty, C.; Taylor, S.E. Contactless bridge weigh-in-motion. J. Bridge Eng. 2016, 217, 04016032. [Google Scholar] [CrossRef]

- Moreu, F.; Li, J.; Jo, H.; Kim, R.E. Reference-free displacements for condition assessment of timber railroad bridges. J. Bridge Eng. 2016, 21, 04015052. [Google Scholar] [CrossRef]

- Xu, Y.; Brownjohn, J.; Kong, D. A non-contact vision-based system for multipoint displacement monitoring in a cable-stayed footbridge. Struct. Control Health Monit. 2018, 25, e2155. [Google Scholar] [CrossRef]

- Hester, D.; Brownjohn, J.; Bocian, M.; Xu, Y. Low cost bridge load test: Calculating bridge displacement from acceleration for load assessment calculations. Eng. Struct. 2017, 143, 358–374. [Google Scholar] [CrossRef]

- Celik, O.; Dong, C.Z.; Catbas, F.N. A computer vision approach for the load time history estimation of lively individuals and crowds. Comput. Struct. 2018, 200, 32–52. [Google Scholar] [CrossRef]

- Catbas, F.N.; Zaurin, R.; Gul, M.; Gokce, H.B. Sensor networks, computer imaging, and unit influence lines for structural health monitoring: Case study for bridge load rating. J. Bridge Eng. 2012, 17, 662–670. [Google Scholar] [CrossRef]

- Khuc, T.; Catbas, F.N. Structural identification using computer vision–based bridge health monitoring. J. Struct. Eng. 2018, 144, 04017202. [Google Scholar] [CrossRef]

- Dong, C.Z.; Celik, O.; Catbas, F.N. Marker-free monitoring of the grandstand structures and modal identification using computer vision methods. Struct. Health Monit. 2019, 18, 1491–1509. [Google Scholar] [CrossRef]

- Yang, Y.; Dorn, C.; Mancini, T.; Talkend, Z.; Kenyone, G.; Farrara, C.; Mascareñasa, D. Blind identification of full-field vibration modes from video measurements with phase-based video motion magnification. Mech. Syst. Signal Process. 2017, 85, 567–590. [Google Scholar] [CrossRef]

- Bao, Y.-Q.; Bao, Y.-Q.; Ou, J.; Li, Hui. Emerging Data Technology in Structural Health Monitoring: Compressive Sensing Technology. J. Civ. Struct. Health Monit. 2014, 4, 77–90. [Google Scholar] [CrossRef]

- Bao, Y.-Q.; Li, H.; Sun, X.-D.; Ou, J.-P. A Data Loss Recovery Approach for Wireless Sensor Networks Using a Compressive Sampling Technique. Struct. Health Monit. 2013, 12, 78–95. [Google Scholar] [CrossRef]

- Bao, Y.-Q.; Zou, Z.-L.; Li, H. Compressive Sensing Based Wireless Sensor for Structural Health Monitoring; 90611W-1-10; SPIE Smart Structures/NDE: San Diego, CA, USA, 2014. [Google Scholar]

- Bao, Y.-Q.; Yan, Y.; Li, H.; Mao, X.; Jiao, W.; Zou, Z.; Ou, J. Compressive Sensing Based Lost Data Recovery of Fast-moving Wireless Sensing for Structural Health Monitoring. Struct. Control Health Monit. 2014, 22, 433–448. [Google Scholar] [CrossRef]

- Guzman-Acevedo, G.M.; Becerra, G.E.V.; Millan-Almaraz, J.R.; Rodríguez-Lozoya, H.E.; Reyes-Salazar, A.; Gaxiola-Camacho, J.R.; Martinez-Felix, C.A. GPS, Accelerometer, and Smartphone Fused Smart Sensor for SHM on Real-Scale Bridges. Adv. Civ. Eng. 2019, 2019, 6429430. [Google Scholar] [CrossRef]

- Xu, Y.; Brownjohn, J.M.W. Review of machine-vision based methodologies for displacement measurement in civil structures. J. Civ. Struct. Health Monit. 2018, 8, 91–110. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M.Q.; Ozer, E.; Fukuda, Y. A vision-based sensor for noncontact structural displacement measurement. Sensors 2015, 15, 16557–16575. [Google Scholar] [CrossRef] [PubMed]

- Feng, D.; Feng, M.-Q. Identification of structural stiffness and excitation forces in time domain using noncontact vision-based displacement measurement. J. Sound Vib. 2017, 406, 15–28. [Google Scholar] [CrossRef]

- Feng, D.; Scarangello, T.; Feng, M.-Q.; Ye, Q. Cable tension force estimate using novel noncontact vision-based sensor. Measurement 2017, 99, 44–52. [Google Scholar] [CrossRef]

- Dong, C.Z.; Ye, X.W.; Jin, T. Identification of structural dynamic characteristics based on machine vision technology. Measurement 2018, 126, 405–416. [Google Scholar] [CrossRef]

- Ye, X.-W.; Dong, C.-Z.; Liu, T. A review of machine vision-based structural health monitoring: Methodologies and applications. J. Sens. 2016, 2016, 7103039. [Google Scholar] [CrossRef]

- Khuc, T.; Catbas, F.N. Computer vision-based displacement and vibration monitoring without using physical target on structures. Struct. Infrastruct. Eng. 2017, 13, 505–516. [Google Scholar] [CrossRef]

- Tian, L.; Pan, B. Remote bridge deflection measurement using an advanced video deflectometer and actively illuminated LED targets. Sensors 2016, 16, 1344. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.J.; Cho, S.; Shinozuka, M.; Yun, C.; Lee, C.; Lee, W. Evaluation of bridge load carrying capacity based on dynamic displacement measurement using real-time image processing techniques. Int. J. Steel Struct. 2006, 6, 377–385. [Google Scholar]

- Feng, D.; Feng, M.-Q. Model updating of railway bridge using in situ dynamic displacement measurement under trainloads. J. Bridge Eng. 2015, 20, 04015019. [Google Scholar] [CrossRef]

- Chen, J.-G.; Adams, T.M.; Sun, H.; Bell, E.S. Camera-based vibration measurement of the world war I memorial bridge in portsmouth, New Hampshire. J Struct. Eng. 2018, 144, 04018207. [Google Scholar] [CrossRef]

- Abraham, L.; Sasikumar, M. Analysis of satellite images for the extraction of structural features. IETE Tech. Rev. 2014, 31, 118–127. [Google Scholar] [CrossRef]

- Milillo, P.; Perissin, D.; Salzer, J.-T.; Lundgren, P.; Lacava, G.; Milillo, G.; Serio, C. Monitoring dam structural health from space: Insights from novel InSAR techniques and multi-parametric modeling applied to the Pertusillo dam Basilicata, Italy. Int. J Appl. Earth Obs. Geoinf. 2016, 52, 221–229. [Google Scholar] [CrossRef]

- Wang, S.-R.; Zhou, Z.-X.; Gao, Y.-M.; Xu, J. Newton-Raphson Algorithm for Pre-offsetting of Cable Saddle on Suspension Bridge. China J. Highw. Transp. 2016, 29, 82–88. [Google Scholar]

- Wang, S.-R.; Zhou, Z.-X.; Wu, H.-J. Experimental Study on the Mechanical Performance of Super Long-Span Self-Anchored Suspension Bridge in Construction Process. China Civ. Eng. J. 2014, 47, 70–77. [Google Scholar]

- Wang, S.-R.; Zhou, Z.-X.; Wen, D.; Huang, Y. New Method for Calculating the Pre-Offsetting Value of the Saddle on Suspension Bridges Considering the Influence of More Parameters. J. Bridge Eng. 2016, 2016, 06016010. [Google Scholar] [CrossRef]

- Zhang, Z.-Y. A flexible new technique for camera calibration. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1330–1334. [Google Scholar] [CrossRef]

- Zhang, Z.-Y. Camera calibration with one-dimensional objects. IEEE Trans. Pattern Anal. Mach. Intell. 2004, 26, 892–899. [Google Scholar] [CrossRef] [PubMed]

- Mezirow, J. Perspective Transformation. Adult Educ. Q. 2014, 28, 100–110. [Google Scholar] [CrossRef]

- Deng, G.-J.; Zhou, Z.-X.; Chu, X.; Lei, Y.-K.; Xiang, X.-J. Method of bridge deflection deformation based on holographic image contour stacking analysis. Sci. Technol. Eng. 2018, 18, 246–253. [Google Scholar]

- Grabner, M.; Grabner, H.; Bischof, H. Fast approximated SIFT. ACCV 2006, 3851, 918–927. [Google Scholar]

- Liu, Y.; Liu, S.-P.; Wang, Z.-F. Multi-focus image fusion with dense SIFT. Inf. Fusion 2015, 23, 139–155. [Google Scholar] [CrossRef]

- Lucena, M.J.; Fuertes, J.M.; Gomez, J.I.; de la Blanca, N.P.; Garrido, A. Optical flow-based probabilistic tracking. In Seventh International Symposium on Signal Processing and Its Applications; IEEE: New York, NY, USA, 2003. [Google Scholar]

- Roth, S.; Black, M.J. On the Spatial Statistics of Optical Flow. Int. J. Comput. Vis. 2007, 74, 33–50. [Google Scholar] [CrossRef]

- Horn, B.K.P.; Schunck, B.G. Determining optical flow. Artif. Intell. 1981, 17, 185–203. [Google Scholar] [CrossRef]

| Serial Number | Damage Conditions | Data Collection Method | ||

|---|---|---|---|---|

| Position | Number | Traditional Method | Visual Method | |

| 1 | 0 | 0 | Dial gauges | Intelligent NRS system |

| 2 | 24 | 2 | Dial gauges | Intelligent NRS system |

| 3 | 23, 24 | 4 | Dial gauges | Intelligent NRS system |

| 4 | 22, 23, 24 | 6 | Dial gauges | Intelligent NRS system |

| 5 | 21, 22, 23, 24 | 8 | Dial gauges | Intelligent NRS system |

| 6 | 20, 21, 22, 23, 24 | 10 | Dial gauges | Intelligent NRS system |

| Serial Number | Item | Section Shape | E (GPa) | ftk (MPa) | σs (MPa) | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| 1 | Main cable | ○ | 195 | 1860 | / | 0.3 |

| 2 | suspender | ○ | 195 | 1860 | / | 0.3 |

| 3 | Main beam |  | 206 | / | 345 | 0.3 |

| 4 | main tower | □ | 206 | / | 345 | 0.3 |

| No. | Deformation of Stacking Analysis (mm) | Measured Deviation % | Relative Error % | ||

|---|---|---|---|---|---|

| Dial gauge Measurement R1 | Finite-Element Method R2 | Noncontact Remote Sensing R3 | |R3–R1|/R1 | |R3–R2|/R2 | |

| 1 | 0.11 | 0 | 0.1 | 9.09% | / |

| 2 | 0.99 | 1 | 1.08 | 9.09% | 8.00% |

| 3 | 1.56 | 1.55 | 1.68 | 7.69% | 8.39% |

| 4 | 5.42 | 5.55 | 5.87 | 8.30% | 5.77% |

| 5 | 17.46 | 17.32 | 18.75 | 7.39% | 8.26% |

| 6 | 15.16 | 15.3 | 16.43 | 8.38% | 7.39% |

| 7 | 5.18 | 5.24 | 5.67 | 9.46% | 8.21% |

| 8 | 0.93 | 0.96 | 1.02 | 9.68% | 6.25% |

| 9 | 0.37 | 0.38 | 0.41 | 10.81% | 7.89% |

| 10 | 0.35 | 0.33 | 0.37 | 5.71% | 12.12% |

| 11 | 0.09 | 0 | 0.08 | 11.11% | / |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, G.; Zhou, Z.; Shao, S.; Chu, X.; Jian, C. A Novel Dense Full-Field Displacement Monitoring Method Based on Image Sequences and Optical Flow Algorithm. Appl. Sci. 2020, 10, 2118. https://doi.org/10.3390/app10062118

Deng G, Zhou Z, Shao S, Chu X, Jian C. A Novel Dense Full-Field Displacement Monitoring Method Based on Image Sequences and Optical Flow Algorithm. Applied Sciences. 2020; 10(6):2118. https://doi.org/10.3390/app10062118

Chicago/Turabian StyleDeng, Guojun, Zhixiang Zhou, Shuai Shao, Xi Chu, and Chuanyi Jian. 2020. "A Novel Dense Full-Field Displacement Monitoring Method Based on Image Sequences and Optical Flow Algorithm" Applied Sciences 10, no. 6: 2118. https://doi.org/10.3390/app10062118

APA StyleDeng, G., Zhou, Z., Shao, S., Chu, X., & Jian, C. (2020). A Novel Dense Full-Field Displacement Monitoring Method Based on Image Sequences and Optical Flow Algorithm. Applied Sciences, 10(6), 2118. https://doi.org/10.3390/app10062118