A Dynamic Coarse Grain Discrete Element Method for Gas-Solid Fluidized Beds by Considering Particle-Group Crushing and Polymerization

Abstract

1. Introduction

2. Mathematical Model

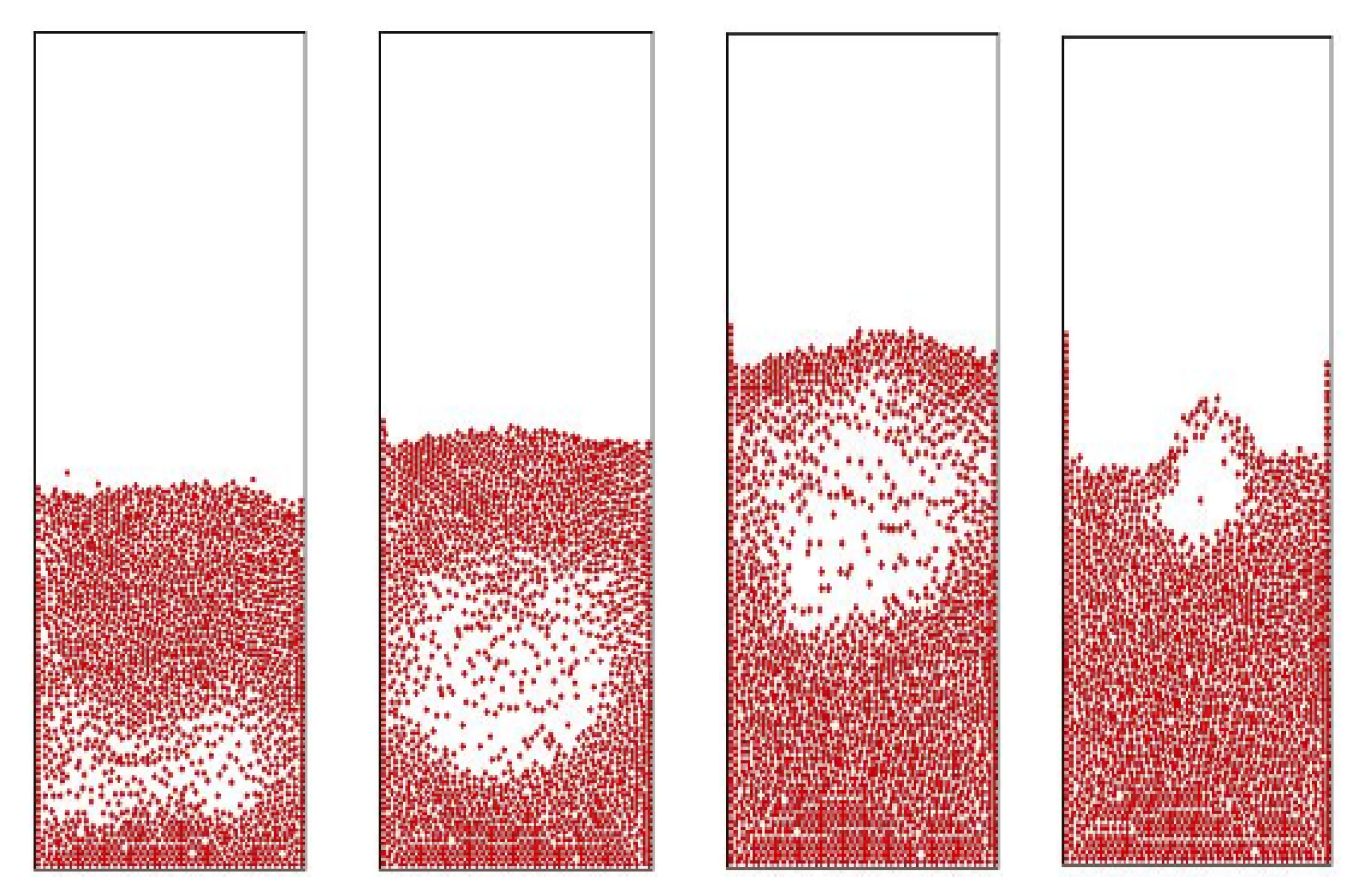

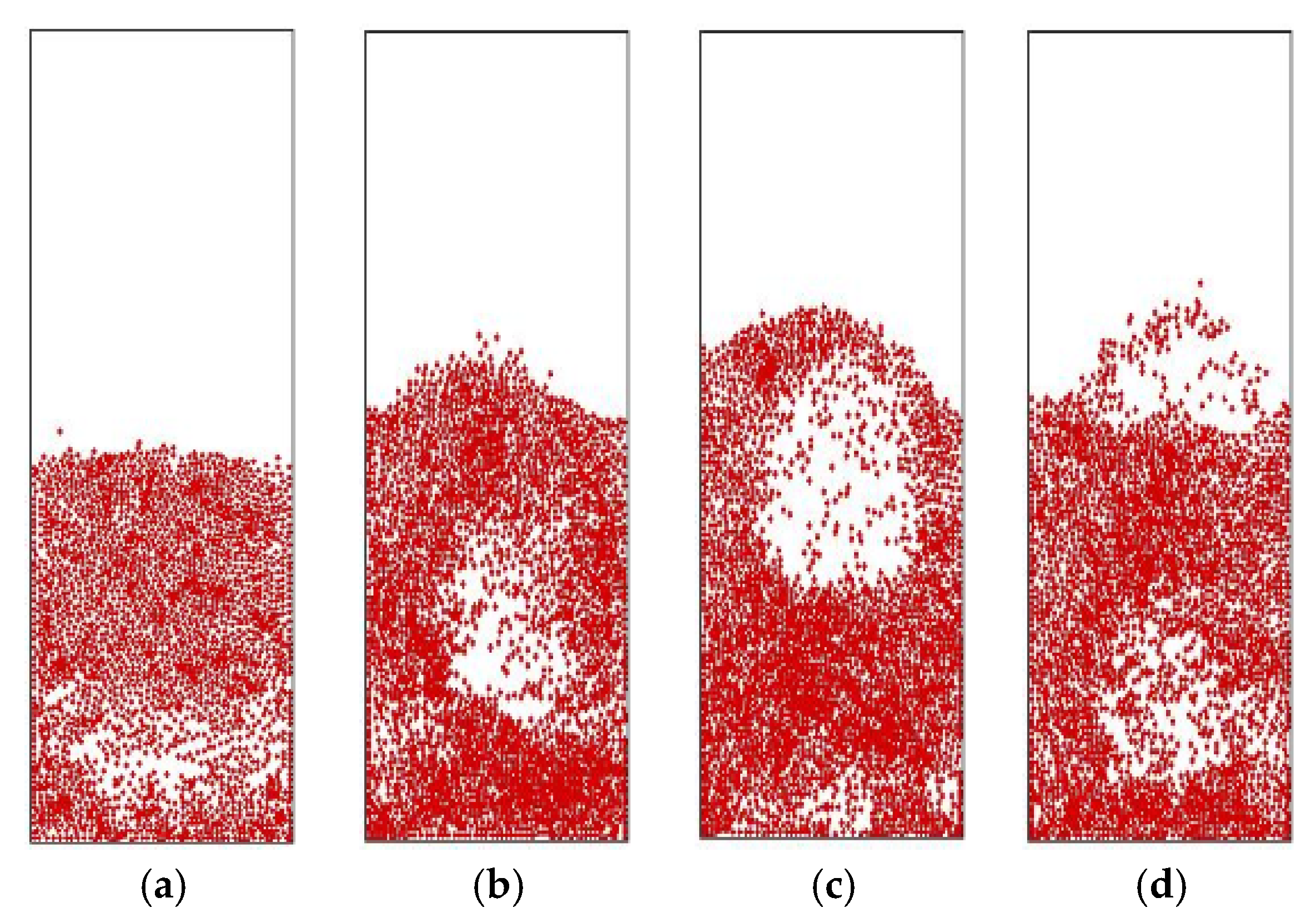

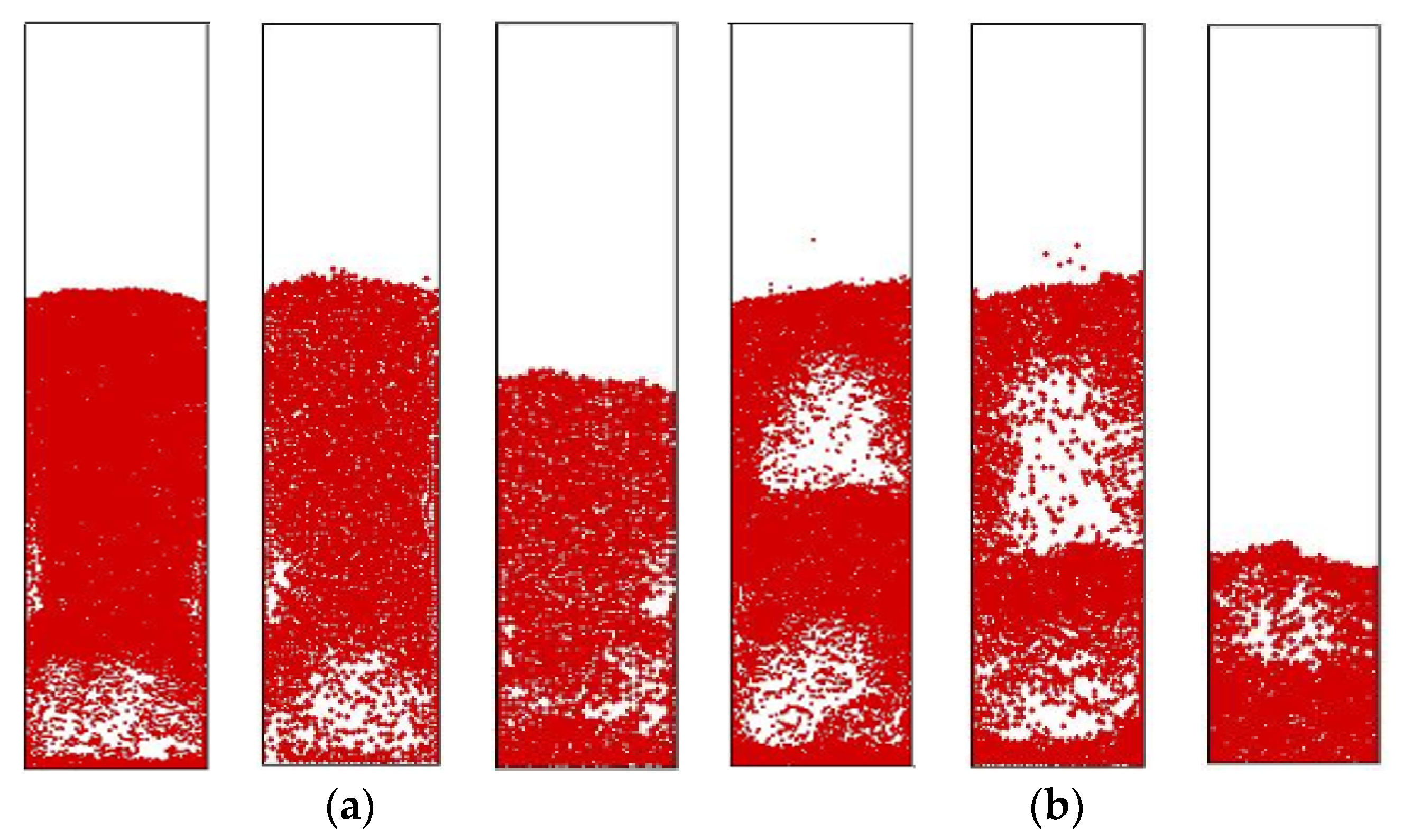

2.1. Coarse Grain DEM Model for Solid Phase

2.1.1. Drag Force

2.1.2. Contact Force

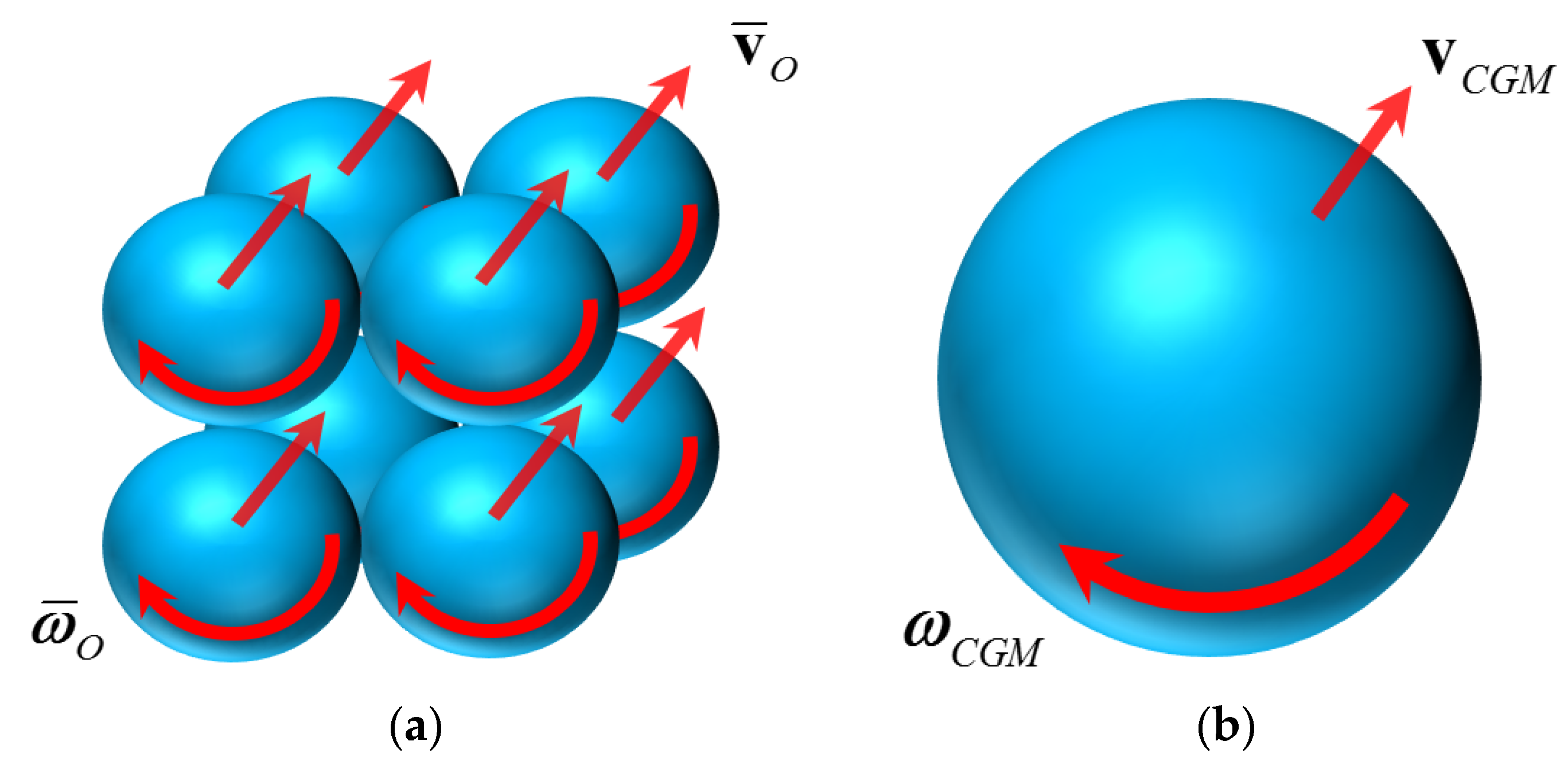

2.1.3. Coarse Graining

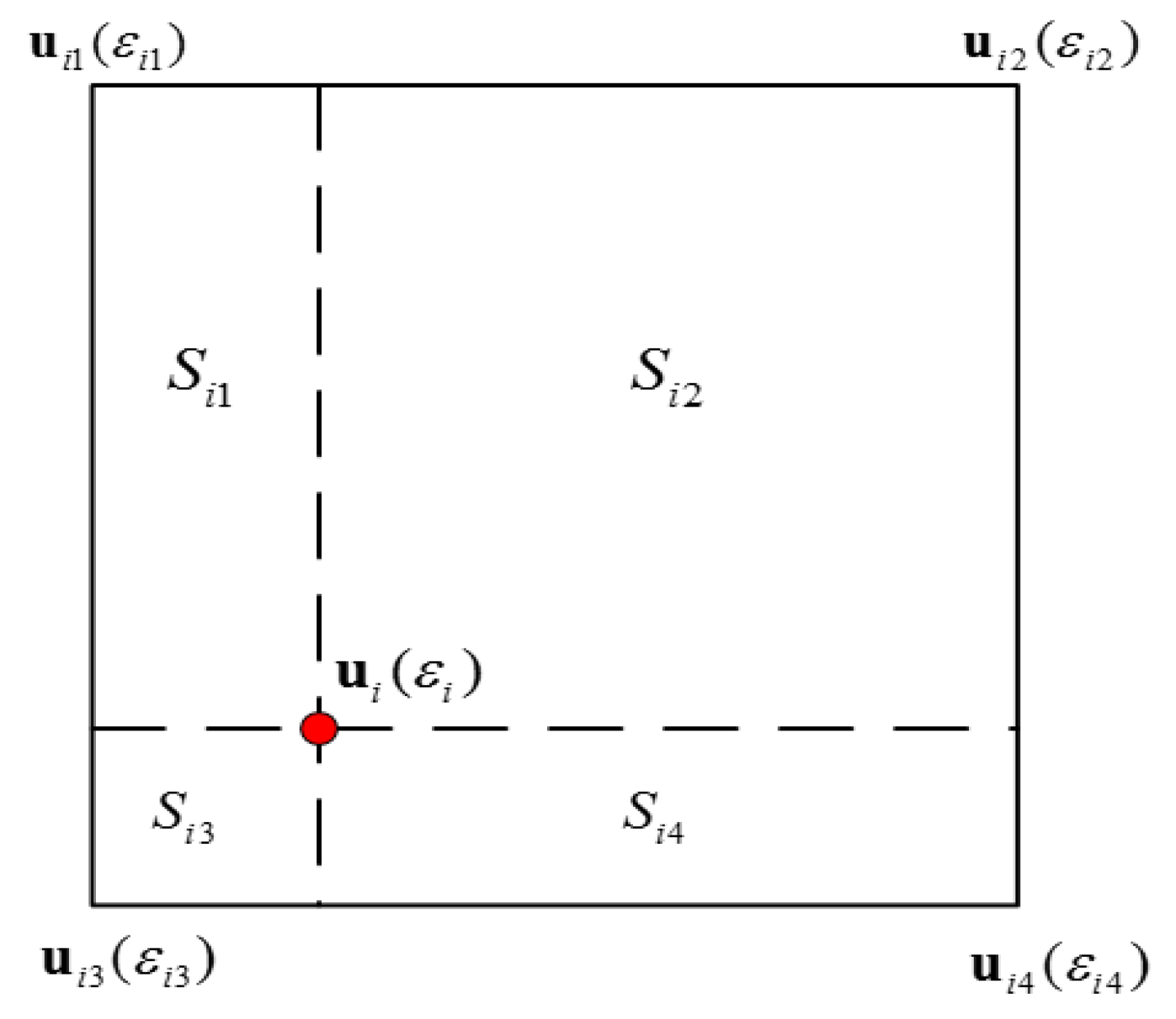

2.2. CFD Model for Gas Phase

2.3. Particle-Group Crushing and Polymerization Model

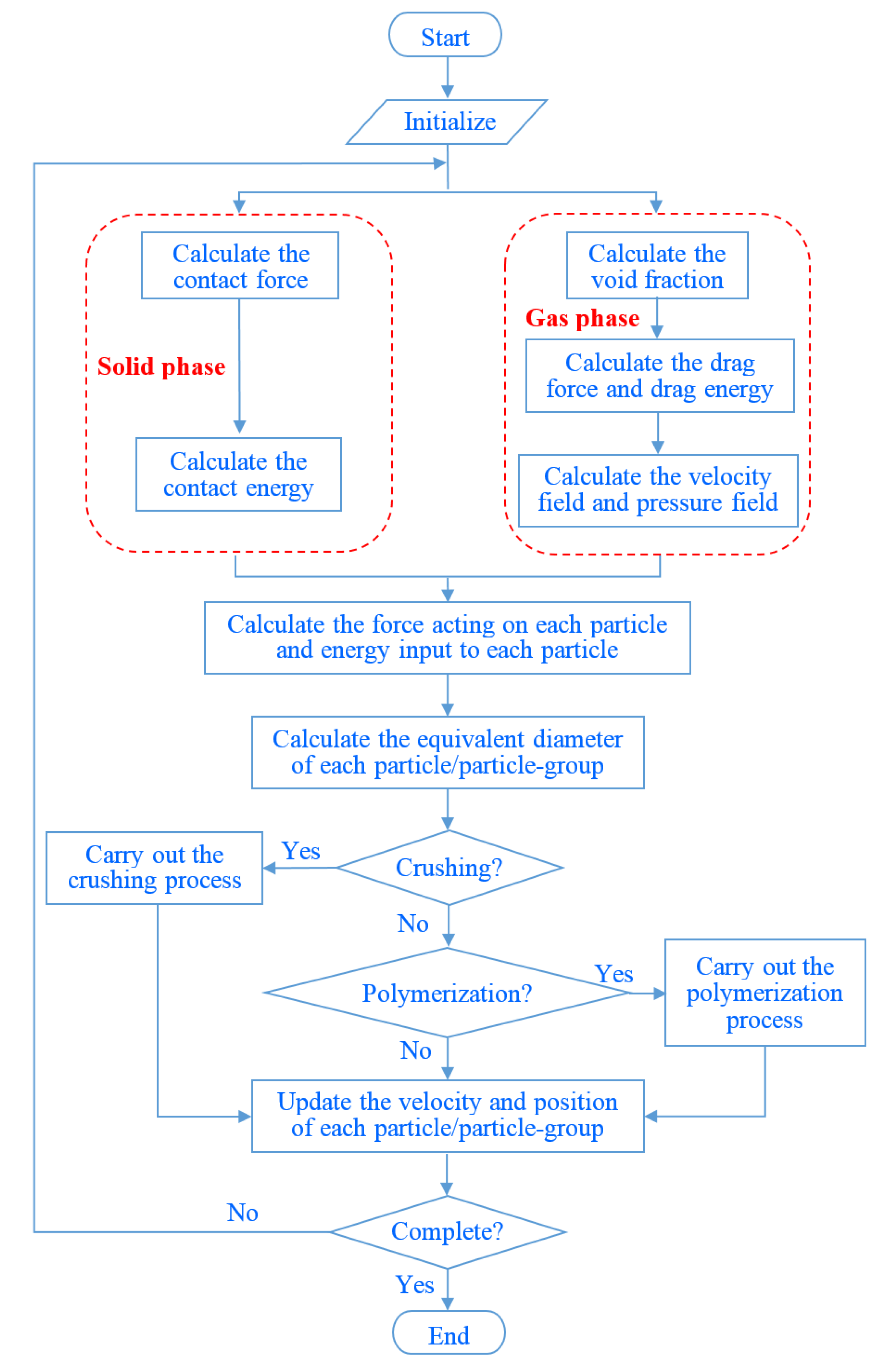

3. Numerical Method

- (1)

- Calculate the pseudo velocity from Equation (51) by substituting the initial velocity .

- (2)

- Solve Equation (54) to obtain the pressure .

- (3)

- Employing the pressure , solve Equation (48) to obtain the velocity .

- (4)

- Solve Equation (56) to obtain .

- (5)

- Correct the velocity to get by use of equations in form of Equation (55).

- (6)

- Return to step 1 and repeat until convergence.

- (7)

- After convergence, calculate the pressure .

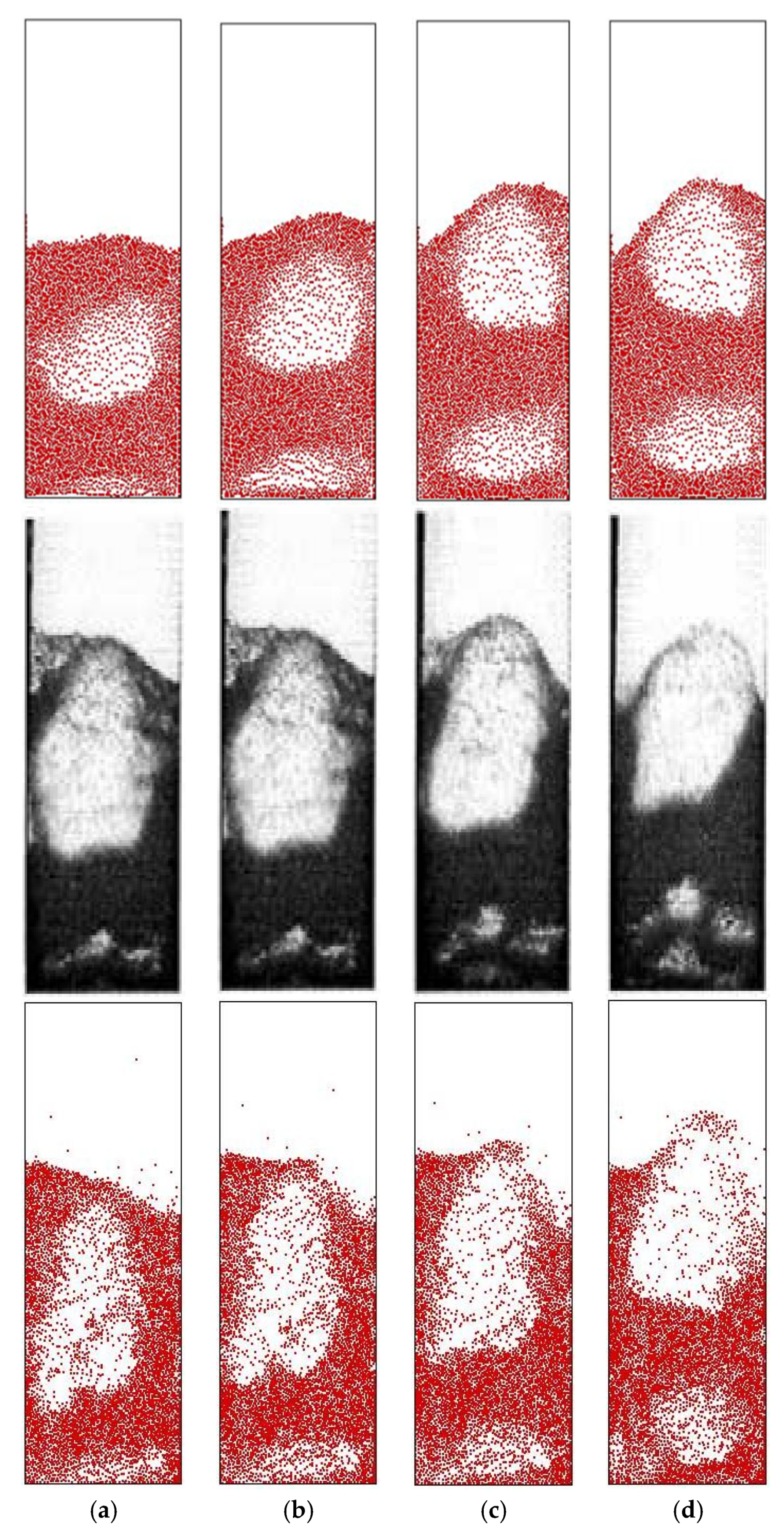

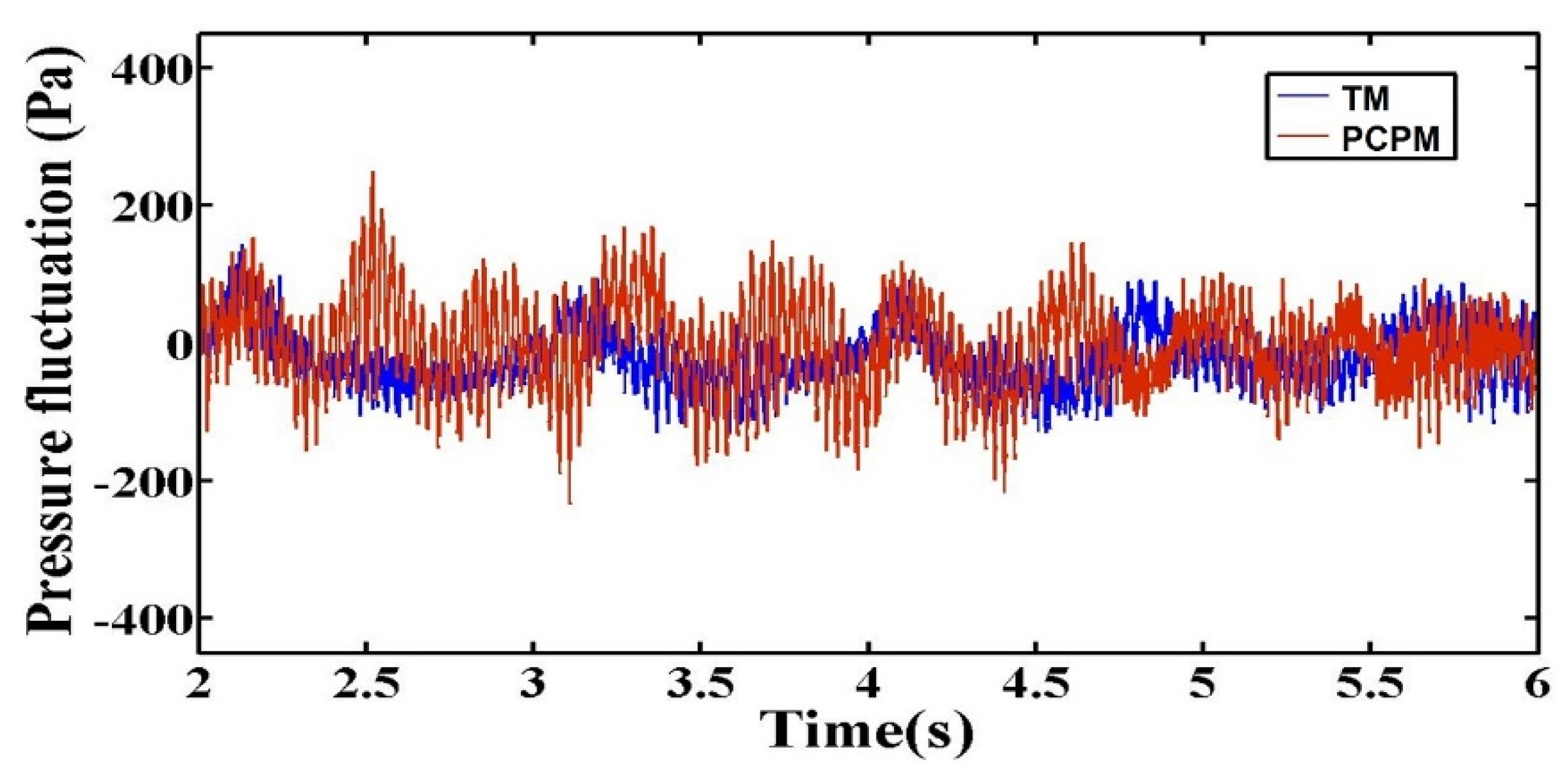

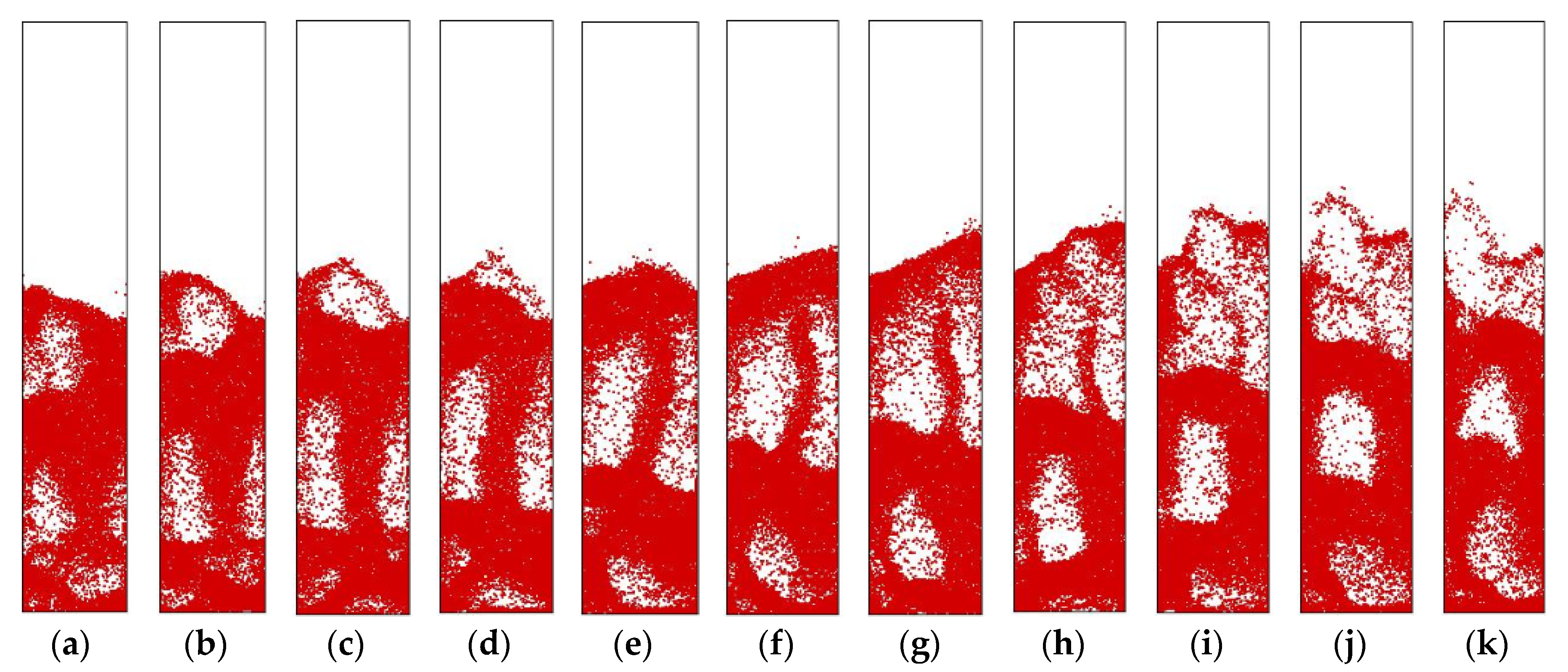

4. Simulation Results

5. Conclusions

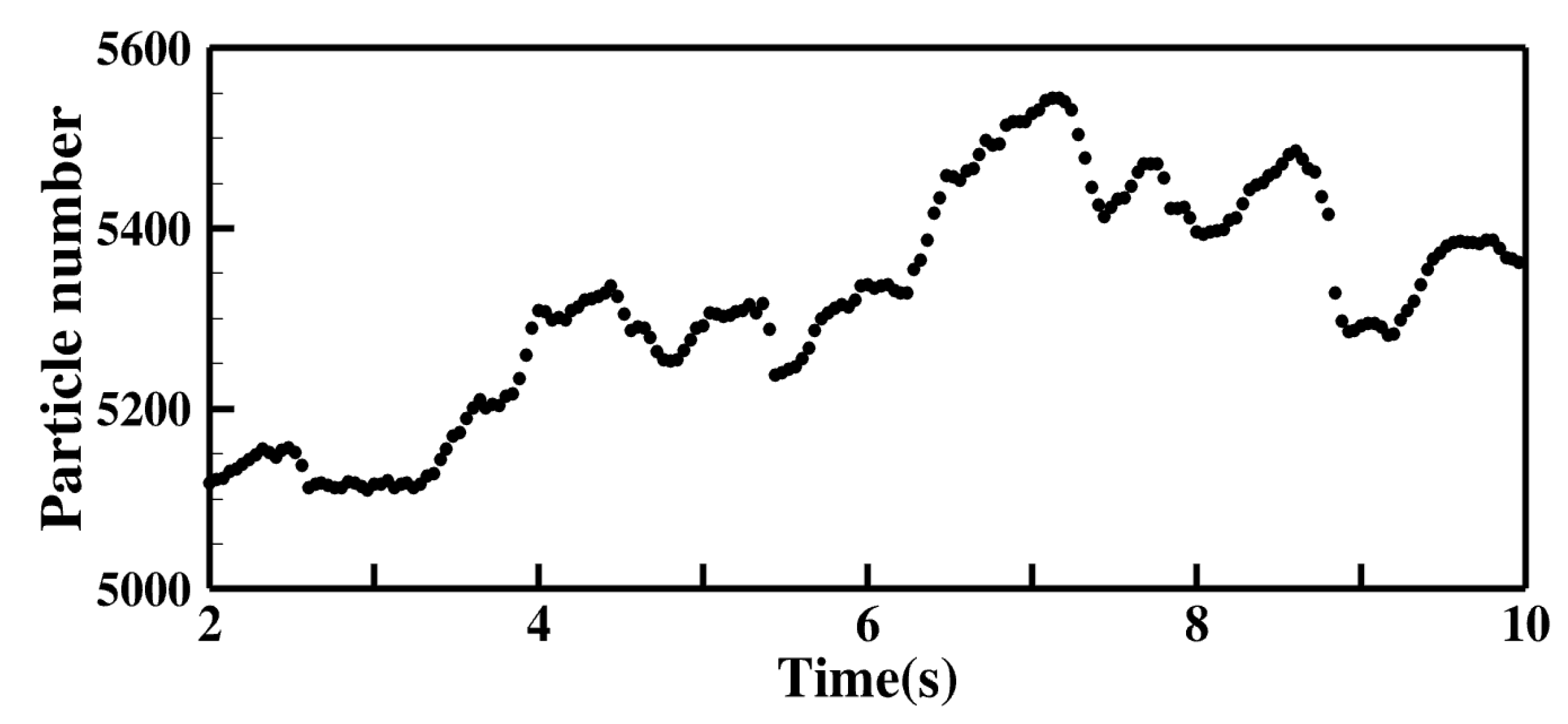

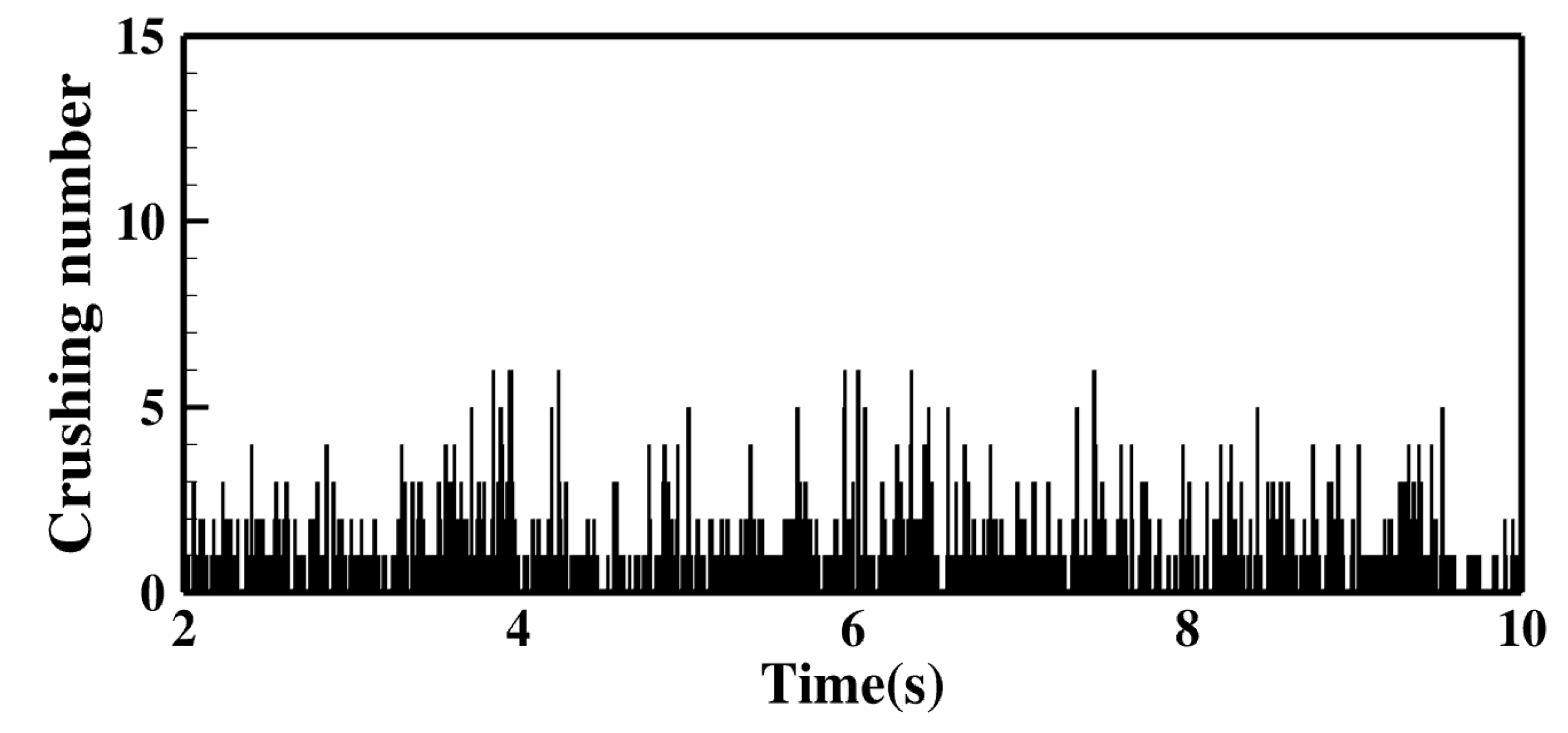

- A dynamic particle-group crushing and polymerization procedure is considered in the coarse grain DEM-CFD model.

- The dynamically coarse graining is based on an EMMS type model.

- Heterogeneities are considered in the coarse graining systems by using the EMMS drag force model.

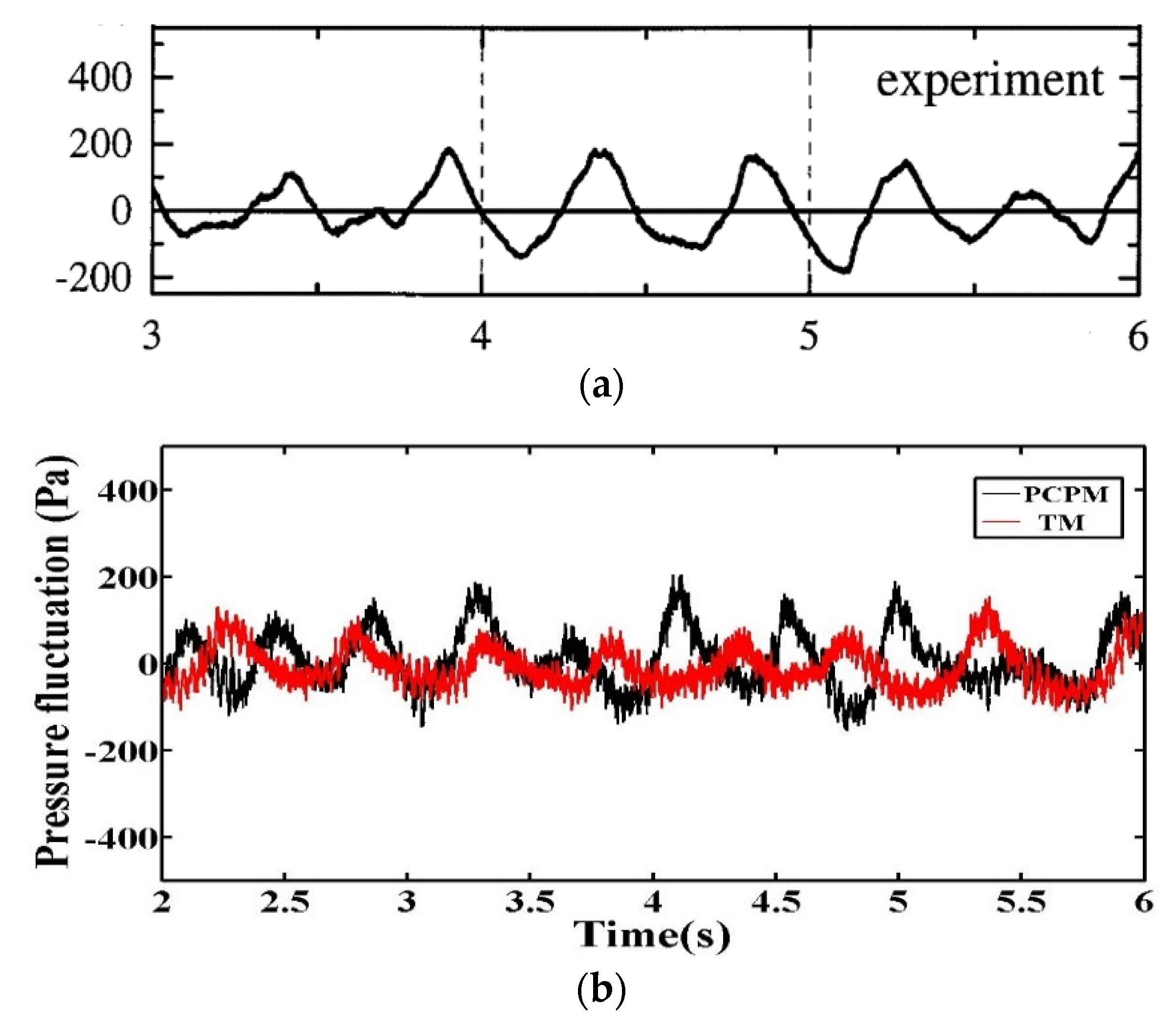

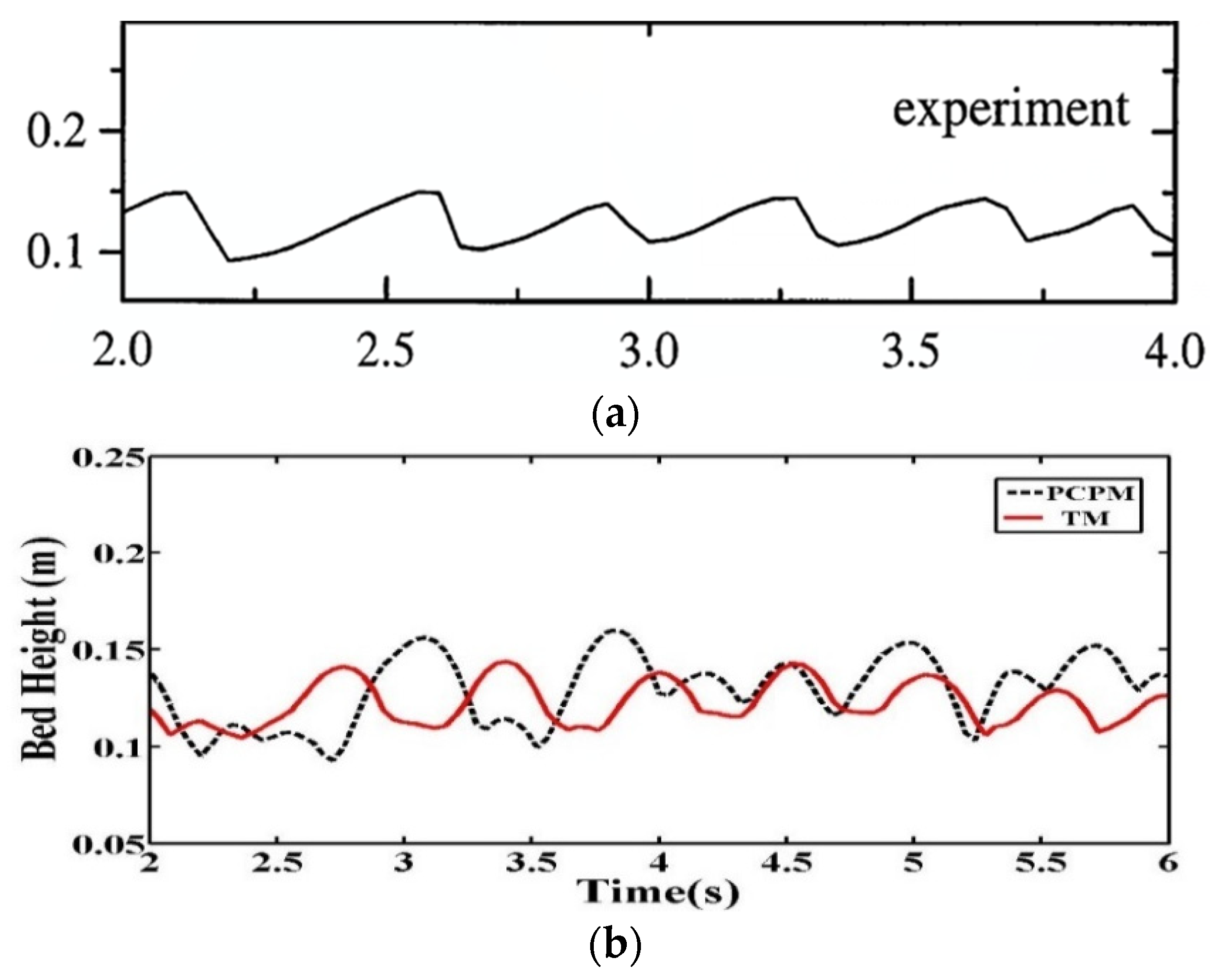

- The method is validated by comparing the simulation results with the experimental ones.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| particle mass, [] | |

| particle volume, [] | |

| particle velocity, [] | |

| gas pressure, [] | |

| drag force, [] | |

| gravitational force, [] | |

| contact force, [] | |

| void fraction, [—] | |

| interphase momentum exchange coefficient, [] | |

| gas velocity, [] | |

| particle diameter, [] | |

| gas density, [] | |

| drag coefficient, [—] | |

| heterogeneity index, [—] | |

| particle Reynolds number, [—] | |

| gas viscosity, [] | |

| normal spring constant, [] | |

| tangential spring constant, [] | |

| normal damping coefficient, [] | |

| tangential damping coefficient, [] | |

| normal overlap between particles, [] | |

| tangential overlap between particles, [] | |

| unit normal vector, [—] | |

| unit tangential vector, [—] | |

| friction coefficient, [—] | |

| particle radius, [] | |

| angular velocity, [] | |

| elasticity modulus, [] | |

| Poisson ratio, [—] | |

| inertial moment, [] | |

| coarse grain ratio, [—] | |

| gravitational acceleration, [] | |

| viscous stress tensor, [] | |

| volume of the computational cell, [] |

References

- Ding, W.; Chen, G.; Qin, M.; He, Y.; Qu, X. Low-cost Ti powders for additive manufacturing treated by fluidized bed. Powder Technol. 2019, 350, 117–122. [Google Scholar] [CrossRef]

- Özkaya, B.; Kaksonen, A.H.; Sahinkaya, E.; Puhakka, J.A. Fluidized bed bioreactor for multiple environmental engineering solutions. Water Res. 2019, 150, 452–465. [Google Scholar] [CrossRef]

- Chyou, Y.P.; Chang, D.M.; Chen, P.C.; Chien, H.Y.; Wu, K.T.; Chein, R.Y. Development of Biomass Gasification Technology with Fluidized-Bed Reactors for Enhancing Hydrogen Generation: Part I, Hydrodynamic Characterization of Dual Fluidized-Bed Gasifiers. Appl. Sci. 2020, 10, 2. [Google Scholar] [CrossRef]

- Pannala, S.; Syamlal, M.; O’Brein, T.J. (Eds.) Computational Gas-Solids Flows and Reacting Systems: Theory, Methods and Practice: Theory, Methods and Practice; IGI Global: Hershey, PA, USA, 2010. [Google Scholar]

- Deen, N.G.; Annaland, M.V.S.; Van der Hoef, M.A.; Kuipers, J.A.M. Review of discrete particle modeling of fluidized beds. Chem. Eng. Sci. 2007, 62, 28–44. [Google Scholar] [CrossRef]

- Wang, W.; Lu, B.; Zhang, N.; Shi, Z.; Li, J. A review of multiscale CFD for gas–solid CFB modeling. Int. J. Multiph. Flow 2010, 36, 109–118. [Google Scholar] [CrossRef]

- Dash, S.; Mohanty, S.; Mishra, B.K. CFD modelling and simulation of an industrial scale continuous fluidized bed roaster. Adv. Powder Technol. 2019. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Peng, W.; Song, S.; Yu, C.; Bao, Y.; Sui, J.; Hu, Y. Forecasting Landslides via Three-Dimensional Discrete Element Modeling: Helong Landslide Case Study. Appl. Sci. 2019, 9, 5242. [Google Scholar] [CrossRef]

- Daraio, D.; Villoria, J.; Ingram, A.; Alexiadis, A.; Hugh Stitt, E.; Marigo, M. Validation of a Discrete Element Method (DEM) Model of the Grinding Media Dynamics within an Attritor Mill Using Positron Emission Particle Tracking (PEPT) Measurements. Appl. Sci. 2019, 9, 4816. [Google Scholar] [CrossRef]

- Tsuji, Y.; Kawaguchi, T.; Tanaka, T. Discrete particle simulation of two-dimensional fluidized bed. Powder Technol. 1993, 77, 79–87. [Google Scholar] [CrossRef]

- Xu, B.H.; Yu, A.B. Numerical simulation of the gas-solid flow in a fluidized bed by combining discrete particle method with computational fluid dynamics. Chem. Eng. Sci. 1997, 52, 2785–2809. [Google Scholar] [CrossRef]

- Wu, G.; Ouyang, J.; Yang, B.; Li, Q. Use of compromise-based local porosities for coarse grid DEM simulation of bubbling fluidized bed with large particles. Adv. Powder Technol. 2013, 24, 68–78. [Google Scholar] [CrossRef]

- Wu, G.; Ouyang, J.; Li, Q. Revised drag calculation method for coarse grid Lagrangian–Eulerian simulation of gas–solid bubbling fluidized bed. Powder Technol. 2013, 235, 959–967. [Google Scholar] [CrossRef]

- Peters, B.; Baniasadi, M.; Baniasadi, M.; Besseron, X.; Donoso, A.E.; Mohseni, M.; Pozzetti, G. XDEM multi-physics and multi-scale simulation technology: Review of DEM–CFD coupling, methodology and engineering applications. Particuology 2019, 44, 176–193. [Google Scholar] [CrossRef]

- Tsuji, T.; Kawaguchi, T.; Tanaka, T. Large-scale DEM-CFD coupling simulation of 3-D bubbling fluidized bed. J. Soc. Powder Technol. Japan 2010, 3, 45–46. [Google Scholar]

- Tsuji, T.; Yabumoto, K.; Tanaka, T. Spontaneous structures in three-dimensional bubbling gas-fluidized bed by parallel DEM–CFD coupling simulation. Powder Technol. 2008, 184, 132–140. [Google Scholar] [CrossRef]

- Van Wachem, B.G.M.; Van der Schaaf, J.; Schouten, J.C.; Krishna, R.; Van den Bleek, C.M. Experimental validation of Lagrangian–Eulerian simulations of fluidized beds. Powder Technol. 2001, 116, 155–165. [Google Scholar] [CrossRef]

- Khawaja, H.A. CFD-DEM and Experimental Study of Bubbling in a Fluidized Bed. J. Comput. Multiph. Flows 2015, 7, 227–240. [Google Scholar] [CrossRef][Green Version]

- Khawaja, H.A. CFD-DEM simulation of minimum fluidisation velocity in two phase medium. Int. J. Multiphysics 2016, 5, 89–99. [Google Scholar] [CrossRef]

- Gupta, P.; Sun, J.; Ooi, J.Y. DEM-CFD simulation of a dense fluidized bed: Wall boundary and particle size effects. Powder Technol. 2016, 293, 37–47. [Google Scholar] [CrossRef]

- Li, T.; Zhang, Y.; Hernández-Jiménez, F. Investigation of particle–wall interaction in a pseudo-2D fluidized bed using CFD-DEM simulations. Particuology 2016, 25, 10–22. [Google Scholar] [CrossRef]

- Chu, K.W.; Wang, B.; Yu, A.B.; Vince, A. CFD-DEM modelling of multiphase flow in dense medium cyclones. Powder Technol. 2009, 193, 235–247. [Google Scholar] [CrossRef]

- Oevermann, M.; Gerber, S.; Behrendt, F. Euler–Lagrange/DEM simulation of wood gasification in a bubbling fluidized bed reactor. Particuology 2009, 7, 307–316. [Google Scholar] [CrossRef]

- Zhuang, Y.; Chen, X.; Liu, D.; Bu, C. CFD–DEM Modeling of O2/CO2 Char Combustion in a Fluidized Bed. In International Symposium on Coal Combustion; Springer: Singapore, 2015; pp. 287–293. [Google Scholar]

- Baniasadi, M.; Baniasadi, M.; Peters, B. Coupled CFD-DEM with heat and mass transfer to investigate the melting of a granular packed bed. Chem. Eng. Sci. 2018, 178, 136–145. [Google Scholar] [CrossRef]

- Pozzetti, G.; Peters, B. A multiscale DEM-VOF method for the simulation of three-phase flows. Int. J. Multiph. Flow 2018, 99, 186–204. [Google Scholar] [CrossRef]

- Zhao, T.; Dai, F.; Xu, N.W.; Liu, Y.; Xu, Y. A composite particle model for non-spherical particles in DEM simulations. Granul. Matter 2015, 17, 763–774. [Google Scholar] [CrossRef]

- Luo, Z.G.; Zhou, H.; Zhang, T.; You, Y.; Zhang, L.J.; Zou, Z.S.; Shen, Y.S. DEM study of blockage behaviour of cohesive fine particles in a packed structure of large particles. Powder Technol. 2017, 314, 102–109. [Google Scholar] [CrossRef]

- Sakai, M.; Abe, M.; Shigeto, Y.; Mizutani, S.; Takahashi, H.; Viré, A.; Percival, J.R.; Xiang, J.; Pain, C.C. Verification and validation of a coarse grain model of the DEM in a bubbling fluidized bed. Chem. Eng. J. 2014, 244, 33–43. [Google Scholar] [CrossRef]

- Sakai, M.; Koshizuka, S. Large-scale discrete element modeling in pneumatic conveying. Chem. Eng. Sci. 2009, 64, 533–539. [Google Scholar] [CrossRef]

- Sakai, M.; Takahashi, H.; Pain, C.C.; Latham, J.P.; Xiang, J. Study on a large-scale discrete element model for fine particles in a fluidized bed. Adv. Powder Technol. 2012, 23, 673–681. [Google Scholar] [CrossRef]

- Sakai, M.; Yamada, Y.; Shigeto, Y.; Shibata, K.; Kawasaki, V.M.; Koshizuka, S. Large-scale discrete element modeling in a fluidized bed. Int. J. Numer. Methods Fluids 2010, 64, 1319–1335. [Google Scholar] [CrossRef]

- Radl, S.; Radeke, C.; Khinast, J.G.; Sundaresan, S. Parcel-based approach for the simulation of gas-particle flows. In Proceedings of the 8th International Conference on CFD in Oil & Gas, Metallurgical and Process Industries, Trondheim, Norway, 21–23 June 2011; Available online: https://pdfs.semanticscholar.org/2277/7350720be0105a239ea771ae2df6befc241e.pdf (accessed on 22 March 2019).

- Girardi, M.; Radl, S.; Sundaresan, S. Simulating wet gas–solid fluidized beds using coarse-grid CFD-DEM. Chem. Eng. Sci. 2016, 144, 224–238. [Google Scholar] [CrossRef]

- Nikolopoulos, A.; Stroh, A.; Zeneli, M.; Alobaid, F.; Nikolopoulos, N.; Ströhle, J.; Karellas, S.; Epple, B.; Grammelis, P. Numerical investigation and comparison of coarse grain CFD–DEM and TFM in the case of a 1 MWth fluidized bed carbonator simulation. Chem. Eng. Sci. 2017, 163, 189–205. [Google Scholar] [CrossRef]

- Li, J.; Cheng, C.; Zhang, Z.; Yuan, J.; Nemet, A.; Fett, F.N. The EMMS model-its application, development and updated concepts. Chem. Eng. Sci. 1999, 54, 5409–5425. [Google Scholar] [CrossRef]

- Xu, G.; Li, J. Analytical solution of the energy-minimization multi-scale model for gas–solid two-phase flow. Chem. Eng. Sci. 1998, 53, 1349–1366. [Google Scholar] [CrossRef]

- Syamlal, M.; O’brien, T.J. Computer simulation of bubbles in a fluidized bed. Proc. AIChE Symp. Ser. 1989, 85, 22–31. [Google Scholar]

- Wen, C.Y.; Yu, Y.H. Mechanics of fluidization. Chem. Eng. Prog. Symp. Ser. 1966, 62, 100–111. [Google Scholar]

- Ergun, S. Fluid flow through packed columns. Chem. Eng. Prog. 1952, 48, 89–94. [Google Scholar]

- Gidaspow, D. Multiphase Flow and Fluidization: Continuum and Kinetic Theory Descriptions; Elsevier Science: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Wang, J.; Ge, W.; Li, J. Eulerian simulation of heterogeneous gas–solid flows in CFB risers: EMMS-based sub-grid scale model with a revised cluster description. Chem. Eng. Sci. 2008, 63, 1553–1571. [Google Scholar] [CrossRef]

- Wang, W.; Li, J. Simulation of gas-solid two-phase flow by a multi-scale CFD approach—Extension of the EMMS model to the sub-grid level. Chem. Eng. Sci. 2007, 62, 208–231. [Google Scholar] [CrossRef]

- Hu, S.; Liu, X. A general EMMS drag model applicable for gas-solid turbulent beds and cocurrent downers. Chem. Eng. Sci. 2019, 205, 14–24. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, M.; Hu, S.; Ge, W. Three-dimensional CFD simulation of tapered gas-solid risers by coupling the improved EMMS drag. Powder Technol. 2019, 352, 305–313. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, F.; Ge, W.; Wang, W. EMMS-based solid stress model for the multiphase particle-in-cell method. Powder Technol. 2020, 360, 1377–1387. [Google Scholar] [CrossRef]

- Liu, X.; Ge, W.; Wang, L. Scale and structure dependent drag in gas-solid flows. AIChE J. 2019. [Google Scholar] [CrossRef]

- Li, F.; Song, F.; Benyahia, S.; Wang, W.; Li, J. MP-PIC simulation of CFB riser with EMMS-based drag model. Chem. Eng. Sci. 2012, 82, 104–113. [Google Scholar] [CrossRef]

- Lu, L.; Xu, J.; Ge, W.; Yue, Y.; Liu, X.; Li, J. EMMS-based discrete particle method (EMMS–DPM) for simulation of gas–solid flows. Chem. Eng. Sci. 2014, 120, 67–87. [Google Scholar] [CrossRef]

- Matsen, J.M. Mechanisms of choking and entrainment. Powder Technol. 1982, 32, 21–33. [Google Scholar] [CrossRef]

| Physical Quantities | Units | Data set |

|---|---|---|

| Particle Density | kg/m3 | 1150 |

| Particle diameter | mm | 1.5 |

| Stiffness | N/m | 800 |

| Coefficient of friction | — | 0.3 |

| Coefficient of restitution | — | 0.9 |

| Gas density | kg/m3 | 1.28 |

| Gas viscosity | N × s/m2 | 1.7 × 10−5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Chen, K.; Kang, T.; Ouyang, J. A Dynamic Coarse Grain Discrete Element Method for Gas-Solid Fluidized Beds by Considering Particle-Group Crushing and Polymerization. Appl. Sci. 2020, 10, 1943. https://doi.org/10.3390/app10061943

Wang X, Chen K, Kang T, Ouyang J. A Dynamic Coarse Grain Discrete Element Method for Gas-Solid Fluidized Beds by Considering Particle-Group Crushing and Polymerization. Applied Sciences. 2020; 10(6):1943. https://doi.org/10.3390/app10061943

Chicago/Turabian StyleWang, Xiaodong, Kai Chen, Ting Kang, and Jie Ouyang. 2020. "A Dynamic Coarse Grain Discrete Element Method for Gas-Solid Fluidized Beds by Considering Particle-Group Crushing and Polymerization" Applied Sciences 10, no. 6: 1943. https://doi.org/10.3390/app10061943

APA StyleWang, X., Chen, K., Kang, T., & Ouyang, J. (2020). A Dynamic Coarse Grain Discrete Element Method for Gas-Solid Fluidized Beds by Considering Particle-Group Crushing and Polymerization. Applied Sciences, 10(6), 1943. https://doi.org/10.3390/app10061943